Review of the Economic and Environmental Impacts of Producing Waxy Crude Oils

Abstract

1. Introduction

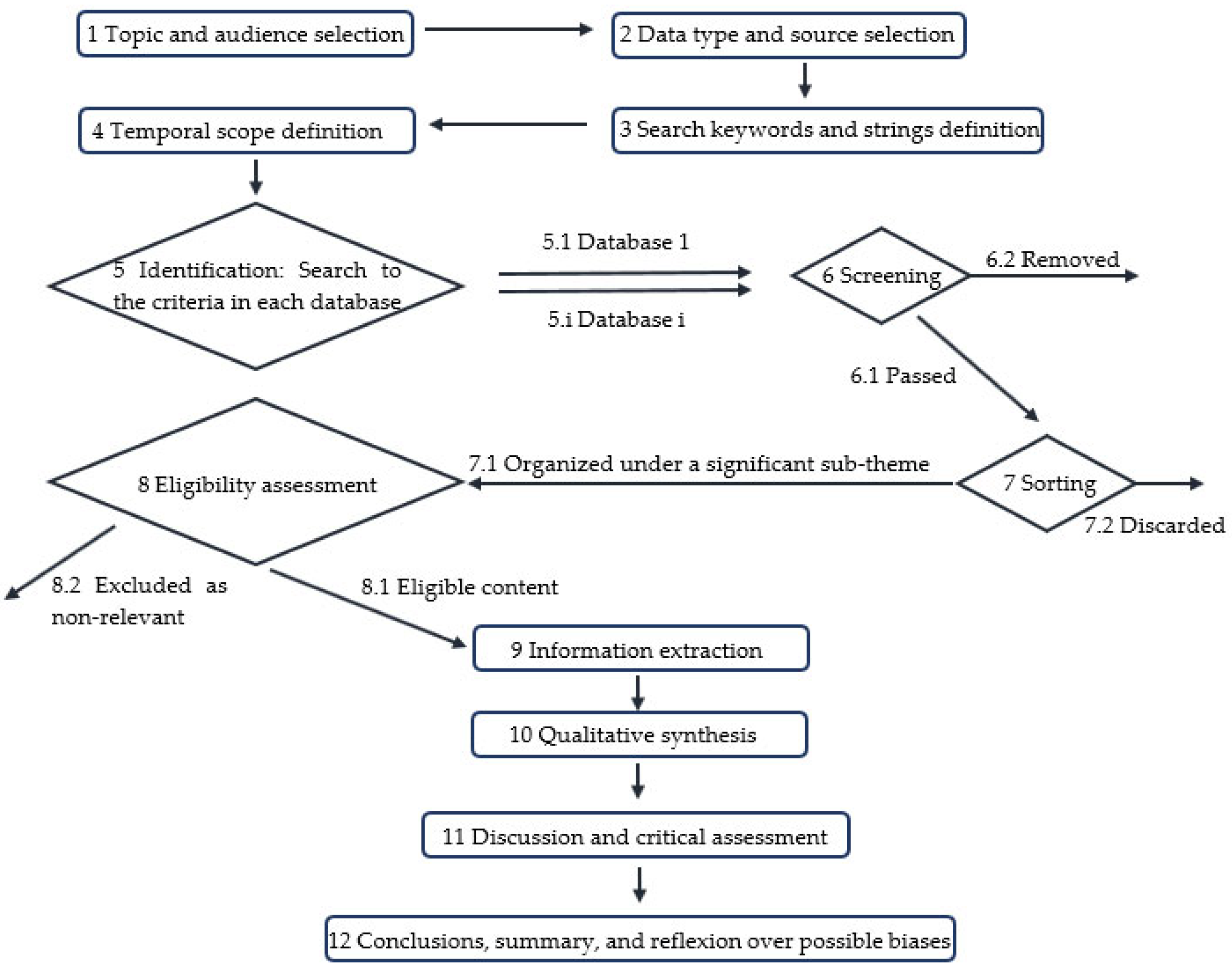

2. Methodology

3. The Problem of Wax Deposition in Energy Production Industries

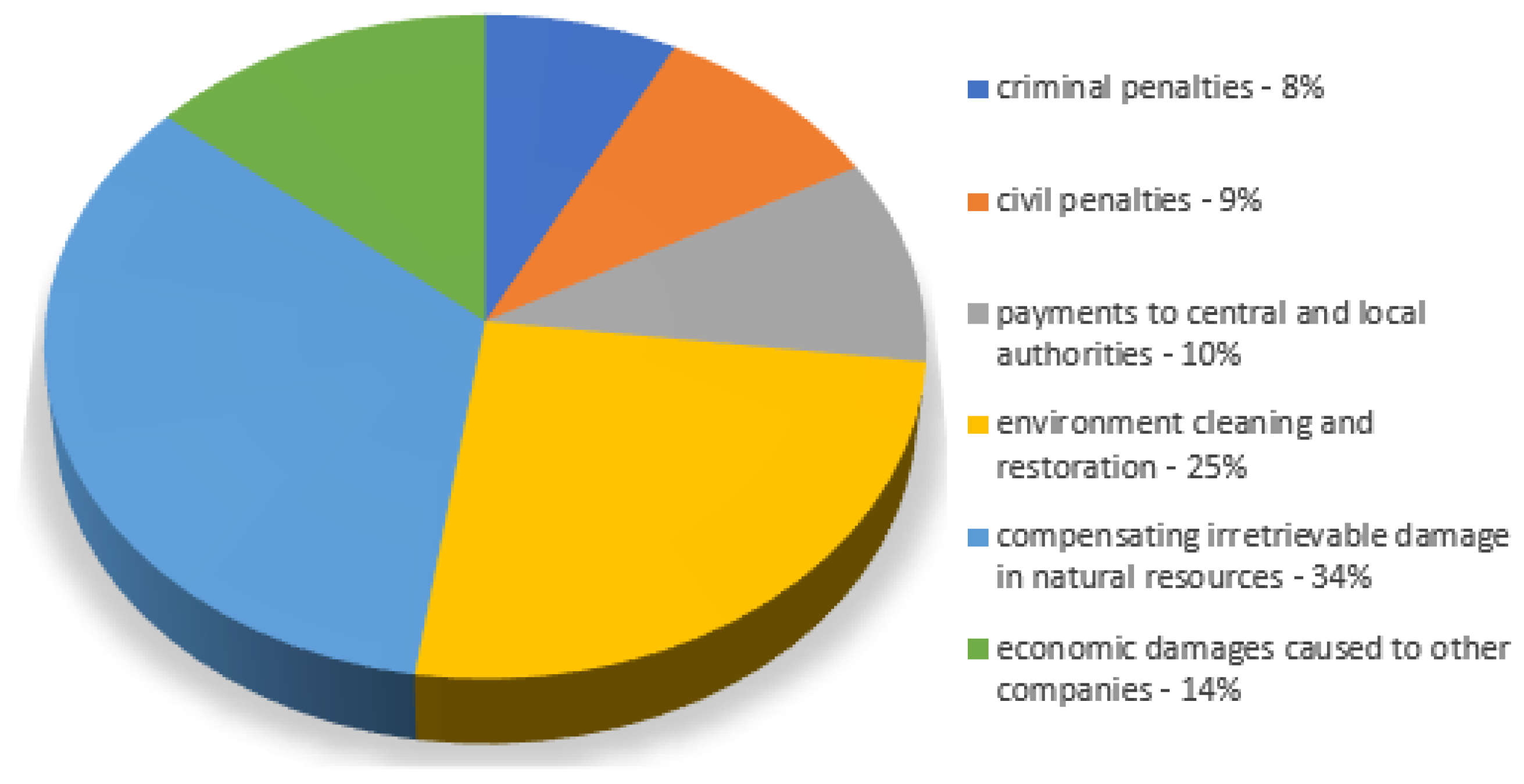

4. The Cost of Spills

5. Operational Costs to Avoid Deposition

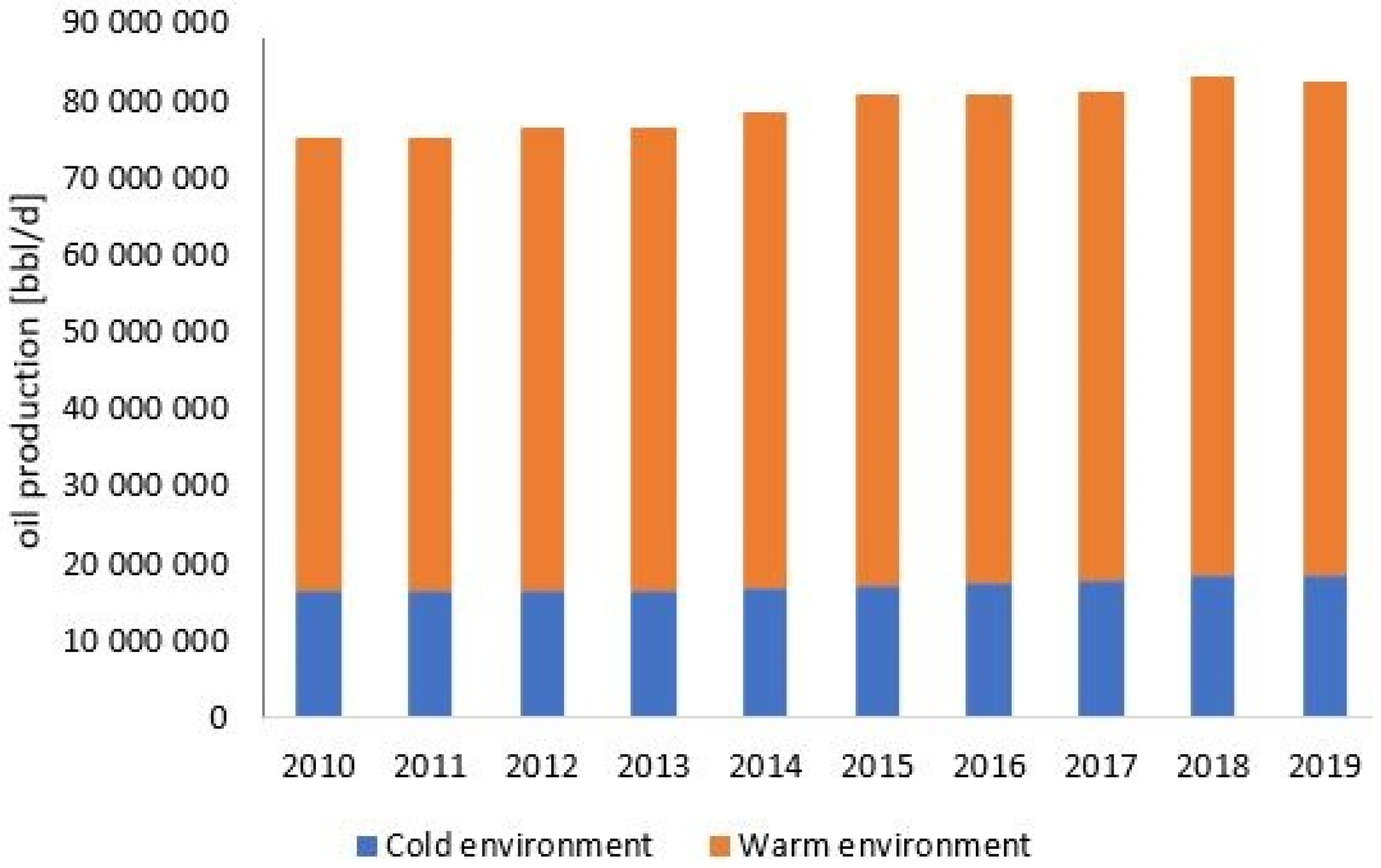

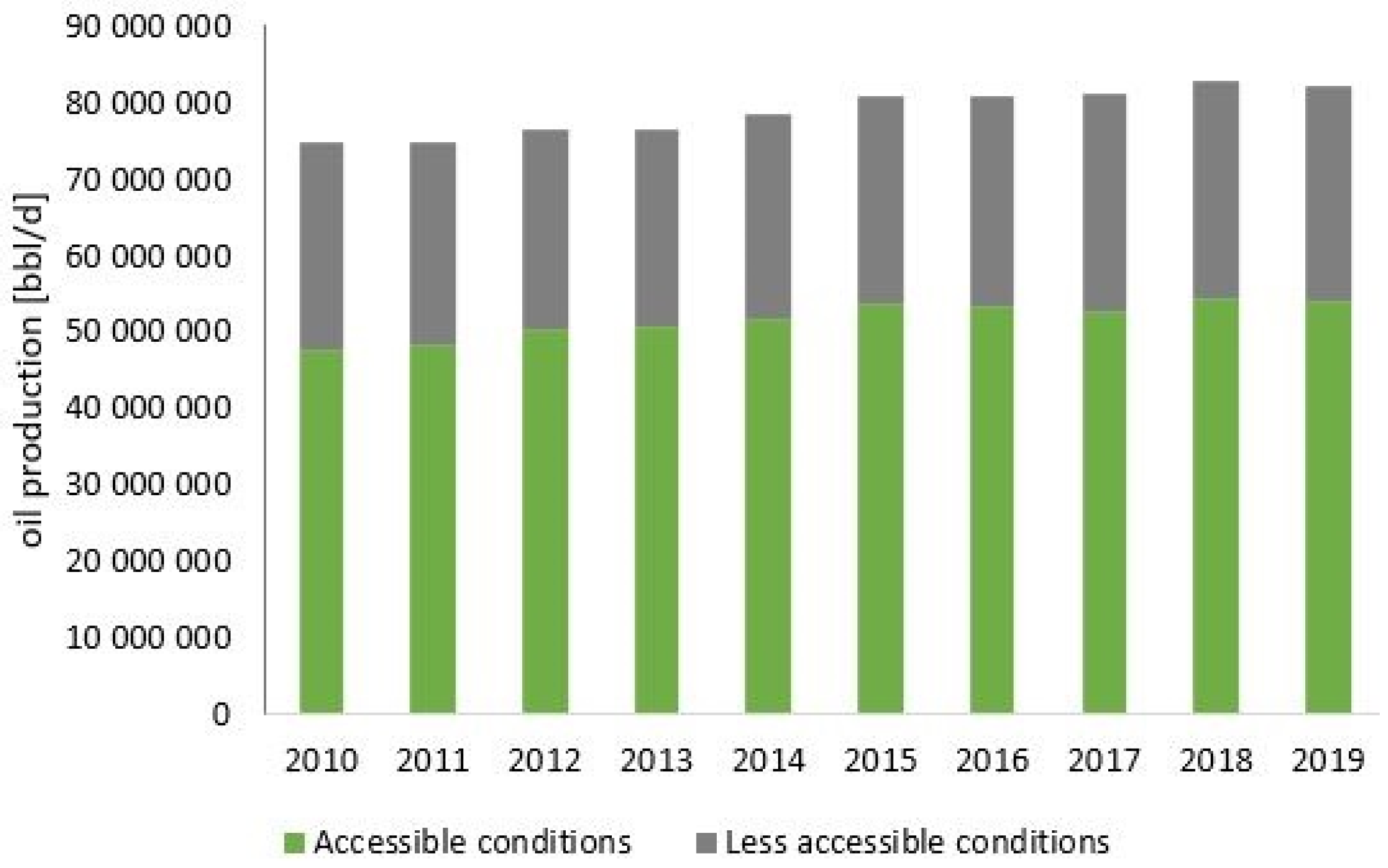

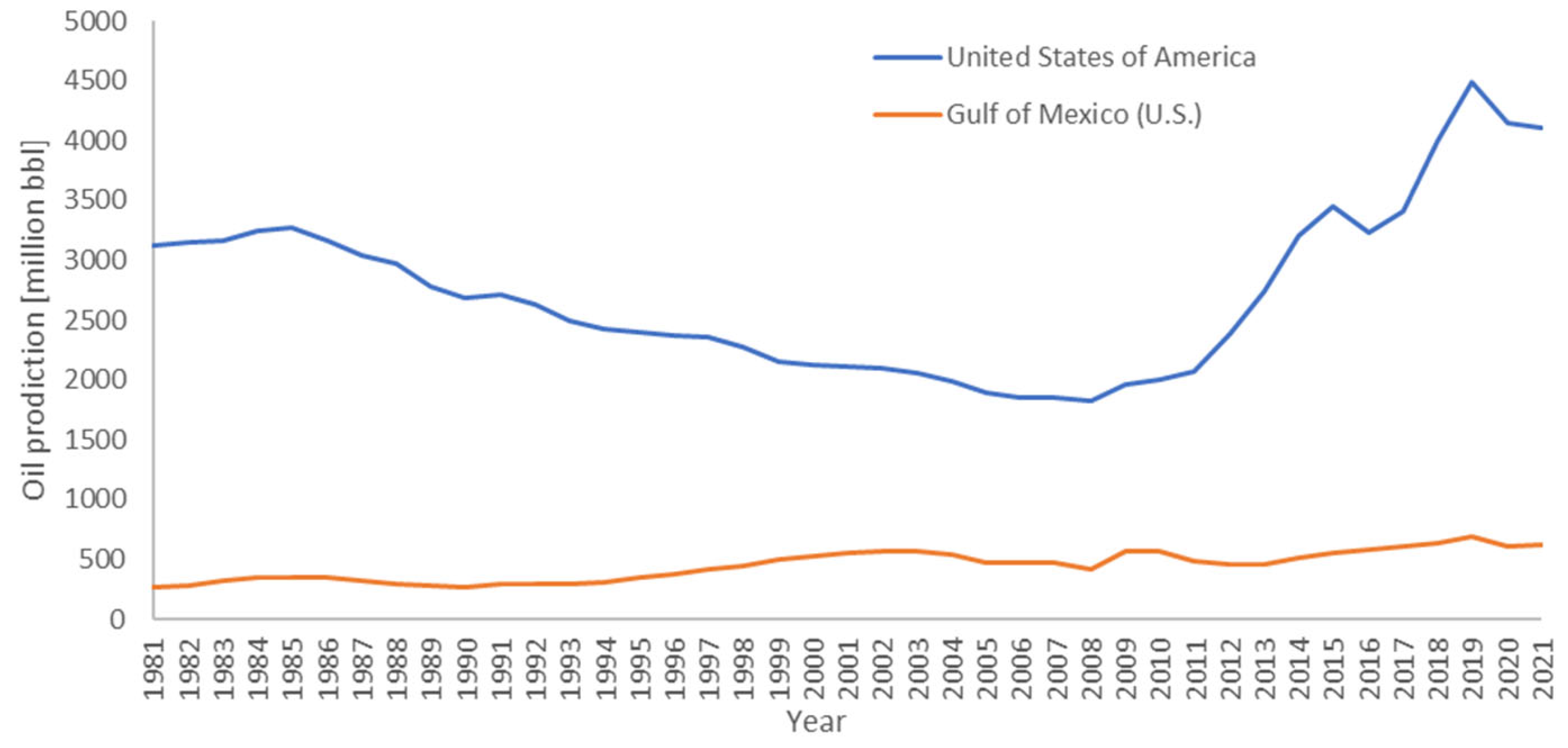

6. Information about Oil Production

7. Information about Wax Deposition in the Oil & Gas Industry

8. Economic and Environmental Implications of Flow Assurance Problems

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bern, P.A.; Withers, V.R.; Cairns, R.J.R. Wax deposition in crude oil pipelines. In Proceedings of the European Offshore Petroleum Conference & Exhibition, London, UK, 21–24 October 1980; pp. 571–575. [Google Scholar]

- Ramirez-Jaramillo, E.; Lira-Galeana, C.; Manero, O. Modeling wax deposition in pipelines. Pet. Sci. Technol. 2004, 22, 821–861. [Google Scholar] [CrossRef]

- Leiroz, A.T.; Azevedo, L.F.A. Studies on the mechanisms of wax deposition in pipelines. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005. ID 17081. [Google Scholar] [CrossRef]

- Edmonds, B.; Moorwood, T.; Szczepanski, R.; Zhang, X. Simulating wax deposition in pipelines for flow assurance. Energy Fuels 2008, 22, 729–741. [Google Scholar] [CrossRef]

