Abstract

The adverse effect of the use of fossil fuels on the environment and public health has given rise to a sustained renewable energy research and development. An important component of global renewable energy mix is the use of loose biomass, including agricultural and forestry residues, to produce solid fuels in the form of briquettes. Briquettes play a significant role in bioenergy mix in developing and developed countries. The production of biomass briquettes often entails the collection, transportation, storage, processing, and compaction of loose biomass that meet specific quality parameters. The densification process often involves the addition of binders to improve the cohesive strength of the briquette material. This paper surveys recent literature from 2012 to 2021 to establish the current state of research on the use of binders in briquette production; and reviews current parameters used in assessing the quality of biomass briquettes with focus on mechanical and handling properties. While a number of quality parameters were identified, their assessment methodologies varied widely in the literature, thus necessitating standardization for comparability purposes. The review also includes factors affecting the wide production and adoption of biomass briquettes in most developing economies and proposes ways of overcoming the bottlenecks.

1. Introduction

Globally, biomass energy has continued to remain an important renewable energy component. It is an important part of national energy mix both for developed and developing countries towards achieving sustainable energy for heating applications, reducing environmental impact, creating bio-economies, reducing over dependence on fossil fuel, improving quality of rural and urban life, and for the production of various biofuels [1,2,3,4,5]. One of the challenges with the utilization of biomass is that they are mostly in loose form having low energy density. Biomass briquetting, a densification technology, is one of the technologies used in improving the potential energy use of biomass primarily for household heating applications and power generation [6]. The general steps in utilizing biomass for solid fuel (briquette) production include sourcing, collection and transportation, drying, size reduction, and densification. Densification process involves the compaction of biomass with or without a binding agent under relatively high temperature and pressure to achieve higher energy per volume of the material. Densification generally increases the bulk density, improves the handling and logistics, reduces the labor costs, improves the thermal properties of biomass as well as the direct or co-combustion of biomass [7,8].

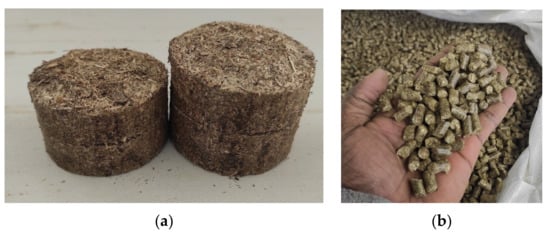

Densified biomass in the form of briquettes (Figure 1a) could take different shapes and sizes, including cylindrical, cubic, and rectangular, with or without a hole in the center [9]. A number of densification systems are employed in the production of briquettes and they include hydraulic piston presses, mechanical piston and ram presses, roller presses, manual presses, and screw extruders [10,11]. A detailed review of biomass briquette production processes and the various accompanying briquetting machines has recently been carried out [12]. While biomass pellets (Figure 1b) are also products of the densification process, they are relatively smaller compared to briquettes. They are usually cylindrical in shape with a diameter of between 3 and 27 mm and a length of between 3 and 31 mm [13]. Briquettes of cylindrical shape are generally between 18 and 55 mm in diameter and 10 and 100 mm in length [14,15]. However, there are generally no recognized standard dimensions distinguishing biomass pellets from briquettes [7].

Figure 1.

(a) Sample of biomass briquettes and (b) biomass pellet samples.

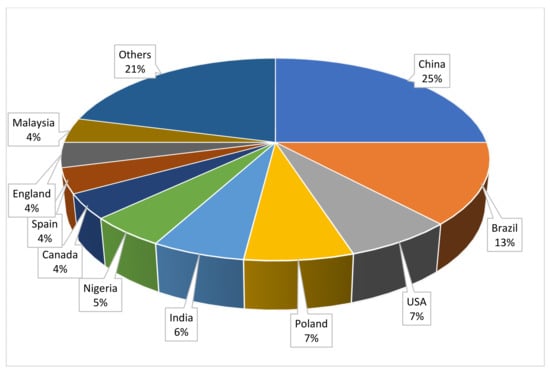

In the past 10 years (2012 to 2021), the number of research publications focused on biomass briquetting has consistently been on the increase on a yearly basis, as identified in the online databases of Web of Science (Web of Science Core Collection. Available online: https://www.webofscience.com/wos/woscc/summary/19d74b6d-60c7-4273-a1fa-a27fb2ea65b6-2c437953/relevance/1 (accessed on 3 January 2022)) and Science Direct (Peer-reviewed journal articles search. Available online: https://www.sciencedirect.com/search?qs=biomass%20briquettes (accessed on 3 January 2022)). In Web of Science, only 24 publications were identified in 2012, and the number rose to 105 in 2021; while in Science Direct, 143 articles were published in 2012, while 439 were published in 2021. This suggests a growing research interest in this area of study. A total of 10 countries account for more than 77% of the total publications (636) identified in the Web of Science database for the 10-year period under consideration and they include China, Brazil, USA, Poland, India, Nigeria, Canada, Spain, England, and Malaysia, in that order (Figure 2). This data is based on the location of the authors of the publications.

Figure 2.

Share of publications on biomass briquetting by the location of authors (2012–2021). Source: https://www.webofscience.com/ (accessed on 3 January 2022).

A number of studies have broadly reviewed different aspects of densification technology, including production processes and briquetting machines [12], devices used for the measurement of various solid fuel properties [7], biomass feedstock, processing characteristics, and the economics of densifying biomass [16], briquetting process variables and combustion [11], and the economics of biomass briquetting [17]. However, recent reviews on the current state of research on biomass briquette binders and briquette quality parameters is lacking in the literature. The main objective of this study is to review the current state of research on the use of binders in biomass briquette production, and briquette quality parameters with the focus on mechanical and handling properties. The briquette qualities considered in this study focus only on the mechanical and handling properties resulting from the briquetting process. It is noteworthy to state that this study did not consider combustion and emission quality factors and only recent literature spanning the period of 10 years from 2012 to 2021 were reviewed.

2. Methodology

In this study, literature including journals, book chapters, PhD theses, and conference proceedings on biomass briquetting spanning a 10-year period from 2012–2021 were considered. Only literatures available in the English language or published in other languages but accompanied with an English translation were considered. The search for literature was conducted over the internet using online databases, including Google Scholar, Scopus, Web of Science, and Science Direct. The search was done using various combinations of key words relevant to the subject matter, such as biomass briquettes, biomass briquetting, biomass briquette and binders, biomass briquette and quality factors or parameters, biomass briquette and adoption or use, biomass briquettes and developing economies or countries. Non-biomass (e.g., coal) related papers were discarded. Based on title and abstract content, only literature that address biomass briquette binders, quality assessment, and briquette adoption or use in developing countries were selected and reviewed. Furthermore, bibliography in key selected documents were also examined with the aim of identifying other relevant papers.

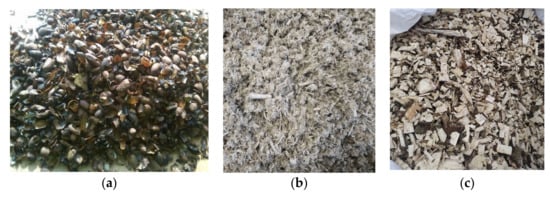

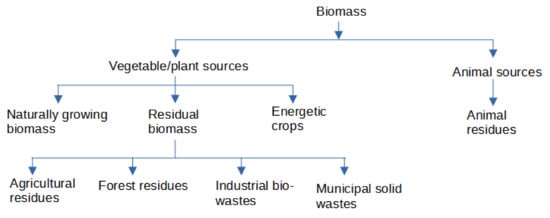

3. Biomass Availability

Biomass generally refers to all biological materials derived from living organisms, including animal, and plant. Within the context of biomass briquetting, an example of biomass would include a wide range of materials, such as wood shavings from forest operations, agricultural residues from agro-processing activities, industrial wastes, animal, and domestic and municipal wastes. Figure 3 shows samples of biomass used for briquette production. The energy contained in biomass can be released through direct combustion or alternatively converted to other biofuels [18]. Biomass may be classified according to their origin as shown in Figure 4.

Figure 3.

Examples of biomass for briquette production (a) agro-processing residues—breadfruit shells, (b) wood fibre, and (c) forest residues—chips from tree branches and small-diameter trees.

The biomass materials are mostly organic remainder generated because of human activities (residual biomass including agroforestry residue, and industrial and municipal bio-wastes) or naturally grown in nature, e.g., energetic crops or naturally growing grasses. For biomass briquetting, vegetable- or plant-derived raw materials are the preferred densification material, while animal-derived biomass is often used as binding material, e.g., cow dung. The predominant use of vegetable or plant biomass sources could be attributed to its wide availability compared to animal derived biomass. Table 1 shows the global quantity of selected biomass from agricultural crops burnt in 2009 and 2019. This represents potential amount of biomass available for biomass briquetting with little or no alternative competitive use. For most of the crops, the amount of burnt biomass has continued to rise, especially in Africa, Asia, and South America. In addition to agroforestry residues, there has been a growing interest in the use of urban and industrial wastes for briquetting [19,20]. This could be attributed to the increasing rural–urban migration resulting in increased generation of industrial and municipal solid wastes. Urban and industrial wastes are expected to find more use in biomass briquetting, particularly in mixed-material briquetting, due to the increasing need to effectively manage such wastes in a sustainable manner.

