State-of-the-Art Review of Fluid Catalytic Cracking (FCC) Catalyst Regeneration Intensification Technologies

Abstract

1. Introduction

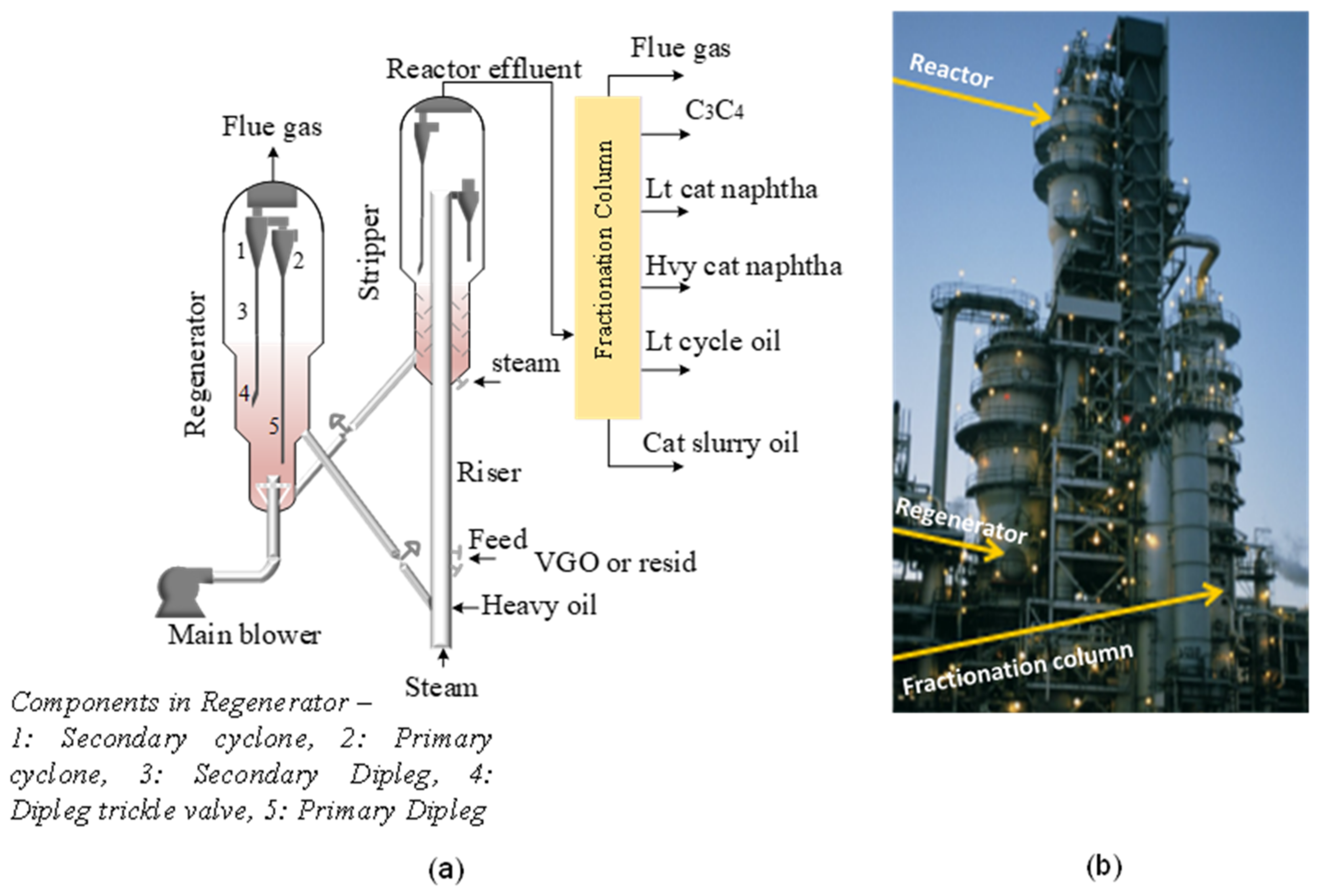

1.1. FCC Process and Its Importance in Petroleum Refineries

- Processing of extremely heavy crude oil fractions. Due to dwindling accessibility to easy-to-process feeds, FCCU can handle diverse feed slates to maximize the refiner’s overall profitability. Commonly used feeds are severely hydrotreated VGOs and resids, such as vacuum distillates (gas oils), vacuum distillation tower bottoms (vacuum resid; raw, hydrotreated, deasphalted), atmospheric distillation tower resid, coker gas oils, clarified oil (CLO), lube extracts and various slops [20,21,22]. The penalties for poor quality of feedstocks in the reactor unit are high coke formation rate (VGO and resid feeds have 5 and 20 wt.% Conradson carbon, respectively) [23], multicore naphtheno-aromatics formation [24], metal poisoning [1], low feed conversion and product selectivity, and in the regenerator, elevated regenerated catalyst temperature and exceeding high heat load [14].

- Production of the majority of the world’s high-quality gasoline. FCCU is currently the major gasoline hub, accounting for nearly 45% of global production, derived from the conversion of unconverted 32–57% bottom fraction, which is low in hydrogen and high in carbon contents [25,26,27]. The naphtha quality is close to the finished gasoline specification [11,28,29,30]. Other desired coproducts include diesel, liquefied petroleum gas (LPG), and light cycle oil (LCO). LPG and distillates are optimized [31], thus lowering the amount of residue or wastes in crude oil, providing more flexibility to the refining processes and adapting to changes in the market.

- Supply of high-quality steam to several process units and power generation. Coke combustion in the regenerator generates a preponderance of heat, which produces a considerable amount of steam used in the other process units within the refinery [36]. Stack flue gases from the regenerator have high thermal profiles ranging between 700–800 °C and pressure between 240–380 kPa. The hot pressurized flue gases effluent can be fed for electric power generation. On average, the electricity generated from the flue gas relatively meets the main air flow power requirements. Based on a barrel per stream day (BPSD), an FCCU capacity of 50,000 BSPD operating at about 310 kPa generates about 200,000 kg/h of flue gas at 720 °C, which are fed into an expander, thus generating an estimated 11 MW of electricity, thereby reducing overall operating cost [37,38].

- Large throughput, short turnaround (TAR), and long shutdown. In most of the refineries across the globe, FCCU has the second largest throughput, after the distillation unit. Each cracking-regeneration cycle is short, taking a maximum of about a 1 min while the unit runs 24 h per day for up to 3 to 5 years between scheduled shutdowns for routine maintenance, renovations or upgrades; recent studies also indicated that better turnaround times have been recorded [19]. The amount of circulated catalyst within this period is in the range of 7 × 1010 kg, while the feedstock processed is in the order of 1010 kg [14]. The frequency of unplanned shutdowns has also significantly decreased due to increasing understanding and application of newer process technologies; this will be explicitly discussed in subsequent sections.

- Adapted to new feedstocks (co-processing biomass-derived oils and conventional crude oil fractions). Concerted efforts have been geared toward the utilization of biomass-based feedstocks (ranging from used vegetable oils, pyrolysis oils, lignocelluloses to non-carbohydrate materials) in the existing FCC infrastructure within the nominal operating conditions, which is a strategic measure to promote biofuel production, fulfill renewable fuels obligations, and lower emissions from the unit [39,40]. Different biomasses (see Appendix A) have been tested both experimentally and by modeling with both promising outcomes and challenges to overcome.

- Essential learning in handling fluid–solid systems for other applications. Several innovations in chemical and pharmaceutical industries with respect to design, scaling and process optimization drew insight from FCCU, and the unit was also the most reputable for particulate technology studies [3,41]. For example, FCCU technology is the cradle for the circulating fast bed reactor being used in many industrial applications today [1]. The understanding of gas-particle mixing, reaction chemistry, hydrodynamics, and heat transfer are important parameters for overall FCC performance. Stripper units operate in bubbling fluidization, the riser in the dilute regime, and the regenerator is the biggest vessel known to operate in turbulence in a fast fluidization regime; the cyclone separator involves the vortex effect. These traverse fluidization regimes and complexities provide confident learning for other applications, even in the space and volcanic studies [42,43].

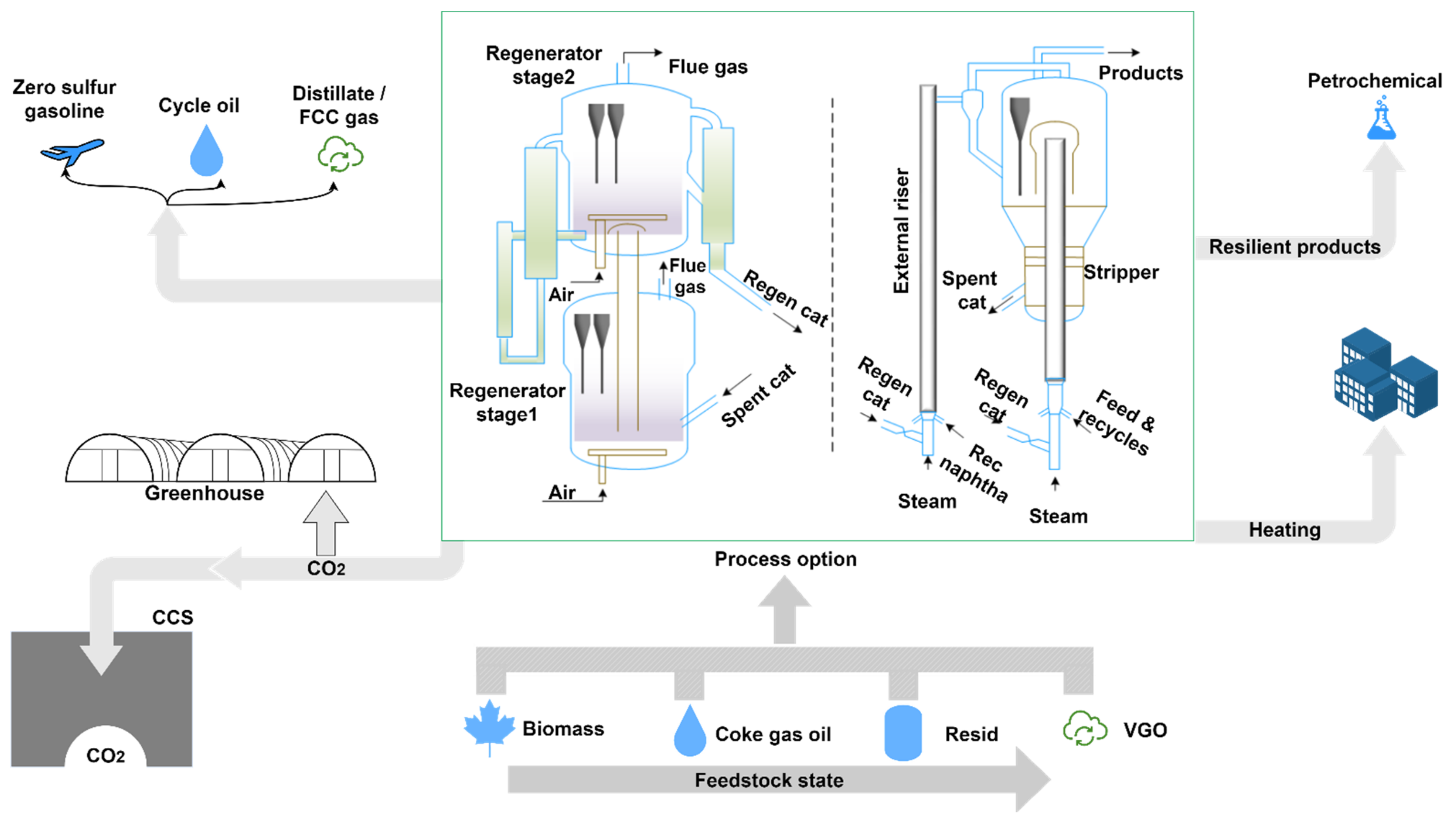

1.2. Future Roles of FCC Process and the Importance of Process Intensification (PI) Technologies

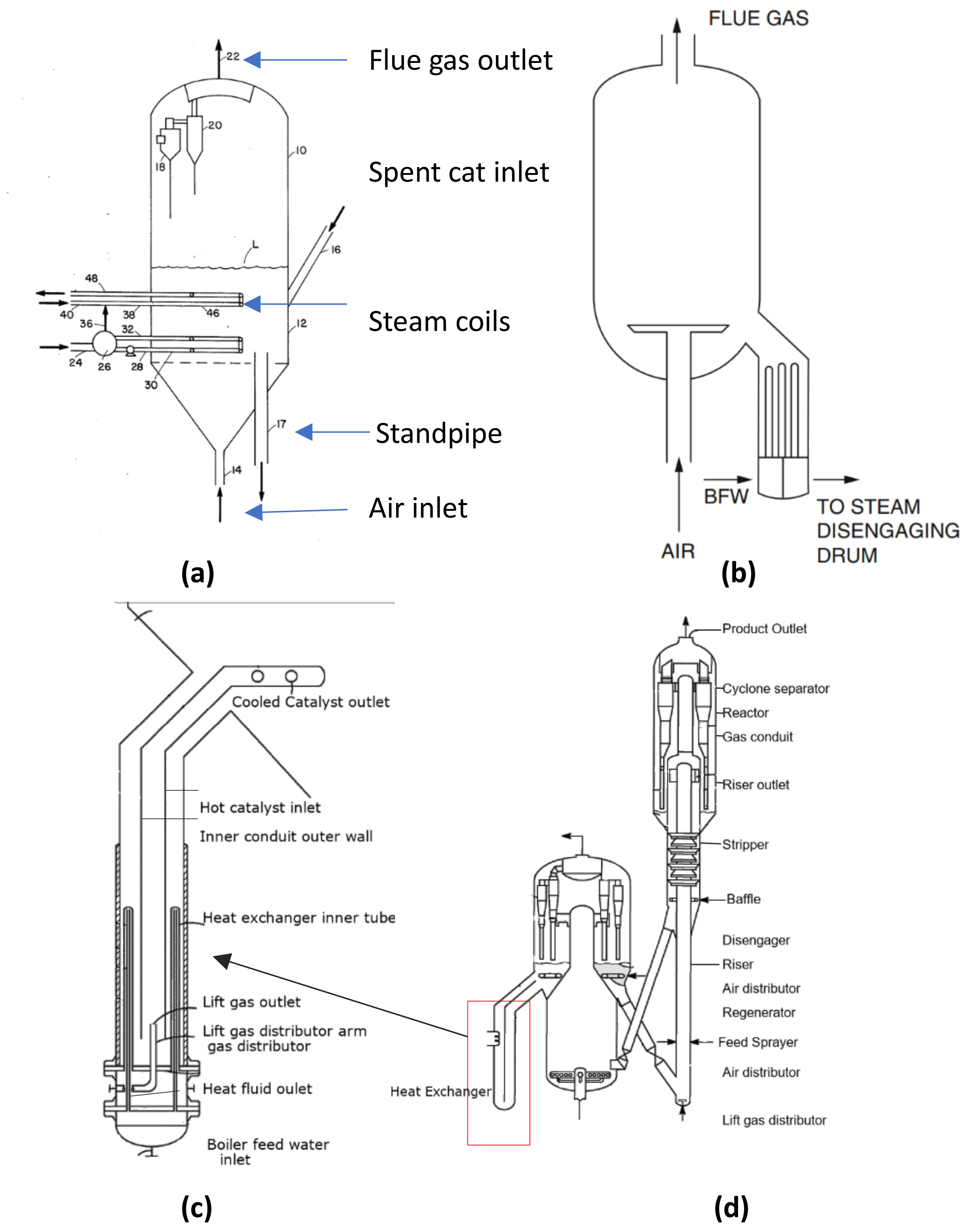

1.3. FCC Regenerator: Functions and Various Designs in Petroleum Refineries

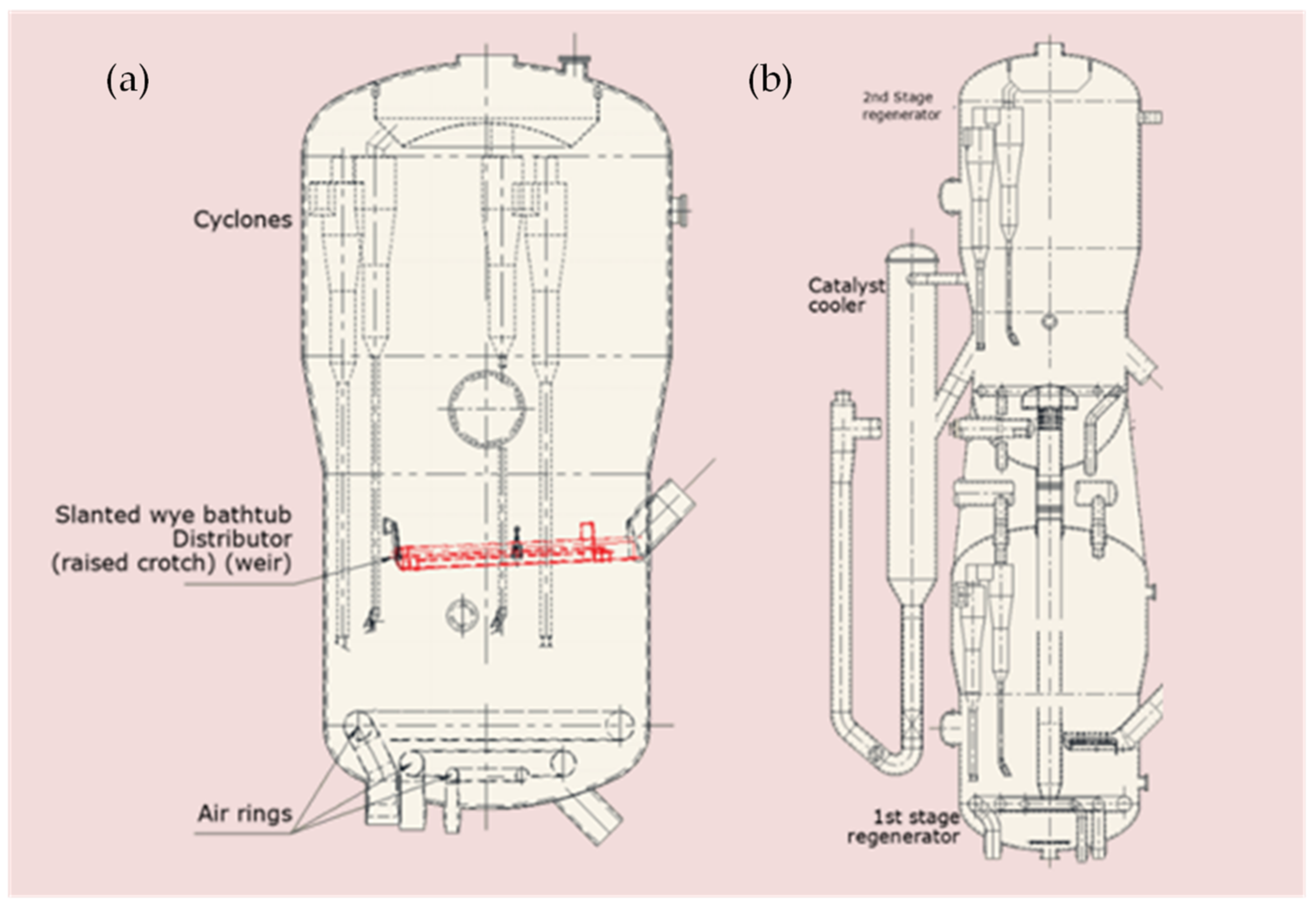

- Standpipes/slide valves: For building a hydraulic head by maintaining a column of fluidized particles. Spent catalyst standpipe transports coked cracking catalysts into the regenerator from the riser, while the regenerated catalyst standpipe allows the return of cleaned catalyst back into the reactor [48]. The embedded discrete slide valve controls the catalyst circulation rate (see Figure 1 and Figure 2).

