Abstract

The present study provides insights into the energy-saving potential of a membrane energy recovery ventilator (ERV) for the management of building air-conditioning loads. This study explores direct (DEC), Maisotsenko cycle (MEC) evaporative cooling, and vapor compression (VAC) systems with ERV. Therefore, this study aims to explore possible air-conditioning options in terms of temperature, relative humidity, human thermal comfort, wet bulb effectiveness, energy saving potential, and CO2 emissions. Eight different combinations of the above-mentioned systems are proposed in this study i.e., DEC, MEC, VAC, MEC-VAC, and their possible combinations with and without ERVs. A building was modeled in DesignBuilder and simulated in EnergyPlus. The MEC-VAC system with ERV achieved the highest temperature gradient, wet bulb effectiveness, energy-saving potential, optimum relative humidity, and relatively lower CO2 emissions i.e., 19.7 °C, 2.2, 49%, 48%, and 499.2 kgCO2/kWh, respectively. Thus, this study concludes the hybrid MEC-VAC system with ERV the optimum system for the management of building air-conditioning loads.

1. Introduction

1.1. Background

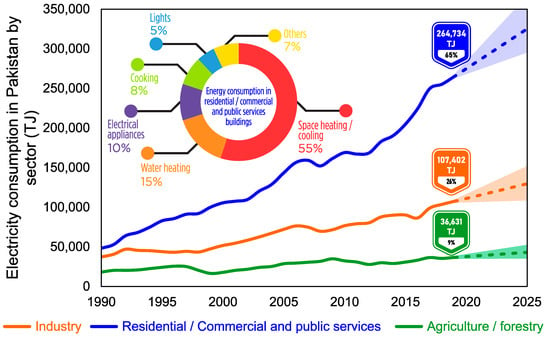

Energy consumption for domestic use/the building sector has forever been soaring, gradually increasing up to 36% (for 2021) of the total global energy consumption []. Pakistan is among the countries with high energy consumption in the building sector (including residential/commercial and public services), leading up to 65% (for 2021) of its total energy consumption [], whereas the energy consumption in the industry and agriculture/forestry sectors in Pakistan was 26% and 9% (for 2021) of the total energy consumption []. In Pakistan, for 2020, more than half (i.e., ~55%) of the total energy consumption in the residential/commercial and public services sectors was consumed in space heating/cooling []. This is due to the geophysical location of the country. Most of Pakistan’s area lies in the hot desert climate classification of the Köppen climate classification, which leads to increased need of space heating/cooling in the winter/summer []. Figure 1 shows the sector-wise energy consumption in Pakistan and energy consumption in buildings. According to Figure 1, residential/commercial and public service buildings consume 264,734 TJ (around 65% of the total sector-wise energy consumption), of which more than half (~55%) is consumed in space heating/cooling. In Pakistan, buildings are not built concerning energy savings or utilization. Generally, standalone vapor compression (VAC) systems are considered suitable for building air-conditioning in Pakistan that contributes to greenhouse gas emissions, ultimately leading to global warming and increased CO2 in the atmosphere. Therefore, alternate building air-conditioning systems are fundamentally needed. Evaporative cooling systems could potentially prove to be an environmentally friendly building air-conditioning option. Moreover, energy in the form of conditioned air is wasted from the exhausts of buildings. This waste energy can be recovered using membrane energy recovery ventilators (ERVs). The ERVs can recover heat, as well as humidity, from the stale exhaust and exchange them with the outside fresh air.

Figure 1.

Energy consumption in Pakistan by sector and energy consumption in buildings, reproduced from [].

1.2. Multi-Stage Air-Conditioning Systems

Evaporative cooling systems coupled with standalone conventional vapor compression systems for the management of building air-conditioning loads and associated applications have been extensively studied in the literature [,,,,,,,,,].

Chun et al. [] thermodynamically analyzed a MEC system coupled with membrane-based dehumidification. The authors concluded that the system performance directly correlated with the outside temperature and humidity ratio. Kowalski et al. [] studied the indirect evaporative cooling and the DEC systems in Poland. The authors concluded that the indirect evaporative cooling system outperformed the DEC. Additionally, the proposed system performed better in the dedicated outside air scenario compared to the recirculation air scenario. Da Veiga et al. [] modeled an evaporative cooling system for building roofs and experimentally validated the results. The authors found a strong correlation between the performance of the proposed system and irradiation, outside temperature, relative humidity, and windspeed. In a follow-up study, da Veiga et al. [] further studied the DEC system on a global level for building roofs. The results indicated that the DEC system is more likely to perform better in a cold semi-arid climate (BSk) and warm desert climate class (BWh) of the Köppen climate classification areas []. Tewari et al. [] experimentally studied the DEC system for office building air-conditioning. According to the results, the optimum relative humidity, temperature, and windspeed for human thermal comfort were 35–85%, 28.8 °C, and 0.75–1.5 m/s, respectively. Kim et al. [] studied the integration of DEC and indirect evaporative cooling systems and compared them with a conventional VAC system in an outdoor air-conditioning system. According to the results, the multi-staging of evaporative cooling systems resulted in a total energy consumption of 1.1 kWh compared to the conventional VAC system (i.e., 2.1 kWh). Cui et al. [] theoretically investigated a MEC system for air-conditioning applications from the viewpoint of wet bulb (WBE) and dewpoint (DPE) effectiveness. According to the results, the proposed system achieved 1.2 to 1.3 WBE and 0.8 to 0.9 DPE under varying inlet temperature and relative humidity conditions. Gómez et al. [] experimentally investigated two modes of air flow in a prototype polycarbonate indirect evaporative cooling system. According to the results, heat transfer, cooling capacity, and thermal effectiveness were improved in the case of the polycarbonate evaporative cooling system. Heidarinejad et al. [] theoretically investigated an indirect evaporative cooling system and a MEC system. Numerical modeling was used to predict the performances of both the systems. According to the results, the WBE performance of the MEC system comparatively increased by 60%. Cui et al. [] used computation fluid dynamics for the performance prediction of the MEC system. The results from the study were within the ±10% range of the actual experimental data. Moreover, the authors summarized that the MEC system could potentially achieve higher WBE and DPE for a larger length-to-height ratio (at least 200 times), lower air velocity (<1.5 m/s), and smaller channel height (<10 mm). Moshari et al. [] studied the performance of a multi-stage evaporative cooling system for a variety of ambient conditions. According to the results, the WBE of the multi-stage evaporative cooling system peaked at 0.9, whereas it was 0.6 in the case of a standalone indirect evaporative cooling system. According to the results, the multi-staging of evaporative cooling systems can improve the performance at the expense of a higher energy input. Cui et al. [] investigated the performance of a multi-stage VAC and indirect evaporative cooling system. According to the results, the EC component pretreated the outside air, resulting in a ~47% drop in the cooling load on the compressor at the VAC stage, which ultimately leads to an appreciable increase in the energy-saving potential. The numerical results from the study were within a 9.7% range of actual experimental data. Campisi et al. [] studied the energy efficiency in a case study of Italy. The authors concluded that the best energy-saving technique was the installation of solar thermal panels with a heat pump for optimum energy savings and lesser CO2 emissions. Obando et al. [] investigated the effect of the temperature of the water on the DEC system for livestock building air-conditioning. According to the experimental results, the supply air temperature dropped 0.7 °C per drop in temperature, and the supply air relative humidity increased by ~0.9%. Badiei et al. [] numerically predicted the MEC performance. The authors concluded that the energy building model accurately predicted the performance of the MEC system as compared to the numerical model. Nada et al. [] analyzed the DEC with cellulose pads for the climatic conditions of Egypt. According to the results, the DEC system achieved a maximum WBE of 0.85 at different ambient conditions. He et al. [] experimentally studied a solar-operated dehumidification unit to pretreat the outside air before entering an evaporative cooling unit. According to the results, the proposed system could achieve a supply temperature and relative humidity of 28 °C and 70%, which satisfied the required human thermal comfort levels. Boukhanouf et al. [] designed and developed a MEC system for the management of building air-conditioning loads in an arid climate. The study proposed porous ceramic and heat pipes for heat exchange purposes. According to the results, the proposed system achieved a peak WBE, COP, and temperature gradient (i.e., referred to as the subtraction of the outside and system outlet temperatures) of 0.8, 11.43, and 14 °C, respectively. Zanchini et al. [] investigated the MEC-VAC system in terms of energy-saving potential for the climatic conditions of North Italy. According to the results, the proposed system yielded 38% energy and electricity savings as compared to the conventional VAC system. Khandelwal et al. [] studied the energy-saving potential of the DEC and MEC systems coupled with a water chiller. According to the results, the proposed systems yielded peak energy savings i.e., 12% and ~15.7%, respectively, whereas the predicted mean vote (PMV) was between −1 and +1.