- Guozhong, Z.; Gang, L. Study on the wax deposition of waxy crude in pipelines and its application. J. Pet. Sci. Eng. 2010, 70, 1–9. [Google Scholar] [CrossRef]

- Huang, Z.; Lee, H.S.; Senra, M.; Scott Fogler, H. A fundamental model of wax deposition in subsea oil pipelines. AIChE J. 2011, 57, 2955–2964. [Google Scholar] [CrossRef]

- Sousa, A.M.; Matos, H.A.; Guerreiro, L. Wax deposition mechanisms and the effect of emulsions and carbon dioxide injection on wax deposition: Critical review. Petroleum 2020, 6, 215–225. [Google Scholar] [CrossRef]

- Sousa, A.M.; Pereira, M.J.; Matos, H.A. Stochastic Analyses on Relative Viscosity of Water- in-oil Emulsions. In Proceedings of the 30th European Syposium on Computer Aided Process Engineering, Milan, Italy, 24–27 May 2020; pp. 121–126. [Google Scholar]

- Rønningsen, H.P.; Bjorndal, B.; Hansen, A.B.; Pedersen, W.B. Wax Precipitation from North Sea Crude Oils. 1. Crystallization and Dissolution Temperatures, and Newtonian and Non-Newtonian Flow Properties. Energy Fuels 1991, 5, 895–908. [Google Scholar] [CrossRef]

- Burger, E.D.; Perkins, T.K.; Striegler, J.H. Studies of Wax Deposition in the Trans Alaska Pipeline. J. Pet. Technol. 1981, 33, 1075–1086. [Google Scholar] [CrossRef]

- Misra, S.; Baruah, S.; Singh, K. Paraffin problems in crude oil production and transportation: A review. SPE Prod. Facil. 1995, 10, 50–54. [Google Scholar] [CrossRef]

- Venkatesan, R. The Deposition and Rheology of Organic Gels. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2004. [Google Scholar]

- Bello, O.O.; Fasesan, S.O.; Teodoriu, C.; Reinicke, K.M. An evaluation of the performance of selected wax inhibitors on paraffin deposition of Nigerian crude oils. Pet. Sci. Technol. 2006, 24, 195–206. [Google Scholar] [CrossRef]

- Towler, B.F.; Chejara, A.K.; Mokhatab, S. Experimental investigations of ultrasonic waves effects on wax deposition during crude-oil production. In Proceedings of the Proceedings—SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar]

- Bacon, M.M.; Romero-Zerón, L.B.; Chong, K.K. Determining wax type: Paraffin or naphthene? SPE J. 2010, 15, 963–968. [Google Scholar] [CrossRef]

- Wei, B. Recent advances on mitigating wax problem using polymeric wax crystal modifier. J. Pet. Explor. Prod. Technol. 2015, 5, 391–401. [Google Scholar] [CrossRef]

- Huang, Z.; Zheng, S.; Fogler, H.S. Wax Deposition: Experimental Characterizations, Theoretical Modeling, and Field Practices; CRC Press: Boca Raton, FL, USA, 2015; ISBN 9781466567672. [Google Scholar]

- Leporini, M.; Terenzi, A.; Marchetti, B.; Giacchetta, G.; Corvaro, F. Experiences in numerical simulation of wax deposition in oil and multiphase pipelines: Theory versus reality. J. Pet. Sci. Eng. 2019, 174, 997–1008. [Google Scholar] [CrossRef]

- Singh, P.; Venkatesan, R.; Fogler, H.S.; Nagarajan, N. Formation and aging of incipient thin film wax-oil gels. AIChE J. 2000, 46, 1059–1074. [Google Scholar] [CrossRef]

- Nguyen, D.A.; Fogler, H.S.; Chavadej, S. Fused chemical reactions. 2. Encapsulation: Application to remediation of paraffin plugged pipelines. Ind. Eng. Chem. Res. 2001, 40, 5058–5065. [Google Scholar] [CrossRef]

- Gluyas, J.G.; Underhill, J.R. The Staffa Field, Block 3/8b, UK North Sea. Geol. Soc. Mem. 2003, 20, 327–333. [Google Scholar] [CrossRef]

- Rosvold, K. Wax Deposition Models. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2008. [Google Scholar]

- Zhu, T.; Walker, J.A.; Liang, J. Evaluation of Wax Deposition and Its Control during Production of Alaska North Slope Oils; University of Alaska: Fairbanks, AK, USA, 2008. [Google Scholar]

- Handal, A.D. Analysis of Some Wax Deposition Experiments in a Crude Oil Carrying Pipe. Master’s Thesis, University of Oslo, Oslo, Norway, 2008. [Google Scholar]

- Bagatin, R.; Busto, C.; Correra, S.; Margarone, M.; Carniani, C.; Eni, E.; Division, P. Wax modeling: There is need for alternatives. In Proceedings of the SPE Russian Oil and Gas Technical Conference and Exhibition, Moscow, Russia, 28–30 October 2008; pp. 1–8. [Google Scholar] [CrossRef]

- Soedarmo, A.A.; Daraboina, N.; Sarica, C. Microscopic Study of Wax Deposition: Mass Transfer Boundary Layer and Deposit Morphology. Energy Fuels 2016, 30, 2674–2686. [Google Scholar] [CrossRef]

- Huang, Z. Application of the Fundamentals of Heat and Mass Transfer to the Investigation of Wax Deposition in Subsea Pipelines. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2011. [Google Scholar]

- Kang, P.S.; Lee, D.G.; Lim, J.S. Status of Wax Mitigation Technologies in Offshore Oil Production. In Proceedings of the Twenty-Fourth International Ocean and Polar Engineering Conference, Busan, Korea, 15–20 June 2014; Volume 3, pp. 31–38. [Google Scholar]

- Chi, Y.; Daraboina, N.; Sarica, C. Investigation of inhibitors efficacy in wax deposition mitigation using a laboratory scale flow loop. AIChE J. 2016, 62, 4131–4139. [Google Scholar] [CrossRef]

- Bilderback, C.A.; McDougall, L.A. Complete Paraffin Control in Petroleum Production. J. Pet. Technol. 1969, 21, 1151–1156. [Google Scholar] [CrossRef]

- Theyab, M.A.; Yahya, S.Y. Introduction to Wax Deposition. Int. J. Petrochem. Res. 2018, 2, 126–131. [Google Scholar] [CrossRef]

- Craddock, H.A.; Mutch, K.; Sowerby, K.; McGregor, S.; Cook, J.; Strachan, C. A case study in the removal of deposited wax from a major subsea flowline system in the gannet field. In Proceedings of the Proceedings—SPE International Symposium on Oilfield Chemistry, Houston, TX, USA, 28 February–2 March 2007. [Google Scholar]

- Kok, M.V.; Saracoglu, R.O. Mathematical modelling of wax deposition in crude oil pipelines (Comparative study). Pet. Sci. Technol. 2000, 18, 1121–1145. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Altman, D.; Antes, G.; Atkins, D.; Barbour, V.; Barrowman, N.; Berlin, J.A.; et al. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, T.; Bernardo, L.; Andrade, J. Topology Optimisation in Structural Steel Design for Additive Manufacturing. Appl. Sci. 2021, 11, 2112. [Google Scholar] [CrossRef]

- Umar, T. Key factors influencing the implementation of three-dimensional printing in construction. Proc. Inst. Civ. Eng. Manag. Procure. Law 2020, 174, 104–117. [Google Scholar] [CrossRef]

- Brunton, R.H. The Production of Paraffin and Paraffin Oils; Columbia University: New York, NY, USA, 1881. [Google Scholar]

- Reistle, C.E., Jr. Summary of Existing Information on Handling Congealing Oils and Paraffin. Trans. AIME 1927, 77, 227–252. [Google Scholar] [CrossRef]

- Jessen, F.W.; Howell, J.N. Effect of Flow Rate on Paraffin Accumulation in Plastic, Steel, and Coated Pipe. Trans. AIME 1958, 213, 80–84. [Google Scholar] [CrossRef]

- Hunt, E.B., Jr. Laboratory Study of Paraffin Deposition. SPE J. Pet. Technol. 1962, 14, 1259–1269. [Google Scholar] [CrossRef]

- Carnahan, N.F. Paraffin Deposition in Petroleum Production. J. Pet. Technol. 1989, 41, 1024–1106. [Google Scholar] [CrossRef]

- McClaflin, G.G.; Whitfill, D.L. Control of Paraffin Deposition in Production Operations. J. Pet. Technol. 1984, 36, 1965–1970. [Google Scholar] [CrossRef]

- Agrawal, K.M.; Khan, H.U.; Surianarayanan, M.; Joshi, G.C. Wax deposition of Bombay high crude oil under flowing conditions. Fuel 1990, 69, 794–796. [Google Scholar] [CrossRef]

- Hsu, J.J.C.; Santamaria, M.M.; Brubaker, J.P. Wax deposition of waxy live crudes under turbulent flow conditions. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 25–28 September 1994. [Google Scholar]

- Kadir, A.A.A.; Ismail, I. Determination of Crystallization of Waxy Crude and the Influence on Diluents. In Proceedings of the Regional Symposium on Chemical Engineering ’97, Johor Bahru, Malaysia, 13–15 October 1997. [Google Scholar]

- Marques, L.C.C.; Machado, A.L.C.; Garcia, R.L.P.; Soldan, A.L.; Campagnolo, E.A. Organic deposition presents challenges in Brazil’s offshore fields. World Oil 1997, 218, 125–128. [Google Scholar]

- Machado, A.L.C.; Lucas, E.F.; González, G. Poly(ethylene-co-vinyl acetate) (EVA) as wax inhibitor of a Brazilian crude oil: Oil viscosity, pour point and phase behavior of organic solutions. J. Pet. Sci. Eng. 2001, 32, 159–165. [Google Scholar] [CrossRef]

- Adewusi, V.A. Waxing tendencies and rheological evaluation of crude-condensate blends for an offshore pipeline transportation. Pet. Sci. Technol. 1998, 32, 159–165. [Google Scholar] [CrossRef]

- Elsharkawy, A.M.; Al-Sahhaf, T.A.; Fahim, M.A. Wax deposition from Middle East crudes. Fuel 2000, 79, 1047–1055. [Google Scholar] [CrossRef]

- Hammami, A.; Raines, M.A. Paraffin deposition from crude oils: Comparison of laboratory results with field data. SPE J. 1999, 4, 9–18. [Google Scholar] [CrossRef]

- Stenvall Skold & Company Chinese Oil Consumption and Investment in Offshore Production. Available online: http://www.stenvall-skoeld.com/1275/china-oil-production-consumption (accessed on 4 July 2020).

