Performance Comparisons of Three-Phase/Four-Wire Model Predictive Control-Based DC/AC Inverters Capable of Asymmetric Operation for Wave Energy Converters

Abstract

1. Introduction

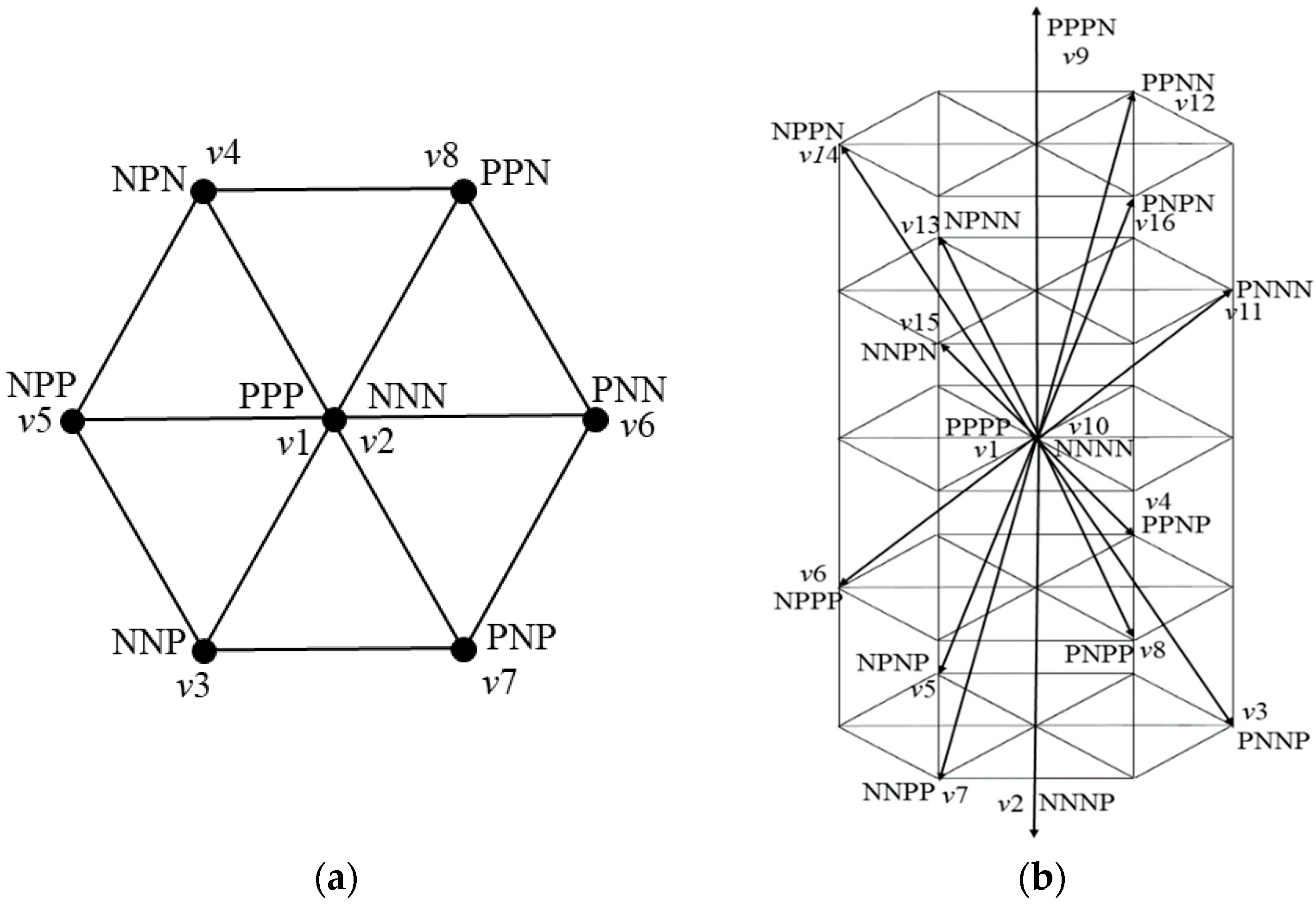

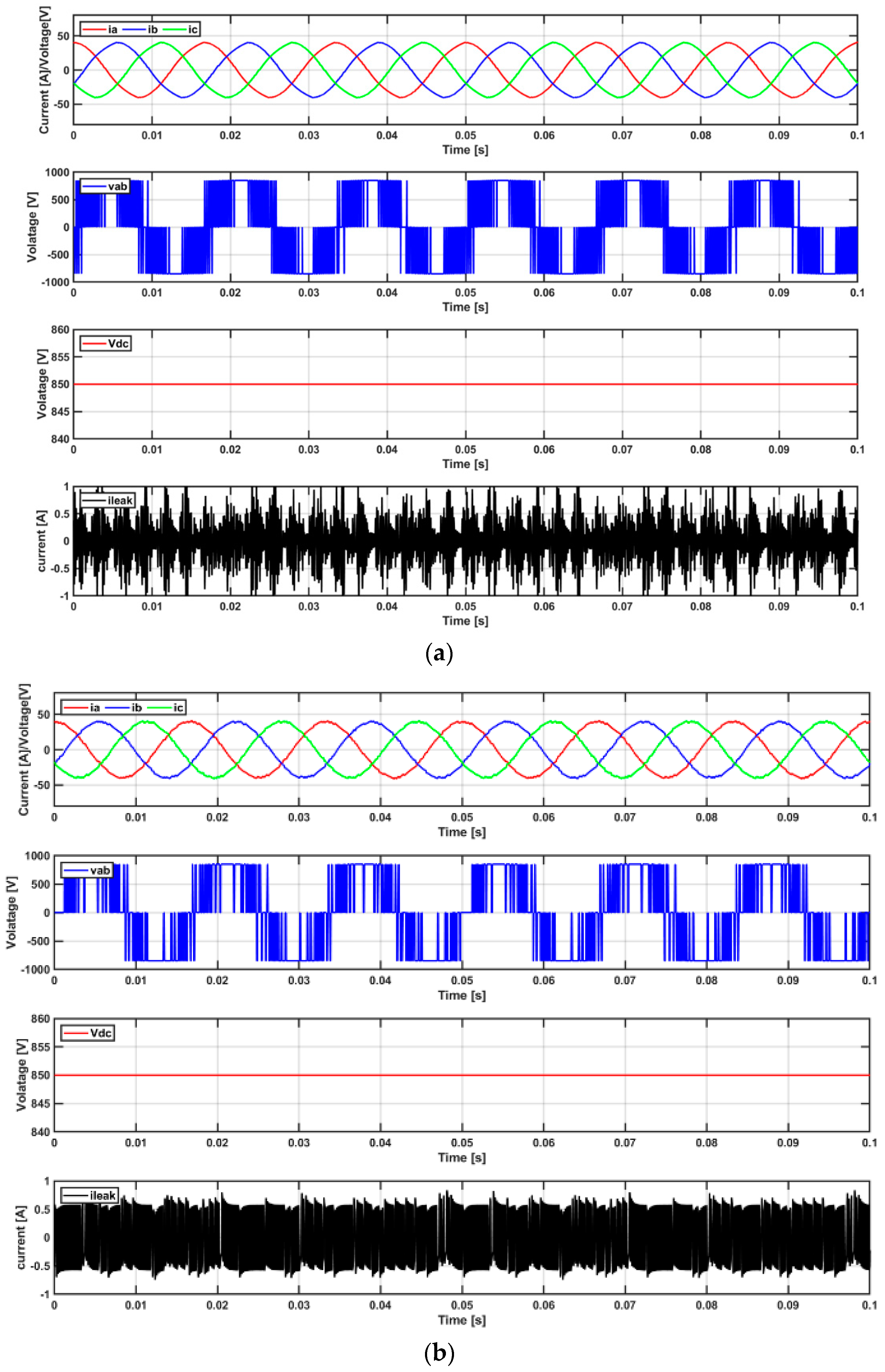

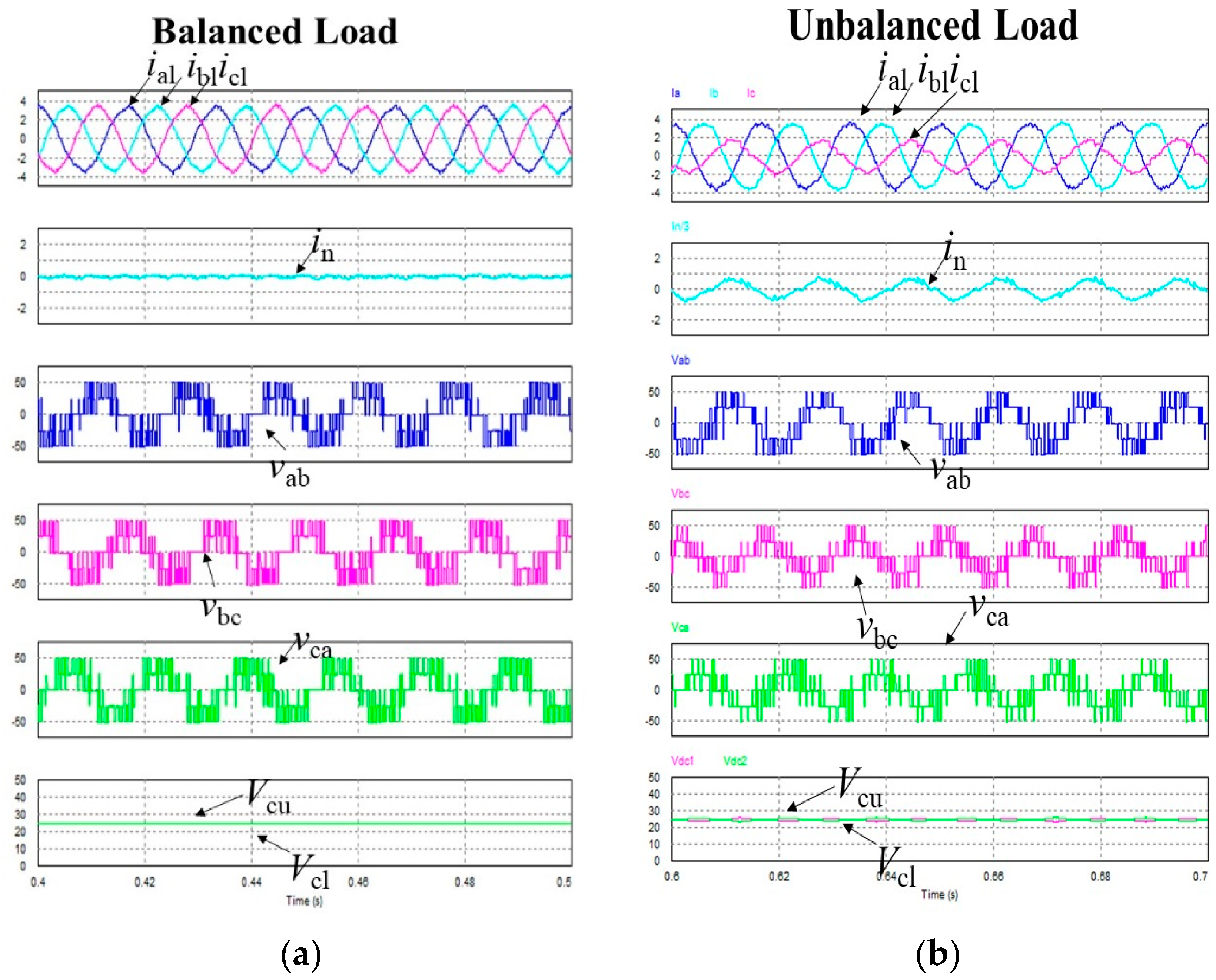

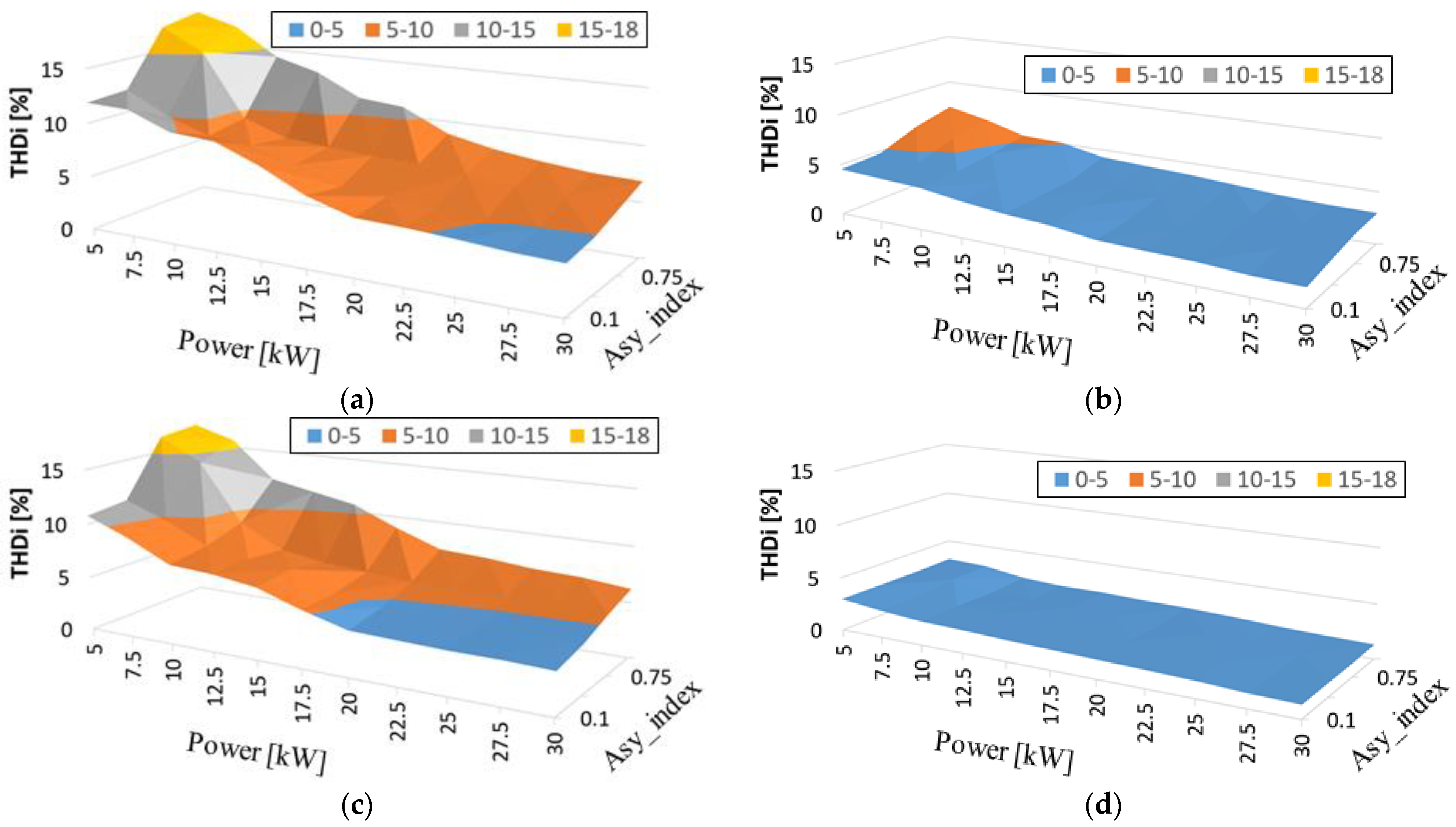

2. Finite-Control Set Model Predictive Control for Three-Phase Four-Wire Inverters

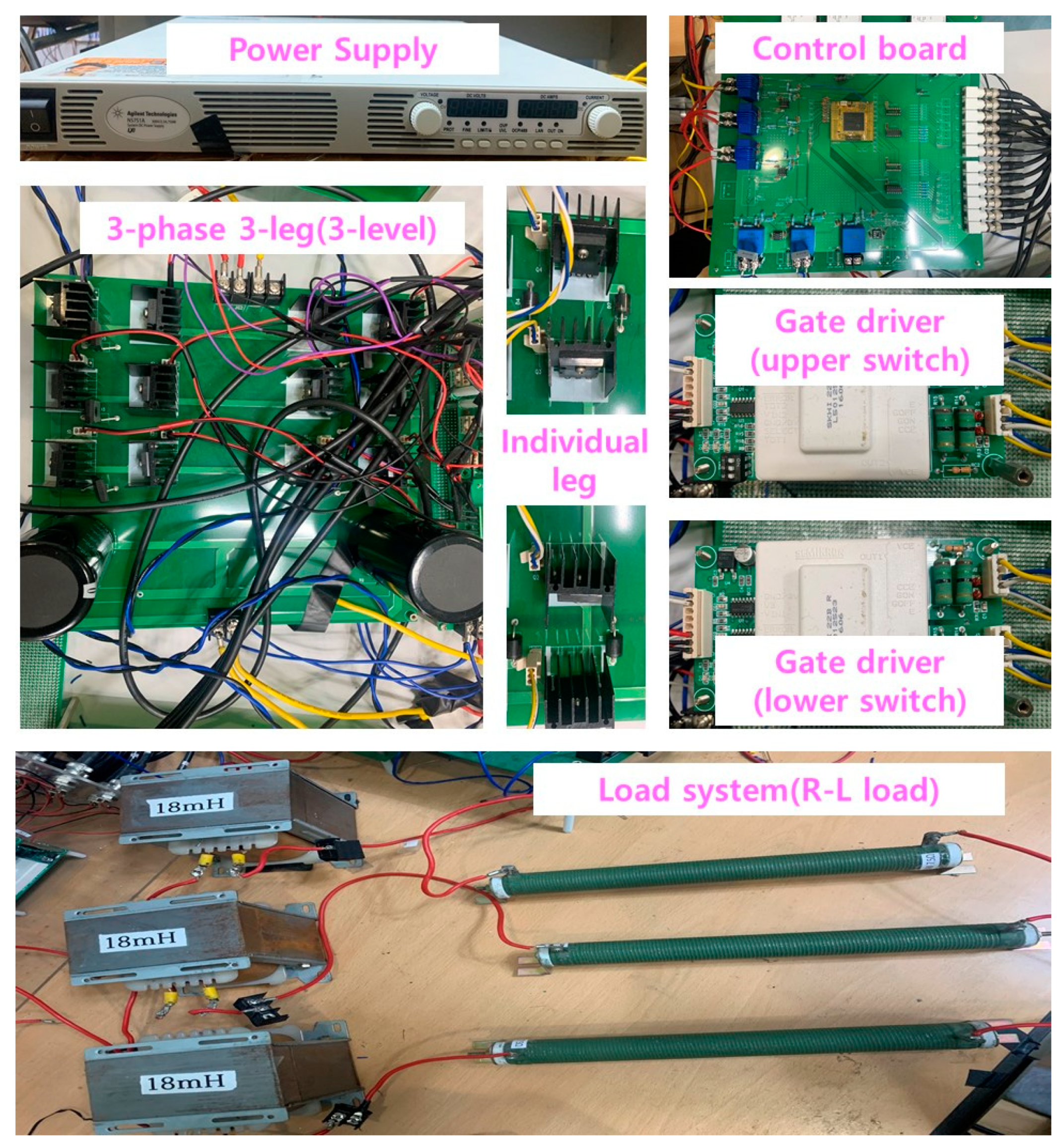

