Long Term Performance Assessment of a Residential PV/Thermal Hybrid System

Abstract

1. Introduction

2. Materials and Methods

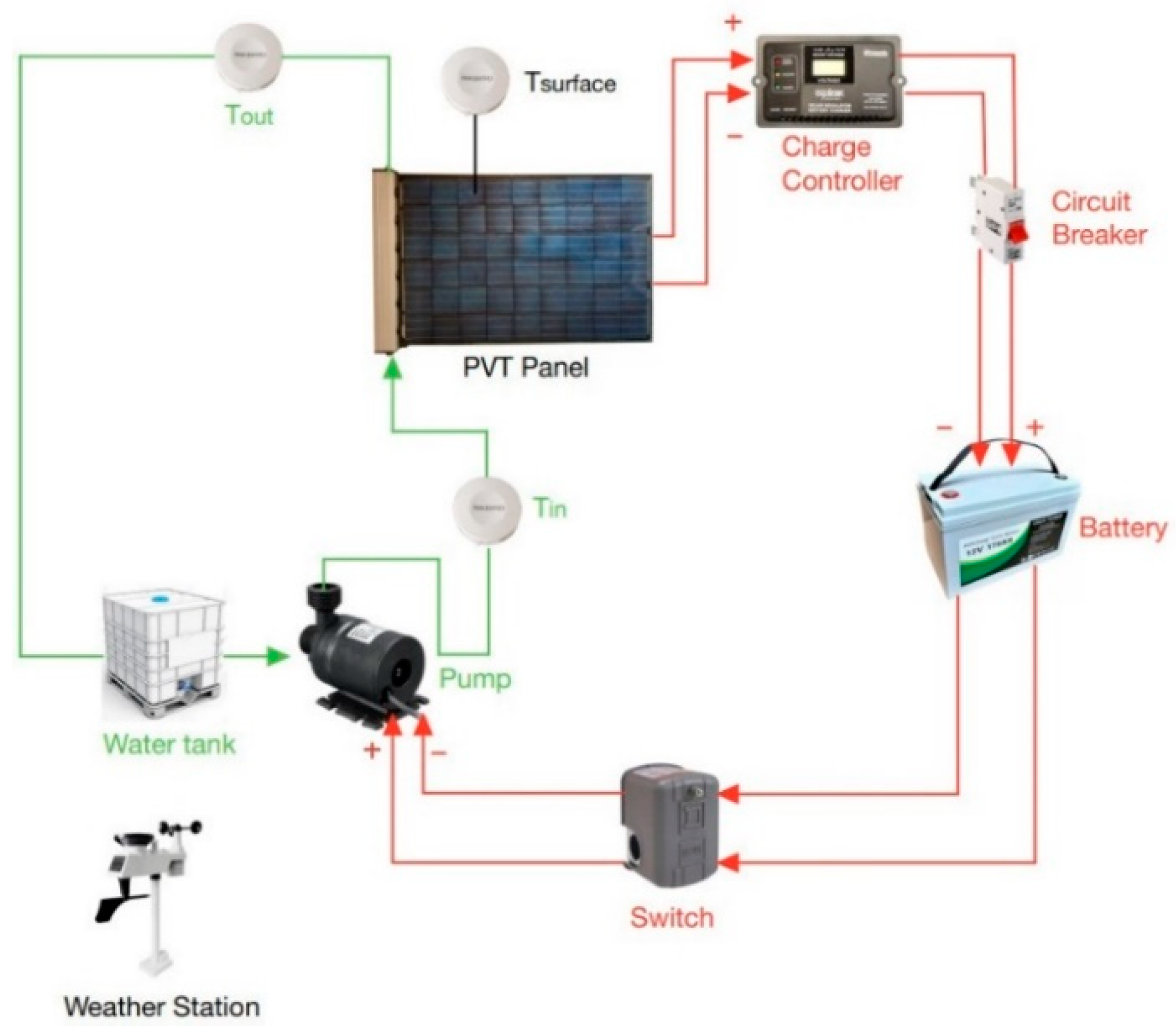

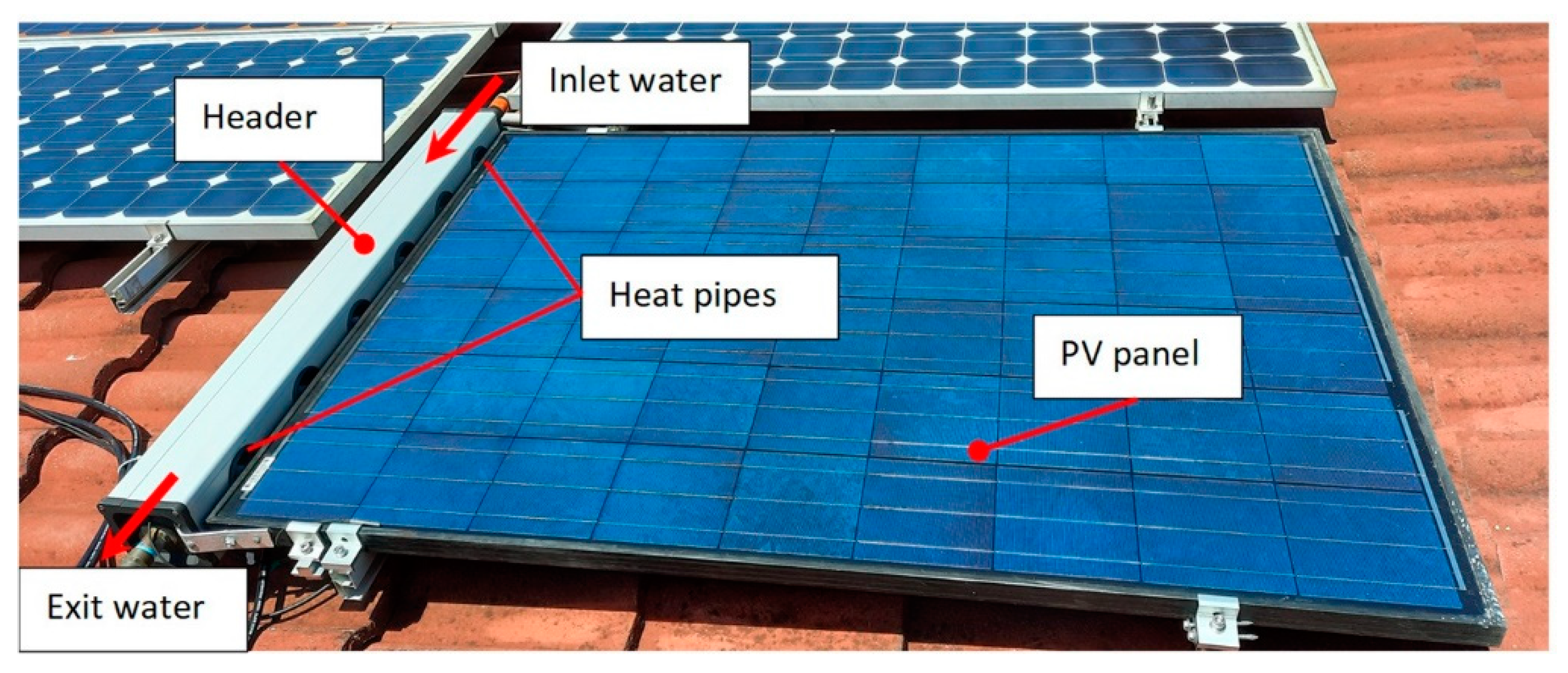

2.1. System and Test Rig Design

2.2. Performance Analysis of PVT Panel

3. Results and Discussions

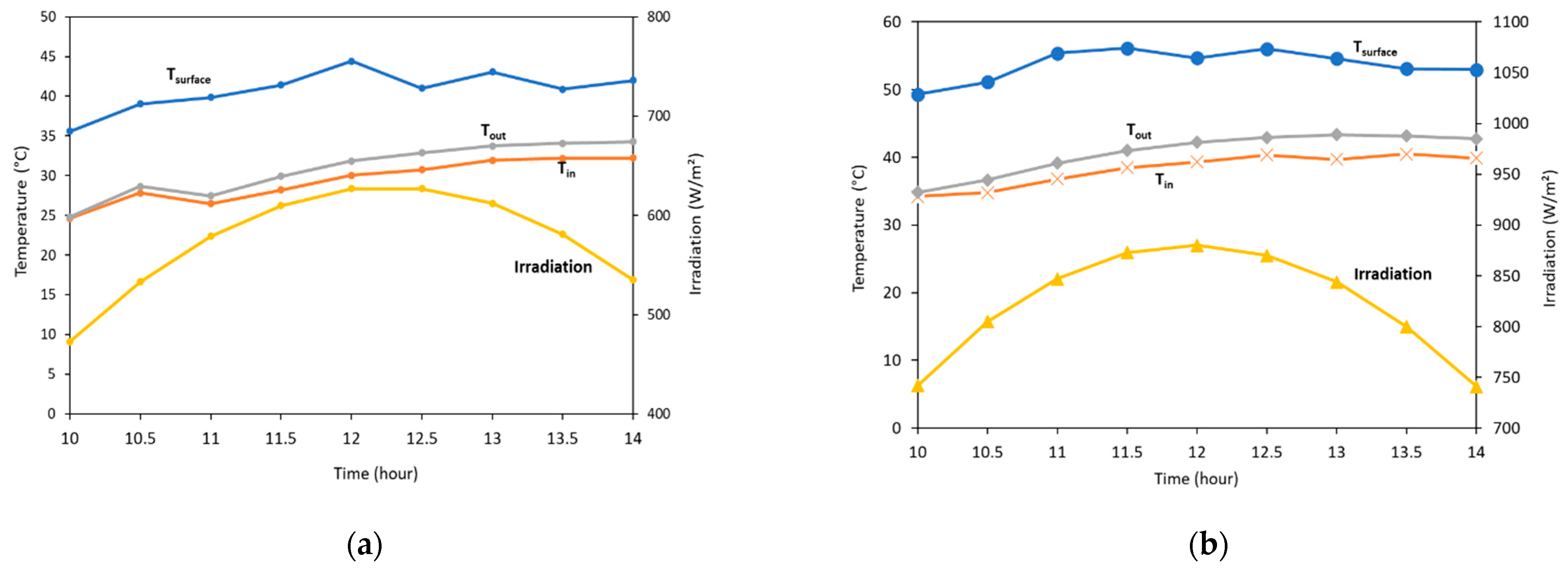

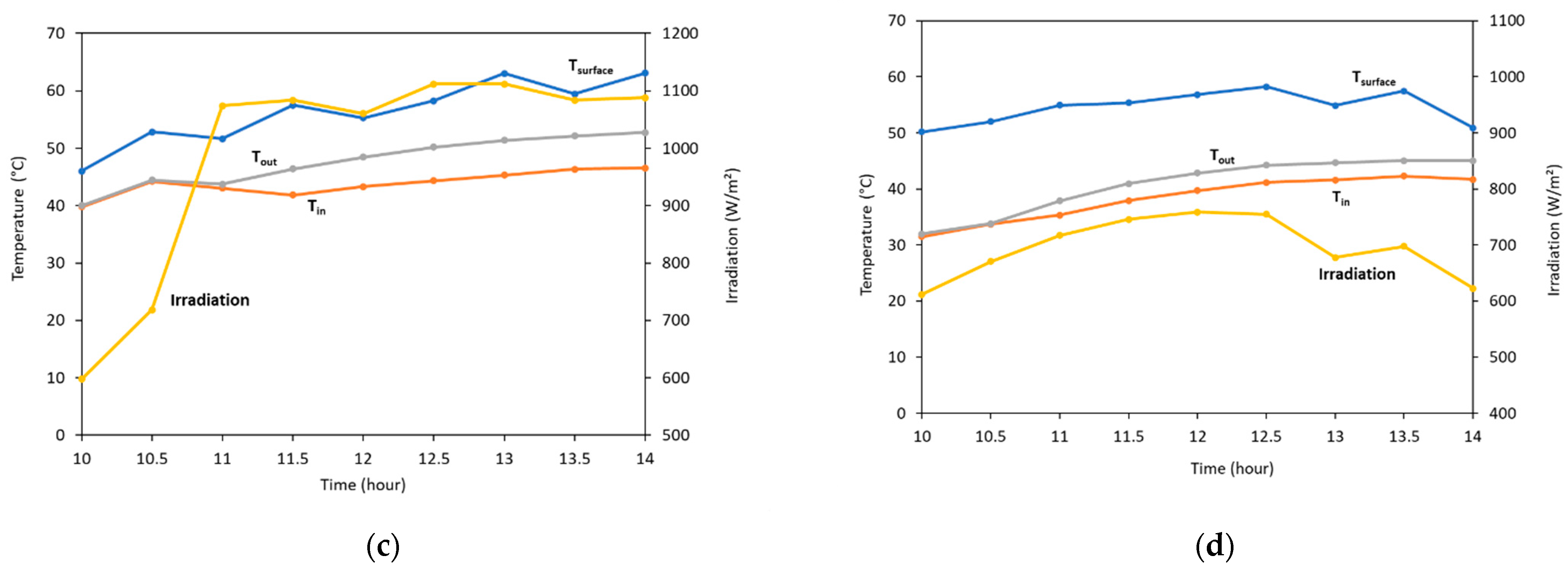

3.1. Analysis of Test Results

- The PVT panel exit water temperature (Tout) is always between (10–15 °C) below the panel surface temperature Tsurface.

- The increase in water temperature (Tout–Tin) within the PVT header is almost constant and found between (2–4 °C) in all seasons. This rise of water temperature depends on water flow rate through the 1 m length of PVT header tube. Although this increase looks small for the first moment, the accumulated heat during the sunshine hours of the specified days is significant as the maximum water tank temperature could reach 25–30 °C above its initial temperature. This water temperature increase within the PVT panel was found not far from other studies such as the one presented by [19] which is in the range 2.9–8 °C, and the study presented by [4] which is in the range 2–3 °C.

