Performance of an Innovative Bio-Based Wood Chip Storage Pile Cover—Can It Replace Plastic Tarps?

Abstract

:1. Introduction

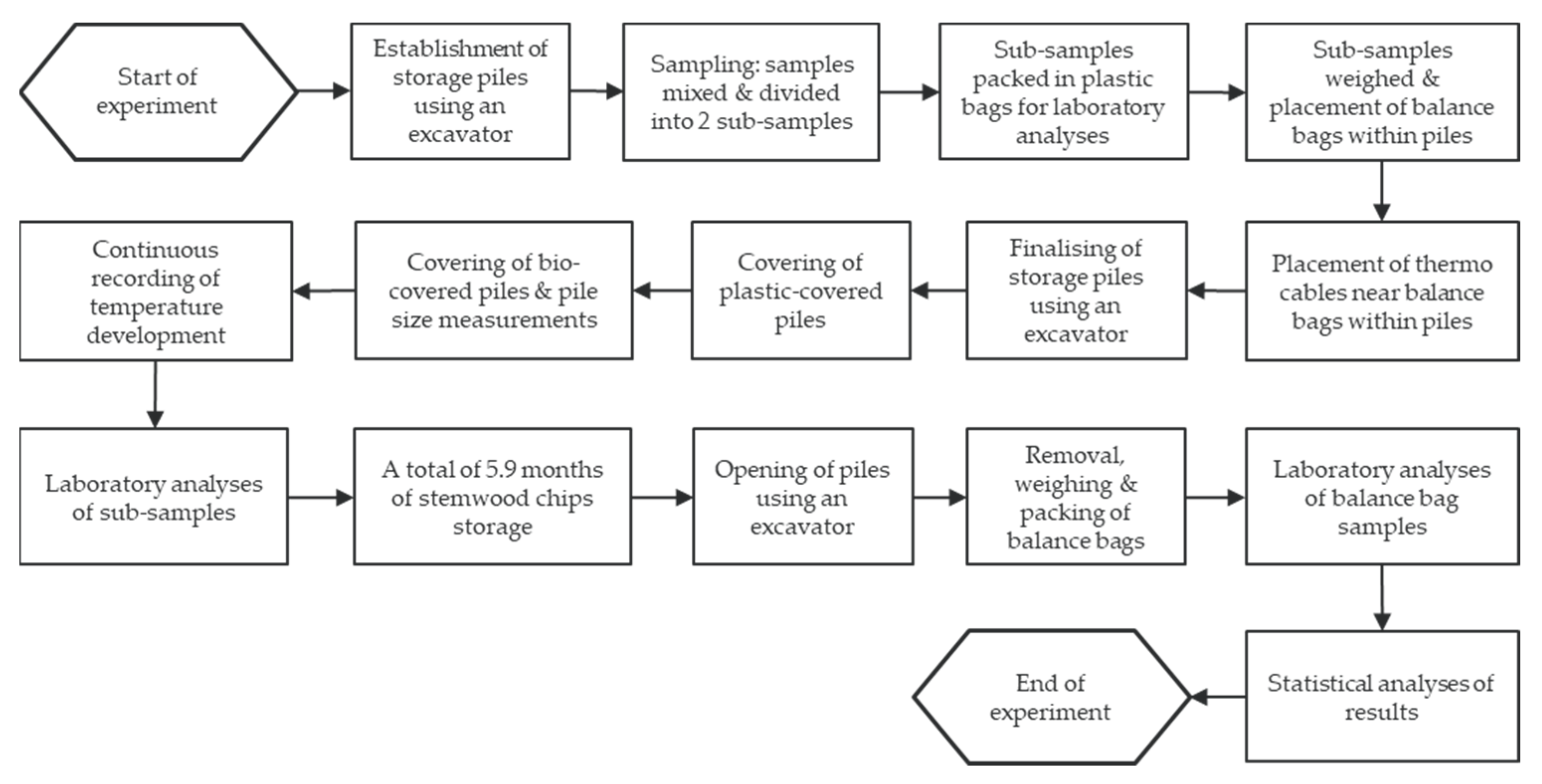

2. Materials and Methods

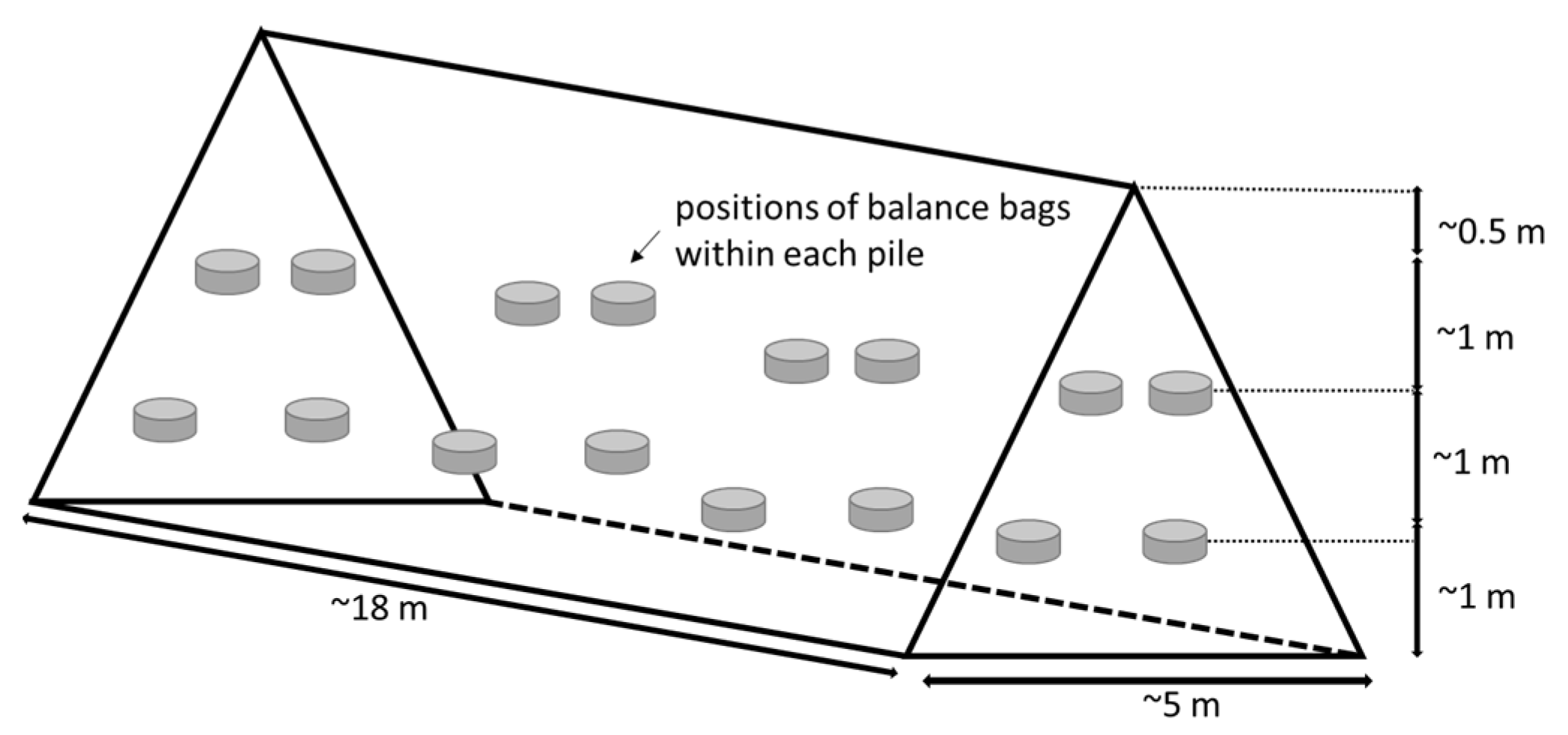

2.1. Experimental Design

2.2. Analyses Methods

3. Results

3.1. Temperature Development in Piles

3.2. Moisture Content Development in Piles

3.3. Heating Value and Energy Content

3.4. Dry Matter Losses (DML) during Storage

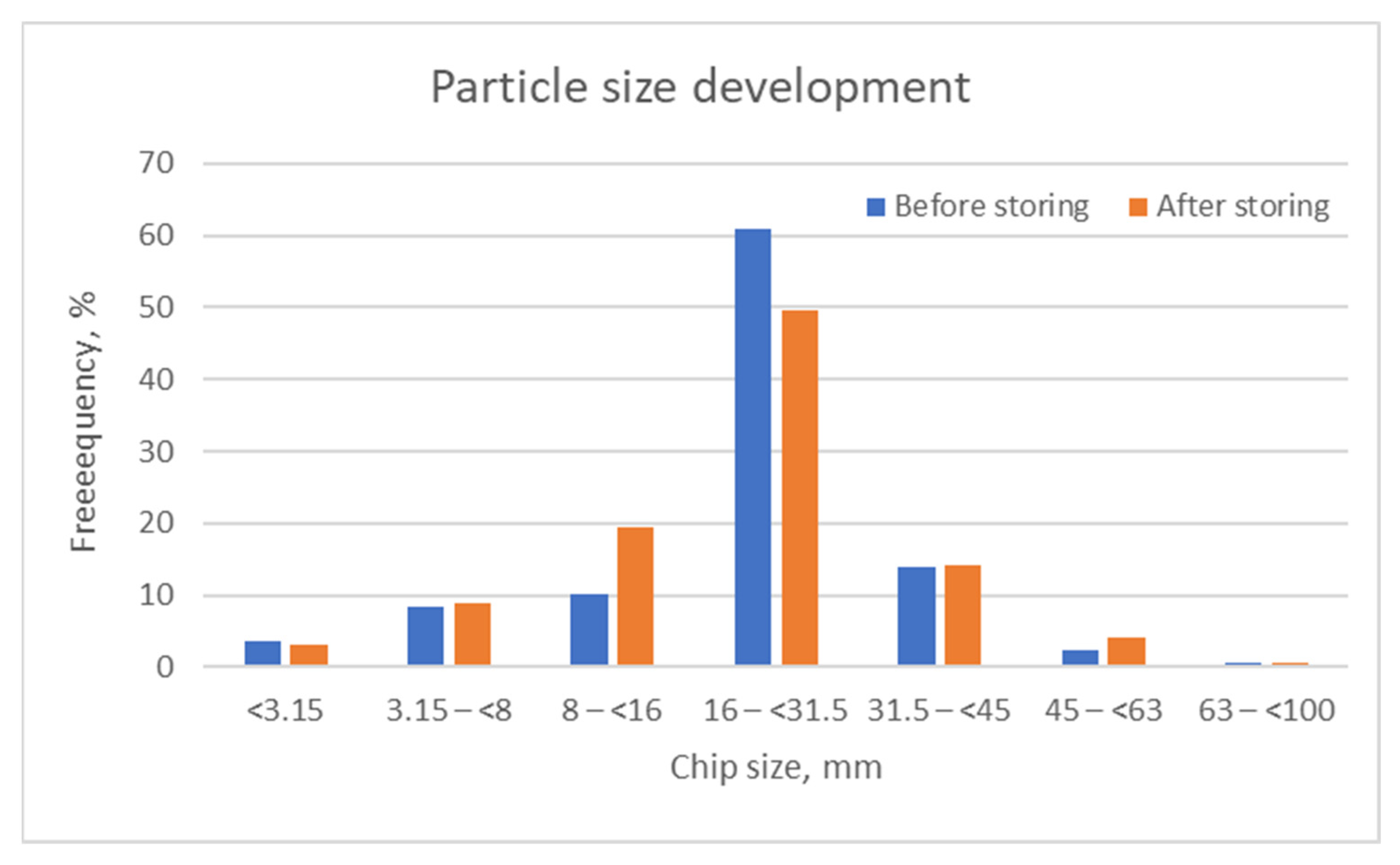

3.5. Basic Density and Results of Particle Size Analyses

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Official Statistics of Finland (OSF). Energy Consumption 2020 (Preliminary); Natural Resources Institute Finland: Helsinki, Finland, 2021; Available online: https://stat.luke.fi/en/energy-consumption-2020-preliminary_en (accessed on 6 September 2021).

- Väätäinen, K.; Anttila, P.; Eliasson, L.; Enström, J.; Laitila, J.; Prinz, R.; Routa, J. Roundwood and Biomass Logistics in Finland and Sweden. Croat. J. For. Eng. 2021, 42, 39–61. [Google Scholar] [CrossRef]

- Väätäinen, K.; Prinz, R.; Malinen, J.; Laitila, J.; Sikanen, L. Alternative operation models for using a feed-in terminal as a part of the forest chip supply system for a CHP plant. GCB Bioenergy 2017, 9, 1657–1673. [Google Scholar] [CrossRef] [Green Version]

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A European Strategy for Plastics in a Circular Economy. Brussels. 16 January 2018, p. 17. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1516265440535&uri=COM:2018:28:FIN (accessed on 16 August 2021).

