Abstract

According to the IPCC, a global carbon budget of 400 GtCO2 is required to limit the temperature rise to 1.5 °C with a 67% likelihood by 2050. The finance industry is increasingly committed to ambitious climate targets. In this article, we describe the detailed methodology and energy model architecture of a MATLAB-based integrated energy assessment model for industry-specific 1.5 °C pathways, with a high technical resolution of target parameters as key performance indicators (KPIs). The additionality of OECM 2.0 is the high technical resolution in terms of the level of detail of industry-specific energy demand and supply parameters that can be modeled—a prerequisite to define industry-specific KPIs. We found that a database of industry-sector-specific energy demands and energy intensities, with a consistent methodology, is required to improve the accuracy of calculations in future research. We supplement the technical documentation with the results for a transport scenario.

1. Introduction

The Paris Climate Agreement [1] ‘notes that (…) emission reduction efforts will be required (…) to hold the increase in the global average temperature to below 2 °C above pre-industrial levels (…)’. The Intergovernmental Panel on Climate Change (IPCC) further quantified the carbon budget to achieve this target in its Sixth Assessment Report of the Working Group [2]. According to the IPCC, a global carbon budget of 400 GtCO2 is required to limit the temperature rise to 1.5 °C with a 67% likelihood by 2050.

To implement those targets, energy- and climate-mitigation pathways are required. Numerous computer models for the analysis and development of energy and emission pathways have been developed over the last few decades. The IPCC Assessment Reports use ‘shared socioeconomic pathways’ (SSPs) [3] to describe different greenhouse gas (GHG) emission pathways. Energy models are required to assess possible energy industry trajectories and the development of energy-related CO2 emissions—as part of the SSP. Many different calculation methods have been established, which mainly differ in the principal task of the model and the level of detail in the GHG emissions and/or energy systems calculated. The various methods of climate–economy modelling use different ways to describe the economy- and climate-relevant parameters as parts of a highly interconnected process [4]. In this context, the economy includes all aspects of the energy system and the policy framework, whereas the climate module reflects various GHG emissions from energy-related and non-energy-related processes, such as land use.

A comprehensive review of energy models, focusing on the usability of those models for decision making, found ‘that a better understanding of user needs and closer cooperation between modelers and users is imperative to truly improve models and unlock their full potential to support the transition towards climate neutrality (…)’ [5].

The Net-Zero Asset Owner Alliance (NZAOA).

The UN-convened Net-Zero Asset Owner Alliance (NZAOA) is an international group of institutional investors committed to transitioning their investment portfolios to net-zero emissions by 2050 [6]. Detailed industry-sector-based energy scenarios are required to implement those net-zero commitments.

The One Earth Climate Model 1.0 (OECM) is an energy scenario model to develop normative energy pathways and based on the Energy System model (ESM) developed by the German Aerospace Center (DLR) [7,8,9], in combination with additional modules to determine detailed energy demand and supply pathways for the transport [9] and power sector [10]. More details about those modules are provided in Section 3. On the basis of the OECM 1.0 [11], the Institute for Sustainable Futures (ISF), University of Technology Sydney (UTS), in close co-operation with institutional investors, have developed an integrated energy assessment model for industry-specific 1.5 °C pathways, with a high technical resolution, for the finance sector. The term ‘technical resolution’ is defined as the level of detail a technical process, such as the production of secondary steel, or the required energy demand per ton-kilometer transported with a containership can be calculated with an energy model. In this article, we describe the detailed methodology and energy model architecture of the advanced OECM 2.0 edition. The methodology is further specified using the example of a global transport scenario.

The contributions of this paper are:

- Description of a novel methodology for a detailed calculation of energy pathways to achieve rapid decarbonization for specific industry sectors.

- It presents the OECM 2.0, a novel object-oriented energy model for the development and simulation of specific 1.5 °C pathways, with a high technical resolution, for the finance sector. The development of this model has been motivated by gaps identified in existing tools.

- To show the performance of the developed tool, it presents a case study and evaluates the computational results.

The rest of the paper is organized as follows: Section 2 compares the features offered by the developed model and those offered by relevant existing tools. Section 3 describes the structure of the proposed model. This is followed by a description of the object-oriented architecture in Section 4. Section 5 presents a case study and simulation results, and Section 6 concludes the paper.

3. Methodology

In this section, we propose a methodology to determine specific 1.5 °C pathways, with a high technical resolution, for the finance sector.

The OECM 1.0 emerged from an interdisciplinary research project between the University of Technology Sydney, the German Aerospace Centre (DLR), and the University of Melbourne, between 2017 and 2019. The task was to develop a detailed 1.5 °C GHG trajectory for 10 world regions. OECM 1.0 was developed on the basis of established DLR and UTS energy models, and consisted of three independent modules:

- Energy System Model (EM): a mathematical accounting system for the energy sector [8]

- Transport scenario model TRAEM (TRAnsport Energy Model) with a high technical resolution [9]

- Power System Analysis Model [R]E 24/7: Simulates the interaction of hourly electricity demand using measured or calculated load curves and power generation, based on generation characteristics, to detect possible periods of under- or oversupply [10].

The advanced OECM 2.0 merges the energy system model EM, the transport model TRAEM, and the power system model [R]E 24/7 into one MATLAB-based energy system module. The Global Industry Classification System (GICS) was used to define the various sectors of the economy. The global finance industry must increasingly undertake mandatory Climate Change Stress Tests for GICS-classified industry sectors in order to develop energy and emission benchmarks to implement the Paris Climate Agreement. This requires a very high technical resolution for the calculation and projection of future energy demands and the supply of electricity, (process) heat, and fuels, which are necessary for the steel and chemical industries. An energy model with a high technical resolution must be able to calculate the energy demand based on either the sector-specific gross domestic product (GDP) projections or market forecasts of material flows, such as the demand for steel, aluminum or cement in tons per year.

Specifically, the methodology proposed in this work considers five fundamental elements (as described below): (i) databases and model calibration; (ii) sector and sub-sector definitions; (iii) cost calculations; (iv) a demand module; and (v) a supply module.

3.1. Comparison OECM 1.0 and Additionalities of OECM 2.0

The motivation to develop the OECM 1.0 further was the need for energy scenarios and emission trajectories that covers a specific sector classified under the GICS system, as set out in Section 2.1. The OECM 1.0 was based on the widely used sectorial breakdown into the main demand sectors of industry and services, buildings, transport and electricity, but did not have the required technical resolution to break down the industry sector further into the individual GICS sectors.

In order to attain the higher technical resolution to model sectors such as the steel industry, the aluminum industry or the food processing industry, three main changes had to be made:

- A.

- Modification of the model architecture to achieve greater flexibility, which allows the calculation of (GICS) subsectors with clearly defined system boundaries.

- B.

- Implementation of the new subsectors in the model

- C.