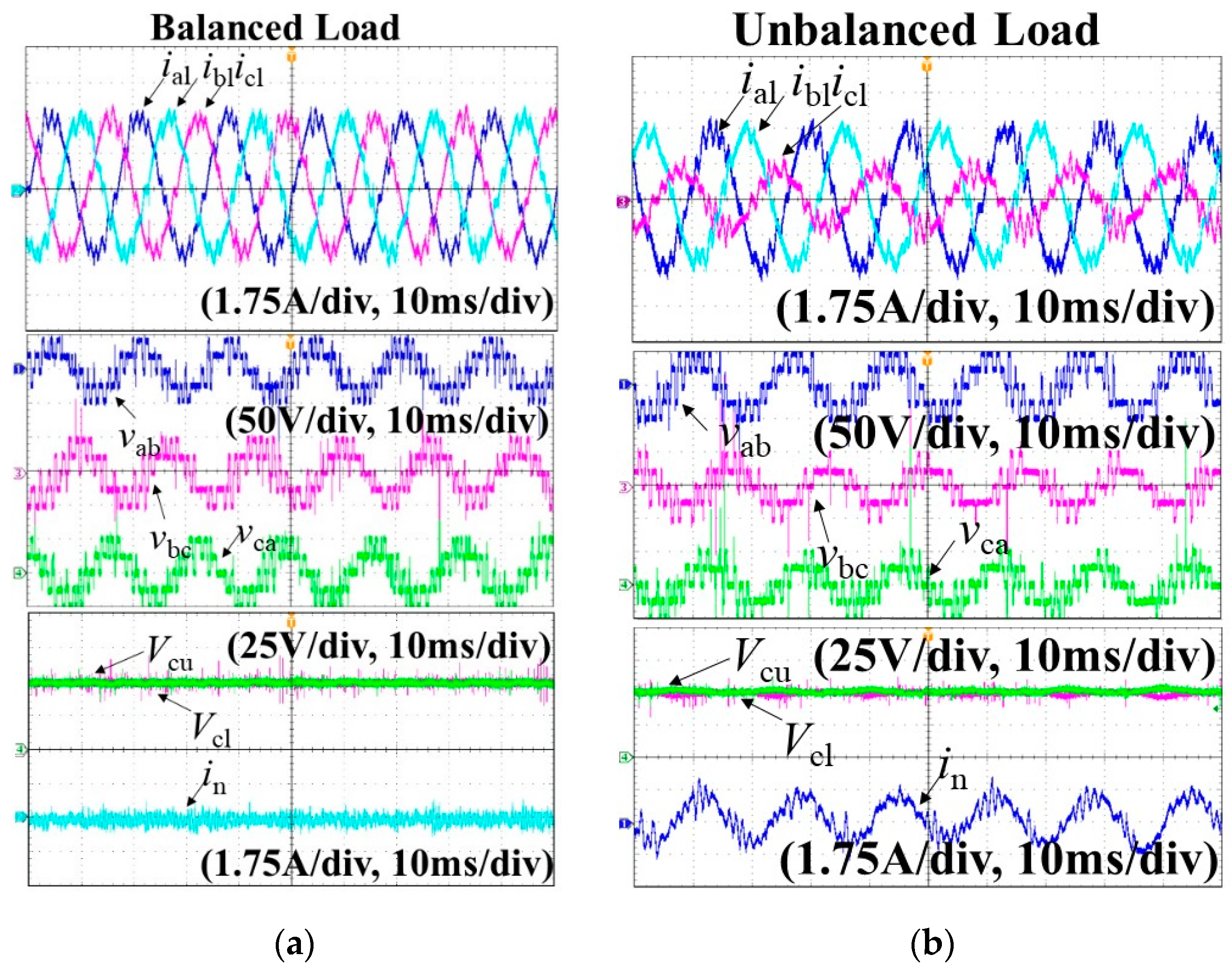

3. Simulation and Experimental Results

4. Conclusions

Funding

Conflicts of Interest

References

- Kouro, S.; Malinowski, M.; Gopakumar, K.; Pou, J.; Franquelo, L.G.; Wu, B.; Rodriguez, J.; Perez, M.A.; Leon, J.I. Recent Advances and Industrial Applications of Multilevel Converters. IEEE Trans. Ind. Electron. 2010, 57, 2553–2580. [Google Scholar] [CrossRef]

- Dijkhuizen, F. Multilevel converters: Review, form, function and motivation. In