Effects of Pre-Crosslinking on Space Charge and Breakdown Characteristics of XLPE Cable Insulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

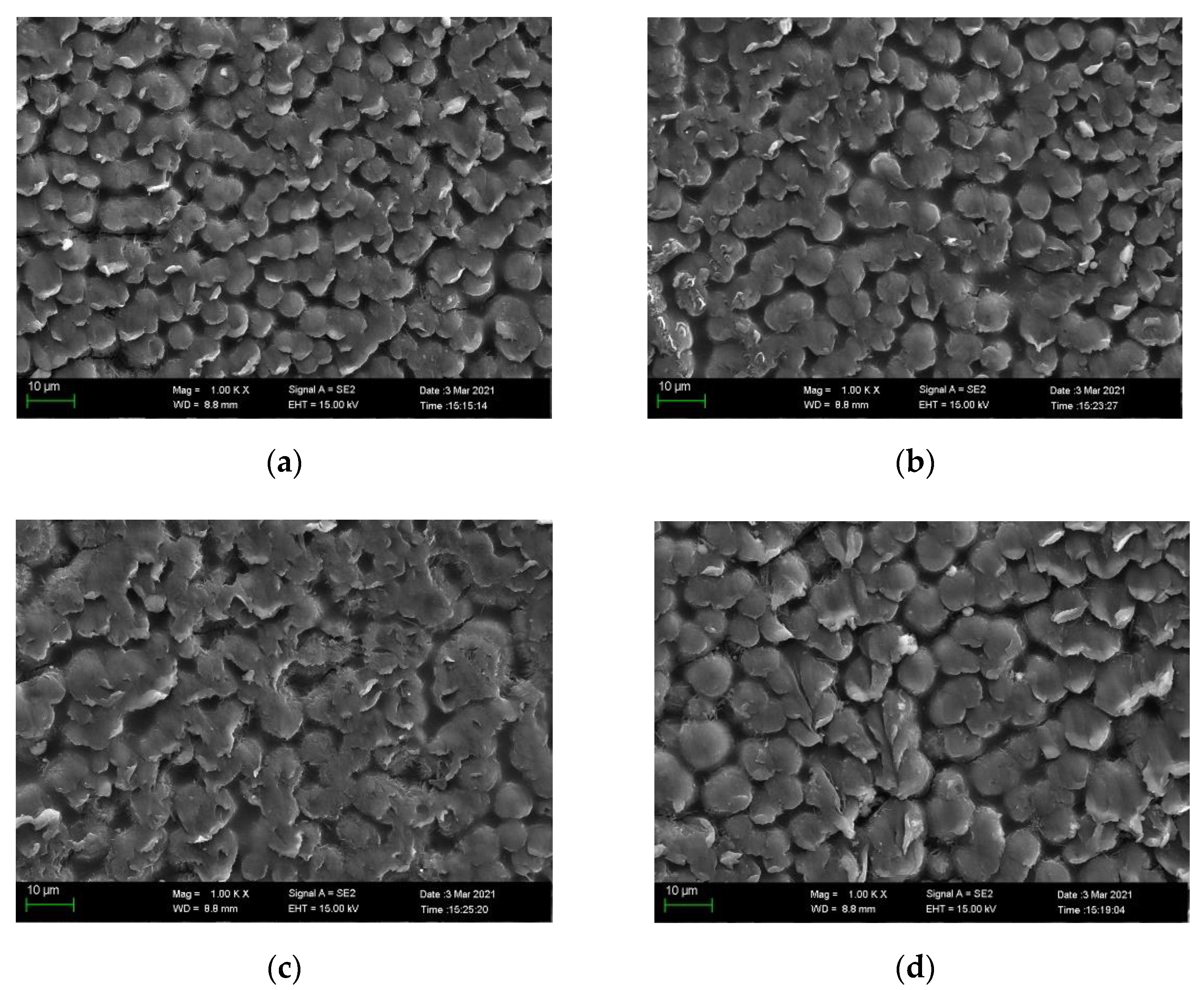

3.1. Effect of Pre-Crosslinking on Crystallization