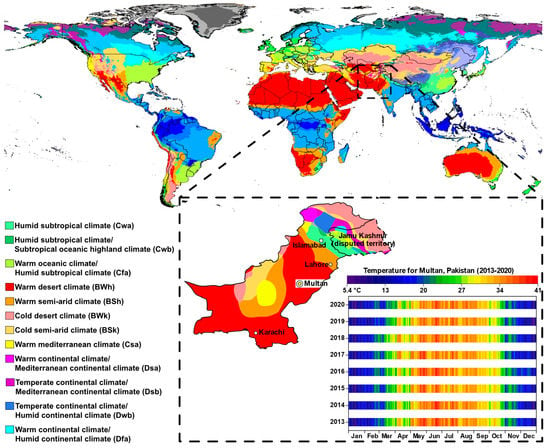

The results from these studies led to general summarizations that (i) multi-stage EC systems can potentially improve the performance from the viewpoints of the WBE, DPE, and system outlet humidity and temperature, and (ii) the MEC system can result in a relatively higher performance for hot and dry climatic conditions. Figure 2 represents the Köppen’s climate classification of the world and Pakistan. Pakistan is represented by the warm desert climate (referred to as BWh), which imposes a need for air conditioning.

Figure 2.

Köppen climate conditions of Pakistan and a temperature profile for Multan, Pakistan, reproduced from [,].

1.3. Membrane Energy Recovery Ventilators

Gao et al. [] studied the membrane energy recovery ventilator (ERV) from the viewpoints of latent heat, sensible heat, and total energy exchange efficiency. According to the results, the developed model accurately predicted the performance of the ERV within ±7% of the actual experimental data for both the summer and winter conditions. Abadi et al. [] studied the condensation phenomenon in the ERV core. According to the results, the exhaust sensible effectiveness was increased due to condensation. However, in countries like Pakistan where most of the region lies in a hot and dry area, condensation is not a problematic factor. Huang et al. [] experimentally investigated an indirect evaporative cooling system coupled with a heat recovery ventilator in different regions of China. According to the results, the performance of the proposed system increased in hot and humid regions (i.e., Guangzhou). Additionally, the authors concluded that the energy-saving potential of the vertical arrangement of the indirect evaporative cooling system was relatively more (~almost twice) compared to the horizontal arrangement. Chen et al. [] investigated the performance of a MEC system coupled with the ERV system for air conditioning in wet markets of Hong Kong. The authors concluded that a MEC-based ERV system resulted in a maximum energy-saving potential (specifically in the summer, up to 45% more) compared to the standalone total energy or heat recovery. Qiu et al. [] developed a regression model for the performance prediction of an ERV system. The authors declared that thermal properties of the membrane in the ERV core were not a prerequisite. The developed numerical polynomial model accurately predicted the results within ±8% of the experimental data. Zhong et al. [] modeled the performance of an ERV system for building air conditioning. The performance of the ERV was influenced by effectiveness, occupancy of the building, and outside air conditions. Moreover, the peak yearly energy efficiency of the ERV in hybrid mode was 43%. Rasouli et al. [] studied an ERV for ten-story building in four different climates of the USA. The authors concluded that the peak energy savings during cooling mode in the summer season was 20% under specified control conditions, whereas it was 40% in the heating mode in the winter. Moreover, the authors declared that the proposed system yielded a higher performance in humid climates with higher latent loads. Zhou et al. [] modeled the performance of the ERV system in Shanghai and Beijing. According to the results, the ERV performed better in Shanghai under winter conditions, resulting in peak energy savings as compared to Beijing.

From the above discussion, to the best of the authors’ knowledge, it can be stated that membrane energy recovery ventilators are not widely used in Pakistan. Therefore, this study provides a comprehensive assessment on the potential investigation of ERV systems for the management of building air-conditioning loads in Pakistan. According to Figure 2, Pakistan is represented by BWh class of Köppen’s climate classification, which enforces a need for air conditioning. In this regard, this study explores combinations of direct (DEC), Maisotsenko cycle (MEC) evaporative cooling, and typical mechanical vapor compression (VAC) systems with a membrane energy recovery ventilator in Pakistan.

2. Materials and Methods

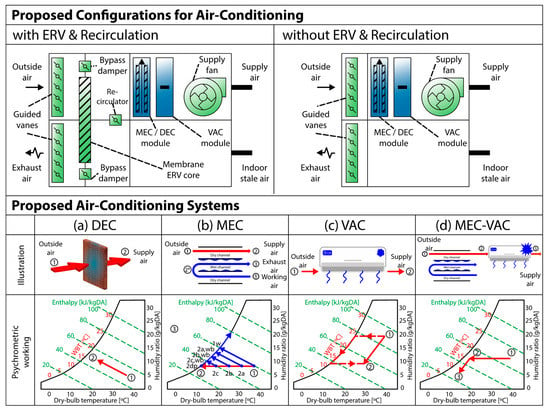

2.1. Building Energy Simulation

A nonresidential, office building (reported in the authors’ previous work []) was used as a baseline for this study. The total area for the building was 3251.74 m2, of which 847.5 m2 was conditioned and 2404.24 m2 was unconditioned of the building area. Figure 3 shows the proposed systems/configurations for the management of building air-conditioning loads. All the proposed systems/configurations presented in Figure 3 were designed in the AHU module of DesignBuilder []. All the thermophysical properties of the baseline building were incorporated in the design in DesignBuilder and simulated using the EnergyPlus simulation engine []. Table 1 shows the details of the design specifications of the building construction and air-conditioning systems. In the present study, standalone direct evaporative cooling (DEC), Maisotsenko cycle evaporative cooling (MEC), conventional vapor compression (VAC), and hybrid MEC-VAC systems are explored as possible alternative options for building air conditioning coupled with two configurations i.e., with and without ERV and recirculation. Figure 3 shows the proposed configurations and air-conditioning systems for energy recovery and building air conditioning. The working phenomenon of each system/configuration studied in this manuscript is given below:

Figure 3.

Proposed configurations and air-conditioning systems for energy recovery and building air conditioning.

Table 1.

Design specifications of the building construction and air-conditioning systems.

- DEC system (Figure 3a). This system humidifies and simultaneously cools the outside air, increasing the humidity of the supply air in an isenthalpic manner.

- MEC system (Figure 3b). This system provides two streams of air, i.e., sensibly cooled air and humidified hot air. Ideally, this system can achieve below the wet bulb temperature, i.e., dewpoint temperature.