- Addition of new energy demand drivers besides population and economic development (GDP).

The flexibility was achieved by merging the previously three independent models into one program. MATLAB was chosen to handle the larger amount of data. The now considerably more extensive model was divided into two modules, which are connected but can still operate independently of one another in order to be able to calculate the energy requirements of individual industries.

Different sectors have different drivers for energy demand. The energy demand of the steel industry, for example, is driven by the annual production in tons of steel, the shares of primary and secondary steel and the required volume of iron ore and therefore the need for iron ore mining. While the main driver for energy demand in the OECM 1.0 was the development of the population and the economic activity in GDP, OECM 2.0 includes industry-specific drivers such annual production volumes e.g., tons of steel or aluminum per year. Table 1 provides the main improvement of OECM 2.0 in form of a synopsis table.

Table 1.

Synopsis OECM 1.0 versus OECM 2.0.

The changes allowed the development of a bottom-up energy demand scenario for various sub-sectors and the calculation of the entire energy system including sector coupling between power, heat and transport.

The higher technical resolution requires more detailed input data such as energy intensities for industrial processes e.g., electricity demand per tons of secondary aluminum or energy demand per freight ton-kilometer for trucks, vans or containerships. Data that might not be available, or only with high uncertainties is discussed in Section 3.5, Section 6 and Section 6.1.

3.2. Databases and Model Calibration

The OECM model uses several databases for the energy statistics, the energy intensities, the technology market shares and other market or socio-economic parameters. The calculation of the energy balance for the base year is based on the International Energy Agency (IEA) Advanced World Energy Balances [22,23].

The IEA energy statistics for a calculated country and/or region are uploaded in the format specified by the IEA database: consumption sectors in rows and energy production by fuel or power generation technology in columns. The data for each year from 2005 onwards until the last year for which data are available are used to calibrate the model. The calibration process was developed by DLR for the Energy System Model which uses MESAP/PlaNet—a commercial energy system analysis software [23,24,25,26,27]. The market shares are calculated based on the IEA statistics and a technical database for energy intensities for various appliances and applications across all sectors for the years 2005 to the latest available year, 2019 in this project. The historic data is used for the calibration of the model as shown in Table 2.

Table 2.

Calibration for calculating the transport demand.

The IEA Energy Statistics ‘Advanced World Energy Balances’ provides the energy demand and supply for the four main transport sectors: road, rail, shipping and aviation. Additional information, such as the division into energy demand for passenger and freight transport, are not included and must be determined by further literature research. Energy intensities for vehicle types, annual usage in kilometers and market shares for each transport mode are required to calculate the transport energy demand for subsectors. The calibration is complete when the sum of all calculated transport technologies, e.g., for diesel, biofuel and electric vehicles, equals the energy demand for road transport provided by the IEA statistic. Table 2 shows all parameters that are necessary for the calibration process using the example of the transport sector.

The future development of transport demand by transport mode is calculated as the annual change in percent (input), which corresponds to a reversal of the calculation method for the calibration process.

This methodology for calibration and projection is used across all sectors.

The developed MATLAB tool can access online data and databases through available application programming interfaces (APIs). For example, the API provides access to nearly 16,000 time series indicators, including population estimates and projections [28]. Likewise, the OECD provides access to datasets through an API. This allows a developer to easily call the API and access data using the code lines in MATLAB.

Table 3 shows the projected transport demand for aviation, navigation, and road transport for the OECM 1.5 °C pathway for transport.

Table 3.

Methodology of OECM 2.0—Projection of future transport demand by transport mode.

3.3. Sectors and Sub-Sectors

The One Earth Climate Model was developed to calculate energy pathways for geographic regions, as documented by [11]. The OECM was further developed to meet the requirements of the financial industry and to design energy and emission pathways for clearly defined industry sectors (sectorial pathways). The finance industry uses different classification systems to describe sub-areas of certain branches of industry. An important system is the Global Industry Classification Standard (GICS) [26]. However, the GICS sub-sectors do not match the IEA statistical breakdown of the energy demands of certain industries. Table 4 and Table 5 show examples of the finance sector calculated using the OECM model, the GICS codes, and the statistical information used. Although the OECM model allows all the GICS code sub-sectors to be calculated, the availability of statistics is the factor limiting the resolution of the sectorial pathways. For example, the statistical data for the textile and leather industry are stored in the IEA database, but the database does not separate the two industries further.

Table 4.

Projection of transport demand based on the changing demand in kilometers for the OECM 1.5 °C pathway.

Table 5.

Examples of industry sub-sectors based on the Global Industry Classification Standard (GICS).

3.4. Cost Calculation

The costs linked to the energy supply in each year of the modelled period include the investment costs related to ‘new capacities’ for technologies and storage (including replacement or decommissioning, based on the assumed technical lifetimes = vintaging), operation and maintenance (O&M) costs as a percentage of the total installed capacities, and fuel costs. Other inputs for each technology and storage type include the capital cost per unit ($/KW), O&M costs as a percentage of the capital cost and unit fuel costs ($/GJ).

Therefore, for each technology or storage type:

- -

- It is assumed that the change in “installed capacity” between each of the years modelled is linear and a linear interpolation between these is considered.

- -

- The “installed capacities” and “new capacities” are inter-related (one depends on the other) in each of the modelled and interpolated years, based on the cumulative capacities in the calculated year and the assumed technology lifetime.

- -

- The capital costs per unit and the fuel costs in each of the modelled years are also interpolated linearly between the modelled years. Therefore, if a scenario is calculated in 5-year steps, e.g., the development from 2025 and 2030, the years 2026 to 2029 are calculated as a linear interpolation.

- -

- Replacement capacities, if required, are also included in each year as part of the investment costs.

- -

- The O&M costs in each of the interpolated years are calculated based on the interpolated installed capacities and the annual O&M input costs (as a percentage of the capital cost).

- -

- Annual fuel costs for non-renewable technologies are calculated based on their output energy (running time) and interpolated fuel costs.

- -

- The resulting “specific costs” ($/kWh) are also calculated from the interpolated energy supplied in each year.

The total specific costs ($/kWh) of a scenario, as practically distributed over the interpolated years, allows the incurred costs for a scenario to be determined.

Limitations: The economic model does not consider the change in the value of money over time. Each year of the modelled period is regarded as if it were the present year, with the multiple costs incurred. Future additions to the model could include the net present costs and the time value of money.

3.5. Demand Module

The demand module uses a bottom-up approach to calculate the energy demand for a process (e.g., steel production) or a consumer (e.g., a household) in a region (e.g., a city, island or country) or transport services over a period of time. One of the most important elements of this approach is the strict separation of the original need (e.g., to get from home to work), how this need can be satisfied (e.g., with a tram), and the kind of energy required to provide this service (in this case, electricity). This basic logic is the foundation for the energy demand calculation across all sectors: buildings, transport, services and industry. Furthermore, the energy services required are defined; electricity, heat (broken down into four heat levels: <100 °C, 100–500 °C, 500–1000 °C and >1000 °C), and fuels for processes that cannot (yet) be electrified. Synthetic fuels, such as hydrogen, are part of both the demand module, because electricity is required to produce them, and the supply module.

