Abstract

This article highlights the need to reduce carbon dioxide emissions by reducing energy consumption. Of course, this can be achieved in various ways, but inter alia, through the practical implementation of the assumptions contained in the CSR programs of individual companies, which include a component on environmental protection and counteracting global warming. The authors also describe a proposal to reduce CO2 emissions by using coke oven gas (if necessary) in exchange for natural gas. Currently, the largest sources of carbon dioxide emissions are the combustion of fossil fuels in power plants, transport—cars and planes, processes related to the production of industrial goods, and deforestation. In the preparation of the article, the analysis of the literature on the subject, analysis of documents, desk research, and two case studies were used. The main goal of the article is to present the possibilities of reducing CO2 emissions by implementing the assumptions of the CSR policy on the example of a selected company (models of such activities are also given). Therefore, the aim of the article is to present selected activities that can contribute to the reduction of carbon dioxide emissions in enterprises; of course, this is specific each time and should be individually selected for each enterprise depending on financial, environmental, and any other conditions. This means that almost all enterprises, organizations, and all other institutions should be obliged to implement an individual environmental policy related to the possibility of reducing carbon dioxide emissions worldwide, and the effects of implementing the assumptions of this policy should be regularly, at least once a year, presented in the CSR reports of a given organization. However, each organization should provide its own examples of how it reduces carbon dioxide emissions. For this reason, this article presents an example of the Marcel CHP plant, which, due to its capabilities, also uses coke oven gas, the use of which results in lower emissions of carbon dioxide than natural gas. Additionally, the article presents a comparative analysis of the use of coke oven gas instead of natural gas. The obtained results show the significant and real possibilities of reducing carbon dioxide emissions.

1. Introduction

It is imperative that company leaders should also be specialists in areas where there is interaction between people: employees, colleagues, customers, and contractors, because positive relationships also mean satisfied shareholders. Focusing on people and on pro-ecological activities [1] should therefore be one of the determinants of creating a strategy for every company. In this regard, companies should strive for organizational effectiveness and focus on a long-term strategy of change in order to meet the challenges and problems of the modern world [2]. The direction of these changes should be set by the CSR strategy. CSR is understood here as a management strategy, according to which companies take into account social interests in their activities and environmental aspects and shape positive relations with various groups of stakeholders. The natural environment is also an important “stakeholder” in corporate social responsibility (CSR) activities [3,4].

Environmental issues have been an integral part of the public debate since the Industrial Revolution. Already in the 17th century, when transport and production based on burning coal developed, the topic of environmental pollution appeared. In the 20th century, human activities significantly influenced the state of the natural environment. The two World Wars and nuclear tests had a great impact on nature, as did the Chernobyl disaster. People’s ecological awareness was growing simultaneously with the progressive processes of environmental degradation. Programs and concepts regarding environmental revitalization are implemented with the use of modern technologies in order to shape environmental awareness [5]. In the 1970s, Earth Day was organized for the first time. The following decades brought concerns about the ozone hole and the related issue of greenhouse gas emissions. The first international climate agreements were established, which resulted in the Montreal and Kyoto Protocols. However, it was not until the 21st century that concerns about the condition of our planet became part of a broad public debate. In 2015, the Paris Climate Agreement produced the first universal, legally binding agreement of 192 countries in the field of climate. A global action plan was identified that was aimed at preventing climate change by limiting global warming to well below 2 °C. In December 2019, the European Commission, in the communication “The European Green Deal”, proposed further-reaching targets for the reduction of greenhouse gas emissions by 2030, according to two scenarios—emission reduction by 50% and 0.55% compared to the base year (1990). In the current COVID-19 pandemic, questions about the future are louder and more frequent. The current pandemic is accompanied by an increasing awareness of the importance of global cooperation and linkages and the need for accountability regarding the effects of a further rise in the average temperature on Earth. Today, man-made increases in temperature compared to pre-industrial times, related to the emission of carbon dioxide into the atmosphere, have brought unprecedented phenomena such as mass extinction of species, record heat, fires, shifting climatic zones, melting glaciers, permafrost thawing, floods, and drought. Failure to tackle global warming is projected to result in a further increase in the Earth’s average temperature by the end of this century, even by 4–7 degrees Celsius or more, leading to an irreversible climate and civilization disaster. With it, infrastructure damage, unprecedented migratory movements, and resource wars can occur [6].

The environmental aspects of CSR are discussed from different perspectives and concern various enterprises and institutions [7]: banking sector [8], hotel sector [9], ready-made garment (RMG) firms [10], food industry [11], rural tourism [12], construction sector [13], mining enterprises [14], water, sewage companies [15], and others. Therefore, in this article, the authors focus on the ecological aspect of the CSR strategy. The aim of the article is therefore to present the possibilities of reducing carbon dioxide emissions through rational management of pro-ecological activities, including by promoting the desired pro-ecological attitudes and behaviors (such as: reducing pollutant emissions and the amount of solid waste produced as part of recycling; through education, better monitoring, and management of waste; and the use of coke oven gas) [16].

2. Materials and Methods

The following assumption was made as a hypothesis: it is possible to limit carbon dioxide emissions through rational management of pro-ecological activities in the context of CSR assumptions. Therefore, the following were adopted as supporting questions:

- What CSR activities can directly contribute to limiting of carbon dioxide emissions?

- How else can you reduce carbon dioxide emissions?

Therefore, on the basis of the available literature on CSR [17] and sustainable development, the issues related to the emission of carbon dioxide (CO2) into the atmosphere were selected and the related assumptions contained in the documents provided by selected large enterprises were analyzed, i.e., the so-called desk research [18,19,20,21,22,23,24]. Then, based on specific examples (case studies), real possibilities of reducing carbon dioxide emissions were indicated, and thus, the possibilities of saving energy.

Desk research’s analysis is based on official statistics documents, reports, analyses, publications, and statistical yearbooks. Desk research is a research method that involves the analysis of available data sources, and in particular, their compilation, mutual verification, and processing. Then, this type of analysis is the basis for drawing conclusions about the problem under study [25,26,27,28,29,30,31].

Therefore, in this article, an analysis based on the desk research method was carried out.