- Knoema Cost of Producing a Barrel of Crude Oil by Country. Available online: https://pt.knoema.com/rqaebad/cost-of-producing-a-barrel-of-crude-oil-by-country (accessed on 4 July 2020).

- Salam, K.K.; Arinkoola, A.O.; Oke, E.O.; Adeleye, J.O. Optimization of operating parameters using response surface methodology for paraffin-wax deposition in pipeline. Pet. Coal 2014, 56, 19–28. [Google Scholar]

- England, J. Exploration and Production Snapshots: Mexico. Available online: https://www2.deloitte.com/us/en/pages/energy-and-resources/articles/exploration-and-production-in-mexico.html (accessed on 4 July 2020).

- Government of India About Exploration & Production. Available online: http://petroleum.nic.in/exploration-production/about-exploration-production (accessed on 4 July 2020).

- Offshore Magazine Top 10 Offshore Producing Countries in 2017. Available online: https://www.offshore-mag.com/production/article/16756124/top-10-offshore-producing-countries-in-2017 (accessed on 4 July 2020).

- Chala, G.T.; Sulaiman, S.A.; Japper-Jaafar, A. Flow start-up and transportation of waxy crude oil in pipelines-A review. J. Nonnewton. Fluid Mech. 2018, 251, 69–87. [Google Scholar] [CrossRef]

- Mohyaldinn, M.E.; Husin, H.; Hasan, N.; Elmubarak, M.M.B.; Genefid, A.M.E.; Dheeb, M.E.A. Challenges during Operation and Shutdown of Waxy Crude Pipelines. In Processing of Heavy Crude Oils—Challenges and Opportunities; BoD—Books on Demand: Norderstedt, Germany, 2019; pp. 1–11. [Google Scholar]

- Henderson, J.; Grushevenko, E. The Future of Russian Oil Production in the Short, Medium, and Long Term. Oxf. Inst. Energy Stud. 2019, 57, 1–22. [Google Scholar]

- Enerdata Global Energy Statistical Yearbook. Available online: https://yearbook.enerdata.net/crude-oil/world-production-statitistics.html (accessed on 4 July 2020).

- The Danish Energy Agency About Oil and Gas. Available online: https://ens.dk/en/our-responsibilities/oil-gas/about-oil-and-gas (accessed on 4 July 2020).

- Gupte, E. Nigerian Oil Output at Risk from Coronavirus as Cases at Offshore Oil Fields Rise. Available online: https://www.spglobal.com/platts/en/market-insights/latest-news/oil/062420-nigerian-oil-output-at-risk-from-coronavirus-as-cases-at-offshore-oil-fields-rise (accessed on 4 July 2020).

- NS Energy Kashagan Oil Field Development. Available online: https://www.nsenergybusiness.com/projects/kashagan-oil-field-development/ (accessed on 4 July 2020).

- EnergyEgypt United Oil & Gas Upgrades Reserves of Egypt’s Abu Sennan. Available online: https://energyegypt.net/tag/production/ (accessed on 4 July 2020).

- Government of Canada Crude Oil Facts. Available online: https://www.nrcan.gc.ca/science-data/data-analysis/energy-data-analysis/energy-facts/crude-oil-facts/20064 (accessed on 4 July 2020).

- BP. BP Statistical Review of World Energy; BP: London, UK, 2020. [Google Scholar]

- U.S. Energy Information Administration Alaska Field Production of Crude Oil. Available online: https://www.eia.gov/dnav/pet/hist/LeafHandler.ashx?n=PET&s=MCRFPAK2&f=A (accessed on 4 July 2020).

- U.S. Energy Information Administration Background Reference: Colombia. Available online: https://www.eia.gov/international/content/analysis/countries_long/Colombia/background.htm (accessed on 4 July 2020).

- U.S. Energy Information Administration Background Reference: Kazakhstan. Available online: https://www.eia.gov/international/content/analysis/countries_long/Kazakhstan/background.htm (accessed on 4 July 2020).

- U.S. Energy Information Administration Petroleum and Other Liquids. Available online: https://www.eia.gov/international/data/world/petroleum-and-other-liquids/more-petroleum-and-other-liquids-data?pd=5&p=00000000000000000000000000000000008&u=0&f=A&v=line&a=-&i=none&vo=value&&t=C&g=00000000000000000000000000000000000000000000000001&l=249-ru (accessed on 4 July 2020).

- U.S. Energy Information Administration Where Our Oil Comes From. Available online: https://www.eia.gov/energyexplained/oil-and-petroleum-products/where-our-oil-comes-from.php (accessed on 4 July 2020).

- Kleinhans, J.W.; Niesen, V.G.; Brown, T.S. Pompano paraffin calibration field trials. In Proceedings of the Proceedings—SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 1–4 October 2000. [Google Scholar]

- Ding, J.; Zhang, J.; Li, H.; Zhang, F.; Yang, X. Flow behavior of Daqing waxy crude oil under simulated pipelining conditions. Energy Fuels 2006, 20, 2531–2536. [Google Scholar] [CrossRef]

- Labes-Carrier, C.; Rønningsen, H.; Kolnes, J.; Leporcher, E. Wax Deposition in North Sea Gas Condensate and Oil Systems: Comparison Between Operational Experience and Model Prediction. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September–2 October 2002. [Google Scholar] [CrossRef]

- Sulaimon, A.A.; Falade, G.K.; Delandro, W. A Proactive Approach For Predicting and Preventing Wax Deposition in Production Tubing Strings: A Niger Delta Experience. J. Pet. Gas Eng. 2010, 1, 26–36. [Google Scholar]

- Adewusi, V.A. Prediction of wax deposition potential of hydrocarbon systems from viscosity-pressure correlations. Fuel 1997, 76, 1079–1083. [Google Scholar] [CrossRef]

- Ajienka, J.A.; Ikoku, C.U. Waxy crude oil handling in Nigeria: Practices, problems, and prospects. Energy Sources 1990, 12, 463–478. [Google Scholar] [CrossRef]

- Azevedo, L.F.A.; Teixeira, A.M. A Critical Review of the Modeling of Wax Deposition Deposition Mechanisms. Pet. Sci. Technol. 2003, 21, 393–408. [Google Scholar] [CrossRef]

- Li, R.; Huang, Q.; Zhang, D.; Zhu, X.; Shan, J.; Wang, J. An aging theory-based mathematic model for estimating the wax content of wax deposits using the Fick’s second law. AIChE J. 2019, 66, e16892. [Google Scholar] [CrossRef]

- Sivakumar, P.; Sircar, A.; Deka, B.; Silviya Anumegalai, A.; Suresh Moorthi, P.; Yasvanthrajan, N. Flow improvers for assured flow of crude oil in midstream pipeline—A review. J. Pet. Sci. Eng. 2018, 164, 24–30. [Google Scholar] [CrossRef]

- Jeirani, Z.; Lashanizadegan, A.; Ayatollahi, S.; Javanmardi, J. The Possibility of Wax Formation in Gas Fields: A Case Study. J. Nat. Gas Chem. 2007, 16, 293–300. [Google Scholar] [CrossRef]

- Bai, Y.; Bai, Q. Subsea Engineering Handbook; Gulf Professional Publishing: Oxford, UK, 2018; ISBN 9780128126226. [Google Scholar]

- Li, R.; Huang, Q.; Huo, F.; Fan, K.; Li, W.; Zhang, D. Effect of shear on the thickness of wax deposit under laminar flow regime. J. Pet. Sci. Eng. 2019, 181, 106212. [Google Scholar] [CrossRef]

- Huang, Z.; Senra, M.; Kapoor, R.; Fogler, H.S. Wax deposition modeling of oil/water stratified channel flow. AIChE J. 2011, 57, 841–851. [Google Scholar] [CrossRef]

- Apte, M.S.; Matzain, A.; Zhang, H.-Q.; Volk, M.; Brill, J.P.; Creek, J.L. Investigation of Paraffin Deposition During Multiphase Flow in Pipelines and Wellbores—Part 2: Modeling. J. Energy Resour. Technol. 2001, 123, 150–157. [Google Scholar] [CrossRef]

- Abu El-Ella, R.; Nassef, E. Determination of Wax Content in Egyptian Crude Oils. Int. J. Eng. Trends Technol. 2014, 8, 93–97. [Google Scholar] [CrossRef]

- Ribeiro, F.S.; Souza Mendes, P.R.; Braga, S.L. Obstruction of pipelines due to paraffin deposition during the flow of crude oils. Int. J. Heat Mass Transf. 1997, 40, 4319–4328. [Google Scholar] [CrossRef]

- Sousa, A.L.; Matos, H.A. Correlations for prediction of molecular diffusivities in liquids at infinite dilution for normal paraffin solutions. Can. J. Chem. Eng. 2019, 98, 1031–1032. [Google Scholar] [CrossRef]

- Al-Sahhaf, T.A.; Fahim, M.A.; Elsharkawy, A. Effect of inorganic solids, wax to asphaltene ratio, and water cut on the stability of water-in-crude oil emulsions. J. Dispers. Sci. Technol. 2009, 30, 597–604. [Google Scholar] [CrossRef]

- Sousa, A.M.; Matos, H.A.; Pereira, M.J. Properties of Crude Oil-in-Water and Water-in-Crude Oil Emulsions: A Critical Review. Ind. Eng. Chem. Res. 2022, 61, 1–20. [Google Scholar] [CrossRef]

- Sousa, A.L.; Matos, H.A.; Guerreiro, L.P. Preventing and removing wax deposition inside vertical wells: A review. J. Pet. Explor. Prod. Technol. 2019, 9, 2091–2107. [Google Scholar] [CrossRef]

- Golczynski, T.S.; Kempton, E.C. Understanding Wax Problems Leads to Deepwater Flow Assurance Solutions. World Oil. 2006, 227, 7–10. [Google Scholar]