Table 1.

Regional burnt biomass (dry matter, Mt).

Figure 4.

Classification of biomass based on the origin (adapted from [21]).

For commercial and sustainable production of fuel briquettes, suitable biomass feedstock must be available, easily collected, transported, and stored for further processing prior to compaction. Agricultural and forest biomass may be considered but they should be readily available in a sustainable manner. Concerns have been expressed on the potential competitive impact of the use of biomass for bioenergy purposes could have on other uses, including food and fodder [21]. The allocation of less fertile lands for the cultivation of energy crops through thought-out mechanisms, regulations, and cooperation among stakeholders have been suggested as means of mitigating against this [22]. Another major constraint in the commercial briquetting of biomass is within the context of supply chain management—the sustainable supply of biomass resource at cost-effective price and volume. This is influenced by a number of factors, including biomass structure, seasonal harvest, and the scattered geographical distribution of biomass that makes it difficult for their collection, transportation, and storage on a large scale [23]. The design of an efficient and effective biomass supply chain thus becomes critical in facilitating sustainable raw material preprocessing and supply for commercial briquetting [24,25]. However, in most developing countries, particularly in sub-Saharan Africa where domestic energy sources are still comprised mainly of firewood, there appears to be non-existence of any formal biomass supply chain structure.

In addition, concerns about raw material quality have also been expressed [26]. To address this, the use of composite raw materials has been explored in the production of briquettes [17,27,28]. This strategy aims to take advantage of differences in the structural and chemical characteristics of different biomass materials on the bonding strength and overall properties of the briquettes. Composite briquettes from materials with similar and compensating characteristics have been studied. Chungcharoen and Srisang [28] suggested the use of small cashew nut sizes in the briquetting of cashew and areca nuts in a composite ratio of 65% to 25%, respectively, to produce high-quality composite briquettes. Lubwama, et al. [29] demonstrated the benefits of producing composite briquette from rice husks, coffee husks, and groundnut shell over single constituent briquettes. The study reported improved heat transfer in composite briquette of coffee and rice husks without binders when placed sequentially in the briquette composition. Obi [30] suggests an optimum blending ratio of 50:50 for composite briquettes of palm kernel shell and sawdust feedstock. However, the increased addition of palm kernel shell reduced the weathering ability of the briquettes. Exploring opportunities in producing composite briquettes thus require further investigations particularly in identifying biomass materials that compensate their individual bonding and combustion properties.

4. Binders in Biomass Briquetting

Biomass generally contain naturally occurring structural binders or stabilizing agents, such as lignin and proteins that are released and activated when biomass is densified at relatively high levels of temperature and pressure [31,32]. This improves the structural particle bonding in biomass briquettes. However, in some cases, the biomass may not contain significant amount of natural binder (lignin) or due to the densification conditions, additional binders may be required to achieve the desired briquette hardness and durability. Briquette binders can be broadly divided into organic and inorganic binders. It could further be divided into organic, inorganic, and compound binders based on their composition [33,34]. The choice of binders among the various types is largely dependent on a number of factors, including the desired bonding strength, low emissions, the effect on combustion performance of the briquette, environmental friendliness, and sustainability and economic availability.

While binders are used to improve bonding between biomass particles during densification, actual mechanism of the bonding process is complex and yet to be fully comprehended [35]. Previous studies have propagated a number of theories to explain particle bonding in biomass densification including attraction forces between biomass particles, adhesion and cohesion forces, solid bridges and mechanical interlocking bonds, interfacial forces, and capillary pressure [36,37,38]. These theories have been approached from both mechanical and chemical point of views thus explaining the influence of biomass structural and chemical substances on the bonding process during densification. In a recent study, Anukam, Berghel, Henrikson, Frodeson and Ståhl [35] provide a detailed review of the current state of knowledge on bonding mechanisms in biomass during the densification process.

4.1. Classification of Briquette Binder

As earlier mentioned, the three broad classes of briquette binders include organic, inorganic, and composite binders. Zhang, et al. [39] noted that organic binders generally have good binding properties, including high impact and abrasion strength, and high-water resistance. However, at high temperature, they decompose easily having poor thermal stability and mechanical strength [40]. They are mostly characterized by extensive availability, low price, high heating value, and low ignition temperature. There are four main types of organic binders and they include biomass (agricultural wastes, forestry biomass, etc.), tar pitch and petroleum bitumen (coal tar pitch, tar residues, etc.), lignosulphonate, and polymer binders (resins, polyvinyl, and starch). Miao, et al. [41] noted that organic binders could further be divided into hydrophobic binders (e.g., asphalt, and coal tar) and hydrophilic binders (e.g., biomass) based on their reaction to water. The poor thermal stability of organic binders has contributed in limiting their commercial application in biomass briquetting [42].

Inorganic binders have strong adhesion, non-pollution with sulfur capture characteristics, low cost, and good hydrophilicity, however, their combustion efficiency is lower due to their limited calorific values, and the ash content is often high [43]. Examples are clay, bentonite, ammonium nitrate, etc. Inorganic binder could be classified into three main types, industrial (bentonite clay, cement, sodium silicate, and magnesium chloride), civilian (limestone, and clay) and environmental protection (desulfurization agents, e.g., iron oxide, magnesium oxide, and calcium oxide) inorganic binders [39]. However, the use of inorganic binders in recent literature for biomass briquetting appears to be limited [44,45,46]. Compound binders comprise the combination of two or more binders with the aim of taking advantage of the multiple binding benefits offered by the different binders, thus yielding briquettes with high mechanical strength and thermal stability. Examples are starch and bentonite, molasses, and carbide lime [47,48]. Zhang, Sun and Xu [39] describes in details the various classifications of briquette binders. Table 2 shows an overview of the strengths and weaknesses of the various binder types.

Table 2.

An overview of the binder types and their characteristics [39].

4.2. Binder Selection

The choice of binders in biomass briquetting is often influenced by a number of factors, including availability, cost, the raw material properties, moisture content of the mix, the densification pressure, and the desired energy content of the briquettes [49]. In most developing communities, cost and availability of the binders are the most important factors that are considered in the selection of binders. The type and quantity of binders applied in biomass briquetting have been linked to the resulting properties of briquettes including their combustion and mechanical properties [29,50,51]. Furthermore, the degree of their influence on the properties of biomass briquettes varies among binders. In the study of the effects of different binders on the briquette properties of carbonized corncob, Aransiola, Oyewusi, Osunbitan, and Ogunjimi [50] reported that briquettes produced with corn starch exhibited better moisture content, relaxed density, and compressive strength compared to those with corn starch and gelatin. An increase in the concentration of African Elemi resin as a binder resulted in increased strength and density of charcoal briquettes [33]. Furthermore, in the production of briquettes from rice and coffee husks using cassava starch and clay as binders, Lubwama and Yiga [52] noted that cassava starch produced briquettes with better physical and calorific properties compared to clay binder. Hence, in the selection of binders for commercial biomass briquetting, assessing the impact of the type and quantity of the binders on the properties of the resulting briquette is significantly important.

In terms of briquetting energy requirement and cost of the briquetting process, Muazu and Stegemann [53] observed that the type of binder applied in the briquetting process may influence the required compaction pressure, temperature, and wear on the production equipment, thus reducing the overall cost of the briquetting process. Gill, et al. [54] observed that the addition of cotton stalk as a binder up to 30% by weight of chopped rice straw significantly reduced the energy requirement for briquetting from 40.4 kW at 10% binder level to 36.6 kW at 30% binder level. Notwithstanding the positive effects of the addition of binders in the densification of loose biomass, some binders could negatively affect some briquette properties (e.g., reduced density, deposit formation, emissions, etc.) and could be competing for other uses including food and industrial uses [55,56]. Studies that are more recent have focused on new binders that are cheaper, improve briquette qualities, sustainable in their use as well as optimizing biomass–binder ratio which are all important in long-term commercial production of biomass briquettes [54,57,58].

4.3. Common Biomass Briquette Binders

As earlier stated, binders are added to biomass densification process in other to improve the compressive strength, abrasion resistance and, in some cases, the energy content of briquettes [53]. Different types of raw materials require different binder types due to their underlying material bonding mechanisms [39]. Binders that are widely used in biomass briquette production are discussed below. Additional examples of commonly used binders identified in the literature are presented in Table 3.

4.3.1. Glycerol

Crude glycerin, a by-product in biodiesel production, has been successfully used as a binding agent in biomass briquetting with significant positive effects on the briquette properties [57,59,60,61]. Although crude glycerin can be purified into valuable chemical for use in the pharmaceutical, food and cosmetics industries, the purification process is rather expensive and inefficient due to a wide variety of impurities it often contains [62]. The glycerin market on the other hand is well saturated and its disposal at landfills is environmentally unsustainable [63,64]. Thus, the price of glycerin has continued to decline making it economically attractive for use as a binder in biomass briquette production. Glycerin has also been used in biomass pellet production [65].

