Real-Time Grid Signal-Based Energy Flexibility of Heating Generation: A Methodology for Optimal Scheduling of Stratified Storage Tanks

Abstract

:1. Introduction

2. Fundamentals of Energy and Exergy Analysis

3. Methodology

3.1. Overview of the ADR Control Strategy

3.2. Step 1: Creation of the Initial Schedule for ADR Operation

3.3. Step 2: Operation and Checking

- Condition (1): The TES should be charged with nominal power () according to the schedule, and the feedback loop reveals that there is not enough energy/exergy ( ≤ stored in TES for flexible operation, thereby causing the heat generator to run on nominal power (Mode 1); however, if enough energy/exergy can be provided, the operation mode corresponds to Condition (3).

- Condition (2): If no initial charging is suggested based on the charging schedule () and there is indeed enough energy/exergy stored ( ≥ , then the heat generator is shut down ; operation proceeds according to Condition (3).

- Condition (3): In order to exploit the ADR potential as much as possible, the operation mode is determined by a grid-supportive signal. If the grid signal is G(t) = I, then the flexibility potential is fully utilized, and the generator charges the TES at nominal power , while, for grid signal G(t) = II, the generator runs in the demand-based operation mode , and, for signal G(t) = III, a shutdown is performed .

4. Case Study

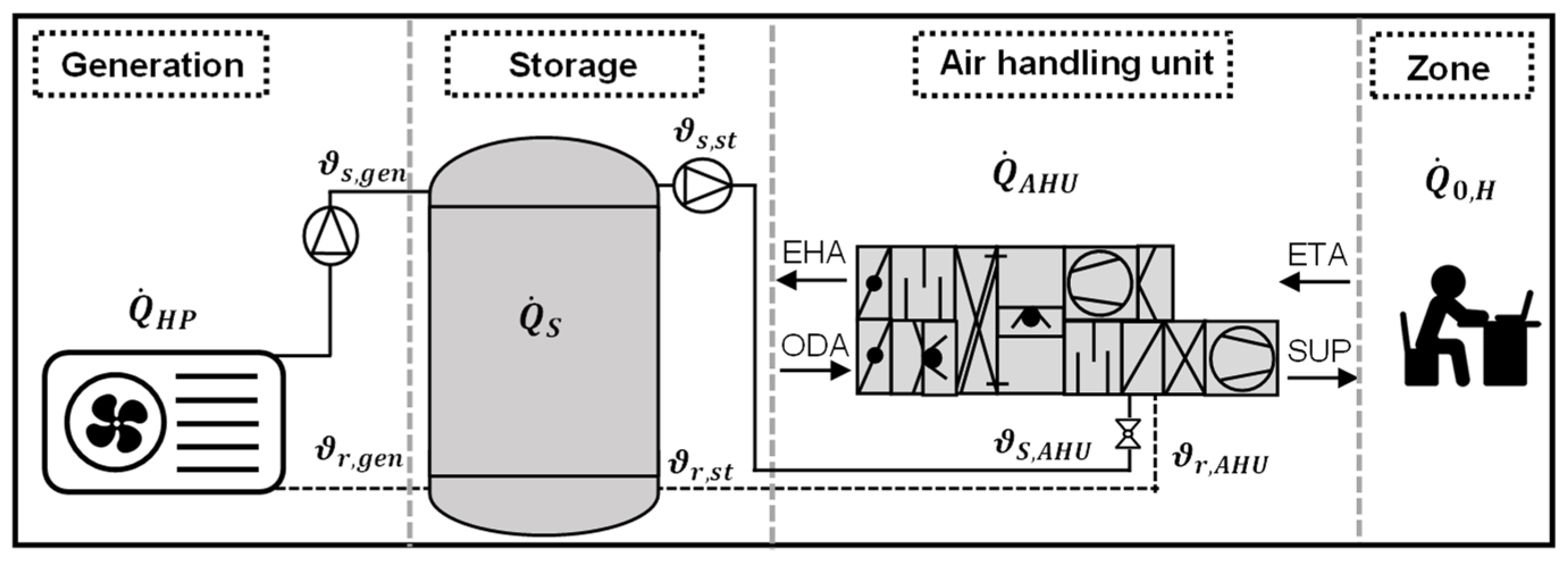

4.1. System Overview

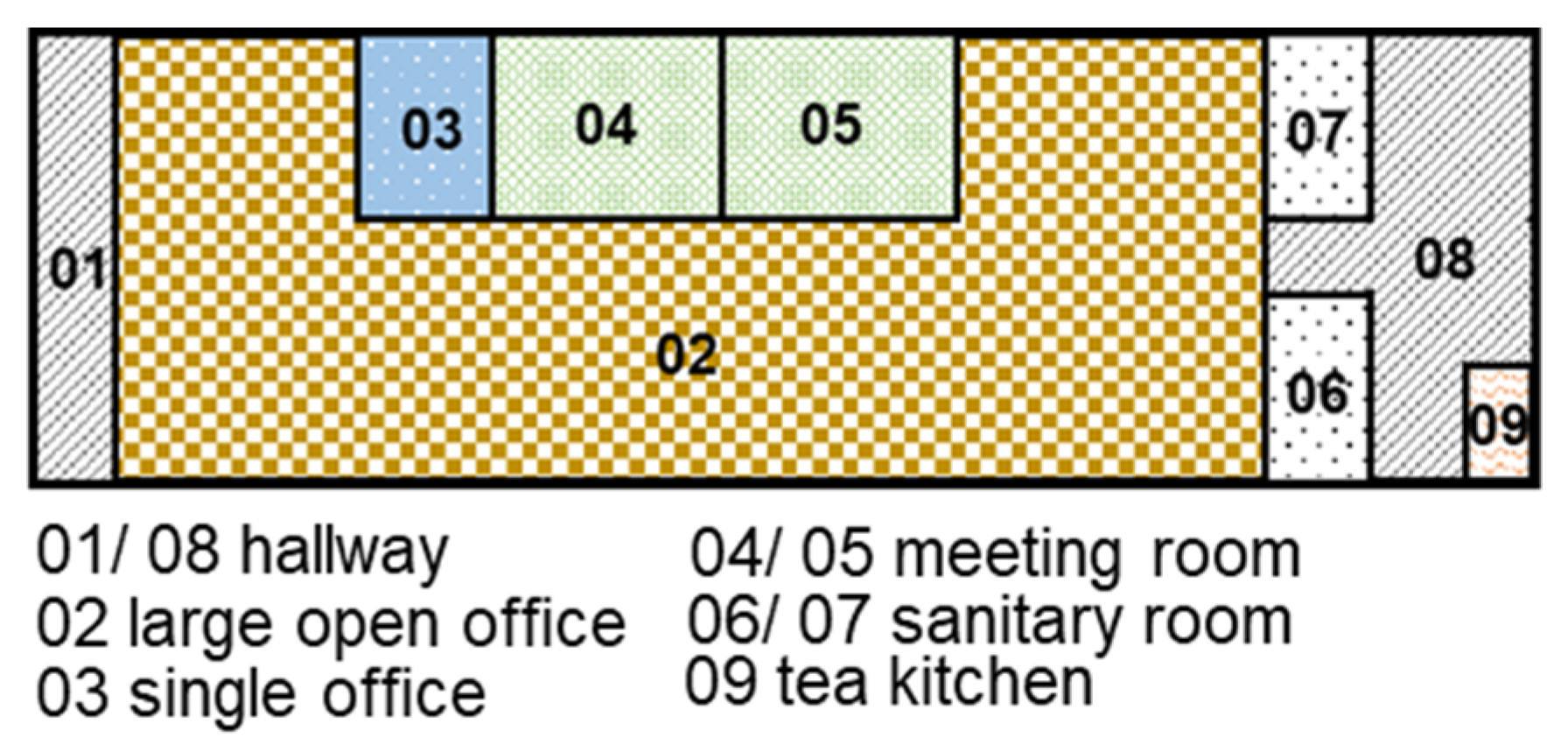

4.2. Building Model

4.3. Air Handling Unit Model

4.4. Heat Pump Model

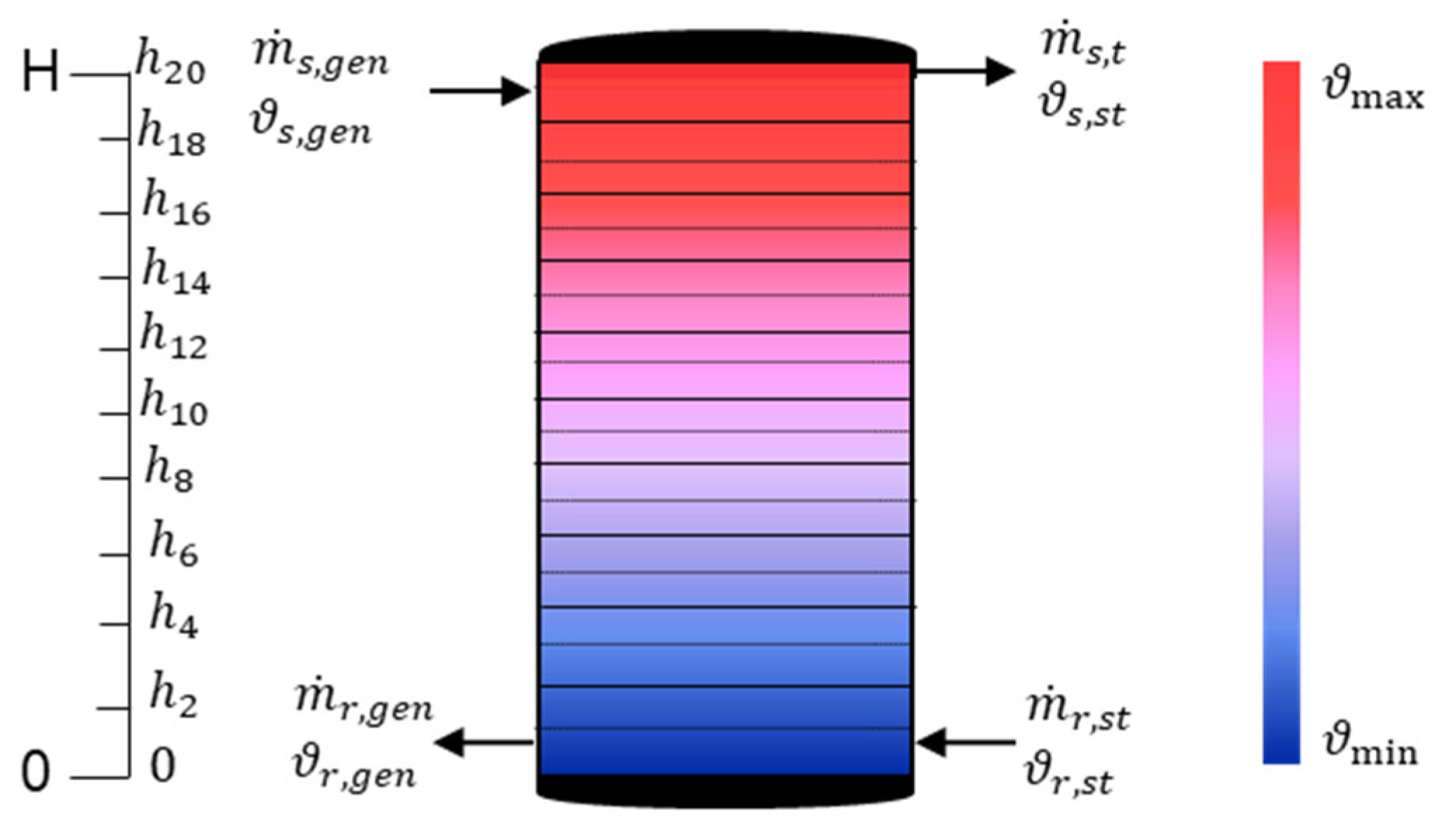

4.5. Storage Tank and Hydraulic System Model

4.6. Pre-Processing of Model Inputs

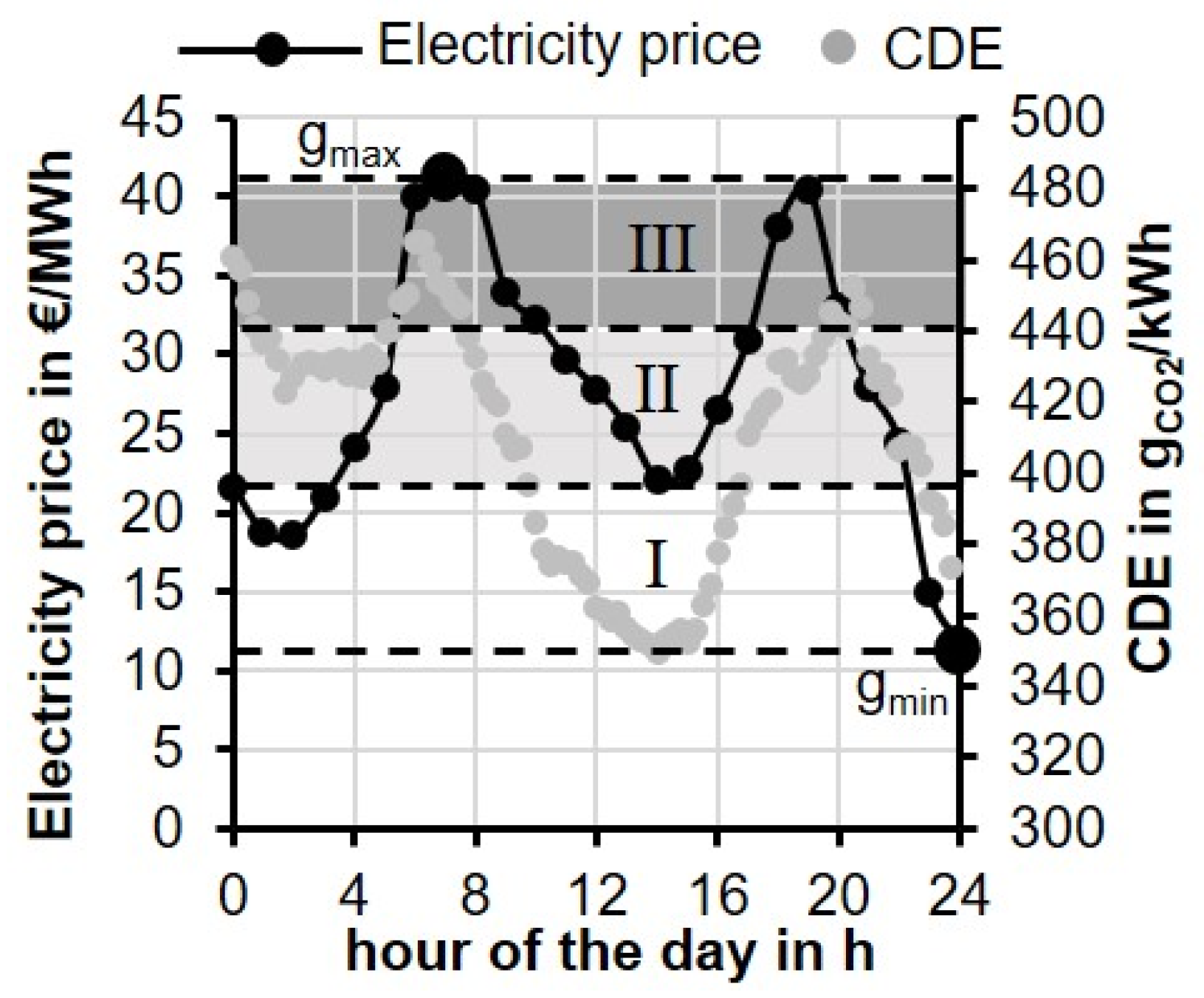

4.6.1. Grid-Supportive Signal

4.6.2. Load Prediction Model

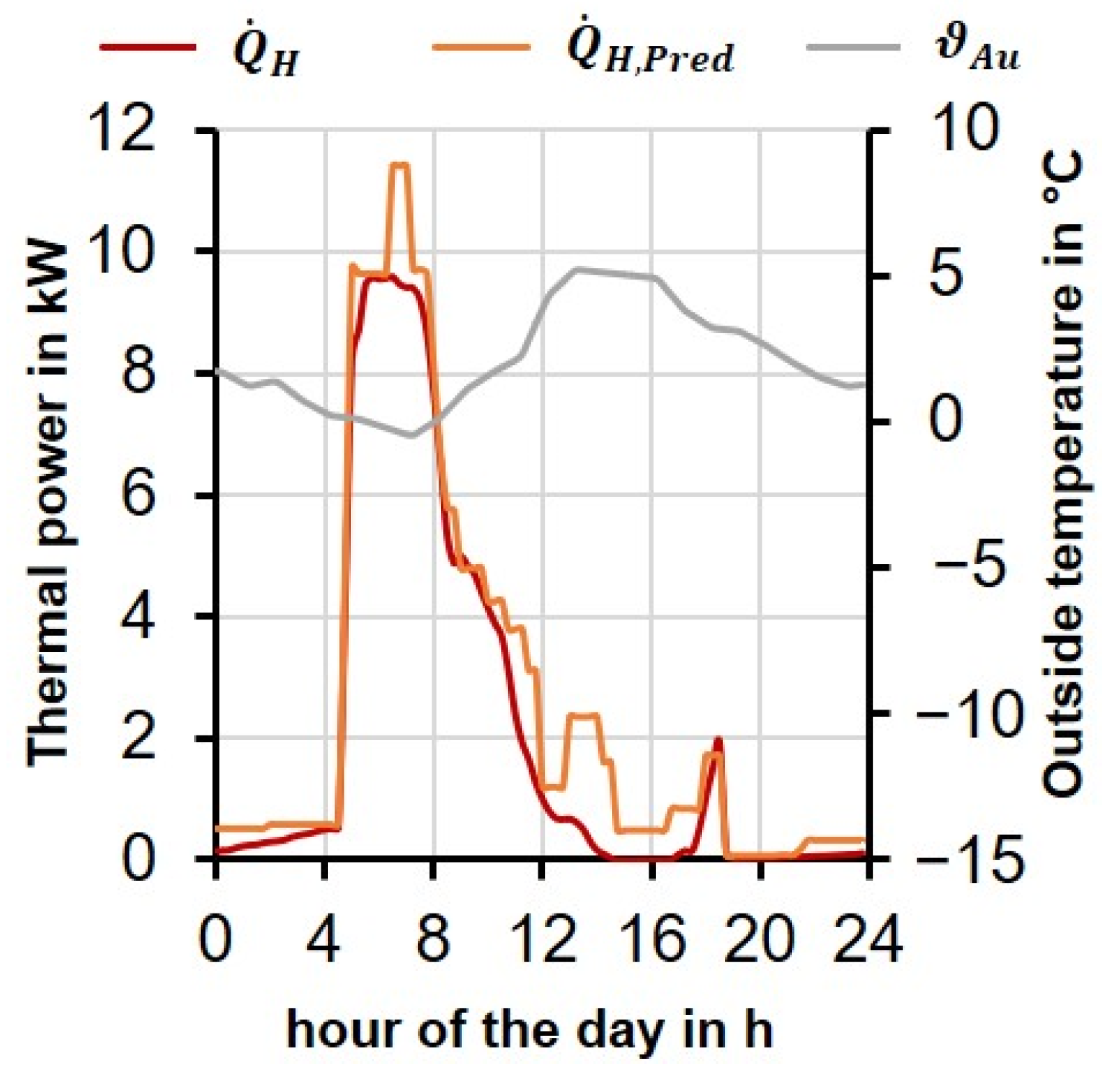

4.6.3. Signal for the Heating Requirement

4.7. MPC Implementation