- The test shows that the PVT system can provide warm water at a temperature greater than the ambient temperature by almost 10–15 °C.

- The heat gain and exit water temperature keep rising 2 h after noon time despite the drop in irradiation level and PVT surface temperature due to the effect of the PVT panel thermal capacity.

- The maximum temperature of the PVT surface varies between 40 °C on a typical winter day to 60 °C on a typical summer day. This PVT surface temperature measurement was compared with similar research [19] and was found to be around 55 °C on typical day in Autumn. Other research [4] shows that PVT surface temperature is in the range 46–53 °C.

- The water inlet temperature (water tank temperature) that can be reached on a typical cold winter day is 30 °C and on a typical summer day is 50 °C. Almost similar rise in water temperature (from 28–47 °C) was reported by [20] on a typical day of maximum solar irradiation equals to 800 W/m2.

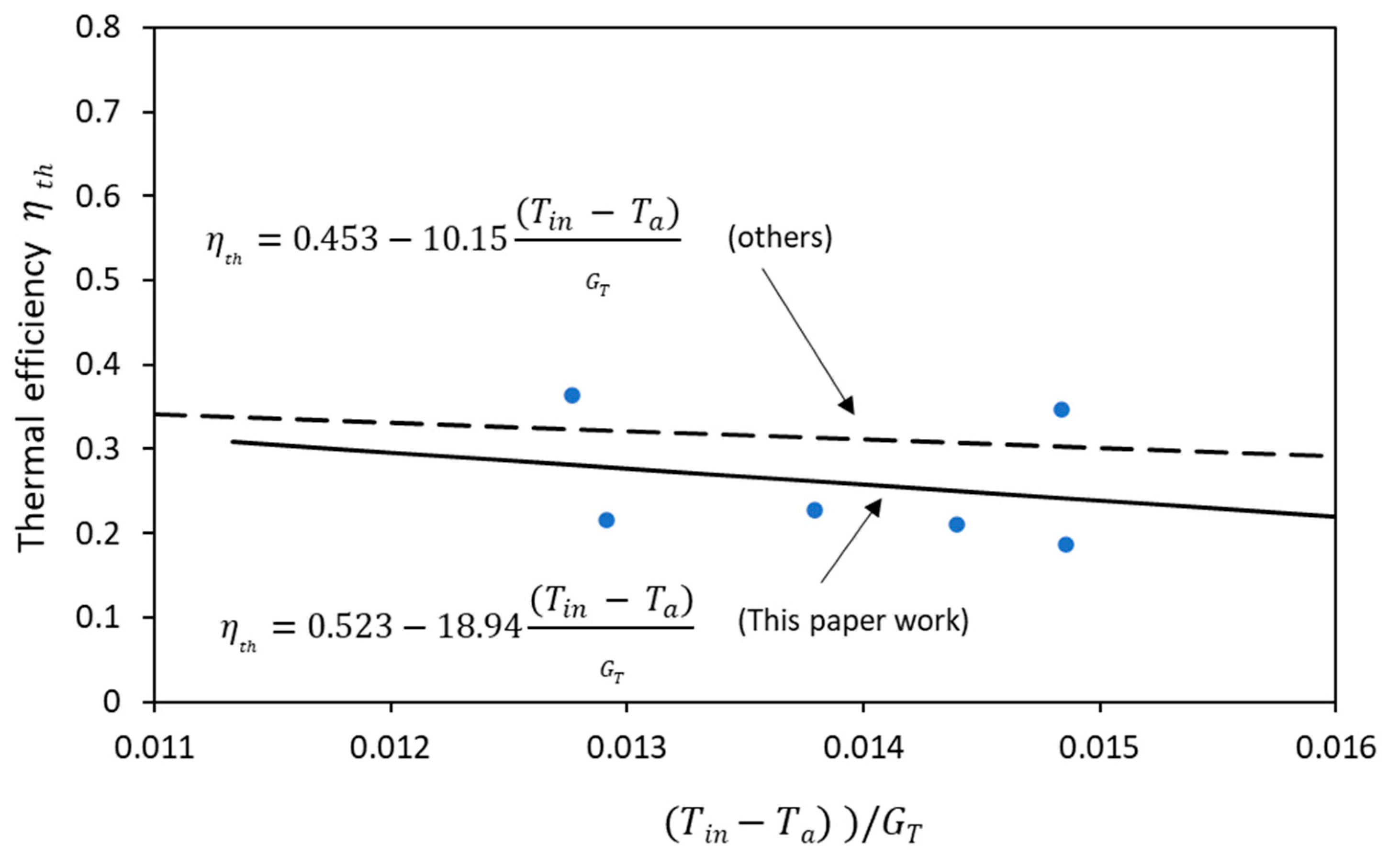

3.2. PVT Thermal Efficiency Equation

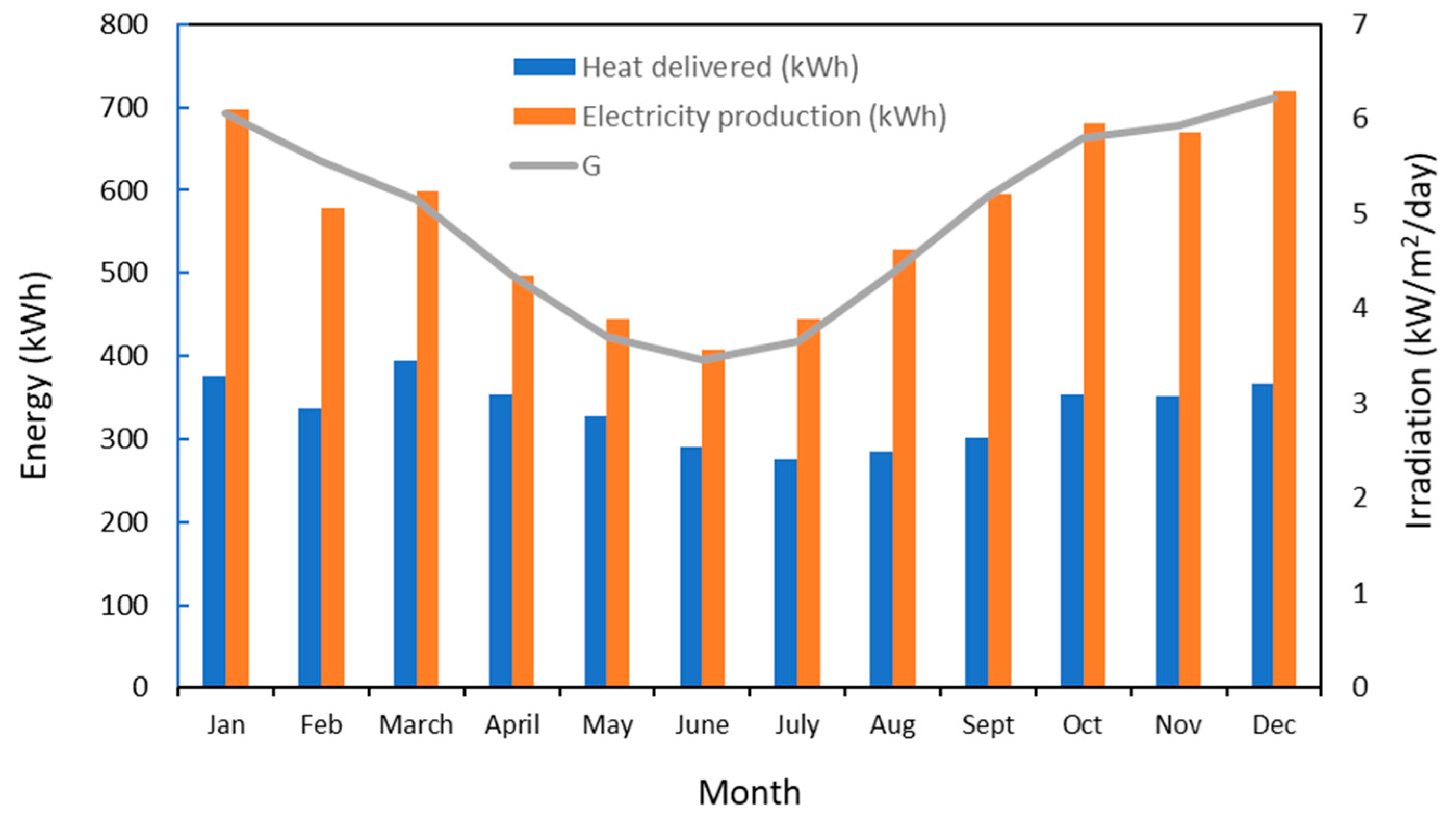

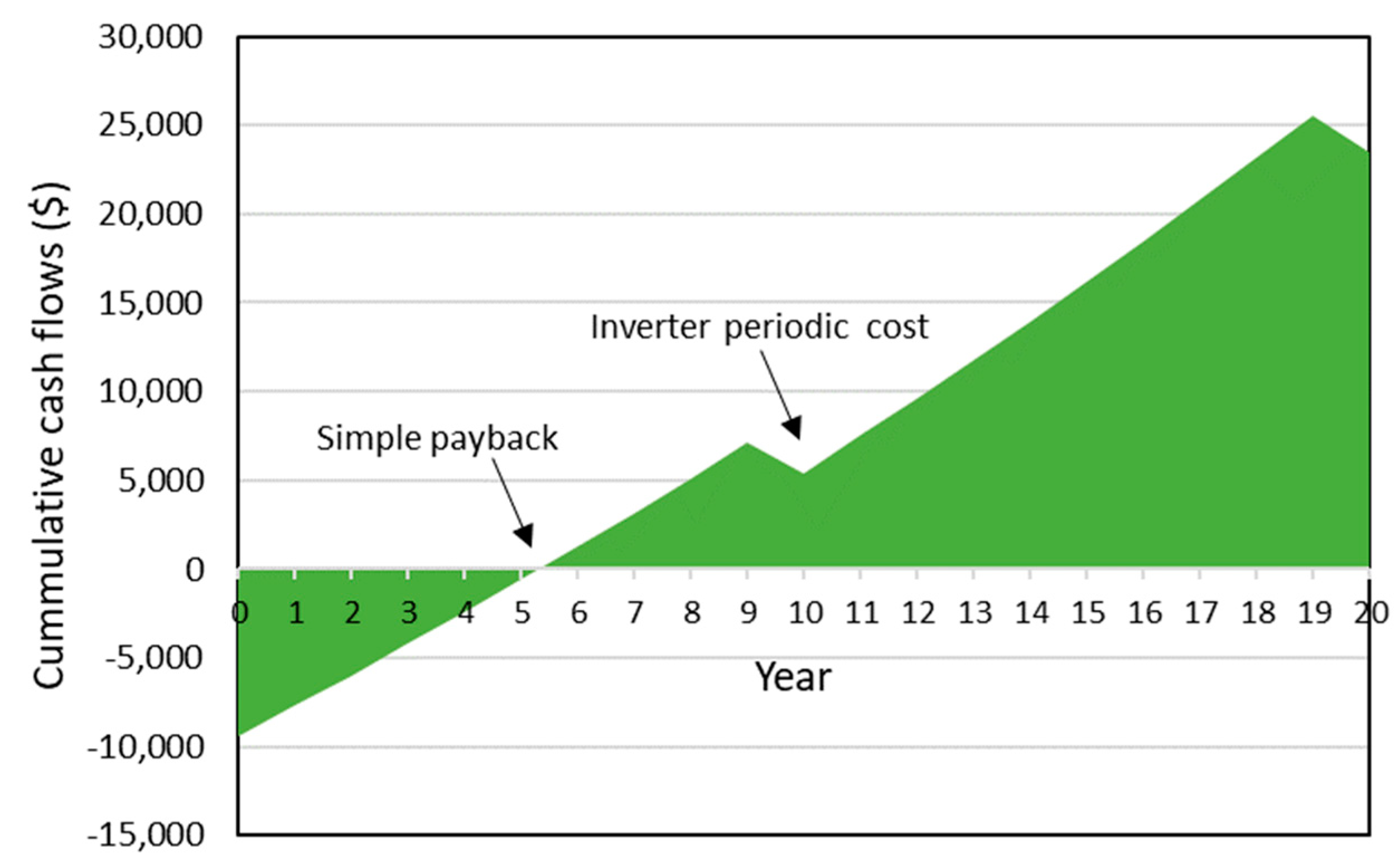

3.3. Feasibility Test of the PVT System

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| A | PVT panel area, m2 |

| APVT | PVT panel aperture area, m2 |

| Cw | Specific heat of water, J/kg.°C |

| FR | heat removal factor |

| G | Solar irradiation, W/m2 |

| GT | Solar global irradiation on titled surface, W/m2 |

| Imp | Current at Pmax, A |

| Isc | Short-circuit current, A |

