Sieving and Covering of Wood Chips Improves Storability

Abstract

:1. Introduction

2. Materials and Methods

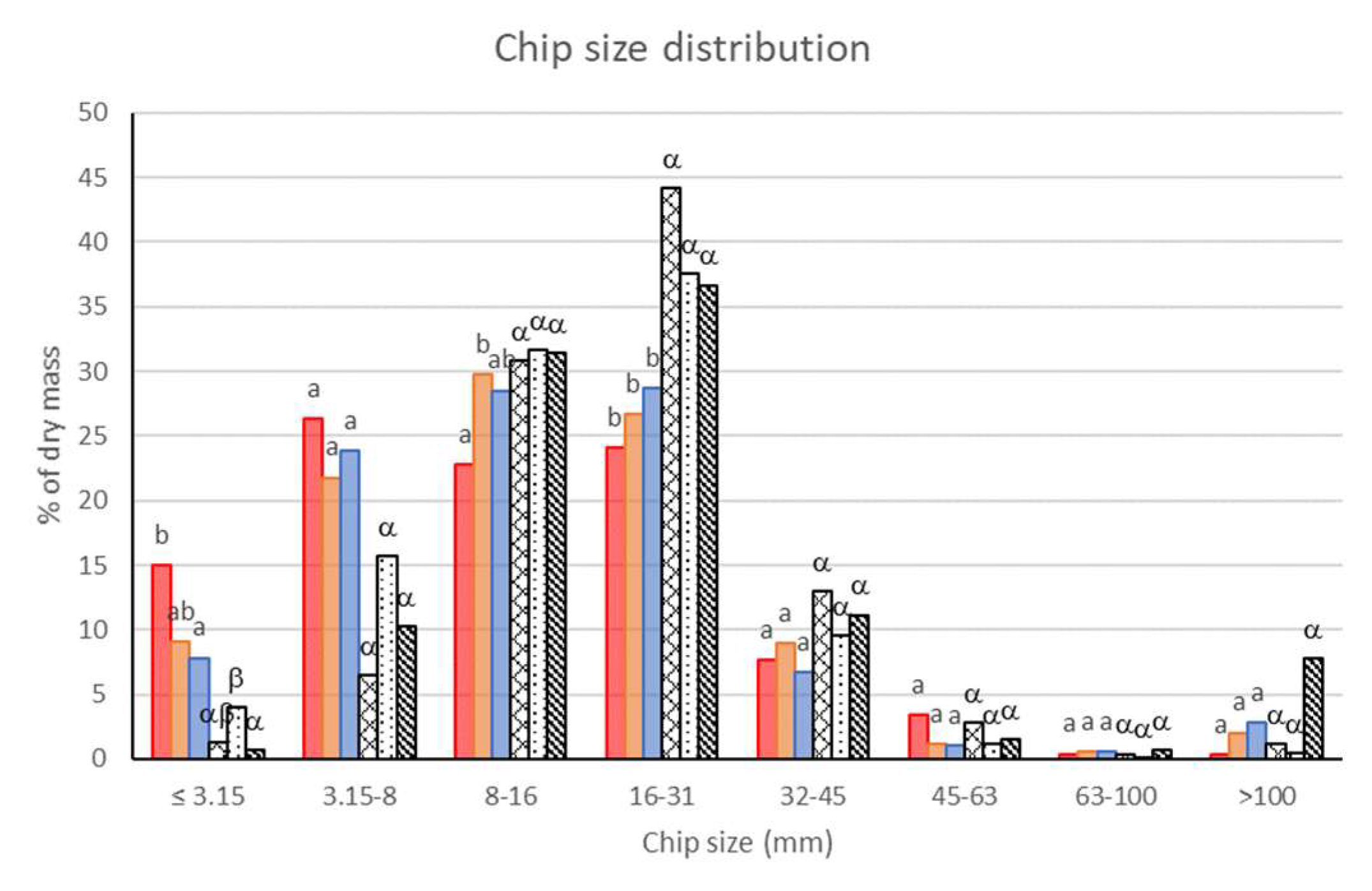

2.1. Material and Storage Locations

