The Potential of Heat Recovery from Wastewater Considering the Protection of Wastewater Treatment Plant Technology

Abstract

1. Introduction

2. Materials and Methods

- The screen hall;

- The building for mechanical thickening of excess sludge;

- The building for digested sludge dewatering;

- The sludge dryer.

- 1 April 2020–1 December 2020: recorded in 5-s intervals;

- 1 December 2020–1 December 2021: recorded in 20-s intervals;

- 1 December 2021–today: recorded in 300-s intervals.

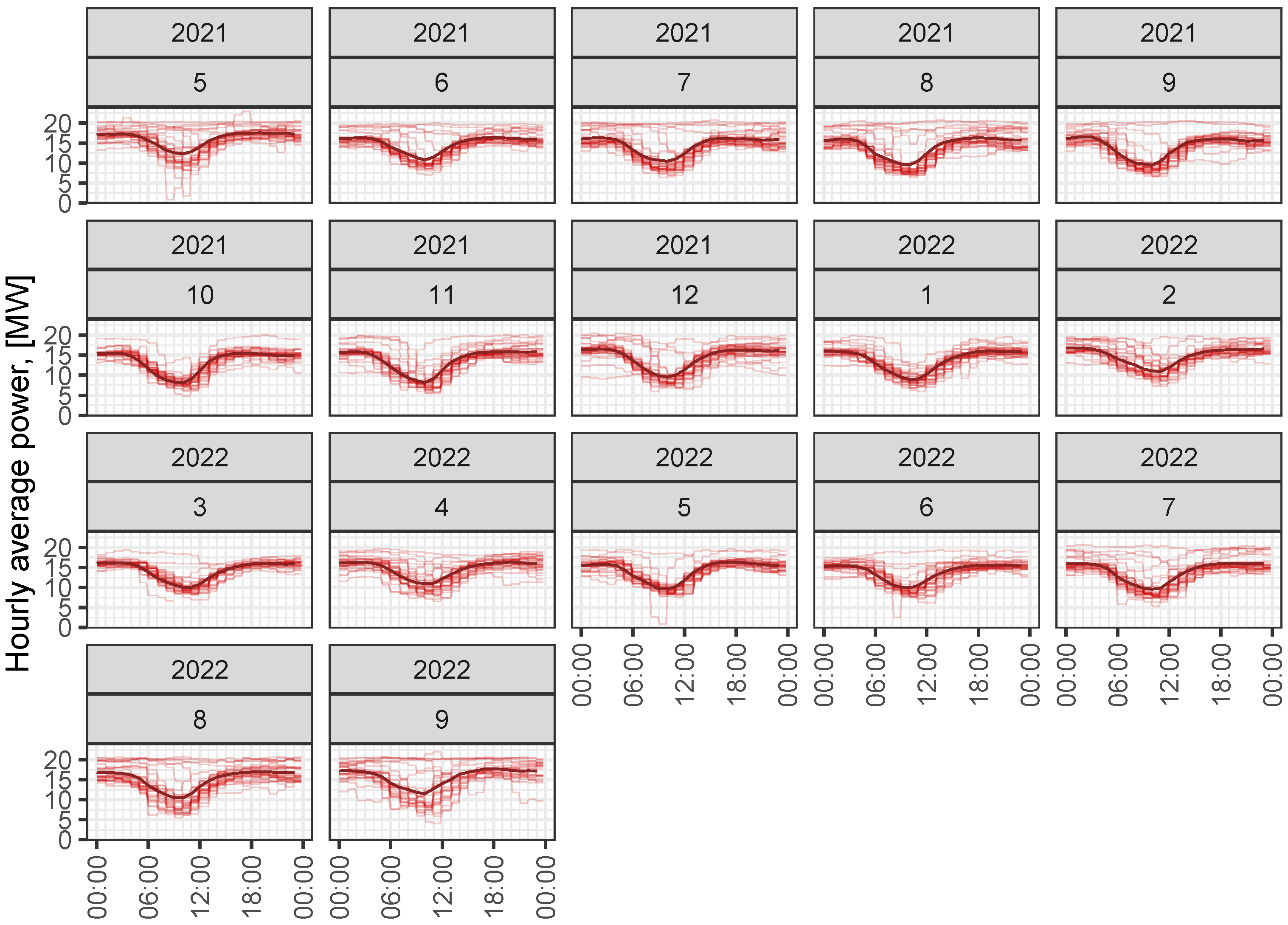

3. Results

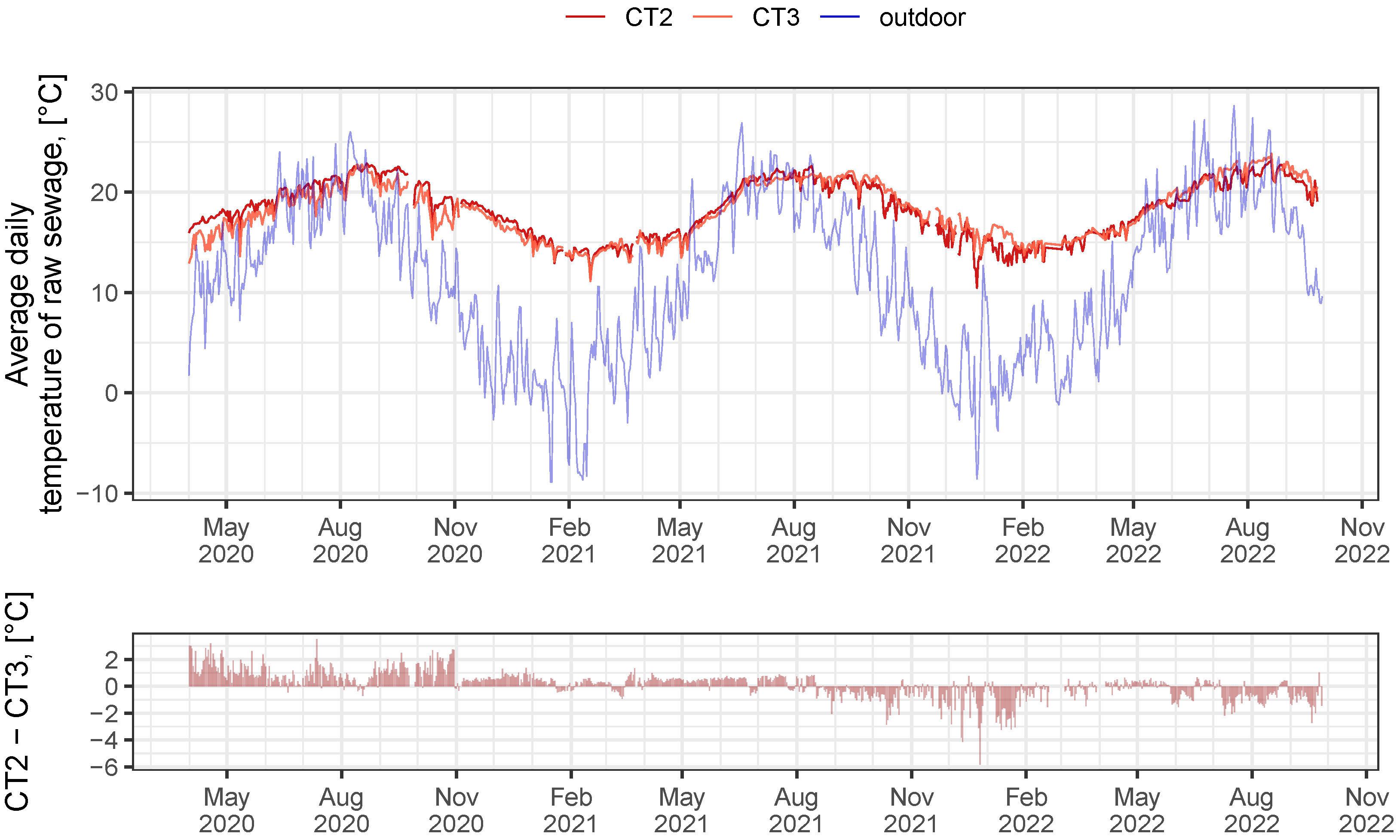

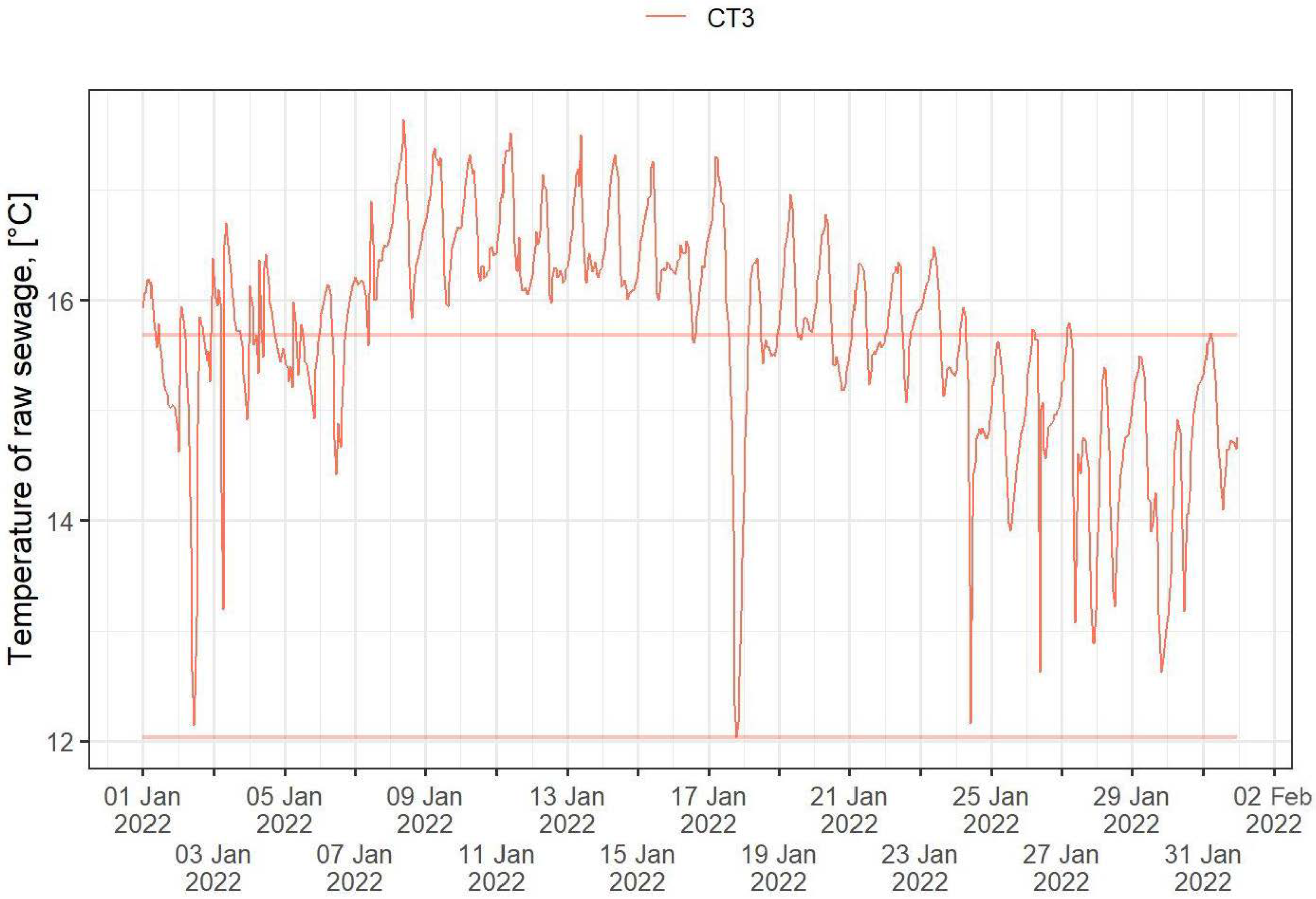

3.1. Raw Sewage Parameters

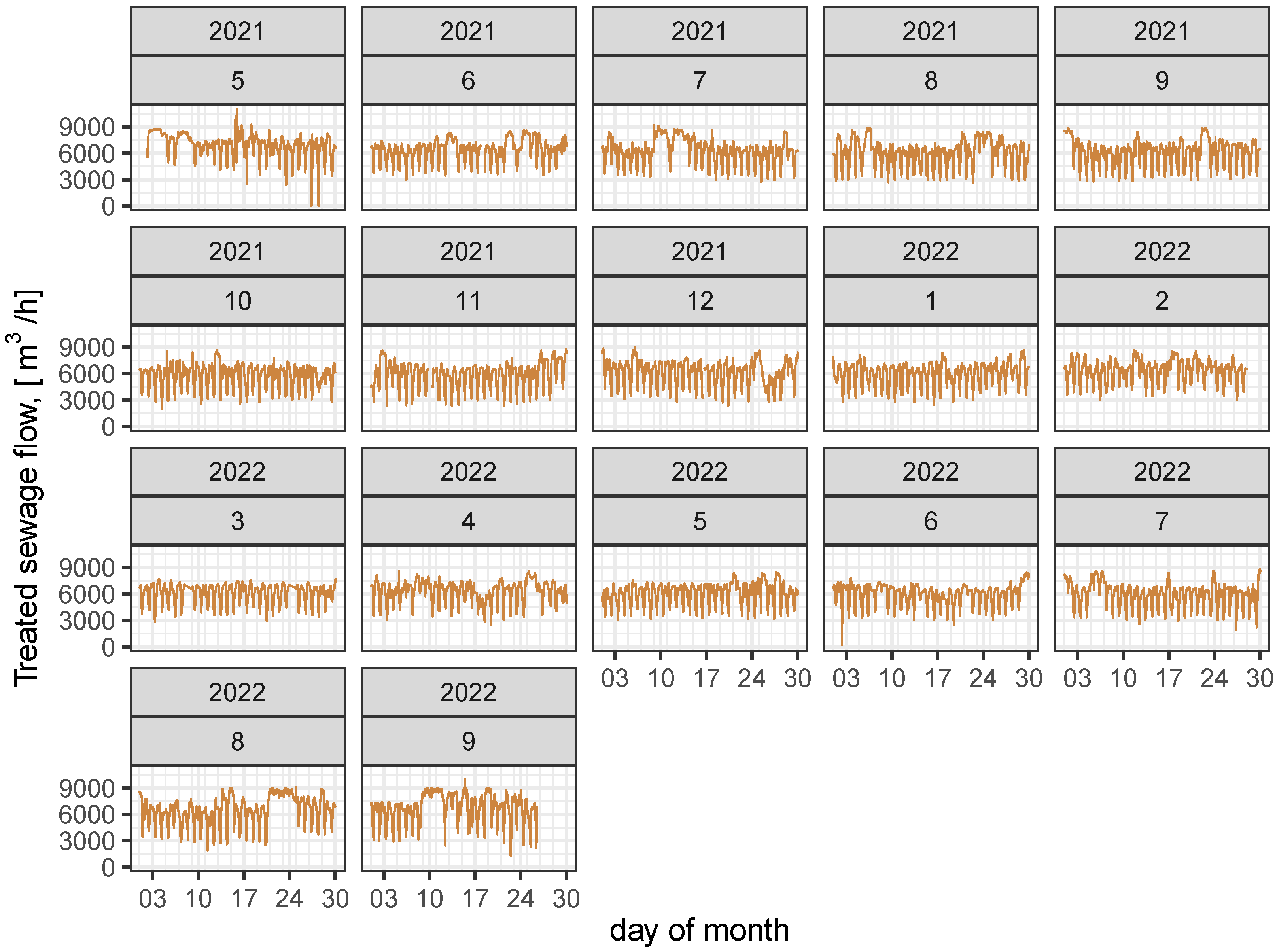

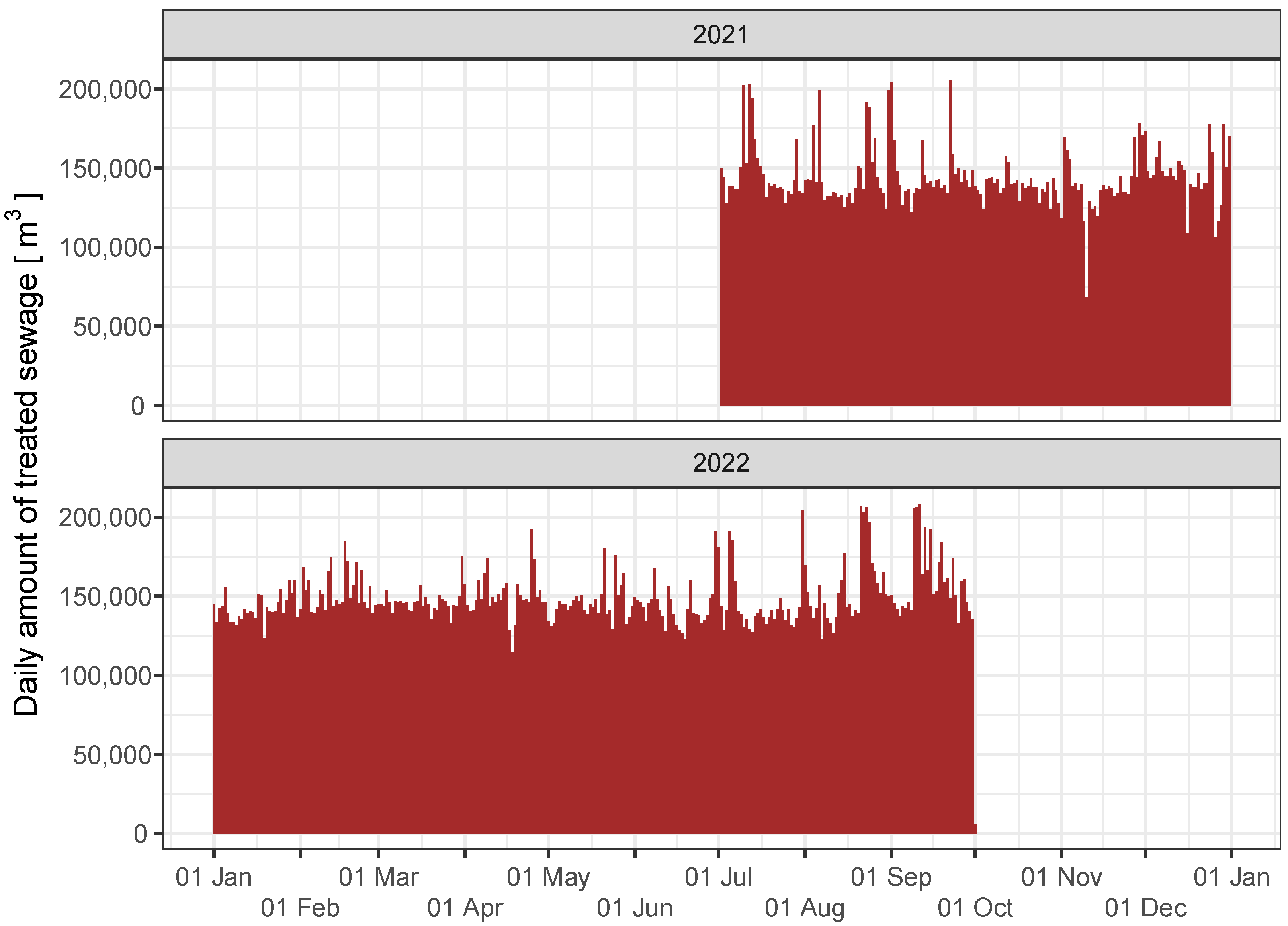

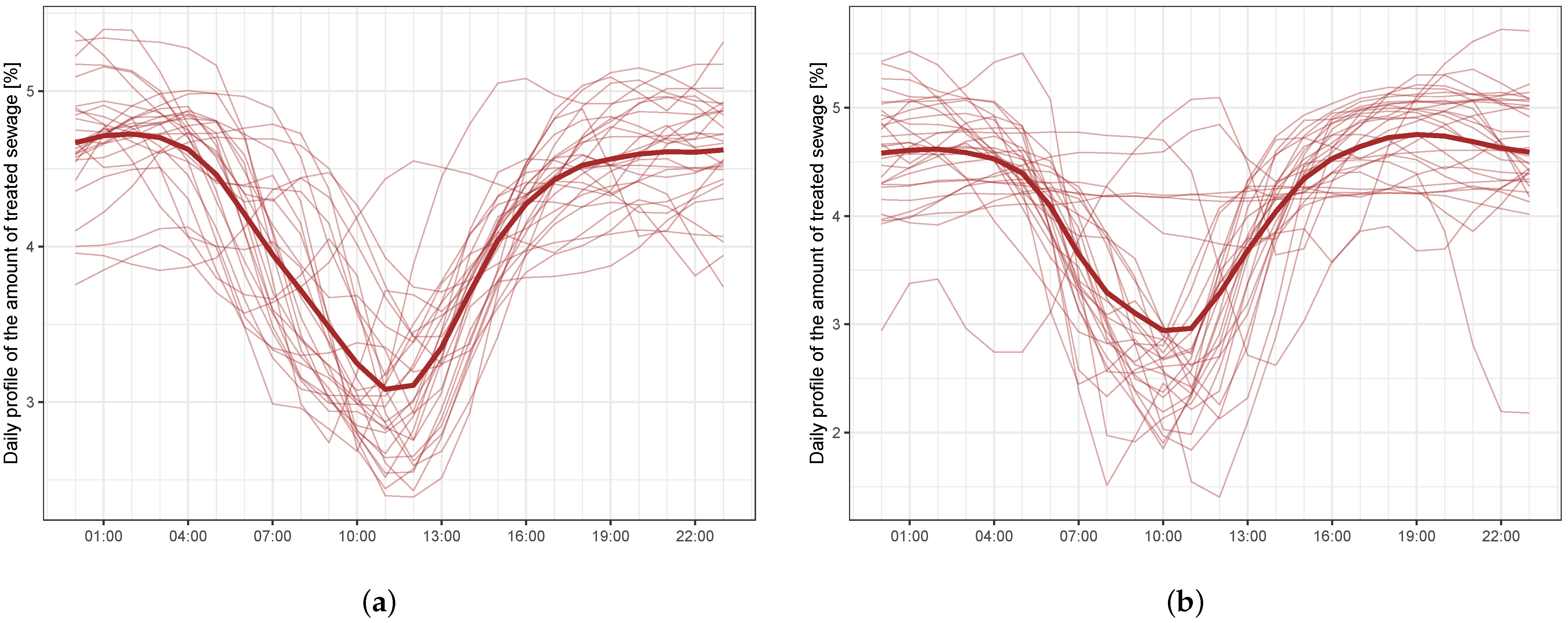

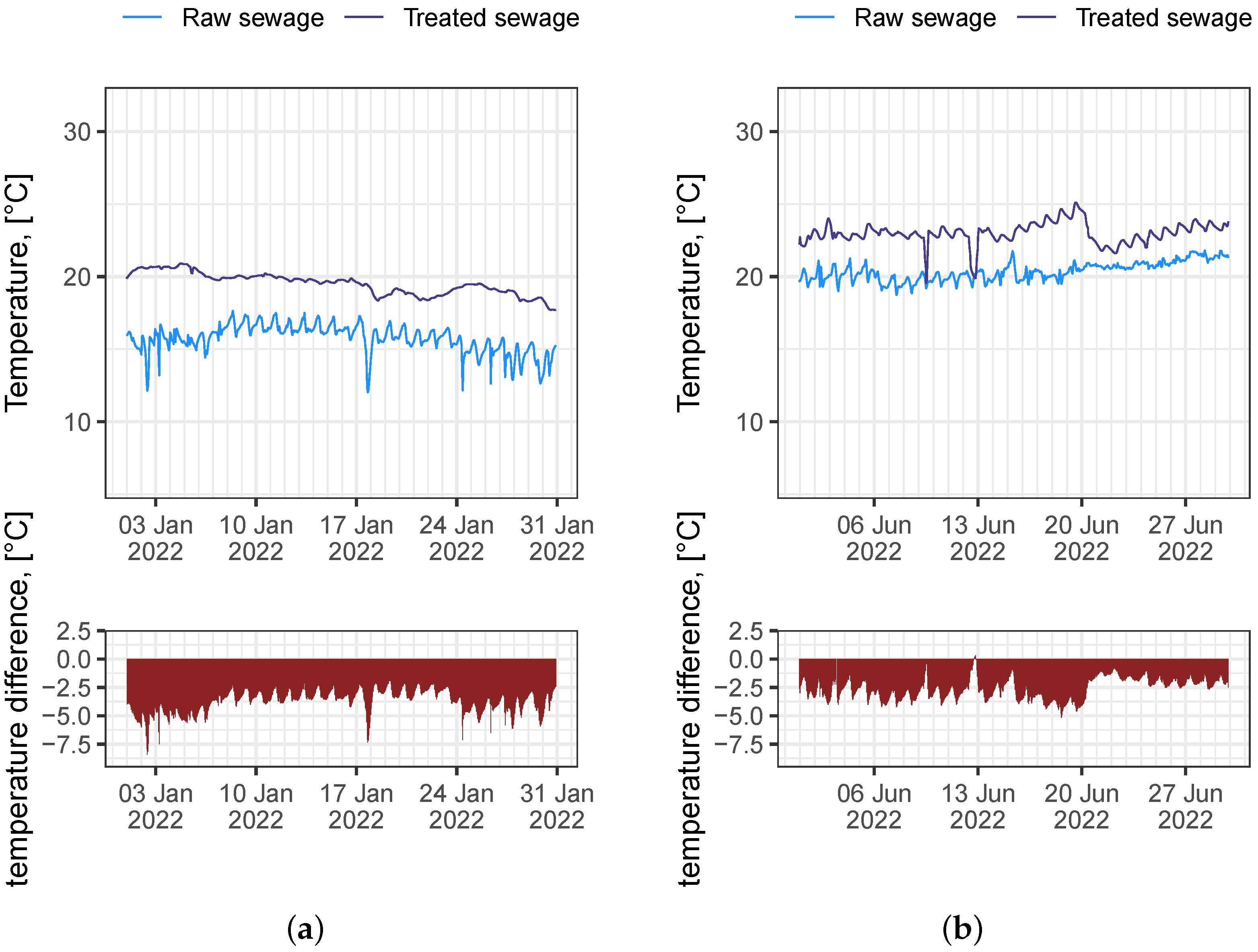

3.2. Parameters of Treated Sewage

4. Discussion

5. Conclusions

- Wastewater has many features that make it an attractive medium constituting a lower source of heat for heat pumps, leading to cheap and low-emission heat.