- Röser, D.; Mola-Yudego, B.; Sikanen, L.; Prinz, R.; Gritten, D.; Emer, B.; Väätäinen, K.; Erkkilä, A. Natural drying treatments during seasonal storage of wood for bioenergy in different European locations. Biomass Bioenergy 2011, 35, 4238–4247. [Google Scholar] [CrossRef]

- Pettersson, M.; Nordfjell, T. Fuel quality changes during seasonal storage of compacted logging residues and young trees. Biomass Bioenergy 2007, 31, 782–792. [Google Scholar] [CrossRef]

- Erber, G.; Kanzian, C.; Stampfer, K. Modelling natural drying of European beech (Fagus sylvatica L.) logs for energy based on meteorological data. Scand. J. For. Res. 2016, 31, 294–301. [Google Scholar] [CrossRef]

- Filbakk, T.; Høibø, O.; Nurmi, J. Modelling natural drying efficiency in covered and uncovered piles of whole broadleaf trees for energy use. Biomass Bioenergy 2011, 35, 454–463. [Google Scholar] [CrossRef]

- Filbakk, T.; Høibø, O.A.; Dibdiakova, J.; Nurmi, J. Modelling moisture content and dry matter loss during storage of logging residues for energy. Scand. J. For. Res. 2011, 26, 267–277. [Google Scholar] [CrossRef]

- Jirjis, R. Storage and drying of wood fuel. Biomass Bioenergy 1995, 9, 181–190. [Google Scholar] [CrossRef]

- Anerud, E.; Krigstin, S.; Routa, J.; Brännström, H.; Arshadi, M.; Helmeste, C.; Bergström, D.; Egnell, G. Dry Matter Losses during Biomass Storage—Measures to Minimize Feedstock Degradation; IEA Bioenergy, 2019; p. 45. Available online: https://www.ieabioenergy.com/wp-content/uploads/2020/01/EIA-Dry-Matter-Loss_Final.pdf (accessed on 19 August 2021).

- Ahtikoski, A.; Routa, J.; Repola, J.; Laitila, J. The financial viability of artificial drying of forest chips, a case study from Northern Finland. J. Clean. Prod. 2019, 212, 1454–1461. [Google Scholar] [CrossRef]

- Krigstin, S.; Helmeste, C.; Wetzel, S.; Volpé, S. Managing self-heating & quality changes in forest residue wood waste piles. Biomass Bioenergy 2020, 141, 105659. [Google Scholar] [CrossRef]

- Routa, J.; Kolström, M.; Ruotsalainen, J.; Sikanen, L. Forecasting moisture changes of energy wood as a part of logistic management. Mezzinatne 2012, 25, 33–35. [Google Scholar]

- Routa, J.; Kolström, M.; Ruotsalainen, J.; Sikanen, L. Validation of prediction models for estimating the moisture content of logging residues during storage. Biomass Bioenergy 2016, 94, 85–93. [Google Scholar] [CrossRef]

- Eliasson, L.; Anerud, E.; Grönlund, Ö.; von Hofsten, H. Managing moisture content during storage of logging residues at landings—Effects of coverage strategies. Renew. Energy 2020, 145, 2510–2515. [Google Scholar] [CrossRef]

- Routa, J.; Brännström, H.; Laitila, J. Effects of storage on dry matter, energy content and amount of extractives in Norway spruce bark. Biomass Bioenergy 2020, 143, 105821. [Google Scholar] [CrossRef]

- Routa, J.; Brännström, H.; Hellström, J.; Laitila, J. Influence of storage on the physical and chemical properties of Scots pine bark. BioEnergy Res. 2021, 14, 575–587. [Google Scholar] [CrossRef]

- Anerud, E.; Routa, J.; Bergström, D.; Eliasson, L. Fuel quality of stored spruce bark—Influence of semi-permeable covering material. Fuel 2020, 279, 118467. [Google Scholar] [CrossRef]

- Hofmann, N.; Mendel, T.; Schulmeyer, F.; Kuptz, D.; Borchert, H.; Hartmann, H. Drying effects and dry matter losses during seasonal storage of spruce wood chips under practical conditions. Biomass Bioenergy 2018, 111, 196–205. [Google Scholar] [CrossRef]

- Anerud, E.; Jirjis, R.; Larsson, G.; Eliasson, L. Fuel quality of stored wood chips—Influence of semi-permeable covering material. Appl. Energy 2018, 231, 628–634. [Google Scholar] [CrossRef]