3. Results

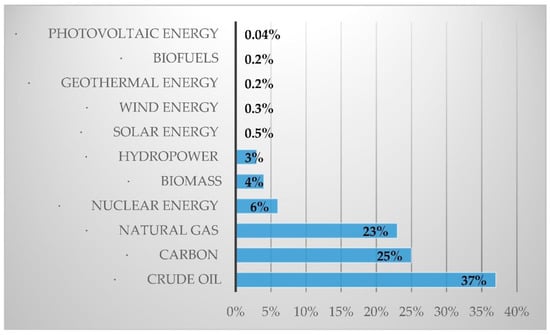

Currently, most energy comes from crude oil, followed by natural gas and coal. Nuclear and hydropower are used only after that. On the other hand, the use of renewable energy sources (such as wind or solar energy) is almost negligible. Activities related to the creation of a sustainable energy strategy and climate change mitigation focus on energy saving and the use of reflection processes to search for sustainable development strategies [32,33]. However, we still have to wait for the effects [34]. Currently, fossil fuels are still the most used for energy production [35].

Below are the dependencies showing the sources of energy used by our civilization [36] (Figure 1):

Figure 1.

Chart: sources of energy. Own study based on data from [36].

It follows from the above that 85% of energy comes from crude oil, natural gas, and coal—the largest emitters of carbon dioxide and other greenhouse gases. Renewable sources are only marginal—solar, wind, geothermal, and biofuels are just over 1% of the energy consumed by mankind. Nevertheless, it should be noted that the amount of energy obtained from renewable sources is growing every year.

However, our civilization needs energy to meet its multiple needs. Thanks to energy from oil, gas, and coal, the following are possible: construction (operation of construction machinery and acquisition of building materials), electricity production (electricity in the socket, lighting, operation of computers, television, refrigerators, etc.), extraction and processing of raw materials (including only fossil fuels), functioning of trade, heating of buildings, high-performance industrial agriculture, infrastructure functioning: telecommunications, water supply, hospitals, hotels, etc., production in factories, production of asphalt, production of fuels for transport (98% of transport is based on oil), production of lubricants, production of paints, solvents and other materials, production of plastic, etc. [37].

Thus, it can be concluded that fossil fuels affect almost all aspects of our lives. For this reason, there is no simple solution to reducing their combustion and carbon dioxide emissions. Independence from fossil fuels is a great challenge. However, there is no other sensible option but to find other sources and reduce the consumption of the existing ones.

On the other hand, the largest sources of carbon dioxide emissions are as follows:

- Fossil fuel combustion in power plants;

- Transport—cars and planes;

- Processes related to the production of industrial goods;

- Deforestation.

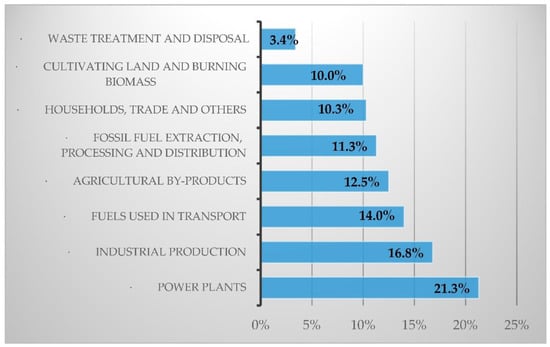

Therefore, the current sources of greenhouse gas emissions to the atmosphere are presented below, broken down by individual sectors of the economy [36] (Figure 2):

Figure 2.

Chart: sources of greenhouse gas emissions to the atmosphere broken down by individual sectors of the economy. Own study based on data from [36].

The total greenhouse gas emissions by sector are presented above: energy, industry, transport, agriculture, fuel extraction, buildings (apartments, shops, offices, etc.), biomass combustion, and waste disposal.

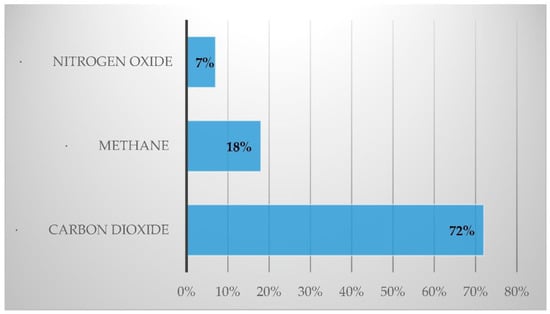

As for the sources of greenhouse gas emissions, the following is a breakdown of emissions by sectors for the three main greenhouse gases—carbon dioxide, methane, and nitrogen oxide [36] (Figure 3):

Figure 3.

Chart: sources of greenhouse gas emissions to the atmosphere broken down by individual sectors of the economy. Own study based on data from [36].

- Carbon dioxide—72%;

- Methane—18%;

- Nitrogen oxide—7%.

As is known, carbon dioxide is produced primarily during the combustion of coal and hydrocarbons such as natural gas and crude oil. Methane is excreted by cattle herds, escapes from natural gas pipelines, and is produced during certain agricultural processes, such as rice cultivation, and also enters the atmosphere as a product of the natural processes of decomposition of organic matter. The combustion of fossil fuels in industry, combined heat and power plants, households, and vehicle engines is responsible for the emission of nitrogen oxides [36].

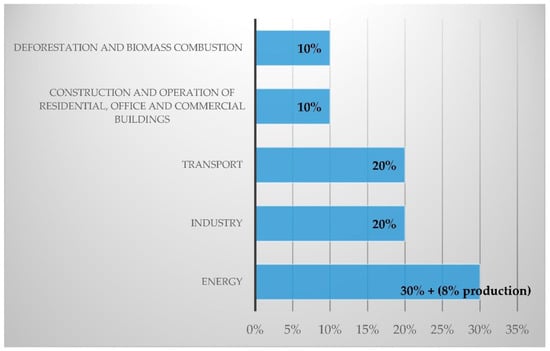

As for carbon dioxide, it is credited with almost ¾ of the influence on the strengthening of the greenhouse effect. Currently, the main sources of carbon dioxide emissions in the world are [36] (Figure 4):

Figure 4.

Chart: the main sources of carbon dioxide emissions in the world. Own study based on data from [36].

- Energy—30% of emissions (+8% production);

- Industry—20%;

- Transport—20%;

- Construction and operation of residential, office, and commercial buildings—10%;

- Deforestation and biomass combustion—10%.

Therefore, the emission of carbon dioxide to the environment and to the atmosphere should be particularly limited in every possible way (both by the workplaces themselves and by energy production companies).

3.1. Reduction of Carbon Dioxide Emissions by Workplaces

Due to the deepening environmental crises and the increasing anthropopressure, companies within the CSR are introducing special programs and environmental policies [37,38,39,40].

Environmental policy should be part of the business management system of every enterprise and an integral element of the CSR strategy. Larger global enterprises [41,42,43] incorporate environmental policy and CSR strategy into the corporate governance (more information available in [44]). They are aware that only by acting in a sustainable and responsible manner can one contribute to reducing negative effects on the natural environment and ensuring that future generations can meet their needs.

