Simulation and Modeling of Ported Shroud Effects on Radial Compressor Stage Stability Limits

Abstract

1. Introduction

2. Materials and Methods

2.1. Reference Centrifugal Compressor with Ported Shroud Geometry

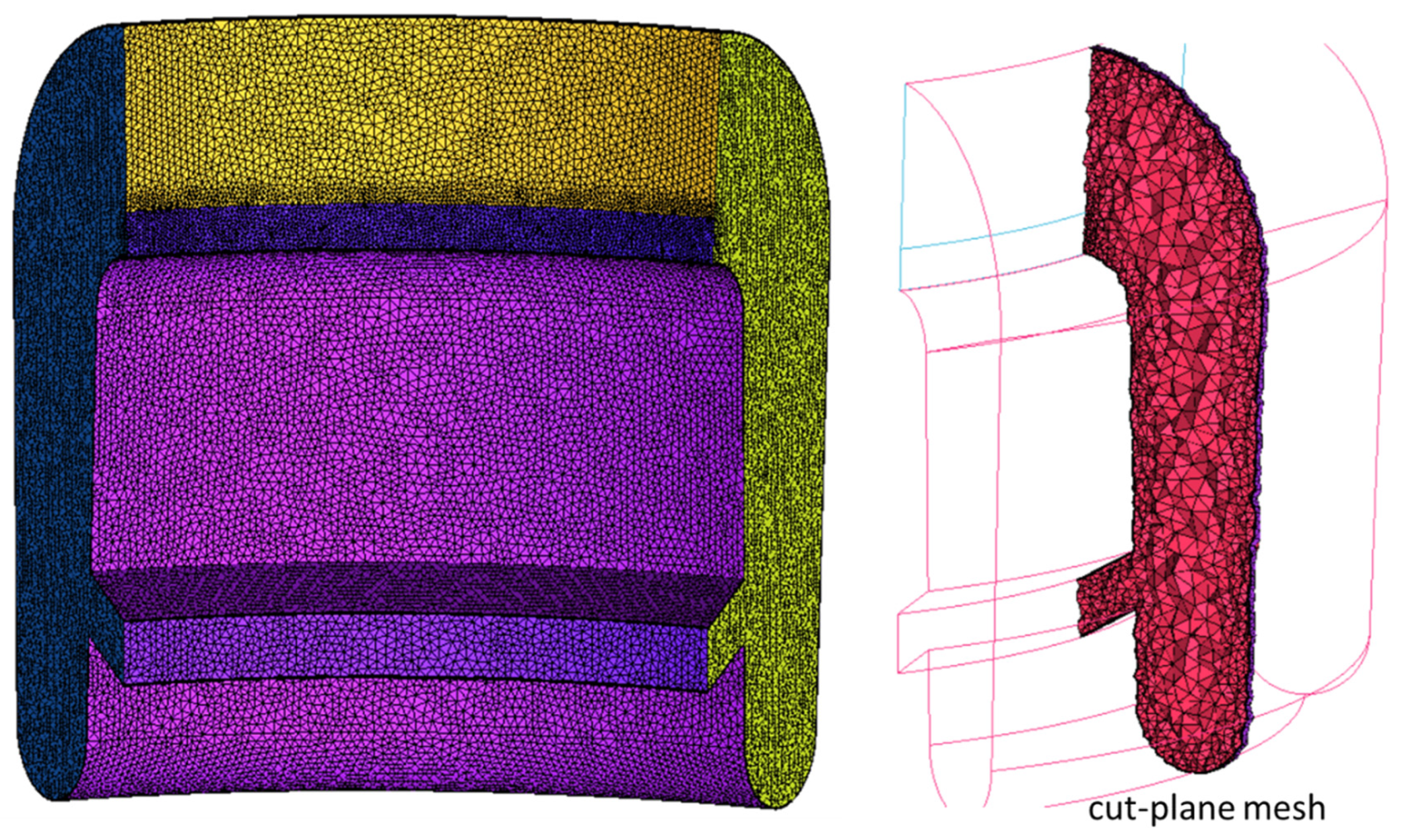

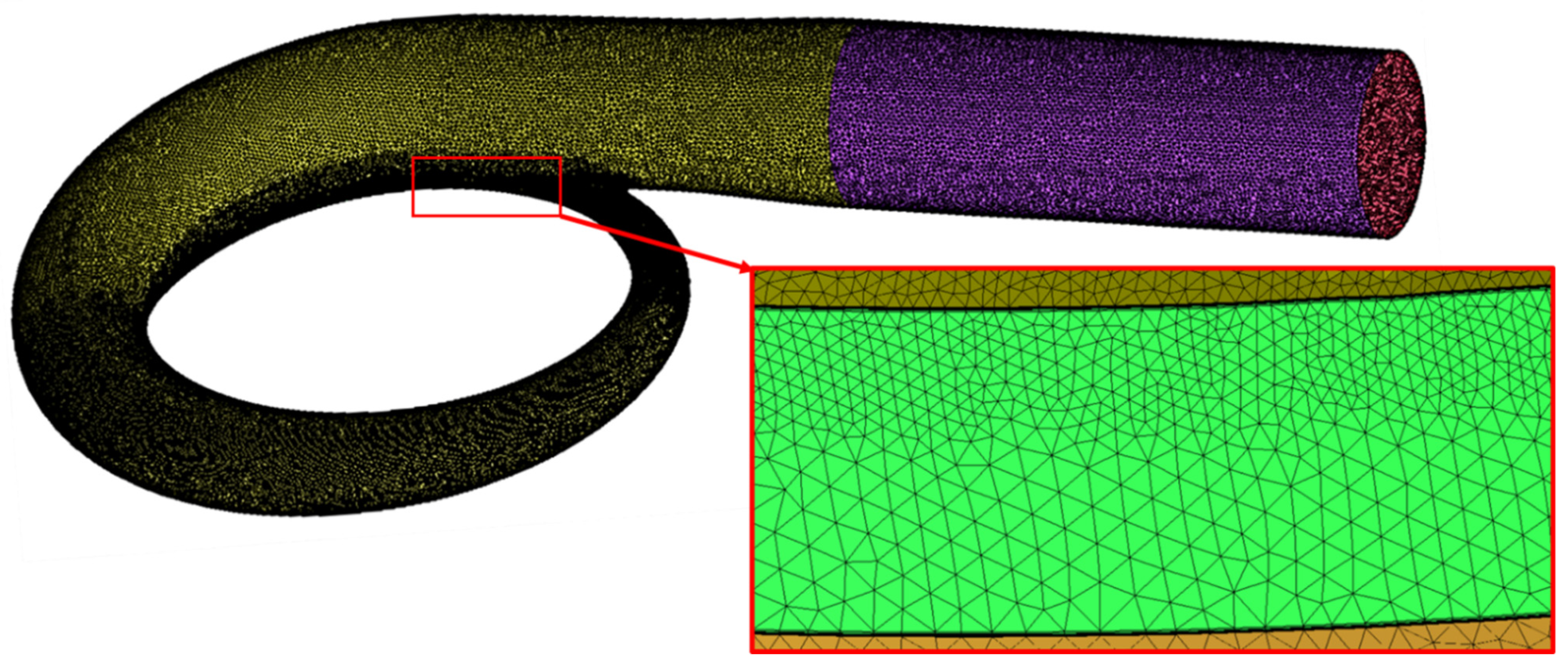

2.2. CFD Model

2.2.1. Simple + Volute Model

2.2.2. Fully 3D Unsteady Model

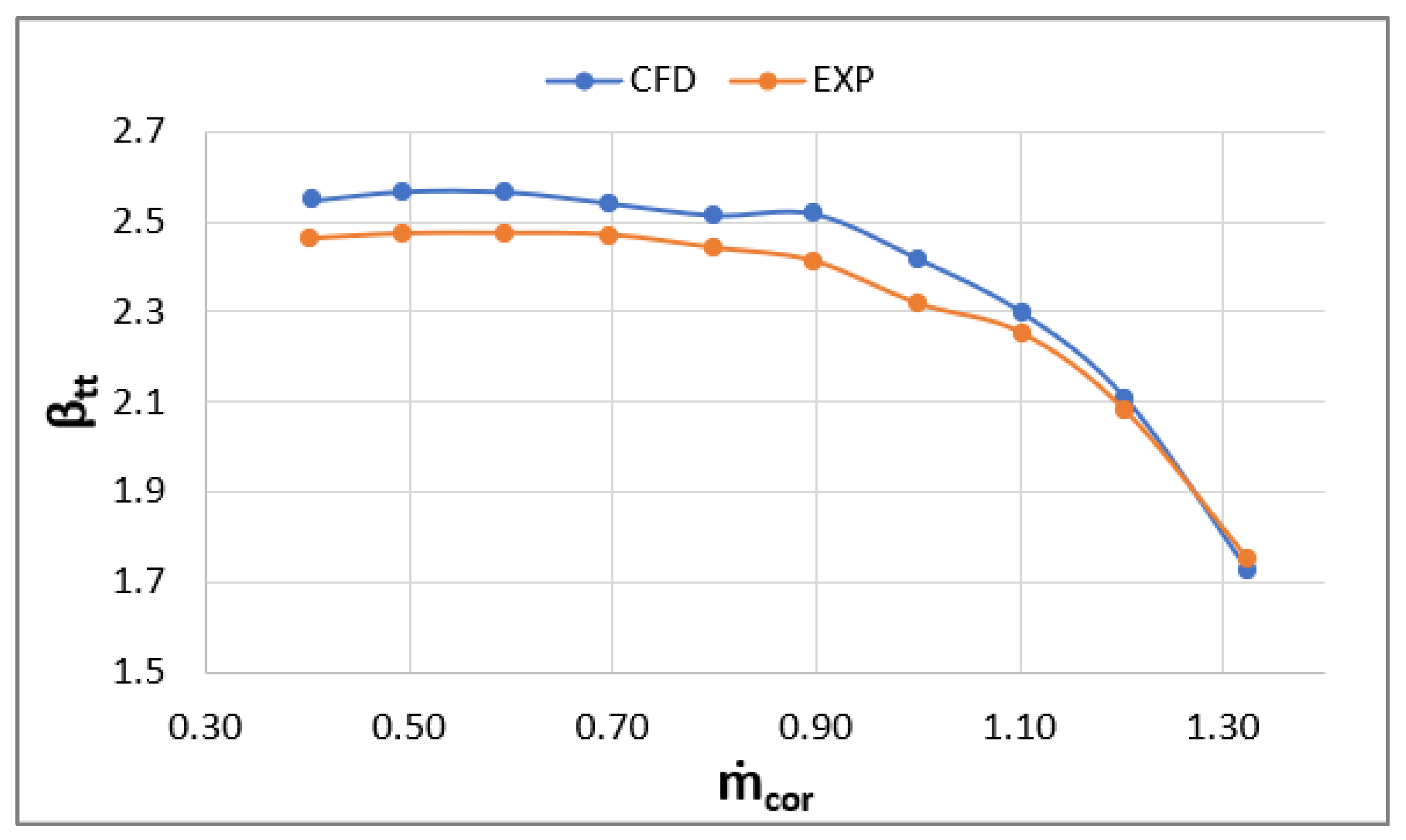

2.3. Validation

3. Results

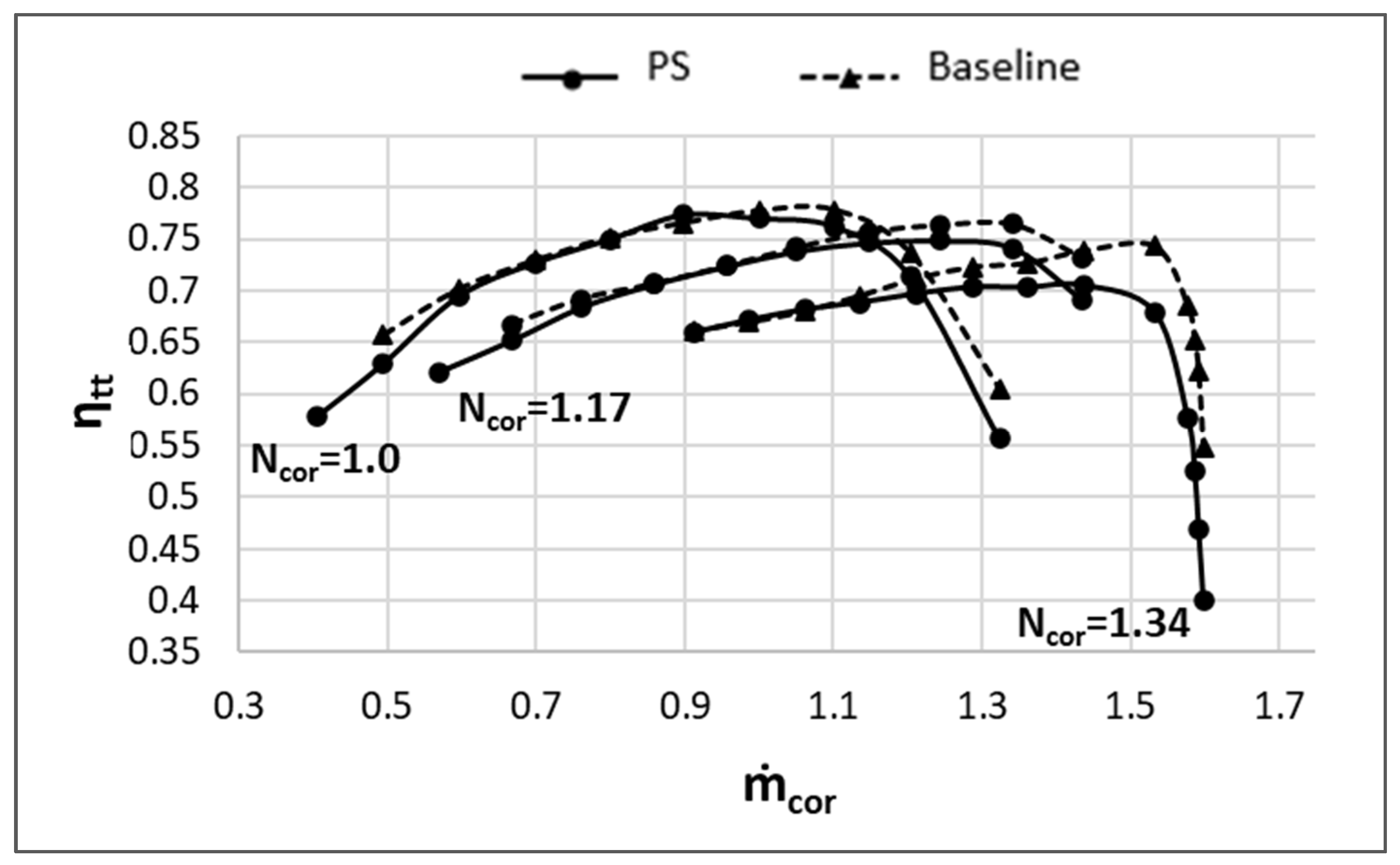

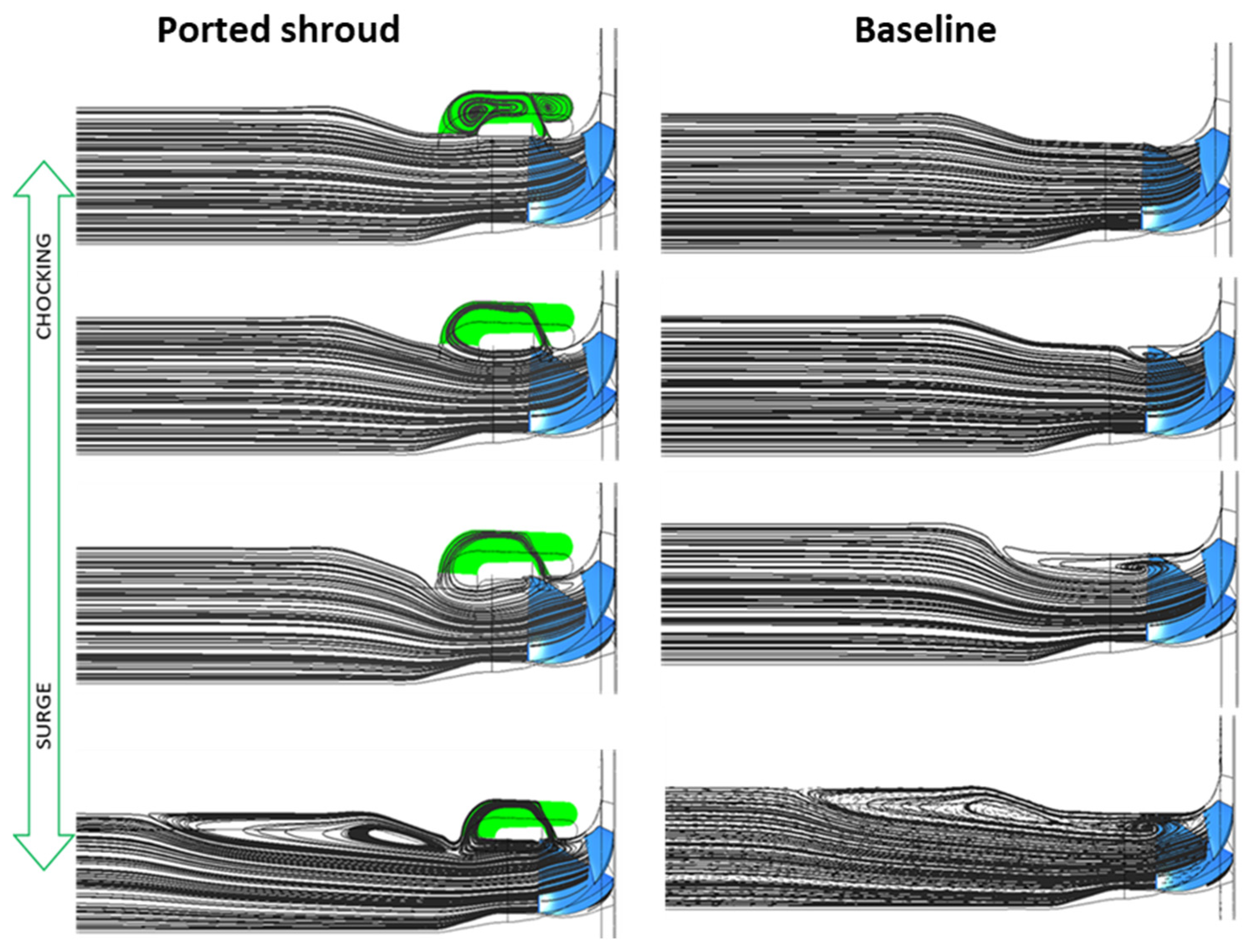

3.1. Performance Comparison between the Compressor with Ported Shroud and Baseline

3.2. Flow Dynamic Analysis

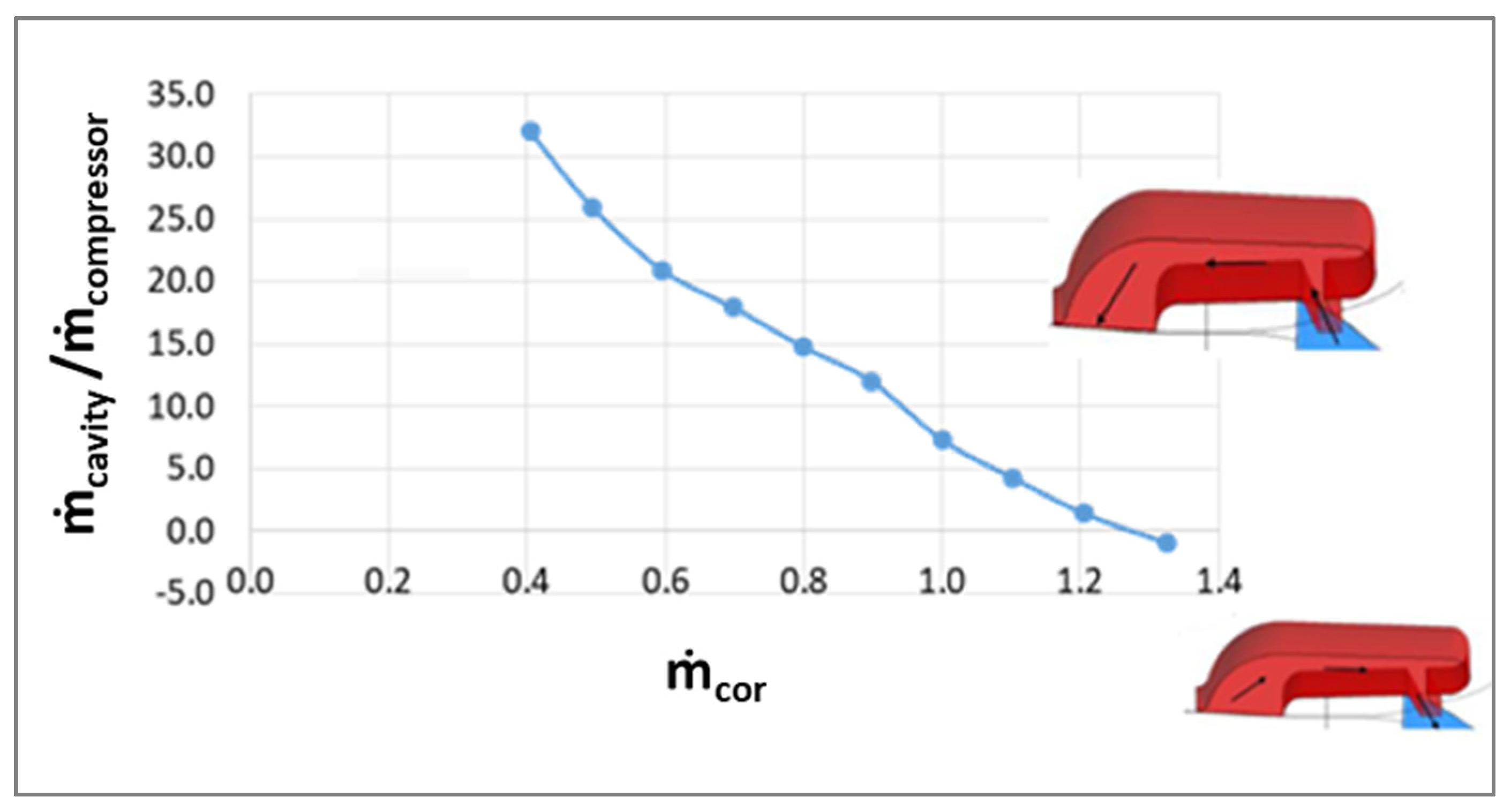

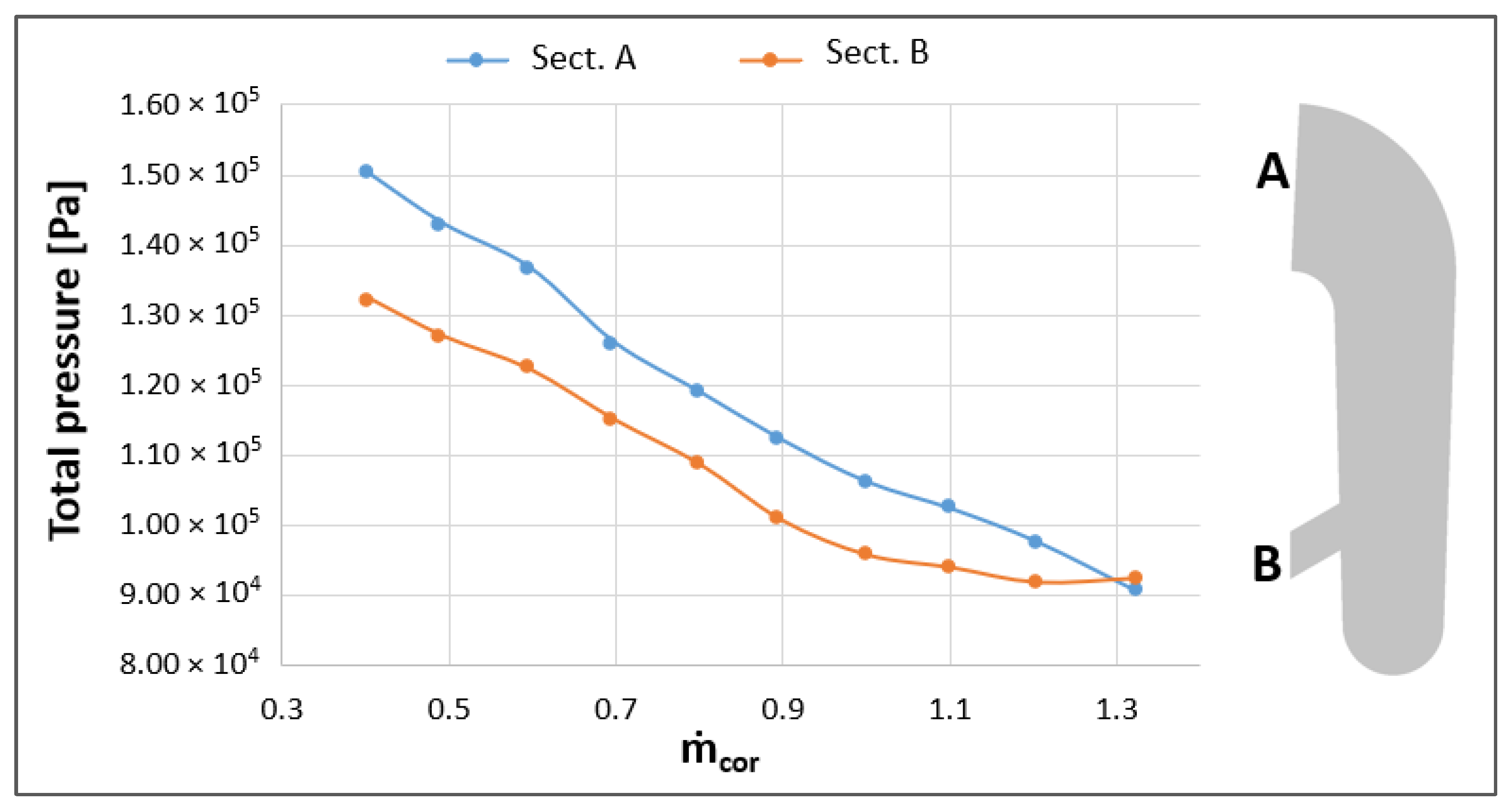

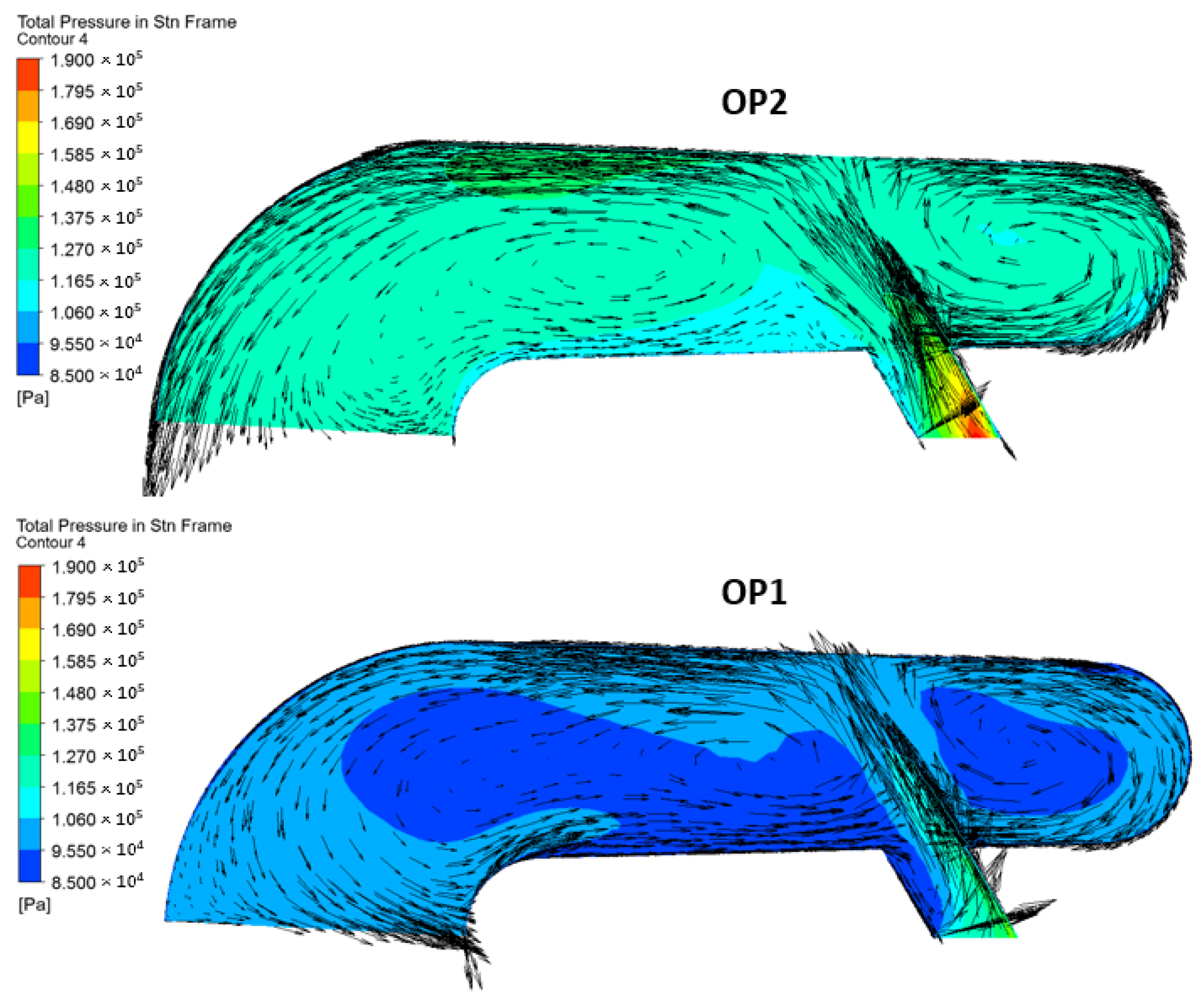

3.2.1. The Cavity

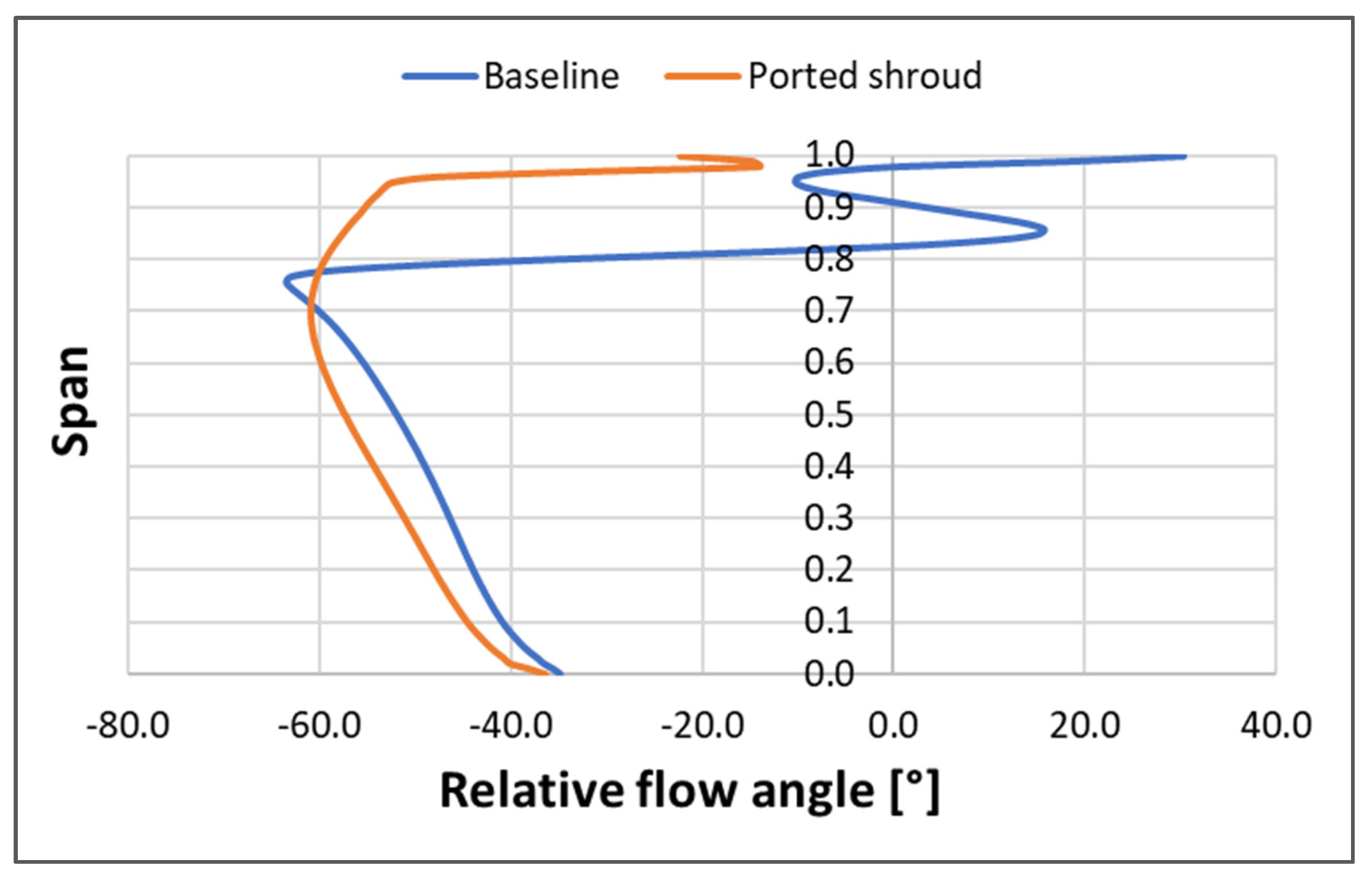

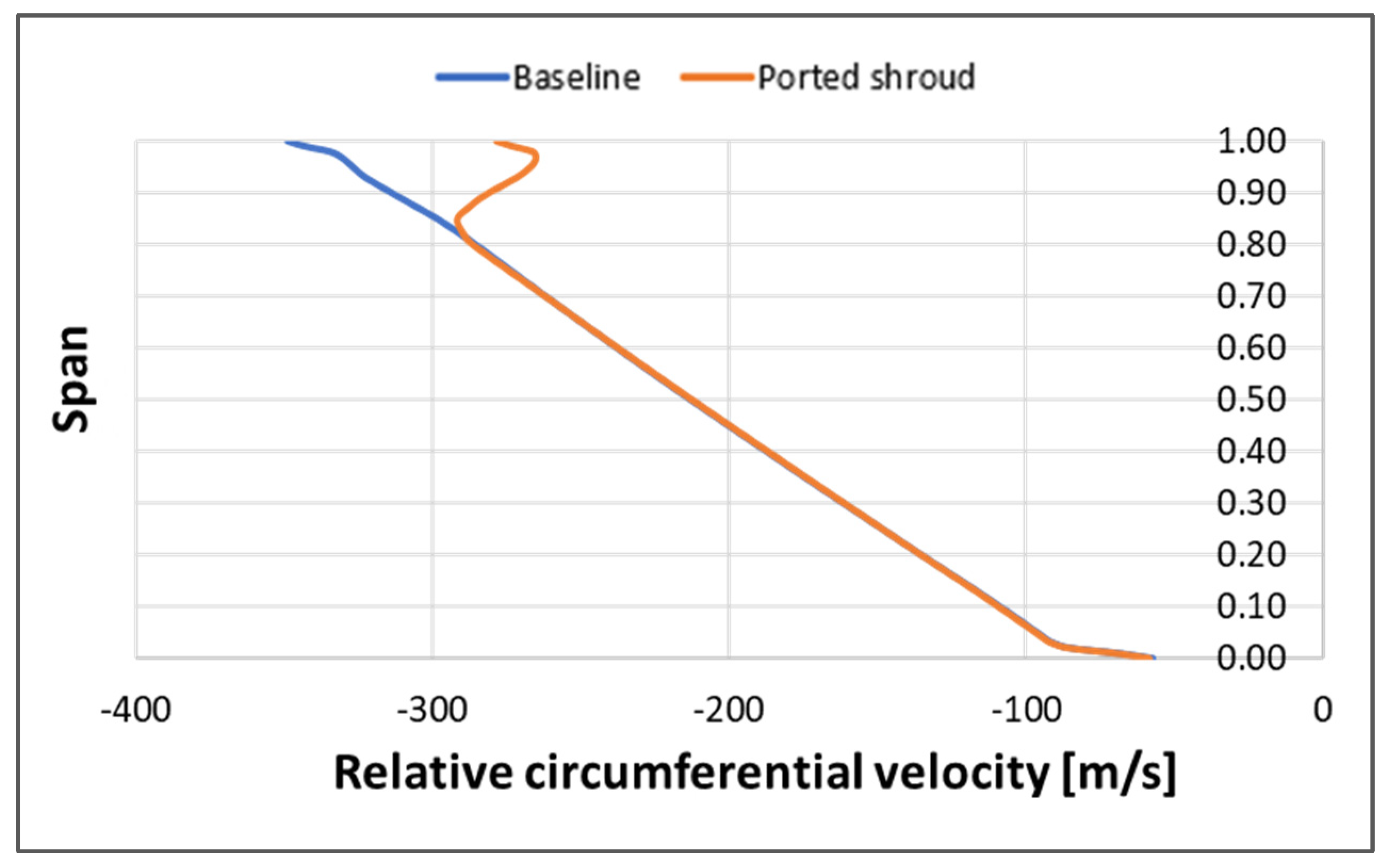