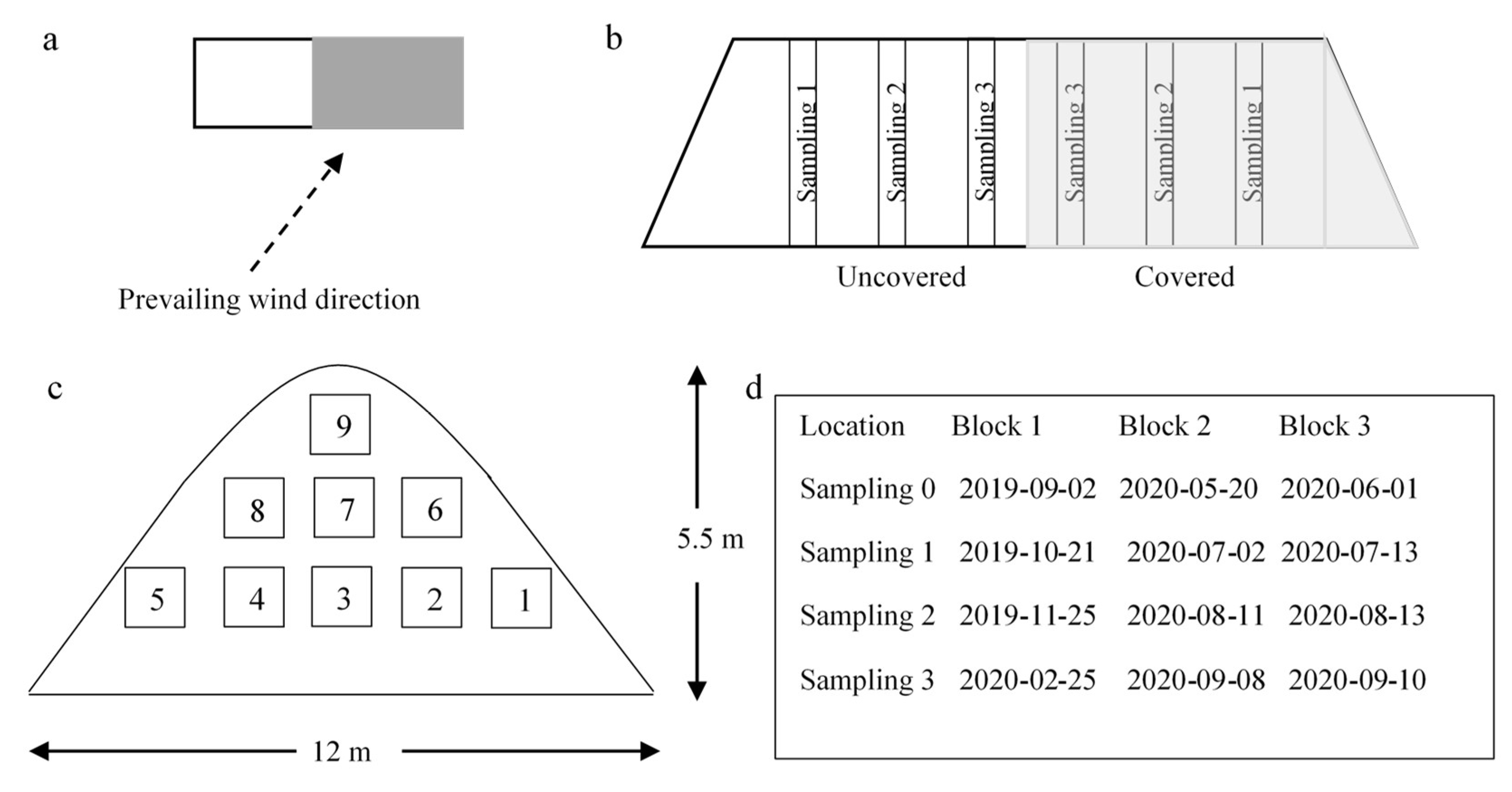

2.2. Field Trial Structure and Sampling

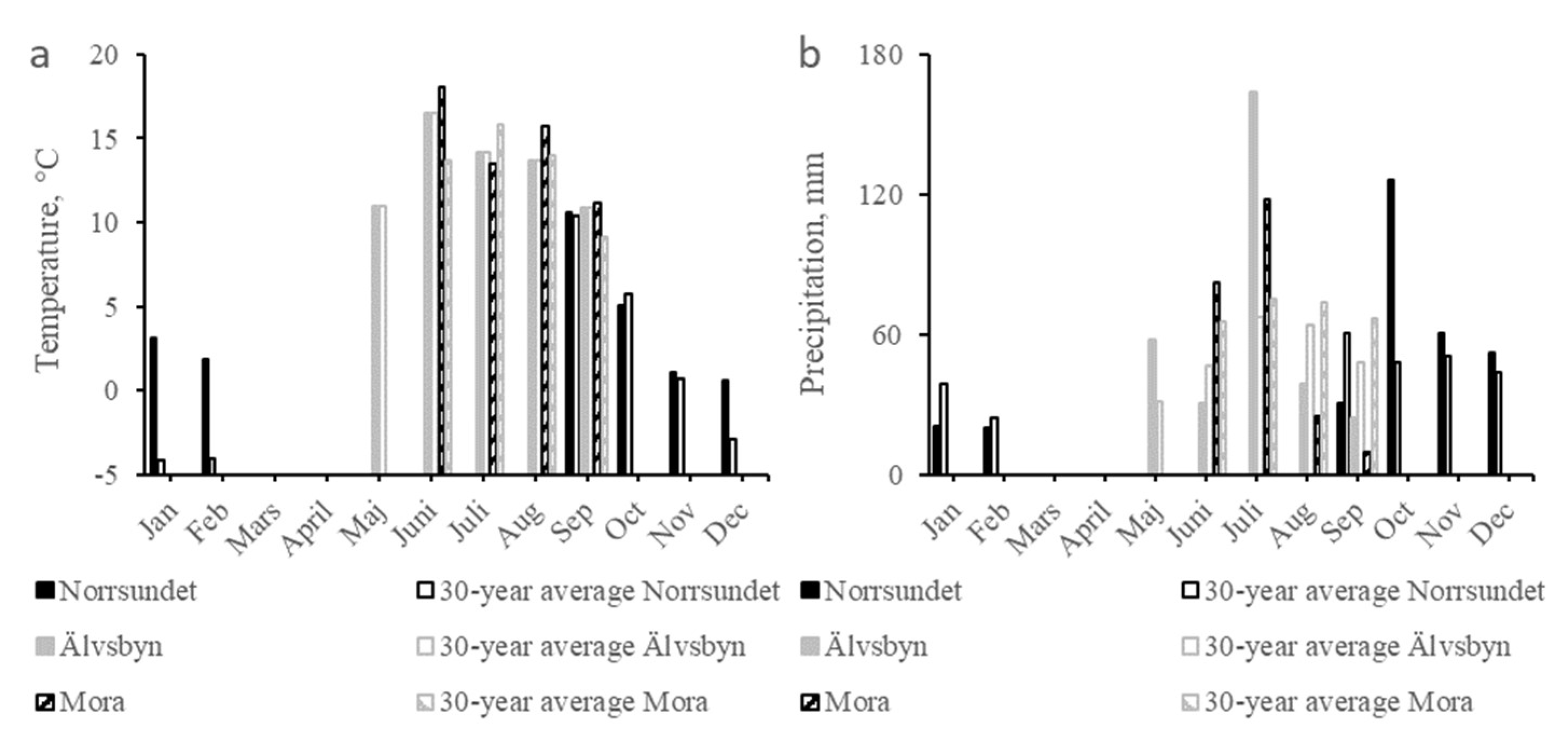

2.3. Meteorological Data for the Storage Sites

2.4. Statistical Analysis