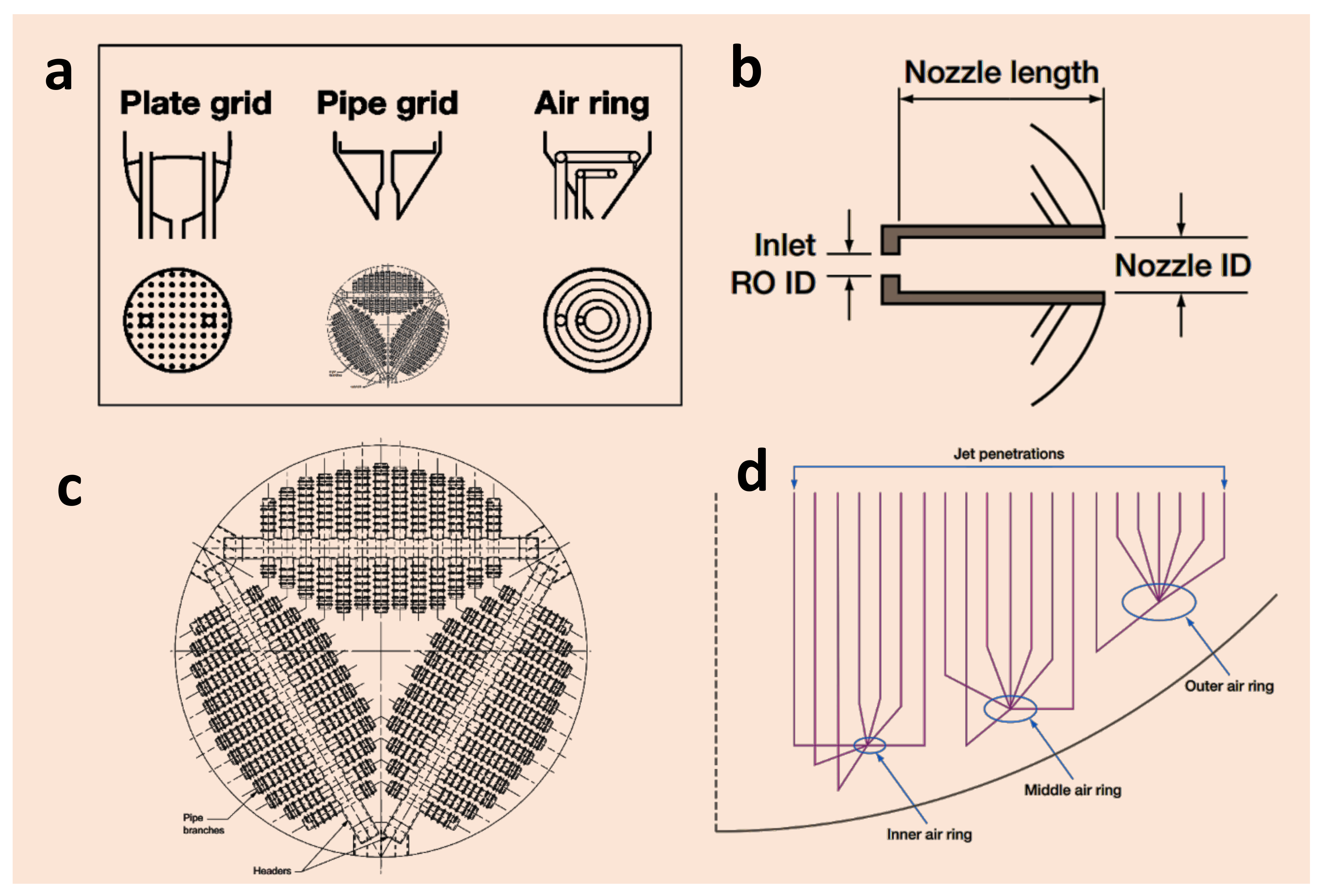

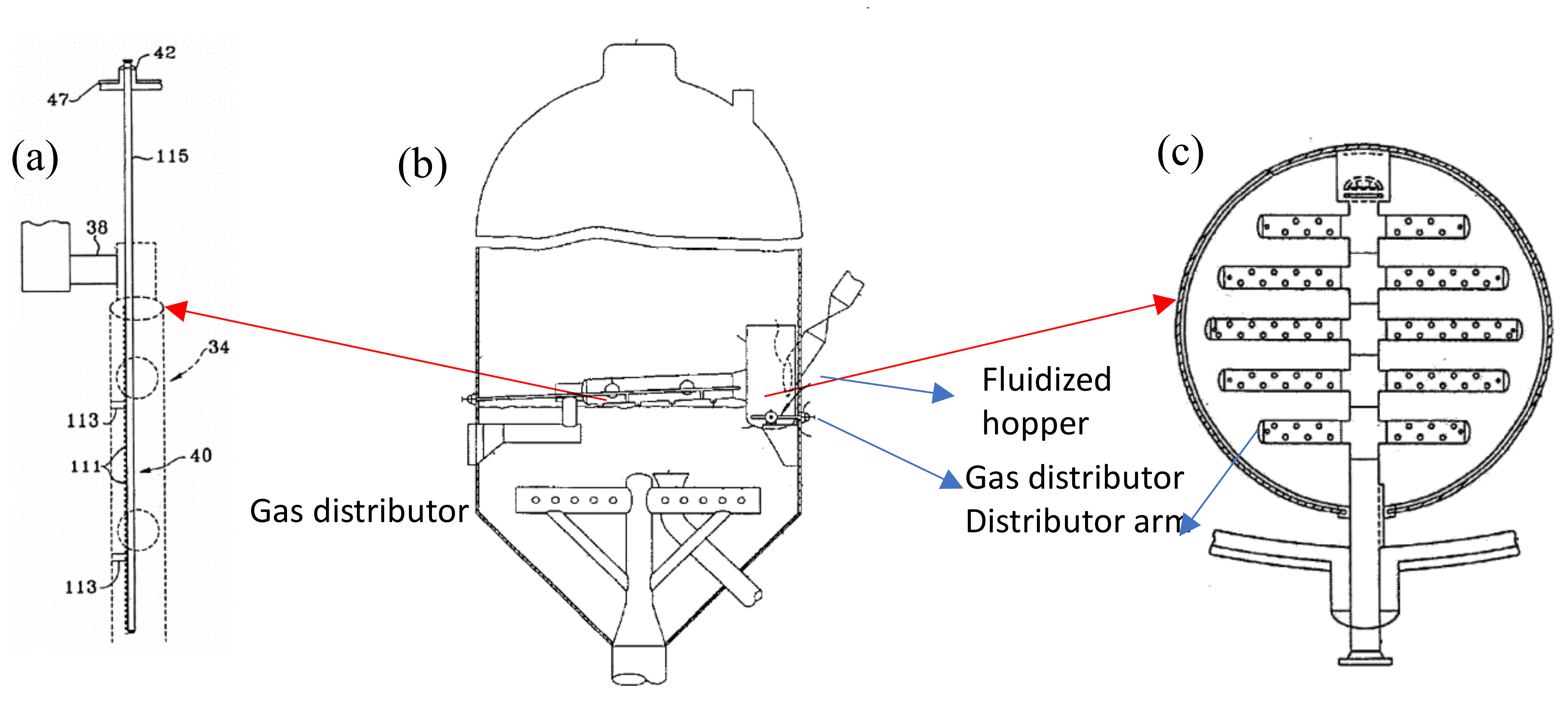

- Air/steam distributor: For even dispersion of feed gas into the regenerator bed cross section [51].

- Cyclones: Usually in multiple pairs (primary and secondary) for separating entrained catalyst particles from flue gas and returning the solids back to the regenerator bed [13].

- Plenum: A device positioned at the top of regenerator system, usually made of carbon steel for receiving flue gases from multiple pairs of cyclones before they are vented out. It also aids in minimizing catalyst loss [1].

- Catalyst cooler: Auxiliary internal used to keep the unit temperature within the tolerance limit. It is one of the most flexible and reliable internals that functions optimally in the range of 100% design duty and can be safely shutdown or restarted during full operation [13].

- Baffles: Auxiliary internal for inducing efficient gas–solid within the regenerator bed, among others [52].

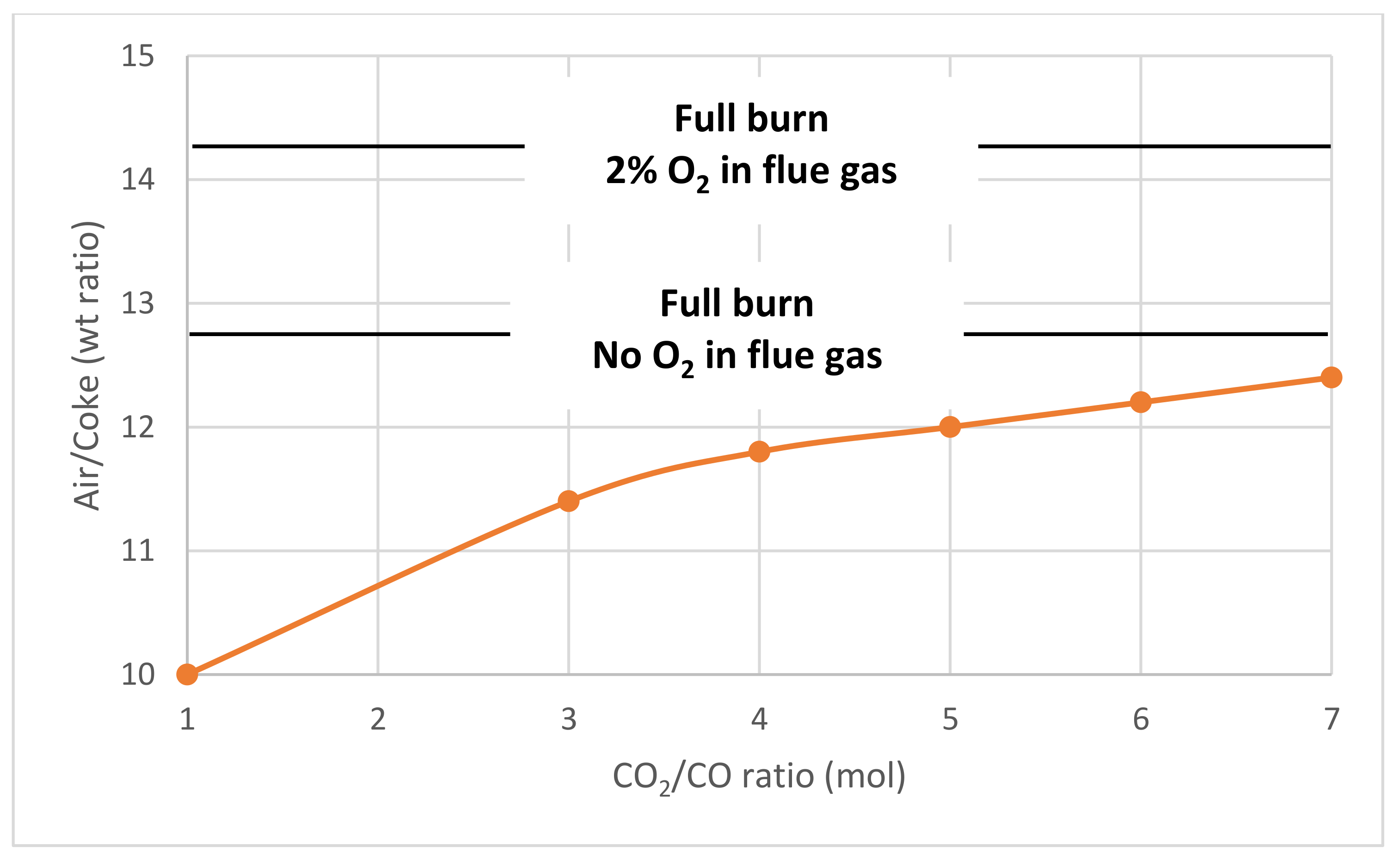

1.3.1. Coke-on-Catalyst Combustion Mechanisms in the Regenerator

1.3.2. Key Process Considerations and Constraints

1.3.3. Alternatives to Coke Combustion Method of Coke-on-Catalyst Removal

1.3.4. Various Needs of PI in FCC Regenerators

- Optimization of geometry to promote intrinsic coke combustion and energy consumption;

- Increase in particle bed density with more uniform horizontal dispersion of gas and solids and a controllable bed expansion to enhance heat transfer;

- Reduction in solids residence time to avoid thermal deactivation;

- Reduction in radial nonuniformity of gas–solid bed mixing to improve bed stability, combustion rate and emission reduction;

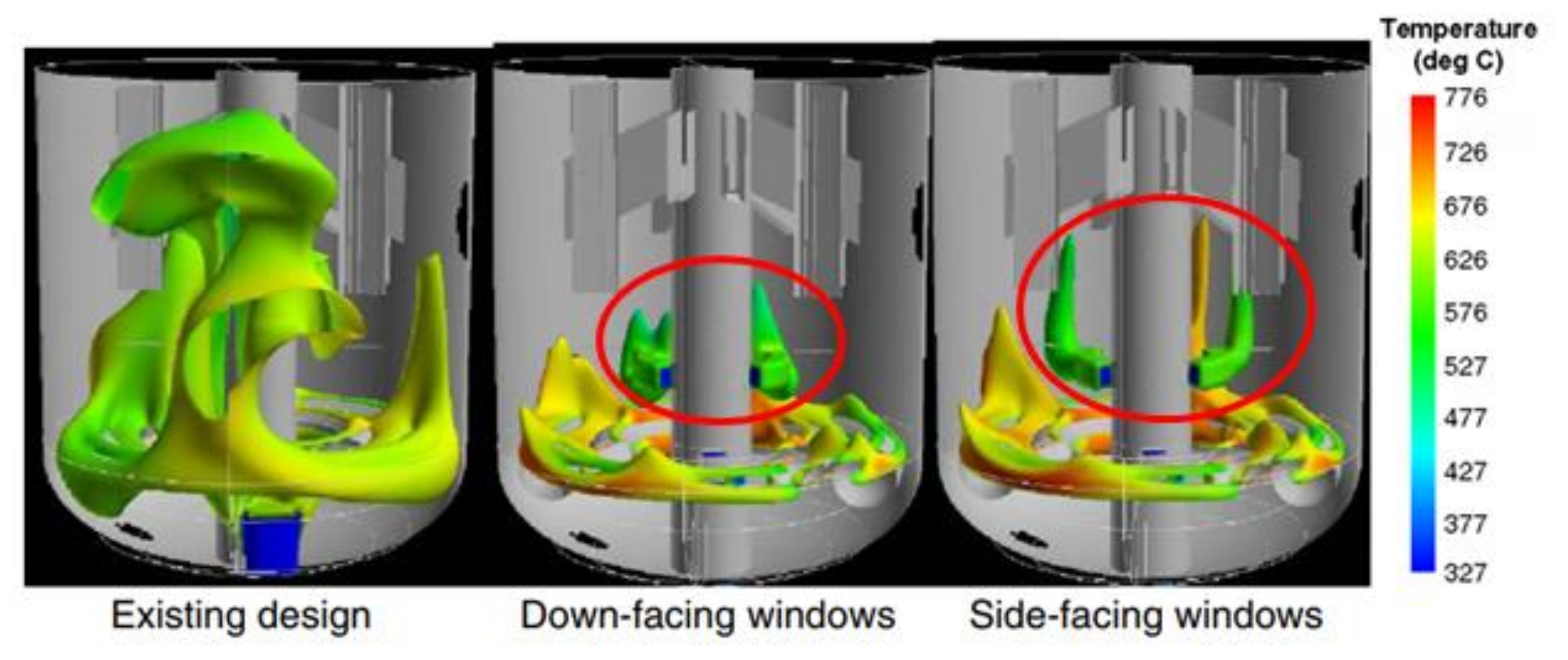

- Prevention of spatial non-uniformities of gas and solids temperature distributions, which forestalls afterburn;

- Increasing the gas–solid slip velocity so as to intensify the gas–solid heat and mass transfer, emission reduction, etc.

1.4. Scope and Objectives

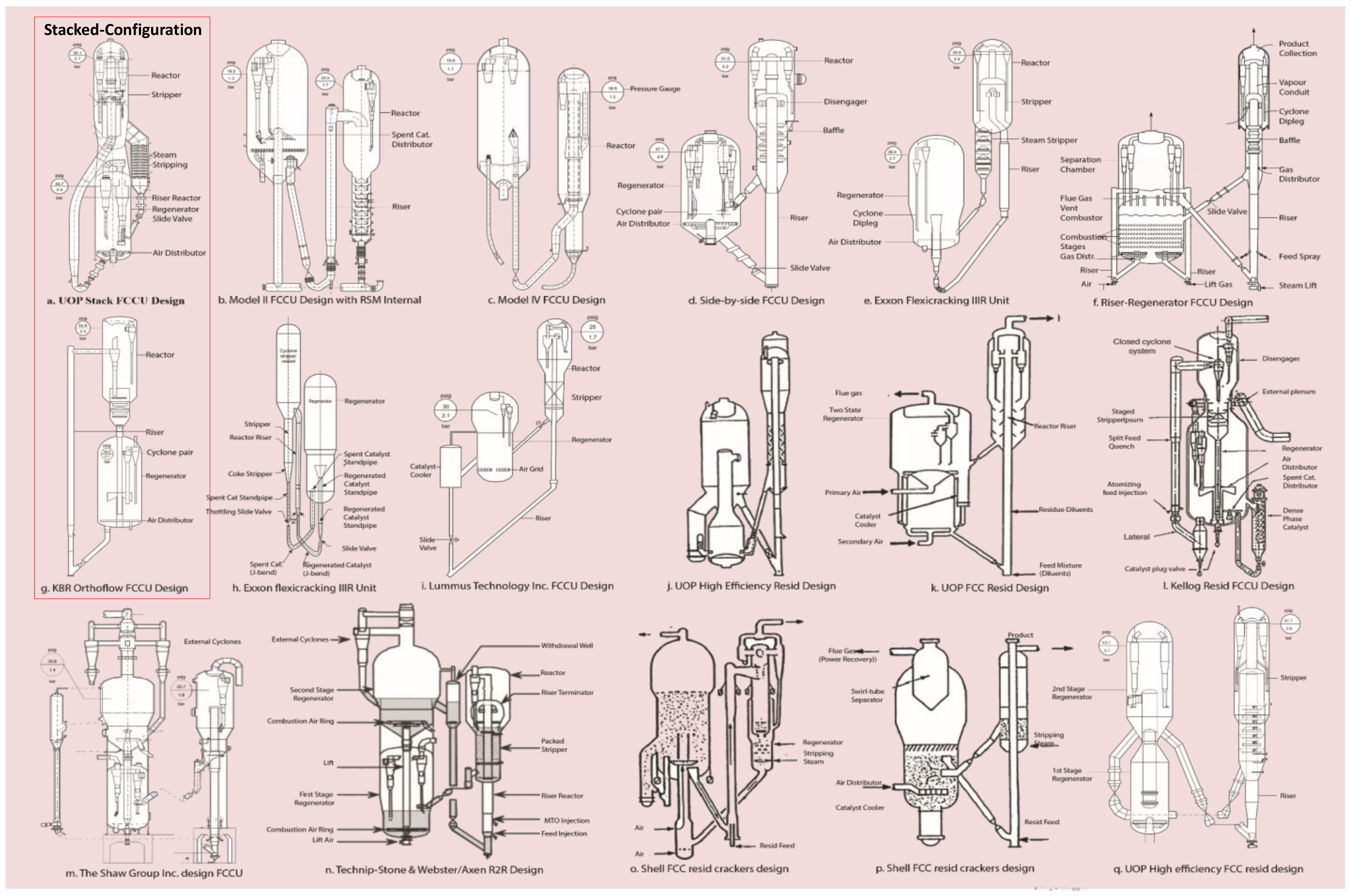

2. Different Designs of FCC Regenerators

2.1. Full Regeneration Design

2.1.1. Single Stage Regenerators

2.1.2. Two-Stage Full Burn Regenerator

2.2. Structural Regenerator Design and Synergistic Integration to Reactor

2.2.1. Design Configuration with FCC Reactors

2.2.2. New Advances in Automation Technology Adapted to Regenerators

- Cyclone separator: velocities, pressure drop;

- Regenerator bed: catalyst level and inventory, superficial gas velocity;

- Slide valve: differential pressure;

- Rate of change of alarms, etc.

| Type | Developer/Licensor | Catalyst Charging Pattern/Additional Features | Strength | Weakness | Status |

|---|---|---|---|---|---|

| Mode I Upflow unit | SOD (ExxonMobil) in 1942 | -Upflow or fast-circulating fluidized bed -Dilute-phase catalyst cooler -External cyclones installed | -Quick separation of from catalyst -Flue gas precipitation | -high catalyst losses (due to inadequate contact time and low dense bed), -high reactor height promoting thermal cracking in the reactor dilute phase -high catalyst loading -natural clay catalyst -operational and mechanical problems -No heat balance | Extinct |

| Model II | Exxon in 1943 | Downflow | -Premix of catalyst and feed before entering the reactor via slide valve -Operates at low velocities -Low catalyst loss | -High pressure drops resulting in rapid erosion problems from long regenerated standpipe | Few still in existence but with modified riser and air distributor configurations |

| Model III | M.W. Kellogg (Shell) 1951 | Downflow Side by side | -low elevation regenerator -Shorter regenerated catalyst standpipe length -high riser with internal stripper -Low catalyst attrition due to the use of microspherical (MS) catalyst -elimination of Cottrell precipitation -elimination of waste-heat boilers | -Rapid Erosion of slide valve and in the perforated grid catalyst distributor | Operational |

| Model IV Side by side unit | SOD ExxonMobil 1945–1952 | -Upflow -No slide valves -Same height reactor and regenerator | -Suitable for Modular scale and large units -Decrease in reactor height -Efficient catalyst transfer rate -Low maintenance menace -Stable fluidization -Better operational flexibility -Low erosion occurrence -Elevated pressure and internal velocities -Catalyst circulation rate regulated by differential pressure between riser and regenerator | -Non-flexible U-bend operation -Potential for catalyst defluidization at the U-bend due to lateral flow pattern -Non-flexible temperature control in the reactor except by adjusting reactor temperature -Unit demands intense supervision | Operational |

| Model IV flexicracker | Exxon 1972, 1993 | -Upflow -No slide valve -Side by side | -Catalyst U-bend standpipe substituted with standpipe linked with an upwardly sloped lateral -Low elevation regenerator -short contact time -Catalyst circulation rate regulated by differential pressure between riser and regenerator | -High CAPEX -Complex process control | Operational |

| High-efficiency two-stage regenerator | UOP 1978 | -Side by side regeneration | Fast fluidization regime Small diameter lift | -Uniform coke burn, -Higher conversion of CO to CO2 and lower NOx emissions | Operational |

| R2R or RFCC | Total 1980s | -2-stage regeneration -Air riser moves semi-regenerated catalyst to full combustion zone Dense-phase coolers | -100% resid feed (atmospheric bottom) -High coke combustion rate -Operates at high temperature -Lower catalyst inventory -Sharp disengagement of product vapors from the catalyst -Cost effective and flexible -high propylene yield -high heat recovery -Numerous turnaround flexibility | -Potential localization of afterburn in the first stage | Operational |

| Millisecond-catalytic cracking (MSCC) | UOP/Coastal 1994 | -Downflow -Side by side regeneration | -Two reaction zones (dual diameter reactor) - Quick catalyst-vapor separation -low-volume cracking reaction zone | High temperature demand | Operational |

| Superflex Kellogg | 2005 | -Countercurrent flow -Side by side regeneration -Proprietary catalyst | High gasoline cracking to olefin | High residence time and temperature | Operational |

| PetroFCC | UOP 2007 | Downflow Side by side | -Dual diameter reactor -Low pressure | -High reaction temperature - High dry gas yield and low gasoline and diesel | Operational |

| Catalytic pyrolysis process (CPP) | RIPP/Sinopec 2010 | Downflow Side by side | -Short residence time | Demands higher regeneration temperature to provide the heat of reaction -Non-flexible reaction | Operational |

| ACO Advanced catalytic olefins | KBR and SK Innovation Global Technology 2011 | Orthoflow and stacked Reactor/Regenerator | -Lower space volume -Lower cracking temperature -Lower coke production | -Non-flexible reaction | Operational |

| HS-FCC | Nippon/Aramco 2011 | -Downflow -Modification in reactor/regenerator and stripping units | -Minimized backmixing -High selectivity to propylene yield | -High CAPEX | Operational |

| Post-riser Regeneration Technology (PRRT) | 2007 | -Downflow -Two risers -Side by side | Large capacity -Ease in starting combustion -High coke combustion efficiency -low | No commercial application |