The energy requirements are assigned to specific locations. This modular structure allows regions to be defined and, if necessary, the supply from other areas to be calculated.

The demand and generation modules are independent and can be used individually or sequentially. Energy demands can be calculated as either synthetic load profiles, which are then summed to annual energy demands, or only as the annual consumption, without an hourly resolution. Whether or not hourly resolution is selected depends to a large extent on the availability of the data. Load profiles, such as those for the chemical industry, are difficult to obtain and are sometimes even confidential.

3.5.1. Input Parameters

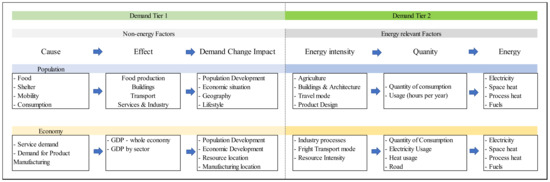

As in basic energy models, the main drivers of the energy demand are the development of the population and economic activity, measured in GDP. Figure 1 shows the basic methodology of the OECM demand module. The tier 1 inputs are population and GDP by region and sector. Whereas ‘population’ defines the number of individual energy services, which determines the energy required per capita, the economic activity (in GDP) defines the number of services and/or products manufactured and sold. The tier 1 demand parameters are determined by the effect that a specific service requires. For population, the demand parameters are defined by the need for food, shelter (buildings), and mobility and, depending on the economic situation and/or lifestyle of the population, the demand for goods and services.

Figure 1.

Tier 1 and tier 2 input parameters for the assessment of energy demand.

Economic activity (measured in GDP) is a secondary input, and is directly and indirectly dependent upon the size of the population. However, a large population does not automatically lead to high economic activity. Both population and projected GDP are inputs from external sources, such as the United Nations or the World Bank. The tier 1 input parameters themselves are strictly non-technical. For instance, the need to produce food can be satisfied without electricity or (fossil) fuels, food production is a service that can be provided with a human workforce

The tier 2 demand parameters are energy-relevant factors, and describe technical applications, their energy intensities, and the extent to which the application is used. For example, if passenger road transport is required, the technical application ‘light duty vehicle (LDV)’ is chosen to satisfy the demand.

In this example, the energy intensity for an LDV with an internal combustion engine (ICE) is, for example, 1.5 MJ/km. The use of the application (=vehicle) is 15,000 km per year, which defines the demand (1.5 MJ/km × 15,000 km/yr = 22,500 MJ/yr). The application, in this example, an LDV with ICE, can be replaced with another technology, such as an electric vehicle with a reduced energy intensity of 0.5 MJ/km. The transport energy demand decreases, while the transport service (15,000 km) remains stable. In a second step, the actual transport service can be reduced or increased, or shifted to another transport mode (such as light rail) by the modeler.

This very basic and simple principle is used for every application in each of the main sectors: residential + buildings, industry, and transport. Those sectors are broken down into multiple sub-sectors, such as aviation, navigation, rail, and road for transport, and further into applications, such as vehicle types. The modular programming allows the addition of as many subsectors and applications as required.

3.5.2. Structure of the Demand Module

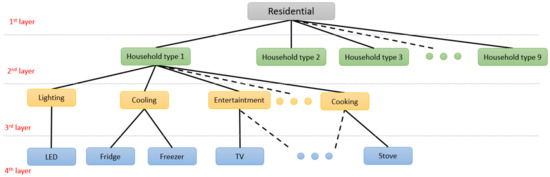

Each of the three sectors, residential & buildings (R), industry (I) and transport (T), has standardized sub-structures and applications. The residential sector R (first layer) has a list of household types (second layer) and each household type has a standard set of services (third layer), such as ‘lighting’, ‘cooling’ or ‘entertainment’. Finally, the applications for each of the services are defined (fourth layer), such as refrigerator or freezer for ‘cooling’. The energy intensity of each application can be altered by the modeler to reflect the status quo in a certain region and/or to reflect improvements in energy efficiency. An illustrative example of the residential sector layers is shown in Figure 2.

Figure 2.

Residential sector sub-structures.

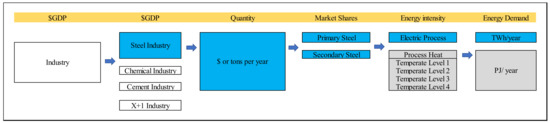

Figure 3 shows an example of the model structure of the industry sector. In the second layer, there are different industries—the OECM uses the GICS classification system for industry sub-sectors. The quantity of energy for each of the sub-sectors is driven by either GDP or the projected quantity of a product, such as the tons of steel produced per year. The market shares of specific manufacturing processes are defined and each process has a specific energy intensity for electricity, (process) heat, and/or fuels.

Figure 3.

Calculation of Industry energy demand.

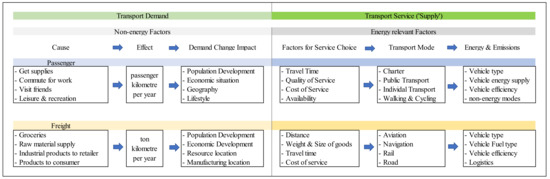

Figure 4 shows the structure for the transport sector. Again, the demand is driven by ‘non-energy’ factors, such as passenger-kilometers and freight-kilometers, and energy-related factors, such as the transport mode and the energy intensity for the different vehicle options.

Figure 4.

Calculation of Transport energy demand.

3.6. Supply Module

After the demand has been calculated, the supply of electricity, heat, and fuels is calculated. The supply does not differentiate between different demand sectors. Therefore, the electricity demand for all sectors—residential, industry, and transport—is summed and is supplied as a whole. Consequently, no specific electric generation mix for the transport sector, for example, is considered.

The supply module consists of three main elements: supply technologies, storage technologies, and the infrastructure for the power supply (capacities of power lines). For the generation of electricity and heat, the program considers all the technologies of the energy market, from both renewable and non-renewable sources. In addition to the generation of pure electricity and heat, the entire range of combined heat and power systems is covered.

Storage technologies include batteries and the use of hydrogen from electrolyzers. The calculation of heat storage is possible, but has not yet been used in the OECM scenarios.

A dispatch strategy is defined for electricity and heat generation that reflects the market and policy factors. Whether electricity from photovoltaics (PV) and onshore and offshore wind turbines have priority dispatch, ahead of fossil fuel power plants and how storage systems are used, can be determined. Each technology has a specific conversion efficiency.

Heat generation technologies are also defined by the temperature levels they can provide. For example, residential solar collectors can only supply low-temperature heat and will therefore not be considered for high-temperature process heat.