- VAC system (Figure 3c). This system is the conventional mechanical vapor compression system based on refrigerant cooling.

- MEC-VAC system (Figure 3d). This system essentially behaves like a hybrid of the MEC and the VAC systems. The MEC system pretreats the outside air (reducing its temperature) to reduce the cooling coil loads in the VAC system.

- Air-conditioning system with ERV and recirculation configuration (Figure 3). This configuration allows the energy from the stale exhaust air to be recovered and exchanged into the supply air before exhaust. Additionally, the recirculation mode is used in this configuration to divert/mix a portion of the outside air depending upon the thermal comfort requirements of the inside conditions.

- Air-conditioning system without ERV and recirculation configuration (Figure 3). This configuration does not allow any sensible/latent energy recovery from the stale air stream, essentially behaving like a simple air handling unit (AHU) consisting of the four proposed air-conditioning systems.

2.2. Performance Assessment Indicators

The temperature gradient, relative humidity, predicted mean vote (PMV), psychrometric profile, carbon dioxide (CO2) emissions, predicted percentage of dissatisfied (PPD), wet bulb effectiveness, electricity consumption, and energy-saving potential were used as the performance indicators. The wet bulb effectiveness of the proposed system was calculated using Equation (1):

where represents the wet bulb effectiveness; represents the dry bulb temperature (°C); and the subscripts , , , and denote the supply air, outside air, wet bulb, and dry bulb temperatures, respectively. Equation (2) was used to calculate the cooling capacity of the proposed systems:

where represents cooling capacity of the system (kW), represents the mass flow rate of air in the system (i.e., ~14.5 kg/s for this study), represents the specific heat capacity, and denotes the difference in the system outlet temperatures between and (°C). Equations (3)–(6) were used to calculate the cooling capacity of the VAC or hybrid VAC systems, with the latent heat transfer taken into account:

where , , , , , , and represent the density of the air (kg/m3), volumetric flow rate (m3/s), total enthalpy of air (J/kg), minimum of the two humidity ratios at and (kg/kg), the total cooling capacity, the total sensible cooling capacity, and the total latent cooling capacity (kW). Equation (7) was used to calculate the average area of a human body to further facilitate the estimation of the total heat and mass transfer from the human body:

where , , and represent the average area, mass, and height of a typical human body. Subscript represents the human body. Equations (8)–(17) were used to calculate the heat gained from the human body (, sol–air temperature (), heat gained from exterior surfaces (), heat gained from fans and motors (), heat gained from walls (), heat gained from windows (), heat gained from the floor (), heat gains/losses from infiltration (), latent load gains/losses through infiltration (), and sensible load gains/losses through infiltration (), respectively. The details of the parameters can be found from the cited literature [].

2.3. Human Thermal Comfort Indices

Comfort for human beings was assessed from the viewpoints of Fanger’s predicted mean vote (PMV) and predicted percentage of dissatisfied (PPD) [,]. Equations (18)–(22) were used to calculate the PMV and PPD. Details of the parameters can be found from the cited literature [].

where MBR denotes the metabolic rate in W m−2, HL denotes the loss of heat from the body in W m−2, TOA denotes the room’s temperature in °C, POA denotes the vapor pressure of the outside air, RCNB denotes the cloth–naked body ratio, CI denotes clothes’ insulation in clo, CT denotes clothes’ temperature in °C, hconv denotes the convective heat transfer coefficient in W m−2 °C−1, MRT denotes the mean radiant temperature in °C, and uOA denotes the air flow velocity in m s−1.

3. Results and Discussion

3.1. Design Parameters

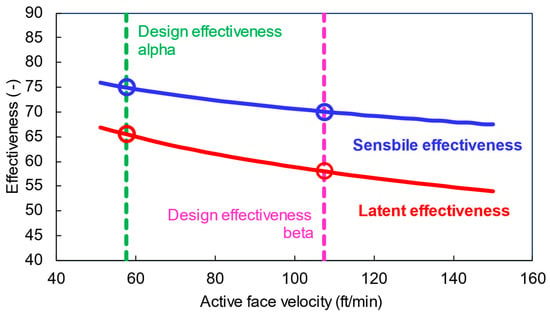

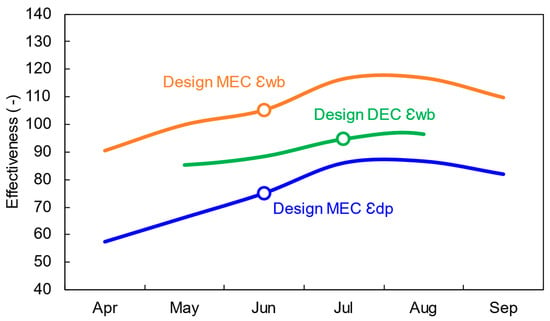

Effectiveness of a high-efficiency energy recovery ventilator (ERV) used as design effectiveness in DesignBuilder at varied design flow rates are presented in Figure 4. Experimental data for the effectiveness was obtained from the literature []. This specific membrane ERV was selected for the study due to its low-pressure drop at the supply air side, high effectiveness towards blocking of a variety of gases, prevention of recirculation of odors into the supply air, and smaller lead time. According to Figure 4, design effectiveness alpha represents the effectiveness at 57.7 ft/min active face velocity, whereas design effectiveness beta represents the effectiveness at 107.5 ft/min active face velocity. The sensible design effectiveness at a 75% heating and cooling flow rate was 0.75, whereas it was 0.70 at a 100% heating and cooling flow rate. The latent design effectiveness at a 75% heating and cooling flow rate was 0.65, whereas it was 0.60 at a 100% heating and cooling flow rate. Figure 5 shows the numerical values of both wet bulb and dewpoint effectiveness of the experimental lab-scale prototypes of the DEC and MEC systems, respectively, for the summer months, obtained from the authors’ previous work []. The design values were used in simulation models developed in DesignBuilder. The design values used in DesignBuilder are presented in Table 1. The developed model was simulated for Multan, Pakistan in EnergyPlus.

Figure 4.

Membrane energy recovery ventilator design effectiveness for DesignBuilder at varied flow rates, reproduced from the literature [].

Figure 5.

Design effectiveness of lab-scale evaporative cooling systems (i.e., MEC εwb, MEC εdp, and DEC εwb) for DesignBuilder for the summer in Multan [].