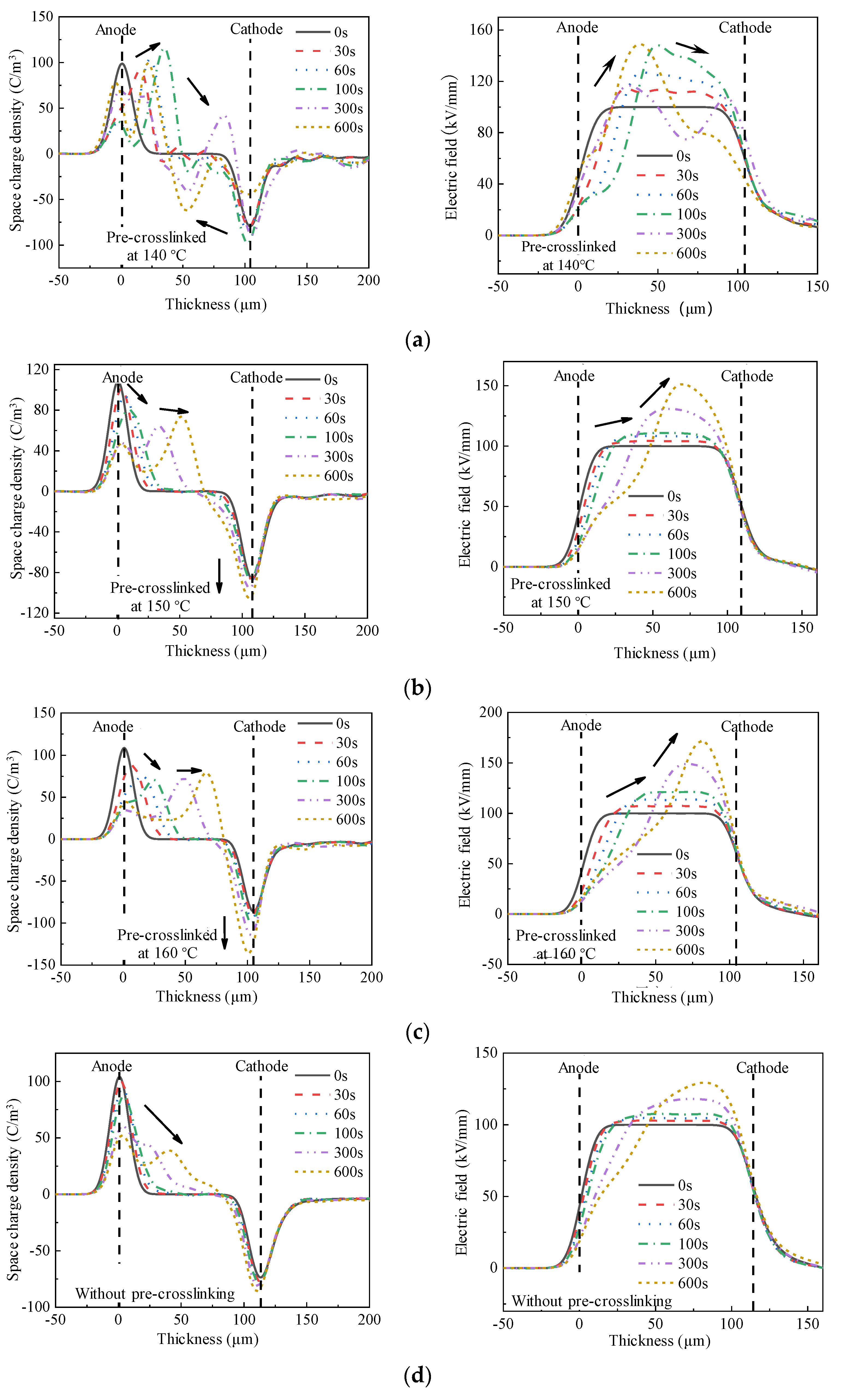

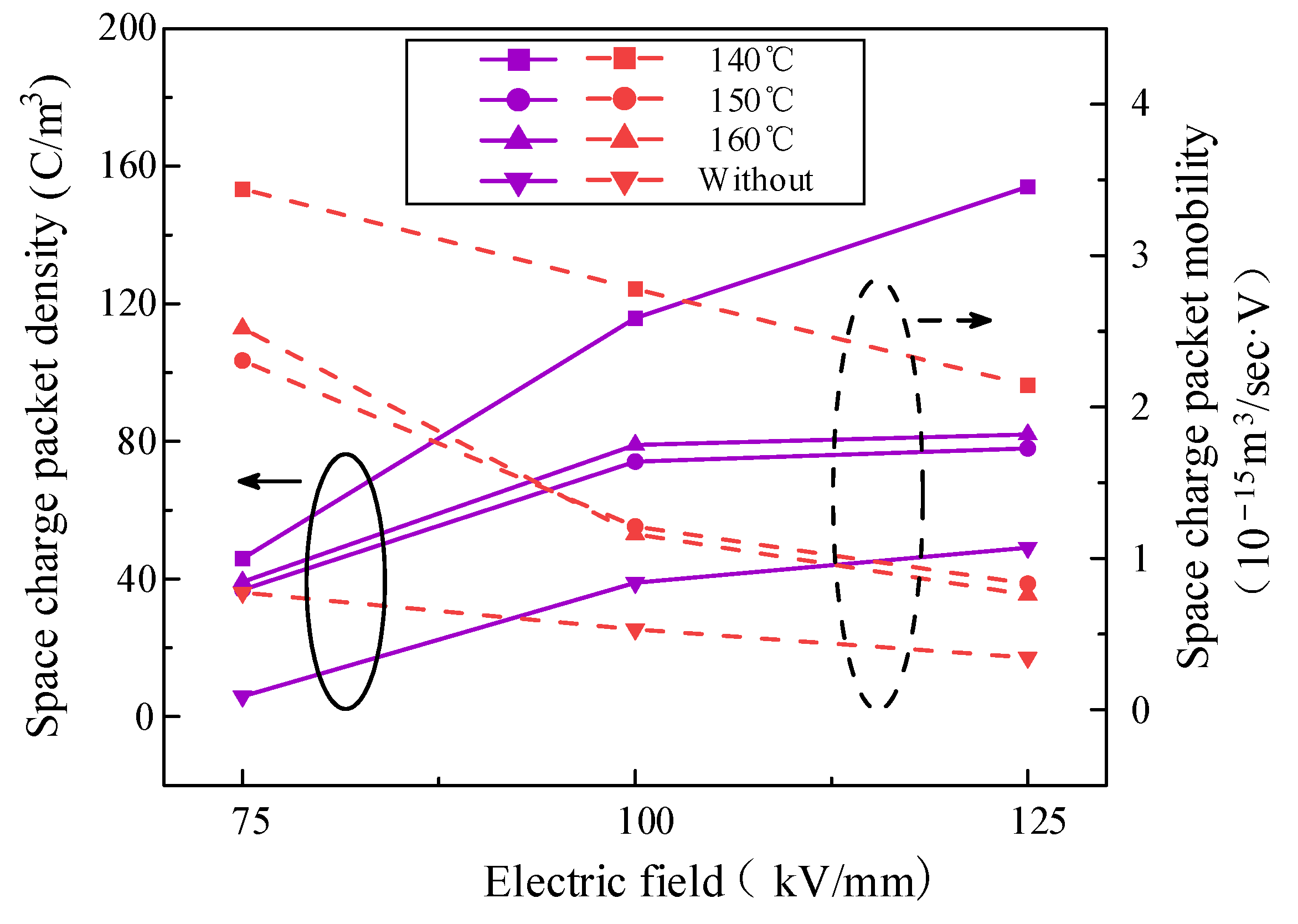

3.2. Effect of Pre-Crosslinking on Space Charge Behaviors

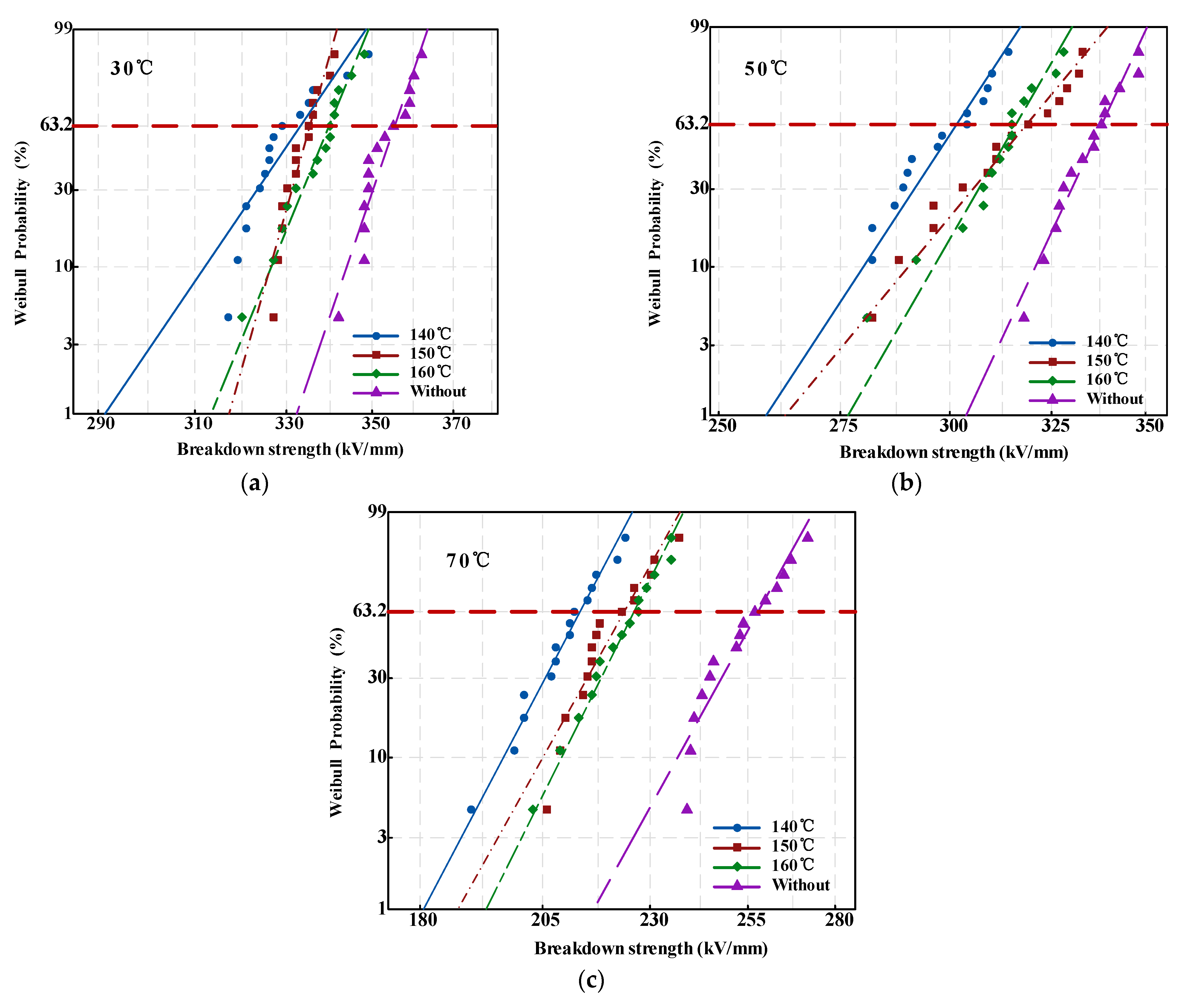

3.3. Effect of Pre-Crosslinking on Breakdown Strength

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Yuan, C.; Li, Q.; Wang, Q.; He, J. Recyclable insulation material for HVDC cables in global energy interconnection. Glob. Energy Interconnect. 2018, 1, 520–526. [Google Scholar]

- Li, Z.L.; Du, B.X. Polymeric insulation for high-voltage DC extruded cables: Challenges and development directions. IEEE Electr. Insul. Mag. 2018, 34, 30–43. [Google Scholar]