- García, M.D.C.; Carbognani, L.; Urbina, A.; Orea, M. Paraffin deposition in oil production. Oil composition and paraffin inhibitors activity. Pet. Sci. Technol. 1998, 16, 1001–1021. [Google Scholar] [CrossRef]

- Del Carmen García, M.; Carbognani, L.; Orea, M.; Urbina, A. The influence of alkane class-types on crude oil wax crystallization and inhibitors efficiency. J. Pet. Sci. Eng. 2000, 25, 99–105. [Google Scholar] [CrossRef]

- Ridzuan, N.; Adam, F.; Yaacob, Z. Molecular recognition of wax inhibitor through Pour Point Depressant type inhibitor. In Proceedings of the Society of Petroleum Engineers—International Petroleum Technology Conference 2014, IPTC 2014—Innovation and Collaboration: Keys to Affordable Energy, Doha, Qatar, 19–22 January 2014. [Google Scholar]

- Adeyanju, O.A.; Oyekunle, L.O. Influence of Long Chain Acrylate Ester Polymers as Wax Inhibitors in Crude Oil Pipelines. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 5–8 August 2014. [Google Scholar]

- Hoffmann, R.; Amundsen, L. Single-phase wax deposition experiments. Energy Fuels 2010, 24, 1069–1080. [Google Scholar] [CrossRef]

- Manfield, P.; Stone, B.; Kwan, T.; Zimmerman, E.; Devlin, P. Wax-On, Wax-Off: Understanding and Mitigating Wax Deposition in a Deepwater Subsea Gas/Condensate Flowline. In Proceedings of the the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2007. [Google Scholar] [CrossRef]

- Huang, Z.; Lu, Y.; Hoffmann, R.; Amundsen, L.; Fogler, H.S. The Effect of Operating Temperatures on Wax Deposition. Energy Fuels 2011, 25, 5180–5188. [Google Scholar] [CrossRef]

- Hoffmann, R.; Amundsen, L.; Huang, Z.; Zheng, S.; Fogler, H.S. Wax deposition in stratified oil/water flow. Energy Fuels 2012, 26, 3416–3423. [Google Scholar] [CrossRef]

- Dall’Acqua, D.; Benucci, M.; Corvaro, F.; Leporini, M.; Cocci Grifoni, R.; Del Monaco, A.; Di Lullo, A.; Passucci, C.; Marchetti, B. Experimental results of pipeline dewatering through surfactant injection. J. Pet. Sci. Eng. 2017, 159, 542–552. [Google Scholar] [CrossRef]

- Myo Thant, M.M.; Mohd Sallehud-Din, M.T.; Hewitt, G.F.; Hale, C.P.; Quarini, G.L. Mitigating flow assurance challenges in deepwater fields using active heating methods. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, MEOS, Manama, Bahrain, 25–28 September 2011; Volume 1, pp. 570–579. [Google Scholar]

- Ashford, J.D.; Blount, C.G.; Marcou, J.A.; Ralph, J.M.; Skaalure, E.W. Annular packer fluids for paraffin control. Model study and successful field application. SPE Prod. Eng. 1990, 5, 351–355. [Google Scholar] [CrossRef]

- Low Flow Study Project Team. Low Flow Impact Study—Final Report; Alyeska Pipeline Service Company: Anchorage, AK, USA, 2011. [Google Scholar]

- Beman, L. The Economic Report of the President; The White House: Washington, DC, USA, 2019. [Google Scholar]

- Speight, J.G. Wax Deposition and Fouling. In Fouling in Refineries; Gulf Professional Publishing: Oxford, UK, 2015; ISBN 9780128007778. [Google Scholar]

- Makwashi, N.; Akubo, S.A.; Sarkodie, K.; Zhao, D. Engaging Best Practices During Waxy Crude Oil Production To Prevent Deposition in the Subsea Pipeline. In Proceedings of the International Conference on Professionalism and Ethics in Construction, London, UK, 22–23 November 2018. [Google Scholar]

- Republic of the Marshall Islands. Deepwater Horizon Marine Casualty Investigation Report; Republic of the Marshall Islands Maritime Administrator: Reston, VA, USA, 2011.

- BP. Deepwater Horizon Accident Investigation Report; BP: London, UK, 2010. [Google Scholar]

- Summerhayes, C. Deep Water—The Gulf Oil Disaster and the Future of Offshore Drilling. Underw. Technol. 2011, 30, 113–115. [Google Scholar] [CrossRef]

- Lubchenco, J.; McNutt, M.K.; Dreyfus, G.; Murawski, S.A.; Kennedy, D.M.; Anastas, P.T.; Chu, S.; Hunter, T. Science in support of the Deepwater Horizon response. Proc. Natl. Acad. Sci. USA 2012, 109, 20212–20221. [Google Scholar] [CrossRef] [PubMed]

- Beyer, J.; Trannum, H.C.; Bakke, T.; Hodson, P.V.; Collier, T.K. Environmental effects of the Deepwater Horizon oil spill: A review. Mar. Pollut. Bull. 2016, 110, 28–51. [Google Scholar] [CrossRef]

- Wigg, H.; Fielder, M. Establishing the true cost of downhole scale control. In Proceedings of the Conference in Solving Oilfield Scaling Problems, Aberdeen, UK, 20 November 1995. [Google Scholar]

- Shutemov, D. Modeling and Management of Scale Potential in an Oil Field Production Network; Norwegian University of Science and Technology: Trondheim, Norway, 2013. [Google Scholar]

- IBIS World. Global Oil & Gas Exploration & Production Industry—Market Research Report; IBIS World: Los Angeles, CA, USA, 2020. [Google Scholar]

- GETI The Global Energy Talent Index Report. Available online: https://www.getireport.com/reports/2019/ (accessed on 17 November 2022).

- Singhal, H.K.; Sahai, G.C.; Pundeer, G.S.; Chandra, K. Designing and selecting wax crystal modifier for optimum field performance based on crude oil composition. In Proceedings of the Proceedings—SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 6–9 October 1991. [Google Scholar]

- Li, G. World Atlas of Oil and Gas Basins; Wiley: Hoboken, NJ, USA; Blackwell: Hoboken, NJ, USA, 2011. [Google Scholar]

- Hu, W.; Bao, J.; Hu, B. Trend and progress in global oil and gas exploration. Pet. Explor. Dev. 2013, 40, 439–443. [Google Scholar] [CrossRef]

- Still, A. The Rising Number of Incomplete Wells in the Largest U.S. Oilfield. Available online: http://fingfx.thomsonreuters.com/gfx/rngs/USA-SHALE/0100409W0N9/index.html (accessed on 16 July 2020).

- International Association of Oil and Gas Producers. Global Production Report 2019; International Association of Oil and Gas Producers: London, UK, 2019. [Google Scholar]

- Sönnichsen, N. Number of Offshore Rigs worldwide as of January 2018 by Region. Available online: https://www.statista.com/statistics/279100/number-of-offshore-rigs-worldwide-by-region/ (accessed on 16 July 2020).

- The Energy Consulting Group North American Rig Counts and Drilling Activity. Available online: http://www.energy-cg.com/US Drilling Activity.html (accessed on 16 July 2020).

- U.S. Energy Information Administration. Drilling Productivity Report 2020; EIA—Energy Information Administration: Washington, DC, USA, 2020.

- Reddy, D.; Swamidas, A. Essentials of Offshore Structures. Framed and Gravity Platforms; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Heidmann, J.C. Oil & Gas From Exploration to Distribution; IFP—Institut Français du Pétrole et des Energies Nouvelles: Paris, France, 2015. [Google Scholar]

- Ribeiro, T.; Rigueiro, C.; Borges, L.; Sousa, A. A comprehensive method for fatigue life evaluation and extension in the context of predictive maintenance for fixed ocean structures. Appl. Ocean Res. 2020, 95, 102050. [Google Scholar] [CrossRef]

- Gomes, J.; Alves, F. O Universo da Indústria Petrolífera—Da Pesquisa à Refinação; Fundação Calouste Gulbenkian: Lisbon, Portugal, 2011. [Google Scholar]

- The UK Oil and Gas Industry Association Limited. Decommissioning Insight 2019; OEUK: London, UK, 2019. [Google Scholar]

- Nations, J.F.; Speice, C.B. The field development of Cognac (Mississippi Cannyon 194) field: A case history. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 26–29 September 1982. [Google Scholar] [CrossRef]

- Boening, D.E.; Howell, E.R. Lena guyed tower project overview. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 7–9 May 1984; pp. 9–17. [Google Scholar] [CrossRef]

- Sterling, G.H.; Krebs, J.E.; Dunn, F.P. The bullwinkle project: An overview. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 1989; pp. 53–62. [Google Scholar] [CrossRef]

- Koon, J.R.; Langewis, C. Jolliet: The Project. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 7–10 May 1990. [Google Scholar]

- Tillinghast, W.S. The deepwater pipeline system on the jolliet project. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 7–10 May 1990; pp. 533–542. [Google Scholar] [CrossRef]

- Cooke, J.C.; Cain, R.E. Development of conventionally uneconomic reserves using subsea completion technology: Garden banks block 224, gulf of Mexico. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1992; pp. 187–198. [Google Scholar] [CrossRef]

- Johnson, H.E.; Kartzke, R.J.; Kruger, R.M. The Mobile Bay project. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 1994; pp. 269–278. [Google Scholar] [CrossRef]

- Kopp, F.; Barry, D.W. Design and installation of Auger pipelines. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 1994; pp. 913–917. [Google Scholar] [CrossRef]

- Clarke, D.G.; Cordner, J.P. BP Exploration’s Pompano subsea development: Operational strategy for a subsea project. Proc. Annu. Offshore Technol. Conf. 1996, 4, 557–568. [Google Scholar]

- Godfrey, D.G.; Haney, J.P.; Pippin, A.E.; Stuart, C.R.; Johnston, D.D.; Oriean, R.H.; Development, S.D. The Mars Project Overview. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1997. [Google Scholar]

- Simon, J.V.; Edel, J.C.; Melancon, C.; Corporation, A.H. An Overview of the Baldpate Project. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 1999; pp. 3–6. [Google Scholar]

- Kennefick, J.; Mcdermott, J.R.; Exploration, P.L.B.; Hervey, D.; Ray, J.J.; Mcdermott, S.A. Morpeth Export System. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 1999; pp. 1–8. [Google Scholar]

- Cranswick, D. Brief Overview of Gulf of Mexico OCS Oil and Gas Pipelines: Installation, Potential Impacts, and Mitigation Measures; US Minerals Management Service: Herndon, VA, USA, 2001.