3.2. Performance Profiles of the Systems

3.2.1. Temperature/Humidity

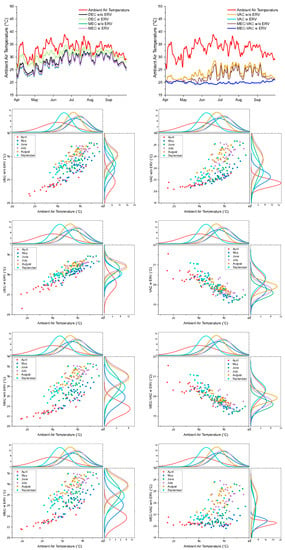

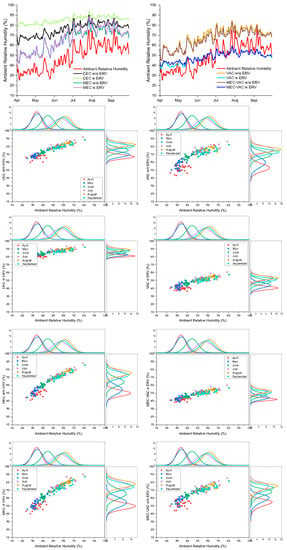

The results from the simulation are presented in Figure 6 and Figure 7. Figure 6 shows the marginal distribution curves of the temperature gradient of the proposed system configurations against the ambient temperature for the summer months of the study area. According to Figure 6, the MEC-VAC system with the ERV and recirculation configuration achieved a maximum temperature gradient of 19.8 °C (on 16 June), with an average 13.2 °C in the summer months. MEC-VAC without the ERV system achieved a maximum temperature gradient of 16.6 °C, with an average of 10.7 °C. It is worth mentioning that the distribution curves in Figure 6 represent the data height in terms of count rather than the relative frequency or density of the data. The DEC and MEC systems could only achieve a maximum temperature gradient of 9.2 °C and 10.8 °C, respectively, without ERV and recirculation configuration, with an average temperature gradient of 4.7 °C and 5.5 °C, respectively. It is worth mentioning that the temperature gradient refers to the subtraction of outside/ambient air and the system outlet temperature. Meanwhile, both the standalone evaporative cooling systems achieved a maximum temperature gradient of 5.9 °C and 10.4 °C, respectively, with the ERV and recirculation configuration in the summer months having an average of 2.3 °C and 5.4 °C. Contrarily, the standalone VAC system achieved a maximum temperature gradient of 13.4 °C and 19.7 °C without and with the ERV and recirculation configurations, with an average temperature gradient of 9.3 °C and 13.2 °C, respectively. From these results, it can be deduced that the standalone VAC system with ERV configuration and the hybrid MEC-VAC system with ERV configuration performed best as compared to the other systems. It could be argued that the VAC with ERV performed nearly equal to the hybrid MEC-VAC with ERV; however, the VAC with ERV system consumed more electricity as compared to the MEC-VAC with ERV system. According to the marginal distribution curves, the MEC-VAC with ERV system yielded an overall smooth performance from the point of view of the supply air temperature. The MEC-VAC with ERV system maintained an overall temperature of ~20–22 °C throughout the summer months. Similarly, the VAC with ERV system also maintained a similar profile of temperature throughout the summer months. The marginal distribution curves of the humidity of the proposed system configurations against the ambient relative humidity for the summer months of the study area are presented in Figure 7. According to Figure 7, the maximum ambient air relative humidity for the summer months was 81%, with an average relative humidity of 48%. It is worth mentioning that the distribution curves in Figure 7 represent the data height in terms of count rather than relative frequency or density of the data. Consequently, the standalone DEC system without and with ERV configuration achieved a maximum relative humidity of 92% and 95%, with an average relative humidity of 76% and 85%, respectively. Similarly, the standalone MEC system without and with ERV configuration achieved a maximum relative humidity of 89% and 90%, with an average relative humidity of 65% and 66%, respectively. The comprehensive results of the study are presented in Table 2.

Figure 6.

Marginal distribution curves of the proposed system configurations’ temperature against the ambient temperature for the summer months of Multan (Pakistan).

Figure 7.

Marginal distribution curves of the proposed system configurations’ relative humidity against the ambient relative humidity for the summer months of Multan (Pakistan).

Table 2.

Comprehensive results of the performances of the proposed systems.

On the other hand, the standalone VAC system without and with ERV configuration achieved a maximum relative humidity of 86% and 60%, with an average relative humidity of 68% and 48%, respectively. Contrarily, the hybrid MEC-VAC system without and with ERV configuration achieved a maximum relative humidity of 85% and 60%, with an average relative humidity of 66% and 49%, respectively. According to these results, the standalone VAC system with the ERV and recirculation configuration and the hybrid MEC-VAC system with the ERV and recirculation configuration achieved the desired average relative humidity level (i.e., 40–60% []) prescribed for human thermal comfort during the summer months of the study area. From Figure 6 and Figure 7, it can be concluded that the standalone VAC system with the ERV and recirculation configuration, and the hybrid MEC-VAC system with the ERV and recirculation configuration achieved the desired performance level in terms of the humidity and temperature required for optimum human thermal comfort.

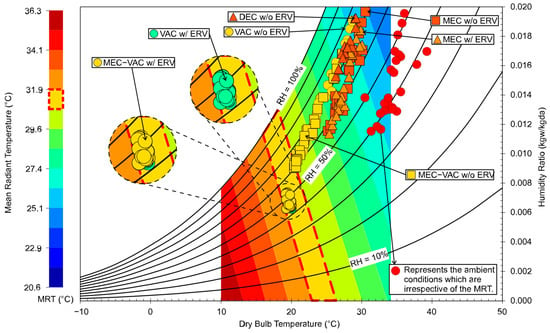

3.2.2. Mean Radiant Temperature

Figure 8 shows the psychrometric performance profile of the proposed system configurations correlating with the mean radiant temperature and human thermal comfort. According to Figure 8, the standalone DEC system without and with the ERV and recirculation configuration achieved a maximum mean radiant temperature of 36.1 °C and 36.9 °C and average MRT of 32.3 °C and 33.4 °C, respectively. However, according to the color-coding in Figure 8, the average MRT of this system should be <26 °C to achieve the optimum human thermal comfort.

Figure 8.

Performance profile of the proposed system configurations correlating with the mean radiant temperature and thermal comfort.

Similarly, the standalone MEC system without and with the ERV and recirculation configuration achieved a maximum mean radiant temperature of 36.0 °C and 35.8 °C, with an average mean radiant temperature of 32.0 °C and 32.5 °C, respectively. However, according to the color-coding in Figure 8, the average MRT of this system should also be <26 °C to achieve the optimum human thermal comfort. Contrarily, the standalone VAC system without and with the ERV and recirculation configuration achieved a maximum mean radiant temperature of 34.2 °C and 29.6, with an average mean radiant temperature of 30.2 °C and 28.2 °C, respectively. However, according to the color-coding in Figure 8, the average MRT of the VAC without the ERV system should be <26 °C, whereas, in the case of the VAC with the ERV system, it should be 30.5 °C–31.9 °C. Although the VAC system with the ERV and recirculation configuration achieved the desired temperature and relative humidity levels (as per Figure 6 and Figure 7), the system failed to achieve the required mean radiant temperature (as per Figure 8). On the other hand, the hybrid MEC-VAC system without and with the ERV and recirculation configuration achieved a maximum mean radiant temperature of 33.5 °C and 31.9 °C, with an average 29.5 °C and 29.6 °C MRT. According to the color-coding in Figure 8, the average MRT for the MEC-VAC without the ERV system should be 29.6 °C–30.5 °C, whereas the MRT for the MEC-VAC system with the ERV system should be 29.6 °C–31.9 °C, respectively. According to these results, the hybrid MEC-VAC system with the ERV and recirculation configuration achieved the desired MRT system outlet humidity and temperature.