3. Results

3.1. Temperature Development within Piles

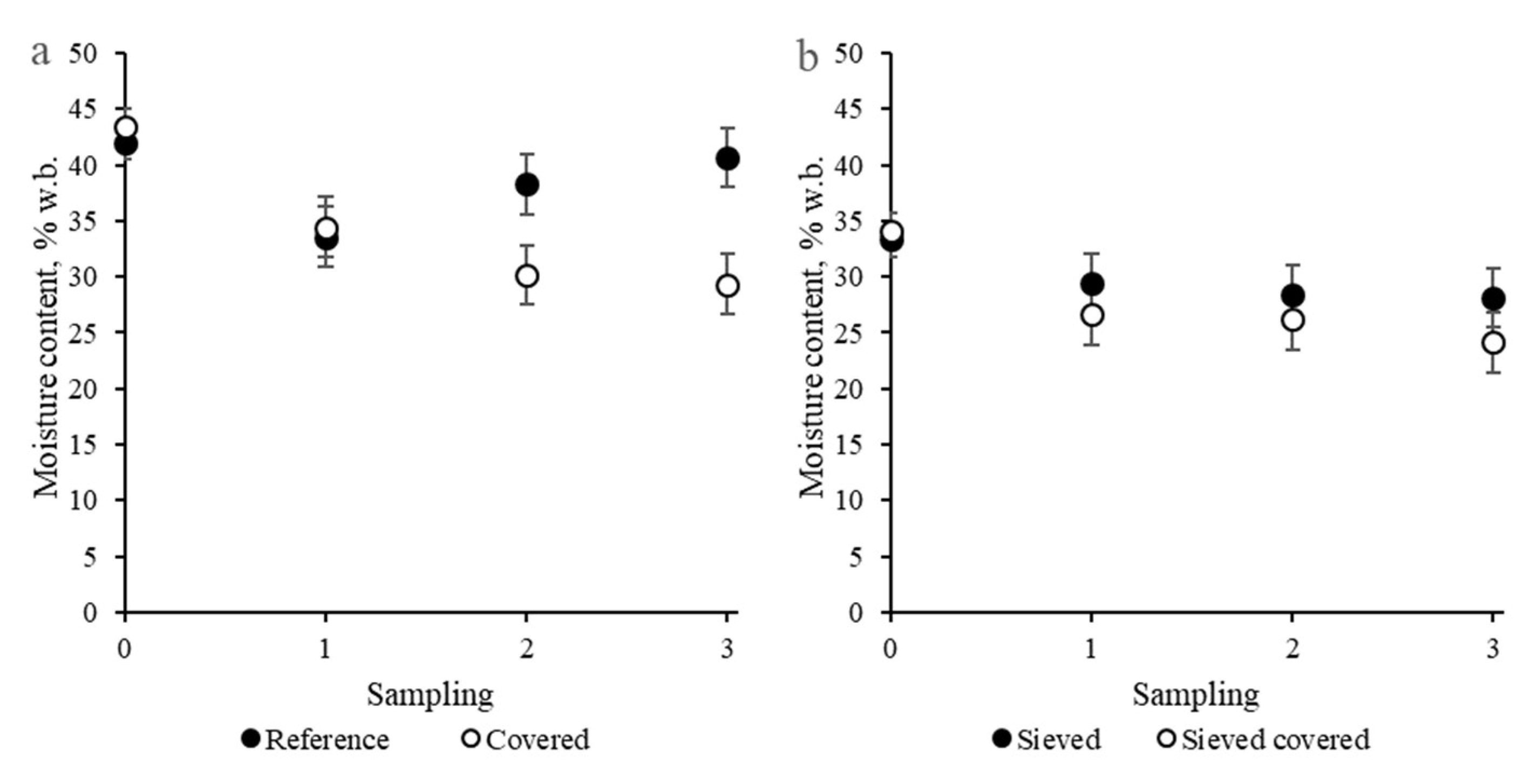

3.2. Moisture Content (M)

3.3. Dry Matter Loss (DML)

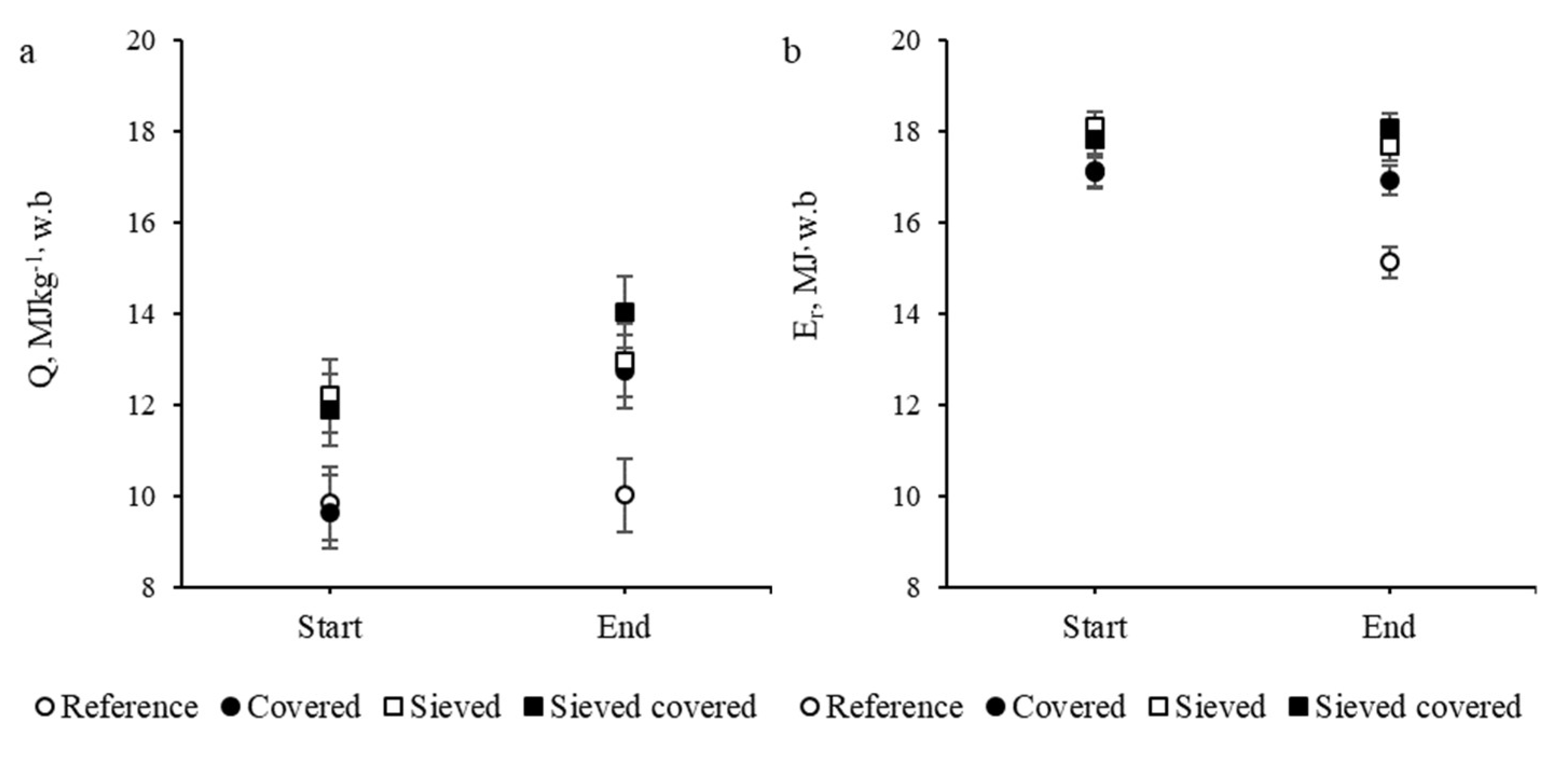

3.4. Net Calorific Value (Q) and Recovered Energy per Initial Mass (Er)

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Olsson, O.; Eriksson, A.; Sjöström, J.; Anerud, E. Keep that fire burning: Fuel supply risk management strategies of Swedish district heating plants and implications for energy security. Biomass Bioenergy 2016, 90, 70–77. [Google Scholar] [CrossRef]