The regional energy demand—as defined in the previous section—can be met by neighboring regions, with importation or, in the case of oversupply, exportation to them. The extent to which electricity can be imported or exported from one region to another is defined by the capacity of regional interconnections, which represent the currently available power line capacities. When variable renewable power generation must be curtailed because the capacity of the power line is restricted, MATLAB documents the quantity, in terms of both capacity (MW) and duration (hours per year). If the curtailment exceeds a certain fixed proportion of the annual usage hours, the additional power line capacity required is increased and documented by the program.

3.6.1. Dispatch Module

The methodology of the dispatch module of the MATLAB-based One Earth Climate Model is based on the previous version of the model [7]. The key inputs are related to the supply technologies, storage types, the dispatch strategy, and the interconnections among regions for possible power exchange (Table 6). Different supply technologies can be selected, each with its technical characteristics, including its efficiency, available installed capacity, fuel type, and regional meteorological data (solar radiation or wind speed) (Table 7). Meteorological data define the capacity factors of solar and wind energy generators as their levels of availability at a 1 h resolution for an entire year.

Table 6.

Example of generation and storage technologies.

Table 7.

Input parameters for the dispatch model.

Table 8, Table 9, Table 10 and Table 11 provide an overview of the possible supply technologies and examples of different dispatch scenarios. The left column shows the available technology options and the right column provides an example of the priority order chosen by the user of OECM 2.0.

Table 8.

Output parameters for the dispatch model.

Table 9.

Technology groups for dispatch order selection.

Table 10.

Technology options—variable renewable energy.

Table 11.

Technology options—dispatch generation.

The supply technologies can be either dispatchable (e.g., gas power plants) or non-dispatchable (e.g., solar PV without storage). The model allows the order in which the supply technologies and storage functions are used to supply the demand. Storage and interconnections cannot be selected as the first elements of supply (Table 8).

Concentrated Solar Power (CSP) plants can be operated with on-site storage technologies and are therefore dispatchable. However, those storage capacities are limited, therefore the MATLAB model classifies CSP plants as Variable Renewable Power Plants. The dispatch order of all power plant technologies is interchangeable. In case solar and wind power plants exceed demand, or other power plants have priority dispatch, the amount of curtailed electricity is documented in MATLAP. Alternatively, surplus production can either be distributed to other regions (=cluster) or assigned to various storage technologies. Different storage technologies are defined by efficiencies, maximum charging and discharging capacities as well as the storage volume in MWh (Table 12).

Table 12.

Technology options—storage technologies.

Limitations: The OECM 2.0 can calculate required power grid transport capacities between individual regions (clusters). However, network services such as inductive power supply and frequency control must be calculated in a dedicated models as the OECM is not designed for this.

3.6.2. Regional Interconnections

The available electricity transport capacities between two geographically connected regions are determined in relation to the generation capacity installed in the region. The required electricity transport capacities within a region cannot be taken into account. Therefore, a region itself is considered a ‘copper plate’; a transmission system where electricity can flow unconstrained from any generation site to any demand site is found in most energy modeling tools [27]. This simplification is required to achieve a short calculation time, while maintaining a high technical and time resolution. The algorithm devised for the function of the interconnectors is based on the following information for each region:

- -

- Unmet load in the region;

- -

- Excess generation from other regions;

- -

- Interconnection capacity between the undersupplied region and each of the other regions;

- -

- Priority of the closest region(s) in exporting power to the undersupplied region.

Electricity demand and supply for each hour of the year are calculated for all regions. In case of a regional undersupply (=unmet load), regions with excess generation are identified. The nearest region with the highest surplus is chosen as the priority electricity supplier. If the electricity supply is still not sufficient, another region with the second highest surplus is chosen. In general, the local electricity supply has priority over electricity export. Only regions that are geographically connected can exchange electricity.

The amount of electricity transported between regions is calculated in megawatts for each hour of the year. The maximum capacity required for the import or export of electricity defines the required transmission capacity. The interconnected capacity can be defined as an input. If the required interconnection capacity exceeds the determined transmission capacity, electricity transfer will be curtailed. This curtailment is recorded and defines transmission capacity increases.

Similar to the supply technologies, different storage technologies (electrical, thermal, or hydrogen) can be defined and selected together with their technical characteristics, such as round-trip efficiency, new or installed capacities in each year of the modelled period, lifetime, maximum depth of discharge, maximum energy out in a time step, and costs. When the total energy delivered by the supply technologies in a region does not meet the demand, energy is discharged from storage (if the storage technology has energy available), following the constraints of the storage operation (maximum energy out per time step, maximum depth of discharge, maximum depth of charge, state of charge) and the order of operation for the defined storage technologies. In the case of a demand deficit after storage, electricity from other regions will be imported. When there is surplus energy generation, the surplus will charge any storage appliances (if available), according to the same constraints of energy storage operation and sequential order.

4. Model Architecture

In this section, we describe how the elements mentioned above in Section 3 can be incorporated in MATLAB. The MATLAB model has an object-oriented structure and two modules, to calculate demand and supply, which can be operated independently of each other. Thus, an energy demand analysis independent of specific supply options or the development of a supply concept based on demand from an external source is possible. Specifically, the architecture of the demand and supply modules developed are formally described below.

4.1. Demand Module Architecture in MATLAB

The demand module is implemented in MATLAB, a widely used programming language for mathematics and science computing. MATLAB allows the integration of a range of tools and databases, and has the flexibility to add and develop new functions. Specifically, the model has been developed using an object-oriented programming approach, allowing extensibility and modularity.

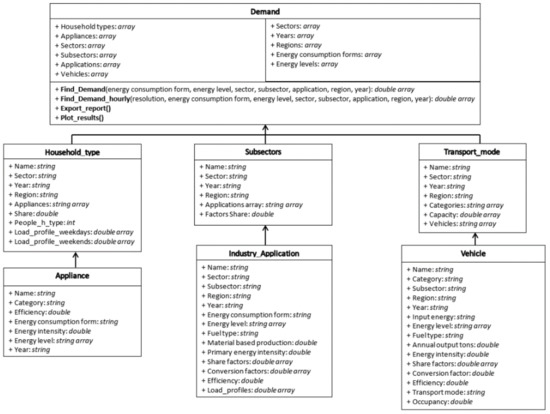

Figure 5 shows the developed demand module in MATLAB. In particular, the demand module encompasses seven classes:

Figure 5.

A Unified Modelling Language (UML) diagram of the demand module in MATLAB, showing its classes, attributes, methods, and associations.