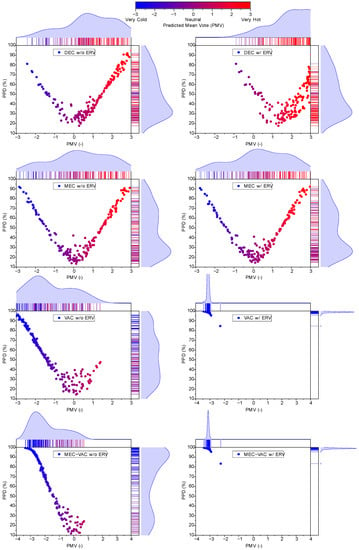

3.2.3. Human Thermal Comfort

The profile of the proposed system/configurations in terms of the predicted percentage dissatisfied (PPD) and predicted mean vote (PMV) for the summer months of the study area is presented in Figure 9. According to Figure 9, the standalone DEC system without the ERV and recirculation configuration achieved a PMV of −2.43 to 3.43. It is worth mentioning that the distribution curves in Figure 9 represent the data height in terms of count rather than the relative frequency or density of the data. Similarly, the standalone DEC system with the ERV and recirculation configuration achieved a PMV of −0.89 to 3.00. Similarly, the standalone MEC system without the ERV and recirculation configuration achieved a PMV of −2.84 to 3.00. In addition, the standalone MEC system with the ERV and recirculation configuration achieved a PMV of −2.77 to 3.00. Additionally, the standalone VAC system without the ERV and recirculation configuration achieved a PMV of −3.00 to 1.39. On the other hand, the standalone VAC system with the ERV and recirculation configuration achieved a PMV of −2.28 to −3.00. Contrarily, the hybrid MEC-VAC system without the ERV and recirculation configuration achieved a PMV of 0.71 to −3.00. In addition, the hybrid MEC-VAC system with the ERV and recirculation configuration achieved a PMV of −2.20 to −3.00. From the predicted percentage of dissatisfied (PPD) point of view, according to Figure 9, both the standalone DEC system without and with the ERV and recirculation configuration achieved a PPD of 17.6–96.7%, with an average of 50% PPD during the summer months of the study area. Additionally, the standalone MEC system without and with the ERV and recirculation configuration achieved a PPD of 13.4–94.5% and 14.4–4.0%, with an average PPD of 46.3% and 45.7%, respectively. Moreover, the standalone VAC system without and with the ERV and recirculation configuration achieved a PPD of 14.4–98.8% and 84.6–99.5%, with an average PPD of 54.0% and 98.7%, respectively. In the case of the hybrid systems, the MEC-VAC system without and with the ERV and recirculation configuration achieved a PPD of 9.4–99.3% and 83.2–99.5%, with an average PPD of 67.2% and 98.7%, respectively. According to the results, the standalone VAC system and the hybrid MEC-VAC system with the ERV and Recirculation configuration achieved more than 98% PPD throughout the summer months, which caused dissatisfaction among the human subjects. In the case of MEC-VAC with the ERV and recirculation configuration, although high PMV and PPD correlate to discomfort under certain conditions, it could be tackled by using an air-conditioning schedule, economizer, and time-to-time operation of the outside air mixing/recirculation.

Figure 9.

Variation in thermal comfort indices (i.e., PMV and PPD) of the proposed system configurations for the summer months.

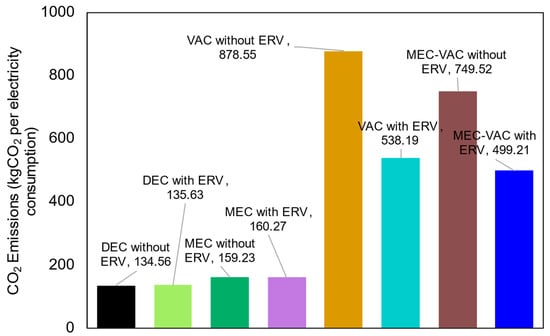

3.2.4. Carbon Dioxide Emissions

Figure 10 shows the annual carbon dioxide (CO2) emissions per kWh electricity usage of the proposed system configurations. A CO2 emission factor of 0.56 kgCO2/kWh of electricity was used in Pakistan []. According to Figure 10, the standalone DEC system without the ERV and recirculation configuration emitted 134.5 kgCO2/kWh, closely followed by the standalone DEC system with the ERV and recirculation configuration, which emitted 135.6 kgCO2/kWh. Similarly, the standalone MEC system without the ERV and recirculation configuration emitted 159.2 kgCO2/kWh. Similarly, the standalone MEC system with the ERV and recirculation configuration emitted 160.2 kgCO2/kWh. In the case of the standalone VAC system without the ERV and recirculation configuration, the CO2 emissions were 878.5 kgCO2/kWh, whereas it was 538.1 kg/CO2/kWh in the case of the VAC system with the ERV and recirculation configuration. On the other hand, the hybrid MEC-VAC system without the ERV and recirculation configuration emitted 749.5 kgCO2/kWh, whereas the MEC-VAC system with the ERV and recirculation configuration emitted 499.2 kgCO2/kWh.

Figure 10.

CO2 emissions per kWh electricity usage of the proposed system configurations.

From these results, it can be safely concluded that, although the CO2 emissions of the standalone EC systems are relatively low, these systems fail to achieve the desired human thermal comfort and fail to provide the optimum management of building air-conditioning loads. On the other hand, the standalone VAC system emits higher CO2 but consumes high energy and fails to achieve the desired human thermal comfort and to provide optimum management of building air-conditioning loads. In contrast, the hybrid MEC-VAC system with the ERV and recirculation configuration emits relatively lower CO2 per kWh and promises to deliver optimum thermal comfort, as well as optimum management of building air-conditioning loads.

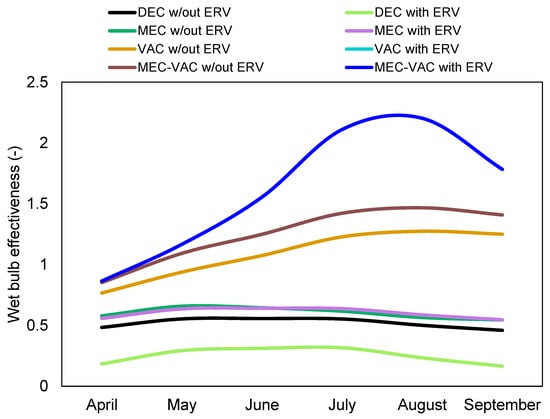

3.2.5. Wet Bulb Effectiveness

The profile of wet bulb effectiveness (WBE) of the proposed system configurations for the summer months of the study area is presented in Figure 11. According to Figure 11, the hybrid MEC-VAC system with the ERV and recirculation configuration achieved a maximum wet bulb effectiveness of 2.2 in August. However, the MEC-VAC system without the ERV and recirculation configuration was the only system that achieved a maximum WBE of 1.46 in August. Similarly, the standalone VAC system with the ERV and recirculation configuration also achieved a maximum wet bulb effectiveness of 2.2 in August. However, the VAC system without the ERV and recirculation configuration only achieved a highest WBE of 1.27 in August. Contrarily, the standalone MEC system with the ERV and recirculation configuration achieved the highest WBE of 0.64 in August. However, the MEC without the ERV and recirculation configuration achieved the highest WBE of 0.65 in May. Similarly, the standalone DEC system without the ERV and recirculation configuration achieved a maximum wet bulb effectiveness of 0.55 in June. On the other hand, the DEC system with the ERV and recirculation configuration achieved a maximum wet bulb effectiveness of 0.31 in July. According to these results, the standalone VAC system and the hybrid MEC-VAC system with the ERV and recirculation configuration achieved the maximum wet bulb effectiveness; however, the standalone VAC system with ERV and recirculation was unable to achieve the desired mean radiant temperature (as per Figure 8) and was therefore unable to optimally manage the building air-conditioning loads. The hybrid MEC-VAC system, however, produced the best wet bulb effectiveness and was able to achieve the desired mean radiant temperature (as per Figure 8), thereby optimally managing the building air-conditioning loads.

Figure 11.

Monthly averaged profile of wet bulb effectiveness of the proposed system configurations for the summer months.

Evidently, from Figure 11, the evaporative cooling systems were thermodynamically limited to the outside conditions of the study area; therefore, their performance was limited. However, for the hybrid air-conditioning system, the system’s output was beyond the psychrometric limits of EC.