- In the case of heat recovery from wastewater, whether raw or treated, there are no periods when the amount of heat extracted drops to zero. This is clearly a different characteristic that distinguishes this type of renewable heat source from others. Both photovoltaics and wind turbines have periods of zero energy production.

- Because of the applied wastewater treatment technology using the activated sludge method, which is sensitive to low temperatures, it is safer to use treated wastewater than raw wastewater as a lower heat source. Excessive cooling of raw wastewater carries the risk of a decrease in the effectiveness of biological treatments, and in extreme cases, inhibits these processes. This may result in the treatment plant failing to meet the specified values of the quality parameters included in the legal specifications of the Water Law Act.

- In the case of large facilities located on the outskirts of cities, the amount of recovered heat may be too large in relation to their own needs. The biogas obtained in the technological process in some cases secures the facility’s own needs in terms of heat and, to some extent, electricity. Therefore, the heat potentially recovered from wastewater should go to other recipients; therefore, it should be possible to transfer the obtained heat to the district heating system. It may be unprofitable, due to the distance and low building density (and consequently low heat density). However, it should be remembered that there are facilities located at a short distance from some sewage treatment plants that have specific demands for heat. In such cases, wastewater heat recovery is an advantageous solution, providing access to cheap and emission-free heat.

- Wastewater, similar to other renewable sources, shows greater heat potential during the summer. However, what makes it different is that the differences in heat delivery potential between summer and winter are not as pronounced as for other zero-emission sources.

- On a daily and annual basis, the profiles of the recoverable amount of heat from wastewater (raw or treated) are best matched to the profiles of the thermal needs of consumers, including municipal consumers (space heating and hot water preparation).

- The sewage treatment plant in Wrocław, similar to other facilities of this type in large cities in Poland, is equipped with several specific solutions. However, the analysis method used for wastewater is universal, regardless of the size and location of a treatment