While the production of biomass briquettes with the addition of low—quantity glycerol has shown desirable briquette qualities, high-quantity addition of the binder in sugarcane and sorghum residues briquettes up to 30 wt.% results in poor briquette quality, including high hygroscopic nature, low energetic value, and poor aesthetics and durability [62].

4.3.2. Starch

Starch is a white powder mostly extracted from various crops, including cereals, rhizomes, and roots, in the form of semi-crystalline granules which are unique to the individual crop source [66]. The application of heat and water to starch brings about the formation of intermolecular hydrogen bonds between the two major polysaccharide components in starch—amylose and amylopectin. This is achieved through the disruption of the granular structure of the starch molecules leading to swelling, hydration, and solubilization [67]. This results in a viscous solution called starch paste that gels as it cools. The transition from granules to starch paste is accompanied by increased viscosity which increases the paste resistance to deformation showing significant binding strength [68]. The high-energy content of starch in addition to its chemical and structural properties makes it an excellent binding agent in biomass densification and remains the most common biomass briquette binder in the literature [28,29,69,70]. However, its use in commercial briquetting has been limited due to its high cost, low coking, and water-proof properties [39].

Borowski, et al. [71] reported a positive effect of native wheat starch and modified wheat starch on the mechanical, physical, and burning properties of charcoal briquettes. Differences were, however, observed between the starch types in terms of the briquette firing up time, burning time, temperature distribution, and smoke intensity. Wirabuana and Alwi [72] used starch at various concentrations in the production of briquettes from Durian peel charcoal. At 3% (w/w) starch concentration, the briquette exhibited the best quality in terms of the parameters assessed. In the study evaluating the effect of cassava starch binder on groundnut shell briquettes, Oyelaran, Bolaji, Waheed and Adekunle [32] reported improvements in the burning rates, specific fuel consumption and thermal efficiencies of the briquettes. Shone and Jothi [51] used cassava starch in the preparation of briquettes from dried teak and rubber tree leaves. The authors recommended a 3:5 biomass–binder ratio as the leafy biomass do not adhere well upon compaction with lower binder content.

While starch binders generally improve physical and mechanical properties of briquettes, Lubwama, Yiga, Muhairwe and Kihedu [29] reported an inhibition of heat transfer in carbonized composite briquettes from rice husks, coffee husks, and groundnut shells. This suggests the need for a more comprehensive assessment of the effects of binders on both physico–mechanical and thermal properties of briquettes, which is currently scarce in the literature.

4.3.3. Algae

Algae are a group of photosynthetic, heterotrophic single-celled organisms inhabiting fresh- and seawater ecosystems, and can easily be cultivated; its production rate is about 50 times faster than most terrestrial biomass [73]. Algae has potential applications in biomass binding due to its high protein and lignin content [74]. The binding capability of algae has been linked to the combination of two constituents of algae, chitin, and proteins, which act as natural binding agents [75]. Algae biomass possesses some characteristics that make them energetically and environmentally attractive for use as a binder including possible year-round cultivation, its ability to thrive in diverse climates and in areas unsuitable for agriculture, and their positive atmospheric effect [76,77].

Muazu and Stegemann [53] investigated the effect of microalgae on the properties of briquettes produced from a blend of rice husk, corncob, and bagasse. The addition of microalgae as a binder significantly improved the density, durability, energy value, mass loss during combustion, and afterglow time of the briquettes. In the production of Jatropha epicarp briquettes with the addition of algal biomass, Costa, Calijuri, Avelar, Carneiro and de Assis [76] reported a decrease in hygroscopicity and fixed carbon content of the briquettes, however an increase was observed in the bulk density, ash content, and energy density. They concluded that the production of Jatropha epicarp briquettes with algal biomass is technically feasible.

While algae have been used as a binding agent, other researchers have used it as the main feedstock after drying to produce briquettes [78]. Marangon, et al. [79] proposed the development of microalgae biomass briquetting as a means of achieving more sustainable energy products with less pressure on the environment. Haykiri-Acma, Yaman and Kucukbayrak [73] produced briquettes from carbonized algae (seaweed) with the addition of binders. The authors reported satisfactory briquette properties irrespective of the binder used. However, inorganic content of the algae became concentrated following carbonization. Amarasekara, et al. [80] produced briquettes from naturally grown algae biomass collected from lakes after open-air drying without the addition of binders. This suggests that algal biomass could potentially serve as briquette raw material or as a binding agent.

4.3.4. Molasses

Molasses represents a low-cost liquid by-product discharged by the centrifuge in the last stage of extraction of sugar from cane or beets by means of repetitive crystallization [81]. It is a thick non-transparent brown to dark brown high-density liquid fully soluble in hot and cold water. The carbohydrate content range from 48 to 53% and the water content lower than 25% [82]. Molasses is often characterized by excellent stability and shelf life due to its high osmotic potential linked to its antimicrobial properties. Furthermore, it is recognized as a cheap and environmentally safe promoter of bonding mechanisms among fine particles as it contains sucrose and gum (including starch) [83]. The bonding property of molasses has traditionally been exploited in the feed industry for the preparation of compound feed, and only in recent decades has it found use in the bioenergy sector [81,84].

In the briquetting study of carbonized water hyacinth, Carnaje, et al. [85] used molasses as the binding agent at different raw material/binder ratio. The results suggest that varying the quantity of molasses in briquettes significantly affect briquette characteristics. Increases were recorded in the volatile matter and fixed carbon content of the briquettes while the ash content decreased as the binder content increased. While Carnaje et al. recommended biomass–molasses ratio of 30:70 by volume in their study, Jittabut [86] used a ratio of 100:50 by mass in briquetting blends of rice straw and sugar cane leaves with molasses as the binding agent. Sen, et al. [87] utilized molasses in the production of briquettes from cassava rhizomes and reported an improvement in density of the briquettes with the addition of molasses. Furthermore, molasses was considered to have added economic benefits. In general, the use of molasses as a binder in briquette production could significantly improve briquette combustion characteristics [73,88].

Table 3.

Binders used in biomass briquette production.

Table 3.

Binders used in biomass briquette production.

| Biomass Briquette Type | Binder Used | Binder Source | Competing Binder Uses | References |

|---|---|---|---|---|

| Organic binders | ||||

| Rice husk and coconut shell | Mango sap/ mucilage | Oozes out at the abscission zone of mango tree stem during mango harvesting. | Exhibits effective anti-fungal, bacterial and microbial activities. May be suitable for use as a preservative and flavouring agent in the food industry. | [89,90,91] |

| Blends of rice husk, corn cob and bagasse; charcoal briquettes | Biosolids | By-product of anaerobic digestion of wastewater sludge during treatment. | Treated biosolids contain valuable organic matter as such can be used as organic manure in agriculture. | [53] |

| Sawdust | Palm oil mill sludge/effluent | A thick brownish semi-liquid bio-waste that generated by palm oil mills during the processing of the palm fruit for palm oil production. | Used as manure, feed supplement and feedstock in the biofuel industry. | [92,93] |

| Rice husk and bran | Okra stem gum | Obtained by blending and hydrating the okra plant stem. | The stem is used as vegetable, fibre and rope. Although not commercially available, it could potentially be used as a coating and flavouring material in the pharmaceutical and food industries. | [94,95] |

| Rice husk and bran | Rice dust | A large amount of rice dust is generated during the milling of rice kernels into flour. | Mostly discarded or fed to poultry. | [94] |

| Rice straw | Sawdust | Generated during the processing of timber. | Mostly discarded but have found use in the construction industry. | [96] |

| Corncob | Gelatin | Obtained from animal collagen by the process of hydrolysis with either acid or alkaline. | Widely used in the food, pharmaceutical, and cosmetic industries for a variety of purposes due to their excellent biocompatibility, biodegradability, and weak antigenicity. | [50,97,98] |

| Sawdust | Neem powder | Could be obtained from neem leaves or the tree. | Neem leaves, fruit, and bark of the tree all possess beneficial medicinal properties and are widely used in the personal hygiene and cosmetic industries. | [99,100] |

| Energy cane and Napier grass | Lignosulfonates | By-product of the wood pulping industry from the production of wood pulp. | Lignosulfonate has excellent dispersing properties, and is utilized as a superplasticizer in concrete or gypsum to maintain adequate fluidity. | [101] |

| Banana leaves, corn cob and oil palm trunk bark | Waste paper pulp | Obtained through waste-paper recycling involving mixing of used paper with water and chemicals to break it down. | Manufacturing of paper-based and industrial materials, e.g., books, filters, etc. | [17,102] |

| Spent coffee grounds | Gums (xanthan and guar) | It is obtained from sugary substrates. | It is widely used as a thickening and gelling additive in the food and feed industries. | [103] |

| Corn stover | biogas-slurry | A by-product of anaerobic digestion produced from biogas plant. | Used in feed and compost making in agriculture. | [104,105] |

| Inorganic binders | ||||

| Corn straw | NovoGro | An industrial by-product from centrifuge fermentation of broth through heating and lime amendment. | Potential uses include bioremediation and soil- improvement purposes. | [106,107] |

| Elephant grass, empty fruit bunch, and wood residues | Thermo plastics, e.g., polyethylene terephthalate and high-density polyethylene. | Waste from food and other material packaging, storage, or container. | For recycling and production of plastic-based items. | [108,109,110,111] |

5. Briquette Quality Parameters

The production of briquettes is usually followed by storage, transportation, handling, and usage. The briquettes often experience different levels of degradation during transportation, storage, and handling due to action of forces (including impact, shear, and compressive) from different equipment acting on the product as well as the influences of environmental factors, such as humidity and rain, leading to swelling and structural losses [112]. Standards are used in assessing quality differences between materials, processes and products, and they provide information on the expected level of performance from products to potential users. The quality and suitability of briquettes for energy use are generally measured by means of some physical and mechanical properties. The most important biomass briquette quality factors include its resistance to crushing (compressive strength), durability (abrasion resistance), impact resistance, and water penetration resistance that are all influenced by the density of briquettes [99,113,114,115].