- Barontini, M.; Scarfone, A.; Spinelli, R.; Gallucci, F.; Santangelo, E.; Acampora, A.; Jirjis, R.; Civitarese, V.; Pari, L. Storage dynamics and fuel quality of poplar chips. Biomass Bioenergy 2014, 62, 17–25. [Google Scholar] [CrossRef]

- Lenz, H.; Idler, C.; Hartung, E.; Pecenka, R. Open-air storage offine and coarse wood chips of poplar from short rotation coppice in covered piles. Biomass Bioenergy 2015, 83, 269–277. [Google Scholar] [CrossRef]

- Pari, L.; Brambilla, M.; Bisaglia, C.; Del Giudice, A.; Croce, S.; Salerno, M.; Gallucci, F. Poplar wood chip storage: Effect of particle size and breathable covering on drying dynamics and biofuel quality. Biomass Bioenergy 2015, 81, 282–287. [Google Scholar] [CrossRef]

- Jirjis, R.; Pari, L.; Sissot, F. Storage of Poplar Wood Chips in Northern Italy. In Proceedings of the World Bioenergy Conference and Exhibition on Biomass for Energy, Jönköping, Sweden, 27–29 May 2008; pp. 107–111. [Google Scholar]

- Anerud, E.; Bergström, D.; Routa, J.; Eliasson, L. Fuel quality and dry matter losses of stored wood chips—Influence of cover material. Biomass Bioenergy 2021, 150, 106109. [Google Scholar] [CrossRef]

- Livetech. Livetech Suoja®. 2021. Available online: https://livetech.fi/en/ (accessed on 27 May 2021).

- SFS-EN 14774-2; Solid Biofuels. Determination of Moisture Content. Oven Dry Method. Part 2: Total Moisture. Simplified Method. Finnish Standards Association: Helsinki, Finland, 2010.

- SFS-EN 14775; Solid Biofuels. Determination of Ash Content. Finnish Standards Association: Helsinki, Finland, 2010.

- SCAN-CM 43:95; Wood Chips for Pulp Production. Basic Density. Scandinavian Pulp, Paper and Board Testing Committee: Stockholm, Sweden, 1995.

- SFS-EN ISO 18125:2017; Solid Biofuels. Determination of Caloric Value. Finnish Standards Association: Helsinki, Finland, 2017.

- Alakangas, E.; Impola, R. Quality Guidelines for Wood Fuels in Finland; VTT-M-04712-15; The Bioenergy Association of Finland, Finnish Energy, Finnish Forest Industries Federation: Helsinki, Finland; VTT Technical Research Centre of Finland: Espoo, Finland, 2015; p. 60. [Google Scholar]

- Thörnqvist, T. Drying and storage of forest residues for energy production. Biomass 1985, 7, 125–134. [Google Scholar] [CrossRef]

- Berg, S.; Bergström, D. Quality variation in comminuted forest fuels delivered during the winter in north Sweden. Int. J. For. Eng. 2021, 32, 11–18. [Google Scholar] [CrossRef]

- Harstela, P. Work studies in forestry. Silva Carelica 1991, 18, 41. [Google Scholar]

- Wästerlund, I.; Nilsson, P.; Gref, R. Influence of storage on properties of wood chip material. J. For. Sci. 2017, 63, 182–191. [Google Scholar] [CrossRef] [Green Version]

| Pile No | Approximate Pile Size (Length, Width, Height), m | Volume, m3 | Cover |

|---|---|---|---|

| K1-PLAST | 18.0 × 5.0 × 3.5 | 214 | plastic |

| K2-BIOCOV | 18.0 × 5.0 × 3.5 | 181 | bio-pile cover |

| K3-NOCOV | 18.0 × 5.0 × 3.5 | 187 | uncovered |

| K4-NOCOV | 18.0 × 5.0 × 3.5 | 197 | uncovered |

| K5-PLAST | 18.0 × 5.0 × 3.5 | 213 | plastic |

| K6-BIOCOV | 18.0 × 5.0 × 3.5 | 177 | bio-pile cover |

| Pile No. | Moisture Content at the Beginning | Moisture Content at the End | Basic Density at the Beginning | Basic Density at the End | Heating Value at the Beginning | Heating Value at the End |