- Wang, L.; Nguyen Thi, M.S. Comparative Stability Analysis of Offshore Wind and Marine-Current Farms Feeding into a Power Grid Using HVDC Links and HVAC Line. IEEE Trans. Power Deliv. 2013, 28, 2162–2171. [Google Scholar]

- Ye, H.; Fechner, T.; Lei, X.; Luo, Y.; Zhou, M.; Han, Z.; Wang, H.; Zhuang, Q.; Xu, R.; Li, D. Review on HVDC cable terminations. High Volt. 2018, 3, 79–89. [Google Scholar]

- Huang, X.Y. Perspective on emerging materials for high voltage applications. High Volt. 2020, 5, 229–230. [Google Scholar]

- Kubota, T.; Takahashi, Y.; Sakuma, S.; Watanabe, M.; Kanaoka, M.; Yamanouchi, H. Development of 500kV XLPE Cables and Accessories for Long Distance Underground Transmission Line. IEEE Trans. Power Deliv. 1994, 9, 1741–1749. [Google Scholar]

- Vahedy, V. Polymer insulated high voltage cables. IEEE Electr. Insul. Mag. 2006, 22, 13–18. [Google Scholar]

- Smedberg, A.; Gustafsson, B.; Hjertberg, T. What is crosslinked polyethylene? IEEE Int. Conf. Solid Dielectr. 2004, 415–418. [Google Scholar]

- Precopio, F. The invention of chemically crosslinked polyethylene. IEEE Electr. Insul. Mag. 1999, 15, 23–25. [Google Scholar]

- China Has Developed the First 500 kV Submarine Cable in the World. Available online: http://www.xinhuanet.com/science/2017-12/04/c_136799927.htm (accessed on 4 December 2017).

- Zhong, L.; Ren, H.; Cao, L.; Zhao, W.; Gao, J. Development of High Voltage Direct Current Extruded Cables. High Volt. Eng. 2017, 43, 3473–3489. (In Chinese) [Google Scholar]

- Harlin, A. Model for XLPE Runtime Prediction for Single-Screw and Conical Extruder in CV Line. In Proceedings of the 52nd IWCS/Focus International Wire & Cable Symposium, Philadelphia, PA, USA, 17–20 November 2003; Tampere University of Technology: Tampere, Finland, 2003. [Google Scholar]

- Tanaka, Y.; Chen, G.; Zhao, Y.; Davies, A.E.; Vaughan, A.S.; Takada, T. Effect of additives on morphologyand space charge accumulation in low density polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 148–154. [Google Scholar]

- Montanari, G.C. Bringing an insulation to failure: The role of space charge. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 339–364. [Google Scholar]

- Zhang, Y.; Lewiner, J.; Alquie, C.; Hampton, N. Evidence of strong correlation between space charge buildup and breakdown in cable insulation. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 778–783. [Google Scholar]

- Li, Z.L.; Fan, M.S.; Zhou, S.F.; Du, B.X. BNNS Encapsulated TiO2 Nanofillers Endow Polypropylene Cable Insulation with Enhanced Dielectric Performance. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1238–1246. [Google Scholar]

- Hanley, T.L.; Burford, R.P.; Fleming, R.J.; Barber, K.W. A general review of polymeric insulation for use in HVDC cables. IEEE Electr. Insul. Mag. 2003, 19, 13–24. [Google Scholar]

- Zhou, Q.; Wu, N.; Liao, R.J.; Zhong, L.S.; Ren, H.Y.; Cao, L. Space Charge Characteristics of Cross-linked Polyethylene with Different Cross-linking Degrees. High Volt. Eng. 2013, 39, 294–301. [Google Scholar]

- Zhang, Z.; Zhao, J.; Zhao, W.; Zhong, L.; Hu, L.; Rao, W.; Zheng, M.; Meng, S. Influence of Morphological Variations in XLPE on the AC Breakdown Performance of Submarine Cable Factory Joint Insulation. High Volt. 2019, 5, 69–75. [Google Scholar]