- Demand class: This is the main class, which describes the residential, industry, and transport sectors, objects that are defined by household type, sub-sector, and transport mode classes, respectively. The attributes that define this class include a range of years, energy consumption forms, energy levels, list of sectors, household types, sub-sectors, applications, appliances, and vehicles. The demand class also has two main types of methods: (i) calculation demand methods, and (ii) printing results methods. The calculation methods use equations and algorithms to calculate and find the demand. For example, the ‘Find Demand’ method can be used to find a wide range of calculations and outputs, e.g., the electricity demand of a group of households for a specified year. The calculation method can calculate the demand for single or aggregated sectors, sub-sectors, or applications, for a single year or a range of years, unique or multiple forms of energy consumption, and single or various types of vehicle categories. The printing results methods can be used to export the results into an Excel spreadsheet or to plot the results using the MATLAB interface. Thus, the outputs of the demand module can be either pre-defined graphs, tables, or data for a standardized report. See Table 13 for a brief description of each method in this class.

Table 13. Dispatch module–inputs, intermediate outputs and outputs.

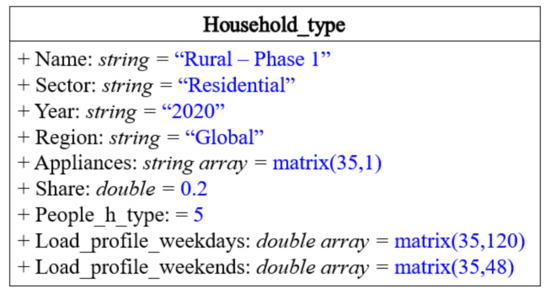

Table 13. Dispatch module–inputs, intermediate outputs and outputs. - Household and appliance classes: These classes are used to define the residential sector. The appliance objects are embedded within the household-type objects (Figure 6). Attributes include names, sectors, and regions, which are defined as string inputs (i.e., text or character inputs), or numerical inputs, which are defined as int (i.e., integers) or double (i.e., numeric variables holding numbers with decimal points). Attributes can also include arrays of strings or double values. Array variables are helpful in input time–series data, such as load profiles. Because households and appliances have their own classes, this architecture is flexible and allows the addition of households with different attributes and different types of appliances.

Figure 6. An example of a Household type object, showing the assigned attributes.

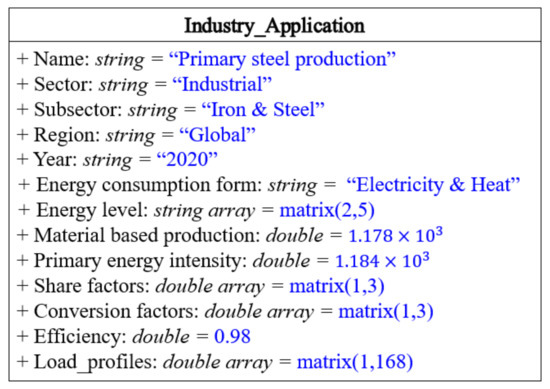

Figure 6. An example of a Household type object, showing the assigned attributes. - Sub-sector and industry application classes: These classes are used to define the industry sector. The industry application objects are embedded within the sub-sector objects. As shown in Figure 7, these classes have their own lists of attributes. Therefore, the module developed can accommodate different types of sub-sectors (e.g., steel, cement, etc.,) and incorporate various types of applications under each sub-sector.

Figure 7. An example of an Industry application object, showing the assigned attributes.

Figure 7. An example of an Industry application object, showing the assigned attributes. - Transport modes and vehicle classes: These classes are used to define the transport sector. The vehicle objects are embedded within the transport mode objects. Therefore, multiple types of transport modes can be defined, such as aviation and navigation, as well as various types of vehicles, such as planes and cruise ships.

Figure 6 and Figure 7 show the high-level class definitions for residential and industry sub-sector objects, respectively. The blue-marked text indicates the defined value for each attribute. For example, one household object with five residents is defined by the name “Rural–Phase 1”, and it has a list of 35 appliance objects, defined with a string array. It is assigned a share factor for 2020 of 0.2, which means that 20% of the households in that specific region and year are defined by this type of household and its attributes. Furthermore, 24 h load profiles are defined for each application for every day, with numerical arrays. For example, weekend load profiles have a size of 35 rows and 48 columns, representing 35 applications and 24 time slots for each weekend day.

The object-oriented architecture allows all these input attributes to be updated or modified easily. These attributes can also be read from a pre-defined Excel spreadsheet. This would facilitate a data input process that follows the array structure, such as the load profile.

Figure 7 shows an example of an industrial application object, which belongs to the sub-sector iron & steel. In this case, the energy consumption form is defined as electricity and heat, which means that it considers the electrical and heat demand. The ‘share factors’ represent the portion of the demand assigned to electricity and heat. The energy level array also allows the pre-defined network to which the application is connected to be defined, as well as the temperature levels. In this particular case, the demand is defined based on the total annual primary energy intensity and the material-based production, which are 1184 GJ/tons and 1178 Mt, respectively, for the specified region and year. The input and output units must be pre-defined when the MATLAB modules are initialized. Other attributes that can be assigned are conversion factors, such as from the primary energy to final energy via an efficiency factor.

Additional attributes and methods can be defined for each class if required and the data are available. Therefore, the demand module class can be extended by defining new classes, attributes and methods.

4.2. Supply Module Architecture in MATLAB

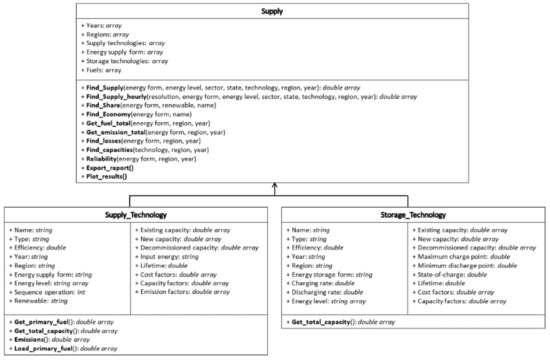

Analogous to the demand module, inputs can be made directly into the supply module via MATLAB or a standardized Excel sheet. The supply module in MATLAB is also based on an object-oriented structure, in which classes and the objects belonging to those classes are built based on attributes and methods.

Figure 8 shows the UML class diagram for the supply module developed in MATLAB. Specifically, the supply module has three main classes:

Figure 8.

A UML diagram of the supply module in MATLAB, showing its classes, attributes, methods, and associations.

- Supply class: This is the main class and it is built on the supply and storage technology objects. Attributes that describe the supply class include years, regions, energy supply forms, fuels, and generation and storage technologies. The supply class has two main types of methods: (i) calculation supply methods; and (ii) printing results methods. The calculation methods implement equations and algorithms to calculate the dispatch and fuel consumption. Table 14 presents a brief description of each method.

Table 14. Methods within the demand class.

Table 14. Methods within the demand class. - Supply technology class: This class is used to define supply technologies. Attributes include name, type, efficiency, year, region and energy supply form and are defined as text inputs. Additional attributes are defined as numerical inputs, such as lifetime, cost and capacity factors. The structure adopted allows the addition of new attributes if required. This class has methods that are used by the main supply class to calculate the primary fuel, emissions, or installed capacity of a specific technology.