3. Measures to Improve Regeneration Performances

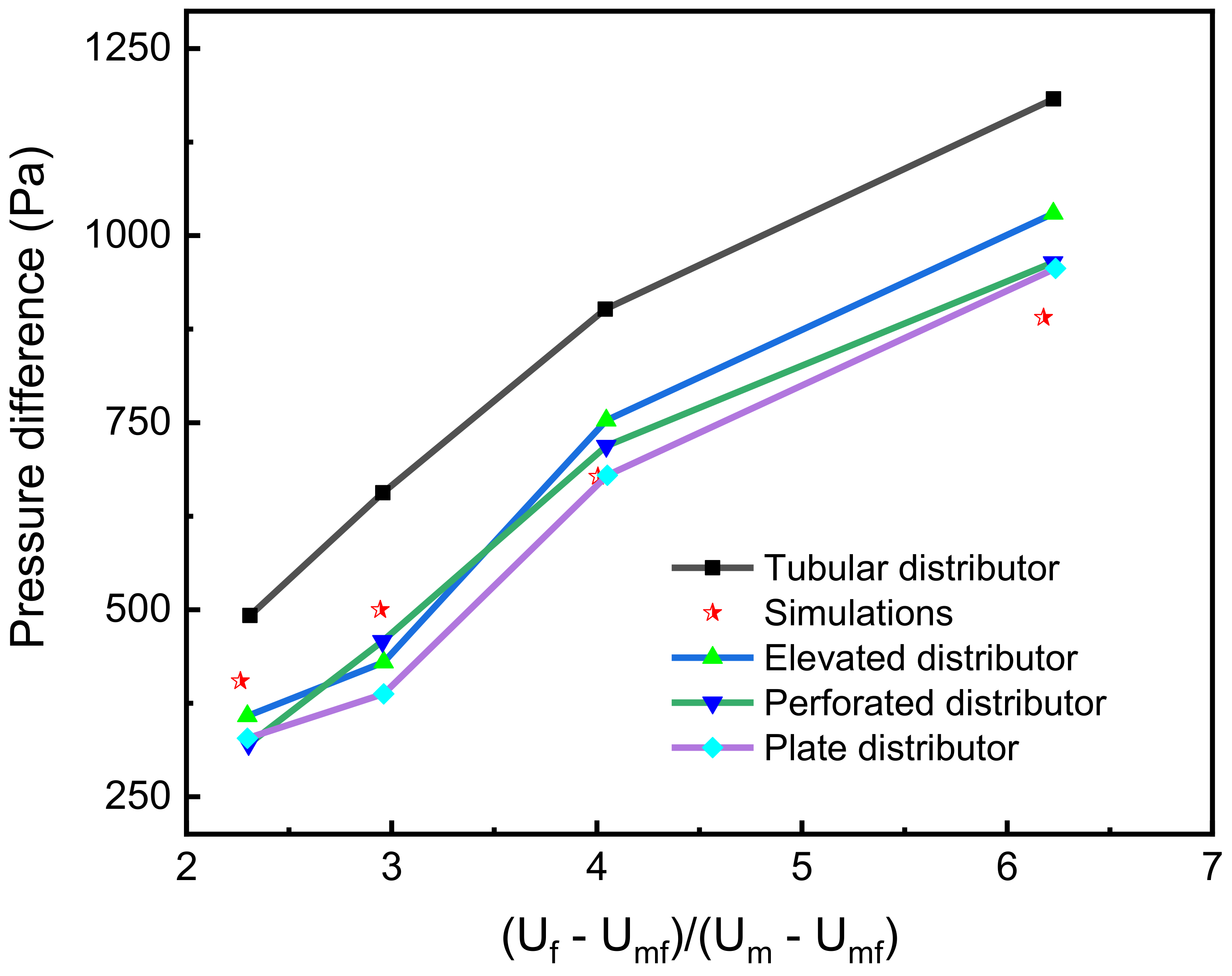

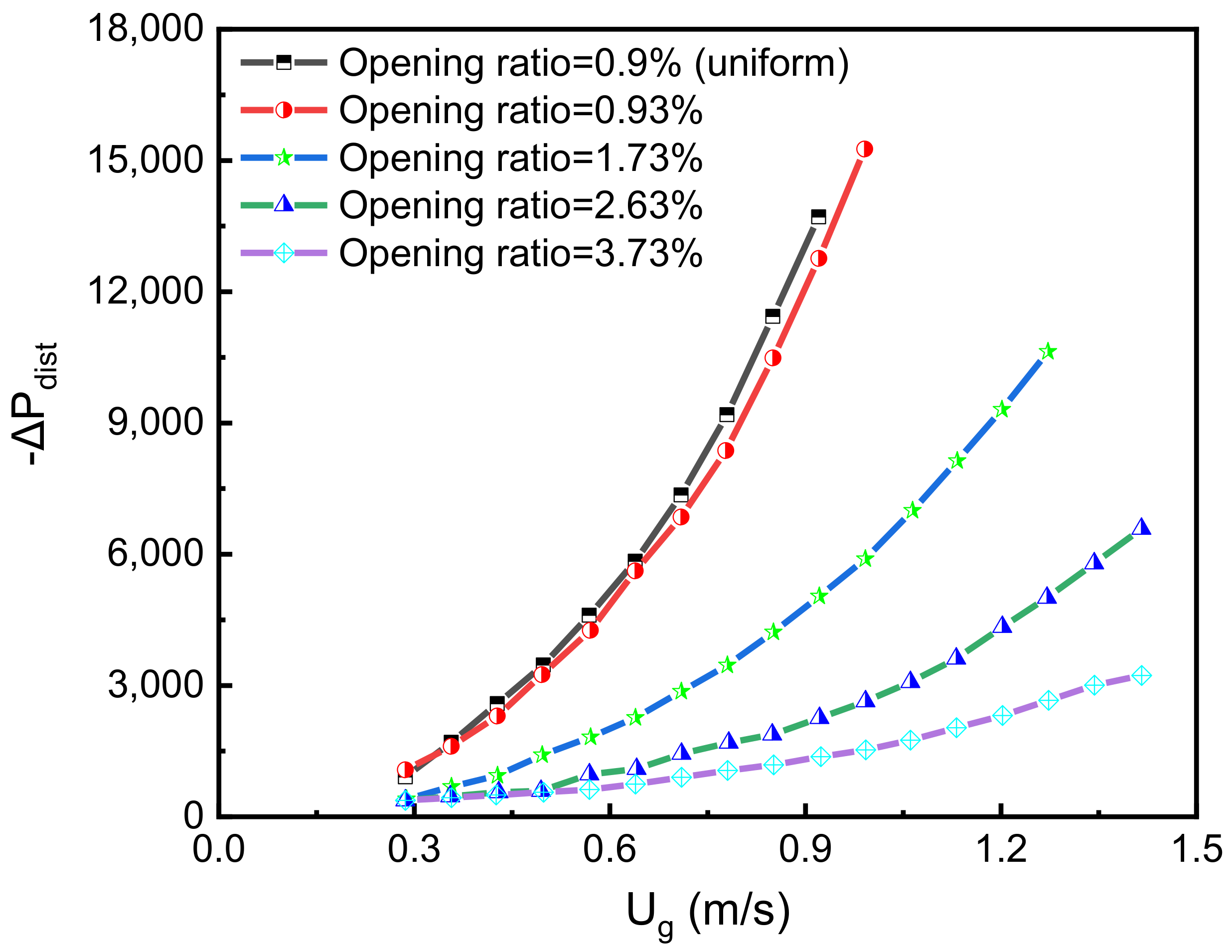

3.1. Main Air Distributor

3.1.1. Effect of Temperature and Pressure

3.1.2. Effect of Distributor Configuration

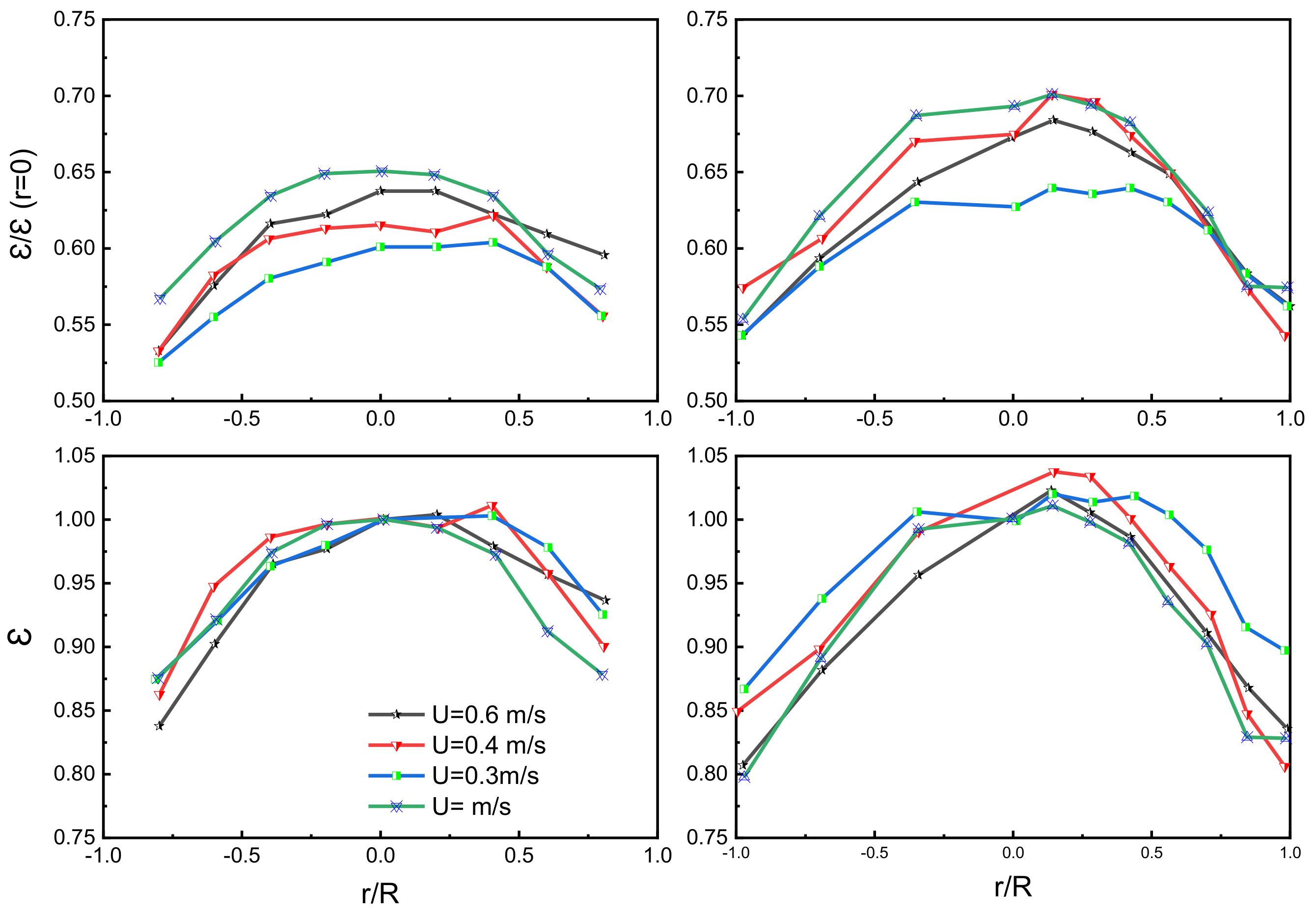

3.1.3. Effect of Distributor Design on Fluidization Quality

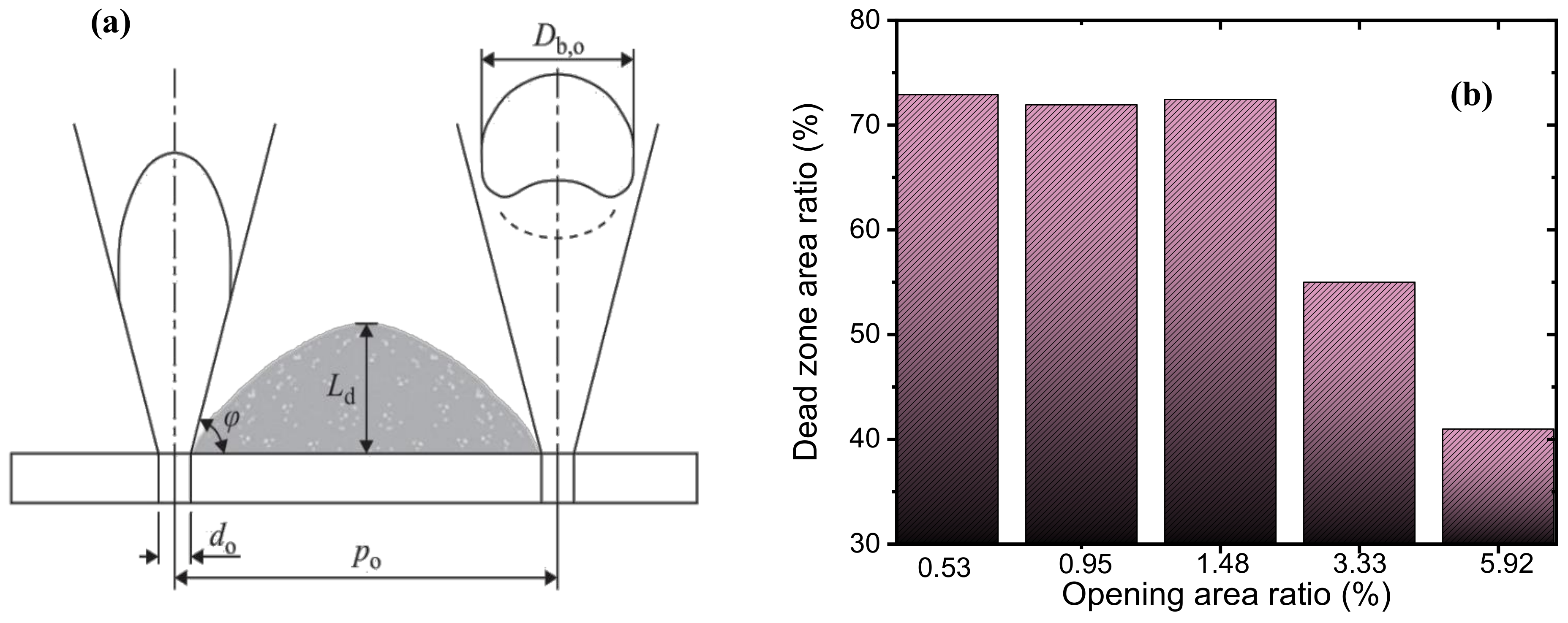

3.1.4. Effect on Dead Zone Formation

- Antisurge not conservative enough = surge

- Antisurge too conservative = loss of efficiency

- MAB venting to atmosphere = noise complaints

- Pump performance curve shift = cavitation

- Sharp vibrations

3.2. Spent Catalyst Distributor

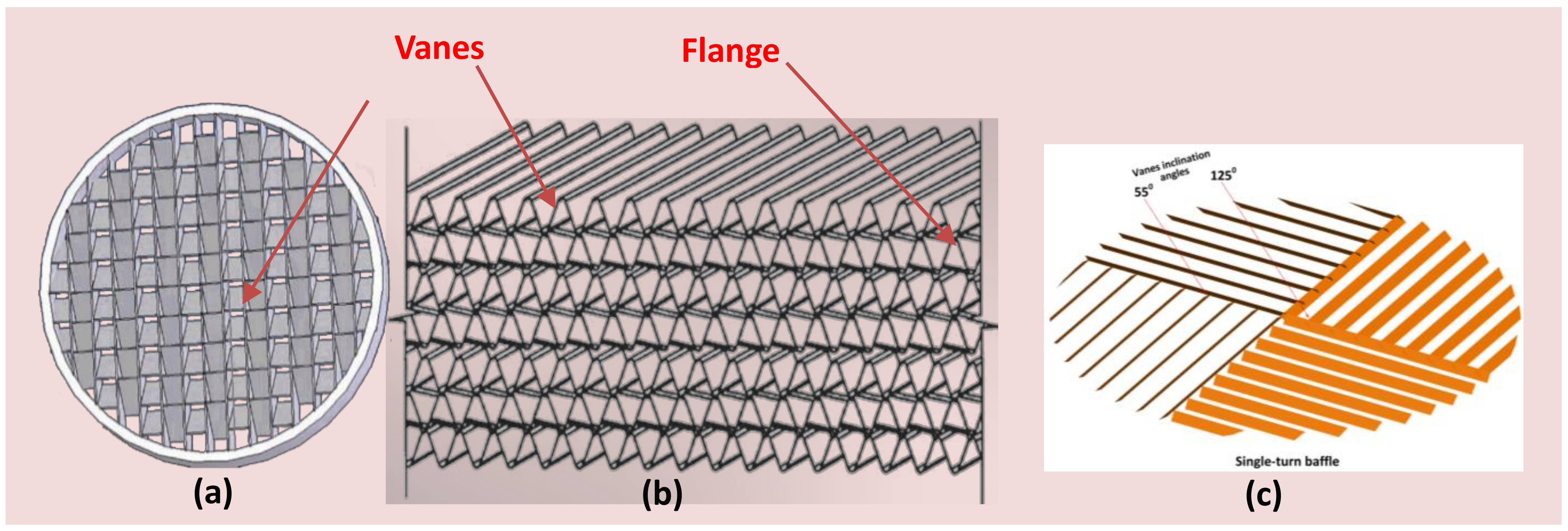

3.3. Baffles and Other Internals

| Baffle Parameter | Degree | Advantages | Disadvantages | Model Geometric | Type/Specification | Reference |

|---|---|---|---|---|---|---|

| Size | Longer length | Increases radial dispersion close to the baffle region Lowers radial temperature gradient Increases particle velocity (especially in the annulus) | Low effect on flow at regions far from the baffles Increases dead zone near the walls (i.e., low particle content in the regions far from the baffles) | 2D 30 × 1 m | Louvers 10, 7.5 and 5 cm | [171] |

| Spacing | Smaller | Increases breaking of large bubbles Improves radial homogeneity Higher dilute flow and low particle near the wall | Increases near wall dead zone Extent of particle segregation is negligible at low gas velocity | 2D 30 × 1 m | Louvers 5, 2.5, and 1 m Perforated 6, 4, and 2 cm | [171,201] |

| Number | Higher | Increases bed expansion Decreases bubbles diameter Bubble energy is weakened, hence coalesce and formation of new bubbles declines More uniform particle distribution around baffles | Increases pressure drop | 2D 1 × 0.1 m | Perforated 4, 3, 2, and 1 | [182,201] |

| Slat Pitch | Smaller | Forces acting on baffles decrease at high superficial gas velocity | Dynamic forces acting on baffle increase at low superficial gas velocity | 3D 0.3 × 0.3 × 5 m Baffle geometry: 0.3 × 0.05 × 0.003 m | Louvers 0.104, 0.071, 0.053, 0.035 m | [183] |

| Superficial gas velocity | Higher | Increases solids segregation efficiency Decrease in time required to attain a steady state Constricts axial particle flow | Higher pressure drop | 3D 0.102 × 6.32 m 3D 0.3 × 0.3 × 5 m | Perforated 1.8–3.1 m/s Ring 1.5–2.5 m/s Louvers 0.2–0.8 m/s | [183,201,202] |

| Opening space | Smaller | Eliminates the formation of large bubbles Reduces bubble energy Improves particle segregation efficiency | Higher dynamic forces on the baffle Higher pressure gradient Increases axial particle velocity | 2D 1 × 0.1 m | Perforated 30.2, 20.5, and 10.6% | [182] |

| Caps | Present | Restrains jet flow entrainment and particle backmixing More uniform particle distribution | Increases pressure drop | 2D 1 × 0.1 m | Perforated 20 mm | [182] |

| Layout position | Higher | Low dynamic force at higher lateral position at high superficial gas velocity | Higher stress is imposed on the annular slat at higher superficial gas velocities | 3D 0.3 × 0.3 × 5 m | Louvers 0.9, 0.7, 0.5, 0.3, and 0.1 m | [183] |

4. Measures to Improve Regenerator Reliability

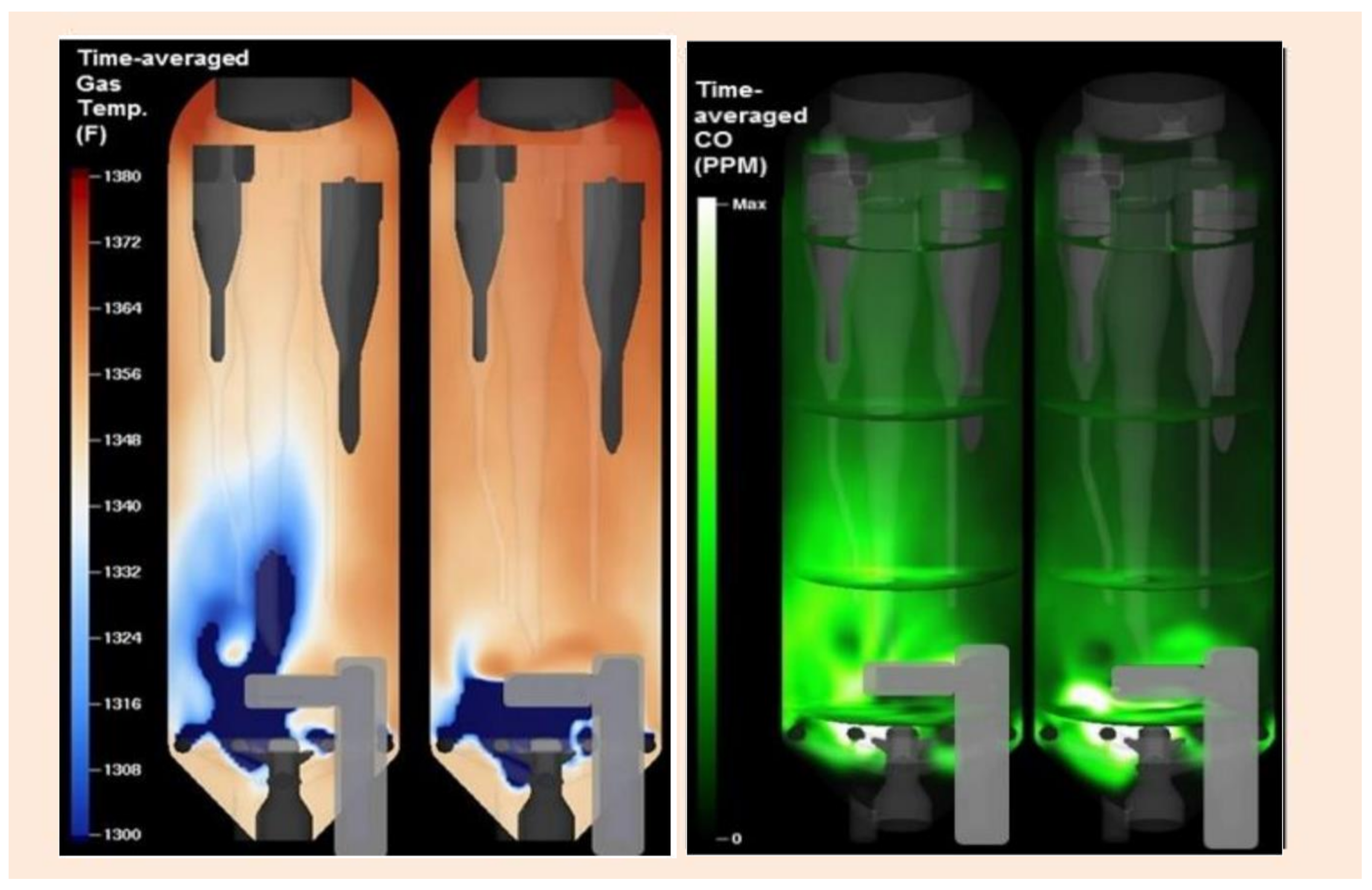

4.1. After-Burn Control Measures

4.1.1. Application of CO Combustion Promoters

4.1.2. Modification of Air/Spent Catalyst Distributor

4.1.3. Pressure and Other Process Adjustments

- Installation of catalyst cooler;

- Injection of torch into the regenerator or slurry oil recycle into the reactor to maintain heat balance across the reactor–regenerator;

- Regulating the regeneration air flowrates to match each air/steam distributor;

- Raising the pressure across the regenerator unit; standpipe, slide valve, air/steam distributor, cyclone diplegs, among others;

- Reducing redundant oxygen provided and optimizing the flue gas excess oxygen;

- Appropriate design or modifications of the gas and spent catalyst distributors to induce uniform distribution of regeneration air and spent catalyst across the dense bed.