3.2.2. Flow Analysis at the Impeller Leading Edge

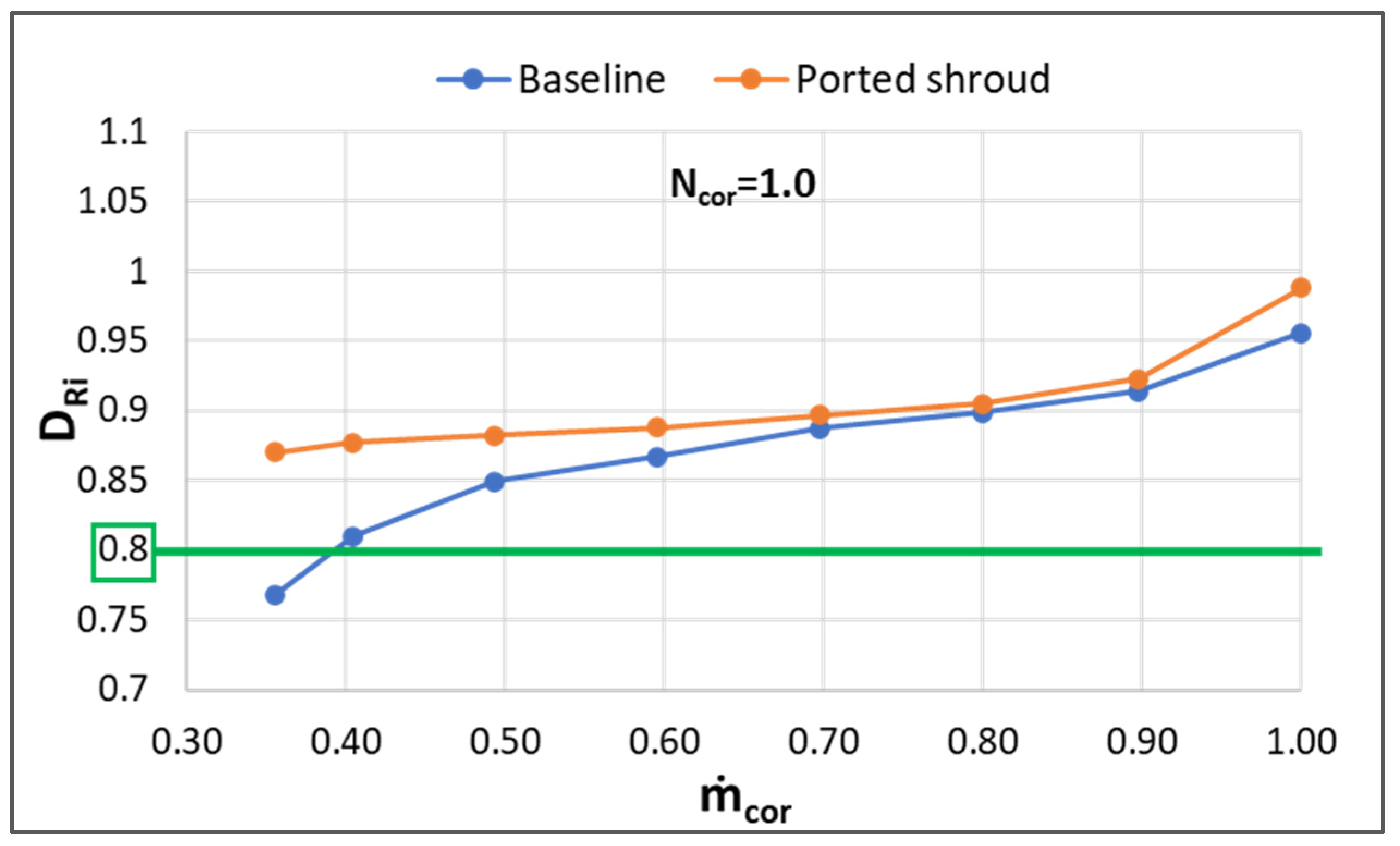

3.3. Stability Criteria

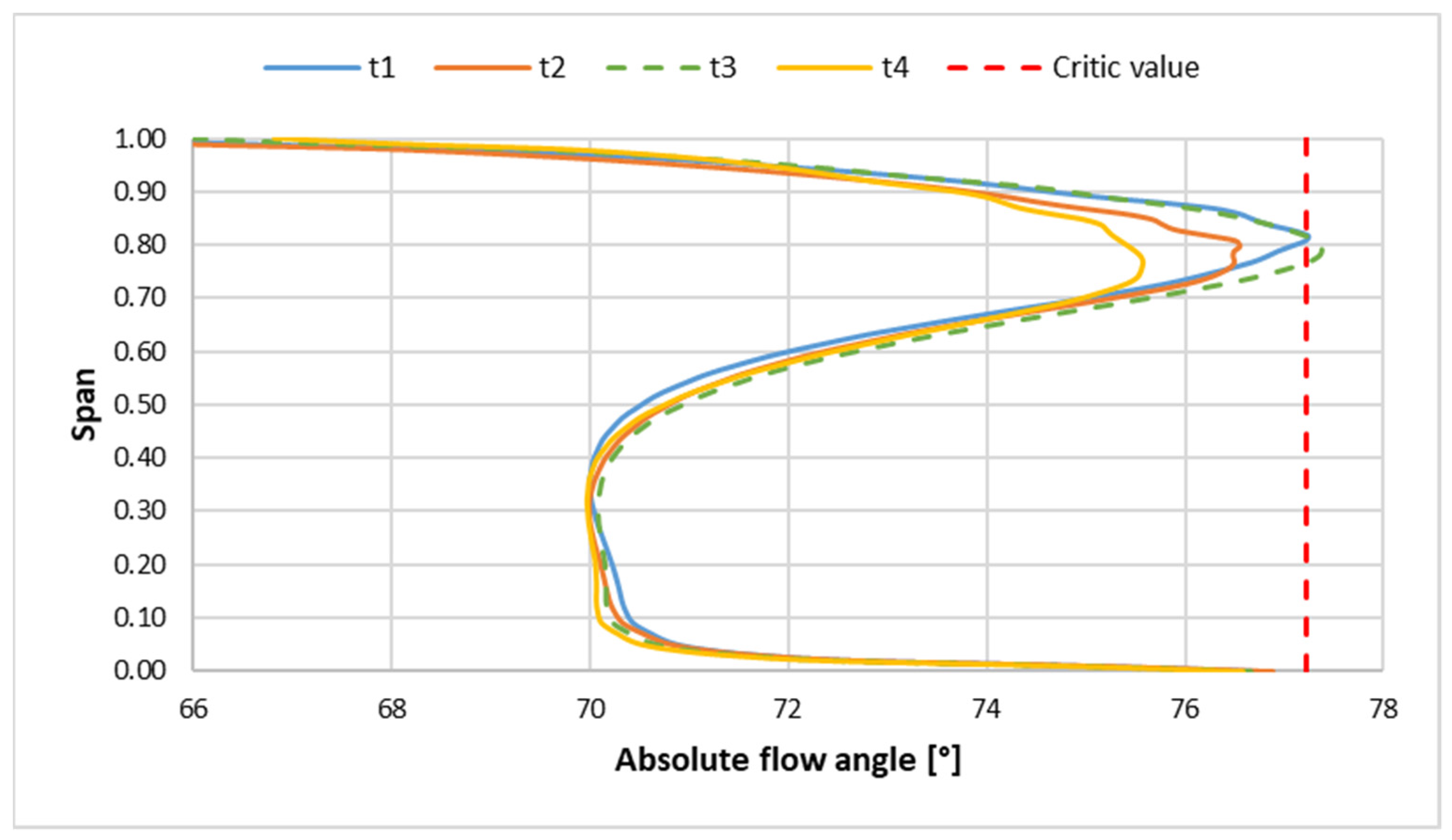

3.4. Unsteady Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Area, [mm2] |

| b | Span height, [mm] |

| Cp | Pressure coefficient: (pout-p1)/(ptrel,1-pout) |

| DRi | Diffusion ratio |

| k | Specific heat coefficient |

| l | Length, [mm] |

| ṁ | Mass flow rate, [kg/s] |

| Ma | Mach number |

| N | Rotational speed, [rpm] |

| p | Pressure, [Pa] |

| R | Radius, [mm] |

| S | Span percentage over critical flow angle |

| SM | Surge margin |

| tc | Tip clearance, [mm] |

| T | Temperature, [K] |

| V | Absolute velocity, [m/s] |

| W | Relative velocity, [m/s] |

| Y+ | Non dimensional boundary layer distance from wall |

| z | Axial coordinate, [mm] |