- Koon, J.R.; Heijermans, B.; Wybro, P.G. Development of the Prince Field. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002; pp. 1569–1584. [Google Scholar] [CrossRef]

- Rijkens, F.; Allen, M.; Hassold, T. Overview of the Canyon Express project, business challenges and “industry firsts”. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2003; pp. 329–337. [Google Scholar] [CrossRef]

- Kopp, F.; Light, B.D.; Preli, T.A.; Rao, V.S.; Stingl, K.H. Design and installation of the Na Kika export pipelines, flowlines and risers. Proc. Annu. Offshore Technol. Conf. 2004, 3, 1694–1707. [Google Scholar] [CrossRef]

- Marshall, R.; McDonald, W. Mardi gras transportation system overview. Proc. Annu. Offshore Technol. Conf. 2004, 2, 1444–1451. [Google Scholar] [CrossRef]

- Holley, S.M.; Abendschein, R.D. Independence Project Overview—A Producer’s Perspective. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2007; pp. 1–6. [Google Scholar] [CrossRef]

- Vercher, C.M.; Dominion, E.; Blakeley, D.; Corp, A.P. Codevelopment of Spiderman and San Jacinto Fields. World Oil 2007, 228, 61–66. [Google Scholar]

- Kaiser, M.J. A Review of Deepwater Pipeline Construction in the U. S. Gulf of Mexico—Contracts, Cost, and Installation Methods. J. Mar. Sci. Appl. 2016, 15, 288–306. [Google Scholar] [CrossRef]

- Kaiser, M.J. Offshore pipeline construction cost in the U.S. Gulf of Mexico. Mar. Policy 2017, 82, 147–166. [Google Scholar] [CrossRef]

- Kaiser, M.J.; Narra, S.U.S. Gulf of Mexico pipeline activity statistics, trends and correlations. Ships Offshore Struct. 2019, 14, 1–22. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration U.S. Field Production of Crude Oil. Available online: https://www.eia.gov/dnav/pet/hist/LeafHandler.ashx?n=pet&s=mcrfpus1&f=a (accessed on 16 July 2020).

- U.S. Energy Information Administration Federal Offshore—Gulf of Mexico Field Production of Crude Oil. Available online: https://www.eia.gov/dnav/pet/hist/LeafHandler.ashx?n=pet&s=mcrfp3fm1&f=a (accessed on 15 July 2020).

- U.S. Energy Information Administration Petroleum and Other Liquids—Crude Oil Including Lease Condensate Production World. Available online: https://www.eia.gov/international/data/world/petroleum-and-other-liquids/annual-petroleum-and-other-liquids-production?pd=5&p=00000000000000000000000000000000002&u=0&f=A&v=mapbubble&a=-&i=none&vo=value&&t=C&g=none&l=249--249&s=94694400000&e=1546300800000 (accessed on 15 July 2020).

- El-Dalatony, M.; Jeon, B.-H.; Salama, E.-S.; Eraky, M.; Kim, W.; Wang, J.; Ahn, T. Occurrence and Characterization of Paraffin Wax Formed in Developing Wells and Pipelines. Energies 2019, 12, 967. [Google Scholar] [CrossRef]

- Sousa, A.M.; Pereira, M.J.; Matos, H.A. Oil-in-water and water-in-oil emulsions formation and demulsification. J. Pet. Sci. Eng. 2022, 210, 110041. [Google Scholar] [CrossRef]

- Lund, H.J. Investigation of Paraffin Deposition during Single Phase Flow in Pipelines. Master’s Thesis, University of Tulsa, Tulsa, OK, USA, 1998. [Google Scholar]

- Hernandez, O.P. Investigation of Single-Phase Paraffin Deposition Characteristics. Master’s Thesis, University of Tulsa, Tulsa, OK, USA, 2002. [Google Scholar]

- Botne, K.K.; Gudmundsson, J.S. Modeling Wax Thickness in Single-Phase Turbulent Flow. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2012. [Google Scholar]

- Thota, S.T.; Onyeanuna, C.C. Mitigation of wax in oil pipelines. Int. J. Eng. Res. Rev. 2016, 4, 39–47. [Google Scholar]

- Tjomsland, T.; Grotle, M.N.; Vikane, O. Scale control strategy and economical consequences of scale at Veslefrikk. In Proceedings of the Society of Petroleum Engineers—International Symposium on Oilfield Scale 2001, Arberdeen, UK, 30–31 January 2001. [Google Scholar]

- Boulding, K.E. The Structure of American Economy, 1919–1929: An Empirical Application of Equilibrium Analysis by Wassily W. Leontief. Can. J. Econ. Polit. Sci. 1942, 8, 124–126. [Google Scholar] [CrossRef]

- Leontief, W.W. The Structure of American Economy, 1919–1939: An Empirical Application of Equilibrium Analysis. Econ. J. 1951, 62, 908–910. [Google Scholar] [CrossRef]

- Joshi, S. Life-Cycle Assessment Using Input-Output Techniques. J. Ind. Ecol. 2000, 3, 95–120. [Google Scholar] [CrossRef]

- Ai, N.; Polenske, K. Socioeconomic impact analysis of yellow-dust storms: An approach and case study for Beijing. Econ. Syst. Res. 2008, 20, 187–203. [Google Scholar] [CrossRef]

- Kitzes, J. An introduction to environmentally-extended input-output analysis. Resources 2013, 2, 489–503. [Google Scholar] [CrossRef]

- Williams, S.K.; Acker, T.; Goldberg, M.; Greve, M. Estimating the economic benefits of wind energy projects using Monte Carlo simulation with economic input/output analysis. Wind Energy 2008, 11, 397–414. [Google Scholar] [CrossRef]

- Lindner, S.; Legault, J.; Guan, D. Disaggregating the electricity sector of china’s input-output table for improved environmental life-cycle assessment. Econ. Syst. Res. 2013, 25, 300–320. [Google Scholar] [CrossRef]

- Nakamura, S.; Nakajima, K.; Kondo, Y.; Nagasaka, T. The Waste Input-Output Approach to Materials Flow Analysis. J. Ind. Ecol. 2007, 11, 50–63. [Google Scholar] [CrossRef]

- Xing, M.; Awuah-Offei, K.; Long, S.; Usman, S. The effect of local supply chain on regional economic impacts of mining. Extr. Ind. Soc. 2017, 4, 622–629. [Google Scholar] [CrossRef]

- Al-Hemoud, A.; Al-Dousari, A.; Misak, R.; Al-Sudairawi, M.; Naseeb, A.; Al-Dashti, H.; Al-Dousari, N. Economic impact and risk assessment of sand and dust storms (SDS) on the oil and gas industry in Kuwait. Sustainability 2019, 11, 200. [Google Scholar] [CrossRef]

- Carson, R.T.; Flores, N.E.; Meade, N.F. Contingent valuation: Controversies and evidence. Environ. Resour. Econ. 2001, 19, 173–210. [Google Scholar] [CrossRef]

- Venkatachalam, L. The contingent valuation method: A review. Environ. Impact Assess. Rev. 2004, 24, 89–124. [Google Scholar] [CrossRef]

- Hausman, J. Contingent valuation: From dubious to hopeless. J. Econ. Perspect. 2012, 26, 43–56. [Google Scholar] [CrossRef]

- Al-Hemoud, A.; Al-Sudairawi, M.; Neelamanai, S.; Naseeb, A.; Behbehani, W. Socioeconomic effect of dust storms in Kuwait. Arab. J. Geosci. 2017, 10, 18. [Google Scholar] [CrossRef]

- Jeong, D.-Y. Socio-Economic Costs from Yellow Dust Damages in South Korea. Korean Soc. Sci. J. 2008, 35, 1–29. [Google Scholar]

- Miri, A.; Ahmadi, H.; Ekhtesasi, M.R.; Panjehkeh, N.; Ghanbari, A. Environmental and socio-economic impacts of dust storms in Sistan Region, Iran. Int. J. Environ. Stud. 2009, 66, 343–355. [Google Scholar] [CrossRef]

- Böhringer, C.; Rutherford, T.F. Combining bottom-up and top-down. Energy Econ. 2008, 30, 574–596. [Google Scholar] [CrossRef]

- Huszar, P.C.; Piper, S.L. Estimating the off-site costs of wind erosion in New Mexico. J. Soil Water Conserv. 1986, 41, 414–416. [Google Scholar]

- Ekhtesasi, M.R.; Sepehr, A. Investigation of wind erosion process for estimation, prevention, and control of DSS in Yazd-Ardakan plain. Environ. Monit. Assess. 2009, 159, 267–280. [Google Scholar] [CrossRef] [PubMed]

- Williams, P.; Young, M. Costing Dust: How Much Does Wind Erosion Cost the People of South Australia? The Commonwealth Scientific and Industrial Research Organisation: Canberra, Australia, 1999.