4.2. Anti-Erosion Measures

- Design of long shrouds to restrain direct fluid jet impingement on the regenerator side walls or on the distributor plate.

- Use of short nozzles mounted over the grid holes to induce jets flow, hence reducing fluid-surface impacts.

- Preferably using volute inlet cyclones for highly loaded catalyst separation while tangential inlet configuration is efficient as secondary cyclones where interference with the inlet catalyst flow stream is rare.

- Increased number of series cyclones, this has been proved to achieve over 99.999% efficiency [231].

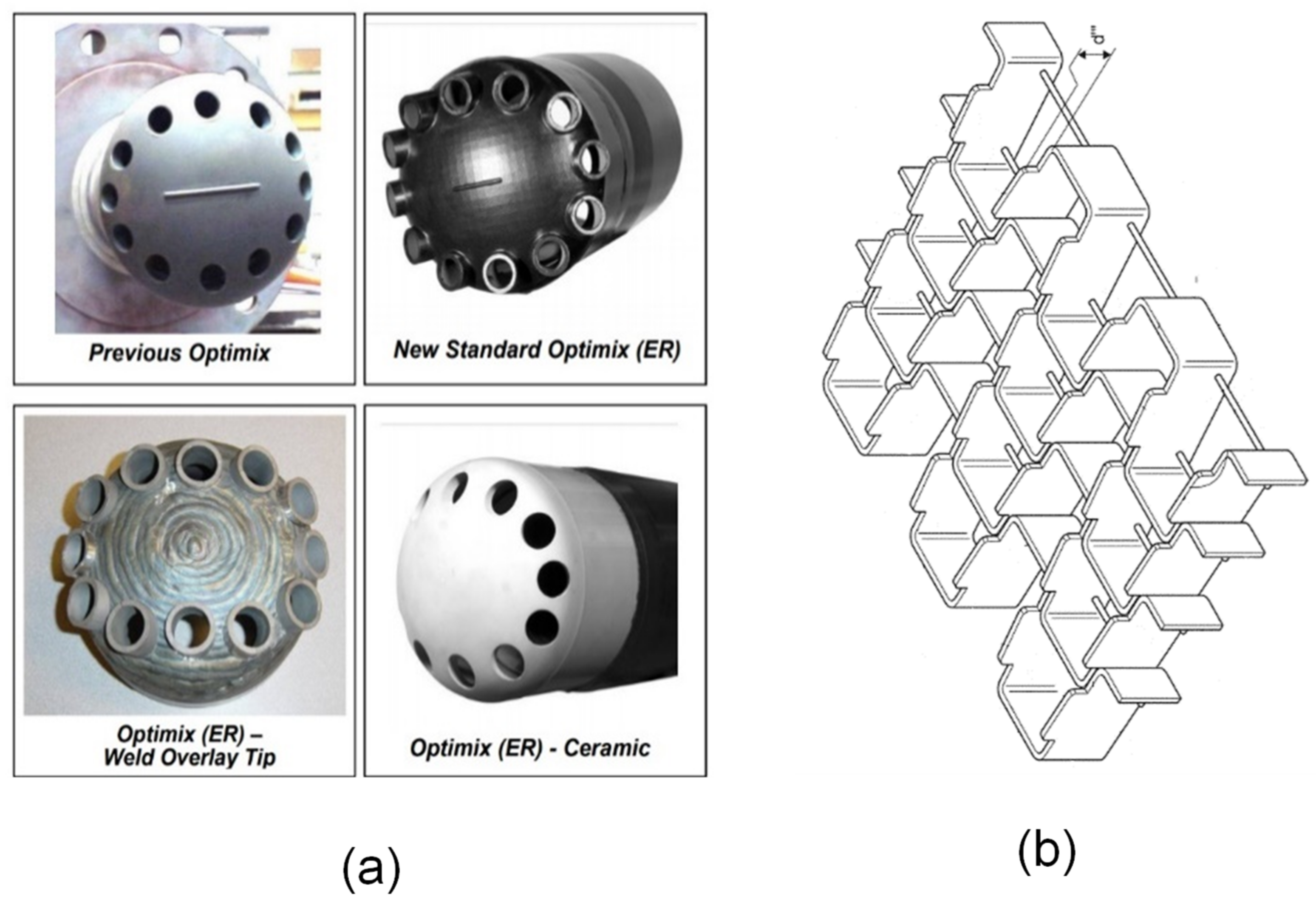

- Cyclone walls must be smooth and coated with composite material (refractory or ceramic) held by a specially designed fastening structure (Hexmesh) made of austenitic stainless steel. This metal-matrix composite (MMC) would help lower corrosion-erosion [232]. An example of hexmesh design is shown in Figure 25b.

- Addition of inhibitors to the coatings or primers of closed loop internals.

- Increasing the thickness and hardness of the materials in vulnerable sections.

- Replacement of metallic distributors with ceramic feed distributors [233].

- Use of durable alloys such as Stellite-types for coating.

- Coatings must be glued well to reduce delamination and lower grain boundary adhesion.

- Reinforced material construction of bellows and expansion joint, including the use of high-quality nickel alloys, titanium and super austenitic stainless steels.

4.3. Catalyst Losses and Countermeasures

- i.

- Operating solutions for catalyst loss control

- Superficial gas velocity and gas composition. Decreasing superficial gas velocities will reduce solid carry-over (entrainment) in the regenerator [238,239]. With increasing Ug bed expansion rises, the velocity of large diameter bubbles increases, leading to forceful eruption and rupturing of bubbles at bed surface. Vertical drag on the solids in the freeboard also increases. These result in high entrainment and in turn high catalyst loss; the solid carry-over rate is proportional to Ug to the power of 3 to 4.

- Particle size distribution (PSD): Keeping the fine particle (0–40 µm to 14–20% will reduce catalyst loss [16]. Although high amounts of fine catalysts promotes high fluidization quality and combustion efficiency as its acts as a lubricant for ease of gas–solid flow, it is also a cause of high entrainment [68].

- Catalyst inventory. The catalyst bed level must be maintained in the regenerator by monitoring and controlling catalyst flow density rate and pressure drop above the gas distributor. A high catalyst circulation rate or catalyst loading directionally increases solid loss in and from the FCC regenerator [199,241].

- Pressure and temperature. Decreasing the operating pressure reduces the gas density and in turn increases solids terminal settling velocity and then results in a reduced entrainment rate, transport disengaging height (TDH) and solids loss rate [242]. Nonetheless, this only applies to a specific pressure range [242]. Regenerators are operated at elevated temperatures and the influence of temperature on catalyst loss is complex because the temperature affects other factors discretely. While some researchers obtained a decrease in entrainment rate and attrition at lower temperatures [243], some found the opposite trend [244], and others even argued temperature to be independent of the solids carry-over rate, albeit at a narrow temperature range [63]. These can be attributed to many variables (gas density, viscosity, cohesive or drag force) that contribute to spatiotemporal distribution of temperature in the device [63,196,240,241,245].

- ii.

- Regenerator hardware solutions for catalyst loss control

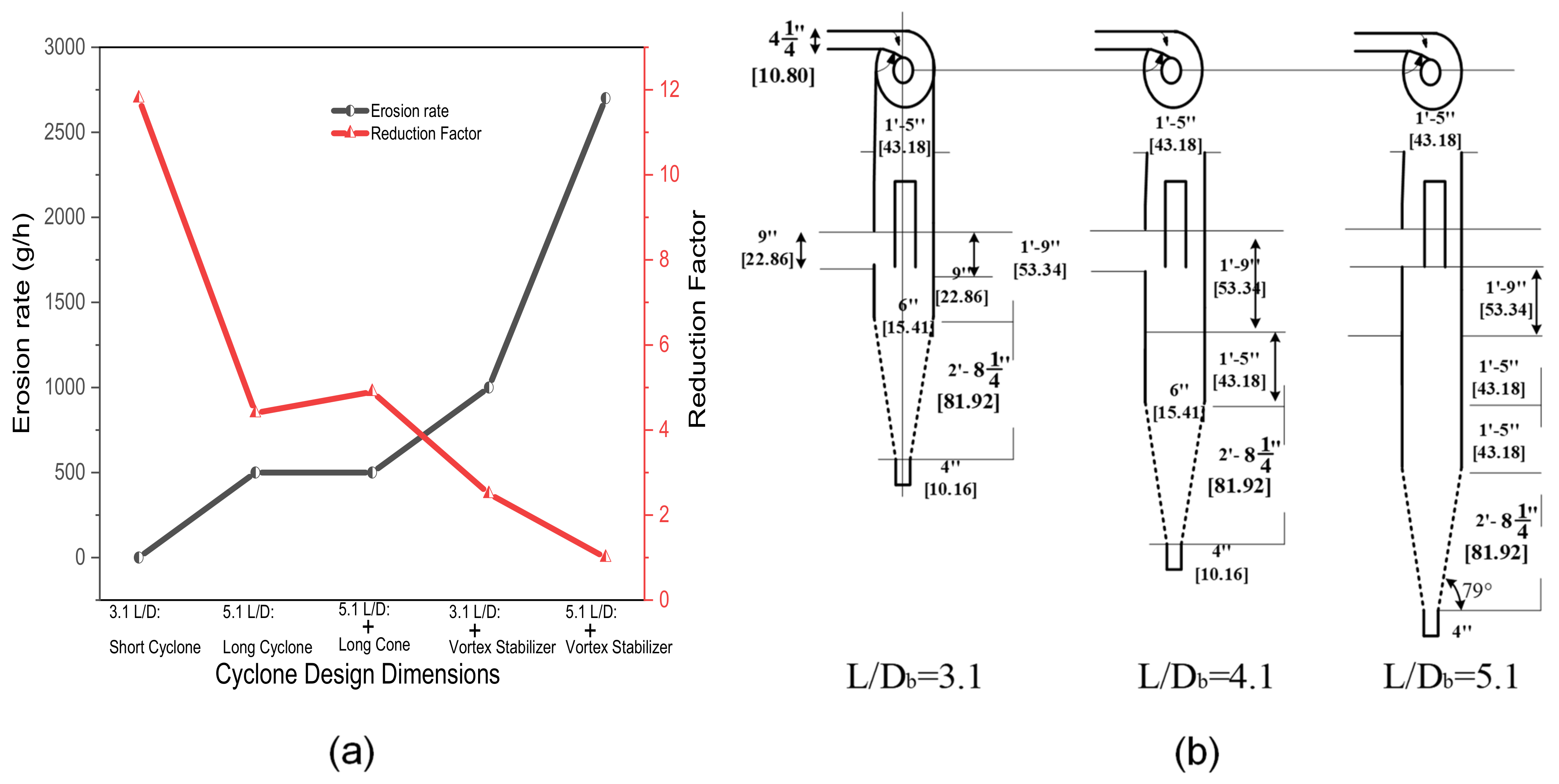

- Cyclones: Geometry of cyclones has negligible impact on attrition rate and catalyst loss rates [247]. Holes in the cyclones and cyclone plenum, and extremely large dipleg diameter reduces cyclone efficiency and recovery rate of catalyst particles and in turn promotes high catalyst loss. Multiple cyclone pairs depending on regenerator capacity (15–22 pairs for 40 m diameter regenerator) could reduce solid loss rate but at the expense of higher maintenance cost and system complexity. Increase in cyclone pairs will also reduce catalyst loading to the cyclones and lowers attrition rate. Holes in the cyclones must be detected early via the pressure loss measurement. The diameter of cyclone dipleg should also be adjusted to the entrainment flux rate [248].

- Column wall lining: Refractory lining of regenerator reinforced by hex-steel must be in a good condition to reduce catalyst flow restricting at the wall which tends to elevate selective carry-over of catalyst fine particles as the center of the bed [13].

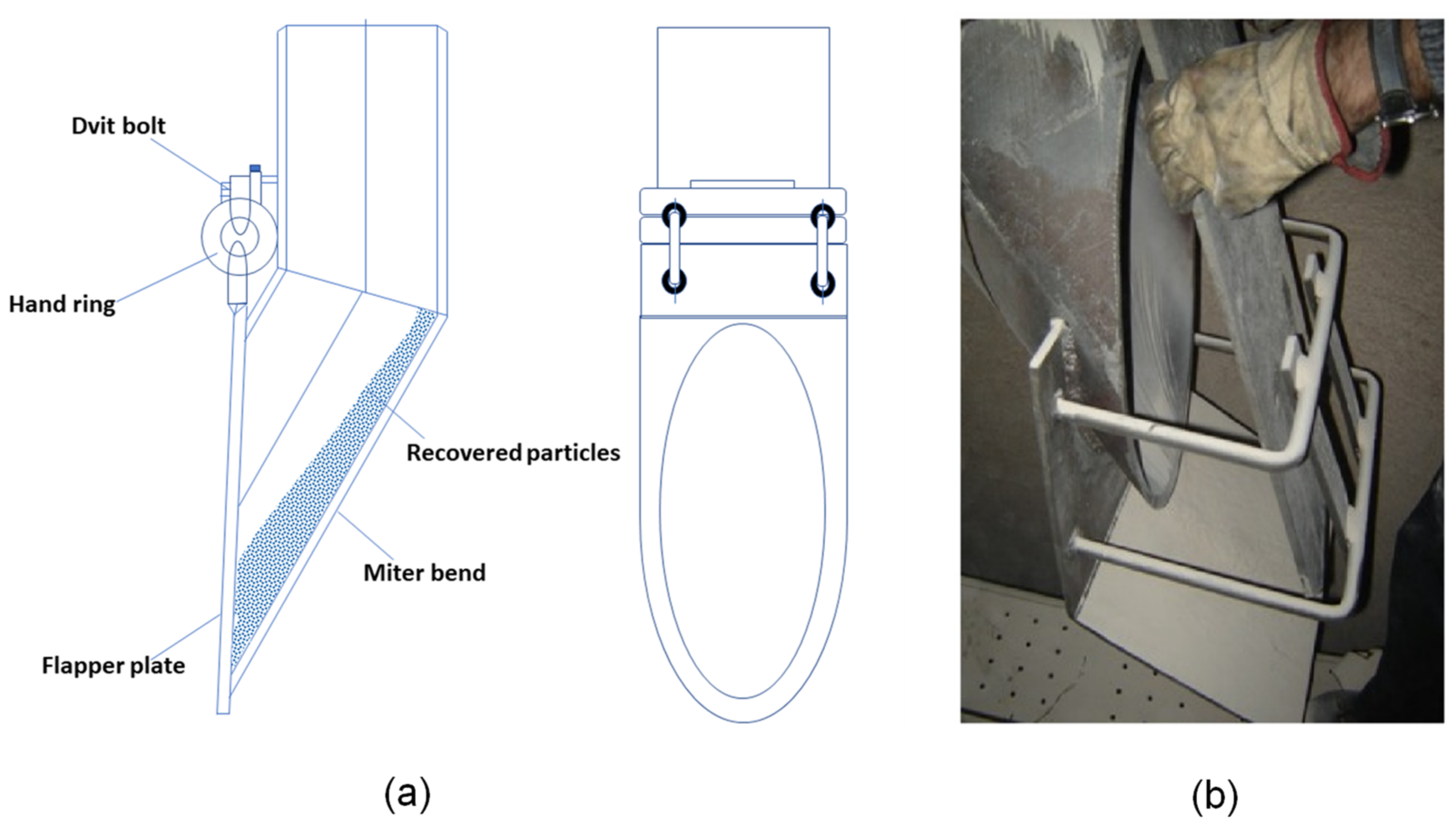

- Trickle valve: Submerged dipleg-trickle valve (Figure 26) often attached to secondary cyclone diplegs must be designed with erosion-resistant flapper surface. Defluidzation of catalyst underneath the submerged trickle valve can result in defluidization of cyclone diplegs, catalyst flow reversal and high catalyst loss rate, which must all be avoided [249].

- Gas distributor. It is imperative to attain a relatively uniform distribution of fluidizing gas through the regenerator. Any faults of the air grid have been found to generate a poor spatial gas distribution [157,238] and can consequently raise the catalyst loss rate. Orifice parameters (design, number, diameter, flowrate, etc.) must be attrition-resistance; in fact, the solid attrition rate is linear to grid jets kinetic energy . By implication, the attrition rate will increase when the pressure rises at a fixed orifice velocity. In theory, raising the gas temperature would lower the attrition rate, but, in reality, a strong supplementary consequence of thermal shocks may be triggered. Additionally, the attrition rates in vertical and radial jets are comparable; nonetheless, abrasion is 5–15 times greater with downward jets. An empirical correlation was developed to quantify the attrition rate instigated by gas jets in multiphase flow reactors as follows [2].where dh is the diameter of the orifice, Uhj is the orifice interjection velocity and is the gas density orifice. α and β, respectively, account for the influence of the particle characteristics and nozzle geometry, while and are the minimum fluidization velocity and superficial gas velocity, respectively.

- Spent catalyst distributor. The spent FCC catalyst should be well and evenly distributed across the catalyst bed to minimize the catalyst loss rate as discussed in Section 3.2.

- Geometry and enlargement of freeboard cross section. Catalyst loss due to entrainment becomes important when the column diameter (Dc) is greater than 100 mm with a linear relationship. Increasing the height and expanding the diameter of the freeboard section could dampen the region gas pressure, reduces gas velocity and attenuates the velocity of entraining solids, leading to an increase in terminal velocity and lower catalyst loss rate [68,238,241].

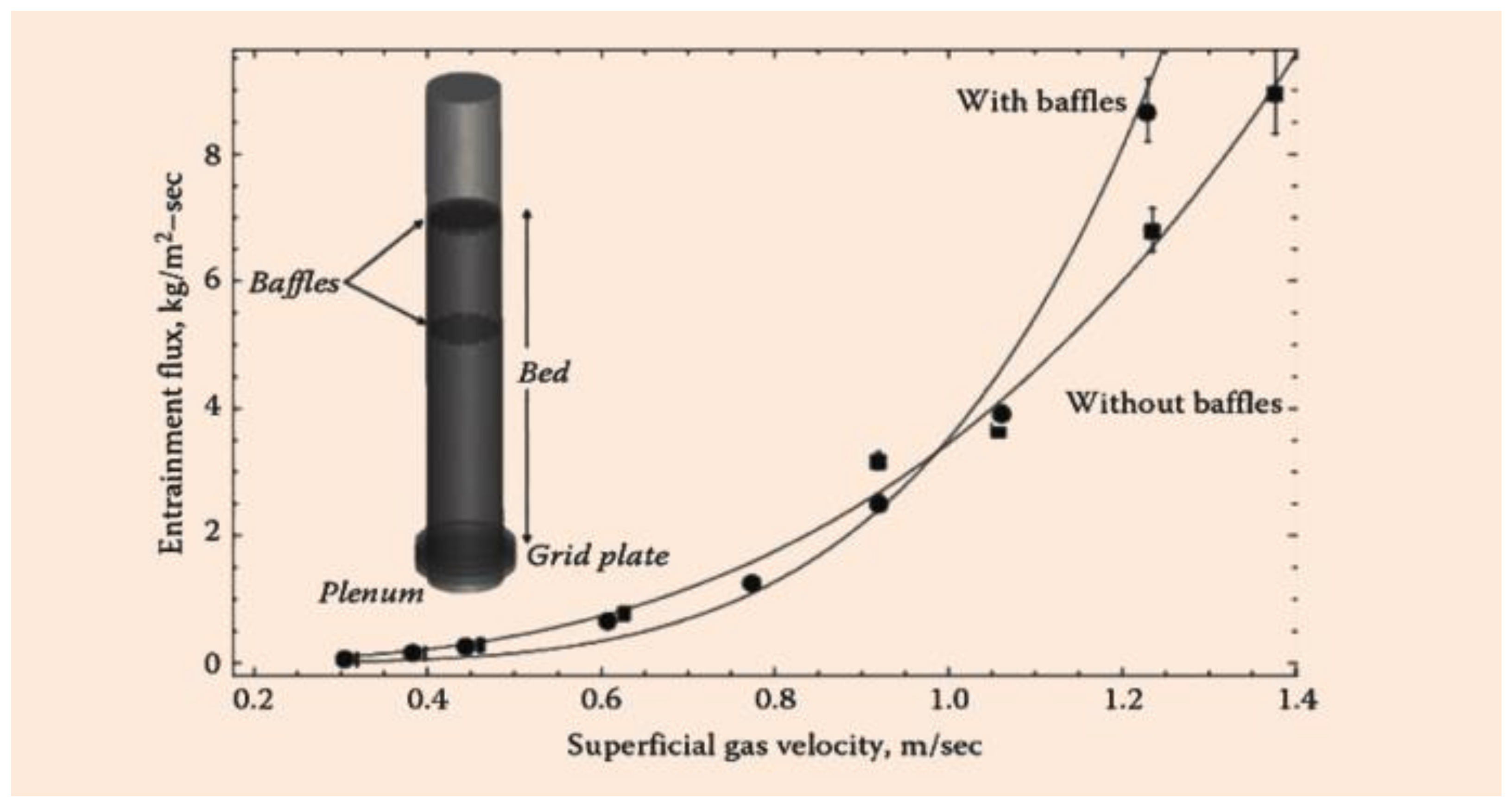

- Installation of internals. Properly installed internals such as baffle and heat exchangers can also mitigate the catalyst loss by reducing entrainment flux in addition to their discrete primary purposes [250]. However, they can also trigger a rise in the fluidizing gas velocity [68]; thus, care is required in their design specification and operation as discussed in Section 3.3.