5. Results and Evaluation of the Control Strategy

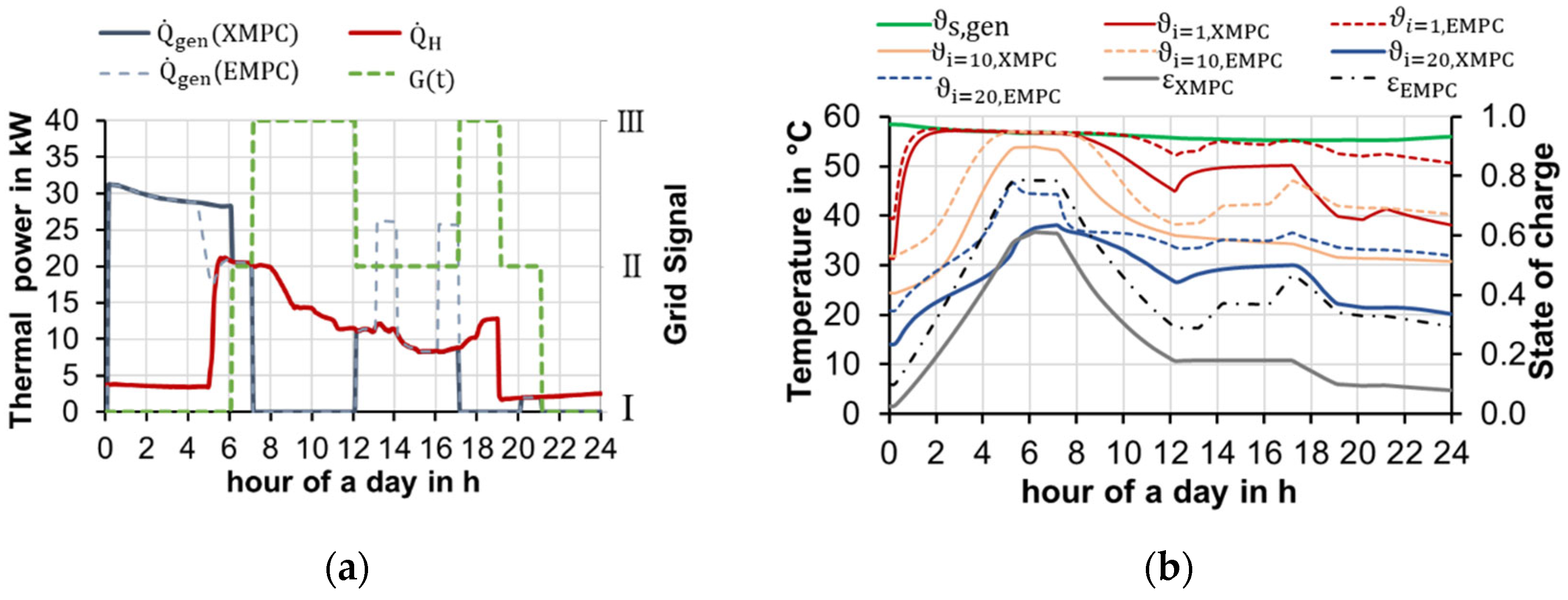

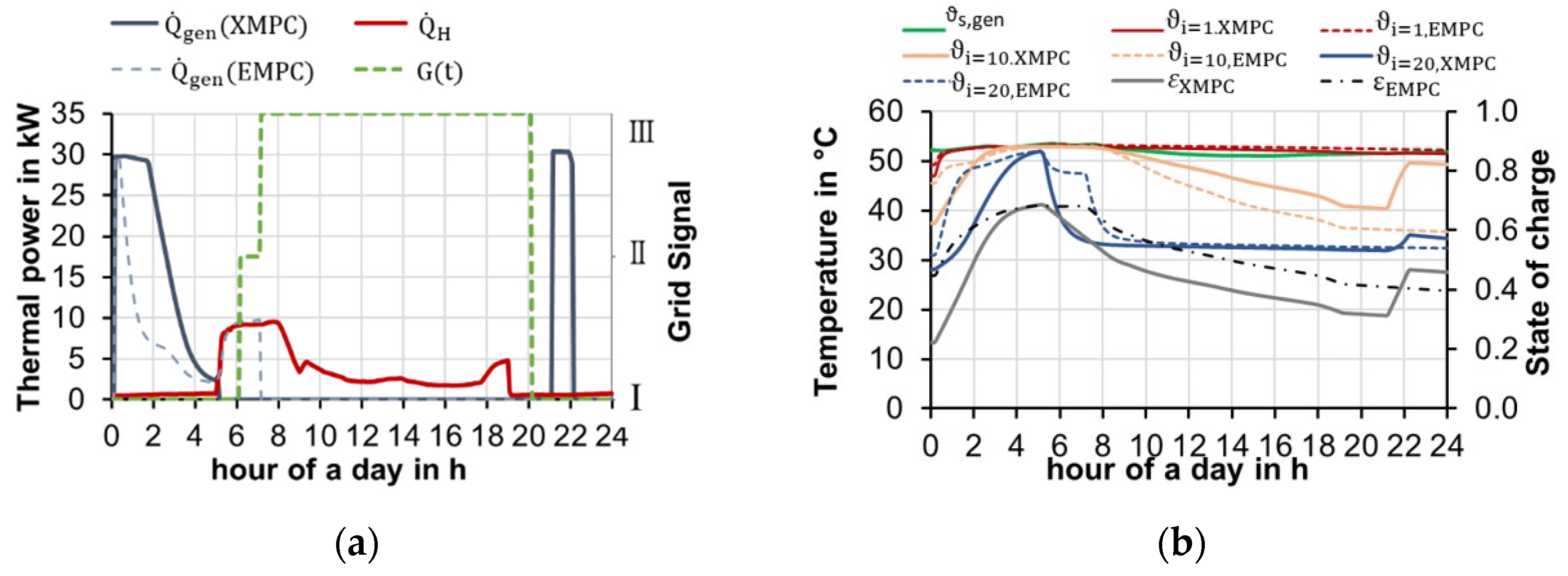

5.1. Analysis on Characteristic Days

5.2. Analysis of Annual Simulation

5.2.1. Dynamic Exergy and Energy Analysis

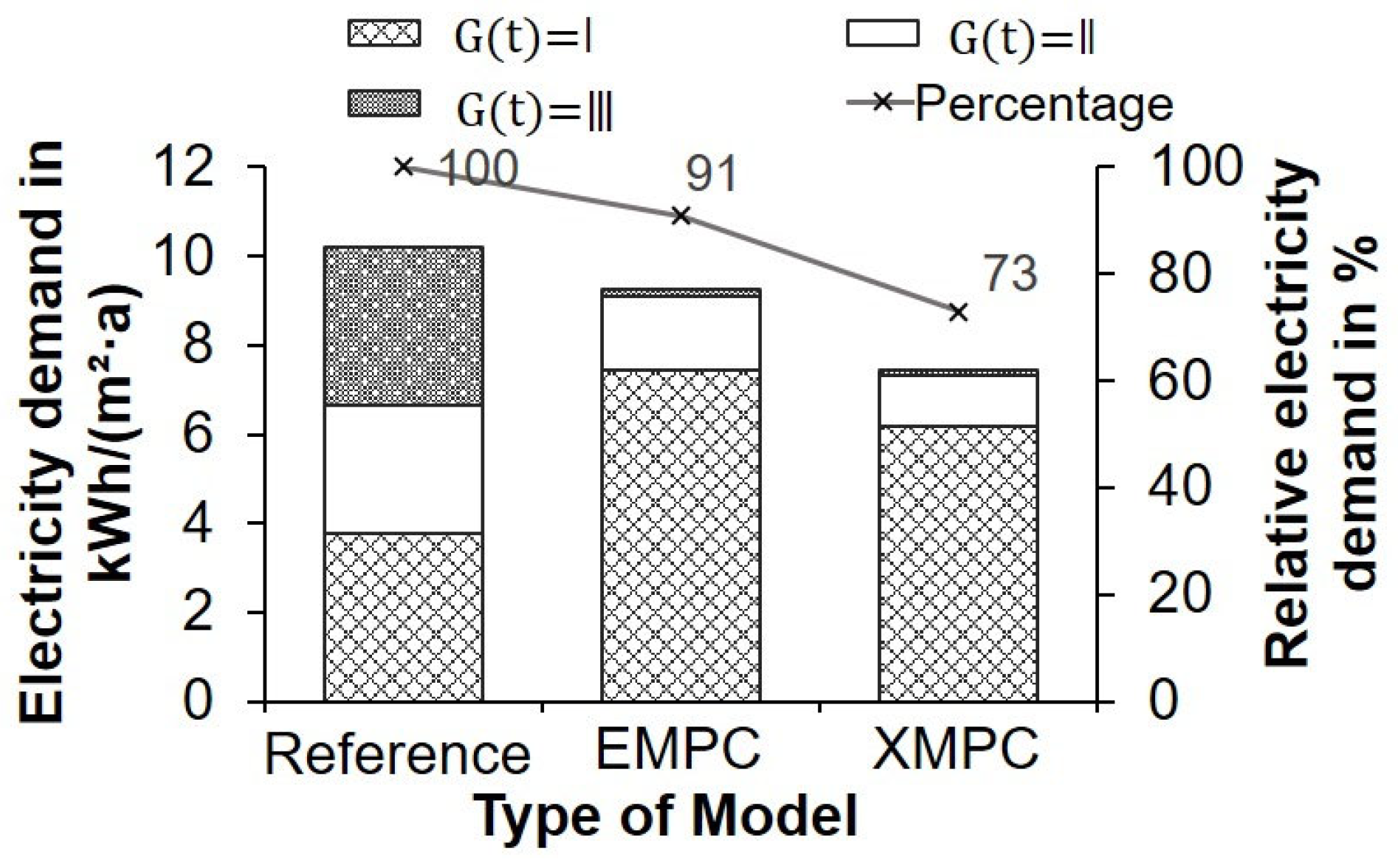

5.2.2. Load Shifting Potential and Electricity Utilization

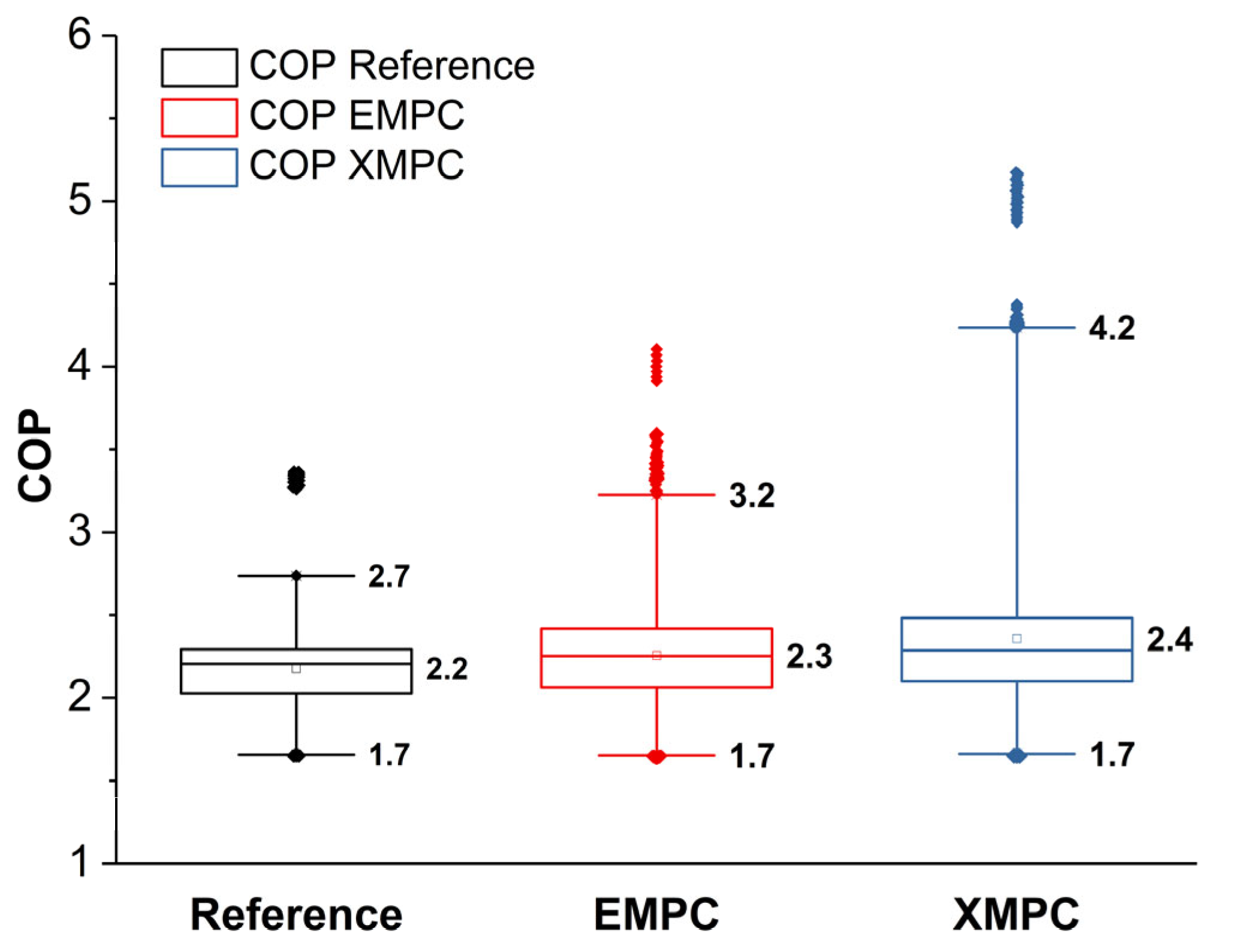

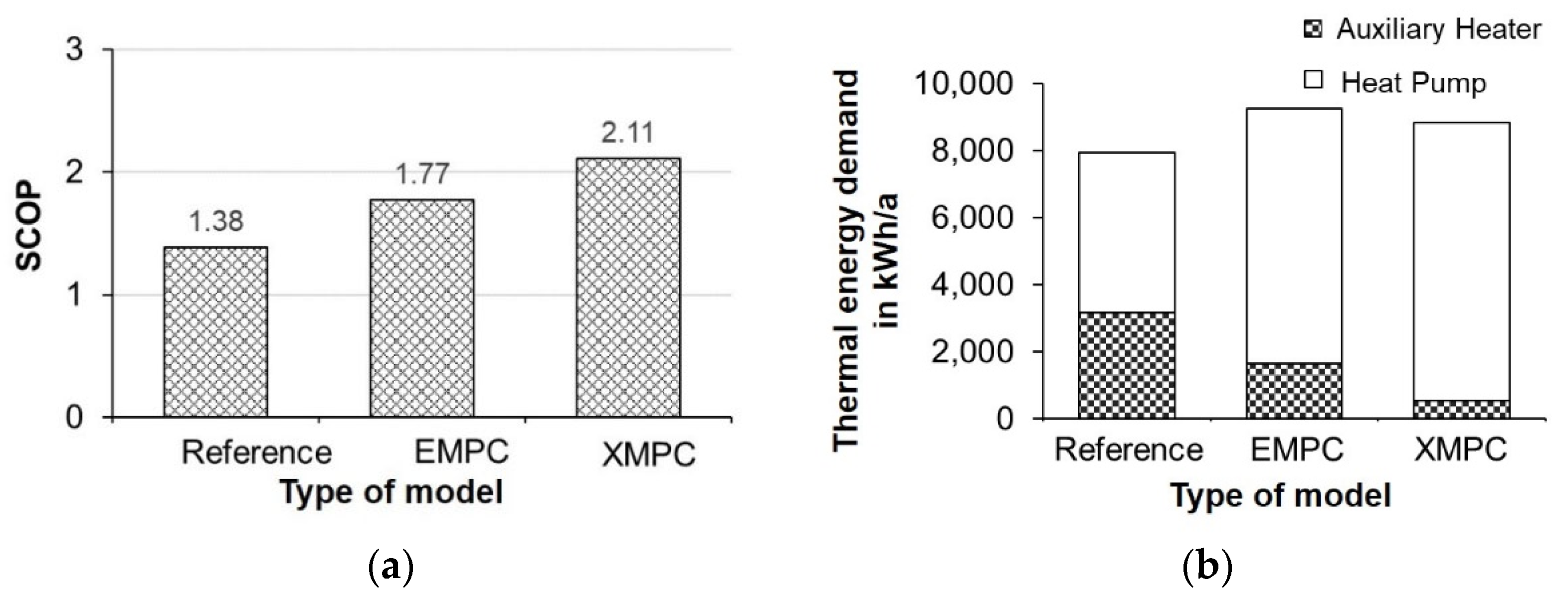

5.2.3. Efficiency of the Heating Generator

5.2.4. Operating Costs and Carbon-Dioxide Emissions

5.3. Stability and Sensitivity Analysis

5.3.1. Influence of the Grid-Supportive Signal