3.1.1. CO2 Reduction through the Implementation of CSR Principles

On 28 October 2010, the ISO 26000 standard was published by the International Organization for Standardization (ISO). This standard is intended to organize the knowledge of corporate social responsibility (CSR). ISO 26000 does not mean certification. On the other hand, it provides practical instruction for the principles of responsible business and provides tips for all types of organizations (not only for enterprises), regardless of their location or size [4].

The ISO 26000 standard distinguishes the following areas of corporate social responsibility:

- Environment;

- Fair market practices;

- Human rights;

- Labor relations;

- Organizational governance;

- Relations with consumers;

- Social commitment.

On the other hand, the tools of corporate social responsibility (CSR) include, among others:

- Activities for the local community (projects for the environment in which the enterprise operates), most often taking the form of activities consisting of: supporting local institutions and people, cooperation with local organizations, creating and implementing programs for children and youth, including environmental programs, and also the implementation of investment activities, taking into account the principles of sustainable development (e.g., road construction);

- Creating social reports—publications presenting the method of managing the company and implementing the company’s strategy, taking into account socially responsible activities, the main essence of which is the company’s transparency;

- Employee volunteering, consisting of volunteering on the part of the company’s employees for pro-ecological and pro-social initiatives, etc.;

- Management systems—introducing transparent and effective management systems, i.e., ISO 9000 Quality Management System, ISO 14000 Environmental Management System (environmental management system), Social Accountability SA 8000 (social responsibility management);

- Product labeling—includes the so-called eco-labeling and social labeling, which consists of informing the consumer about the ecological aspects of the product (environmental, health) and social aspects. As a result, labeled products stand out from other products on the market, allowing consumers to make informed choices. At the same time, manufacturers provide reliable information about the composition of products and the content of individual ingredients;

- Pro-ecological activities—activities aimed at environmental protection and investments minimizing the impact on the environment, including initiatives such as: implementation of environmental policy, sustainable management of raw materials, waste segregation, environmental education of employees and customers, including the implementation of ecological technological processes and ecological products and services;

- Employee programs—including environmental education programs for employees and their families, e.g., through the implementation of integration programs;

- Social campaigns—they enable enterprises to influence the attitudes of society through the media; these campaigns are aimed at helping those in need (e.g., transferring some of the profits from the sale of a specific product to social goals or pro-environmental activities) or increasing social awareness on a specific topic (e.g., environmental protection, consumer education);

- Supply chain management—application of the principles of corporate social responsibility at every stage of the supply chain, implementation of standards for all contractors, etc., in accordance with ISO 28000—Supply Chain Security Management [4].

The research of the Institute for Democracy and Private Enterprise shows that companies applying CSR principles benefit from the following numerous advantages compared to other enterprises:

- Benefits resulting from the social environment—reducing the negative impact of enterprises on the natural environment;

- Economic benefits—they have higher current liquidity and obtain higher profitability of sales;

- Environmental benefits: rational management of natural resources and waste, involvement of other business partners in the chain of environmental responsibility and initiating joint pro-ecological activities, as well as popularizing pro-ecological ideas [4,42].

According to the authors, CSR principles should be implemented in enterprises in accordance with the principles of the Deming cycle (PDCA) [6], that is: Plan, Do, Check, Action, the next development of which is the continuous improvement model, defined by the acronym “DMAICS”, derived from the words: Define, Measure, Analyze, Improve, Control, Standardize:

- Plan—at this stage, these are, for example, pro-ecological activities for the local community, projects for the environment in which the company operates;

- Do—pro-ecological activities, i.e., activities for environmental protection, investments minimizing the impact on the environment. These include initiatives such as the implementation of environmental policy, sustainable management of raw materials, waste segregation, environmental education of employees and customers, as well as the implementation of ecological technological processes and ecological services and products;

- Check—verification of the assumptions of pro-ecological activities and the status of their implementation;

- Action—the implementation of planned activities, including, for example, social campaigns enabling enterprises, through the media, to achieve environmental goals, including those contributing to the reduction of carbon dioxide emissions.

3.1.2. An Example of Reducing Carbon Dioxide Emissions Based on Desk Research of Publicly Available Documents of a Selected Global Company

In line with the assumptions of the previously mentioned case study methodology, a good example of reducing carbon dioxide emissions is one of the corporate initiatives, “Citizen of the Planet”—COTP—an initiative implemented by the Teleperformance Group [45].

Teleperformance Group is a global company, founded around 40 years ago, located in 76 countries, providing services to world leaders in the e-commerce industry, such as banking, electronics, electronic and retail trade, financial services, energy, fast moving consumer goods (FMCG), media, healthcare sector, etc. Digital integrated business services of this company combine people’s work and advanced technologies to provide customers with the highest quality. While technology creates new ways of working, relevant interaction experts remain committed to creating unique combinations of hard competences with empathy and communication skills. Therefore, the pro-ecological activity of the company as an employer for nearly 223,000 employees in 76 countries is not without significance.

Teleperformance Group takes responsibility for the social and environmental effects of its business activities. Therefore, it is strongly committed to reducing its carbon footprint, minimizing the negative impact on the environment by acting in a sustainable manner, to ensure that future generations can meet their own needs.

For this reason, Citizen of the Planet (COTP) was created—a global corporate initiative launched in 2008 to ensure that Teleperformance operates in an environmentally friendly and responsible manner. As part of their joint activities for our planet, buildings/commercial facilities in all countries in which the company operates are improved in such a way as to be consistent with the principles of sustainable development.

This includes:

- Reduction of water consumption (e.g., by installing photocells) and paper;

- Reducing the consumption of fossil fuels: oil and gas (the use of videoconferences instead of traveling to meetings by car);

- Reduction of pollutant emissions and the amount of solid waste generated as part of recycling;

- Education for sustainable development;

- Better monitoring and management of waste streams (also by introducing dedicated recycling points in all buildings/premises where the company operates);

- Promotion and functioning in accordance with the principle that one should act to create a “paperless” environment;

- Encouraging the optimization of energy consumption and gas emissions to the atmosphere.

As part of the Citizen of the Planet (COTP) initiative, the company constantly monitors the consumption of energy, water, paper, and other waste, monitors carbon footprint emissions, and regularly publishes reports on these topics on its website, such as below [45] (Table 1).

Table 1.

Impact of the activities of the Teleperformance Group within the Citizen of the Planet (COTP) initiative.

The Science-Based Targets initiative (SBTi) is a joint initiative of various entities acting for climate protection aimed at increasing the ambition of enterprises in the field of climate action by mobilizing companies to reduce greenhouse gas emissions and reduce carbon footprint emissions in line with the level of decarbonization required by science in order to limit warming to less than 1.5 °C/2 °C compared to pre-industrial temperatures. Launched in 2015, this initiative defines and promotes best practice for science-based goal setting, offers resources and guidance, and independently evaluates and approves company goals.