Proceedings of the EVER 2012, Monte-Carlo, Monaco, 10–13 October 2012. [Google Scholar]

- Chaturvedi, P.; Jain, S.; Agarwal, P. Carrier-Based Common Mode Voltage Control Techniques in Three-Level Diode-Clamped Inverter. Adv. Power Electron. 2012, 2012, 327157. [Google Scholar] [CrossRef]

- Videt, A.; Le Moigne, P.; Idir, N.; Baudesson, P.; Cimetiere, X. A New Carrier-Based PWM Providing Common-Mode-Current Reduction and DC-Bus Balancing for Three-Level Inverters. IEEE Trans. Ind. Electron. 2007, 54, 3001–3011. [Google Scholar] [CrossRef]

- Djeghloud, H.; Benalla, H. Space vector pulse width modulation applied to the three-level voltage inverter. IEEE Trans. Power Electron. 2004, 19, 732–738. [Google Scholar]

- Busquets-Monge, S.; Bordonau, J.; Boroyevich, D.; Somavilla, S. The nearest three virtual space vector PWM—A modulation for the comprehensive neutral-point balancing in the three-level NPC inverter. IEEE Power Electron. Lett. 2004, 2, 11–15. [Google Scholar] [CrossRef]

- Mohapatra, S.R.; Agarwal, V. Model Predictive Controller with Reduced Complexity for Grid-Tied Multilevel Inverters. IEEE Trans. Ind. Electron. 2018, 66, 8851–8855. [Google Scholar] [CrossRef]

- Yaramasu, V.; Rivera, M.; Wu, B.; Rodriguez, J. Model predictive current control of two-level four-leg inverters—Part I: Concept, algorithm, and simulation analysis. IEEE Trans. Power Electron. 2012, 28, 3459–3468. [Google Scholar] [CrossRef]