5.3.2. Influence of the Tank Size

5.3.3. Influence of Dimension and Type of Heat Pumps

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ai | The surface area of the TES of the layer i (m2) |

| Heat capacity of the water (J/(kg∙K)) | |

| Day-ahead costs for electricity from the grid (EUR /kWh) | |

| Heat capacity of the layer i of the TES (W/K) | |

| CDE | Carbon dioxide emissions (kgCO2) |

| Carbon dioxide emission factor for electricity generation (kgCO2/kWh) | |

| COP | Coefficient of performance (-) |

| COP of Carnot cycle (-) | |

| Full-load efficiency (-) | |

| DOF | Defrost factor (-) |

| E(S) | Information entropy (-) |

| Energy demand forecast of the HVAC for each day (Wh) | |

| Energy demand forecast of the HVAC system for rest of the day (Wh) | |

| Energy supplied to the TES (Wh) | |

| Energy loss of the TES (Wh) | |

| Energy recovered from the TES and utilized by the HVAC system (Wh) | |

| Energy storage capacity of the TES (Wh) | |

| Energy stored in the TES at time t (Wh) | |

| g(t) | Continuous grid supportive signal (-) |

| Lowest discrete grid signal within a day (-) | |

| Discrete grid supportive signal, discrete grid signal (-) | |

| Discrete grid supportive signal based on carbon dioxide emission factor (-) | |