5. Environmental Issues

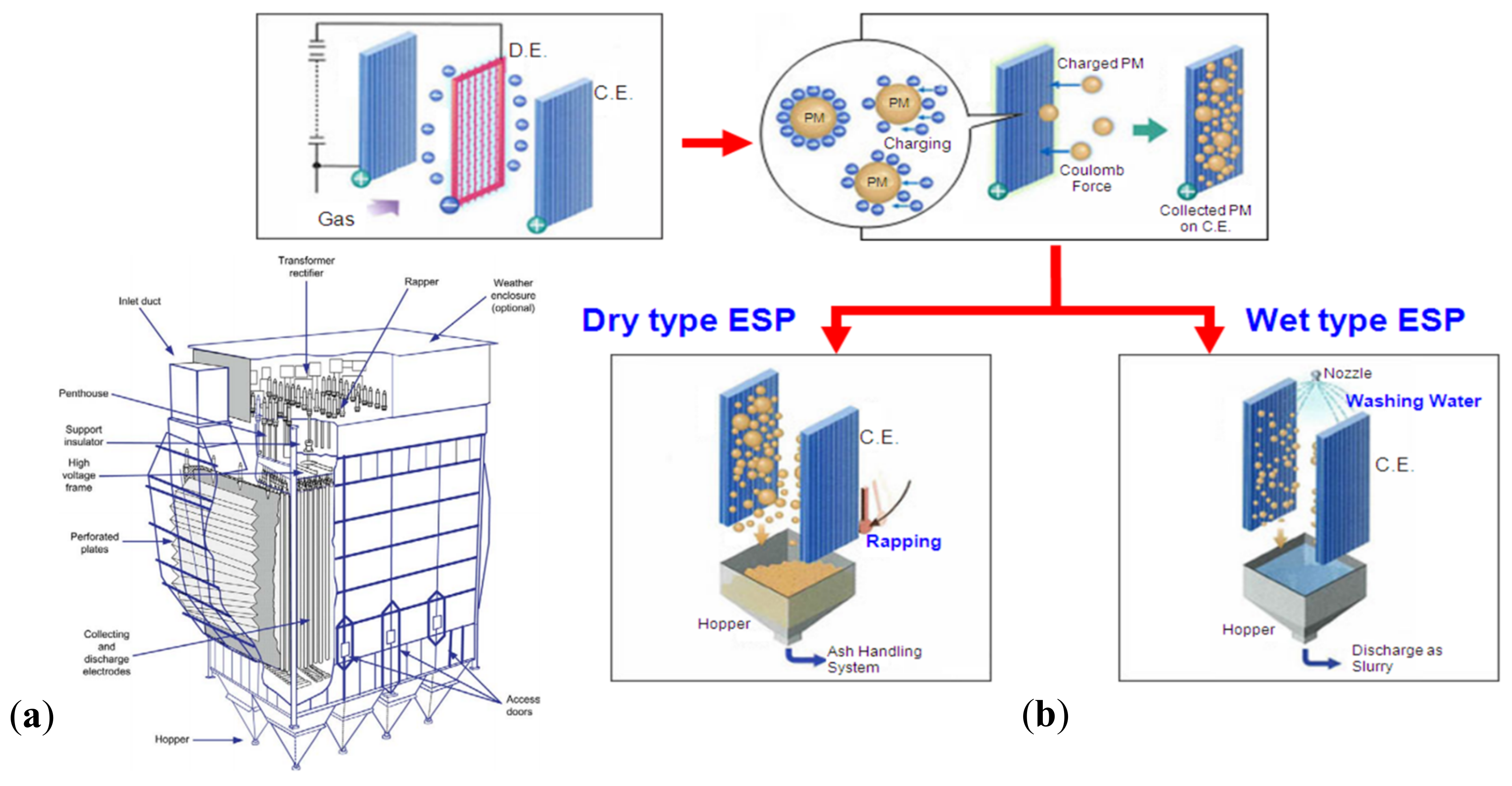

5.1. Process Intensification for Particulate Matter (PM) Reduction

- i.

- Third-Stage/Fourth-Stage Separator

- ii.

- Dry or Wet Electrostatic Precipitator (DESP or WESP)

- iii.

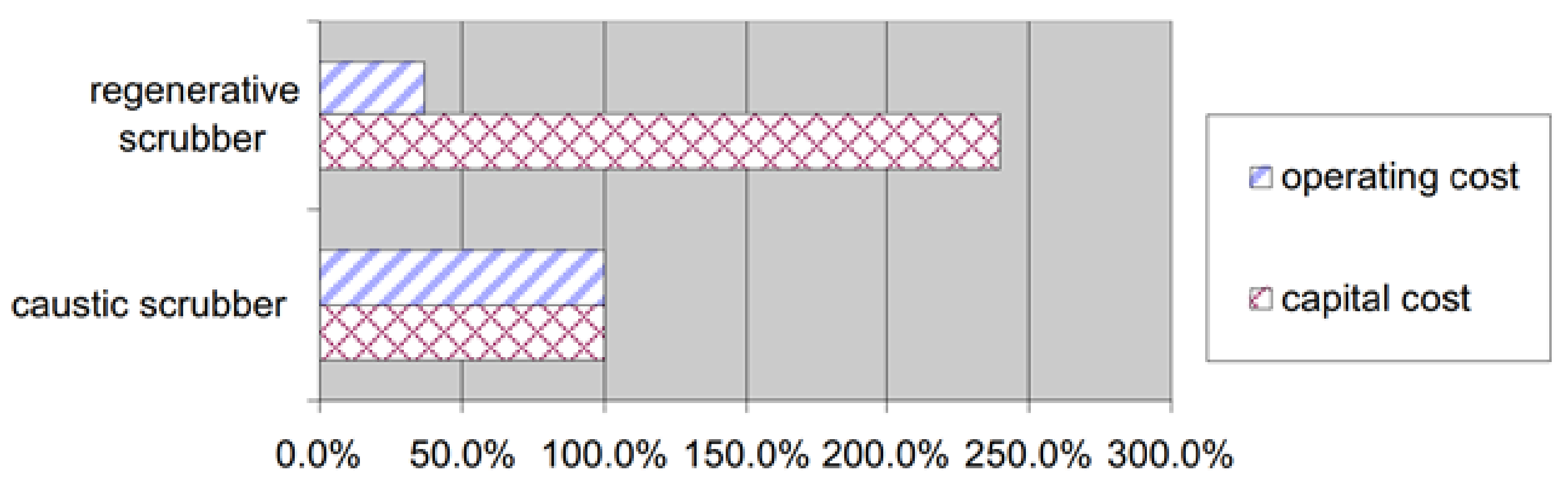

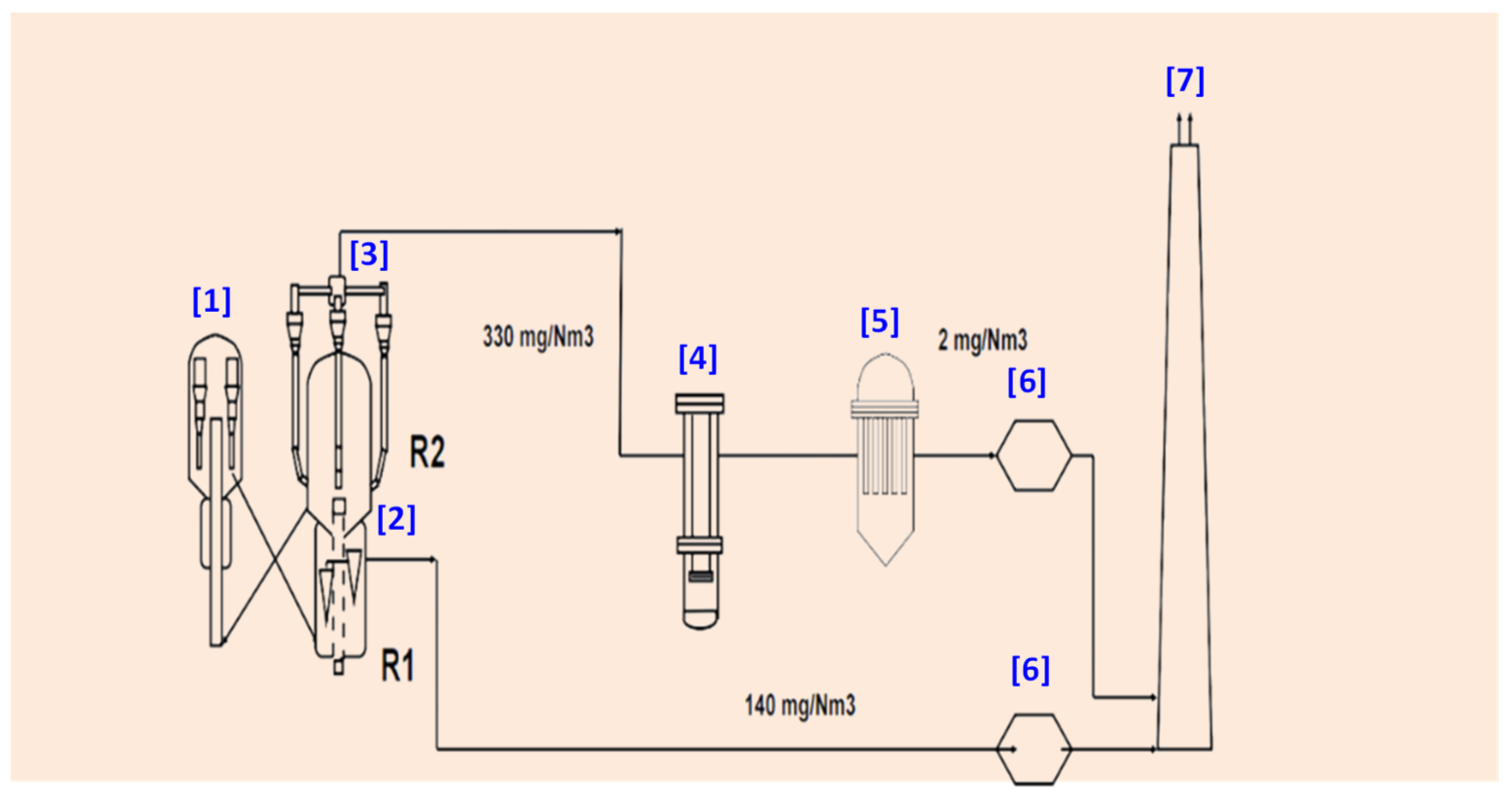

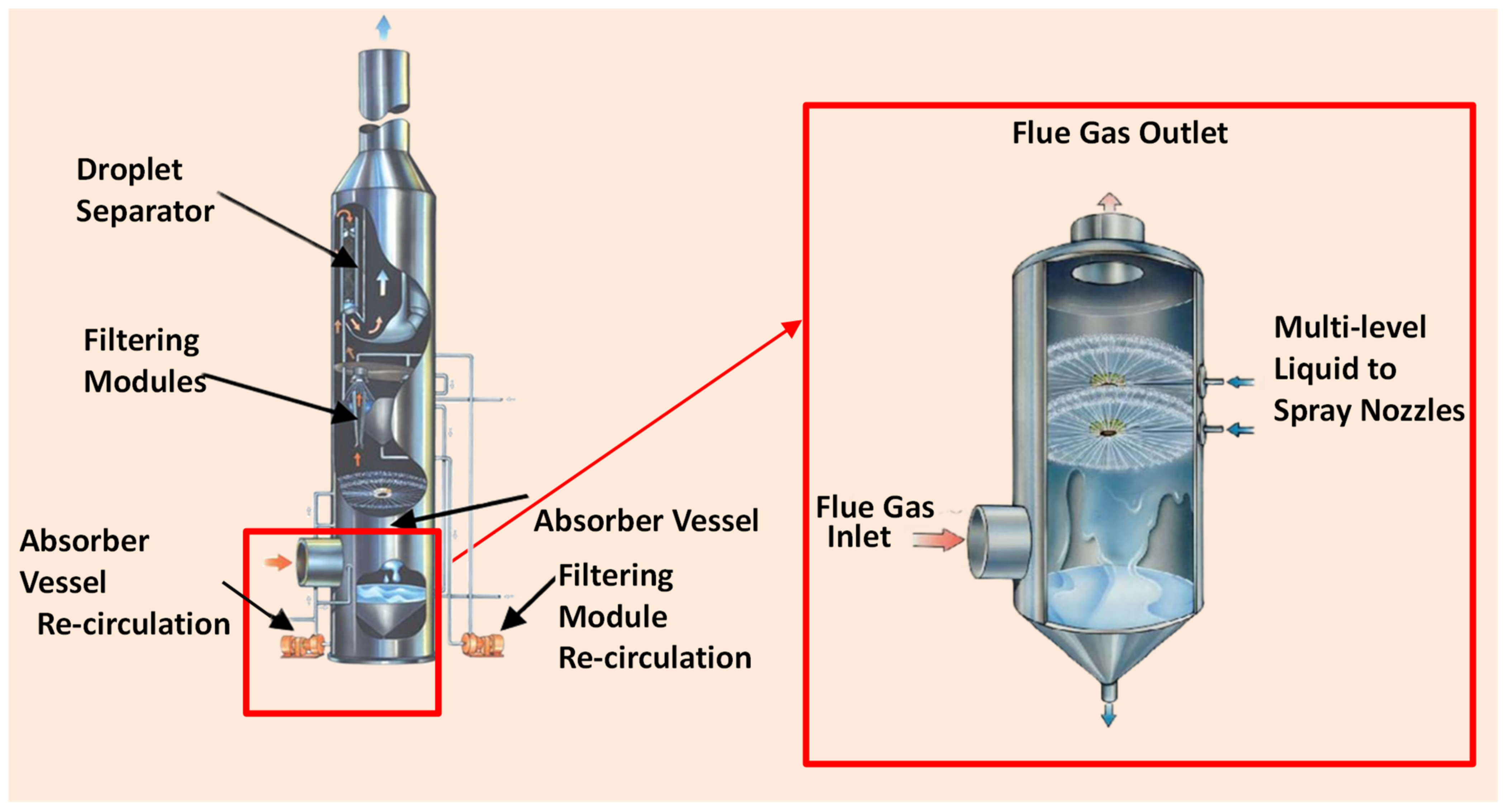

- Regenerative and Non-regenerative flue gas scrubber

5.2. Process Intensification for SOx Reduction

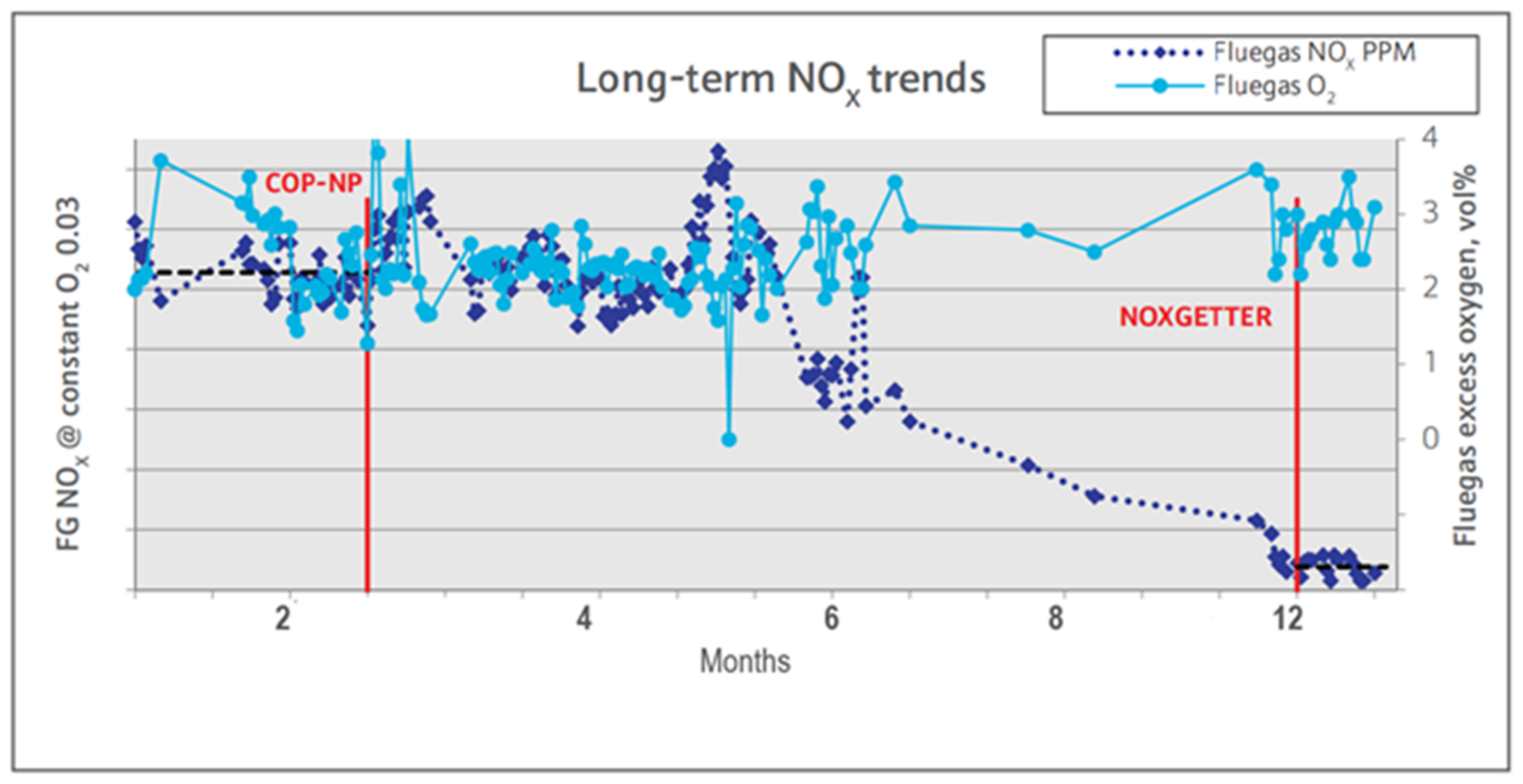

5.3. Process Intensification for FCC Regenerator Flue Gas NOx Emission Reduction

6. Conclusions

- The key features of the newer regenerator designs include several transitions, dilute cooler and bed steam coils to dense bed coolers, carbon steel hardware to highly mechanically forgiving alloys (chrome-moly steel), standpipe inlet from inlet hopper to disk design, catalyst transfer via the standpipe, post-riser regeneration, partial CO combustion or complete CO combustion to multistage regeneration, high temperature operation tolerance (704–732 °C) for coke and full CO burning, and reduced catalyst inventories resulting from better knowledge of coke burning chemistry.

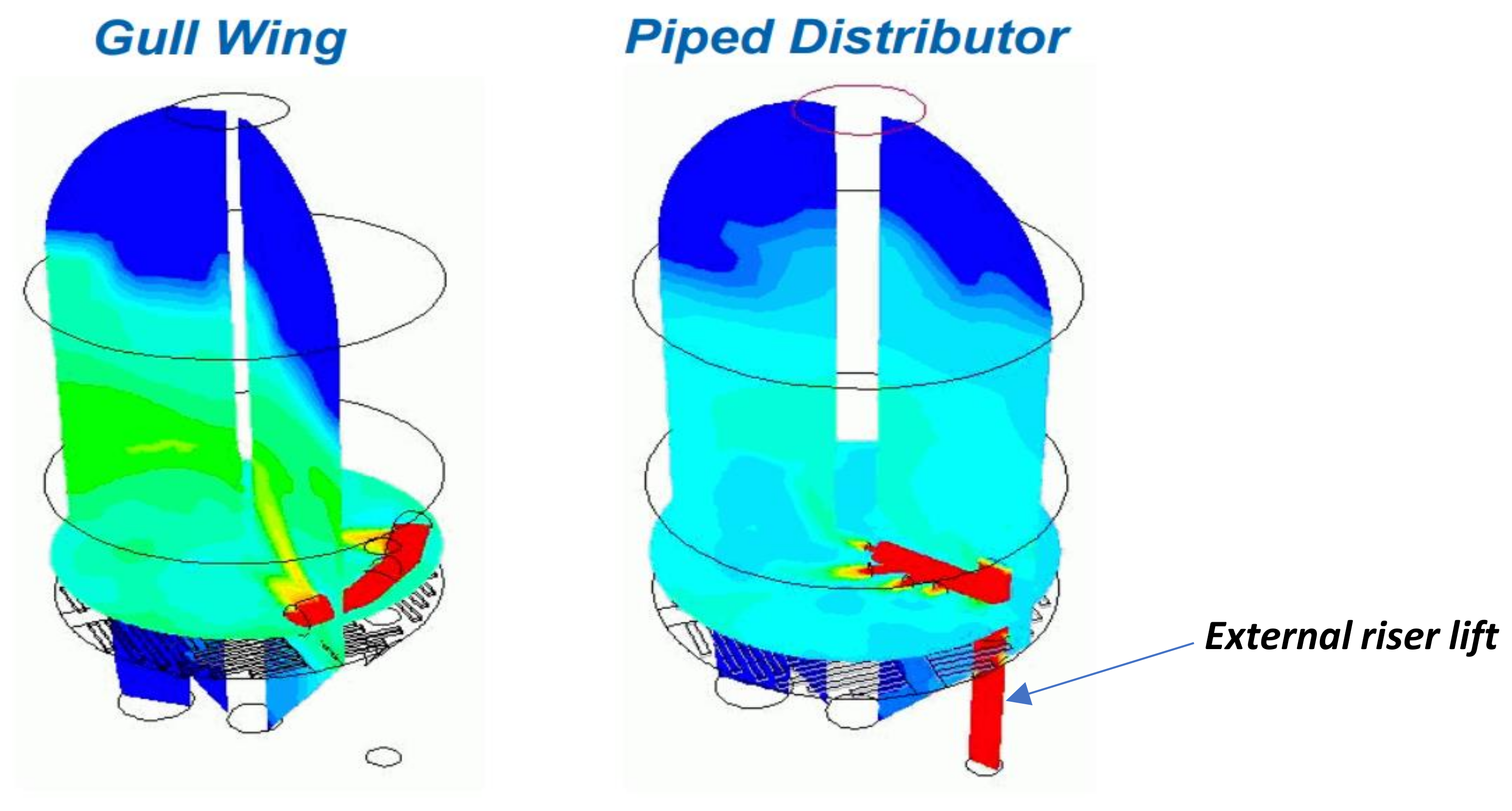

- Maldistribution of spent catalyst and feed gas accounts for two-thirds of the process intensification and reliability problems in the regenerator. Poor axial and radial distributions of catalyst and air across the bed cross section are the precursors to high entrainment of particles in the freeboard, high catalyst loss, extreme erosion and afterburn. Nonuniform radial gas–solid mixing is mostly likely when catalysts are charged into the bed through sidewall, especially when equipped with a ski-jump distributor, newer catalyst distributors have reduced this nonuniformity phenomenon. A pipe grid catalyst distributor is found to be more effective than the counterpart gulf design.