plant, including one outside of Poland. The choice of where the heat pump is installed or the decision to cool raw sewage (in the case of heat recovery at this technological stage) are individual decisions, which take into account the specificity of a given sewage treatment plant. However, it should be emphasized that the assumptions adopted in the analyses are conservative, and the potential for recovering more heat in particular locations should be taken into account. This does not change the fact that the proposed methodology is strictly utilitarian.

- A wastewater treatment plant is a facility that consumes large amounts of energy in the form of electricity and heat. However, the main demand is for electricity. In terms of heat supply, the technological needs of such a treatment plant are limited to heating closed fermentation chambers. Waste heat from electricity production is used for this purpose. This form of energy is obtained in the process of burning biogas produced in the process of mesophilic fermentation.

- The supplied amount of energy is required to carry out the technological process and cannot be limited. This results in a slight increase in the temperature of the treated sewage, which is discharged to the receiver (river), and the heat is irretrievably lost.

- The amount of heat that can be recovered from wastewater, especially treated wastewater, usually exceeds the wastewater treatment plant’s own demand for this form of energy. If part of the heat recovered from wastewater is used in the treatment process, it translates into a reduction in the consumption of other primary energy mediums (usually gas or electricity). Therefore, regardless of the form in which the recovered heat is used, the proposed solution is justified, as there is no other method for reducing the energy input in the technological process. If heat is not recovered from raw or treated sewage, then a large amount of heat is dissipated in the receiver (river).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Longo, S.; D’Antoni, B.M.; Bongards, M.; Chaparro, A.; Cronrath, A.; Fatone, F.; Lema, J.M.; Mauricio-Iglesias, M.; Soares, A.; Hospido, A. Monitoring and diagnosis of energy consumption in wastewater treatment plants. A state of the art and proposals for improvement. Appl. Energy 2016, 179, 1251–1268. [Google Scholar] [CrossRef]