- Windisch, J.; Väätäinen, K.; Anttila, P.; Nivala, M.; Laitila, J.; Asikainen, A.; Sikanen, L. Discrete-event simulation of an information-based raw material allocation process for increasing the efficiency of an energy wood supply chain. Appl. Energy 2015, 149, 315–325. [Google Scholar] [CrossRef]

- Väätäinen, K.; Prinz, R.; Malinen, J.; Laitila, J.; Sikanen, L. Alternative operation models for using a feed-in terminal as a part of the forest chip supply system for a CHP plant. GCB Bioenergy 2017, 9, 1657–1673. [Google Scholar] [CrossRef] [Green Version]

- Jirjis, R. Storage and drying of wood fuel. Biomass Bioenergy 1995, 9, 181–190. [Google Scholar] [CrossRef]

- Nurmi, J. The storage of logging residue for fuel. Biomass Bioenergy 1999, 17, 41–47. [Google Scholar] [CrossRef]

- Nurmi, J.; Hillebrand, K. The fuel quality of Norway spruce logging residues in relation to storage logistics. For. Res. Bull. 2001, 203, 42–46. [Google Scholar]

- Nordfjell, T.; Liss, J.-E. Compressing and Drying of Bunched Trees from a Commercial Thinning. Scand. J. For. Res. 2000, 15, 284–290. [Google Scholar] [CrossRef]

- Pettersson, M.; Nordfjell, T. Fuel quality changes during seasonal storage of compacted logging residues and young trees. Biomass Bioenergy 2007, 31, 782–792. [Google Scholar] [CrossRef]

- Filbakk, T.; Høibø, O.; Nurmi, J. Modelling natural drying efficiency in covered and uncovered piles of whole broadleaf trees for energy use. Biomass Bioenergy 2011, 35, 454–463. [Google Scholar] [CrossRef]

- Eliasson, L.; Anerud, E.; Grönlund, Ö.; von Hofsten, H. Managing moisture content during storage of logging residues at landings–Effects of coverage strategies. Renew. Energy 2020, 145, 2510–2515. [Google Scholar] [CrossRef]

- Krigstin, S.; Wetzel, S. A review of mechanisms responsible for changes to stored woody biomass fuels. Fuel 2016, 175, 75–86. [Google Scholar] [CrossRef]

- Thörnqvist, T. Drying and storage of forest residues for energy production. Biomass 1985, 7, 125–134. [Google Scholar] [CrossRef]

- BNilsson, B.; Blom, Å.; Thörnqvist, T. The influence of two different handling methods on the moisture content and composition of logging residues. Biomass Bioenergy 2013, 52, 34–42. [Google Scholar] [CrossRef]

- Wästerlund, I.; Nilsson, P.; Gref, R. Influence of storage on properties of wood chip material. J. For. Sci. 2017, 63, 182–191. [Google Scholar]

- Anerud, E.; Jirjis, R.; Larsson, G.; Eliasson, L. Fuel quality of stored wood chips—Influence of semi-permeable covering material. Appl. Energy 2018, 231, 628–634. [Google Scholar] [CrossRef]

- Anerud, E.; Bergström, D.; Routa, J.; Eliasson, L. Fuel quality and dry matter losses of stored wood chips—Influence of cover material. Biomass Bioenergy 2021, 150, 106109. [Google Scholar] [CrossRef]

- Anerud, E.; Eriksson, A. Evaluation of an improved design for large-scale storage of wood chip and bark. Biomass-Bioenergy 2021, 154, 106255. [Google Scholar] [CrossRef]