As can be seen from the above summaries, through the implementation of the assumptions contained in the Citizen of the Planet (COTP) initiative, the Teleperformance Group has recorded a year-to-year decrease in carbon footprint emissions per employee, a continuous increase in the share of renewable energy in the total consumption of the Teleperformance Group, as well as the growth of donations collected for environmental purposes.

Moreover, the achievement of these strategic goals depends, for example, on the annual variable remuneration of the management staff in the company.

3.2. Reduction of Carbon Dioxide Emissions by Companies Involved in Energy Production

Moreover, companies involved in the production of energy should undoubtedly take into account the reduction of carbon dioxide emissions in their activities [40].

Therefore, using the method of comparative analysis, this article compares the combustion process of natural gas and coke oven gas in terms of carbon dioxide emissions [46].

Most of the available and commonly used gaseous fuels contain the element carbon C, which is most often found in combustible components, chemical compounds—mainly as methane CH4 (possibly also higher CmHn hydrocarbons, e.g., ethane C2H6, propane C3H8, butane C4H10) and carbon monoxide CO.

Combustion of each of these compounds leads, inter alia, to the formation of additional particles (which are numerically equal to the number of carbon atoms C) of carbon dioxide CO2, which is usually discharged together with the remaining components of the exhaust gas into the environment.

Examples of oxidation reactions of components containing the element carbon C:

- Methane:CH₄ + 2 O2 → CO2 + 2 H2O

- Carbon monoxide:CO + 0.5 O2 → CO2

Each emission of carbon dioxide CO2 to the environment is currently assessed very negatively, because this compound (3-atom gas) is one of the greenhouse gases (i.e., polyatomic gases that contain at least 3 atoms in a particle/particle).

Combustible gases commonly used for energy purposes in the economy are: natural gas (NG—natural gas) and coke oven gas (COG—coke oven gas).

Natural gas (NG) belongs to the group of fossil fuels, while coke oven gas (COG) is obtained during the production of metallurgical coke, necessary in the blast furnace production of pig iron.

3.2.1. Types of Natural Gas

Natural gas (the so-called blue fuel) is a type of natural, organic fossil fuel. Natural gas occurs in many places on Earth—its deposits are often associated with oil and hard coal deposits, although there are also places where only gas is present. The top five gas producers in the world include the USA, Russia, Iran, Canada, and China. Among the countries which extract the most gas in the world, apart from Russia, there are only two other European countries—Norway, which is in the top ten (approx. 3% of global production) and the United Kingdom (approx. 1%), which closes the list [47].

Under natural conditions, natural gas is a mixture of various gases and chemical compounds, in which methane is the dominant part. The remaining components can be both other flammable gases, such as ethane, propane, or butane, and non-flammable gases, such as nitrogen, water vapor, or CO2. The gas is often contaminated with various types of chemicals and solid particles [48].

Therefore, the composition of natural gas varies greatly depending on the place of its occurrence and extraction. In order for blue fuel to enter distribution networks, natural gas must undergo various chemical processes, as a result of which unnecessary components are removed from its composition. Therefore, after extraction, the natural gas is industrially cleaned and treated so that it meets the quality parameters that define, among others, minimum calorific value. In addition, the gas undergoes one more process—the so-called odorization. As a result of this process, the gas obtains a characteristic smell that is easy to detect if the installation becomes unsealed.

The main difference between the types of gas is in terms of the minimum level of heat of combustion:

- E-type high-methane natural gas—this is a gas with high methane content (about 98%) and trace amounts of nitrogen (about 1%) and flammable gases (about 1%). The minimum heat of combustion for E-type gas was set at 34 MJ/m3n. Type E high-methane natural gas is distributed in municipal gas networks as the so-called network fuel for household, corporate, industrial, and municipal use;

- Ln and Lm nitrogen-rich natural gas—this is natural gas with the lowest relative methane content—in the Ln gas type it is less than 66%, and in the Lm gas type less than 61%. The gas contains a significant amount of nitrogen (at least 32%) and negligible amounts of combustible gases and CO2 (about 1% each). The minimum heat of combustion for Ln and Lm natural gas was set at 22 MJ/m3n and 18 MJ/m3n, respectively;

- Ls nitrogen-rich natural gas—a gas with a reduced volume of methane in relation to the LW-type nitrogen-rich gas (here the volume of methane is less than 72%) with a large admixture of non-flammable nitrogen (about 27%) and trace amounts of combustible gases and CO2 (about 1% each). The minimum heat of combustion of Ls nitrogen-rich gas was set at 26 MJ/m3n;

- Lw nitrogen-rich natural gas—a gas with a much smaller amount of methane by volume (less than 80%), with an admixture of non-flammable nitrogen (about 20%) and combustible gases (about 1%). The minimum heat of combustion for the Lw nitrogen-rich gas was set at 30 MJ/m3n [47].

Natural gas from group L is supplied in local networks as fuel for use in households and local companies. Lw nitrogen-rich gas is the subject of supplies more often. Ls nitrogen-rich natural gas is usually supplied to local users only in the vicinity of the gas intake (mine). Ln and Lm gas, on the other hand, are not supplied in all countries, although the regulations define their quality parameters.

In addition to the above-mentioned types of gaseous fuel, LPG can also be supplied in the distribution network. There are basically two types of gas offered by gas sellers:

- Propane-butane gas with a high level of heat of combustion determined at not less than 111.6 MJ/m3n;

- Propane-butane gas with a relatively low level of heat of combustion determined at not less than 23.3 MJ/m3n.

It is worth adding that liquefied petroleum gas (propane-butane), unlike high-methane E-type natural gas and L-group gases, is an artificially obtained gas—it is a byproduct of, e.g., crude oil refining and natural gas extraction, and the ignition temperature of liquefied gas is lower than that of natural gas (approximately 460 °C and 600 °C, respectively) [47].

3.2.2. Comparative Analysis of Combustible Gases—Natural Gas and Coke Oven Gas—In Terms of Reducing CO2 Emissions

In this aspect, an approximate quantitative comparative analysis of globally important combustible gases (natural gas and coke oven gas), needed for energy purposes, will be performed.