- Kim, S.-E.; Park, S.-Y.; Kwak, S. Simplified Model Predictive Control Method for Three-Phase Four-Leg Voltage Source Inverters. J. Power Electron. 2016, 16, 2231–2242. [Google Scholar] [CrossRef][Green Version]

- Chan, R.; Kim, K.-H.; Park, J.-Y.; Kwak, S.-S. Simplified Model Predictive Control with preselection Technique for Reduction of Calculation Burden in 3-Level 4-Leg NPC Inverter. In Proceedings of the 2020 IEEE Applied Power Electronics Conference and Exposition (APEC), New Orleans, LA, USA, 15–19 March 2020; pp. 2291–2296. [Google Scholar] [CrossRef]

- Roh, C.; Kwak, S.; Choi, S. Three-phase three-level four-leg NPC converters with advanced model predictive control. J. Power Electron. 2021, 21, 1574–1584. [Google Scholar] [CrossRef]

- Mohapatra, S.R.; Agarwal, V. An Improved Reduced Complexity Model Predictive Current Controller for Grid-Connected Four-Leg Multilevel Inverter. IEEE Trans. Ind. Appl. 2019, 56, 498–506. [Google Scholar] [CrossRef]

- Falcão, A.F.; Cândido, J.J.; Justino, P.A.; Henriques, J.C. Hydrodynamics of the IPS buoy wave energy converter including the effect of non-uniform acceleration tube cross section. Renew. Energy 2012, 41, 105–114. [Google Scholar] [CrossRef]

- Babarit, A.; Clément, A. Optimal latching control of a wave energy device in regular and irregular waves. Appl. Ocean Res. 2006, 28, 77–91. [Google Scholar] [CrossRef]

- António, F.D.O. Modelling and control of oscillating-body wave energy converters with hydraulic power take-off and gas accumulator. Ocean. Eng. 2007, 34, 2021–2032. [Google Scholar]

- Cho, B.-H.; Yang, D.-S.; Park, S.-Y.; Choi, K.-S.; Lee, D.-H.; Byun, S.-H.; Jung, H. Modeling and control of a 75kW class variable liquid-column oscillator for highly efficient wave energy converter. Ocean Eng. 2011, 38, 436–443. [Google Scholar] [CrossRef]

- Luan, H.; Onar, O.C.; Khaligh, A. Dynamic Modeling and Optimum Load Control of a PM Linear Generator for Ocean Wave Energy Harvesting Application. In Proceedings of the 2009 Twenty-Fourth Annual IEEE Applied Power Electronics Conference and Exposition, Washington, DC, USA, 15–19 February 2009; pp. 739–743. [Google Scholar] [CrossRef]

- Wang, L.; Lee, D.-J.; Lee, W.-J.; Chen, Z. Analysis of a novel autonomous marine hybrid power generation/energy storage system with a high-voltage direct current link. J. Power Sources 2008, 185, 1284–1292. [Google Scholar] [CrossRef]

- Aubry, J.; Ben Ahmed, H.; Multon, B. Sizing Optimization Methodology of a Surface Permanent Magnet Machine-Converter System over a Torque-Speed Operating Profile: Application to a Wave Energy Converter. IEEE Trans. Ind. Electron. 2011, 59, 2116–2125. [Google Scholar] [CrossRef]

- Alberdi, M.; Amundarain, M.; Garrido, A.; Garrido, I. Neural control for voltage dips ride-through of oscillating water column-based wave energy converter equipped with doubly-fed induction generator. Renew. Energy 2012, 48, 16–26. [Google Scholar] [CrossRef]

- Park, J.S.; Hyon, B.J.; Yun, J.; Lee, J.; Choi, J.-Y.; Choi, J.-S.; Hong, K. Vector Control for Wave Power Generation System using Permanent Magnet Linear Synchronous Generator. J. Korean Soc. Mar. Environ. Energy 2016, 19, 120–128. [Google Scholar] [CrossRef]

- Blanco, M.; Ramirez, D.; Zarei, M.E.; Gupta, M. Dual multivector model predictive control for the power converters of a floating OWC WEC. Int. J. Electr. Power Energy Syst. 2021, 133, 107263. [Google Scholar] [CrossRef]

- Cortes, P.; Rodriguez, J.; Silva, C.; Flores, A. Delay Compensation in Model Predictive Current Control of a Three-Phase Inverter. IEEE Trans. Ind. Electron. 2011, 59, 1323–1325. [Google Scholar] [CrossRef]

| Voltage Vectors | Switching State | Voltage | Voltage Vectors | Switching State | Voltage | ||||

|---|---|---|---|---|---|---|---|---|---|

| va | vb | vc | va | vb | vc | ||||

| v1 | PPP | 1 | 1 | 1 | v5 | NPP | 0 | 1 | 1 |

| v2 | NNN | 0 | 0 | 0 | v6 | PNN | 1 | 0 | 0 |

| v3 | NNP | 0 | 0 | 1 | v7 | PNP | 1 | 0 | 1 |

| v4 | NPN | 0 | 1 | 0 | v8 | PPN | 1 | 1 | 0 |

| Voltage Vectors | Switching State | Voltage | Voltage Vectors | Switching State | Voltage | ||||