| M | Mass of tank water, kg |

| Water flow rate, kg/s | |

| nc | Number of PV cell in PV panel |

| NPVT | Number of PVT |

| P | Transient power generated by PV panel, W |

| Pmax | Rated maximum power, W |

| Ptotal | Total transient energy gained by PVT panel, W |

| Pwp | Water pump input power, W |

| QB | Energy provided by booster, J |

| Qg | Heat gained by m2 of PVT panel, J |

| QHW | Energy required by HW tank/day, J |

| QHWS | Heat gained by one PVT, J |

| (QHWS)T | Total heat required by the PVT system, J |

| qHWS | Transient heat gain by PVT system, W |

| Rp | Power ratio |

| Ta | Ambient temperature, °C |

| Tc | PV cell temperature, °C |

| Ti | Tank temperature at current time step, °C |

| Ti+1 | Tank temperature at next time step, °C |

| Tin | Temperature at inlet, °C |

| Tmax | Maximum tank temperature, °C |

| Tout | Temperature at outlet, °C |

| Tsurface | PVT panel surface temperature, °C |

| UL | Heat transfer coefficient, W/m2 °C |

| Vmp | Voltage at Pmax, V |

| Voc | Open-circuit voltage, V |

| η | Overall thermal/electrical efficiency |

| ηth | Instantaneous thermal efficiency |

| τα | Transmissivity and absorptivity of the PVT surface |

| Subscript | |

| hri | First hour |

| hrf | Last hour |

| op | Operational condition |

| st | Standard condition |

| th | Thermal |

| e | Electric |

References

- Odeh, S.; Nguyen, T. Assessment Method to Identify the Potential of Rooftop PV Systems in the Residential Districts. Energies 2021, 14, 4240. [Google Scholar] [CrossRef]