| Zb | Blades number |

| α | Absolute flow angle: arctg(Vth/Va) |

| β | Pressure ratio |

| γ | Flow angle: arctg(Vr/Va) |

| η | Efficiency |

| Subscripts | |

| 0 | Model inlet (adduction duct inlet) |

| 1 | Impeller inlet |

| 4 | Diffuser inlet |

| 5 | Diffuser outlet |

| 6 | Volute outlet |

| a | Axial |

| A | Upstream interface of the ported shroud |

| B | Downstream interface of the ported shroud |

| c | Critic |

| cor | Corrected |

| eff | Effective |

| EXP | Experimental |

| LE | Leading edge |

| m | Meridional |

| max | Maximum |

| min | Minimum |

| out | Rotor outlet |

| PS | Ported shroud |

| r | Radial |

| rel | In relative frame |

| rot | Rotor |

| t | Total |

| TE | Trailing edge |

| TIP | Tip blade |

| th | Circumferential |

| vol | Volute |

| Acronyms | |

| CFD | Computer fluid dynamic |

References

- Ricardo, M.B.; Apostolos, P.; Yang, M. Overview of boosting options for future downsized engines. Sci. China Technol. Sci. 2011, 54, 318–331. [Google Scholar] [CrossRef]

- Alshammari, M.; Alshammari, F.; Pesyridis, A. Electric boosting and energy recovery systems for engine downsizing. Energies 2019, 12, 4636. [Google Scholar] [CrossRef]

- Rodgers, C. Centrifugal Compressor Inlet Guide Vanes for Increased Surge Margin. J. Turbomach. 1991, 113, 696–702. [Google Scholar] [CrossRef]

- Whitfield, A.; Abdullah, A.H. The performance of a Centrifugal Compressor with High Inlet Prewhirl. J. Turbomach. 1998, 120, 487–493. [Google Scholar] [CrossRef]

- Ishida, M.; Sakaguchi, D.; Ueki, H. Effect of Pre-Swirl on Unstable Flow Suppression in a Centrifugal Impeller with Ring Groove Arrangement. In Proceedings of the ASME Turbo Expo: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2006; GT2006-90400. p. 90400. [Google Scholar]