|---|---|---|---|---|---|---|---|---|---|

| va | vb | vc | va | vb | vc | ||||

| v1 | PPPP | 0 | 0 | 0 | v9 | PPPN | 1 | 1 | 1 |

| v2 | NNNP | −1 | −1 | −1 | v10 | NNNN | 0 | 0 | 0 |

| v3 | PNNP | 0 | −1 | −1 | v11 | PNNN | 1 | 0 | 0 |

| v4 | PPNP | 0 | 0 | −1 | v12 | PPNN | 1 | 1 | 0 |

| v5 | NPNP | −1 | 0 | −1 | v13 | NPNN | 0 | 1 | 0 |

| v6 | NPPP | −1 | 0 | 0 | v14 | NPPN | 0 | 1 | 1 |

| v7 | NNPP | −1 | −1 | 0 | v15 | NNPN | 0 | 0 | 1 |

| v8 | PNPP | 0 | −1 | 0 | v16 | PNPN | 1 | 0 | 1 |

| Voltage Vectors | Switching State | Voltage | Voltage Vectors | Switching State | Voltage | ||||

|---|---|---|---|---|---|---|---|---|---|

| va | vb | vc | va | vb | vc | ||||

| v1 | PPP | 0.5 | 0.5 | 0.5 | v15 | ONO | 0 | −0.5 | 0 |

| v2 | NNN | −0.5 | −0.5 | −0.5 | v16 | PON | 0.5 | 0 | −0.5 |

| v3 | OOO | 0 | 0 | 0 | v17 | OPN | 0 | 0.5 | −0.5 |

| v4 | POO | 0.5 | 0 | 0 | v18 | NPO | −0.5 | 0.5 | 0 |

| v5 | ONN | 0 | −0.5 | −0.5 | v19 | NOP | −0.5 | 0 | 0.5 |

| v6 | PPO | 0.5 | 0.5 | 0 | v20 | ONP | 0 | −0.5 | 0.5 |

| v7 | OON | 0 | 0 | −0.5 | v21 | PNO | 0.5 | −0.5 | 0 |

| v8 | OPO | 0 | 0.5 | 0 | v22 | PNN | 0.5 | −0.5 | −0.5 |

| v9 | NON | −0.5 | 0 | −0.5 | v23 | PPN | 0.5 | 0.5 | −0.5 |

| v10 | OPP | 0 | 0.5 | 0.5 | v24 | NPN | −0.5 | 0.5 | −0.5 |

| v11 | NOO | −0.5 | 0 | 0 | v25 | NPP | −0.5 | 0.5 | 0.5 |

| v12 | OOP | 0 | 0 | 0.5 | v26 | NNP | −0.5 | −0.5 | 0.5 |

| v13 | NNO | −0.5 | −0.5 | 0 | v27 | PNP | 0.5 | −0.5 | 0.5 |

| v14 | POP | 0.5 | 0 | 0.5 | |||||

| Voltage Vectors | Switching State | Output Phase Voltage | Voltage Vectors | Switching State | Output Phase Voltage | ||||