| Discrete grid supportive signal based on electricity price (-) | |

| H | Total height of the TES (m) |

| Ht | Heating requirement signal (-) |

| Total mass of the water in the TES (kg) | |

| Design mass flow rate of the hydraulic system (kg/s) | |

| Water mass flow rate of the loop between heat generator and TES (kg/s) | |

| Design mass flow rate of the heat generator (kg/s) | |

| Water mass flow rate of the loop between TES and HVAC system (kg/s) | |

| Number of modeled layers in the TES (-) | |

| OC | Operating costs (EUR) |

| Probability of each data group (-) | |

| Electrical power of the building energy system (W) | |

| Electricity power of the heat generator (kW) | |

| Electricity power of the hydraulic system (kW) | |

| Electricity power of the heat pump (kW) | |

| Electrical power of the circulation pump (W) | |

| PDH | Percentage of dissatisfied hour (%) |

| PLF | Partial load factor (-) |

| Heating energy demand (kWh) | |

| Heating energy demand of the heat pump (kWh) | |

| Heating energy demand of the auxiliary electrical heating (kWh) | |

| Thermal power of the heat generator (kW) | |

| Heat flux due to heat conduction of the adjacent layer i (W) | |

| Heating power of the HVAC system (kW) | |

| Predicted heating power (kW) | |

| Thermal power of the auxiliary electrical heating (kW) | |

| Thermal power of the heat pump (kW) | |

| Heat flux supplied to the layer i in the TES (W) | |

| Heat flux due to mixing caused by the flow momentum of the layer i (W) | |

| Heat flux recovered from the layer i in the TES (W) | |

| Heat flux due to losses of the layer i from the TES to the ambient (W) | |

| Nominal heating power of the building (kW) | |

| SCOP | Seasonal coefficient of performance (-) |

| SF | Safety factor (-) |

| U | Heat transfer coefficient to the ambient of the TES (W/(m2∙K)) |

| Volume flow rate of the hydraulic pump (kg/s) | |

| Volume of the TES (m3) | |

| Electricity energy demand of the heat pump (Wh) | |

| Electricity energy demand of the heat generator (Wh) | |

| Electricity energy demand of the building energy system (Wh) | |

| Initial charging schedule (-) | |

| Greek symbols | |

| Heat pump coefficient (-) | |

| Heat pump coefficient (-) | |

| Overall energy efficiency (%) | |

| Efficiency of the circulation pump (-) | |

| Efficiency of the auxiliary electrical heating (-) | |

| Density of the water (kg/m3) | |

| Time interval (h) | |

| Overall exergy efficiency (%) | |

| The temperature of the hot heat reservoir of a Carnot machine (K) | |

| Outside ambient temperature () | |

| The temperature of the of the cold heat reservoir a Carnot machine (K) | |

| Water temperature of the layer i in the TES () | |

| Return water temperature of the HVAC system () | |

| Return water temperature to the heat generator () | |

| Return water temperature to the storage () | |

| Supply water temperature of the HVAC system () | |

| Supply water temperature of the heat generator () | |

| Supply water temperature of the storage () | |

| Ambient temperature of the TES (K) | |

| Pressure losses in the hydraulic system (Pa) | |

| Change of stored energy quantity in the TES during an observed period (Wh) | |

| Change of exergy quantity in the TES during an observed period (Wh) | |

| Range of the continuous grid supportive signal within a day (-) | |

| Temperature spread of the HVAC system under nominal conditions (K) | |

| Energy/exergy-based transient state of charge of the TES | |

| Exergy destruction due to irreversibility (Wh) | |

| Exergy demand forecast of the HVAC system for each day (Wh) | |

| Exergy demand forecast of the HVAC system for rest of the day (Wh) | |

| Exergy supplied to the TES (Wh) | |

| Exergy loss of the TES (Wh) | |

| Exergy recovered from the TES and utilized by the HVAC system (Wh) | |

| Exergy storage capacity of the TES (Wh) | |

| Exergy stored in the TES at time t (Wh) | |

| Exergy thermal power of the heat generator (W) | |

| Exergy thermal power forecast of the HVAC system (W) | |

| Acronyms | |

| ADR | Active Demand Response |

| AHU | Air Handling Unit |

| BES | Building Energy System |

| EMPC | Energy-based Model Predictive Control |

| HiL | Hardware-in-the-Loop |

| HVAC | Heating Ventilation and Air-Conditioning |

| ID3 | Iterative Dichotomiser 3 |

| KPI | Key Performance Indicator |

| Micro-CSP | Micro-scale Concentrated Solar Power |

| MILP | Mixed-Integer Linear Programming |

| MPC | Model Predictive Control |

| STES | Seasonal Thermal Energy Storage |

| TES | Thermal Energy Storage |

| XMPC | Exergy-based Model Predictive Control |

Appendix A

| Air temperature | −7 °C | 2 °C | 7 °C |

| Supply temperature | 35 °C | ||

| Relative thermal power | 0.69 | 0.85 | 1.0 |

| COP | 2.8 | 3.2 | 3.8 |

| Supply temperature | 45 °C | ||

| Relative thermal power | 0.66 | 0.82 | 0.97 |

| COP | 2.3 | 2.7 | 3.2 |

| Supply temperature | 55 °C | ||

| Relative thermal power | 0.64 | 0.80 | 0.95 |

| COP | 1.9 | 2.1 | 2.6 |

| Air temperature | −7 °C | 2 °C | 7 °C |

| Supply temperature | 35 °C | ||

| Maximal thermal power in kW | 26.07 | 34.28 | 38.84 |

| 2.8 | 3.2 | 3.8 | |

| Thermal power of test points in kW | 23.46 | 28.90 | 34.00 |

| 2.8 | 3.2 | 3.8 | |

| Minimal thermal power in kW | 5.21 | 6.86 | 7.77 |

| 2.6 | 3.0 | 3.6 | |

| Supply temperature | 45 °C | ||

| Maximal thermal power in kW | 24.93 | 32.79 | 37.15 |

| 2.3 | 2.7 | 3.2 | |

| Thermal power of test points in kW | 22.44 | 27.88 | 32.98 |

| 2.3 | 2.7 | 3.2 | |

| Minimal thermal power in kW | 4.99 | 6.56 | 7.43 |

| 2.1 | 2.5 | 3.0 | |

| Supply temperature | 55 °C | ||

| Maximal thermal power in kW | 24.18 | 31.79 | 36.02 |

| 1.9 | 2.1 | 2.6 | |

| Thermal power of test points in kW | 21.76 | 27.20 | 32.30 |

| 1.9 | 2.1 | 2.6 | |

| Minimal thermal power in kW | 4.84 | 6.36 | 7.20 |

| 1.7 | 1.9 | 2.4 | |

| Energy Source | CDE in kg/kWh |

|---|---|

| Brown coal | 1.118 |

| Hard coal | 0.821 |

| Natural gas | 0.367 |

| Other conventional fuels (oil) | 1.0 |

Appendix B

Appendix C

References

- Sawin, J.L.; Sverrisson, F.; Rutovitz, J.; Dwyer, S.; Teske, S.; Murdock, H.E.; Adib, R.; Guerra, F.; Blanning, L.H.; Hamirwasia, V.; et al. Renewables 2018—Global Status Report: A Comprehensive Annual Overview of The State of Renewable Energy; REN21: Paris, France, 2018; ISBN 978-3-9818911-3-3. [Google Scholar]

- European Commission. Stepping up Europe’s 2030 Climate Ambition Investing in a Climate-Neutral Future for the Benefit of Our People; European Commission: Brussel, Belgium, 17 September 2020; Available online: https://knowledge4policy.ec.europa.eu/publication/communication-com2020562-stepping-europe%E2%80%99s-2030-climate-ambition-investing-climate_en#:~:text=17%20September%202020-,Communication%20COM%2F2020%2F562%3A%20Stepping%20up%20Europe’s%202030%20climate,the%20benefit%20of%20our%20people&text=With%20the%202030%20Climate%20Target,below%201990%20levels%20by%202030 (accessed on 24 January 2022).

- Gellings, C.W.; Smith, W.M. Integrating demand-side management into utility planning. Proc. IEEE 1989, 77, 908–918. [Google Scholar] [CrossRef]

- Ulbig, A.; Andersson, G. On operational flexibility in power systems. In Proceedings of the IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012. [Google Scholar]

- Stinner, S.; Huchtemann, K.; Müller, D. Quantifying the operational flexibility of building energy systems with thermal energy storages. Appl. Eng. 2016, 181, 140–154. [Google Scholar] [CrossRef]

- Reynders, G.; Diriken, J.; Saelens, D. Generic characterization method for energy flexibility: Applied to structural thermal storage in residential buildings. Appl. Eng. 2017, 198, 192–202. [Google Scholar] [CrossRef] [Green Version]

- Hurtado, L.A.; Rhodes, J.D.; Nguyen, P.H.; Kamphuis, I.G.; Webber, M.E. Quantifying demand flexibility based on structural thermal storage and comfort management of non-residential buildings: A comparison between hot and cold climate zones. Appl. Eng. 2017, 195, 1047–1054. [Google Scholar] [CrossRef]

- Lund, P.D.; Lindgren, J.; Mikkola, J.; Salpakari, J. Review of energy system flexibility measures to enable high levels of variable renewable electricity. Renew. Sustain. Energy Rev. 2015, 45, 785–807. [Google Scholar] [CrossRef] [Green Version]