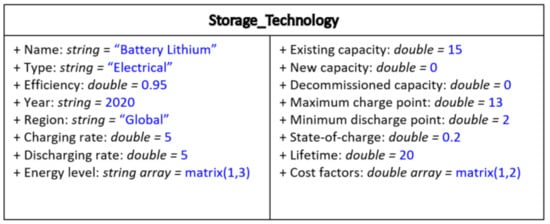

- Storage technology class: This class is used to defined storage technologies. The attributes include name, type, efficiency, year, region and energy storage form and are defined as text inputs Other numerical attributes include charging and discharging rates, capacity, cost factors, and state of charge.

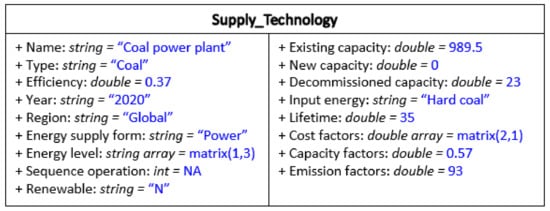

Figure 9 and Figure 10 show the high-level class definitions for supply technologies and storage objects, respectively. The text in blue indicates the defined value for each attribute. For example, the supply technology object in Figure 9 has the name “coal power plant”; its input energy is defined as hard coal, and the object is associated with the electricity energy form. The attributes in Figure 9 consider the year 2020 and a global scenario. For example, the existing capacity is defined as 989.5 GW and the decommissioned capacity is 23 GW. The lifetime of this object is 35 years.

Figure 9.

An example of a supply technology object, showing the assigned attributes.

Figure 10.

An example of a storage technology object, showing the assigned attributes.

An example of a storage object is shown in Figure 10. The attributes of this object include text inputs, such as its name “battery lithium” and its type “electrical”. This object has numerical attributes such as the efficiency (equal to 0.95 for this object), and the charging and discharging rates (fixed at 5 kW). Note that the units for each attribute are defined when the module is initialized in MATLAB.

The supply module architecture developed is flexible to accommodate different types of supply and storage technologies. Additional attributes or methods can be added easily to the model.

5. OECM 1.5 °C Transport Trajectory

This section provides the calculated results for the OECM 1.5 °C transport pathway, calculated with the described methodology.

5.1. OECM 1.5 °C Transport Demand Calculation

The global transport energy demand was calculated with the economic and technical parameters shown in Table 3. Transport mode shifts for passenger and freight transport are assumed. These assumptions are manual inputs in MATLAB. Table 15 and Table 16 show the assumed changes in the transport modes relative to 2019, for passenger and freight transport. The main driver of the transport mode shifts is energy efficiency, towards lower energy intensities per kilometer.

Table 15.

Methods within the supply class.

Table 16.

Global: Development of behavioral changes in passenger travel (based on pkm) by transport mode.

The energy demands for aviation, navigation and road transport are calculated with the documented input parameters and the methodology shown in Figure 4. Table 17 shows the results broken down into three transport modes and separated into passenger and freight transport. The energy demands for the manufacture of airplanes, ships and road vehicles are provided. The energy demand for the actual transport services is calculated on the basis of the transport kilometers required, the vehicles chosen for each transport mode and the assumed improvements in energy efficiency for the transport technologies.

Table 17.

Global: Development of changes in freight logistics (based on tkm) by transport mode.

In contrast, the energy demand for the manufacture of transport equipment, (e.g., car manufacture) is calculated from the assumed development of GDP and the standard energy efficiencies, in MJ per $GDP.

The technical resolution of standard energy assessment tools, such as REMIND [18] see Section 2.1), cannot differentiate the energy demand for specific manufacturing processes (such as car manufacture), and the energy demand would be part of the industry sector. Financial institutions and institutional investors that have agreed to net-zero targets require sector-specific benchmarks for clearly defined investment sectors to set their targets. However, those investment sectors are not consistent with the breakdown of the demand sectors used in standard energy statistics. Therefore, the OECM methodology presented here closes the knowledge gap and provides a flexible tool with which to calculate benchmarks for various combinations of sub-sectors on the basis of standard energy statistical databases, such as the IEA World Energy Balances [28].

5.2. OECM 1.5 °C Transport Energy Supply Calculation

After the energy requirements of the different sectors are calculated, we turn to the supply of energy. Table 18 shows the energy supply requirements for the transport modes analyzed and the manufacture of transport equipment. The chosen application, which is in the context of transport the various vehicle technologies, determines the change in the energy sources required, e.g., from petrol or diesel to bio-diesel, hydrogen, or electricity.

Table 18.

Transport energy demand by transport mode under the OECM 1.5 °C pathway.

The demand for fuels and fuel types is directly related to the vehicle technology selected, and is therefore not technology neutral for the supply side. However, a shift towards synthetic fuels and/or electricity will increase the electricity demand, but will not influence the electricity generation technology, as such. The development of the electricity generation technology mix is determined by the carbon intensity of the generation technology, the locally available renewable energy resources, and the available infrastructure.

Increased electrification significantly reduces the final energy demand of the transport sector, whereas the actual transport service in terms of kilometers will remain stable for passenger transport (+1% between 2020 and 2050) and will increase for freight transport (+15% between 2020 and 2050).

The additional electricity demand of the transport sector is added to the overall power generation requirement and calculated with the OECM demand module described in Section 4.2. The global electricity supply shares, under the OECM 1.5 °C pathway, are shown in Table 19. The specific CO2 emissions for electric vehicles, in CO2 per kilometer, and for the production of hydrogen, are calculated with the average specific CO2 emissions per kilowatt hour of generated electricity (carbon intensity of electricity). The same values for the electricity carbon intensity for each year are used for all sectors and industries analyzed, e.g., for transport, the steel industry, or residential electricity supply.

Table 19.

Energy supply requirements for aviation, navigation, road transport and the manufacture of transport equipment.

5.3. OECM 1.5 °C Transport Carbon Intensity Calculation

In the last step, the carbon intensity and the overall carbon emissions are calculated from the primary energy demand by fuel and sector, and from the emission factors for hard coal, brown coal (lignite), oil and gas shown in Table 20. The emission factor for fuels are stable across the entire time series, whereas the carbon intensity for electricity changes with the renewable electricity share (see data provided in Table 19, last row).

Table 20.

Global electricity supply shares under the OECM 1.5 °C pathway.

Table 21 shows the calculated carbon intensities and total carbon emissions by transport mode for the OECM 1.5 °C transport pathway. The total energy-related CO2 emissions for, e.g., aviation per year, set the maximum annual CO2 emission target, the cumulative emissions between 2020 and 2050, and the overall carbon budget under the 1.5 °C target (Table 22). The average specific CO2 emissions per person kilometer and per ton-kilometer represent the technical benchmarks for aviation services.