- Saha, S.L.; Kurokawa, J.; Matsui, J.; Imamura, H. Passive Control of Rotating Stall in a Parallel-Wall Vaned Diffuser by J-Grooves. J. Fluids Eng. 2001, 123, 507–515. [Google Scholar] [CrossRef]

- Macdougal, I.; Elder, R.L. The Improvements of Operating Range in a Small, High Speed, Centrifugal Compressor Using Casing Treatment. In Proceedings of the IMechE Conference on Turbochargers and Turbocharging C32/82, London, UK, 2–28 April 1982. [Google Scholar]

- Zheng, X.; Zhang, Y.; Yang, M.; Bamba, T.; Tamaki, H. Stability Improvement of High-Pressure-Ratio Turbocharger Centrifugal Compressor by Asymmetrical Flow Control—Part II: Nonaxisymmetrical Self-Recirculation Casing Treatment. J. Turbomach. 2002, 135, 021007. [Google Scholar] [CrossRef]

- Sivagnanasundaram, S.; Spence, S.; Early, J.; Nikpour, B. An impact of Various Shroud Bleed Slot configurations and Cavity Vanes on Compressor Map Width and the Inducer Flow Field. J. Turbomach. 2013, 135, 041003. [Google Scholar] [CrossRef]

- Guleren, K.M.; Afgan, I.; Turan, A. Predictions of Turbulent Flow for the Impeller of a NASA Low-Speed Centrifugal Compressor. J. Turbomach. 2010, 132, 021005. [Google Scholar] [CrossRef]

- Fisher, F.B. Application of Map Width Enhancement Devices to Turbocharger Compressor Stages. J. Engines 1988, 97, 1303–1310. [Google Scholar]

- Bousquet, Y.; Carbonneau, X.; Dufour, G.; Binder, N.; Trebinjac, I. Analysis of the Unsteady Flow Field in a Centrifugal Compressor from Peak Efficiency to Near Stall with Full-Annulus Simulations. Int. J. Rot. Mach. 2014, 2014, 729629. [Google Scholar] [CrossRef][Green Version]

- Hunziker, R.; Dickman, H.P.; Emmrich, R. Numerical and experimental investigations of a centrifugal compressor with an inducer casing bleed system. Proc. Inst. Mech. Eng. Part A J. Power Energy 2001, 215, 783–791. [Google Scholar] [CrossRef]

- Yamaguchi, N. The Development of Effective Casing Treatment for Turbocharger Compressors. In Proceedings of the IMechE Seventh International Conference, London, UK, 14–15 May 2002. [Google Scholar]

- Tamaki, H. Effect of Recirculation Device on Performance of High-Pressure Ratio Centrifugal Compressor. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010; Volume 44021, pp. 1879–1889. [Google Scholar]

- Tamaki, H. Effect of recirculation device with counter swirl vane on performance of high-pressure ratio centrifugal compressor. J. Turbomach. 2012, 134, 051036. [Google Scholar] [CrossRef]