- Trapote, A.; Albaladejo, A.; Simón, P. Energy consumption in an urban wastewater treatment plant: The case of Murcia Region (Spain). Civ. Eng. Environ. Syst. 2014, 13, 304–310. [Google Scholar] [CrossRef]

- Chae, K.J.; Kang, J. Estimating the energy independence of a municipal wastewater treatment plant incorporating green energy resources. Energy Convers. Manag. 2013, 75, 664–672. [Google Scholar] [CrossRef]

- Li, Z.; Zou, Z.; Wang, L. Analysis and Forecasting of the Energy Consumption in Wastewater Treatment Plant. Math. Probl. Eng. 2019. [Google Scholar] [CrossRef]

- Haslinger, J.; Krampe, J.; Lindtner, S. Operating costs and energy demand of wastewater treatment plants in Austria: Benchmarking results of the last 10 years. Water Sci. Technol. 2016, 74, 2620–2626. [Google Scholar] [CrossRef]

- Panepinto, D.; Fiore, S.; Zappone, M.; Genon, G.; Meucci, L. Evaluation of the energy efficiency of a large wastewater treatment plant in Italy. Appl. Energy 2016, 161, 404–411. [Google Scholar] [CrossRef]

- UE. On the Promotion of the Use of Energy from Renewable Sources. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32018L2001&qid=1671879795350&from=EN (accessed on 10 November 2022).