- Chow, T.T.; He, W.; Ji, J. Hybrid photovoltaic-thermosyphon water heating system for residential application. Sol. Energy 2006, 80, 298–306. [Google Scholar] [CrossRef]

- Gang, P.; Fu, H.; Zhang, T.; Ji, J. A numerical and experimental study on a heat pipe PV/T system. Sol. Energy 2011, 85, 911–921. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, Q.; Xiao, L.; Guo, F. A heat pipe photovoltaic/thermal (PV/T) hybrid system and its performance Evaluation. Energy Build. 2011, 43, 3558–3567. [Google Scholar] [CrossRef]

- Huang, C.; Sung, H.; Yen, K. Experimental Study of Photovoltaic/Thermal (PV/T) Hybrid System. Int. J. Smart Grid Clean Energy 2012, 2, 148–152. [Google Scholar] [CrossRef]

- Herrando, M.; Freeman, J.; Ramos, A.; Zabalza, I.; Markides, N.C. Energetic and economic optimization of a novel hybrid PV-thermal system for domestic combined heating and power. In Proceedings of the International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Portoroz, Slovenia, 17–19 July 2017; Volume 13, pp. 966–971. [Google Scholar]

- Herrando, M.; Markides, N.C.; Hellgardt, K. A UK-based assessment of hybrid PV and solar-thermal systems for domestic heating and power: System performance. Appl. Energy 2014, 122, 288–309. [Google Scholar] [CrossRef]

- Hui, L.; Chow, T.; Ji, J. Building-integrated heat pipe photovoltaic/thermal system for use in Hong Kong. Sol. Energy 2017, 155, 1084–1091. [Google Scholar]