The basic, typical composition (volume fractions equal to the mole fractions of the main components) of natural gas (NG) is as follows:

methane: CH4 = 92.8%, ethane: C2H6 = 2.5%, propane C3H8 = 1.6%,

carbon dioxide CO2 = 0.5%, nitrogen N2 = 2.6%

carbon dioxide CO2 = 0.5%, nitrogen N2 = 2.6%

As a typical (exemplary) composition of the purified coke oven gas, one can assume:

hydrogen: H2 = 64.2%, methane: CH4 = 24.0%, carbon monoxide: CO = 5.8%, nitrogen: N2 = 5.1%,

oxygen: O2 = 0.9%

oxygen: O2 = 0.9%

It is easy to see that the dominant component of coke oven gas is hydrogen H2 [49,50,51,52]. This is in line with the suggestion that has been promoted for some time that it is hydrogen H2 that should be treated in the future as a prospective potential energy carrier.

3.2.3. An Example of Analysis of the Composition of Natural and Coke Oven Gas Burned in the “Marcel” CHP Plant—Case Study

Therefore, as part of the comparative analysis of natural gas and coke oven gas, the β index will be defined, defining the amount of greenhouse gas emissions to the environment (mainly carbon dioxide CO2 emission) from 1 m3n of natural gas and coke oven gas, for example in the “Marcel” CHP plant [52,53].

“Marcel” CHP plant—it is a CHP plant located in Poland, in the Silesian Voivodeship, in the town of Radlin. The plant has existed since 1 October 1998, when it was separated from the Coal Mine “Marcel”, and before that, since 1908, the combined heat and power plant existed as part of the “Marcel” Coal Mine. The CHP plant uses hard coal supplied from the nearby Coal Mine “Marcel” and waste coke oven gas from the nearby Radlin coking plant as fuel, and the additional fuel is biomass. “Marcel” CHP has concessions from the Energy Regulatory Office for:

- Heat generation;

- Heat transmission and distribution;

- Electricity generation;

- Transmission and distribution of electricity.

Based on the basic combustion reactions of combustible gas components, e.g., Equations (1) and (2), one can write:

- Combustion reactions of selected gas components:

for methane: CH4 + 2⋅O2 → CO2 + 2 H2O

for ethane: C2H6 + 3.5⋅O2 → 2⋅CO2 + 3⋅H20

for propane: C3H8 + 5⋅O2 → 3⋅CO2 + 4⋅H20

for carbon monoxide: CO + 0.5⋅O2 → CO2

- For natural gas (NG):

Indicator βNG, (m3n CO2)/(m3n NG), where n—m3n normal, i.e., at pressure pn = 1 bar and at a temperature of Tn = 273 K, it is:

βNG = 0.928 + 2 × 0.025 + 3 × 0.016 + 0.005 = 1.031 (m3n CO2)/(m3n NG)

- For coke oven gas (COG):

Indicator βNG, (m3n CO2)/(m3n COG), where n—m3n normal, i.e., at pressure pn = 1 bar and temperature Tn = 273 K, it is:

βCOG = 0.24 + 0.058 = 0.298 (m3n CO2)/(m3n COG) → less CO2 than in natural gas

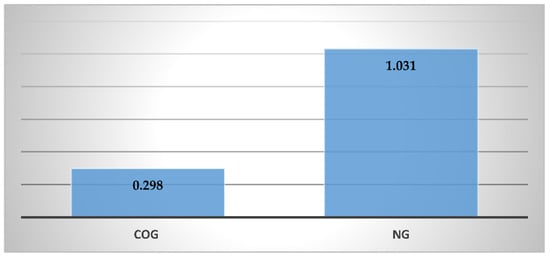

The estimates (Figure 5) show that the unit CO2 greenhouse gas emission from the combustion of natural gas (NG) is significantly higher (about 3.46 times) than the unit CO2 greenhouse gas emission from the combustion of coke oven gas (COG).

Figure 5.

Chart: relative amount of CO2 formation, m3n CO2/m3n gas. Own study based on data from “Marcel” heat and power plant.

This is all down to the relatively high pure hydrogen content of H2 in the coke oven gas. Therefore, coke oven gas, which is in fact an additional product in the production of metallurgical coke, should be rationally managed, preferably at the site of its production. A significant part of this gas is already used to fire the coke oven battery itself (heating a new coal charge), and the rest may be an excellent boiler fuel in a nearby CHP plant (generation of electricity and heating heat).

In addition to the results of the analysis of carbon dioxide CO2 emissions in relation to 1 m3n of consumed gas (natural NG, coke oven COG) presented above, it is also worth analyzing the amount of this emission in relation to the amount of chemical energy obtained during the combustion of a given gas.

The measure here is the calorific value of individual gases, which is as follows:

- Natural gas is approx. 32.1 MJ/m3n,and;

- Coke oven gas is on the order of 19.8 MJ/m3n.

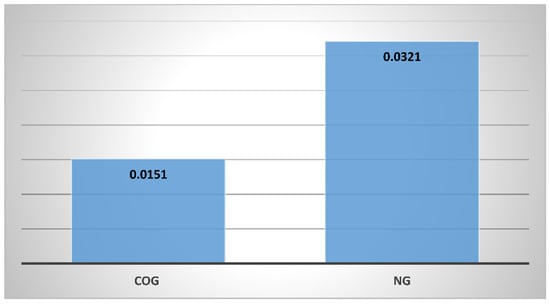

In this case, (in terms of) the relative value of CO2 emissions, it is more favorable for coke oven gas, because (Figure 6):

Figure 6.

Chart: relative amount of CO2 generation, m3n CO2/MJ. Own study based on data from “Marcel” heat and power plant.

(1.031/32.1) > (0.298/19.8);

That is: 0.0321 (m3n CO2/MJ—for NG) > 0.0151 (m3n CO2/MJ—for COG).

In addition, it should be taken into account that natural gas must be burdened with significant energy expenditure (and therefore also appropriate CO2 emission) related to the transport of this energy carrier over long distances (from the place of acquisition to the use station), while coke oven gas is usually utilized near the place of collection.

4. Discussion

Based on a desk research analysis of available programs and strategic documents of individual companies, devoted to supporting and implementing CSR principles in terms of reducing carbon dioxide emissions and comparative analysis of combustible gases, it is possible to state that currently the key tasks for humanity include:

- Being an industry leader in conducting business in a sustainable manner;

- Building experiences in the workplace;

- Educating employees on environmental issues, for example, through revitalization or volunteering to create “proactive eco-citizenship” so that they become better inhabitants of our planet [49];

- Educating and engaging employees and encouraging them in efforts to protect the environment, also outside the workplace, in their homes, and in the neighborhood where they live;

- Investing in improving the quality of the working environment in buildings/premises [50,52] where activities are conducted in accordance with the “Premises” standard, taking into account the principles described in the LEED standard [51];

- Providing alternative means of transport;

- Reduction of the carbon footprint per employee (carbon footprint—CF) worldwide;

- Enterprises are recommended to use ecological marketing tools [3].