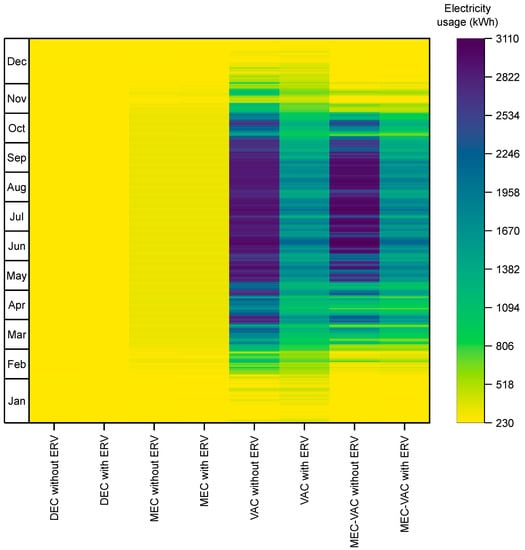

3.2.6. Electricity Consumption

The annual electricity usage of the proposed systems is presented in Figure 12. According to the results, the standalone DEC system without the ERV and recirculation configuration consumed a maximum and minimum annual electricity of 281.6 kWh/day and 231.3 kWh/day, with an average of 266.5 kWh/day annual electricity. Similarly, the DEC system with the ERV and recirculation configuration consumed a maximum and minimum annual electricity of 281.5 kWh/day and 231.7 kWh/day, with an average of 268.6 kWh/day annual electricity. On the other hand, the standalone MEC system without the ERV and recirculation configuration consumed a maximum and minimum annual electricity of 354.6 kWh/day and 231.3 kWh/day, with an average of 315.3 kWh/day annual electricity. Similarly, the MEC system with the ERV and recirculation configuration consumed a maximum and minimum annual electricity of 354.6 kWh/day and 232.4 kWh/day, with an average of 317.4 kWh/day annual electricity. However, the standalone VAC system without the ERV and recirculation configuration consumed a maximum and minimum annual electricity of 3018.6 kWh/day and 231.3 kWh/day, with an average of 1739.7 kWh/day annual electricity. Similarly, the VAC system with the ERV and recirculation configuration consumed a maximum and minimum annual electricity of 2176.6 kWh/day and 240.0 kWh/day, with an average of 1065.7 kWh/day annual electricity. In contrast, the hybrid MEC-VAC without the ERV and recirculation configuration consumed a maximum and minimum annual electricity of 3106.7 kWh/day and 231.3 kWh/day, with an average of 1484.2 kWh/day annual electricity. However, the MEC-VAC system with the ERV and recirculation configuration consumed a maximum and minimum annual electricity of 2176.6 kWh/day and 232.4 kWh/day, with an average of 988.5 kWh/day annual electricity. Evidently, from the results, the standalone evaporative cooling systems were not feasible from the viewpoint of energy savings. However, the standalone VAC and the hybrid MEC-VAC systems with the ERV and recirculation configuration proved to have energy savings throughout the year.

Figure 12.

Annual electricity usage of the proposed system configurations.

3.2.7. Energy Saving Potential

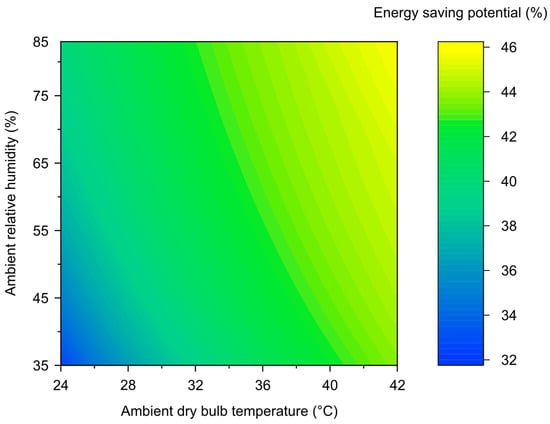

Correlation contours of the energy-saving potential (%) of the membrane energy recovery ventilator and recirculation configuration of the DEC system in terms of the outside humidity and temperature for the summer months are presented in Figure 13. According to Figure 13, the energy-saving potential of the standalone DEC system with the ERV and recirculation configuration increased with the increasing ambient temperature and relative humidity. According to the results, the standalone DEC system with the ERV and recirculation configuration achieved a maximum and minimum energy-saving potential of 47.8% and 29.1%, with an average energy-saving potential of 39.4%. Similarly, other systems with the ERV and recirculation configuration also saved energy as compared to their respective counterpart systems without the ERV and recirculation configuration.

Figure 13.

Energy-saving potential (%) of the membrane energy recovery ventilator and recirculation configuration of the DEC system in terms of the outside humidity and temperature for the summer months.

Being a developing country, it is extremely challenging for Pakistan to stop expanding energy interests. Therefore, it is crucial to investigate potential energy technologies in the air-conditioning sector. The present research study is limited to numerical simulations that can only provide an approximate estimation of the energy-saving potential of ERV systems. However, in future research directions, the ERV systems could be experimentally investigated in commercial buildings of Pakistan. Moreover, the experimental energy-saving potential of such systems could be validated with the numerically simulated results presented in the current study. Being a cheaper source of air-conditioning, conventional air-conditioning techniques coupled with ERV and recirculation renders incredible possibilities for accomplishing energy security, independence to address energy issues, natural assurance, and supportable monetary development. Moreover, energy conservation, efficiency improvement of the current air-conditioning systems, and mitigation measures can also be undertaken to mitigate CO2 emissions.

4. Conclusions

The current study intended to explore possible alternative options, i.e., standalone direct (DEC), Maisotsenko cycle (MEC) evaporative cooling systems, typical mechanical vapor compression (VAC), and hybrid MEC-VAC systems coupled with two configurations, i.e., with and without membrane energy recovery ventilator (ERV) and recirculation, for the management of building air-conditioning loads in Multan (Pakistan). Commonly, the DEC and the VAC systems are used for building air conditioning without any regard to the waste of energy through building exhaust. Therefore, eight possible combinations of the above-mentioned systems are proposed in this study. The building model was developed and simulated in DesignBuilder and EnergyPlus. The essential conclusions of the study are:

- The MEC-VAC system with the ERV and recirculation configuration provided a temperature gradient of 19.7 °C with average relative humidity of 49%, whereas other systems failed to compete in terms of the temperature gradient and relative humidity.

- All the systems except the MEC-VAC with the ERV and recirculation configuration failed to achieve the required mean radiant temperature, matching with their respective psychrometric performances.

- All the systems except the standalone evaporative cooling systems achieved slightly cool to extremely cool PMV with 20–98% PPD.

- The VAC with ERV and recirculation and MEC-VAC with ERV and recirculation systems achieved a maximum wet bulb effectiveness of 2.2 out of all the proposed systems.

- Among the studied systems, the standalone VAC system without the ERV and recirculation configuration resulted in the highest CO2 emissions, i.e., 878.5 kgCO2/kWh, whereas the MEC-VAC system with the ERV and recirculation configuration resulted in a relatively lower CO2 emission, i.e., 499.2 kgCO2/kWh.

The hybrid MEC-VAC system with the ERV and recirculation configuration could achieve the desired results from the viewpoints of the temperature gradient, relative humidity, wet bulb effectiveness, mean radiant temperature, and CO2 emissions. Therefore, this study concludes the hybrid MEC-VAC system with the ERV and recirculation configuration is the optimum feasible option for the management of building air-conditioning loads.