- Diallo, T.; Yu, M.; Zhou, J.; Zhao, X.; Shittu, S.; Li, G.; Ji, J.; Hardy, D. Energy performance analysis of a novel solar PVT loop heat pipe employing a microchannel heat pipe evaporator and a PCM triple heat exchanger. Energy 2019, 167, 866–888. [Google Scholar] [CrossRef]

- Abdul-Ganiyu, S.; Quansah, D.; Ramde, W.E.; Seidu, R.; Adaramola, S.M. Investigation of solar photovoltaic-thermal (PVT) and solar photovoltaic (PV) performance: A case study in Ghana. Energies 2020, 13, 2701. [Google Scholar] [CrossRef]

- Sheshpoli, A.Z.; Jahanian, O.; Nikzadfar, K.; Delavar, A.M. Numerical and experimental investigation on the performance of hybrid PV/thermal systems in the north of Iran. Sol. Energy 2020, 215, 108–120. [Google Scholar] [CrossRef]

- Khordehgah, N.; Zabnienska-Góra, A.; Jouhara, H. Energy Performance Analysis of a PV/T System Coupled with Domestic Hot Water System. ChemEngineering 2020, 4, 22. [Google Scholar] [CrossRef]

- Xie, Y.; Simbamba, M.M.; Cao, X.; Sun, L.; Zhou, J.; Yuan, Y. Comparison Study of a Novel Tank PV/T Hot Water System and a Heat Pipe PV/T System. J. Therm. Sci. 2022, 31, 2009–2021. [Google Scholar] [CrossRef]

- Eshghi, H.; Kahani, M.; Zamen, M. Cooling of Photovoltaic Panel Equipped with Single Circular Heat Pipe: An Experimental Study. Renew. Energy Res. Appl. 2022, 3, 229–235. [Google Scholar]

- Odeh, S.; Habbouchi, S. Hybrid Energy Production PV Solar Panel. Australian Patent AU 20131000028 B4, 14 March 2013. [Google Scholar]

- Solcast API. Live and Forecast Solar and Weather Data. 2022. Available online: https://toolkit.solcast.com.au/legacy-live-forecast (accessed on 2 November 2022).