Table 21.

Emission factors used for the OECM 1.5 °C pathways.

Table 22.

Transport: carbon intensity and total energy-related CO2 emission by sector for the OECM 1.5 °C transport pathway.

6. Conclusions

To develop and calculate detailed energy scenarios for specific GICS-defined industry and service sectors requires energy models with a high technical resolution. There are currently no energy models on the market that calculate energy scenarios within the system boundaries defined according to the Global Industry Classification System (GICS). The OECM 2.0 closes this gap. The model architecture of the existing OECM 1.0 was modified to allow the integration of more technical parameters. The integration of new industrial areas required the calculation of energy consumption for sector-specific processes which led to a higher data volume. The OECM 2.0 uses MATLAB to process the data and to enable a flexible presentation of results.

In this paper, we documented the development and calculation of a 1.5 °C pathway for the GICS sector 2030 Transportation with the OECM 2.0 as a case study. The scenarios were further divided in 203010 Air Freight & Logistics, 20302010 Airlines (passenger transport), 203030 Marine transport and 203040 Road & Rail transport. The higher technical resolution of the OECM 2.0 allowed the development of an individual scenario for the different GICS sectors. However, the high technical resolution requires more detailed input parameters such as passenger-kilometers per year and the breakdown by vehicle type and transport mode. The required input data is not always available for all countries and/or industries. However, sufficient data is available to calculate the trajectories for aviation, shipping, road and rail transport on a global level.

6.1. OECM 2.0 Output and Area of Use

The additionality of OECM 2.0 provides a high resolution of the sector-specific parameters for both demand and supply, which are required as key performance indicators (KPIs) by the finance industry. Table 23 provides an overview of the main KPI parameters and the areas of their use, with a focus on the needs of institutional investors.

Table 23.

Examples of energy-related key performance indicators (KPIs) for net-zero target setting, calculated with OECM 2.0 for four sectors.

Commodities and/or GDP are the main drivers of the energy demand for industries. The projection of, for example, the global steel demand in tons per year, over the next decades, are discussed with the industry and/or client. The OECM 2.0 can calculate either a single specific sector only or a whole set of sectors. In the case of global scenario development, various industry projections are combined to estimate both the total energy supply required and the potential energy-related emissions. Thus, a global carbon budget can be broken down into the carbon budgets of specific industries.

Energy intensities are both input data for the base year and a KPI for future projections. The effect of a targeted reduction in the energy intensity in a given year and the resulting energy demand and carbon emissions can be calculated, for example for the transport service industry.

All sector demands are supplied by the same energy supply structure in terms of electricity, process heat (for each temperature level) and total final energy. Finally, specific emissions, such as CO2 per ton-kilometer, CO2 per ton of steel or per cubic meter of waste water treatment, are calculated and can be used to set industry targets.

All input and output OECM data are available as MATLAB-based tables or graphs, or as standard Excel-based reports.

6.2. Model Dynamics

A detailed assessment of the energy demand based on industry products, such as the amount of steel or aluminum used and/or the economic projections (for example for sub-sectors of the chemical industry), combined with very high technical resolution, allows the development of the electricity and fuel demand to be comprehensively mapped with steadily increasing sector coupling. A high degree of electrification for heating and transport, to replace fuels, requires an energy scenario to be modelled that includes an electricity system analysis to assess the infrastructural changes required (i.e., the power grid). OECM 2.0 combines an integrated energy assessment tool with a system analysis module. Net-zero pledges for specific industries lead to more detailed energy scenarios for specific industry sectors. The steel industry, for example, favors hydrogen-based steel production, which will have a significant impact on the hydrogen demand and the electricity needed to produce it. OECM 2.0 takes this development into account and allows the modeler to change from a yearly to an hourly resolution when developing load curves for industries and/or the entire power system, when simulating an electricity supply with high shares of variable renewable power plants.

Another example in which a long-term scenario analysis must be combined with a system analysis occurs in the chemical industry. The switch to electrical process heat will not only significantly increase the power requirement, but also the power load. The decision to use electric or hydrogen-based process heat requires the analysis of the regional infrastructure to allow the development of a cost-effective solution.

The OECM 2.0 program is modular and currently includes 12 different industry sectors. Its expansion to more sectors and sub-sectors is possible without great effort, and thus increases the accuracy of the analysis of electricity and fuel requirements. This interaction between a technology change in one sector (e.g., to move to electric process heat) and the technical and cost implications for other sectors (e.g., power utilities and grid operators) is a central component of the model dynamics.

6.3. Limitations

Industry-specific energy intensities and energy demands are not available for a variety of industries. In particular, the energy intensities for sub-sectors of the chemical industry are either unavailable or confidential. A database of energy intensities is required to develop more detailed scenarios. Although energy intensities can be estimated based on the available data, the input parameters are usually derived from various sources, which may not follow the same methodology. Energy intensities based on GDP, for example, are calculated with either nominal GDP, real GDP, or purchasing power parity GDP. Furthermore, energy intensities can be provided as the final energy or primary energy. In some cases, this information is not available at all. A database of industry-specific energy demands and energy intensities, with a consistent methodology, is required to improve the accuracy of calculations in future research.

Author Contributions

Conceptualization, S.T.; methodology, S.T.; software, J.G.; validation, S.T. and J.G.; formal analysis, J.G.; investigation, S.T.; resources, S.T. and J.G.; data curation, S.T. and J.G.; writing—original draft preparation, S.T.; writing—review and editing, S.T. and J.G.; visualization, J.G.; supervision, S.T.; project administration, S.T.; funding acquisition, S.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Climate Foundation (ECF), 23 Rue de la Science, 1040 Brussels, Belgium (grant number 2101-61369).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank Jihane Assaf for her support in the early phase of the demand module coding in MATLAB, Anna Irmisch of ECF and members of the Net-Zero Asset Owner Alliance especially Elke Pfeiffer, Jesica Andrews, Markus Zimmer and Marcus Bruns. Furthermore, we would like to thank Thomas Pregger, Sonja Simon and Tobias Naegler, German Aerospace Center Institute of Networked Energy Systems Energy Systems Analysis for ongoing support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United Nations Climate Change. Report of the Conference of the Parties on its Twenty-First Session; United Nations Climate Change: Bonn, Germany, 2015. [Google Scholar]

- IPCC. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Chen, Y., Goldfarb, L., Gomis, M.I., Matthews, J.B.R., Berger, S., et al., Eds.; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar]

- Carbon, B. Explainer: How ‘Shared Socioeconomic Pathways’ Explore Future Climate Change. 2018. Available online: https://www.carbonbrief.org/explainer-how-shared-socioeconomic-pathways-explore-future-climate-change (accessed on 31 January 2022).