The above assumptions can also be achieved by limiting the impact of information and communication technologies on the natural environment, thanks to the principles of “green IT”. These principles recommend that one should consider the environmental costs and the environmental impact of computer equipment energy, both in terms of the product, the computer itself, and the way it is used.

It is also recommended that business travel (both air and local) be restricted in all countries where the company operates.

In addition, carpooling and the use of public transport are promoted and supported.

Additionally, cooperation should be undertaken primarily with suppliers who consciously implement environmental management systems in order to reduce the amount of generated waste of all kinds [52,53,54,55,56,57,58].

In addition, the actual implementation of the idea of using coke oven gas in exchange for natural gas requires a very extensive analysis and is associated with large infrastructure investments both on the part of the gas supplier and end-user. Therefore, this issue requires a thorough analysis of the implementation feasibility, including the scope and time scale of possible implementation, which may be the subject of further works by larger research teams in the near future. Due to formal limitations, this article primarily contains a brief analysis of the idea of using coke oven gas in exchange for natural gas, which may also be an interesting subject for research by other scientists. It should be noted once again that the purpose of the article is to present, as examples, only some of the ideas implemented by selected companies to reduce carbon dioxide emissions.

The text presents simplified (technical) analytical calculations aimed at signaling, above all, the good technical suitability of coke oven gas (the possibility of its effective use also in the future) and its ecological advantage over the commonly used natural gas.

This issue was presented in the most accessible way (appropriate quantitative and energy indicators were defined and introduced separately for natural gas and coke oven gas), which should be understandable to any reader interested in this subject.

Further, more complete development of and approach to the issue of the rational use of solid fuels (coking coal) should also include the original, the so-called “technology of coal coking and selective extraction of coke oven gas”, which will be the subject of future interest and wider research.

Using the technology of selective coke oven gas extraction produces a much better gas, with significantly higher hydrogen content: H2 ≥ 75%, while the produced metallurgical coke finds wide technical application; it is necessary in smelting and obtaining pig iron in the blast furnace process, and thus in steel production, and is thus widely sought after in the world economy.

However, care should always be taken not to allow the use of both natural gas and coke oven gas on a larger scale. After combustion, both natural gas and coke oven gas contribute to an increase in the greenhouse gas content in the atmosphere (natural gas to a greater extent, coke oven gas to a lesser extent), which is detrimental to the climate. We must defend the climate with all our strength, and if we want to extract and utilize coal, it should rather be coking coal, by first subjecting it to the coking process. Metallurgical coke is needed, and coke oven gas has (as shown in the article) an ecological advantage over natural gas. Only when the appropriate hydrogen technologies for steel smelting are developed, will it be possible to completely abandon the use of hard coal [52,53,54,55,56,57,58].

5. Conclusions

Therefore, on the basis of the above, it can be concluded that the hypothesis made at the beginning of the article, that it is possible to limit carbon dioxide emissions through rational management of pro-ecological activities in the context of CSR assumptions, has been confirmed.

Conclusions can be here described on three levels:

- Theoretical,

- Managerial, and

- Practical implications.

In terms of the level of theoretical implication, each functioning organization (institution, enterprise) should conduct constant analyses of activities in relation to the set environmental goals through regular reviews of these activities in terms of achieving environmental goals at the level of the entire company.

In order to contribute to the reduction of carbon dioxide emissions in enterprises, it is therefore necessary to establish a specific environmental policy, which should be implemented depending on financial, environmental, and other conditions.

As for the level of management implications, as part of the company’s environmental policy, the following should be set: environmental goals and their expected results, ways and methods of achieving them, along with a description of the implementation of measures taken to reduce carbon dioxide emissions, as well as energy savings.

In practice, this may mean that almost all enterprises, organizations, and all other institutions should be obliged to implement such individual environmental policies related to the need to reduce carbon dioxide emissions worldwide. The effects of implementing these assumptions should, however, be regularly (at least once a year) presented in the CSR reports of a given organization, taking into account their own examples of how a given organization reduces carbon dioxide emissions.

Therefore, more caution should be taken when closing coking coal mines [59,60]. Of course, it is understandable that the total amount of natural gas consumed in the national economy is many times the amount of available coke oven gas, but such comparative analyses are of great importance.

All options for reducing the consumption of consumables should be investigated. However, in many cases, this still depends on the country in which the company operates.

Author Contributions

Conceptualization, A.K., S.P. and K.A.P.-L.; methodology, A.K., S.P. and K.A.P.-L.; validation, A.K. and S.P.; formal analysis, A.K. and S.P.; investigation, S.P. and K.A.P.-L.; resources, S.P. and K.A.P.-L.; data curation, K.A.P.-L.; writing—original draft preparation, A.K. and K.A.P.-L.; writing—review and editing, A.K. and K.A.P.-L.; visualization, S.P.; supervision, A.K.; funding acquisition, A.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research received funding under the research subsidy of the Department of Applied Social Sciences of the Faculty of Organization and Management of the Silesian University of Technology for the year 2022 (13/020/BK_22/0072).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

https://gml.noaa.gov/aggi/aggi.html, https://teleperformance.cotecorp.com/wp-content/uploads/2021/03/02-Strategy_21.pdf, https://poprostuenergia.pl/blog/rodzaje-gazu-ziemnego/, https://ziemianarozdrozu.pl/encyklopedia/38/energia-i-emisje-co2, https://www.senat.gov.pl/gfx/senat/pl/senatopracowania/192/plik/ot-683.pdf.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Energia i Emisje CO2. Available online: https://ziemianarozdrozu.pl/encyklopedia/38/energia-i-emisje-co2 (accessed on 24 April 2021).

- Leonov, S.V.; Vasilyeva, T.A.; Shvindina, H.O. Methodological approach to design the organizational development evaluation system. Sci. Bull. Polissia 2017, 2, 51–56. [Google Scholar] [CrossRef] [Green Version]

- Kuzior, A.; Lobanova, A. Tools of Information and Communication Technologies in Ecological Marketing under Conditions of Sustainable Development in Industrial Regions (Through Examples of Poland and Ukraine). J. Risk Financ. Manag. 2020, 13, 238. [Google Scholar] [CrossRef]

- CSR—Społeczna Odpowiedzialność Biznesu. Available online: https://www.parp.gov.pl/csr (accessed on 24 April 2021).