- Sufficient transport gas must be supplied to keep the catalyst fluidized in the spent catalyst standpipe before being discharged into the spent catalyst distributor, otherwise catalyst slumping will be promoted, leading to poor regeneration. Short circuiting of spent catalysts can be impeded by closing the radial openings/nozzles along the spent catalyst distributor directly facing the standpipe or discharge ports. The influence of this on the distributor pressure drop, however, requires further assessment.

- An efficient gas distributor is linear to good regeneration. Most of the newer air distributors can provide relatively uniform gas dispersion with few performance superiorities over each other. The ring gas distributor can operate at a low pressure drop with better lateral distribution coverage of the bed cross-section. However, the pipe grid has a similar dispersion efficiency but suffers from mechanical attenuation due to its arms’ constant cyclical oscillations.

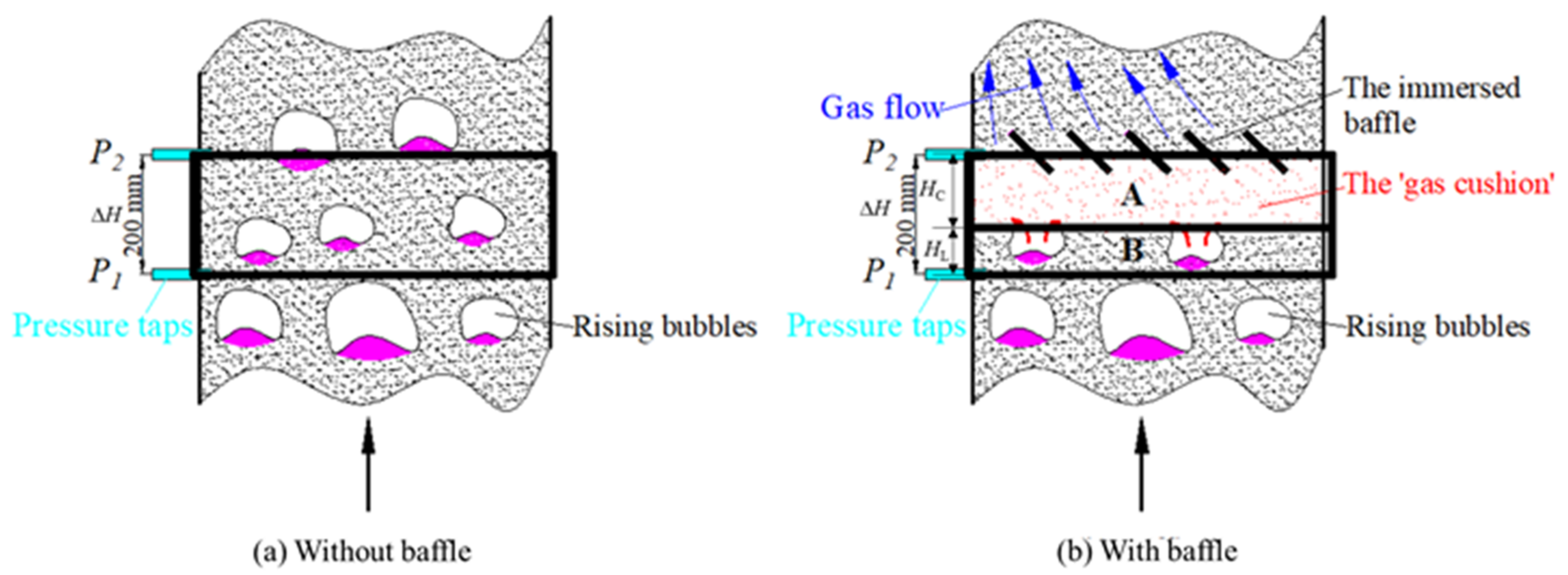

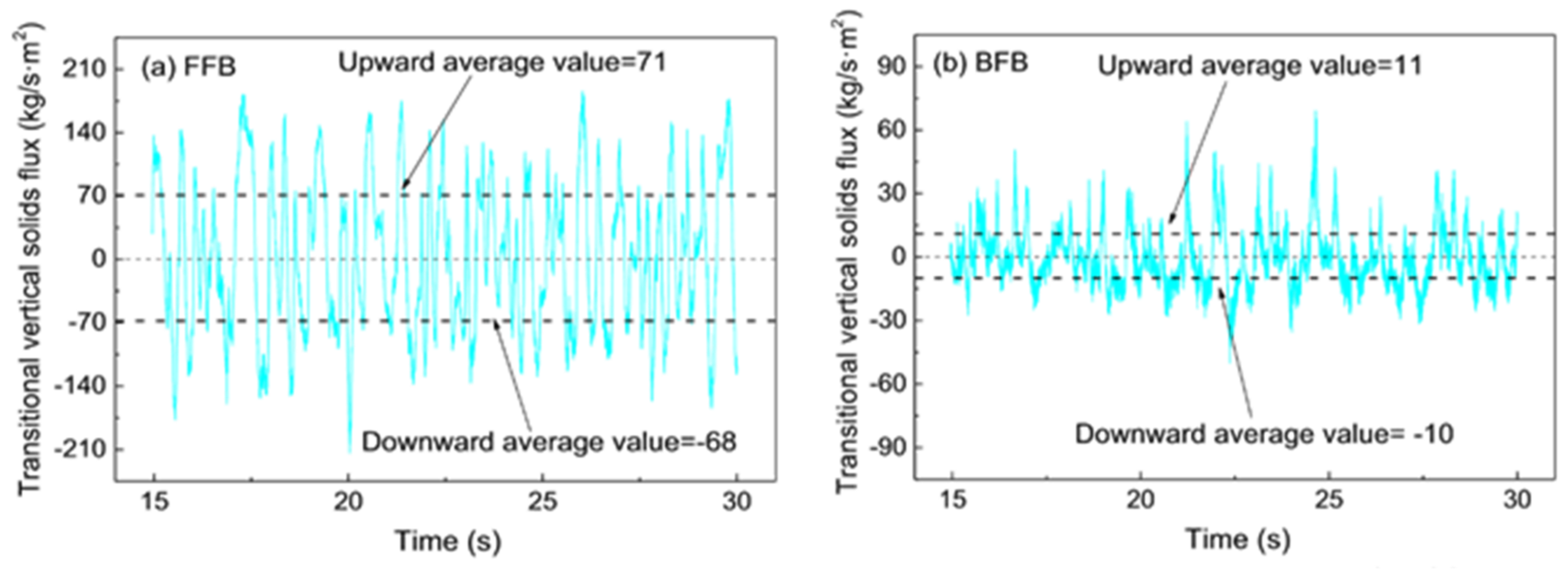

- Installing baffles or other internals into the dense bed or freeboard can significantly suppress gas bypass or backmixing, reduce catalyst entrainment, break large bubbles, and promote even gas–solid dispersion in the bed. It significantly achieves these by distorting core–annular flow structure and compelling redistribution of gas and solids. The multilayered horizontal baffle has been proved as an effective solution not only for minimizing gas bypass but also for enhancing radial gas dispersion in the bed, but a correct geometric construction is required, which has been suggested. Additionally, maintaining differential pressure balance is a new promising route to mitigating gas bypass effect. A circumspective rise in the regenerator pressure is found to significantly deteriorate the intensity of gas bypassing, and as a result impede adverse combustion of CO in the dilute phase. It is still presently hard to achieve this industrially since the pressure balance control simultaneously interacts with the reactor–regenerator circuit.

- In regard to the influence of oxygen on afterburn effect, distinct peculiarities in full or partial burn mode are found to be key factors. Supplementing the feed gas with pure O2 or increasing the fraction of O2 is essential in full burn while minimizing the O2 level below the stoichiometry requirement is perpetually needed for a partial combustion system. In addition, to control for the afterburn effect, pressure taps must be consistently monitored to forestall catalyst flow reversal due to negative differential pressure balance.

- High-temperature erosion can be considerably curtailed, especially in the cyclone system through design modification that encompasses longer dipleg, bigger cone angle, bigger diameter and material fortification of the hardware surface. The latter is effective for chemical erosion/corrosion (oxidization attack) mitigation.

- Commingling of process intensification strategies and structural modifications can further reduce particulates, SOx, CO and NOx emissions from regenerator to meet present and future legislation requirements. However, the existing control strategies must be further strengthened. In complete combustion mode, the CO/CO2 ratio must be minimized to promote less reductive environment for NOx formation. For full burn units, the sweet spot of oxygen must be targeted where the surfeit of O2 is close to zero, which will push the reaction in the direction of N2 formation. To this effect, counter-current regenerators instead of concurrent regenerators are well suited to accomplish this. Emission reduction additives in small quantities have also proven to be a reliable emission control option, lowering Pt concentration or switching to non-platinum-based additive in CO combustors results in excellent NOx and afterburn mitigation.

7. Future Prospects and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Feedstock | Bio-Oils: VGO Blending Ratio | Catalyst | Operating Temperature (°C) | Key Findings | Author |

|---|---|---|---|---|---|

| HDO oil from pine sawdust | 1:20 1:10 1:5 0:1 | E-CAT | 482 | Coke, dry gas, increased with bio-oils. High bottom fraction yield and low gasoline yield | [296] |

| Pine woodchips 500 µm | 1:2, 3:10 10:0 | NiMo-Al2O3 | 350 | Coke and dry gas selectivity rises with increase in bio-oil ratio. While diesel selectivity increases, that of gasoline declines | [297] |

| HDO-oil | 1:4 | Y-zeolite | 500 | High yields of coke, aromatics and olefins. Poor quality of LCO and gasoline quality compared to pure VGO | [298] |

| Pyrolysis Oil from forest residue | 1:10 | E-CAT | 350 | Low coke formation under high pure oxygen gas content (about 28 wt.%) condition, and vice versa | [299] |

| HDO-oil from pine wood | 1:4 | Fresh FCC, HY-zeolite, HZSM-5 | 500 | Structure of zeolite catalyst influences cracking reaction, lignin polymers over the catalyst decomposed into methoxyphenols but phenolic content was poorly converted, increase in olefin, aromatics, LPG over gasoline with high coke yield. Best activity observed in FCC | [300] |

| Pyrolysis liquids (PLs) | 1:9 0:10 | NiCuMo/SiO2 | 525 | Low gasoline and dry gas yields and high bottom, LCO, and coke yields compared to pure VGO | [301] |

| Palm oil | 1:2 | USY+ZSM-5 | 500–520 | High liquid yield of nearly 79.2%, high yield of LPG but low gasoline yield. Gasoline quality meets fuel standards | [302] |

| FAME | 0–100 2:5 1:2 | E-CAT | 550 | Decrease in gasoline and increase in LO, resid and coke with increase in bio-oil. | [303] |

| Rapeseed oil | 7.5:15 | E-CAT | 550 | Increase in diesel cetane index | |

| HPO | 1:10 | E-CAT | 560 | Hydrotreating pyro-oil improved naphtha quality compared to pure VGO | [304] |

References

- Letzsch, W. Fluid Catalytic Cracking (FCC) in Petroleum Refining. In Handbook of Petroleum Processing; Treese, A., Pujadó, P.R., Jones, S.J.D., Eds.; Springer: London, UK, 2015; pp. 261–316. [Google Scholar]

- Grace, J.R.; Bi, X.; Ellis, N. Essentials of Fluidization Technology; KGaA: Boschstr. 12, 69469; Wiley-VCH Verlag GmbH & Co.: Weinheim, Germany, 2020. [Google Scholar]

- Li, J.; Ge, W.; Wang, W.; Yang, N.; Liu, X.; Wang, L.; He, X.; Wang, X.; Wang, J.; Kwauk, M. From Multiscale Modeling to Meso-Science; Hong Kong University of Science and Technology: Berlin-Heidelberg, Germany, 2013. [Google Scholar]

- Sabahi, A.; Loebl, A.J.; Galvada, S.; Francis, J.A.; Iyyamperumal, E. FCC Catalyst with More than One Silica, Its Preparation and Use. U.S. Patent 16/322,779, 4 July 2019. [Google Scholar]

- Hosseinpour, N.; Mortazavi, Y.; Khodadadi, A.A. Cumene cracking activity and enhanced regeneration of FCC catalysts comprising HY-zeolite and LaBO3 (B = Co, Mn, and Fe) perovskites. Appl. Catal. A Gen. 2014, 487, 26–35. [Google Scholar] [CrossRef]

- Li, Z.; Lu, C.-X. FCC riser quick separation system: A review. Pet. Sci. Technol. 2016, 13, 776–781. [Google Scholar] [CrossRef]

- Xie, J.; Zhong, W.; Yu, A. MP-PIC modeling of CFB risers with homogeneous and heterogeneous drag models. Adv. Powder Technol. 2018, 29, 2859–2871. [Google Scholar] [CrossRef]

- Myers, D.N.; Palmas, P.; Johnson, D.R.; van Opdorp, P.J. Advanced Elevated Feed Distribution System for Very Large Diameter RCC Reactor Risers. U.S. Patent Application No. 11/541,052, 3 April 2008. [Google Scholar]

- Yang, C.; Chen, X.; Zhang, J.; Li, C.; Shan, H. Advances of two-stage riser catalytic cracking of heavy oil for maximizing propylene yield (TMP) process. Appl. Petrochem. Res. 2014, 4, 435–439. [Google Scholar]

- Hsu, C.S.; Robinson, P.R. Gasoline Production. In Petroleum Science and Technology; Springer: Berlin/Heidelberg, Germany, 2019; pp. 189–210. [Google Scholar]

- He, L.J.; Zheng, S.Q.; Dai, Y.L. An FCC catalyst for maximizing gasoline yield. J. Chem. Chem. Eng. 2017, 66, 9–15. [Google Scholar] [CrossRef]

- Dean, C.; Letzsch, W.S. How to make anything with a catalytic cracker. In Hydrocarbon Processing; Gulf Publishing Co.: Houston, TX, USA, 2014. [Google Scholar]

- Sadeghbeigi, R. Fluid catalytic cracking handbook. In An Expert Guide to the Practical Operation, Design, and Optimization of FCC Units, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2020. [Google Scholar]

- Jones, D.S.J.; Treese, S.A. Environmental Control and Engineering in Petroleum Processing. In Handbook of Petroleum Processing; Springer: Cham, Switzerland, 2015; pp. 1219–1308. [Google Scholar]

- Lesage, R.; Simon, H. Anchoring Structure for an Anti-Erosion Coating, in Particular for Protecting a Wall of an FCC Unit. U.S. Patent 10,799,846, 13 October 2020. [Google Scholar]

- Sadeghbeigi, R. Fluid Catalytic Cracking Handbook: An Expert Guide to the Practical Operation, Design, and Optimization of FCC Units; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Grosdidier, P.; Mason, A.; Aitolahti, A.; Heinonen, P.; Vanhamäki, V. FCC unit reactor-regenerator control. Comput. Chem. Eng. Technol. 1993, 17, 165–179. [Google Scholar] [CrossRef]

- Dong, Q.; Bai, S.; Liu, Y.; Li, N.; Zhao, L.; Liu, S. Research progress of regenerator in FCC unit. J. Chem. Ind. Eng. 2013, 34, 1–4. [Google Scholar]

- Sadeghbeigi, R. Process Description. In Fluid Catalytic Cracking Handbook; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Venugopal, R.; Selvavathy, V.; Lavanya, M.; Balu, K. Additional feedstock for fluid catalytic cracking unit. Pet. Sci. Technol. 2008, 26, 436–445. [Google Scholar] [CrossRef]

- Natalie, P.; Larry, H.; George, Y.; Grace, D. Profiting with FCC feedstock diversity. In Digital Refining Processing; Operations and Maintenance; W. R. Grace & Co.: Columbia, MD, USA, 2006; pp. 1–9. [Google Scholar]

- Olafadehan, O.; Daramola, O.; Sunmola, O.; Abatan, G. Modelling and simulation of riser reactor of a commercial fluid catalytic cracking unit using 6-lump kinetics of vacuum gas oil. Pet. Petrochem. Eng. J. 2019, 3, 000194. [Google Scholar]

- Letzsch, W.S.; Ashton, A.G. Chapter 12 The effect of feedstock on yields and product quality. Stud. Surf. Sci. Catal. 1993, 76, 441–498. [Google Scholar]

- Rodgers, R.P.; Mapolelo, M.M.; Robbins, W.K.; Chacón-Patiño, M.L.; Putman, J.C.; Niles, S.F.; Rowland, S.M.; Marshall, A.G. Combating selective ionization in the high resolution mass spectral characterization of complex mixtures. Faraday Discuss. 2019, 218, 29–51. [Google Scholar] [CrossRef] [PubMed]

- Altgelt, K.H. Composition and Analysis of Heavy Petroleum Fractions; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Al-Mutaz, I.; Al-Fariss, T. Optimum gasoline production in oil refineries by linear programming. Oil Gas Eur. Mag. 1997, 23, 43. [Google Scholar]

- Chen, Y.-M. Applications for fluid catalytic cracking. In Handbook of Fluidization and Fluid-Particle Systems; Marcel Dekker: New York, NY, USA, 2003; pp. 379–396. [Google Scholar]

- Jin, N.; Wang, G.; Yao, L.; Hu, M.; Gao, J. Synergistic process for FCC light cycle oil efficient conversion to produce high-octane number gasoline. Ind. Eng. Chem. Res. 2016, 55, 5108–5115. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Lyu, Y.; Liu, X.; Zhang, J.; Gu, Y.; Huang, J.; Mintova, S.; Yan, Z. Intra-crystalline mesoporous SAPO-11 prepared by a grinding synthesis method as FCC promoters to increase iso-paraffin of gasoline. Micropor. Mesopor. Mater. 2020, 305, 110320. [Google Scholar] [CrossRef]

- Karthikeyani, A.V.; Anantharaman, N.; Prabhu, K.M.; Kumaresan, L.; Pulikottil, C.A.; Ramakumar, S.S.V. In Situ FCC gasoline sulfur reduction using spinel based additives. Int. J. Hydrog. Energy 2017, 42, 26529–26544. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, W.; Wang, Z.; Hou, K.; Ouyang, F.; Li, D. A 12-lump kinetic model for heavy oil fluid catalytic cracking for cleaning gasoline and enhancing light olefins yield. Pet. Sci. Technol. 2020, 38, 912–921. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Trent, D.L. Propylene oxide. In Kirk-Othmer Encyclopedia of Chemical Technology; Wiley Online Library: Hoboken, NJ, USA, 2000. [Google Scholar]

- Bedell, M.W.; Ruziska, P.A.; Steffens, T.R. On-purpose propylene from olefinic streams. Davison Catalagram 2004, 94, 33–42. [Google Scholar]

- Koempel, H.; Liebner, W. Lurgi’s Methanol To Propylene (MTP®) report on a successful commercialisation. Stud. Surf. Sci. Catal. 2007, 167, 261–267. [Google Scholar]

- Hsu, C.S.; Robinson, P.R. Cracking. In Petroleum Science and Technology; Springer: Berlin/Heidelberg, Germany, 2019; pp. 211–244. [Google Scholar]

- McGehee, J.F. Cogeneration Process for a Regenerator in an FCC System. U.S. Patent 7,802,435, 28 August 2010. [Google Scholar]

- Upson, L.L.; Rosser, F.S.; Hemler, C.L.; Palmas, P.; Bell, L.E.; Reagan, W.J.; Hedrick, B.W. Fluid Catalytic Cracking (FCC) Units, Regeneration. In Kirk-Othmer Encyclopedia of Chemical Technology; Wiley Online Library: Hoboken, NJ, USA, 2004; pp. 700–734. [Google Scholar]

- Hsu, C.S.; Robinson, P.R. Midstream Transportation, Storage, and Processing. In Petroleum Science and Technology; Springer: Berlin/Heidelberg, Germany, 2019; pp. 385–394. [Google Scholar]

- Speight, J. Catalytic Cracking. In Heavy Extra-Heavy Oil Upgrading Technologies; Gulf Professional Publishing: Oxford, UK, 2013; pp. 39–67. [Google Scholar]

- Wang, J. Continuum theory for dense gas-solid flow: A state-of-the-art review. Chem. Eng. Sci. 2020, 215, 115428. [Google Scholar] [CrossRef]

- Grace, J.R. Introduction, history and applications. In Essentials of Fluidization Technology; Wiley-VCH: Weinhard, Germany, 2020; pp. 11–31. [Google Scholar]

- Horio, M. Fluidization in natural phenomena. In Chemistry, Molecular Sciences and Chemical Engineering; Reedijk, J., Ed.; Elsevier: Waltham, MA, USA, 2017. [Google Scholar]

- OPEC. Historical Production Data. In OPEC Monthly Oil Market ReportVienna; Ayed, S.A., Ed.; OPEC: Vienna, Austria, 2020; pp. 1–93. [Google Scholar]

- Tragesser, S. FCC Regenerator Design to Minimize Catalyst Deactivation and Emissions; Shaw Energy and Chemicals Group: Houston, YX, USA, 2018; pp. 1–37. [Google Scholar]

- Leger, C.; Lenhert, D.; Scalise, J. FCC regenerator off gas: Cost effective emissions control. Refin. Oper. 2015, 1. Available online: https://www.lindeus.com/-/media/corporate/praxairus/documents/reports-papers-case-studies-and-presentations/industries/refining/ertc_conox_paper.pdf?rev=c3e1f85389c943bea45a0ae11a03f674 (accessed on 11 January 2022).