- Nikpour, B. Turbocharger Compressor Flow Range Improvement for Future Heavy Duty Diesel Engines. In Proceedings of the THIESEL 2004 Conference on Thermo-and Fluid Dynamic Processes in Diesel Engines, Valencia, Spain, 7–10 September 2004. [Google Scholar]

- Xiao, J.; Xu, W.; Gu, C.; Shu, X. Self-recirculating casing treatment for a radial compressor. Chin. J. Mech. Eng. 2009, 22, 567–573. [Google Scholar] [CrossRef]

- Kanzaka, T.; Ibaraki, S. Feature of Internal Flow Phenomena of Self Recirculation Casing Treatment in a Centrifugal Compressor for Turbochargers. In Proceedings of the 1st Global Power and Propulsion Forum; GPPF-2017-66; Global Power and Propulsion Society: Zug, Switzerland, 2017. [Google Scholar]

- Marelli, S.; Misley, A.; Taylor, A.; Silvestri, P.; Capobianco, M.; Canova, M. Experimental Investigation on Surge Phenomena in an Automotive Turbocharger Compressor. In Proceedings of the WCX World Congress Experience, Detroit, MI, USA, 10–12 April 2018; SAE Technical Paper 2018-01-0976. SAE: Warrendale, PA, USA, 2018. [Google Scholar]

- Marelli, S.; Misley, A.; Ferrando, M. Experimental Investigation in Turbocharger Compressors during Surge Operation. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, London, UK, 22–26 June 2020; Paper GT2020-15174. ASME: New York, NY, USA, 2020. [Google Scholar]

- Guillou, E.; Gancedo, M.; Gutmark, E.; Mohamed, A. PIV investigation of the flow induced by a passive surge control method in a radial compressor. Exp. Fluids 2012, 53, 619–635. [Google Scholar] [CrossRef]

- He, X.; Zheng, X. Roles and mechanisms of casing treatment on different scales of flow instability in high pressure ratio centrifugal compressors. Aerosp. Sci. Technol. 2019, 84, 734–746. [Google Scholar] [CrossRef]

- Sharma, S.; Broatch, A.; Garcia-Tiscar, J.; Nickson, A.K.; Allport, J.M. Acoustic and pressure characteristics of a ported shroud turbocompressor operating at near surge conditions. Appl. Acoust. 2019, 148, 434–447. [Google Scholar] [CrossRef]

- Sharma, S.; Broatch, A.; García-Tíscar, J.; Allport, J.M.; Nickson, A.K. Acoustic characteristics of a ported shroud turbocompressor operating at design conditions. Int. J. Engine Res. 2020, 21, 1454–1468. [Google Scholar] [CrossRef]

- Gooding, W.J.; Fabian, J.; Key, N. Numerical Analysis of Unsteady Vaned Diffuser Flow in a Centrifugal Compressor. In Proceedings of the 23rd International Society for Air Breathing Engines Conference, Manchester, UK, 3–8 September 2017. Paper ISABE 2017-21417. [Google Scholar]

- Carretta, M.; Cravero, C.; Marsano, D. Numerical Prediction of Centrifugal Compressor Stability Limit. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017; Paper GT2017-63352. ASME: New York, NY, USA, 2017. [Google Scholar]

- Bardelli, M.; Cravero, C.; Marini, M.; Marsano, D.; Milingi, O. Numerical Investigation of Impeller-Vaned Diffuser Interaction in a Centrifugal Compressor. Appl. Sci. 2019, 9, 1619. [Google Scholar] [CrossRef]

- Cravero, C.; Marsano, D. Criteria for the Stability Limit Prediction of High-Speed Centrifugal Compressors with Vaneless Diffuser. Part I: Flow Structure Analysis. In Proceedings of the ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, Online, 21–25 September 2020; Paper GT2020-14579. ASME: New York, NY, USA, 2017. [Google Scholar]

- Cravero, C.; Marsano, D. Criteria for the Stability Limit Prediction of High-Speed Centrifugal Compressors with Vaneless Diffuser. Part II: The development of Prediction Criteria. In Proceedings of the ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, Online, 21–25 September 2020; Paper GT2020-14589. ASME: New York, NY, USA, 2017. [Google Scholar]

- Leutcha, P.J. Analysis and Design Criteria for Centrifugal Compressors with Ported Shroud. Ph.D. Thesis, University of Genoa, Genoa, Italy, May 2021. [Google Scholar]

- Menter, F.; Kuntz, M.; Langstry, R. Ten years of industrial experience with the SST turbulence model. Turbul. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- Smirnov, P.; Menter, F. Sensitization of the SST turbulence model to rotation and curvature by applying the Spalart-Shur correction term. J. Turbomach. 2009, 131, 041010. [Google Scholar] [CrossRef]

- Dixon, S.L.; Hall, C. Fluid Mechanics and Thermodynamics of Turbomachinery; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Senoo, Y.; Kinoshita, Y. Limits of Rotating Stall and Stall in Vaneless Diffuser of Centrifugal Compressors. In Proceedings of the ASME Turbo Expo, London, UK, 9–13 April 1978; Paper 78 GT 19. ASME: New York, NY, USA, 2017. [Google Scholar]

| Geometric Parameter | Value |

|---|---|

| Impeller blade number: Zb | 6 + 6 |

| Span at diffuser inlet: b4/R4 | 0.0706 |

| Radius at rotor leading edge hub: RLE,hub/R4 | 0.1755 |

| Radius at rotor leading edge tip: RLE,tip/R4 | 0.7166 |

| Radius at diffuser outlet: R5/R4 | 1.5323 |

| Ported Shroud length: lPS/R4 | 0.8201 |

| Vertical position of the downstream interface of the ported shroud: zPS-impeller/R4 | 0.5141 |

| Maximum radius of the volute: Rmax,vol/R4 | 2.3519 |

| Mesh | Cell Number (Mcells) | ptA–ptB (Pa) | MRF |

|---|---|---|---|

| M1 | 0.6 | 31,400 | 26.59 |

| M2 | 1.05 | 25,000 | 25.91 |

| M3 | 1.7 | 24,900 | 25.88 |

| Variable | Best Efficiency OP1 | Near Surge OP2 |

|---|---|---|

| MRF (%) | 7.0 | 25.91 |

| Va (m/s) | 43.8 | −8.9 |

| Vth (m/s) | 91.6 | 198.9 |

| Vr (m/s) | −20.9 | −58.3 |

| α (°) | 63.7 | −48.6 |

| γ (°) | −26.5 | 46.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cravero, C.; Leutcha, P.J.; Marsano, D. Simulation and Modeling of Ported Shroud Effects on Radial Compressor Stage Stability Limits. Energies 2022, 15, 2571. https://doi.org/10.3390/en15072571

Cravero C, Leutcha PJ, Marsano D. Simulation and Modeling of Ported Shroud Effects on Radial Compressor Stage Stability Limits. Energies. 2022; 15(7):2571. https://doi.org/10.3390/en15072571

Chicago/Turabian StyleCravero, Carlo, Philippe Joe Leutcha, and Davide Marsano. 2022. "Simulation and Modeling of Ported Shroud Effects on Radial Compressor Stage Stability Limits" Energies 15, no. 7: 2571. https://doi.org/10.3390/en15072571

APA StyleCravero, C., Leutcha, P. J., & Marsano, D. (2022). Simulation and Modeling of Ported Shroud Effects on Radial Compressor Stage Stability Limits. Energies, 15(7), 2571. https://doi.org/10.3390/en15072571