- Kuzior, A. Polskie i niemieckie doświadczenia w projektowaniu i wdrażaniu zrównoważonego rozwoju [Polish and German Experiences in Planning and Implementation of Sustainable Development]. Probl. Ekorozw. Probl. Sustain. Dev. 2010, 5, 81–89. [Google Scholar]

- Kustroń, P.; Pająk, T. Cykl Deminga. In Encyklopedia Zarządzania. Available online: https://mfiles.pl/pl/index.php/Cykl_Deminga (accessed on 24 April 2021).

- Ali, S.S.; Kaur, R. Effectiveness of corporate social responsibility (CSR) in implementation of social sustainability in warehousing of developing countries: A hybrid approach. J. Clean. Prod. 2021, 324, 129154. Available online: https://www.sciencedirect.com/science/article/pii/S0959652621033400 (accessed on 15 December 2021). [CrossRef]

- Chaudhry, S.M.; Saeed, A.; Ahmed, R. Carbon neutrality; The role of banks in optimal environmental management strategies. J. Environ. Manag. 2021, 299, 113545. [Google Scholar] [CrossRef] [PubMed]

- Hassan, T.H.; Shehata, H.S.; El-Dief, M.; Salem, A.E. The social responsibility of tourism and hotel establishments and their role in sustainable tourism development in Al-Ahsa, Saudi Arabia. Geoj. Tour. Geosites 2021, 33, 1564–1570. [Google Scholar] [CrossRef]

- Sarkar, A.; Qian, L.; Peau, A.K. Overview of green business practices within the Bangladeshi RMG industry: Competitiveness and sustainable development perspective. Environ. Sci. Pollut. Res. 2020, 27, 22888–22901. [Google Scholar] [CrossRef] [PubMed]

- Topleva, S.A.; Prokopov, T.V. Integrated business model for sustainability of small and medium-sized enterprises in the food industry: Creating value added through eco-design. Br. Food J. 2020, 122, 1463–1483. [Google Scholar] [CrossRef]

- Kallmuenzer, A.; Nikolakis, W.; Peters, M.; Zanon, J. Trade-offs between dimensions of sustainability: Exploratory evidence from family firms in rural tourism regions. J. Sustain. Tour. 2018, 26, 1204–1221. [Google Scholar] [CrossRef]

- Domínguez-Herrera, M.M.; González-Morales, O.; González-Díaz, E. Corporate social responsibility of the construction sector in Spain. In Corporate Social Responsibility (CSR): Practices, Issues and Global Perspectives; Willumstad School of Business, Adelphi University: Garden City, NY, USA, 2018; pp. 215–268. [Google Scholar]

- Ravochkin, N.; Shchennikov, V.; Syrov, V. Corporate Social and Ecological Responsibility of Russian Coal Mining Companies. E3S Web Conf. 2017, 21, 04017. [Google Scholar] [CrossRef] [Green Version]

- Kuzior, A.; Ober, J.; Karwot, J. Stakeholder Expectation of Corporate Social Responsibility Practices: A Case Study of PWiK Rybnik, Poland. Energies 2021, 14, 3337. [Google Scholar] [CrossRef]

- Postrzednik, S. Selective obtaining of the coke oven gas. In KARBO; No 4; Instytut Chemicznej Przeróbki Węgla: Zabrze, Poland, 2011. [Google Scholar]

- Meseguer-Sánchez, V.; Gálvez-Sánchez, F.J.; López-Martínez, G.; Molina-Moreno, V. Corporate Social Responsibility and Sustainability. A Bibliometric Analysis of Their Interrelations. Sustainability 2021, 13, 1636. [Google Scholar] [CrossRef]

- Babbie, E. The Practice of Social Research; Cengage Learning: Boston, MA, USA, 2020. [Google Scholar]

- Bartnikowska, U. Analiza Wtórna Jakościowych Danych Zastanych: Przegląd Założeń i Aplikacji Metodologicznych “Jakościowe Badania Pedagogiczne”; Wydawnictwo Naukowe Uniwersytetu Szczecińskiego: Szczecin, Poland, 2017. [Google Scholar]

- Bednarowska, Z. Desk Research—Wykorzystanie Potencjału Danych Zastanych w Prowadzeniu Badań Marketingowych i Społecznych “Marketing i Rynek”; Uniwersytet Jagielloński w Krakowie: Kraków, Poland, 2015. [Google Scholar]

- Krzyszkowski, J. Analiza Dotychczasowych Doświadczeń (Desk Research) w Obszarze Pracy Socjalnej i Polityki Społecznej “Stowarzyszenie c.a.l.”; Uniwersytet Łódzki: Łódź, Poland, 2013. [Google Scholar]

- Makowska, M. Analiza Danych Zastanych. Przewodnik dla Studentów; Wydawnictwo Naukowe Scholar: Warszawa, Poland, 2013. [Google Scholar]

- Frankfort-Nachmias, C.; Nachmias, D.; DeWaard, J. Research Methods in the Social Sciences; Worth Publishers: New York, NY, USA, 2015. [Google Scholar]

- Smith, E. Using Secondary Data in Educational and Social Research; McGraw-Hill Education: New York, NY, USA, 2008. [Google Scholar]

- Biostat: Analiza Danych Zastanych (Desk Research). Available online: https://www.biostat.com.pl/desk-research.php (accessed on 24 April 2021).

- Grebski, M. Mobility of the Workforce and Its Influence on Innovativeness (Comparative Analysis of the United States and Poland). Prod. Eng. Arch. 2021, 27, 272–276. [Google Scholar] [CrossRef]

- Ober, J.; Kochmańska, A. Adaptation of Innovations in the IT Industry in Poland: The Impact of Selected Internal Communication Factors. Sustainability 2022, 14, 140. [Google Scholar] [CrossRef]

- Dmitruki, J.; Gawinecki, J. Metody Wielowymiarowej Analizy Porównawczej—Budowa i Zastosowanie; Biuletyn WAT: Warszawa, Poland, 2017; Volume LXVI, No. 4. [Google Scholar]

- Rataj, M. Analiza porównawcza sposobu pomiaru jakości spalania gazu w palnikach odkrytych. Nafta-Gaz 2011, 67, 263–267. [Google Scholar]

- Kożuch, A.; Marzec, I. Studium przypadku jako strategia badawcza w naukach społecznych. J. Sci. Gen. Tadeusz Kosciuszko Mil. Acad. Land Forces 2014, 172, 32–44. [Google Scholar] [CrossRef]

- Mielcarek, P. Metoda case study w rozwoju teorii naukowych. In Organizacja i Kierowanie; SGH: Warszawa, Poland, 2014; p. 161. [Google Scholar]

- Luboińska, U. Emisja Gazów Cieplarnianych. Wybrane Zagadnienia Dotyczące Emisji CO2 w Polsce. Opracowania Tematyczne OT-683. Kancelaria Senatu, Biuro Analiz, Dokumentacji i Korespondencji, Warszawa. 2020; p. 3f. Available online: https://www.senat.gov.pl/gfx/senat/pl/senatopracowania/192/plik/ot-683.pdf (accessed on 24 April 2021).