5.1. Compressive Strength

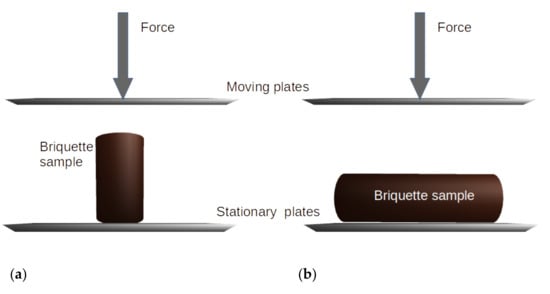

Compressive strength simulates the maximum compressive force a briquette can withstand during transportation, handling and storage. For densified biomaterial, compressive strength is defined as the maximum axial force it could withstand until fracture or rupture, or a measure of its internal bonding strength [116]. If the force is applied perpendicular to the cylinder axis, the resultant measurement is referred to as tensile strength. Bazargan, Rough and McKay [15] noted that, in general, briquette strength is higher in the cylindrical axis direction (compressive strength) compared to the strength of the briquette when measured perpendicular to the cylindrical axis (tensile strength) (Figure 5a,b). This presents a basis to argue that determining tensile strength might be more appropriate for briquettes, as noted in Gilvari, de Jong and Schott [7].

Figure 5.

Typical orientation of biomass briquette sample during (a) compressive strength, and (b) tensile strength testing.

Different equipment with similar working principles can be used to measure the compressive strength of biomass briquettes [33,117,118]. The sample material is placed between two horizontal plates and the sample is compressed at a constant rate until fracture or breakage. The rate of application of pressure on the plates, however, varies in the literature and this potentially makes it difficult to compare the strength of biomass briquettes. In particular, the relationship between compression rate and compressive/tensile strength is missing in the literature [7]. Other methods have also been explored in expressing the strength of biomass briquettes and they include hardness (a measure of the force required to break or disintegrate a briquette) [119], and bending strength—the maximum force a material can withstand in bending when concentrated on a spot [120]. However, compressive strength of briquettes has remained the preferred quality parameter of choice in the literature [121,122,123,124].

5.2. Abrasion Resistance (Mechanical Durability)

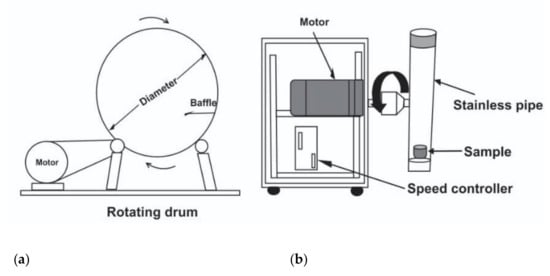

Abrasion resistance is a measure of briquettes ability to remain intact under the influence of abrasive forces during handling, storage, and transportation [125]. Information on biomass briquette durability is important in mitigating against dust generation and possible dust explosion. Two different equipment is widely used in the literature for determining the durability of biomass briquettes, and they include rotating drum and tumbler. The rotating drum (Figure 6a) consists of a cylindrical chamber with baffles inside which rotates around its axial direction [7] while a tumbler (Figure 6b) generally consists of a tubular vessel, a rotation speed-setting devices and a motor; the tubular vessel rotates against its cylindrical axis [126]. A cuboid formed using angle iron frame rotated by means of a hollow shaft fixed diagonally through it has also been used as a tumbler [99]. The general operating principle entails placing a known mass of briquette sample in the device, which exposes them to shocks and abrasion for a specified period of time and rotational speed. Durability is then calculated as a percentage of the mass loss obtained through sieving divided by the initial mass of the sample.

Figure 6.

(a) Rotating drum adapted from [7] and (b) schematic of a tumbler adapted from [126].

Severy, et al. [127] placed nine briquettes in a 572 mm diameter cylindrical tumbler rotating at 21 rpm for 5 min. After tumbling, all the material remaining on a 50.8 mm mesh sieve was weighed as the durable fraction of the briquettes. Tumuluru, et al. [128] in their study tumbled 10 briquettes in a tumbling durability tester for 3 min at 40 rpm. Ţenu, Roman, Senila, Roşca, Cârlescu, Băetu, Arsenoaia, Dumitrachi, and Corduneanu [125] used a rotating drum of 598 mm in length and 598 mm diameter. The drum was rotated at 21 rev/min for a total of 5 min. The durability of the briquettes was expressed as a ratio of the initial weight of the briquette to its final weight not passing a 45 mm sieve. Granado, et al. [129] rotated cassava residue briquettes in a rotating drum at a speed of 35 rpm for 15 min after which the briquette was passed through a sieve of 2.36 mm. The mass of the briquette retained on the sieve was used to calculate the durability of the briquette.

Information in the literature suggest that there is no single recognized procedure for assessing the abrasion resistance of biomass briquettes that allows for comparability of different briquettes. Irrespective of the equipment used, researchers often use different rotational speeds and different sieve sizes to obtain the mass loss, making it difficult to compare reported values. An increase or decrease in operation time and rotational speed of the working chamber of durability devices, for example, could influence the durability of briquettes [130]. Temmerman, et al. [131], in an earlier study comparing the durability of densified briquettes, reported that the durability of briquettes was influenced by measurement methods. This therefore necessitates the need for a standardized methodology for measuring biomass briquette durability that could be compared among different briquette types. An initial attempt in developing a standard device for determining the durability of briquettes is reported in Obidziński, et al. [132].

5.3. Impact Resistance

The impact resistance of briquettes measures their resistance to breakage when dropped from a specified test height onto a floor of known material surface. The percentage weight loss is reported as a measure of the briquette resistance to impact. The resistance is mostly influenced by the binding strength of the briquette material. In the literature, impact resistance is also referred to as shattering resistance, shattering test, or drop test [99,133]. Impact resistance is important in understanding the behavior of briquettes during unloading or emptying onto ground surfaces or transferring from chutes into bins.

Impact resistance index (IRI) introduced by Richards [113] remains prominent in the literature. IRI is based on the percentage ratio of average number of times a biomass briquette is dropped on a concrete floor from a specified height of 2 m until it fractures to the average number of resulting pieces the briquette breaks into. Richards [113] recommends a minimum acceptable IRI of 50 for biomass briquettes produced for domestic and industrial applications. Saikia and Baruah [134] dropped rice straw, banana leaf, and teak leaf briquettes twice from a height of 1.83 m onto a concrete floor. The authors reported an impact resistance index of 200. Okot, et al. [135] and Okot, et al. [136] determined the impact resistance of biomass briquettes by allowing them to fall under gravity four times from a height of 1.85 m onto a metallic plate. Percentage residual weight of the briquettes was determined after each drop and the piece with the highest weight was used for the next drop until the fourth. The impact resistance was expressed as a percentage of the final weight to the initial weight. Sawadogo, et al. [137] followed the procedure described by Richards [113], however the number of times the briquettes were dropped from a height of 2 m and the nature of the ground surface were not stated.

Sunnu, Adu-Poku, and Ayetor [114] determined the IRI of biomass briquettes from agricultural wastes by dropping the briquettes five times from a height of 2 m onto a concrete surface. After five drops, the broken pieces of briquettes because of the impact were collected and weighed, however, only the pieces that weighed 5% or more of the initial weight were considered when calculating the IRI following Equation (1).

N is the number of drops and n is the number of pieces that weighed 5% or more of the initial weight of the briquette after N drops. For composite briquette of coal and wood fines, Adeleke, Odusote, Ikubanni, Lasode, Malathi, and Pasawan [115] dropped three samples of the composite briquettes from a height of 2 m until fracture. The number of drops was however divided by the drop height and the IRI expressed as in Equation (2).