- Hofmann, N.; Mendel, T.; Schulmeyer, F.; Kuptz, D.; Borchert, H.; Hartmann, H. Drying effects and dry matter losses during seasonal storage of spruce wood chips under practical conditions. Biomass Bioenergy 2018, 111, 196–205. [Google Scholar] [CrossRef]

- Lenz, H.; Idler, C.; Hartung, E.; Pecenka, R. Open-air storage of fine and coarse wood chips of poplar from short rotation coppice in covered piles. Biomass Bioenergy 2015, 83, 269–277. [Google Scholar] [CrossRef]

- Lenz, H.; Pecenka, R.; Idler, C.; Dumfort, S.; Whittaker, C.; Ammon, C.; Hartung, E. Continuous weighing of a pile of poplar wood chips—A comparison of methods to determine the dry matter losses during storage. Biomass Bioenergy 2017, 96, 119–129. [Google Scholar] [CrossRef]

- Barontini, M.; Scarfone, A.; Spinelli, R.; Gallucci, F.; Santangelo, E.; Acampora, A.; Jirjis, R.; Civitarese, V.; Pari, L. Storage dynamics and fuel quality of poplar chips. Biomass Bioenergy 2014, 62, 17–25. [Google Scholar] [CrossRef]

- Pari, L.; Brambilla, M.; Bisaglia, C.; Del Giudice, A.; Croce, S.; Salerno, M.; Gallucci, F. Poplar wood chip storage: Effect of particle size and breathable covering on drying dynamics and biofuel quality. Biomass Bioenergy 2015, 81, 282–287. [Google Scholar] [CrossRef]

- Manzone, M.; Balsari, P. Poplar woodchip storage in small and medium piles with different forms, densities and volumes. Biomass Bioenergy 2016, 87, 162–168. [Google Scholar] [CrossRef] [Green Version]

- Afzal, M.; Bedane, A.; Sokhansanj, S.; Mahmood, W. Storage of comminuted and uncomminuted forest biomass and its effect on fuel quality. BioResources 2009, 5, 55–69. [Google Scholar]

- Manzone, M.; Balsari, P.; Spinelli, R. Small-scale storage techniques for fuel chips from short rotation forestry. Fuel 2013, 109, 687–692. [Google Scholar] [CrossRef]

- Pecenka, R.; Lenz, H.; Idler, C.; Daries, W.; Ehlert, D. Development of bio-physical properties during storage of poplar chips from 15 ha test fields. Biomass Bioenergy 2014, 65, 13–19. [Google Scholar] [CrossRef]

- Hofmann, N.; Borchert, H. Influence of fuel quality and storage conditions on oxygen consumption in two different wood chip assortments—Determination of the storage-stable moisture content. Fuel 2021, 309, 122196. [Google Scholar] [CrossRef]

- Wetzel, S.; Volpe, S.; Damianopoulos, J.; Krigstin, S. Can Biomass Quality Be Preserved through Tarping Comminuted Roadside Biomass Piles? Forests 2017, 8, 305. [Google Scholar] [CrossRef] [Green Version]

- Anerud, E.; Larsson, G.; Eliasson, L. Storage of Wood Chips: Effect of Chip Size on Storage Properties. Croat. J. For. Eng.: J. Theory Appl. For. Eng. 2020, 41, 1–11. [Google Scholar] [CrossRef]

- Baadsgaard-Jensen, J. Storage and Energy Economy of Ehunk and Chip Piles, Research Report-Exploitation of Marginal Forest Resources for Fuel. 1998. Available online: https://www.osti.gov/etdeweb/biblio/7840176 (accessed on 24 March 2022).

- Eliasson, L.; Anerud, E.; Eriksson, A.; von Hofsten, H. Productivity and costs of sieving logging residue chips. Int. J. For. Eng. 2021, 33, 80–86. [Google Scholar] [CrossRef]

- Eliasson, L.; von Hofsten, H.; Johannesson, T.; Spinelli, R.; Thierfelder, T. Effects of sieve size on chipper productivity, fuel consumption and chip size distribution for open drum chippers. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2015, 36, 11–17. [Google Scholar]

- SS-EN 15149-1:2010; Anon, Solid Biofuels–Determination of Particle Size Distribution–Part 1: Oscillating Screen Method Using Sieve Apertures of 1 mm and Above. Swedish Standard Institute: Stockholm, Sweden, 2010.