- Nikas, A.; Doukas, H.; Papandreou, A. A Detailed Overview and Consistent Classification of Climate-Economy Models. In Understanding Risks and Uncertainties in Energy and Climate Policy: Multidisciplinary Methods and Tools for a Low Carbon Society; Springer Science and Business Media: Berlin, Germany, 2019; pp. 1–54. [Google Scholar]

- Süsser, D.; Gaschnig, H.; Ceglarz, A.; Stavrakas, V.; Flamos, A.; Lilliestam, J. Better suited or just more complex? On the fit between user needs and modeller-driven improvements of energy system models. Energy 2022, 239, 121909. [Google Scholar] [CrossRef]

- NZAOA. UN-convened Net-Zero Asset Owner Alliance—Institutional Investors Transitioning Their Portfolios to Net Zero GHG Emissions by 2050. 2021. Available online: https://www.unepfi.org/net-zero-alliance/ (accessed on 3 October 2021.).

- Teske, S.; Pregger, T.; Simon, S.; Naegler, T.; Pagenkopf, J.; van den Adel, B. Methodology. In Achieving the Paris Climate Agreement Goals: Global and Regional 100% Renewable Energy Scenarios with Non-Energy GHG Pathways for +1.5 °C and +2 °C, Teske, S., Ed.; Springer International Publishing: New York, NY, USA, 2019; pp. 25–78. [Google Scholar]

- Simon, S.; Naegler, T.; Gils, H.C. Transformation towards a renewable energy system in Brazil and Mexico—Technological and structural options for Latin America. Energies 2018, 11, 907. [Google Scholar] [CrossRef] [Green Version]

- Cui, P.; He, J.; Fang, J.; Xu, X.; Cui, J.; Yang, S. Research on method for adaptive imbalance vibration control for rotor of var-iable-speed mscmg with active-passive magnetic bearings. J. Vib. Control. 2015, 23, 167–180. [Google Scholar] [CrossRef]

- Teske, S. Bridging the Gap between Energy and Grid Models, Developing an Integrated Infrastructural Planning Model for 100% Renewable Energy Systems in Order to Optimize the Interaction of Flexible Power Generation, Smart Grids and Storage Technologies. Ph.D. Thesis, University of Flensburg, Frensburg, Germany, 2015. [Google Scholar]

- Wang, X.; Zhang, Y.; Gao, P. Design and Analysis of Second-Order Sliding Mode Controller for Active Magnetic Bearing. Energies 2020, 13, 5965. [Google Scholar] [CrossRef]

- Seidenberger, T.; Thrän, D.; Offermann, R.; Seyfert, U.; Buchhorn, M.; Zeddies, J. Global Biomass Potentials. Investigation and Assessment of Data, Remote Sensing in Biomass Potential Research, and Country-Specific Energy Crop Potentials. In EPIC3energy [R]evolution—A Sustainable World Energy Outlook, 3; Electronic Publication Information Center (ePIC): Washington, DC, USA, 2010; pp. 166–168. [Google Scholar]

- Farjana, S.H.; Huda, N.; Mahmud, M.A.P.; Saidur, R. Solar process heat in industrial systems—A global review. Renew. Sustain. Energy Rev. 2018, 82, 2270–2286. [Google Scholar] [CrossRef] [Green Version]

- Ringkjøb, H.-K.; Haugan, P.M.; Solbrekke, I.M. A review of modelling tools for energy and electricity systems with large shares of variable renewables. Renew. Sustain. Energy Rev. 2018, 96, 440–459. [Google Scholar] [CrossRef]

- Teske, S.; Niklas, S.; Talwar, S.; Atherton, A. 1.5 °C pathways for the Global Industry Classification (GICS) sectors chemicals, aluminium, and steel. SN Appl. Sci. 2022, 4, 125. [Google Scholar] [CrossRef] [PubMed]

- Grubler, A.; Wilson, C.; Bento, N.; Boza-Kiss, B.; Krey, V.; Mccollum, D.L.; Rao, N.D.; Riahi, K.; Rogelj, J.; De Stercke, S.; et al. A low energy demand scenario for meeting the 1.5 °C target and sustainable development goals without negative emission technologies. Nat. Energy 2018, 3, 515–527. [Google Scholar] [CrossRef]

- Rogelj, J.; Popp, A.; Calvin, K.V.; Luderer, G.; Emmerling, J.; Gernaat, D.; Fujimori, S.; Strefler, J.; Hasegawa, T.; Marangoni, G.; et al. Scenarios towards limiting global mean temperature increase below 1.5 °C. Nat. Clim. Chang. 2018, 8, 325–332. [Google Scholar] [CrossRef]

- Luderer, G.; Leimbach, M.; Bauer, N.; Kriegler, E.; Baumstark, L.; Bertram, C. Description of the REMIND Model (Version 1.6). SSRN.2015. Available online: https://ssrn.com/abstract=2697070 (accessed on 25 March 2022).

- IPCC. Global Warming of 1.5°C; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Wachtmeister, H.; Henke, P.; Höök, M. Oil projections in retrospect: Revisions, accuracy and current uncertainty. Appl. Energy 2018, 220, 138–153. [Google Scholar] [CrossRef]

- IEA. World Energy Balances 2020; IEA: Paris, France, 2020; Available online: https://www.iea.org/data-and-statistics?country=WORLD&fuel=Energy transition indicators&indicator=TFCShareBySectorn (accessed on 23 March 2022).

- IEA. IEA World Energy Statistics and Balances; IEA: Paris, France, 2021; Available online: https://doi.org/https://doi.org/10.1787/enestats-data-en (accessed on 10 January 2022).

- Seven2one. Mesap/PlaNet Software Framework; Seven2one Modelling, Mesap4, Release 4.14.1.9; Seven2one Informations Système GmbH: Karlsruhe, Germany, 2012. [Google Scholar]

- Schlenzig, C. Energy planning and environmental management with the information and decision support system MESAP. Int. J. Glob. Energy Issues 1999, 12, 81–91. [Google Scholar] [CrossRef]

- World Bank. World Development Indicators. 2021, pp. 2–6. Available online: http://wdi.worldbank.org/table/4.2# (accessed on 3 July 2021).

- MSCI. The Global Industry Classification Standard (GICS). 2021. Available online: https://www.msci.com/our-solutions/indexes/gics (accessed on 3 October 2021).

- Avrin, A.-P. International Institute for Applied Systems Analysis. Implications of Electricity Transmission for Integrating Variable Renewable Energies—Young Scientists Summer Program—IIASA. 2016. Available online: https://iiasa.ac.at/web/scientificUpdate/2015/cb/Avrin-Anne-Perrine3.html (accessed on 20 February 2022).

- IEA. World Energy Balances 2021; IEA: Paris, France, 2021; Available online: https://www.iea.org/data-and-statistics/data-product/world-energy-balances (accessed on 25 October 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).