It is clear that while the impact resistance of biomass briquettes entails a free fall from a known height onto a specified surface, the number of drops, the height of fall, and the selection of the resulting pieces due to the impact forces are not consistent in the literature. Even in comparing similar briquettes, the number of drops were varied [33]. Until there is consistency in the procedure for calculating impact resistance, comparability of briquette quality on this basis will remain unrealistic, leaving users to subjectively assess the impact resistance of briquettes based on usage experience.

5.4. Water Penetration Resistance

Biomass-based materials are hydrophilic in nature and so are biomass briquettes; some biomass-based briquettes are very sensitive to moisture and a small amount of water could significantly decrease their quality [7,138]. In the literature, water-resistance ability of biomass briquettes is measured by a water-immersion test done in the laboratory as opposed to the open environment. This quality parameter is particularly important for the storage and transportation of briquettes in high humid environment or when exposed to rain. While moisture adsorption test (to determine the amount of moisture a sample can adsorb under constant temperature and humidity) is common with pellets, it is rarely applied to briquettes [7,139].

Fadele, et al. [140] and Anggraeni, et al. [141] measured the water resistance of biomass briquettes by immersing them in a water bath for two minutes and calculating the percentage of water absorbed using Equation (3). The water resistance of the briquettes was then determined by subtracting the percentage water absorbed from 100.

where is the mass of the hydrated briquette (g) and is the initial mass of the briquette before hydration (g). Other researchers immersed the briquettes in water for 30 s at room temperature [142,143]. In some studies, water resistance has been expressed as a measure of time taken before the onset of dispersion of briquettes when immersed in water at room temperature [58,144,145].

One key factor that influences the water resistance of briquettes is the amount of binding agent used in the briquette making, particularly hydrophobic binders [140]. Researchers have reported significant influence of binders on the water resistance of biomass briquettes [39,99]. The increased water resistance of briquettes has been linked to the increasing interlocking of the briquette particles thus resulting in negligible pore spaces as binder quantity is increased [140]. Similarly, briquettes with large particle sizes exhibit poor water resistance due to their porous nature thus allowing for easy water penetration [141]. Other factors influencing water resistance of briquettes include briquetting temperature and holding time [142].

At the moment, there is no uniform standard or procedure for assessing the water-resistance capability of briquettes; the closest to uniformity appears to be a measure of the time before the onset of dispersion of briquettes when immersed in water. A standard method could help provide a more realistic expectation on the condition of briquettes when stored in different environmental conditions.

5.5. Briquette Density

The density of briquettes can be expressed as either compressed density or relaxed density. The compressed density is the density of the briquette just immediately after compaction while the relaxed density represents the density measured after a certain period following compaction. These density measures have become an important factor due to the possible volume expansion or shrinkage of briquettes in the axial and lateral directions immediately after densification. Relaxation ratio is often used to measure the relative expansion or shrinkage of briquettes after production. It is expressed as the ratio of the compressed density to the relaxed density [30,146].

Density itself is generally measured as the ratio of mass and sample volume, which includes the existing pore volume. The compressed density of briquettes is generally determined immediately after ejection from the briquetting machine as the ratio of measured weight to the calculated volume [146]. For relaxed density, Mitchual, Frimpong-Mensah, and Darkwa [117] it for sawdust briquettes 30 days after densification. The mass of the briquettes was determined using a laboratory electronic balance and the dimensions measured using a digital vernier caliper. Other studies measured the relaxed density after the briquette reached a constant moisture constant following densification [30]. The density of biomass briquettes could be significantly influenced by a number of process variables, including moisture content, particle size, quantity of binder, compaction temperature, and pressure [11,92,147].

The bulk density of a group of briquettes has also been reported; it is an important property of briquettes for packaging, transportation, and storage efficiency. Karunanithy, et al. [148] measured the bulk density of briquettes using 2000 mL glass container following the procedure described in [149]. The bulk density was calculated from the mass of the briquettes that occupied the container. Brand, et al. [150] measured the bulk density of briquettes by means of geometric measurements suggesting that the bulk density of cylindrical shaped briquettes can be calculated using their individual dimensions. Bulk density of briquettes should however be regarded as a dynamic property rather than static as they are not dependent only on the biomass material but on the briquette arrangement, container material and its surface roughness, the capacity of the container, the filling method, and the density measurement method [7,151].

6. Briquette Utilization in Developing Economies

Generally, biomass energy has continued to remain the preferred alternative in meeting rural heating energy requirement in most developing countries [9]. This is mainly due to the benefits it potentially offers including driving rural bio-economic activities (such as establishing new markets, creating new job opportunities, etc.), environmental benefits (carbon neutrality, and improved waste management), and increased energy independence [23,152]. Further, it leads to improved use of locally available biomass resources, thus contributing to better and sustainable living condition [153].

Biomass briquette is used extensively for household heating applications and power generation in Europe, America, and some parts of Asia, but its use in some developing countries (e.g., Sub-Saharan Africa) has been significantly limited [154]. Most of the heating energy needs of rural people are met by the direct burning of wood and other loose biomass in three-stone fire and other low-efficiency stoves. The limited production and use of briquettes could be linked to a lack of developed supply chain structure for biomass in both agricultural and forestry-related industries [23,154]. An efficient and structurally developed supply chain is essential in providing appropriate biomass in a sustainable manner for the production and development of markets for biomass briquettes. The financial viability of biomass briquetting is largely dependent on the cost of the feedstock which is influenced by the location, type of biomass, and, on a broader scope, the existence of efficient supply chain networks [155]. Typical supply chain structure would comprise primary biomass producers/suppliers (household owners, wood processors, forest owners, etc.), intermediaries or purchasing agents, briquette enterprises, and the briquette fuel users.

The lack of appropriate government-backed policies (laws, regulations, and standards) that could drive biomass energy use in rural areas is another factor affecting the wide spread use of abundant biomass for briquette production. Nguyen, et al. [156] highlighted two important issues that need to be addressed by governments of developing countries, and they include policy and regulatory uncertainties, and high investment risks. Shen, et al. [157] suggest that the adoption of cleaner fuels may require more research evidences on its potential economic, environmental, and health benefits that could provide references for policy-makers. The literature, however, is filled with a plethora of data on the positive impacts of biofuels. While some countries have adopted the use of densified biomass on industrial scale, its use in some countries is limited. The level and scale of biomass briquette adoption could be a case of individual government priority. Policy-based issues that require government attention include enforcement of existing forestry regulations, ease of setting up briquette businesses, tax exemptions, and creating new markets for biomass briquettes [158].

Another key factor limiting the development of biomass briquette industry is the lack of appropriate technology suitable for developing bio-economies. While attempts have been made at developing low-cost briquetting machines [144,159], they often lack the capacity for commercial-scale production and may not meet the quality requirements for commercial briquettes. Encouraging and supporting the development and transfer of appropriate technologies remain an effective strategy for the rapid development of biomass briquette driven rural bioeconomy. In addition, appropriate briquetting machines must be followed up with commercially available improved cook stoves that are both appropriate for the target users in terms of culture, burning efficient, emissions, and convenience [157]. Both market development and appropriate briquette technology could significantly influence the wide adoption of biomass briquettes [160]. The governments through strategic education and sensitization programs must carefully address issues, such as technical specification and standardization, proper installation and use of briquetting machines and cook stoves, and potential health and environmental benefits from the use of briquettes.

7. Conclusions and Future Research Direction

Biomass briquetting technology has continued to remain an important part of global bioenergy supply, particularly for heating application and power generation both in developing and developed economies. Beyond household heating applications, the briquetting of loose biomass into solid fuel makes the materials suitable for further energy applications, including biochemical, thermochemical, and co-firing applications. The cohesion ability of densified biomass is significantly influenced by the use of binders, which could be organic, inorganic or composite, and they could further influence the overall cost of briquette production. This becomes significantly important for low-lignin-content biomass, thus making the identification and selection of binders a significant process in biomass briquetting.

The important quality parameters of biomass briquettes include compressive strength, mechanical, impact- and water-resistance, and briquette density, and are measured using different standard measurement procedures. This makes it difficult comparing different biomass briquettes based on these quality parameters. There is the urgent need for the standardization of measurement procedures for biomass briquette quality assessment. The wide production and adoption of biomass briquettes in developing countries has continued to remain limited and the motivation for biomass-driven clean-energy technology is low. However, government incentives through favorable policies in the form of financial support, knowledge, and awareness creation, indigenous and appropriate technology transfer, and improved power supply can significantly improve the development of rural biomass briquette industry in developing economies.