- Du, Y.; Sun, L.; Berrouk, A.S.; Zhang, C.; Chen, X.; Fang, D.; Ren, W. Novel integrated reactor-regenerator model for the fluidized catalytic cracking unit based on an equivalent reactor network. Energy Fuels 2019, 33, 7265–7275. [Google Scholar] [CrossRef]

- Knowlton, T.M.; Karri, S.B.R. Standpipes and return systems, separation sevices, and feeders. In Essentials of Fluidization Technology; Wiley-VCH: Weinhard, Germany, 2020; pp. 203–237. [Google Scholar]

- Zhang, Y.; Zha, C.; Yu, S. Experimental study on a new FCC spent catalyst distributor. In Fluidization XV; Chaouki, J., Bi, X., Cocco, R., Eds.; SEMANTIC SCHOLAR: Seattle, WA, USA, 2016. [Google Scholar]

- Chen, Y.-M.; Patel, M.S. Spent Catalyst Distributor. U.S. Patent 6,797,239, 28 August 2004. [Google Scholar]

- Mirek, P. Air distributor pressure drop analysis in a circulating fluidized-bed boiler for non-reference operating conditions. Chem. Eng. Technol. 2020, 43, 2233–2246. [Google Scholar] [CrossRef]

- Zhang, Y. Baffles and Aids to Fluidization. In Essentials of Fluidization Technology; Wiley-VCH: Weinhard, Germany, 2020; pp. 431–455. [Google Scholar]

- Cerqueira, H.S.; Sievers, C.; Joly, G.; Magnoux, P.; Lercher, J.A. Multitechnique characterization of coke produced during commercial resid FCC operation. Ind. Eng. Chem. Res. 2005, 44, 2069–2077. [Google Scholar] [CrossRef]

- Kalota, S.A.; Rahmim, I.I. Solve the five most common FCC problems. In Proceedings of the Advances in Fluid Catalytic Cracking I, New Orleans, LA, USA, 30 March–3 April 2003. [Google Scholar]

- Ahmed, N.A.; Mustala, M.A.; Seory, A.M.A. Computational fluid dynamics simulation of a fluid catalytic cracking regenerator. Univ. Khartoum Eng. J. 2016, 5, 82. [Google Scholar]

- Chang, J.; Wang, G.; Lan, X.; Gao, J.; Zhang, K. Computational investigation of a turbulent fluidized-bed FCC regenerator. Ind. Eng. Chem. Res. 2013, 52, 4000–4010. [Google Scholar] [CrossRef]

- Tang, G.; Silaen, A.K.; Wu, B.; Fu, D.; Agnello-Dean, D.; Wilson, J.; Meng, Q.; Khanna, S.; Zhou, C.Q. Numerical simulation and optimization of an industrial fluid catalytic cracking regenerator. Appl. Therm. Eng. 2017, 112, 750–760. [Google Scholar] [CrossRef]

- Amblard, B.; Singh, R.; Gbordzoe, E.; Raynal, L. CFD modeling of the coke combustion in an industrial FCC regenerator. Chem. Eng. Sci. 2017, 170, 731–742. [Google Scholar] [CrossRef]

- Berrouk, A.S.; Huang, A.; Bale, S.; Thampi, P.; Nandakumar, K. Numerical simulation of a commercial FCC regenerator using multiphase particle-in-cell methodology (MP-PIC). Adv. Powder Technol. 2017, 28, 2947–2960. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Huangfu, L.; Yu, F.; Chen, Z.; Li, C.; Liu, Z.; Yu, J.; Gao, S. The simultaneous removal of SO2 and NO from flue gas over activated coke in a multi-stage fluidized bed at low temperature. Fuel 2020, 275, 117862. [Google Scholar] [CrossRef]

- Arbel, A.; Huang, Z.; Rinard, I.H.; Shinnar, R.; Sapre, A. Dynamic and control of fluidized catalytic crackers. 1. Modeling of the current generation of FCC’s. Ind. Eng. Chem. Res. 1995, 34, 1228–1243. [Google Scholar] [CrossRef]

- Cocco, R.; Karri, S.R.; Knowlton, T. Introduction to fluidization. Chem. Eng. Prog. 2014, 110, 21–29. [Google Scholar]

- Alsmari, T.A.; Grace, J.R.; Bi, X.T. Effects of superficial gas velocity and temperature on entrainment and electrostatics in gas–Solid fluidized beds. Chem. Eng. Sci. 2015, 123, 49–56. [Google Scholar] [CrossRef]

- Gao, X.; Li, T.; Sarkar, A.; Lu, L.; Rogers, W.A. Development and validation of an enhanced filtered drag model for simulating gas-solid fluidization of Geldart a particles in all flow regimes. Chem. Eng. Sci. 2018, 184, 33–51. [Google Scholar] [CrossRef]

- Kim, S.W.; Kim, S.D. Void properties in dense bed of cold-flow fluid catalytic cracking regenerator. Processes 2018, 6, 80. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, C. Experimental study and modeling on effects of a new multilayer baffle in a turbulent fluid catalytic cracking regenerator. Ind. Eng. Chem. Res. 2014, 53, 2062–2066. [Google Scholar] [CrossRef]

- Speight, J. Catalytic Cracking Processes. In Heavy Oil Recovery and Upgrading; Gulf Professional Publishing: Oxford, UK, 2019; pp. 357–421. [Google Scholar]

- Fotovat, F. Entrainment from bubbling and turbulent Beds. In Essentials of Fluidization Technology; Wiley-VCH: Weinheim, Germany, 2020; pp. 181–202. [Google Scholar]

- Letzsch, W.; Santner, C.; Tragesser, S. Improving the profitability of the FCCU. Chem. Ind. 2010, 129, 91–100. [Google Scholar]

- Zhang, F.; Zhang, Z.; Liu, Y.; Zhong, Z.; Xing, W. Effect of gas distributor on hydrodynamics and the rochow reaction in a fluidized bed membrane reactor. Ind. Eng. Chem. Res. 2016, 55, 10600–10608. [Google Scholar] [CrossRef]

- Windows-Yule, C.R.K.; Gibson, S.; Werner, D.; Parker, D.J.; Kokalova, T.Z.; Seville, J.P.K. Effect of distributor design on particle distribution in a binary fluidised bed. Powder Technol. 2020, 367, 1–9. [Google Scholar] [CrossRef]

- Schwarz, M.P. Simulation of the BP FCC regenerator: Coke combustion and temperature distribution. In Proceedings of the Chemeca: Knowledge Innovation (Conference), Engineers Australia, Auckland, New Zealand, 17–20 September 2006; pp. 701–707. [Google Scholar]

- Bai, D.; Zhu, J.-X.; Jin, Y.; Yu, Z. Novel designs and simulations of FCC riser regeneration. Ind. Eng. Chem. Res. 1997, 36, 4543–4548. [Google Scholar] [CrossRef]

- Cabrera, C.A.; Myers, D.N.; Hammershaimb, H.U. Partial CO Combustion with Staged Regeneration of Catalyst. U.S. Patent 4,849,091, 18 July 1989. [Google Scholar]

- Letzsch, W. Process and Apparatus for Controlling Catalyst Temperature in a Catalyst Stripper. U.S. Patent 7,273,543, 25 August 2007. [Google Scholar]

- Wilson, J.W. FCC regenerator afterburn–Causes and cures. In Proceedings of the Annual Meeting of the NPRA (National Petrochemical and Refiners Association), Washington, DC, USA, 10 June 2003. [Google Scholar]

- Schwarz, M.P.; Lee, J. Reactive CFD simulation of an FCC regenerator. Asia-Pac. J. Chem. Eng. 2007, 2, 347–354. [Google Scholar] [CrossRef]

- Matula, J.P.; Weinberg, H.N.; Weissman, W. Flexicoking: An Advanced Fluid Coking Process, Preprint 4572, From proceedings–American Petroleum Institute. Div. Refin. 1972, 52, 665–681. [Google Scholar]

- Hsing, H.; Mudra, J., IV. Fluid Catalytic Cracking Process Yielding Hydrogen. U.S. Patent 5,362,380, 8 November 1993. [Google Scholar]

- Corma, A.; Palomares, A.E.; Rey, F. Optimization of SOx additives of FCC catalysts based on MgO-Al2O3 mixed oxides produced from hydrotalcites. Appl. Catal. B-Environ. 1994, 4, 29–43. [Google Scholar] [CrossRef]

- Hettinger, W.P., Jr. Catalysis challenges in fluid catalytic cracking: A 49 year personal account of past and more recent contributions and some possible new and future directions for even further improvement. Catal. Today 1999, 53, 367–384. [Google Scholar] [CrossRef]

- Corma, A.; Sauvanaud, L.; Doskocil, E.; Yaluris, G. Coke steam reforming in FCC regenerator: A new mastery over high coking feeds. J. Catal. 2011, 279, 183–195. [Google Scholar] [CrossRef][Green Version]

- Miller, R.; Johnson, T.; Santner, C.; Avidan, A.; Beech, J. Comparison between Single and Two-Stage FCC Regenerators; National Petroleum Refiners Association: Washington, DC, USA, 1996. [Google Scholar]

- Pan, J.; Wu, G.; Yang, D. Thermal-hydraulic calculation and analysis on water wall system of 600 MW supercritical CFB boiler. Appl. Therm. Eng. 2015, 82, 225–236. [Google Scholar] [CrossRef]

- Chinsuwan, A.; Dutta, A.; Janlasad, N. Prediction of the heat flux profile on the furnace wall of circulating fluidized bed boilers. J. Energy Inst. 2014, 87, 314–320. [Google Scholar] [CrossRef]

- Ganapathy, V. Steam Generators and Waste Heat Boilers: For Process and Plant Engineers; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Kakac, S.; Liu, H.; Pramuanjaroenkij, A. Heat Exchangers: Selection, Rating, and Thermal Design; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Singh, R.; Gbordzoe, E. Modeling FCC spent catalyst regeneration with computational fluid dynamics. Powder Technol. 2017, 316, 560–568. [Google Scholar] [CrossRef]

- Haddad, J.H.; Owen, H.; Ross, M.S. Catalyst Regeneration in a Single Stage Regenerator Converted to a Two Stage High Efficiency Regenerator. U.S. Patent 5,158,919A, 27 October 1992. [Google Scholar]

- Ding, J.; Freeman, B.; Rochelle, G.T. Regeneration design for NGCC CO2 capture with amine-only and hybrid amine/membrane. Energy Procedia 2017, 114, 1394–1408. [Google Scholar] [CrossRef]

- Myers, D.N.; Tretyak, M.; Pittman, R.M.; Niewiedzial, S. FCC Spent Catalyst Distributor. U.S. Patent 7,368,090 B2, 6 May 2008. [Google Scholar]

- Palmas, P.; Myers, D.N. Catalyst Cooler for Regenerated Catalyst. U.S. Patent 9,587,824 B2, 7 March 2017. [Google Scholar]

- Bai, Y. Heat transfer in the circulating fluidized bed of a commercial catalyst cooler. Powder Technol. 2000, 111, 83–93. [Google Scholar] [CrossRef]

- Chan, T.Y.; Soni, D.S. Advances in catalyst cooler technology. In Digital Refining Processing, Operations and Maintenance; Digital Refining: Croydon, UK, 1999; pp. 1–5. [Google Scholar]

- Johnson, D.R.; Brandner, K.J. FCC Catalyst Cooler. U.S. Patent 5,209,287, 11 May 1993. [Google Scholar]

- Lomas, D.A.; Thompson, G.J. Fluid Catalyst Regeneration Process. U.S. Patent 4,353,812, 12 October 1982. [Google Scholar]

- Stankiewicz, A.; van Gerven, T.; Stefanidis, G. The Fundamentals of Process Intensification; Wiley-VCH: Weunheim, Germany, 2019. [Google Scholar]

- Luckenbach, E.C. Method of Temperature Control in Catalyst Regeneration. U.S. Patent 4,009,121, 22 February 1977. [Google Scholar]

- Owen, H. Method for Catalytic Cracking of Residual Oils. U.S. Patent 3,886,060A, 27 May 1975. [Google Scholar]

- Li, J.; Yao, X.; Liu, L.; Zhong, X.; Lu, C. Heat transfer characterization and improvement in an external catalyst cooler fluidized bed. Particuology 2020, 56, 103–112. [Google Scholar] [CrossRef]

- Bubalik, M.; Nagy, L.; Csaszar, Z.; Thernesz, A. Installation of an electrostatic precipitator in the FCC plant of Duna Refinery (DR). MOL Sci. Mag. 2010, 2, 52–59. [Google Scholar]

- Golden, S.W. Approaching the revamp. In Hydrocarbon Technology International; Process Consulting Services, Inc.: Houston, TX, USA, 1995; pp. 47–55. [Google Scholar]

- Carter, M.A.; Camille, A.K.; Fewel, K.; Ciobotaru, R.; Diwanji, B. Catalyst Heat Removal Cluster and Tube Design. U.S. Patent 10,782,075B2, 22 September 2020. [Google Scholar]

- Lomas, D.A. Inverted Backmix Coolers for FCC Units. U.S. Patent 5,212,129A, 18 May 1993. [Google Scholar]

- Lengemann, R.A. FCC Process with Dual Function Catalyst Cooling. U.S. Patent 5,800,697, 1 January 1998. [Google Scholar]

- Wang, H.; Chai, Z.; Zheng, T. Analysis of pneumatic controlled external cooler in FCC unit. Pet. Refin. Eng. 2003, 11, 12–14. [Google Scholar]

- Yao, X.; Sun, F.; Zhang, Y.; Lu, C. Experimental validation of a new heat transfer intensification method for FCC external catalyst coolers. Chem. Eng. Processing Process Intensif. 2014, 75, 19–30. [Google Scholar] [CrossRef]

- Mozón, E.M.L.; de Pádua, T.F.; Braga, M.G.R.; Lopes, G.C. CFD preliminary study of gas-solid flow in FCC catalyst coolers. In Proceedings of the Modelling, Simulation and Identification/841: Intelligent Systems and Control, Campinas, Brazil, 16–18 August 2016. [Google Scholar]

- Li, J.; Yao, X.; Liu, L.; Lu, C. Investigation on distribution of particles in inlet region of an FCC external catalyst cooler with different inlet structures. Powder Technol. 2020, 362, 267–277. [Google Scholar] [CrossRef]

- Hedrick, B.W. Three-Stage Counter-Current FCC Regenerator. U.S. Patent 7,915,191, 29 March 2011. [Google Scholar]

- Miller, R.; Yang, Y.; Johnson, T. RegenMaxTM Technology, Staged Combustion in a Single Regenerator. In Proceedings of the 1999 NPRA Annual Meeting, San Antonio, TX, USA, 21–23 March 1999. AM-99-14. [Google Scholar]

- Raterman, M.F. Two-Stage Fluid Bed Regeneration of Catalyst with Shared Dilute Phase. U.S. Patent 5,198,397, 30 March 1993. [Google Scholar]

- Jin, Y.; Yu, Z.-Q.; Bai, D.; Wei, F. Downlink FCC Riser Two-Stage Regeneration Unit. China Patent No. 932199720, 30 July 1993. [Google Scholar]

- Davydov, L.; Sandacz, M.S.; Palmas, P.; Fei, Z.; Lippmann, M. FCC Counter-Current Regenerator with a Regenerator Riser. U.S. Patent 10,751,684 B2, 25 August 2020. [Google Scholar]

- Rowe, F. Regeneration of Cracking Catalyst in Two Successive Zones. U.S. Patent 4,388,218, 14 June 1983. [Google Scholar]

- Long, S.L.; Ross, J.L.; Krishnaiah, G. Apparatus for Controlling Catalyst Temperature during Regeneration. U.S. Patent 5,571,482, 5 November 1996. [Google Scholar]

- Li, J.; Luo, G.; Wei, F. A multistage NOx reduction process for a FCC regenerator. Chem. Eng. J. 2011, 173, 296–302. [Google Scholar] [CrossRef]

- Mann, R. Fluid catalytic cracking: Some recent developments in catalyst particle design and unit hardware. Catal. Today 1993, 1, 509–528. [Google Scholar] [CrossRef]

- Zhang, C.; Qian, W.; Wang, Y.; Luo, G.; Wei, F. Heterogeneous catalysis in multi-stage fluidized bed reactors: From fundamental study to industrial application. Can. J. Chem. Eng. 2019, 97, 636–644. [Google Scholar] [CrossRef]

- Pereira, H.B.; Sandes, E.F.; Gilbert, W.R.; Roncolatto, R.E.; Gobbo, R.; Casavechia, L.C.; Candido, W.V.C.; Bridi, P.E.; Brasileiro, S.P. Impact of FCC Regenerator Design in the NOx Emissions. In Proceedings of the Rio Oil and Gas Expo and Conference 2012, Rio de Janeiro, Brazil, 17–20 September 2012. [Google Scholar]

- Letzsch, W. Fluid catalytic cracking (FCC). In Handbook of Petroleum Processing; Springer: Berlin/Heidelberg, Germany, 2008; pp. 239–286. [Google Scholar]

- Bai, D.; Zhu, J.; Jin, Y.; Yu, Z. Simulation of FCC catalyst regeneration in a riser regenerator. Chem. Eng. J. 1998, 71, 97–109. [Google Scholar] [CrossRef]

- Liu, X.; Lu, C.; Shi, C. Post-riser regeneration technology in FCC unit. Petrol. Sci. 2007, 4, 91–96. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Y.; Oloruntoba, A.; Yue, J. MP-PIC simulation of the effects of spent catalyst distribution and horizontal baffle in an industrial FCC regenerator. Part I: Effects on hydrodynamics. Chem. Eng. J. 2021, 412, 128634. [Google Scholar] [CrossRef]

- Miller, R.B.; Yang, Y.-L. Staged Catalyst Regeneration in a Baffled Fluidized Bed. U.S. Patent 6,503,460, 7 July 2003. [Google Scholar]

- Gao, Z.; Chai, X.; Zhou, E.; Jia, Y.; Duan, C.; Tang, L. Effect of the distributor plugging ways on fluidization quality and particle stratification in air dense medium fluidized bed. Int. J. Min. Sci. Technol. 2020, 30, 883–888. [Google Scholar] [CrossRef]

- Chen, Y.; Brosten, D.J. Standpipe Inlet Enhancing Particulate Solids Circulation for Petrochemical and Other Processes. U.S. Patent 6,228,328B1, 8 May 2001. [Google Scholar]

- Huq, I.; Moran, M.; Sorensen, R.C. Modifications to model IV fluid catalytic cracking units to improve dynamic performance. AlChE J. 1995, 41, 1481–1499. [Google Scholar] [CrossRef]

- Chen, Y.M. Recent advances in FCC technology. Powder Technol. 2006, 163, 2–8. [Google Scholar] [CrossRef]

- Kauff, D.A.; Bartholic, D.B.; Steves, C.A.; Keim, M.R. Successful application of the MSCC process, CONF-960356. In Proceedings of the 1996 National Petroleum Refiners Association Annual Meeting, San Antonio, TX, USA, 17–19 May 1996. [Google Scholar]

- Hsu, C.S.; Robinson, P.R. Springer Handbook of Petroleum Technology; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Sexton, J.A. FCC cyclone using acoustic detectors. U.S. Patent 10,239,034, 26 March 2019. [Google Scholar]

- Chen, Y.M. Evolution of FCC-past present and guture and the challenges of operating a high temperature CFB system. In Proceedings of the 10th International Conferences on Circulating Fluidized Beds and Fluidization Technology, ECI Symposium Series, Sun River, OR, USA, 1–5 May 2013; p. 29. [Google Scholar]

- Li, G.; Yang, X.; Dai, G. CFD simulation of effects of the configuration of gas distributors on gas–liquid flow and mixing in a bubble column. Chem. Eng. Sci. 2009, 64, 5104–5116. [Google Scholar] [CrossRef]

- Karri, S.R.; Werther, J. Gas distributor and plenum design in fluidized beds. In Handbook of Fluidization and Fluid-Particle Systems; Yang, W.-C., Ed.; Marcel Dekker: New York, NY, USA, 2003; pp. 155–170. [Google Scholar]

- Li, G.; Cai, Q.; Dai, G.; Yang, X. Numerical simulations of fluid dynamics and mixing in a large shallow bubble column: Effects of the sparging pipe allocations for multiple-pipe gas distributors. Int. J. Eng. Syst. Model. Simul. 2009, 1, 165–175. [Google Scholar] [CrossRef]

- Kaewklum, R.; Kuprianov, V.I. Experimental studies on a novel swirling fluidized-bed combustor using an annular spiral air distributor. Fuel 2010, 89, 43–52. [Google Scholar] [CrossRef]

- Sánchez-Delgado, S.; Marugán-Cruz, C.; Serrano, D.; Briongos, J.V. Distributor performance in a bubbling fluidized bed: Effects of multiple gas inlet jet and bubble generation. Chem. Eng. Sci. 2019, 195, 367–380. [Google Scholar] [CrossRef]

- Cocco, R.; Shaffer, F.; Karri, S.R.; Hays, R.; Knowlton, T. Particle Clusters in Fluidized Beds. Proc. Int. Conf. Fluidization XIII—New Paradigm in Fluidization Engineering; ECI: Westover, MD, USA, 16–21 May 2010; pp. 45–48. [Google Scholar]

- Cooper, C. FCC Air/Steam Rings; Shaw’s Energy & Chemicals Group: Baton Rouge, LA, USA, 2011. [Google Scholar]

- Wolschlag, L.; Couch, K. UOP FCC innovations developed using sophisticated engineering tools. In Proceedings of the 3rd AIChE Regional Process Technology Conference Texas, Galveston, TX, USA, 6–7 October 2011. [Google Scholar]

- Wells, J.W. Streaming flow in large scale fluidization, Paper 201e. In Proceedings of the AIChE Annual Meeting, Particle Technology Forum, Reno, NV, USA, 4–9 November 2001. [Google Scholar]

- Filho, R.M.; Batista, L.L.; Fusco, M. A fast fluidized bed reactor for industrial FCC regenerator. Chem. Eng. Sci. 1996, 51, 1807–1816. [Google Scholar] [CrossRef]

- Sánchez-Prieto, J.; Soria-Verdugo, A.; Briongos, J.; Santana, D. The effect of temperature on the distributor design in bubbling fluidized beds. Powder Technol. 2014, 261, 176–184. [Google Scholar] [CrossRef]

- Dhotre, M.T.; Joshi, J.B. Design of a gas distributor: Three-dimensional CFD simulation of a coupled system consisting of a gas chamber and a bubble column. Chem. Eng. J. 2007, 125, 149–163. [Google Scholar] [CrossRef]

- Kwangbyol, J.; Yali, F.; Haoran, L. Effect of gas distributor structure on fluidization characteristics in a gas-solid fluidized bed. China Pet. Processing Petrochem. Technol. 2020, 22, 102–110. [Google Scholar]