|---|---|---|---|---|---|---|

| % | % | kg m−3 | kg m−3 | MJ kg−1 | MJ kg−1 | |

| K1-PLAST | 35.35 ± 2.9 | 28.14 ± 3.6 | 441.9 ± 24.6 | 430.61 ± 20.2 | 19.72 ± 0.3 | 19.79 ± 0.3 |

| K2-BIOCOV | 37.05 ± 2.9 | 30.74 ± 4 | 429.0 ± 11.5 | 413.41 ± 16.1 | 20.14 ± 0.4 | 19.83 ± 0.5 |

| K3-NOCOV | 34.32 ± 2.3 | 36.71 ± 12.5 | 437.4 ± 26.8 | 418.77 ± 28.9 | 19.57 ± 0.1 | 19.32 ± 0.3 |

| K4-NOCOV | 33.77 ± 2.8 | 33.48 ± 9.3 | 436.9 ± 20.3 | 418.02 ± 16.5 | 19.62 ± 0.2 | 19.12 ± 0.2 |

| K5-PLAST | 36.31 ± 4.4 | 27.86 ± 3.1 | 441.3 ± 21.0 | 430.60 ± 23.6 | 19.81 ± 0.3 | 19.16 ± 0.1 |

| K6-BIOCOV | 38.35 ± 2.6 | 36.16 ± 10.2 | 451.1 ± 26.7 | 430.65 ± 26.1 | 20.09 ± 0.2 | 19.25 ± 0.2 |

| Average (K) | 35.86 ± 3.39 | 32.18 ± 8.58 | 439.60 ± 22.83 | 423.68 ± 23.0 | 19.82 ± 0.34 | 19.43 ± 0.41 |

| Pile No | MWh m−3, Fresh | MWh m−3, after Storage | Difference, % |

|---|---|---|---|

| K1-PLAST | 2.27 ± 0.11 | 2.26 ± 0.08 | 0.71 |

| K2-BIOCOV | 2.24 ± 0.05 | 2.15 ± 0.07 | 4.04 |

| K3-NOCOV | 2.23 ± 0.14 | 2.09 ± 0.22 | 6.24 |

| K4-NOCOV | 2.23 ± 0.10 | 2.08 ± 0.11 | 6.68 |

| K5-PLAST | 2.26 ± 0.16 | 2.17 ± 0.14 | 4.38 |

| K6-BIOCOV | 2.33 ± 0.11 | 2.14 ± 0.20 | 7.96 |

| Average (K) | 2.26 ± 0.12 | 2.15 ± 0.15 | 5.01 |

| Pile No. | Dry Matter Loss During 5.9 Months of Storage, % | Dry Matter Loss per Month, % |

|---|---|---|

| K1-PLAST | 3.33 ± 2.6 | 0.57 ± 0.5 |

| K2-BIOCOV | 3.37 ± 3.1 | 0.57 ± 0.5 |

| K3-NOCOV | 4.62 ± 2.4 | 0.78 ± 0.4 |

| K4-NOCOV | 3.89 ± 2.7 | 0.66 ± 0.5 |

| K5-PLAST | 2.46 ± 1.3 | 0.42 ± 0.2 |

| K6-BIOCOV | 5.15 ± 5.1 | 0.87 ± 0.9 |

| Average (K) | 3.74 ± 3.2 | 0.63 ± 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prinz, R.; Routa, J.; Anerud, E.; Bergström, D.; Sikanen, L. Performance of an Innovative Bio-Based Wood Chip Storage Pile Cover—Can It Replace Plastic Tarps? Energies 2022, 15, 1680. https://doi.org/10.3390/en15051680

Prinz R, Routa J, Anerud E, Bergström D, Sikanen L. Performance of an Innovative Bio-Based Wood Chip Storage Pile Cover—Can It Replace Plastic Tarps? Energies. 2022; 15(5):1680. https://doi.org/10.3390/en15051680

Chicago/Turabian StylePrinz, Robert, Johanna Routa, Erik Anerud, Dan Bergström, and Lauri Sikanen. 2022. "Performance of an Innovative Bio-Based Wood Chip Storage Pile Cover—Can It Replace Plastic Tarps?" Energies 15, no. 5: 1680. https://doi.org/10.3390/en15051680

APA StylePrinz, R., Routa, J., Anerud, E., Bergström, D., & Sikanen, L. (2022). Performance of an Innovative Bio-Based Wood Chip Storage Pile Cover—Can It Replace Plastic Tarps? Energies, 15(5), 1680. https://doi.org/10.3390/en15051680