To continue to promote the briquetting of biomass as a sustainable alternative bioenergy option, the standardization of briquette quality measurement will continue to remain an important consideration for both briquette producers and consumers. This thus presents a relatively broad scope of research opportunities in briquette quality measurement and methods standardization. A key research direction in this regards is identifying how different quality measurement methodologies influence measured quality parameters of briquettes using a wide range of biomass types. Furthermore, identifying and or developing methodologies that reflect the true quality of briquettes, which could serve as standard procedures for measuring key biomass briquette quality parameters, could help address the long established problem of comparability of briquettes from difference biomass. It is important that standard procedures developed for biomass briquette quality measurement are both effective and simple to carry out without significant technicalities in terms of processes and equipment requirement. This is in consideration that biomass are largely available in rural or developing economies where the briquettes are produced for cost-effectiveness. As such, it should be easy to measure briquette quality parameters at such locations. This could solve the challenge of comparability of briquettes from biomass of different types and production processes.

While important biomass briquette quality parameters are discussed in this study, the quality requirements for the future may differ from what it is today. This is because biomass briquette production needs, processes, and utilization routes are constantly improving and changing with the discovery of new options. Research in this direction will need to keep evolving with new demand from the industry. Ultimately, the future quality requirement for briquettes will be determined by the needs of the industry and consumers utilizing the briquettes for various bioenergy purposes.

Author Contributions

Conceptualization, O.F.O. and R.P.; methodology, O.F.O.; resources, O.F.O. and R.P.; writing—original draft preparation, O.F.O., R.P. and M.J.C.; writing—review and editing, O.F.O., R.P. and M.J.C.; supervision, R.P.; funding acquisition, O.F.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Alexander von Humboldt Foundation, Bonn, Germany. The publication of this article was funded by the Open Access Fund of the Leibniz Association.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- IEA. International Energy Agency World Energy Outlook. 2021. Available online: https://iea.Blob.Core.Windows.Net/assets/4ed140c1-c3f3-4fd9-acae-789a4e14a23c/worldenergyoutlook2021.Pdf (accessed on 13 November 2021).

- Hoang, A.T.; Nguyen, X.P. Integrating renewable sources into energy system for smart city as a sagacious strategy towards clean and sustainable process. J. Clean. Prod. 2021, 305, 127161. [Google Scholar] [CrossRef]

- Atabani, A.; Tyagi, V.K.; Fongaro, G.; Treichel, H.; Pugazhendhi, A.; Hoang, A.T. Integrated Biorefineries, Circular Bio-Economy, and Valorization of Organic Waste Streams with Respect to Bio-Products; Springer: Berlin/Heidelberg, Germany, 2021; p. 1. [Google Scholar]

- Hoang, A.T.; Ong, H.C.; Fattah, I.R.; Chong, C.T.; Cheng, C.K.; Sakthivel, R.; Ok, Y.S. Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process. Technol. 2021, 223, 106997. [Google Scholar] [CrossRef]

- Hoang, A.T. 2-methylfuran (mf) as a potential biofuel: A thorough review on the production pathway from biomass, combustion progress, and application in engines. Renew. Sustain. Energy Rev. 2021, 148, 111265. [Google Scholar] [CrossRef]

- Carter, E.; Shan, M.; Zhong, Y.; Ding, W.; Zhang, Y.; Baumgartner, J.; Yang, X. Development of renewable, densified biomass for household energy in china. Energy Sustain. Dev. 2018, 46, 42–52. [Google Scholar] [CrossRef]

- Gilvari, H.; de Jong, W.; Schott, D.L. Quality parameters relevant for densification of bio-materials: Measuring methods and affecting factors-a review. Biomass Bioenergy 2019, 120, 117–134. [Google Scholar] [CrossRef]

- Chaney, J.; Clifford, M.; Wilson, R. On the heat pulse method for the determination of the thermal properties of biomass briquettes. Int. Rev. Mech. Eng. 2012, 6, 277–283. [Google Scholar]

- Chaney, J.; Clifford, M.; Wilson, R. An experimental study of the combustion characteristics of low-density biomass briquettes. Biomass Mag. 2010, 1, 1–8. [Google Scholar]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Dinesha, P.; Kumar, S.; Rosen, M.A. Biomass briquettes as an alternative fuel: A comprehensive review. Energy Technol. 2019, 7, 1801011. [Google Scholar] [CrossRef]

- Marreiro, H.M.; Peruchi, R.S.; Lopes, R.M.; Andersen, S.L.; Eliziário, S.A.; Rotella Junior, P. Empirical studies on biomass briquette production: A literature review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Jiang, L.; Yuan, X.; Xiao, Z.; Liang, J.; Li, H.; Cao, L.; Wang, H.; Chen, X.; Zeng, G. A comparative study of biomass pellet and biomass-sludge mixed pellet: Energy input and pellet properties. Energy Convers. Manag. 2016, 126, 509–515. [Google Scholar] [CrossRef]

- Sengar, S.; Mohod, A.; Khandetod, Y.; Patil, S.; Chendake, A. Performance of briquetting machine for briquette fuel. Int. J. Energy Eng. 2012, 2, 28–34. [Google Scholar] [CrossRef]

- Bazargan, A.; Rough, S.L.; McKay, G. Compaction of palm kernel shell biochars for application as solid fuel. Biomass Bioenergy 2014, 70, 489–497. [Google Scholar] [CrossRef]

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A review of densified solid biomass for energy production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Abd Manaf, L.; Roslan, A.M. Evaluation of hybrid briquettes from corncob and oil palm trunk bark in a domestic cooking application for rural communities in Nigeria. J. Clean. Prod. 2021, 284, 124745. [Google Scholar] [CrossRef]

- Sahu, S.G.; Chakraborty, N.; Sarkar, P. Coal–biomass co-combustion: An overview. Renew. Sustain. Energy Rev. 2014, 39, 575–586. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Yancey, N.A.; Kane, J.J. Pilot-scale grinding and briquetting studies on variable moisture content municipal solid waste bales–impact on physical properties, chemical composition, and calorific value. Waste Manag. 2021, 125, 316–327. [Google Scholar] [CrossRef]

- Manirakiza, N.; Ndikumana, T.; Jung, C.G. Towards the promotion of fuel briquettes using municipal solid waste and residual biomass in Burundi. Int. J. Environ. 2020, 9, 14–31. [Google Scholar] [CrossRef]

- Roberts, J.J.; Cassula, A.M.; Prado, P.O.; Dias, R.A.; Balestieri, J.A.P. Assessment of dry residual biomass potential for use as alternative energy source in the party of general pueyrredón, argentina. Renew. Sustain. Energy Rev. 2015, 41, 568–583. [Google Scholar] [CrossRef]

- Vávrová, K.; Knápek, J.; Weger, J. Modeling of biomass potential from agricultural land for energy utilization using high resolution spatial data with regard to food security scenarios. Renew. Sustain. Energy Rev. 2014, 35, 436–444. [Google Scholar] [CrossRef]

- Liu, L.; Wang, D.; Gao, L.; Duan, R. Distributed heating/centralized monitoring mode of biomass briquette fuel in chinese northern rural areas. Renew. Energy 2020, 147, 1221–1230. [Google Scholar] [CrossRef]

- Lin, T.; Rodríguez, L.F.; Davis, S.; Khanna, M.; Shastri, Y.; Grift, T.; Long, S.; Ting, K. Biomass feedstock preprocessing and long-distance transportation logistics. GCB Bioenergy 2016, 8, 160–170. [Google Scholar] [CrossRef]

- Nunes, L.J.; Matias, J.C.; Loureiro, L.M.; Sá, L.C.; Silva, H.F.; Rodrigues, A.M.; Causer, T.P.; DeVallance, D.B.; Ciolkosz, D.E. Evaluation of the potential of agricultural waste recovery: Energy densification as a factor for residual biomass logistics optimization. Appl. Sci. 2021, 11, 20. [Google Scholar] [CrossRef]

- Zakaria, I.H.; Ibrahim, J.A.; Othman, A.A. Introducing Briquette Storage System in Value Chain of Oil Palm Fiber Waste for Optimal Electricity Grid Supply: Biogas. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; p. 020156. [Google Scholar]

- Rezania, S.; Din, M.F.M.; Kamaruddin, S.F.; Taib, S.M.; Singh, L.; Yong, E.L.; Dahalan, F.A. Evaluation of water hyacinth (eichhornia crassipes) as a potential raw material source for briquette production. Energy 2016, 111, 768–773. [Google Scholar] [CrossRef]

- Chungcharoen, T.; Srisang, N. Preparation and characterization of fuel briquettes made from dual agricultural waste: Cashew nut shells and areca nuts. J. Clean. Prod. 2020, 256, 120434. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A.; Muhairwe, F.; Kihedu, J. Physical and combustion properties of agricultural residue bio-char bio-composite briquettes as sustainable domestic energy sources. Renew. Energy 2020, 148, 1002–1016. [Google Scholar] [CrossRef]

- Obi, O.F. Evaluation of the physical properties of composite briquette of sawdust and palm kernel shell. Biomass Convers. Biorefin. 2015, 5, 271–277. [Google Scholar] [CrossRef]

- Mani, S.; Sokhansanj, S.; Bi, X.; Turhollow, A. Economics of producing fuel pellets from biomass. Appl. Eng. Agric. 2006, 22, 421–426. [Google Scholar] [CrossRef]