Author Contributions

Conceptualization, H.A. and M.S.; Data curation, H.A., M.S. and U.S.; Formal analysis, H.A., M.S., U.S., M.W.S. and M.F.; Funding acquisition, M.S. and S.M.I.; Investigation, H.A., M.S., M.W.S., M.U.K. and M.A.J.; Methodology, H.A., M.S., U.S., M.W.S., M.F. and M.A.J.; Project administration, M.S. and S.M.I.; Resources, M.S.; Software, H.A., U.S. and M.W.S.; Supervision, M.S.; Validation, H.A., M.S. and U.S.; Visualization, H.A., M.S., S.M.I. and M.U.K.; Writing—original draft, H.A. and M.S.; and Writing—review and editing, M.W.S., M.F., S.M.I., M.U.K. and M.A.J. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the support from the Researchers Supporting Project number (RSP-2021/100), King Saud University, Riyadh, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors acknowledge the support from the Researchers Supporting Project number (RSP-2021/100), King Saud University, Riyadh, Saudi Arabia. This research was carried out in the Department of Agricultural Engineering, Bahauddin Zakariya University, Multan, Pakistan with the support of BZU Director Research/ORIC grants awarded to Principal Investigator Muhammad Sultan.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United Nations Environment Programme. 2021 Global Status Report for Buildings and Construction: Towards a Zero-Emission; United Nations Environment Programme: Nairobi, Kenya, 2021. [Google Scholar]

- International Energy Agency. World Energy Balances; International Energy Agency: Paris, France, 2021. [Google Scholar]

- European Commission. In Focus: Energy Efficiency in Buildings; European Commission: Brussels, Belgium, 2020.

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and Future Köppen-Geiger Climate Classification Maps at 1-Km Resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- International Energy Agency Data and Statistics. Available online: https://www.iea.org/data-and-statistics (accessed on 12 December 2021).

- Noor, S.; Ashraf, H.; Sultan, M.; Khan, Z.M. Evaporative Cooling Options for Building Air-Conditioning: A Comprehensive Study for Climatic Conditions of Multan (Pakistan). Energies 2020, 13, 3061. [Google Scholar] [CrossRef]

- Harby, K.; Gebaly, D.R.; Koura, N.S.; Hassan, M.S. Performance Improvement of Vapor Compression Cooling Systems Using Evaporative Condenser: An Overview. Renew. Sustain. Energy Rev. 2016, 58, 347–360. [Google Scholar] [CrossRef]

- Ibrahim, N.I.; Al-Farayedhi, A.A.; Gandhidasan, P. Experimental Investigation of a Vapor Compression System with Condenser Air Pre-Cooling by Condensate. Appl. Therm. Eng. 2017, 110, 1255–1263. [Google Scholar] [CrossRef]

- Kojok, F.; Fardoun, F.; Younes, R.; Outbib, R. Hybrid Cooling Systems: A Review and an Optimized Selection Scheme. Renew. Sustain. Energy Rev. 2016, 65, 57–80. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Li, J.; Zhao, X. Energy Savings of Hybrid Dew-Point Evaporative Cooler and Micro-Channel Separated Heat Pipe Cooling Systems for Computer Data Centers. Energy 2018, 163, 629–640. [Google Scholar] [CrossRef] [Green Version]

- Raza, H.M.U.; Ashraf, H.; Shahzad, K.; Sultan, M.; Miyazaki, T.; Usman, M.; Shamshiri, R.R.; Zhou, Y.; Ahmad, R. Investigating Applicability of Evaporative Cooling Systems for Thermal Comfort of Poultry Birds in Pakistan. Appl. Sci. 2020, 10, 4445. [Google Scholar] [CrossRef]

- Sultan, M.; Ashraf, H.; Miyazaki, T.; Shamshiri, R.R.; Hameed, I.A. Temperature and Humidity Control for the Next Generation Greenhouses: Overview of Desiccant and Evaporative Cooling Systems. In Next-Generation Greenhouses for Food Security; IntechOpen: London, UK, 2021. [Google Scholar]

- Noor, S.; Ashraf, H.; Sultan, M.; Miyazaki, T.; Mahmood, M.H.; Khan, Z.M. Investigation of Direct and Indirect Evaporative Cooling Options for Greenhouse Air Conditioning in Multan (Pakistan). In Proceedings of the International Exchange and Innovation Conference on Engineering & Sciences (IEICES), Fukuoka City, Japan, 22–23 October 2020; pp. 110–115. [Google Scholar]

- Noor, S.; Ashraf, H.; Hussain, G.; Sultan, M.; Miyazaki, T.; Shakoor, A.; Mahmood, M.H.; Riaz, M. Spatiotemporal Investigation of Evaporative Cooling Options for Greenhouse Air-Conditioning Application in Pakistan. Fresenius Environ. Bull. 2021, 30, 21. [Google Scholar]

- Ashraf, H.; Noor, S.; Sultan, M.; Khan, Z.M. Energy Saving Potential of Evaporative Cooling Systems Compared to Traditional Air Conditioners. In Proceedings of the International Conference on Mechanical Engineering—2020 (ICME-20), Lahore, Pakistan, 29–30 January 2020; UET: Lahore, Pakistan, 2020; pp. 75–81. [Google Scholar]

- Chun, L.; Gong, G.; Peng, P.; Wan, Y.; Chua, K.J.; Fang, X.; Li, W. Research on Thermodynamic Performance of a Novel Building Cooling System Integrating Dew Point Evaporative Cooling, Air-Carrying Energy Radiant Air Conditioning and Vacuum Membrane-Based Dehumidification (DAV-Cooling System). Energy Convers. Manag. 2021, 245, 114551. [Google Scholar] [CrossRef]

- Kowalski, P.; Kwiecień, D. Evaluation of Simple Evaporative Cooling Systems in an Industrial Building in Poland. J. Build. Eng. 2020, 32, 101555. [Google Scholar] [CrossRef]

- da Veiga, A.P.; Güths, S.; da Silva, A.K. Evaporative Cooling in Building Roofs: Theoretical Modeling and Experimental Validation (Part-1). Sol. Energy 2020, 207, 1122–1131. [Google Scholar] [CrossRef]

- da Veiga, A.P.; Güths, S.; da Silva, A.K. Evaporative Cooling in Building Roofs: Local Parametric and Global Analyses (Part-2). Sol. Energy 2020, 207, 1009–1020. [Google Scholar] [CrossRef]

- Tewari, P.; Mathur, S.; Mathur, J.; Kumar, S.; Loftness, V. Field Study on Indoor Thermal Comfort of Office Buildings Using Evaporative Cooling in the Composite Climate of India. Energy Build. 2019, 199, 145–163. [Google Scholar] [CrossRef]

- Kim, M.-H.; Jeong, J.-W. Cooling Performance of a 100% Outdoor Air System Integrated with Indirect and Direct Evaporative Coolers. Energy 2013, 52, 245–257. [Google Scholar] [CrossRef]

- Cui, X.; Chua, K.J.; Yang, W.M.; Ng, K.C.; Thu, K.; Nguyen, V.T. Studying the Performance of an Improved Dew-Point Evaporative Design for Cooling Application. Appl. Therm. Eng. 2014, 63, 624–633. [Google Scholar] [CrossRef]

- Velasco Gómez, E.; Tejero González, A.; Rey Martínez, F.J. Experimental Characterisation of an Indirect Evaporative Cooling Prototype in Two Operating Modes. Appl. Energy 2012, 97, 340–346. [Google Scholar] [CrossRef]

- Heidarinejad, G.; Moshari, S. Novel Modeling of an Indirect Evaporative Cooling System with Cross-Flow Configuration. Energy Build. 2015, 92, 351–362. [Google Scholar] [CrossRef]

- Cui, X.; Chua, K.J.; Yang, W.M. Numerical Simulation of a Novel Energy-Efficient Dew-Point Evaporative Air Cooler. Appl. Energy 2014, 136, 979–988. [Google Scholar] [CrossRef]