- Spriet, J.; McNabola, A.; Neugebauer, G.; Stoeglehner, G.; Ertl, T.; Kretschmer, F. Spatial and temporal considerations in the performance of wastewater heat recovery systems. J. Clean. Prod. 2020, 247, 119583. [Google Scholar] [CrossRef]

- Nagpal, H.; Spriet, J.; Murali, M.K.; McNabola, A. Heat Recovery from Wastewater—A Review of Available Resource. Water 2021, 13, 1274. [Google Scholar] [CrossRef]

- Kretschmer, F.; Simperler, L.; Ertl, T. Analysing wastewater temperature development in a sewer system as a basis for the evaluation of wastewater heat recovery potentials. Energy Build. 2016, 128, 639–648. [Google Scholar] [CrossRef]

- Bertrand, A.; Aggoune, R.; Maréchal, F. In-building waste water heat recovery: An urban-scale method for the characterisation of water streams and the assessment of energy savings and costs. Appl. Energy 2017, 192, 110–125. [Google Scholar] [CrossRef]

- Cecconet, D.; Raček, J.; Callegari, A.; Hlavínek, P. Energy Recovery from Wastewater: A Study on Heating and Cooling of a Multipurpose Building with Sewage-Reclaimed Heat Energy. Sustainability 2020, 12, 116. [Google Scholar] [CrossRef]

- Cipolla, S.S.; Maglionico, M. Heat Recovery from Urban Wastewater: Analysis of the Variability of Flow Rate and Temperature in the Sewer of Bologna, Italy. Energy Procedia 2014, 45, 288–297. [Google Scholar] [CrossRef]

- Golzar, F.; Silveira, S. Impact of wastewater heat recovery in buildings on the performance of centralized energy recovery—A case study of Stockholm. Appl. Energy 2021, 297, 117141. [Google Scholar] [CrossRef]

- Alnahhal, S.; Spremberg, E. Contribution to Exemplary In-house Wastewater Heat Recovery in Berlin, Germany. Procedia CIRP 2016, 40, 35–40. [Google Scholar] [CrossRef]

- Abdel-Aal, M.; Schellart, A.; Kroll, S.; Mohamed, M.; Tait, S. Modelling the potential for multi-location in-sewer heat recovery at a city scale under different seasonal scenarios. Water Res. 2018, 145, 618–630. [Google Scholar] [CrossRef]

- Pelda, J.; Holler, S. Spatial distribution of the theoretical potential of waste heat from sewage: A statistical approach. Energy 2019, 180, 751–762. [Google Scholar] [CrossRef]

- Dürrenmatt, D.J.; Wanner, O. A mathematical model to predict the effect of heat recovery on the wastewater temperature in sewers. Water Res. 2014, 48, 548–558. [Google Scholar] [CrossRef]

- Wanner, O.; Panagiotidis, V.; Clavadetscher, P.; Siegrist, H. Effect of heat recovery from raw wastewater on nitrification and nitrogen removal in activated sludge plants. Water Res. 2005, 39, 4725–4734. [Google Scholar] [CrossRef]

- Guo, J.; Peng, Y.; Huang, H.; Wang, S.; Ge, S.; Zhang, J.; Wang, Z. Short- and long-term effects of temperature on partial nitrification in a sequencing batch reactor treating domestic wastewater. J. Hazard. Mater. 2010, 179, 471–479. [Google Scholar] [CrossRef]

- Yuan, J.; Dong, W.; Sun, F.; Zhao, K. Low temperature effects on nitrification and nitrifier community structure in V-ASP for decentralized wastewater treatment and its improvement by bio-augmentation. Environ. Sci. Pollut. Res. 2017, 25, 6584–6595. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, H.; Xia, L.; Shi, H.; Shen, T.; Wang, Z.; Wang, G.; Wang, Y. Study of operational conditions of simultaneous nitrification and denitrification in a Carrousel oxidation ditch for domestic wastewater treatment. Bioresour. Technol. 2010, 101, 901–906. [Google Scholar] [CrossRef] [PubMed]

- Salvetti, R.; Azzellino, A.; Canziani, R.; Bonomo, L. Effects of temperature on tertiary nitrification in moving-bed biofilm reactors. Water Res. 2006, 40, 2981–2993. [Google Scholar] [CrossRef] [PubMed]

- Kehrein, P.; Van Loosdrecht, M.; Osseweijer, P.; Garfí, M.; Dewulf, J.; Posada, J. A critical review of resource recovery from municipal wastewater treatment plants—Market supply potentials, technologies and bottlenecks. Environ. Sci. Water Res. Technol. 2020, 6, 877–910. [Google Scholar] [CrossRef]