- Odeh, S.; Behnia, M. Development of PV Module Efficiency Using Water Cooling. Heat Transf. Eng. J. 2009, 30, 499–505. [Google Scholar] [CrossRef]

- RETScreen Expert, Clean Energy Management Software, Version 8.1, CanmetENERGY; Natural Resources Canada: Vancouver, BC, Canada, 2022.

- Jouhara, H.; Szulgowska-Zgrzywa, M.; Sayegh, M.A.; Milko, J.; Danielewicz, J.; Nannou, T.K.; Lester, S.P. The performance of a heat pipe based solar PV/T roof collector and its potential contribution in district heating applications. Energy 2017, 136, 117–125. [Google Scholar] [CrossRef]

- Pei, G.; Fu, H.; Zhu, H.; Ji, J. Performance study and parametric analysis of a novel heat pipe PV/T system. Energy 2012, 37, 384–395. [Google Scholar]

- Duffie, J.; Beckman, W. Solar Engineering of Thermal Processes, 4th ed.; Wiley & Sons: Hoboken, NJ, USA, 2013; Chapter 6; pp. 288–301. [Google Scholar]

- Kim, J.H.; Kim, J.T. Comparison of Electrical and Thermal Performances of Glazed and Unglazed PVT Collectors. Int. J. Photoenergy 2012, 2012, 957847. [Google Scholar] [CrossRef]

| Component | Specification |

|---|---|

| PVT panel | Rated Maximum Power (Pmax) = 200 W Voltage at Pmax (Vmp) = 26.26 V Current at Pmax (Imp) = 7.63 A Open-circuit Voltage (Voc) = 33.6 V Short-circuit current (Isc) = 8.11 A Number of cells = 54 polycrystalline cells Cell Technology: Ploy Si PV panel weight = 17 kg PVT panel weight = 25 kg PV panel dimension (mm) = 1488 × 990 × 35 |

| Temperature sensor | Dimension (mm) = 56 × 19 Weight = 21 g Temperature range = −40 °C to 100 °C Wireless range = 50 m Typical temperature accuracy = ±0.3 °C |

| Water Pump | Voltage = DC-12 V Working current = 920 mAh ± 15% Input power = 18 W Flow = 800 L/H ± 15% Pump dimensions (mm) = 80 × 77 × 49 |

| Weather station | Temperature range = −40 °C to 100 °C Wind speed range = 0 to 50 m/s irradiation = 0 to 1600 W/m2 UV index = 1 to 15+ |

| Battery | Voltage = 2 × 12 V, 9 Ah, deep cycle |

| Water tank | Capacity = 20 L |

| Month | PVT Heat (QWHS) kJ/m2 | Booster Energy (QB) kJ Per 100 L Tank | HW Tank Energy (QHW) kJ Per 100 L Tank | PVT System Energy (QHWS)T kJ Per 100 L Tank | Number of PVT Panels kJ Per 100 L Tank | Solar Energy Contribution |

|---|---|---|---|---|---|---|

| Winter | 3024 | 11,604 | 20,173 | 8569 | 1.9 | 0.42 |

| Spring | 1220 | 10,471 | 13,393 | 2922 | 1.6 | 0.22 |

| Summer | 3984 | 5622 | 15,696 | 10,074 | 1.7 | 0.64 |

| Autumn | 4146 | 8807 | 17,339 | 8531 | 1.4 | 0.49 |

| Season | Maximum Efficiency | Minimum Efficiency |

|---|---|---|

| Autumn | 49% | 28% |

| Summer | 65% | 31% |

| Winter | 45% | 26% |

| Spring | 58% | 29% |

| PV Panels Area | PV System Capacity | PV Panel Cost | Feed-In Tariff | Rooftop PVT Area | PVT System Extra Cost | Hot Water Tank Capacity | Project Life | Inflation Ratio |

|---|---|---|---|---|---|---|---|---|

| (m2) | kW | AU$/kW | UA$/kWh | (m2) | USD/m2 | L/day | Year | % |

| 31.7 | 5 | 1000 | 0.15 | 8.8 | 500 | 300 | 20 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Odeh, S.; Feng, J. Long Term Performance Assessment of a Residential PV/Thermal Hybrid System. Energies 2023, 16, 121. https://doi.org/10.3390/en16010121

Odeh S, Feng J. Long Term Performance Assessment of a Residential PV/Thermal Hybrid System. Energies. 2023; 16(1):121. https://doi.org/10.3390/en16010121

Chicago/Turabian StyleOdeh, Saad, and Junxi Feng. 2023. "Long Term Performance Assessment of a Residential PV/Thermal Hybrid System" Energies 16, no. 1: 121. https://doi.org/10.3390/en16010121

APA StyleOdeh, S., & Feng, J. (2023). Long Term Performance Assessment of a Residential PV/Thermal Hybrid System. Energies, 16(1), 121. https://doi.org/10.3390/en16010121