|---|---|---|---|---|---|---|---|---|---|

| van | vbn | vcn | van | vbn | vcn | ||||

| v1 | NNNN | 0 | 0 | 0 | v42 | OOOP | −0.5 | −0.5 | −0.5 |

| v2 | NNNO | −0.5 | −0.5 | −0.5 | v43 | OOPN | 0.5 | 0.5 | 1 |

| v3 | NNNP | −1 | −1 | −1 | v44 | OOPO | 0 | 0 | 0.5 |

| v4 | NNON | 0 | 0 | 0.5 | v45 | OOPP | −0.5 | −0.5 | 0 |

| v5 | NNOO | −0.5 | −0.5 | 0 | v46 | OPNN | 0.5 | 1 | 0 |

| v6 | NNOP | −1 | −1 | −0.5 | v47 | OPNO | 0 | 0.5 | −0.5 |

| v7 | NNPN | 0 | 0 | 1 | v48 | OPNP | −0.5 | 0 | −1 |

| v8 | NNPO | −0.5 | −0.5 | 0.5 | v49 | OPON | 0.5 | 1 | 0.5 |

| v9 | NNPP | −1 | −1 | 0 | v50 | OPOO | 0 | 0.5 | 0 |

| v10 | NONN | 0 | 0.5 | 0 | v51 | OPOP | −0.5 | 0 | −0.5 |

| v11 | NONO | −0.5 | 0 | −0.5 | v52 | OPPN | 0.5 | 1 | 1 |

| v12 | NONP | −1 | −0.5 | −1 | v53 | OPPO | 0 | 0.5 | 0.5 |

| v13 | NOON | 0 | 0.5 | 0.5 | v54 | OPPP | −0.5 | 0 | 0 |

| v14 | NOOO | −0.5 | 0 | 0 | v55 | PNNN | 1 | 0 | 0 |

| v15 | NOOP | −1 | −0.5 | −0.5 | v56 | PNNO | 0.5 | −0.5 | −0.5 |

| v16 | NOPN | 0 | 0.5 | 1 | v57 | PNNP | 0 | −1 | −1 |

| v17 | NOPO | −0.5 | 0 | 0.5 | v58 | PNON | 1 | 0 | 0.5 |

| v18 | NOPP | −1 | −0.5 | 0 | v59 | PNOO | 0.5 | −0.5 | 0 |

| v19 | NPNN | 0 | 1 | 0 | v60 | PNOP | 0 | −1 | −0.5 |

| v20 | NPNO | −0.5 | 0.5 | −0.5 | v61 | PNPN | 1 | 0 | 1 |

| v21 | NPNP | −1 | 0 | −1 | v62 | PNPO | 0.5 | −0.5 | 0.5 |

| v22 | NPON | 0 | 1 | 0.5 | v63 | PNPP | 0 | −1 | 0 |

| v23 | NPOO | −0.5 | 0.5 | 0 | v64 | PONN | 1 | 0.5 | 0 |

| v24 | NPOP | −1 | 0 | −0.5 | v65 | PONO | 0.5 | 0 | −0.5 |

| v25 | NPPN | 0 | 1 | 1 | v66 | PONP | 0 | −0.5 | −1 |

| v26 | NPPO | −0.5 | 0.5 | 0.5 | v67 | POON | 1 | 0.5 | 0.5 |

| v27 | NPPP | −1 | 0 | 0 | v68 | POOO | 0.5 | 0 | 0 |

| v28 | ONNN | 0.5 | 0 | 0 | v69 | POOP | 0 | −0.5 | −0.5 |

| v29 | ONNO | 0 | −0.5 | −0.5 | v70 | POPN | 1 | 0.5 | 1 |

| v30 | ONNP | −0.5 | −1 | −1 | v71 | POPO | 0.5 | 0 | 0.5 |

| v31 | ONON | 0.5 | 0 | 0.5 | v72 | POPP | 0 | −0.5 | 0 |

| v32 | ONOO | 0 | −0.5 | 0 | v73 | PPNN | 1 | 1 | 0 |

| v33 | ONOP | −0.5 | −1 | −0.5 | v74 | PPNO | 0.5 | 0.5 | −0.5 |

| v34 | ONPN | 0.5 | 0 | 1 | v75 | PPNP | 0 | 0 | −1 |

| v35 | ONPO | 0 | −0.5 | 0.5 | v76 | PPON | 1 | 1 | 0.5 |

| v36 | ONPP | −0.5 | −1 | 0 | v77 | PPOO | 0.5 | 0.5 | 0 |

| v37 | OONN | 0.5 | 0.5 | 0 | v78 | PPOP | 0 | 0 | −0.5 |

| v38 | OONO | 0 | 0 | −0.5 | v79 | PPPN | 1 | 1 | 1 |

| v39 | OONP | −0.5 | −0.5 | −1 | v80 | PPPO | 0.5 | 0.5 | 0.5 |

| v40 | OOON | 0.5 | 0.5 | 0.5 | v81 | PPPP | 0 | 0 | 0 |

| v41 | OOOO | 0 | 0 | 0 | |||||

| Parameters | Values |

|---|---|

| RLoad (Load resistance) | 7.5 Ω |

| LLoad (Load inductance) | 24.2 mH |

| Cdc (DC capacitance) | 4400 µF |

| Vdc (DC voltage) | 850 V |

| Tsp (sampling period) | 50 µs |

| Parameters | Values |

|---|---|

| RLoad (Load restistance) | 3 Ω |

| LLoad (Load inductance) | 18 mH |

| Cdc (DC capacitance) | 2200 µF |

| Vdc (DC voltage) | 50 V |

| Tsp (sampling period) | 200 µs |

| Abbreviation | Meaning | Units |

|---|---|---|

| DC input voltage | V | |

| DC capacitance | µF | |

| Upper capacitor voltage | V | |

| Lower capacitor voltage | V | |

| Load resistor | Ω | |

| Load inductor | mH | |

| Load voltage (x = a, b, c) | V | |

| Load current (x = a, b, c) | A | |

| Reference load current (x = a, b, c) | A | |

| Cost function of current control | A | |

| Upper capacitor current | A | |

| Lower capacitor current | A | |

| Total cost function | A | |

| Weighting factor | A/V | |

| Total harmonic distortion | % | |

| Leakage current | A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roh, C. Performance Comparisons of Three-Phase/Four-Wire Model Predictive Control-Based DC/AC Inverters Capable of Asymmetric Operation for Wave Energy Converters. Energies 2022, 15, 2839. https://doi.org/10.3390/en15082839

Roh C. Performance Comparisons of Three-Phase/Four-Wire Model Predictive Control-Based DC/AC Inverters Capable of Asymmetric Operation for Wave Energy Converters. Energies. 2022; 15(8):2839. https://doi.org/10.3390/en15082839

Chicago/Turabian StyleRoh, Chan. 2022. "Performance Comparisons of Three-Phase/Four-Wire Model Predictive Control-Based DC/AC Inverters Capable of Asymmetric Operation for Wave Energy Converters" Energies 15, no. 8: 2839. https://doi.org/10.3390/en15082839

APA StyleRoh, C. (2022). Performance Comparisons of Three-Phase/Four-Wire Model Predictive Control-Based DC/AC Inverters Capable of Asymmetric Operation for Wave Energy Converters. Energies, 15(8), 2839. https://doi.org/10.3390/en15082839