- Hao, X.; Wang, X.; Liu, R.; Li, S.; van Loosdrecht, M.C.; Jiang, H. Environmental impacts of resource recovery from wastewater treatment plants. Water Res. 2019, 160, 268–277. [Google Scholar] [CrossRef]

- Yang, X.; Wei, J.; Ye, G.; Zhao, Y.; Li, Z.; Qiu, G.; Li, F.; Wei, C. The correlations among wastewater internal energy, energy consumption and energy recovery/production potentials in wastewater treatment plant: An assessment of the energy balance. Sci. Total Environ. 2020, 714, 136655. [Google Scholar] [CrossRef]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Bio/Technol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

| Month | Year | Average Raw Sewage Temperature at the Inflow | Average Ambient Temperature | |

|---|---|---|---|---|

| Technological Line | Technological Line | |||

| 4 | 2020 | 17.2 | 15.4 | 10.6 |

| 5 | 2020 | 18.1 | 17.0 | 12.4 |

| 6 | 2020 | 19.5 | 19.0 | 18.4 |

| 7 | 2020 | 20.9 | 19.9 | 19.3 |

| 8 | 2020 | 22.0 | 21.6 | 21.1 |

| 9 | 2020 | 21.8 | 20.4 | 15.9 |

| 10 | 2020 | 19.5 | 18.0 | 11.4 |

| 11 | 2020 | 18.6 | 18.2 | 6.3 |

| 12 | 2020 | 17.0 | 16.2 | 2.8 |

| 1 | 2021 | 14.7 | 14.5 | 0.1 |

| 2 | 2021 | 13.9 | 13.6 | 0.1 |

| 3 | 2021 | 14.7 | 14.6 | 4.5 |

| 4 | 2021 | 15.5 | 15.0 | 6.8 |

| 5 | 2021 | 16.8 | 16.4 | 12.7 |

| 6 | 2021 | 20.0 | 19.7 | 20.5 |

| 7 | 2021 | 21.6 | 21.2 | 21.1 |

| 8 | 2021 | 21.4 | 21.4 | 18.1 |

| 9 | 2021 | 20.9 | 21.4 | 15.8 |

| 10 | 2021 | 19.2 | 20.1 | 10.5 |

| 11 | 2021 | 14.8 | 16.3 | 5.6 |

| 12 | 2021 | 14.8 | 16.3 | 1.2 |

| 1 | 2022 | 14.2 | 15.7 | 2.4 |

| 2 | 2022 | 14.1 | 14.5 | 4.8 |

| 3 | 2022 | 15.1 | 15.4 | 15.8 |

| 4 | 2022 | 16.2 | 16.1 | 20.5 |

| 5 | 2022 | 18.4 | 18.4 | 20.4 |

| 6 | 2022 | 20.1 | 20.4 | 21.2 |

| 7 | 2022 | 21.2 | 22.0 | 13.6 |

| 8 | 2022 | 22.1 | 22.7 | 10.6 |

| 9 | 2022 | 20.7 | 21.6 | 12.4 |

| Month | Year | Average Daily Volume of Treated Sewage m | Average Monthly Adjusted Temperature of Treated Wastewater |

|---|---|---|---|

| 5 | 2021 | - | 19.9 |

| 6 | 2021 | - | 24.0 |

| 7 | 2021 | 142,987.3 | 24.6 |

| 8 | 2021 | 146,677.8 | 23.0 |

| 9 | 2021 | 146,547.0 | 23.6 |

| 10 | 2021 | 138,349.8 | 22.4 |

| 11 | 2021 | 138,377.3 | 22.5 |

| 12 | 2021 | 146,279.7 | 14.9 |

| 1 | 2022 | 142,450.9 | 13.0 |

| 2 | 2022 | 153,232.2 | 12.5 |

| 3 | 2022 | 146,145.2 | 13.7 |

| 4 | 2022 | 150,977.3 | 14.6 |

| 5 | 2022 | 145,686.2 | 20.3 |

| 6 | 2022 | 143,489.8 | 23.0 |

| 7 | 2022 | 144,770.0 | 22.6 |

| 8 | 2022 | 155,683.4 | 23.6 |

| 9 | 2022 | 156,186.5 | 21.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartnicki, G.; Ziembicki, P.; Klimczak, M.; Kalitka, A. The Potential of Heat Recovery from Wastewater Considering the Protection of Wastewater Treatment Plant Technology. Energies 2023, 16, 227. https://doi.org/10.3390/en16010227

Bartnicki G, Ziembicki P, Klimczak M, Kalitka A. The Potential of Heat Recovery from Wastewater Considering the Protection of Wastewater Treatment Plant Technology. Energies. 2023; 16(1):227. https://doi.org/10.3390/en16010227

Chicago/Turabian StyleBartnicki, Grzegorz, Piotr Ziembicki, Marcin Klimczak, and Agnieszka Kalitka. 2023. "The Potential of Heat Recovery from Wastewater Considering the Protection of Wastewater Treatment Plant Technology" Energies 16, no. 1: 227. https://doi.org/10.3390/en16010227

APA StyleBartnicki, G., Ziembicki, P., Klimczak, M., & Kalitka, A. (2023). The Potential of Heat Recovery from Wastewater Considering the Protection of Wastewater Treatment Plant Technology. Energies, 16(1), 227. https://doi.org/10.3390/en16010227