- Oyelaran, O.A.; Bolaji, B.O.; Waheed, M.A.; Adekunle, M.F. Performance evaluation of the effect of binder on groundnut shell briquette. Appl. Sci. Eng. Prog. 2015, 8, 11–19. [Google Scholar] [CrossRef]

- Kivumbi, B.; Jande, Y.A.; Kirabira, J.B.; Kivevele, T.T. Production of carbonized briquettes from charcoal fines using African elemi (Canarium schweinfurthii) resin as an organic binder. In Energy Sources, Part A: Recovery, Utilization, and Environmental Effects; Taylor Francis: Abingdon-on-Thames, UK, 2021; pp. 1–17. [Google Scholar]

- Montiano, M.; Fernández, A.; Díaz-Faes, E.; Barriocanal, C. Tar from biomass/coal-containing briquettes. Evaluation of pahs. Fuel 2015, 154, 261–267. [Google Scholar] [CrossRef]

- Anukam, A.; Berghel, J.; Henrikson, G.; Frodeson, S.; Ståhl, M. A review of the mechanism of bonding in densified biomass pellets. Renew. Sustain. Energy Rev. 2021, 148, 111249. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Jen, T.-C.; Mahamood, R.M.; Akinlabi, E.T. Densification of agro-residues for sustainable energy generation: An overview. Bioresour. Bioprocess. 2021, 8, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Manickam, I.N.; Ravindran, D.; Subramanian, P. Biomass densification methods and mechanism. Cogener. Distrib. Gener. J. 2006, 21, 33–45. [Google Scholar] [CrossRef]

- Samuelsson, R.; Larsson, S.H.; Thyrel, M.; Lestander, T.A. Moisture content and storage time influence the binding mechanisms in biofuel wood pellets. Appl. Energy 2012, 99, 109–115. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, Y.; Xu, Y. Review of briquette binders and briquetting mechanism. Renew. Sustain. Energy Rev. 2018, 82, 477–487. [Google Scholar] [CrossRef]

- Han, H.; Duan, D.; Yuan, P. Binders and bonding mechanism for rhf briquette made from blast furnace dust. ISIJ Int. 2014, 54, 1781–1789. [Google Scholar] [CrossRef]

- Miao, Z.; Zhang, P.; Li, M.; Wan, Y.; Meng, X. Briquette preparation with biomass binder. In Energy Sources, Part A: Recovery, Utilization, and Environmental Effects; Taylor Francis: Abingdon-on-Thames, UK, 2019; pp. 1–11. [Google Scholar]

- Yun, Z.; Dongsheng, F.; Huaan, Z.; Yang, Y.; Wenjing, W. Research progress of briquette binder. Clean Coal Technol. 2014, 20, 24–28. [Google Scholar]

- Shu, M.Y.; Yin, H.Y.; Liu, G.H. In Experimental researches on composite bentonite-based briquette binder. Adv. Mater. Res. 2012, 496, 276–280. [Google Scholar] [CrossRef]

- Chukwuneke, J.; Umeji, A.; Obika, E.; Fakiyesi, O. Optimization of composite briquette made from sawdust/rice husk using starch and clay binder. Int. J. Integr. Eng. 2021, 13, 208–216. [Google Scholar]

- Gebresas, A.; Asmelash, H.; Berhe, H.; Tesfay, T. Briquetting of charcoal from sesame stalk. J. Energy 2015, 2015, 1–6. [Google Scholar] [CrossRef]

- Afsal, A.; David, R.; Baiju, V.; Suhail, N.M.; Parvathy, U.; Rakhi, R. Experimental investigations on combustion characteristics of fuel briquettes made from vegetable market waste and saw dust. Mater. Today Proc. 2020, 33, 3826–3831. [Google Scholar] [CrossRef]

- Deshannavar, U.B.; Hegde, P.G.; Dhalayat, Z.; Patil, V.; Gavas, S. Production and characterization of agro-based briquettes and estimation of calorific value by regression analysis: An energy application. Mater. Sci. Energy Technol. 2018, 1, 175–181. [Google Scholar] [CrossRef]

- Buravchuk, N.; Gur’yanova, O. Technology for the joint briquetting of waste coal and sawdust. Solid Fuel Chem. 2018, 52, 308–312. [Google Scholar] [CrossRef]

- Olugbade, T.; Ojo, O.; Mohammed, T. Influence of binders on combustion properties of biomass briquettes: A recent review. BioEnergy Res. 2019, 12, 241–259. [Google Scholar] [CrossRef]

- Aransiola, E.; Oyewusi, T.; Osunbitan, J.; Ogunjimi, L. Effect of binder type, binder concentration and compacting pressure on some physical properties of carbonized corncob briquette. Energy Rep. 2019, 5, 909–918. [Google Scholar] [CrossRef]

- Shone, C.; Jothi, T. Preparation of gasification feedstock from leafy biomass. Environ. Sci. Pollut. Res. 2016, 23, 9364–9372. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A. Characteristics of briquettes developed from rice and coffee husks for domestic cooking applications in Uganda. Renew. Energy 2018, 118, 43–55. [Google Scholar] [CrossRef]

- Muazu, R.I.; Stegemann, J.A. Biosolids and microalgae as alternative binders for biomass fuel briquetting. Fuel 2017, 194, 339–347. [Google Scholar] [CrossRef]

- Gill, N.; Dogra, R.; Dogra, B. Influence of moisture content, particle size, and binder ratio on quality and economics of rice straw briquettes. BioEnergy Res. 2018, 11, 54–68. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Muazu, R.I.; Stegemann, J.A. Effects of operating variables on durability of fuel briquettes from rice husks and corn cobs. Fuel Process. Technol. 2015, 133, 137–145. [Google Scholar] [CrossRef]

- Petricoski, S.M.; Feiden, A.; de Oliveira, A.F.; Tokura, L.K.; Siqueira, J.A.C.; Bonassa, G.; Zilli, B.M.; Gentelini-Marquez, D.P.; de Souza, S.N.M.; Feiden, E. Briquettes produced with a mixture of urban pruning waste, glycerin and cassava processing residue. J. Agric. Sci. 2020, 12, 158–169. [Google Scholar] [CrossRef]

- Samomssa, I.; Nono, Y.J.; Cârâc, G.; Gurău, G.; Dinică, M.R.; Kamga, R. Optimization of fuel briquette production from cassava peels, plantain peels and corn cobs. J. Mater. Cycles Waste Manag. 2021, 2021, 1–13. [Google Scholar] [CrossRef]

- Wongwuttanasatian, T.; Sakkampang, C. Combustion characteristics and emission of briquette fuel from biomass mixed with glycerin. Combust. Sci. Technol. 2016, 188, 1011–1019. [Google Scholar] [CrossRef]

- Raslavičius, L. Characterization of the woody cutting waste briquettes containing absorbed glycerol. Biomass Bioenergy 2012, 45, 144–151. [Google Scholar] [CrossRef]

- Helwani, Z.; Ramli, M.; Rusyana, A.; Marlina, M.; Fatra, W.; Idroes, G.M.; Suhendra, R.; Ashwie, V.; Mahlia, T.M.I.; Idroes, R. Alternative briquette material made from palm stem biomass mediated by glycerol crude of biodiesel byproducts as a natural adhesive. Processes 2020, 8, 777. [Google Scholar] [CrossRef]

- De Almeida Moreira, B.R.; da Silva Viana, R.; Moreira, S.D.; dos Santos Lima, M.; Magalhães, A.C.; Miasaki, C.T.; Caraschi, J.C. Biomass-glycerol briquettes are not necessarily mechanically stable and energetically effective. Waste Dispos. Sustain. Energy 2020, 2, 291–303. [Google Scholar] [CrossRef]

- Ayoub, M.; Abdullah, A.Z. Critical review on the current scenario and significance of crude glycerol resulting from biodiesel industry towards more sustainable renewable energy industry. Renew. Sustain. Energy Rev. 2012, 16, 2671–2686. [Google Scholar] [CrossRef]

- Hartini, S.; Puspitasari, D.; Aisy, N.R.; Widharto, Y. In Eco-efficiency level of production process of waste cooking oil to be biodiesel with life cycle assessment. E3S Web of Conf. 2020, 202, 10004. [Google Scholar] [CrossRef]

- Bala-Litwiniak, A.; Radomiak, H. Possibility of the utilization of waste glycerol as an addition to wood pellets. Waste Biomass Valoriz. 2019, 10, 2193–2199. [Google Scholar] [CrossRef]

- Bertoft, E. Understanding starch structure: Recent progress. Agronomy 2017, 7, 56. [Google Scholar] [CrossRef]

- Ai, Y.; Jane, J.-L. Understanding starch structure and functionality. In Starch in Food; Elsevier: Amsterdam, The Netherlands, 2018; pp. 151–178. [Google Scholar]

- Zobel, H.F. Gelatinization of starch and mechanical properties of starch pastes. In Starch: Chemistry and Technology; Elsevier: Amsterdam, The Netherlands, 1984; pp. 285–309. [Google Scholar]