- Bergstrom, J.C.; Taylor, L.O. Using meta-analysis for benefits transfer: Theory and practice. Ecol. Econ. 2006, 60, 351–360. [Google Scholar] [CrossRef]

- Tozer, P.; Leys, J. Dust storms—What do they really cost? Rangel. J. 2013, 35, 131–142. [Google Scholar] [CrossRef]

- Sousa, A.M.; Ribeiro, T.P.; Pereira, M.J.; Matos, H.A. On the economic impact of wax deposition on the oil and gas industry. Energy Convers. Manag. X 2022, 16, 100291. [Google Scholar] [CrossRef]

- Cernea, M.M. Using knowledge from social science in development projects. Proj. Apprais. 1994, 9, 83–94. [Google Scholar] [CrossRef]

- Slootweg, R.; Vanclay, F.; van Schooten, M. Function evaluation as a framework for the integration of social and environmental impact assessment. Impact Assess. Proj. Apprais. 2001, 19, 19–28. [Google Scholar] [CrossRef]

- Vanclay, F. Conceptualising social impacts. Environ. Impact Assess. Rev. 2002, 22, 183–211. [Google Scholar] [CrossRef]

- Gramling, R.; Freudenburg, W.R. Opportunity-Threat, Development, and Adaptation: Toward a Comprehensive Framework for Social Impact Assessment. Rural Sociol. 1992, 57, 216–234. [Google Scholar] [CrossRef]

- Hilson, G.; Basu, A.J. Devising indicators of sustainable development for the mining and minerals industry: An analysis of critical background issues. Int. J. Sustain. Dev. World Ecol. 2003, 10, 319–331. [Google Scholar] [CrossRef]

- Mitchell, R.E.; Parkins, J.R. The challenge of developing social indicators for cumulative effects assessment and land use planning. Ecol. Soc. 2011, 16, 29. [Google Scholar] [CrossRef]

- Uhlmann, V.; Rifkin, W.; Everingham, J.A.; Head, B.; May, K. Prioritising indicators of cumulative socio-economic impacts to characterise rapid development of onshore gas resources. Extr. Ind. Soc. 2014, 1, 189–199. [Google Scholar] [CrossRef]

- Brereton, D.; Pattenden, C. Measuring what matters: Monitoring the contribution of a new mining project to community sustainability. In Proceedings of the Third International Conference on Sustainable Development in the Minerals Industry, Milos Island, Greece, 17–20 June 2007; pp. 327–332. [Google Scholar]

- Brereton, D.; Parmenter, J. Indigenous Employment in the Australian Mining Industry. J. Energy Nat. Resour. Law 2008, 26, 66–90. [Google Scholar] [CrossRef]

- Franks, D.M.; Brereton, D.; Moran, C.J. Managing the cumulative impacts of coal mining on regional communities and environments in Australia. Impact Assess. Proj. Apprais. 2010, 28, 299–312. [Google Scholar] [CrossRef]

- Wimo, A.; Jönsson, L.; Bond, J.; Prince, M.; Winblad, B. The worldwide economic impact of dementia 2010. Alzheimer’s Dement. 2013, 9, 1–11.e3. [Google Scholar] [CrossRef]

- Upson, S.; Clarke, C. Socio-economic assessment in the extractive industries-Avoiding the pitfalls. Extr. Ind. Soc. 2015, 2, 671–675. [Google Scholar] [CrossRef]

- AETC Ltd. Environmental and Social Impact Assessment Baku—Tbilisi—Ceyhan Oil Pipeline; AETC Ltd.: Leeds, UK, 2002. [Google Scholar]

- Holden, M. Sustainable Seattle: The Case of the Prototype Sustainability Indicators Project. In Community Quality-of-Life Indicators; Springer: Cham, Switzerland, 2006. [Google Scholar]

- Duinker, P.N.; Greig, L.A. Scenario analysis in environmental impact assessment: Improving explorations of the future. Environ. Impact Assess. Rev. 2007, 27, 206–219. [Google Scholar] [CrossRef]

- Cantrill, J.G. Amplifiers on the commons: Using indicators to foster place-based sustainability initiatives. Environ. Commun. 2012, 6, 5–22. [Google Scholar] [CrossRef]

- Bloomer, C.M. Production Increase Environmental Statement; European Union: Brussels, Belgium, 2018. [Google Scholar]

- Peterson, C.H.; Rice, S.D.; Short, J.W.; Esler, D.; Bodkin, J.L.; Ballachey, B.E.; Irons, D.B. Long-Term Ecosystem Response to the Exxon Valdez Oil Spill. Science 2003, 302, 2082–2086. [Google Scholar] [CrossRef] [PubMed]

- Barron, M.G.; Vivian, D.N.; Heintz, R.A.; Yim, U.H. Long-Term Ecological Impacts from Oil Spills: Comparison of Exxon Valdez, Hebei Spirit, and Deepwater Horizon. Environ. Sci. Technol. 2020, 54, 6456–6467. [Google Scholar] [CrossRef]

- Crone, T.J.; Tolstoy, M. Magnitude of the 2010 Gulf of Mexico Oil Leak. Science 2010, 330, 634. [Google Scholar] [CrossRef]

- Joye, S.B. Deepwater Horizon, 5 years on. Science 2015, 349, 592–593. [Google Scholar] [CrossRef]

- Arekhi, M.; Terry, L.G.; John, G.F.; Clement, T.P. Environmental fate of petroleum biomarkers in Deepwater Horizon oil spill residues over the past 10 years. Sci. Total Environ. 2021, 791, 148056. [Google Scholar] [CrossRef]

- Lin, Q.; Mendelssohn, I.A.; Graham, S.A.; Hou, A.; Fleeger, J.W.; Deis, D.R. Response of salt marshes to oiling from the Deepwater Horizon spill: Implications for plant growth, soil surface-erosion, and shoreline stability. Sci. Total Environ. 2016, 557–558, 369–377. [Google Scholar] [CrossRef]

- Hester, M.W.; Willis, J.M.; Rouhani, S.; Steinhoff, M.A.; Baker, M.C. Impacts of the Deepwater Horizon oil spill on the salt marsh vegetation of Louisiana. Environ. Pollut. 2016, 216, 361–370. [Google Scholar] [CrossRef]

- Zengel, S.; Montague, C.L.; Pennings, S.C.; Powers, S.P.; Steinhoff, M.; Fricano, G.; Schlemme, C.; Zhang, M.; Oehrig, J.; Nixon, Z.; et al. Impacts of the Deepwater Horizon Oil Spill on Salt Marsh Periwinkles (Littoraria irrorata). Environ. Sci. Technol. 2016, 50, 643–652. [Google Scholar] [CrossRef]

- Kırman, Z.D.; Sericano, J.L.; Wade, T.L.; Bianchi, T.S.; Marcantonio, F.; Kolker, A.S. Composition and depth distribution of hydrocarbons in Barataria Bay marsh sediments after the Deepwater Horizon oil spill. Environ. Pollut. 2016, 214, 101–113. [Google Scholar] [CrossRef] [PubMed]

- Moody, R.M.; Cebrian, J.; Heck, K.L., Jr. Interannual Recruitment Dynamics for Resident and Transient Marsh Species: Evidence for a Lack of Impact by the Macondo Oil Spill. PLoS ONE 2013, 8, e58376. [Google Scholar] [CrossRef] [PubMed]

- Quigg, A.; Parsons, M.; Bargu, S.; Ozhan, K.; Daly, K.L.; Chakraborty, S.; Kamalanathan, M.; Erdner, D.; Cosgrove, S.; Buskey, J.; et al. Marine phytoplankton responses to oil and dispersant exposures: Knowledge gained since the Deepwater Horizon oil spill. Mar. Pollut. Bull. 2021, 164, 112074. [Google Scholar] [CrossRef] [PubMed]

- White, H.K.; Hsing, P.; Cho, W.; Shank, T.M.; Cordes, E.E.; Quattrini, A.M.; Roberts, H.H.; Shedd, W.; Reddy, C.M.; Fisher, C.R. Impact of the Deepwater Horizon oil spill on a deep-water coral community in the Gulf of Mexico. Proc. Natl. Acad. Sci. USA 2012, 109, 20303–20308. [Google Scholar] [CrossRef] [PubMed]

- Kimes, N.E.; Callaghan, A.V.; Suflita, J.M.; Morris, P.J. Microbial transformation of the Deepwater Horizon oil spill—Past, present, and future perspectives. Front. Microbiol. 2014, 5, 603. [Google Scholar] [CrossRef]

- Mcclain, C.R.; Nunnally, C.; Benfield, M.C. Persistent and substantial impacts of the Deepwater Horizon oil spill on deep-sea megafauna. R. Soc. 2019, 6, 191164. [Google Scholar] [CrossRef]

- Reuscher, M.G.; Baguley, J.G.; Conrad-forrest, N.; Cooksey, C.; Hyland, J.L.; Lewis, C.; Montagna, P.A.; Ricker, R.W.; Rohal, M.; Washburn, T. Temporal patterns of Deepwater Horizon impacts on the benthic infauna of the northern Gulf of Mexico continental slope. PLoS ONE 2017, 12, e0179923. [Google Scholar] [CrossRef] [PubMed]

- Powers, S.P.; Grabowski, J.H.; Roman, H.; Geggel, A.; Rouhani, S.; Oehrig, J.; Baker, M. Consequences of large-scale salinity alteration during the Deepwater Horizon oil spill on subtidal oyster populations. Mar. Ecol. Prog. Ser. 2017, 576, 175–187. [Google Scholar] [CrossRef]

- Fallon, J.A.; Smith, E.P.; Schoch, N.; Paruk, J.D.; Adams, E.A.; Evers, D.C.; Jodice, P.G.R.; Perkins, C.; Schulte, S.; Hopkins, W.A. Hematological Indices of Injury to Lightly Oiled Birds from the Deepwater Horizon Oil Spill. Environ. Toxicol. Chem. 2017, 9999, 451–461. [Google Scholar] [CrossRef]

- Dubansky, B.; Whitehead, A.; Miller, T.; Rice, C.D.; Galvez, F. Multitissue Molecular, Genomic, and Developmental Effects of the Deepwater Horizon Oil Spill on Resident Gulf Killifish (Fundulus grandis). Environ. Sci. Technol. 2013, 47, 5074–5082. [Google Scholar] [CrossRef]

- Daly, K.L.; Remsen, A.; Outram, D.M.; Broadbent, H.; Kramer, K.; Dubickas, K. Resilience of the zooplankton community in the northeast Gulf of Mexico during and after the Deepwater Horizon oil spill. Mar. Pollut. Bull. 2021, 163, 111882. [Google Scholar] [CrossRef] [PubMed]

- Vander Zanden, H.B.; Bolten, A.B.; Tucker, A.D.; Hart, K.M.; Lamont, M.M.; Fujisaki, I.; Reich, K.J.; Addison, D.S.; Mansfield, K.L.; Phillips, K.F.; et al. Biomarkers reveal sea turtles remained in oiled areas following the Deepwater Horizon oil spill. Ecol. Appl. 2016, 26, 2145–2155. [Google Scholar] [CrossRef] [PubMed]