- Moshari, S.; Heidarinejad, G.; Fathipour, A. Numerical Investigation of Wet-Bulb Effectiveness and Water Consumption in One-and Two-Stage Indirect Evaporative Coolers. Energy Convers. Manag. 2016, 108, 309–321. [Google Scholar] [CrossRef]

- Cui, X.; Chua, K.J.; Islam, M.R.; Ng, K.C. Performance Evaluation of an Indirect Pre-Cooling Evaporative Heat Exchanger Operating in Hot and Humid Climate. Energy Convers. Manag. 2015, 102, 140–150. [Google Scholar] [CrossRef]

- Campisi, D.; Gitto, S.; Morea, D. An Evaluation of Energy and Economic Efficiency in Residential Buildings Sector: A Multi-Criteria Analisys on an Italian Case Study. Int. J. Energy Econ. Policy 2018, 8, 185–196. [Google Scholar]

- Obando, F.A.; Montoya, A.P.; Osorio, J.A.; Damasceno, F.A.; Norton, T. Evaporative Pad Cooling Model Validation in a Closed Dairy Cattle Building. Biosyst. Eng. 2020, 198, 147–162. [Google Scholar] [CrossRef]

- Badiei, A.; Akhlaghi, Y.G.; Zhao, X.; Li, J.; Yi, F.; Wang, Z. Can Whole Building Energy Models Outperform Numerical Models, When Forecasting Performance of Indirect Evaporative Cooling Systems? Energy Convers. Manag. 2020, 213, 112886. [Google Scholar] [CrossRef]

- Nada, S.A.; Elattar, H.F.; Mahmoud, M.A.; Fouda, A. Performance Enhancement and Heat and Mass Transfer Characteristics of Direct Evaporative Building Free Cooling Using Corrugated Cellulose Papers. Energy 2020, 211, 118678. [Google Scholar] [CrossRef]

- He, W.; Xilian, L.; Yuhui, S.; Min, Z.; Zhaolin, G. Research of Evaporative Cooling Experiment in Summer of Residential Buildings in Xi’an. Energy Procedia 2018, 152, 928–934. [Google Scholar] [CrossRef]

- Boukhanouf, R.; Amer, O.; Ibrahim, H.; Calautit, J. Design and Performance Analysis of a Regenerative Evaporative Cooler for Cooling of Buildings in Arid Climates. Build. Environ. 2018, 142, 1–10. [Google Scholar] [CrossRef]

- Zanchini, E.; Naldi, C. Energy Saving Obtainable by Applying a Commercially Available M-Cycle Evaporative Cooling System to the Air Conditioning of an Office Building in North Italy. Energy 2019, 179, 975–988. [Google Scholar] [CrossRef]

- Khandelwal, A.; Talukdar, P.; Jain, S. Energy Savings in a Building Using Regenerative Evaporative Cooling. Energy Build. 2011, 43, 581–591. [Google Scholar] [CrossRef]

- Ashraf, H.; Sultan, M.; Shamshiri, R.R.; Abbas, F.; Farooq, M.; Sajjad, U.; Md-Tahir, H.; Mahmood, M.H.; Ahmad, F.; Taseer, Y.R.; et al. Dynamic Evaluation of Desiccant Dehumidification Evaporative Cooling Options for Greenhouse Air-Conditioning Application in Multan (Pakistan). Energies 2021, 14, 1097. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger Climate Classification Updated. Meteorol. Zeitschrift 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Gao, H.; Li, Z.; Qiu, S.; Yang, B.; Li, S.; Wen, Y. Energy Exchange Efficiency Prediction from Non-Linear Regression for Membrane-Based Energy-Recovery Ventilator Cores. Appl. Therm. Eng. 2021, 197, 117353. [Google Scholar] [CrossRef]

- Abadi, I.R.; Aminian, B.; Nasr, M.R.; Huizing, R.; Green, S.; Rogak, S. Experimental Investigation of Condensation in Energy Recovery Ventilators. Energy Build. 2022, 256, 111732. [Google Scholar] [CrossRef]

- Huang, S.; Li, W.; Lu, J.; Li, Y. Experimental Study on Two Type of Indirect Evaporative Cooling Heat Recovery Ventilator. Procedia Eng. 2017, 205, 4105–4110. [Google Scholar] [CrossRef]

- Chen, Y.; Luo, Y.; Yang, H. Fresh Air Pre-Cooling and Energy Recovery by Using Indirect Evaporative Cooling in Hot and Humid Region—A Case Study in Hong Kong. Energy Procedia 2014, 61, 126–130. [Google Scholar] [CrossRef] [Green Version]

- Qiu, S.; Li, S.; Wang, F.; Wen, Y.; Li, Z.; Li, Z.; Guo, J. An Energy Exchange Efficiency Prediction Approach Based on Multivariate Polynomial Regression for Membrane-Based Air-to-Air Energy Recovery Ventilator Core. Build. Environ. 2019, 149, 490–500. [Google Scholar] [CrossRef]

- Zhong, X.; Wu, W.; Ridley, I.A. Assessing the Energy and Indoor-PM2.5-Exposure Impacts of Control Strategies for Residential Energy Recovery Ventilators. J. Build. Eng. 2020, 29, 101137. [Google Scholar] [CrossRef]

- Rasouli, M.; Simonson, C.J.; Besant, R.W. Applicability and Optimum Control Strategy of Energy Recovery Ventilators in Different Climatic Conditions. Energy Build. 2010, 42, 1376–1385. [Google Scholar] [CrossRef]

- Zhou, Y.P.; Wu, J.Y.; Wang, R.Z. Performance of Energy Recovery Ventilator with Various Weathers and Temperature Set-Points. Energy Build. 2007, 39, 1202–1210. [Google Scholar] [CrossRef]

- Designbuilder Software Ltd. DesignBuilder 6.1; DesignBuilder: Gloucestershire, UK, 2021. [Google Scholar]

- U.S. Department of Energy (DOE); National Renewable Energy Laboratory (NREL). EnergyPlus 9.3; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2020.

- Sheldon, R.A. Fundamentals of Green Chemistry: Efficiency in Reaction Design. Chem. Soc. Rev. 2012, 41, 1437–1451. [Google Scholar] [CrossRef] [Green Version]

- Akbari, H.; Havenith, G.; Al-Sahhaf, A. A Database of Static Clothing Thermal Insulation and Vapor Permeability Values of Non-Western Ensembles for Use in ASHRAE Standard 55, ISO 7730, and ISO 9920: Discussion. ASHRAE Conf. 2015, 121, 215. [Google Scholar]

- Fanger, P.O. Thermal Comfort: Analysis and Applications in Environmental Engineering, 1st ed.; Danish Technical Press: Copenhagen, Denmark, 1970; ISBN 9780070199156. [Google Scholar]

- ISO 7730; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Standardization Organization: Geneva, Switzerland, 2005.

- CORE. Energy Recovery Solutions Core M-ERV250. Available online: https://core.life/en/resources/spec/m-erv250/ (accessed on 10 October 2021).

- Raza, H.M.U. Investigation of Evaporative Cooling Based Low-Cost Air-Conditioning Technologies for Pakistan. Ph.D. Thesis, Agricultural Engineering, Bahauddin Zakariya University, Multan, Pakistan, 2018. [Google Scholar]

- ASHRAE. ASHRAE Handbook—Fundamentals (SI); American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2017. [Google Scholar]

- Yousuf, I.; Ghumman, A.R.; Hashmi, H.N.; Kamal, M.A. Carbon Emissions from Power Sector in Pakistan and Opportunities to Mitigate Those. Renew. Sustain. Energy Rev. 2014, 34, 71–77. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).