- Velusamy, S.; Subbaiyan, A.; Thangam, R.S. Combustion characteristics of briquette fuels from sorghum panicle–pearl millets using cassava starch binder. Environ. Sci. Pollut. Res. 2021, 28, 21471–21485. [Google Scholar] [CrossRef] [PubMed]

- Okwu, M.O.; Samuel, O.D. Adapted hyacinth briquetting machine for mass production of briquettes. Energy Sources Part A Recovery Util. Environ. Effects 2018, 40, 2853–2866. [Google Scholar] [CrossRef]

- Borowski, G.; Stępniewski, W.; Wójcik-Oliveira, K. Effect of starch binder on charcoal briquette properties. Int. Agrophys. 2017, 31, 571. [Google Scholar] [CrossRef]

- Wirabuana, A.D.; Alwi, R.S. Influence of starch binders composition on properties of biomomass briquettes from durian peel (durio kutejensis becc). In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2021; p. 020020. [Google Scholar]

- Haykiri-Acma, H.; Yaman, S.; Kucukbayrak, S. Production of biobriquettes from carbonized brown seaweed. Fuel Process. Technol. 2013, 106, 33–40. [Google Scholar] [CrossRef]

- Nagarajan, D.; Varjani, S.; Lee, D.-J.; Chang, J.-S. Sustainable aquaculture and animal feed from microalgae–nutritive value and techno-functional components. Renew. Sustain. Energy Rev. 2021, 150, 111549. [Google Scholar] [CrossRef]

- Ververis, C.; Georghiou, K.; Danielidis, D.; Hatzinikolaou, D.; Santas, P.; Santas, R.; Corleti, V. Cellulose, hemicelluloses, lignin and ash content of some organic materials and their suitability for use as paper pulp supplements. Bioresour. Technol. 2007, 98, 296–301. [Google Scholar] [CrossRef]

- De OliveiraCosta, T.; Calijuri, M.L.; Avelar, N.V.; de Cassia de Oliveira Carneiro, A.; de Assis, L.R. Energetic potential of algal biomass from high-rate algal ponds for the production of solid biofuels. Environ. Technol. 2017, 38, 1926–1936. [Google Scholar]

- Savage, P.E.; Hestekin, J.A. A perspective on algae, the environment, and energy. Environ. Prog. Sustain. Energy 2013, 32, 877–883. [Google Scholar] [CrossRef]

- Rawat, S.; Kumar, S. Critical review on processing technologies and economic aspect of bio-coal briquette production. Prep. Biochem. Biotechnol. 2021, 23, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Marangon, B.B.; Calijuri, M.L.; de Siqueira Castro, J.; Assemany, P.P. A life cycle assessment of energy recovery using briquette from wastewater grown microalgae biomass. J. Environ. Manag. 2021, 285, 112171. [Google Scholar] [CrossRef] [PubMed]

- Amarasekara, A.; Tanzim, F.S.; Asmatulu, E. Briquetting and carbonization of naturally grown algae biomass for low-cost fuel and activated carbon production. Fuel 2017, 208, 612–617. [Google Scholar] [CrossRef]

- Olbrich, H. The Molasses; Biotechnologie-Kempe GmbH: Kleinmachnow, Germany, 2006; p. 128. [Google Scholar]

- Mordenti, A.L.; Giaretta, E.; Campidonico, L.; Parazza, P.; Formigoni, A. A review regarding the use of molasses in animal nutrition. Animals 2021, 11, 115. [Google Scholar] [CrossRef] [PubMed]

- Ashori, A.; Marashi, M.; Ghasemian, A.; Afra, E. Utilization of sugarcane molasses as a dry-strength additive for old corrugated container recycled paper. Compos. Part B Eng. 2013, 45, 1595–1600. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, J.; Jiang, H. Microbial production of value-added bioproducts and enzymes from molasses, a by-product of sugar industry. Food Chem. 2021, 346, 128860. [Google Scholar] [CrossRef]

- Carnaje, N.P.; Talagon, R.B.; Peralta, J.P.; Shah, K.; Paz-Ferreiro, J. Development and characterisation of charcoal briquettes from water hyacinth (Eichhornia crassipes)-molasses blend. PLoS ONE 2018, 13, e0207135. [Google Scholar] [CrossRef]

- Jittabut, P. Physical and thermal properties of briquette fuels from rice straw and sugarcane leaves by mixing molasses. Energy Procedia 2015, 79, 2–9. [Google Scholar] [CrossRef]

- Sen, R.; Wiwatpanyaporn, S.; Annachhatre, A.P. Influence of binders on physical properties of fuel briquettes produced from cassava rhizome waste. Int. J. Environ. Waste Manag. 2016, 17, 158–175. [Google Scholar] [CrossRef]

- Anatasya, A.; Umiati, N.A.K.; Subagio, A. The effect of binding types on the biomass briquette calorific value from cow manure as a solid energy source. E3S Web Conf. 2019, 125, 13004. [Google Scholar] [CrossRef]

- Rodiah, S.; Al Jabbar, J.; Ramadhan, A.; Hastati, E. Investigation of mango (Mangifera odorate) sap and starch as organic adhesive of bio-briquette. J. Phys. Conf. Ser. 2021, 1943, 012185. [Google Scholar] [CrossRef]

- Karunanayake, K. A qualitative analysis of mango (mangifera indica L.) latex and anatomy of latex canals. J. Sci. 2019, 10, 11–20. [Google Scholar] [CrossRef][Green Version]

- Negi, P.; John, S.K.; Rao, P.U. Antimicrobial activity of mango sap. Eur. Food Res. Technol. 2002, 214, 327–330. [Google Scholar]

- Obi, O.F. Evaluation of the effect of palm oil mill sludge on the properties of sawdust briquette. Renew. Sustain. Energy Rev. 2015, 52, 1749–1758. [Google Scholar] [CrossRef]

- Foo, K.; Hameed, B. Insight into the applications of palm oil mill effluent: A renewable utilization of the industrial agricultural waste. Renew. Sustain. Energy Rev. 2010, 14, 1445–1452. [Google Scholar] [CrossRef]

- Yank, A.; Ngadi, M.; Kok, R. Physical properties of rice husk and bran briquettes under low-pressure densification for rural applications. Biomass Bioenergy 2016, 84, 22–30. [Google Scholar] [CrossRef]

- Bemiller, J.N.; Whistler, R.L.; Barkalow, D.G.; Chen, C.-C. Aloe, chia, flaxseed, okra, psyllium seed, quince seed, and tamarind gums. In Industrial Gums; Elsevier: Amsterdam, The Netherlands, 1993; pp. 227–256. [Google Scholar]

- Rahaman, S.A.; Salam, P.A. Characterization of cold densified rice straw briquettes and the potential use of sawdust as binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Liu, D.; Nikoo, M.; Boran, G.; Zhou, P.; Regenstein, J.M. Collagen and gelatin. Annu. Rev. Food Sci. Technol. 2015, 6, 527–557. [Google Scholar] [CrossRef]

- Su, K.; Wang, C. Recent advances in the use of gelatin in biomedical research. Biotechnol. Lett. 2015, 37, 2139–2145. [Google Scholar] [CrossRef]

- Rajaseenivasan, T.; Srinivasan, V.; Qadir, G.S.M.; Srithar, K. An investigation on the performance of sawdust briquette blending with neem powder. Alex. Eng. J. 2016, 55, 2833–2838. [Google Scholar] [CrossRef]

- Novotnik, B.; Zuliani, T.; Ščančar, J.; Milačič, R. Content of trace elements and chromium speciation in neem powder and tea infusions. J. Trace Elem. Med. Biol. 2015, 31, 98–106. [Google Scholar] [CrossRef]

- Manouchehrinejad, M.; Yue, Y.; de Morais, R.A.L.; Souza, L.M.O.; Singh, H.; Mani, S. Densification of thermally treated energy cane and napier grass. BioEnergy Res. 2018, 11, 538–550. [Google Scholar] [CrossRef]

- Bamisaye, A.; Rapheal, I.A. Effect of binder type on the naoh-treated briquettes produced from banana leaves. Biomass Convers. Biorefin. 2021. [Google Scholar] [CrossRef]

- Espuelas, S.; Marcelino, S.; Echeverría, A.; Del Castillo, J.; Seco, A. Low energy spent coffee grounds briquetting with organic binders for biomass fuel manufacturing. Fuel 2020, 278, 118310. [Google Scholar] [CrossRef]

- Sun, Y.; Ding, N.; Xing, Y. Key techniques and parameters for briquetting corn stover sprayed with biogas slurry in a cold region in china. Energy Sources Part A Recovery Util. Environ. Effects 2016, 38, 1219–1235. [Google Scholar] [CrossRef]

- Zhu, L.; Yan, C.; Li, Z. Microalgal cultivation with biogas slurry for biofuel production. Bioresour. Technol. 2016, 220, 629–636. [Google Scholar] [CrossRef]