- Hassan, M.; Schwarz, M.P.; Yuqing, F.; Rafique, M.; Witt, P.; Huilin, L. Numerical investigation of solid circulation flux in an internally circulating fluidized bed with different gas distributor designs. Powder Technol. 2016, 301, 1103–1111. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, T.; Wang, C.; Sha, Z. Hydrodynamic behavior of an internally circulating fluidized bed with tubular gas distributors. Particuology 2013, 11, 664–672. [Google Scholar] [CrossRef]

- Rahimpour, F.; Zarghami, R.; Mostoufi, N. Effect of distributor on fluidized bed hydrodynamics. Can. J. Chem. Eng. 2017, 95, 2221–2234. [Google Scholar] [CrossRef]

- Sathiyamoorthy, D.; Horio, M. On the influence of aspect ratio and distributor in gas fluidized beds. Chem. Eng. J. 2003, 93, 151–161. [Google Scholar] [CrossRef]

- Knowlton, T.; Hirsan, I. The effect of pressure on jet penetration in semi-cylindrical gas-fluidized beds. In Fluidization; Springer: Berlin/Heidelberg, Germany, 1980; pp. 315–324. [Google Scholar]

- Lau, R.; Sim, W.S.B.; Mo, R. Effect of gas distributor on hydrodynamics in shallow bubble column reactors. Can. J. Chem. Eng. 2009, 87, 847–854. [Google Scholar] [CrossRef]

- Sobrino, C.; Ellis, N.; de Vega, M. Distributor effects near the bottom region of turbulent fluidized beds. Powder Technol. 2009, 189, 25–33. [Google Scholar] [CrossRef]

- Chyang, C.-S.; Lieu, K.; Hong, S.-S. The effect of distributor design on gas dispersion in a bubbling fluidized bed. J. Chin. Inst. Chem. Eng. 2008, 39, 685–692. [Google Scholar] [CrossRef]

- Kulkarni, A.V.; Badgandi, S.V.; Joshi, J.B. Design, Design of ring and spider type spargers for bubble column reactor: Experimental measurements and CFD simulation of flow and weeping. Chem. Eng. Res. Des. 2009, 87, 1612–1630. [Google Scholar] [CrossRef]

- Kulkarni, A.V. Design of a pipe/ring type of sparger for a bubble column reactor. Chemi. Eng. Technol. 2010, 33, 1015–1022. [Google Scholar] [CrossRef]

- Oloruntoba, A.; Zhang, Y.; Xiao, H. Study on effect of gas distributor in fluidized bed reactors by hydrodynamics-reaction-coupled simulations. Chem. Eng. Res. Des. 2022, 177, 431–447. [Google Scholar] [CrossRef]

- Hilal, N.; Ghannam, M.; Anabtawi, M. Effect of bed diameter, distributor and inserts on minimum fluidization velocity. Chem. Eng. Technol. 2001, 24, 161–165. [Google Scholar] [CrossRef]

- Dhrioua, M.; Hassen, W.; Kolsi, L.; Anbumalar, V.; Alsagri, A.S.; Borjini, M.N. Gas distributor and bed material effects in a cold flow model of a novel multi-stage biomass gasifier. Biomass Bioenergy 2019, 126, 14–25. [Google Scholar] [CrossRef]

- Ouyang, F.; Levenspiel, O. Spiral distributor for fluidized beds. Ind. Eng. Chem. Process Des. Dev. 1986, 25, 504–507. [Google Scholar] [CrossRef]

- Son, S.-Y.; Lee, D.H.; Han, G.Y.; Kim, D.J.; Sim, S.J.; Kim, S.D. Effect of air distributor on the fluidization characteristics in conical gas fluidized beds. Korean J. Chem. Eng. 2005, 22, 315–320. [Google Scholar] [CrossRef]

- Akbari, V.; Borhani, T.N.G.; Aramesh, R.; Hamid, M.K.A.; Shamiri, A.; Hussain, M.A. Evaluation of hydrodynamic behavior of the perforated gas distributor of industrial gas phase polymerization reactor using CFD-PBM coupled model. Comput. Chem. Eng. J. 2015, 82, 344–361. [Google Scholar] [CrossRef]

- Pham, H.H.; Lim, Y.-I.; Han, S.; Lim, B.; Ko, H.-S. Hydrodynamics and design of gas distributor in large-scale amine absorbers using computational fluid dynamics. Korean J. Chem. Eng. 2018, 35, 1073–1082. [Google Scholar] [CrossRef]

- Bussey, B.K.; Glasgow, P.E.; Kalota, S.A.; Niccum, P.K. Spent Catalyst Distribution. U.S. Patent 5,773,378A, 30 June 1998. [Google Scholar]

- Sapre, A.; Leib, T.; Anderson, D. FCC regenerator flow model. Chem. Eng. Sci. 1990, 45, 2203–2209. [Google Scholar] [CrossRef]

- Hu, C.; Zhou, Z.; Zhang, J.; Si, X. A survey on life prediction of equipment. Chin. J. Aeronaut. 2015, 28, 25–33. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Y.; Liu, T.; Oloruntoba, A. MP-PIC simulation of the effects of spent catalyst distribution and horizontal baffle in an industrial FCC regenerator. Part II: Effects on regenerator performance. Chem. Eng. J. Adv. 2021, 421, 129694. [Google Scholar] [CrossRef]

- Serrand, W.; Holmes, P.; Steffens, T.R.; Terry, P.H.; Eberly, P.E. Catalytic Cracking Process with Circulation of Hot, Regenerated Catalyst to the Stripping Zone. U.S. Patent No. 5,348,642A, 20 September 1994. [Google Scholar]

- Shabaker, H.A. Temperature Control of Exothermic Reactions. U.S. Patent 2,816,010A, 10 December 1957. [Google Scholar]

- Parker, J.; Blaser, P. Validation and utilization of CFD for reducing CO emissions from an FCC regenerator. In Proceedings of the 5th Annual TRC-Idemitsu Workshop, Abu Dhabi, United Arab Emirates, 11–15 February 2015. [Google Scholar]

- Shah, M.T.; Pareek, V.K.; Evans, G.M.; Utikar, R.P. Effect of baffles on performance of fluid catalytic cracking riser. Particuology 2018, 38, 18–30. [Google Scholar] [CrossRef]

- Harrison, D.; Grace, J.R. Fluidized beds with internal baffles. In Fluidization; Academic Press: Cambridge, UK, 1971. [Google Scholar]

- Markham, C.L.; Muldowney, G.P. Baffled FCC Regeneration Process and Apparatus. U.S. Patent 5,288,397A, 22 February 1994. [Google Scholar]

- Veluswamy, G.K.; Upadhyay, R.K.; Utikar, R.P.; Evans, G.M.; Tade, M.O.; Glenny, M.E.; Roy, S.; Pareek, V.K. Hydrodynamics of a fluid catalytic cracking stripper using γ-ray densitometry. Ind. Eng. Chem. Res. 2011, 50, 5933–5941. [Google Scholar] [CrossRef]

- Grace, J.R. Hydrodynamics of Bubbling Fluidization. In Essentials of Fluidization Technology; Wiley-VCH: Weinheim, Germany, 2020; pp. 131–152. [Google Scholar]

- Zhang, Y. Hydrodynamic and Mixing Properties of a Novel Baffled Fluidized Bed. Ph.D. Dissertation, China University of Petroleum, Beijing, China, 2009. [Google Scholar]

- Kwauk, M. Chemical Engineering Handbook; Shi, J., Wang, J., Eds.; Chemical Industry Press: Beijing, China, 1996; pp. 94–95. [Google Scholar]

- Zhang, Y.; Grace, J.R.; Bi, X.; Lu, C.; Shi, M. Effect of louver baffles on hydrodynamics and gas mixing in a fluidized bed of FCC particles. Chem. Eng. Sci. 2009, 64, 3270–3281. [Google Scholar] [CrossRef]

- Issangya, A.; Karri, S.B.R.; Knowlton, T.; Cocco, R. Effects of Bed Diameter, Baffles, Fines Content and Operating Conditions on Pres Sure Fluctuations in Fluidized Beds of FCC Catalyst Particles. In ECI Symposium Series, Proceedings of the Fourteenth International Conference on Fluidization–From Fundamentals to Products, New York, NY, USA, 26–31 May 2013; Kuipers, J.A.M., Mudde, R.F., van Ommen, J.R., Deen, N.G., Eds.; Engineering Conferences International (ECI): New Delhi, India, 2013; pp. 477–484. [Google Scholar]

- Yang, S.; Peng, L.; Liu, W.; Zhao, H.; Lv, X.; Li, H.; Zhu, Q. Simulation of hydrodynamics in gas-solid bubbling fluidized bed with louver baffles in three dimensions. Powder Technol. 2016, 296, 37–44. [Google Scholar] [CrossRef]

- Wang, S.; Luo, K.; Hu, C.; Fan, J. CFD-DEM study of the effect of ring baffles on system performance of a full-loop circulating fluidized bed. Chem. Eng. Sci. 2018, 196, 130–144. [Google Scholar] [CrossRef]

- Zhu, X.; Feng, X.; Zou, Y.; Shen, L. Effect of baffles on bubble behavior in a bubbling fluidized bed for chemical looping processes. Particuology 2020, 53, 154–167. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, Y.; Zhang, S.; Oloruntoba, A. Effect of structure parameters on forces acting on the baffles used in gas-solids fluidized beds. Particuology 2022, 61, 111–119. [Google Scholar] [CrossRef]

- Samruamphianskun, T.; Piumsomboon, P.; Chalermsinsuwan, B. Effect of ring baffle configurations in a circulating fluidized bed riser using CFD simulation and experimental design analysis. Chem. Eng. J. 2012, 210, 237–251. [Google Scholar] [CrossRef]

- Jin, Y.; Wei, F.; Wang, Y. Effect of internal tubes and baffles. In Hanbook of Fluidization and Fluid-Particle Systems; Yang, W.-C., Ed.; Chemical Industries-New York-Marcel Dekker: New York, NY, USA, 2003; pp. 171–200. [Google Scholar]

- Nagahashi, Y.; Grace, J.R.; Lim, K.S.; Asako, Y. Dynamic force reduction and heat transfer improvement for horizontal tubes in large-particle gas-fluidized beds. J. Therm. Sci. 2008, 17, 77–83. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, S.; Wang, R.; Zhang, Y. Dynamic forces on a horizontal slat immersed in a fluidized bed of fine particles. J. Chem. Eng. Res. Des. 2017, 117, 604–613. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, S.; Zhang, Y.; Grace, J.R. Forces on an immersed horizontal slat during starting up a fluidized bed. Chem. Eng. Sci. 2017, 173, 402–410. [Google Scholar] [CrossRef]

- Nagahashi, Y.; Takeuchi, H.; Grace, J.R.; Yoshioka, D.; Tsuji, T.; Tanaka, T. Dynamic forces on an immersed cylindrical tube and analysis of particle interaction in 2D-gas fluidized beds. Adv. Powder Technol. 2018, 29, 3552–3560. [Google Scholar] [CrossRef]

- Xiong, Y. Strength of Materials Mechanics; Science Press: Beijing, China, 2009; pp. 279–916. [Google Scholar]

- Issangya, A.; Karri, S.R.; Knowlton, T. Effect of baffles on jet streaming in deep fluidized beds of Group A particles. In Proceedings of the Circulating Fluidized Bed Technology IX, Hamburg, Germany, 13–16 May 2008; Werther, J., Nowak, W., Wirth, K., Hartge, E., Eds.; pp. 105–110. [Google Scholar]

- Liu, D.; Zhang, Y.; Yuan, Y.; Grace, J.R. Effect of particle properties on forces on an immersed horizontal slat during start-up of a fluidized bed. Chem. Eng. Res. Des. 2020, 159, 105–114. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Chen, L.; Lu, C. Systematic investigation of particle segregation in binary fluidized beds with and without multilayer horizontal baffles. Ind. Eng. Chem. Res. 2012, 51, 5022–5036. [Google Scholar] [CrossRef]

- Issangya, A.S.; Karri, S.R.R.; Knowlton, T.; Cocco, R. Use of pressure to mitigate gas bypassing in fluidized beds of FCC catalyst particles. Powder Technol. 2016, 290, 53–61. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Y.; Zhang, H. CPFD simulation on effects of louver baffles in a two-dimensional fluidized bed of Geldart A particles. Adv. Powder Technol. 2019, 30, 2712–2725. [Google Scholar] [CrossRef]

- Cocco, R.; Hays, R.; Karri, S.B.K.R.; Knowlton, T.M. The effect of cohesive forces on catalyst entrainment in fluidized bed regenerators. In Advances in Fluid Catalytic Cracking; Occelli, M.L., Ed.; CRC Press: Boca Raton, FL, USA, 2010; pp. 155–172. [Google Scholar]

- Baron, T.; Briens, C.L.; Bergougnou, M.A. Reduction of particle entrainment from gas-fluidized beds with a screen of floating balls, Paper 150N, CONF-871113. In Proceedings of the American Institute of Chemical Engineers Annual Meeting, New York, NY, USA, 15 November 1987. [Google Scholar]

- George, S.; Grace, J. Entrainment of particles from a pilot scale fluidized bed. Can. J. Chem. Eng. 1981, 59, 279–284. [Google Scholar] [CrossRef]

- Kunii, D.; Levenspiel, O. Chapter 3-Fluidization and Mapping of Regimes. In Fluidization Engineering, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 1991; pp. 61–94. [Google Scholar]

- Issangya, A.S.; Karri, S.B.R.; Knowlton, T.M.; Cocco, R. Effect of gas bypassing in deep beds on cyclone dipleg operation. In ECI Symposium Series, Proceedings of the 10th International Conference on Circulating Fluidized Beds and Fluidization Technology-CFB-10, Sun River, OR, USA, 1–5 May 2011; Knowlton, T., PSRI, Eds.; ECI: New Delhi, India, 2013. [Google Scholar]

- Chyang, C.-S.; Wu, K.-T.; Ma, T.-T. Particle segregation in a screen baffle packed fluidized bed. Powder Technol. 2002, 126, 59–64. [Google Scholar] [CrossRef]

- Jiang, P.; Bi, H.; Jean, R.-H.; Fan, L.-S. Baffle effects on performance of catalytic circulating fluidized bed reactor. AIChE J. 1991, 37, 1392–1400. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Z.; Rincon, D.; Christofides, P.D. Operational safety via model predictive control: The Torrance refinery accident revisited. Chem. Eng. Res. Des. 2019, 149, 138–146. [Google Scholar] [CrossRef]

- Kassel, L.S. Prevention of Afterburning in Fluidized Catalytic Cracking Processes. U.S. Patent 2,436,927A, 2 March 1948. [Google Scholar]

- Blaser, P.; Pendergrass, J.; Gabites, J.; Brooke, A. Viva Energy′s Geelong refinery reduces FCCU turnaround risk. Hydrocarb. Process. 2018, 1–6. Available online: https://www.hydrocarbonprocessing.com/magazine/2018/september-2018/special-focus-refining-technology/viva-energy-s-geelong-refinery-reduces-fccu-turnaround-risk (accessed on 11 January 2022).

- Clark, S.; Fletcher, R.; Blaser, P. Identifying the root cause of afterburn in fluidized catalytic crackers. In Proceedings of the Annual Meeting of American Fuel & Petrochemical Manufacturers AM-16-15, San Francisco, CA, USA, 13–15 March 2016. [Google Scholar]

- William, M.; Heigl, J.J. Method of Detecting Incipient Afterburning during Regeneration. U.S. Patent 2,545,162A, 13 March 1951. [Google Scholar]

- Wu, D.; Schmidt, M.; Huang, X.; Verplaetsen, F. Self-ignition and smoldering characteristics of coal dust accumulations in O2/N2 and O2/CO2 atmospheres. Proc. Combust. Inst. 2017, 36, 3195–3202. [Google Scholar] [CrossRef]

- Chester, A.W. Chapter 6 CO combustion promoters: Past and present. In Studies in Surface Science and Catalysis; Elsevier: Amsterdam, The Netherlands, 2007; pp. 67–77, 166. [Google Scholar]

- Wang, R.; Luo, X.; Xu, F. Economic and control performance of a fluid catalytic cracking unit: Interactions between combustion air and CO promoters. Ind. Eng. Chem. Res. 2014, 53, 287–304. [Google Scholar] [CrossRef]

- Iliopoulou, E.F.; Efthimiadis, E.A.; Nalbandian, L.; Vasalos, I.A.; Barth, J.O.; Lercher, J.A. Ir-based additives for NO reduction and CO oxidation in the FCC regenerator: Evaluation, characterization and mechanistic studies. Appl. Catal. B-Environ. 2005, 60, 277–288. [Google Scholar] [CrossRef]

- Iliopoulou, E.F.; Efthimiadis, E.A.; Vasalos, I.A. Ag-based catalytic additives for the simultaneous reduction of NO and CO emissions from the regenerator of a FCC unit. Ind. Eng. Chem. Res. 2004, 43, 1388–1394. [Google Scholar] [CrossRef]

- Iliopoulou, E.F.; Efthimiadis, E.A.; Vasalos, I.A.; Barth, J.O.; Lercher, J.A. Effect of Rh-based additives on NO and CO formed during regeneration of spent FCC catalyst. Appl. Catal. B-Environ. 2004, 47, 165–175. [Google Scholar] [CrossRef]

- Wen, B.; He, M.; Costello, C. Simultaneous catalytic removal of NOx, SOx, and CO from FCC regenerator. Energy Fuels 2002, 16, 1048–1053. [Google Scholar] [CrossRef]

- Stockwell, D.M. Lower Temperature CO Promoters for FCC with Low NOx. U.S. Patent 20070129234A1, 7 June 2007. [Google Scholar]

- Vaarkamp, M.; Stockwell, D.M. CO Oxidation Promoters for Use in FCC Processes. U.S. Patent 7,959,792B2, 14 June 2011. [Google Scholar]

- Schön, A.; Dacquin, J.-P.; Granger, P.; Dujardin, C. Non stoichiometric La1-yFeO3 perovskite-based catalysts as alternative to commercial three-way-catalysts?—Impact of Cu and Rh doping. Appl. Catal. B-Environ. 2018, 223, 167–176. [Google Scholar] [CrossRef]

- Yang, X.; Liu, G.; Li, Y.; Zhang, L.; Wang, X.; Liu, Y. Novel Pt–Ni bimetallic catalysts Pt (Ni)–LaFeO3/SiO2 via lattice atomic-confined reduction for highly efficient isobutane dehydrogenation. Trans. Tianjin Univ. 2019, 25, 245–257. [Google Scholar] [CrossRef]

- Zhang, L.; Filot, I.A.; Su, Y.-Q.; Liu, J.-X.; Hensen, E.J. Understanding the impact of defects on catalytic CO oxidation of LaFeO3-supported Rh, Pd, and Pt single-atom catalysts. J. Phys. Chem. C 2019, 123, 7290–7298. [Google Scholar] [CrossRef] [PubMed]

- Schoen, A.; Dujardin, C.; Dacquin, J.-P.; Granger, P. Enhancing catalytic activity of perovskite-based catalysts in three-way catalysis by surface composition optimisation. Catal. Today 2015, 258, 543–548. [Google Scholar] [CrossRef]

- Wu, Y.; Ni, X.; Beaurain, A.; Dujardin, C.; Granger, P. Stoichiometric and non-stoichiometric perovskite-based catalysts: Consequences on surface properties and on catalytic performances in the decomposition of N2O from nitric acid plants. Appl. Catal. B-Environ. 2012, 125, 149–157. [Google Scholar] [CrossRef]

- Ellis, N. Experimental Investigation of Fluidized Bed Systems. In Essentials of Fluidization Technology; Wiley-VCH: Weinhard, Germany, 2020; pp. 75–108. [Google Scholar]

- Vannasing, D.; Hulfachor, J. Erosion Resistance of Tungsten-Carbide Coatings for Steel Pipes in Fluid Catalytic Cracking Units, Chevron-Material Engineering Report; Chevron ETC: Richmond, CA, USA, 2019; pp. 1–42. [Google Scholar]

- di Natale, F.; Nigro, R. An experimental procedure to estimate tube erosion rates in bubbling fluidised beds. Powder Technol. 2016, 287, 96–107. [Google Scholar] [CrossRef]

- Willbourne, P. Barriers to superior FCC cyclone performance. Primary causes, repair options and design solutions. In Proceedings of the 15th Grace EMEA FCC Technology Conference, Barcelona, Spain, 21–24 April 2015; pp. 1–30. [Google Scholar]

- Nnabalu, C.R.; Falcone, G.; Bortone, I. The role of fluid catalytic cracking in process optimisation for petroleum refineries. Int. J. Chem. Mol. Eng. 2019, 13, 370–376. [Google Scholar]

- Bryant, H.S.; Silverman, R.W.; Zenz, F.A. How dust in gas affects cyclone pressure drop. Hydrocarb. Process 1983, 62, 87–90. [Google Scholar]

- Blaser, P.; Thibault, S.; Sexton, J.A. Use of computational modeling for FCC reactor cyclone erosion reduction at the marathon petroleum catlettsburg refinery. In Proceedings of the 14th International Conference on Fluidization–From Fundamentals to Products, Noordwijkerhout, The Netherlands, 26–31 May 2013; Engineering Conferences International ECI Digital Archives. Kuipers, J.A.M., Mudd, R.F., van Ommen, J.R., Deen, N.G., Eds.; pp. 1–9. [Google Scholar]

- Karri, S.B.R.; Davuluri, R.P. Dilute-Phase Pneumatic Conveying–Design Aspects of Bend Types; Research Report 71; Particulate Solid Research, Inc.: Chicago, IL, USA, 1995. [Google Scholar]

- Tilly, T.P. Erosion caused by airborne particles. Wear 1969, 14, 63–79. [Google Scholar] [CrossRef]

- Koffman, L. The cleaning of engine air Part 2. In Gas Oil Power; Roki Co., Ltd.: Rayong, Thailand, 1953; pp. 89–94. [Google Scholar]

- Decker, S.; Simon, H. Element for Anchoring an Anti-Erosion Coating to an Inner Wall of a Chamber of an FCC Unit. U.S. Patent 10,048,006, 14 August 2018. [Google Scholar]

- Clough, M.; Pope, J.C.; Lin, L.T.X.; Komvokis, V.; Pan, S.S.; Yilmaz, B.J. Nanoporous materials forge a path forward to enable sustainable growth: Technology advancements in fluid catalytic cracking. Micropor. Mesopor. Mat. 2017, 254, 45–58. [Google Scholar] [CrossRef]

- Zhang, H.; Degrève, J.; Baeyens, J.; Wu, S.-Y. Powder attrition in gas fluidized beds. Powder Technol. 2016, 287, 1–11. [Google Scholar] [CrossRef]