- SS-EN 14774; Anon, Solid biofuels–Determination of Moisture Content–Oven Dry Method–Part 1: Total Moisture–Reference Method. Swedish Standards Institute: Stockholm, Sweden, 2009.

- SS-EN 14918; Anon, Solid Biofuels–Determination of Calorific Value. Swedish Standards Institute: Stockholm, Sweden, 2010.

- Kuptz, D.; Hartmann, H. Prediction of air pressure resistance during the ventilation of wood chips as a function of multiple physical fuel parameters. Biomass Bioenergy 2021, 145, 105948. [Google Scholar] [CrossRef]

- Kons, K.; Bergström, D.; Di Fulvio, F. Effects of sieve size and assortment on wood fuel quality during chipping operations. Int. J. For. Eng. 2015, 26, 114–123. [Google Scholar] [CrossRef]

| Location/Block | Unsieved Wood Chips | Sieved Wood Chips |

|---|---|---|

| Block 1 | 618 | 781 |

| Block 2 | 975 | 1100 |

| Block 3 | 1185 | 1315 |

| Standard | Reference | |

|---|---|---|

| Particle size distribution | SS-EN 15149-1: 2010 | [33] |

| Moisture content (M) expressed on a wet weight basis | SS-EN 14774: 2009 | [34] |

| Gross and net calorific value, expressed on a dry weight and wet weight basis respectively | SS-EN 14918: 2010 | [35] |

| Effect | Df | Sum Sq (SS) | Mean Sq (MS) | F-value | p-Value |

|---|---|---|---|---|---|

| Intercept | 1 | 16,331 | 16,331 | 369 | 0.000 |

| Block | 2 | 1857 | 928 | 21 | 0.000 |

| Sieved | 1 | 2642 | 2642 | 60 | 0.000 |

| Covered | 1 | 237 | 237 | 5 | 0.021 |

| Block *Sieved | 2 | 729 | 364 | 8 | 0.000 |

| Block *Covered | 2 | 658 | 329 | 7 | 0.001 |

| Sieved*Covered | 1 | 250 | 250 | 6 | 0.018 |

| Block *Sieved*Covered | 2 | 33 | 17 | 0 | 0.687 |

| Error | 288 | 12,740 | 44 |

| Treatment | Sampling 1 (42–49 Days) | Sampling 2 (73–84 Days) | Sampling 3 (101–176 Days) |

|---|---|---|---|

| Uncovered | 5.37aα | 6.52bα | 10.63cα |

| Covered | 3.64aβ | 4.84bβ | 5.88cβ |

| Sieved uncovered | 1.22aγ | 1.40aγ | 1.47aγ |

| Sieved covered | 0.75aγ | 0.97aγ | 1.18aγ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anerud, E.; Bergström, D.; Routa, J.; Eliasson, L. Sieving and Covering of Wood Chips Improves Storability. Energies 2022, 15, 2953. https://doi.org/10.3390/en15082953

Anerud E, Bergström D, Routa J, Eliasson L. Sieving and Covering of Wood Chips Improves Storability. Energies. 2022; 15(8):2953. https://doi.org/10.3390/en15082953

Chicago/Turabian StyleAnerud, Erik, Dan Bergström, Johanna Routa, and Lars Eliasson. 2022. "Sieving and Covering of Wood Chips Improves Storability" Energies 15, no. 8: 2953. https://doi.org/10.3390/en15082953

APA StyleAnerud, E., Bergström, D., Routa, J., & Eliasson, L. (2022). Sieving and Covering of Wood Chips Improves Storability. Energies, 15(8), 2953. https://doi.org/10.3390/en15082953