- Zahn, Z.; Wang, W.; Ninghua, N.; Sun, S.; Qinghua, Q.; Liang, L.; Xidong, X.; Guan, G.; Zhichen, Z. Morphology effects on space charge characteristics of low density polyethylene. Jpn. J. Appl. Phys. 2011, 50, 017101. [Google Scholar]

- Zhang, H.; Chen, M.; Wang, Y.; Wu, J.; Yin, Y. Interaction Effects of Three Major Crosslinking Byproducts on Space Charge Accumulation in Polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 710–718. [Google Scholar]

- Li, Z.; Du, B.; Han, C.; Xu, H. Trap Modulated Charge Carrier Transport in Polyethylene/Graphene Nanocomposites. Sci. Rep. 2017, 7, 4015. [Google Scholar]

- Zhou, Y.; Hu, J.; Dang, B.; He, J. Mechanism of highly improved electrical properties in polypropylene by chemical modification of grafting maleic anhydride. J. Phys. D Appl. Phys. 2016, 49, 415301. [Google Scholar]

- Cheng, Z.; Zekai, L.U.; Zhang, L. Space Charge Behavior of DC Cable’s XLPE Material at High Temperatures. High Volt. Eng. 2018, 44, 2664–2671. [Google Scholar]

- Zhao, J.; Chen, G.; Lewin, P.L. Investigation into the formation of charge packets in polyethylene: Experiment and simulation. J. Appl. Phys. 2012, 112, 1546–1551. [Google Scholar]

- Jones, J.P.; Llewellyn, J.P.; Lewis, T.J. The contribution of Field Induced Morphological Change to the Electrical Aging and Breakdown of Polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 951–966. [Google Scholar]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers; Peter Peregrinus: London, UK, 1992. [Google Scholar]

- Matsui, K.; Tanaka, Y.; Takada, T.; Fukao, T.; Fukunaga, K.; Maeno, T.; Alison, J.M. Space charge behavior in low-density polyethylene at pre-breakdown. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 406–415. [Google Scholar]

| Temperature (°C) | Pre-Crosslinking Temperature (°C) | SCALE Parameter α (kV/mm) | Shape Parameter β |

|---|---|---|---|

| 30 | 140 | 333.4 | 34.20 |

| 150 | 335.4 | 82.56 | |

| 160 | 339.8 | 57.00 | |

| Without pre-crosslinking | 355.5 | 68.22 | |

| 50 | 140 | 301.7 | 30.50 |

| 150 | 318.9 | 24.10 | |

| 160 | 316.1 | 34.64 | |

| Without pre-crosslinking | 338.3 | 42.94 | |

| 70 | 140 | 213.5 | 27.58 |

| 150 | 223.9 | 25.91 | |

| 160 | 226.1 | 29.26 | |

| Without pre-crosslinking | 258.2 | 26.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Wu, Y.; Fu, C.; Meng, S.; Peng, C.; Li, Z.; Du, B. Effects of Pre-Crosslinking on Space Charge and Breakdown Characteristics of XLPE Cable Insulation. Energies 2022, 15, 2360. https://doi.org/10.3390/en15072360

Zhang Z, Wu Y, Fu C, Meng S, Peng C, Li Z, Du B. Effects of Pre-Crosslinking on Space Charge and Breakdown Characteristics of XLPE Cable Insulation. Energies. 2022; 15(7):2360. https://doi.org/10.3390/en15072360

Chicago/Turabian StyleZhang, Zhenpeng, You Wu, Chao Fu, Shaoxin Meng, Chao Peng, Zhonglei Li, and Boxue Du. 2022. "Effects of Pre-Crosslinking on Space Charge and Breakdown Characteristics of XLPE Cable Insulation" Energies 15, no. 7: 2360. https://doi.org/10.3390/en15072360

APA StyleZhang, Z., Wu, Y., Fu, C., Meng, S., Peng, C., Li, Z., & Du, B. (2022). Effects of Pre-Crosslinking on Space Charge and Breakdown Characteristics of XLPE Cable Insulation. Energies, 15(7), 2360. https://doi.org/10.3390/en15072360