- Encyklopedia, Ziemia na rozdrożu. Available online: https://ziemianarozdrozu.pl/encyklopedia (accessed on 24 April 2021).

- Kuzior, A.; Kwilinski, A.; Hroznyi, I. The Factorial-Reflexive Approach to Diagnosing the Executors’ and Contractors’ Attitude to Achieving the Objectives by Energy Supplying Companies. Energies 2021, 14, 2572. [Google Scholar] [CrossRef]

- Postrzednik, S. Feste Brennstoffe: Analyse des Entgasungsprozesses—Anwendung des Einflußfaktoren—Prozeßfunktionen—Algorithmus. Erdöl Kohle Erdgas Petrochem. Hydrocarb. Technol. 1991, 44, 207–212. [Google Scholar]

- Global Monitoring Laboratory. Earth System Research Laboratories. Available online: https://gml.noaa.gov/aggi/aggi.html (accessed on 15 December 2021).

- SEGRO—Polityka Różnorodności i Integracji. Available online: https://www.segro.com/~/media/Files/S/Segro/documents/2018/Diversity-policies/SEGRO%20Diversity%20and%20Inclusion%20Policy%20Polish%20Version%202018.pdf (accessed on 24 April 2021).

- Integrated Performance Dashboard [from Teleperformance Group]. Available online: https://teleperformance.cotecorp.com/wp-content/uploads/2021/03/02-Strategy_21.pdf (accessed on 24 April 2021).

- MARSH—Różnorodność i Integracja. Available online: https://www.marsh.com/pl/pl/about-us/diversity-inclusion.html (accessed on 24 April 2021).

- Postrzednik, S. Analysis of Factors Determining the Course of Solid Fuel Devolatilization and Energy Consumption. Coke Mak. Int. 1991, 3, 48. [Google Scholar]

- Kwilinski, A.; Kuzior, A. Cognitive Technologies in the Management and Formation of Directions of the Priority Development of Industrial Enterprises. Manag. Syst. Prod. Eng. 2020, 28, 133–138. [Google Scholar] [CrossRef]

- Postrzednik-Lotko, K. Instrumenty wspierające etyczne zarządzanie przedsiębiorstwem globalnym. In Globalne Konteksty Poszanowania Praw i Wolności Człowieka; Kuzior, A., Ed.; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2020; pp. 249–259. [Google Scholar]

- Rymarczyk, J. Internacjonalizacja i Globalizacja Przedsiębiorstwa; Polskie Wydawnictwo Ekonomiczne: Warszawa, Poland, 2004. [Google Scholar]

- Oncioiu, I.; Petrescu, A.-G.; Bîlcan, F.-R.; Petrescu, M.; Fülöp, M.T.; Topor, D.I. The Influence of Corporate Governance Systems on a Company’s Market Value. Sustainability 2020, 12, 3114. [Google Scholar] [CrossRef] [Green Version]

- Teleperformance Citizen of the Planet Report. Available online: https://www.youtube.com/watch?v=WDh0Uv-2xwg (accessed on 24 April 2021).

- Karcz, A. Gaz koksowniczy jako surowiec do produkcji wodoru. Polityka Energetyczna 2009, 12, 111. [Google Scholar]

- Types of Natural Gas. Available online: https://poprostuenergia.pl/blog/rodzaje-gazu-ziemnego/ (accessed on 24 April 2021).

- Łukaszczyk, Z.; Badura, H.; Dźwigoł, R. Analiza kształtowania się wydajności otworów drenażowych metanu ze ścian eksploatacyjnych węgla kamiennego jako źródła energii—Studium przypadku. Rynek Energii 2021, 1, 16–25. [Google Scholar]

- Chodyński, A. Odpowiedzialność Ekologiczna w Proaktywnym Rozwoju Przedsiębiorstw, Krakowskie Towarzystwo Edukacyjne sp. z o.o.; Oficyna Wydawnicza AFM: Kraków, Poland, 2011. [Google Scholar]

- Shoko, E.; McLellan, B.; Dicks, A.L.; Da Costa, J.C.D. Hydrogen from coal: Production and utilization technologies. Int. J. Coal Geol. 2006, 65, 213–222. [Google Scholar] [CrossRef]

- Certyfikacja LEED w Pigułce. Available online: https://www.ecosquad.pl/leed-certyfikacja-wielokryterialna-leed--w-pigu-ce.html (accessed on 24 April 2021).

- Tippmer, K. Möglichkeiten der Gewinnung von Wasserstoff aus Kokereigas und Anwendung bei der Kohleveredelung. In Vortragsveröffentlichungen Kokereitechnik; Verein Deutscher Kokereifachleute e. V.: Essen, Germany, 1993. [Google Scholar]

- Tramer, A.; Ściażko, M.; Karcz, A. Techniczne aspekty wykorzystania gazu koksowniczego do pozyskiwania wodoru. Przemysł Chem. 2005, 84, 815–819. [Google Scholar]

- Whysall, M.; PICIO, K.W. Selection and revamp of hydrogen purification processes. In AIChE Spring Meeting; American Institute of Chemical Engineers: Houston, TX, USA, 1999. [Google Scholar]

- Grzegorczyk, W. (Ed.) Wybrane Problemy Zarządzania i Finansów; Wydawnictwo Uniwersytetu Łódzkiego: Łódź, Poland, 2015. [Google Scholar]

- Głowacka, E. Metoda case study w badaniach i dydaktyce bibliotekoznawstwa i informacji naukowej. Przegląd Bibl. 1986, 54, 25–32. [Google Scholar]

- Griffin, R.W. Fundamentals of Management; Cengage Learning, Inc.: Boston, MA, USA, 2015. [Google Scholar]

- Rej, Ł.; Maga, J.; Brzegowy, A. System zarządzania środowiskowego. In Encyklopedia Zarządzania; UE: Kraków, Poland, 2021; Available online: https://mfiles.pl/pl/index.php/System_zarz%C4%85dzania_%C5%9Brodowiskowego (accessed on 24 April 2021).

- Case Study. Available online: https://mfiles.pl/pl/index.php/Case_study (accessed on 24 April 2021).

- Sobolewski, A.; Ściążko, M. Rynek koksu i węgla koksowego na świecie. In KARBO; Wydanie Specjalne: Instytut Chemicznej Przeróbki Węgla: Zabrze, Poland, 2009; p. 7. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).