- Reardon, S. Ten Months After Deepwater Horizon, Picking Up the Remnants of Health Data. Science 2011, 331, 1252. [Google Scholar] [CrossRef] [PubMed]

- Barron, M.G. Ecological Impacts of the Deepwater Horizon Oil Spill: Implications for Immunotoxicity. Toxicol. Pathol. 2012, 40, 315–320. [Google Scholar] [CrossRef] [PubMed]

- Safford, T.G.; Ulrich, J.D.; Hamilton, L.C. Public perceptions of the response to the Deepwater Horizon oil spill: Personal experiences, information sources, and social context. J. Environ. Manag. 2012, 113, 31–39. [Google Scholar] [CrossRef]

- Daly, K.L.; Passow, U.; Chanton, J.; Hollander, D. Assessing the impacts of oil-associated marine snow formation and sedimentation during and after the Deepwater Horizon oil spill. Anthropocene 2016, 13, 18–33. [Google Scholar] [CrossRef]

- Stout, S.A.; Rouhani, S.; Liu, B.; Oehrig, J.; Ricker, R.W.; Baker, G.; Lewis, C. Assessing the footprint and volume of oil deposited in deep-sea sediments following the Deepwater Horizon oil spill. Mar. Pollut. Bull. 2016, 114, 327–342. [Google Scholar] [CrossRef]

- Stout, S.A.; Payne, J.R. Macondo oil in deep-sea sediments: Part 1—Sub-sea weathering of oil deposited on the seafloor. Mar. Pollut. Bull. 2016, 111, 365–380. [Google Scholar] [CrossRef]

- Gullett, B.K.; Aurell, J.; Holder, A.; Mitchell, W.; Greenwell, D.; Hays, M.; Conmy, R.; Tabor, D.; Preston, W.; George, I.; et al. Characterization of emissions and residues from simulations of the Deepwater Horizon surface oil burns. Mar. Pollut. Bull. 2017, 117, 392–405. [Google Scholar] [CrossRef]

- Wade, T.L.; Sericano, J.L.; Sweet, S.T.; Knap, A.H.; Guinasso, N.L., Jr. Spatial and temporal distribution of water column total polycyclic aromatic hydrocarbons (PAH) and total petroleum hydrocarbons (TPH) from the Deepwater Horizon (Macondo) incident. Mar. Pollut. Bull. 2015, 103, 286–293. [Google Scholar] [CrossRef]

- Kujawinski, E.B.; Soule, M.C.K.; Valentine, D.L.; Boysen, A.K.; Longnecker, K.; Redmond, M.C. Fate of Dispersants Associated with the Deepwater Horizon Oil Spill. Environ. Sci. Technol. 2011, 45, 1298–1306. [Google Scholar] [CrossRef] [PubMed]

- Spaulding, M.; Li, Z.; Mendelsohn, D.; Crowley, D.; French-mccay, D.; Bird, A. Application of an Integrated Blowout Model System, OILMAP DEEP, to the Deepwater Horizon (DWH) Spill. Mar. Pollut. Bull. 2017, 120, 37–50. [Google Scholar] [CrossRef]

- Nyankson, E.; Gupta, R.B. Advancements in Crude Oil Spill Remediation Research After the Deepwater Horizon Oil Spill. Water Air Soil Pollut. 2016, 227, 29. [Google Scholar] [CrossRef]

- Payne, J.R.; Driskell, W.B. Macondo oil in northern Gulf of Mexico waters—Part 1: Assessments and forensic methods for Deepwater Horizon o ff shore water samples. Mar. Pollut. Bull. 2018, 129, 399–411. [Google Scholar] [CrossRef]

- Schaum, J.; Cohen, M.; Perry, S.; Artz, R.; Draxler, R.; Frithsen, J.B.; Heist, D.; Lorber, M.; Phillips, L. Screening Level Assessment of Risks Due to Dioxin Emissions from Burning Oil from the BP Deepwater Horizon Gulf of Mexico Spill. Environ. Sci. Technol. 2010, 9, 9383–9389. [Google Scholar] [CrossRef] [PubMed]

- Umar, H.A.; Khanan, M.F.A.; Ogbonnaya, C.; Shiru, M.S.; Ahmad, A.; Baba, A.I. Environmental and socioeconomic impacts of pipeline transport interdiction in Niger Delta, Nigeria. Heliyon 2021, 7, e06999. [Google Scholar] [CrossRef] [PubMed]

- Eghonghon, K.; Athar, H.; Oluwaseun, C.; Osagie, U.; Birundu, R.; Abifarin, O. Environmental implications of petroleum spillages in the Niger Delta region of Nigeria: A review. J. Environ. Manag. 2021, 293, 112872. [Google Scholar] [CrossRef]

- Zacharias, D.C.; Gama, C.M.; Fornaro, A. Mysterious oil spill on Brazilian coast: Analysis and estimates. Mar. Pollut. Bull. 2021, 165, 112125. [Google Scholar] [CrossRef]

- Soares, E.C.; Bispo, M.D.; Vasconcelos, V.C.; Soletti, J.I.; Carvalho, S.H.V.; de Oliveira, M.J.; dos Santos, M.C.; dos Santos Freire, E.; Nogueira, A.S.P.; da Silva Cunha, F.A.; et al. Oil impact on the environment and aquatic organisms on the coasts of the states of Alagoas and Sergipe, Brazil—A preliminary evaluation. Mar. Pollut. Bull. 2021, 171, 112723. [Google Scholar] [CrossRef]

- Yu, J.; Zhou, D.; Yu, M.; Yang, J.; Li, Y. Environmental threats induced heavy ecological burdens on the coastal zone of the Bohai Sea, China. Sci. Total Environ. 2020, 765, 142694. [Google Scholar] [CrossRef]

- Scarlett, A.G.; Nelson, R.K.; Gagnon, M.M.; Holman, A.I.; Reddy, C.M.; Sutton, P.A.; Grice, K. MV Wakashio grounding incident in Mauritius 2020: The world’s first major spillage of Very Low Sulfur Fuel Oil. Mar. Pollut. Bull. 2021, 171, 112917. [Google Scholar] [CrossRef] [PubMed]

- Atlas, R.M.; Hazen, T.C.; Berkeley, L. Oil Biodegradation and Bioremediation: A Tale of the Two Worst Spills in U.S. History. Environ. Sci. Technol. 2011, 45, 6709–6715. [Google Scholar] [CrossRef] [PubMed]

- Hazen, T.C.; Dubinsky, E.A.; DeSantis, T.Z.; Andersen, G.L.; Piceno, Y.M.; Singh, N.; Jansson, J.K.; Probst, A.; Borglin, S.E.; Fortney, J.L.; et al. Deep-Sea Oil Plume Enriches Indigenous Oil-Degrading Bacteria. Science 2010, 330, 204–208. [Google Scholar] [CrossRef] [PubMed]

- Grosell, M.; Pasparakis, C. Physiological Responses of Fish to Oil Spills. Ann. Rev. Mar. Sci. 2021, 13, 137–160. [Google Scholar] [CrossRef]

- Suslick, S.B.; Furtado, R. Quantifying the value of technological, environmental and financial gain in decision models for offshore oil exploration. J. Pet. Sci. Eng. 2001, 32, 115–125. [Google Scholar] [CrossRef]

- Bock, M.; Robinson, H.; Wenning, R.; French-mccay, D.; Rowe, J.; Hayward, A. Comparative risk assessment of oil spill response options for a deepwater oil well blowout: Part II. Relative risk methodology. Mar. Pollut. Bull. 2018, 133, 984–1000. [Google Scholar] [CrossRef]

- Kennedy, C.J.; Cheong, S. Lost ecosystem services as a measure of oil spill damages: A conceptual analysis of the importance of baselines. J. Environ. Manag. 2013, 128, 43–51. [Google Scholar] [CrossRef]

- Hook, S. Beyond thresholds: A holistic approach to impact assessment is needed to enable accurate predictions of environmental risk from oil spills. Integr. Environ. Assess. Manag. 2020, 16, 813–830. [Google Scholar] [CrossRef]

- Gong, Y.; Zhao, X.; Cai, Z.; Reilly, S.E.O.; Hao, X.; Zhao, D. A review of oil, dispersed oil and sediment interactions in the aquatic environment: Influence on the fate, transport and remediation of oil spills. Mar. Pollut. Bull. 2013, 79, 16–33. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, H.; Li, Y.; Xu, H.; Pan, Z.; Dai, P.; Wang, H.; Yang, Q. A review of treatment technologies for produced water in offshore oil and gas fields. Sci. Total Environ. 2021, 775, 145485. [Google Scholar] [CrossRef]

- Hoang, A.T.; Nguyen, X.P.; Duong, X.Q.; Huynh, T.T. Sorbent-based devices for the removal of spilled oil from water: A review. Environ. Sci. Pollut. Res. 2021, 28, 28876–28910. [Google Scholar] [CrossRef] [PubMed]

| Stage | Included | Excluded |

|---|---|---|

| 5 Identification | n = approximately 400 to 450, of which 336 were eligible | |

| 6 Screening | n = 311 | n = 25 |

| 7 Sorting | n = 278 | n = 33 |

| 8 Eligibility | n = 214 | n = 64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sousa, A.M.; Ribeiro, T.P.; Pereira, M.J.; Matos, H.A. Review of the Economic and Environmental Impacts of Producing Waxy Crude Oils. Energies 2023, 16, 120. https://doi.org/10.3390/en16010120

Sousa AM, Ribeiro TP, Pereira MJ, Matos HA. Review of the Economic and Environmental Impacts of Producing Waxy Crude Oils. Energies. 2023; 16(1):120. https://doi.org/10.3390/en16010120

Chicago/Turabian StyleSousa, Ana M., Tiago P. Ribeiro, Maria J. Pereira, and Henrique A. Matos. 2023. "Review of the Economic and Environmental Impacts of Producing Waxy Crude Oils" Energies 16, no. 1: 120. https://doi.org/10.3390/en16010120

APA StyleSousa, A. M., Ribeiro, T. P., Pereira, M. J., & Matos, H. A. (2023). Review of the Economic and Environmental Impacts of Producing Waxy Crude Oils. Energies, 16(1), 120. https://doi.org/10.3390/en16010120