- Dickinson, R.M.; Cruickshank, C.A.; Harrison, S.J. Charge and discharge strategies for a multi-tank thermal energy storage. Appl. Eng. 2013, 109, 366–373. [Google Scholar] [CrossRef]

- Klein, K.; Herkel, S.; Henning, H.-M.; Felsmann, C. Load shifting using the heating and cooling system of an office building: Quantitative potential evaluation for different flexibility and storage options. Appl. Eng. 2017, 203, 917–937. [Google Scholar] [CrossRef]

- Han, Y.M.; Wang, R.Z.; Dai, Y.J.; Deng, J. Analysis on energy storage of new thermally stratified solar water tank. J. Chem. Ind. 2006, 57, 156–160. [Google Scholar]

- Han, Y.M.; Wang, R.Z.; Dai, Y.J. Thermal stratification within the water tank. Renew. Sustain. Energy Rev. 2009, 13, 1014–1026. [Google Scholar] [CrossRef]

- Rosen, M.A.; Tang, R.T.; Dincer, I. Effect of stratification on energy and exergy capacities in thermal storage systems. Int. J. Eng. Res. 2003, 28, 177–193. [Google Scholar] [CrossRef]

- Haller, M.Y.; Cruickshank, C.A.; Streicher, W.; Harrison, S.J.; Andersen, E.; Furbo, S. Methods to determine stratification efficiency of thermal energy storage processes—Review and theoretical comparison. Solar Eng. 2009, 83, 1847–1860. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Du, R.; Wang, Y.; Tu, J. A new design concept of thermal storage tank for adaptive heat charging in solar heating system. Appl. Therm. Eng. 2019, 165, 114617. [Google Scholar] [CrossRef]

- Rosen, M.A.; Pedinelli, N.; Dincer, I. Energy and exergy analyses of cold thermal storage systems. Int. J. Eng. Res. 1999, 23, 1029–1038. [Google Scholar] [CrossRef]

- Campos, C.A.; Odriozola, M.; Sala, J.M. Implications of the modelling of stratified hot water storage tanks in the simulation of CHP plants. Eng. Convers. Manag. 2011, 52, 3018–3026. [Google Scholar] [CrossRef]

- Rezaie, B.; Reddy, B.V.; Rosen, M.A. Exergy analysis of thermal energy storage in a district energy application. Renew. Eng. 2015, 74, 848–854. [Google Scholar] [CrossRef]

- Rosen, M.A.; Hooper, F.C. Evaluating the energy and exergy contents of stratified thermal energy storages for selected storage-fluid temperature distributions. In Proceedings of the International Solar Energy Society World Congress, Denver, CO, USA, 19–23 August 1991. [Google Scholar]

- Rosengarten, G.; Morrisom, G.; Behnia, M. A second law approach to characterising thermally stratified hot water storage with application to solar water heaters. Trans. ASME 1999, 121, 194–200. [Google Scholar] [CrossRef]

- Rosen, M.A. The exergy of stratified thermal energy storages. Sol. Eng. 2001, 71, 173–185. [Google Scholar] [CrossRef]

- Fischer, D.; Madani, H. On heat pumps in smart grids: A review. Renew. Sustain. Energy Rev. 2017, 70, 342–357. [Google Scholar] [CrossRef] [Green Version]

- Afram, A.; Janabi-Sharifi, F. Theory and Applications of HVAC Control Systems—A Review of Model Predictive Control (MPC). In Building and Environment; Elsvier: Amsterdam, The Netherlands, 2014; pp. 343–355. [Google Scholar]

- Le, K.X.; Huang, M.J.; Wilson, C.; Shah, N.N.; Hewitt, N.J. Tariff-based load shifting for domestic cascade heat pump with enhanced system energy efficiency and reduced wind power curtailment. Appl. Eng. 2020, 257, 113976. [Google Scholar] [CrossRef]

- Baeten, B.; Rogiers, F.; Helsen, L. Reduction of heat pump induced peak electricity use and required generation capacity through thermal energy storage and demand response. Appl. Eng. 2017, 195, 184–195. [Google Scholar] [CrossRef]

- Schütz, T.; Streblow, R.; Müller, D. A comparison of thermal energy storage models for building energy system optimization. Eng. Build. 2015, 93, 23–31. [Google Scholar] [CrossRef]

- Renaldi, R.; Kiprakis, A.; Friedrich, D. An optimisation framework for thermal energy storage integration in a residential heat pump heating system. Appl. Eng. 2017, 186, 520–529. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Borrelli, F.; Hencey, B.; Coffey, B.; Bengea, S.; Haves, P. Model predictive control for the operation of building cooling systems. IEEE Trans. Contr. Syst. Technol. 2012, 20, 796–803. [Google Scholar] [CrossRef] [Green Version]

- Fischer, D.; Toral, T.R.; Lindberg, K.B.; Wille-Haussmann, B.; Madani, H. Investigation of thermal storage operation strategies with heat pumps in German multi family houses. Eng. Proced. 2014, 58, 137–144. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, Y.; Yan, C.; Wang, S. MPC-based optimal scheduling of grid-connected low energy buildings with thermal energy storages. Eng. Build. 2015, 86, 415–426. [Google Scholar] [CrossRef]

- Reddy, C.R.; Shahbakhti, M.; Robinett, R.D.; Razmara, M. Exergy-wise predictive control framework for optimal performance of MicroCSP systems for HVAC applications in buildings. Eng. Convers. Manag. 2020, 210, 112711. [Google Scholar] [CrossRef]

- Jonin, M.; Khosravi, M.; Eichler, A.; Villasmil, W.; Schuetz, P.; Jones, C.N.; Smith, R.S. Exergy-based model predictive control for design and control of a seasonal thermal energy storage system. J. Phys. Conf. Ser. 2019, 1343, 12066. [Google Scholar] [CrossRef]

- Baranski, M.; Fütterer, J.; Müller, D. Distributed exergy-based simulation-assisted control of HVAC supply chains. Eng. Build. 2018, 175, 131–140. [Google Scholar] [CrossRef]

- Sayadi, S.; Tsatsaronis, G.; Morosuk, T.; Baranski, M.; Sangi, R.; Müller, D. Exergy-based control strategies for the efficient operation of building energy systems. J. Clean. Prod. 2019, 241, 118277. [Google Scholar] [CrossRef]

- Razmara, M.; Maasoumy, M.; Shahbakhti, M.; Robinett, R.D. Exergy-based model predictive control for building HVAC systems. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015; pp. 1677–1682, ISBN 978-1-4799-8684-2. [Google Scholar]

- Dincer, I.; Rosen, M.A. Exergy: Energy, Environment and Sustainable Development, 2nd ed.; Elsevier: Oxford, UK, 2007; ISBN 978-0-08-097089-9. [Google Scholar]

- Atikol, U. A simple peak shifting DSM (demand-side management) strategy for residential water heaters. Energy 2013, 62, 435–440. [Google Scholar] [CrossRef]

- Perrot, P. A to Z of Thermodynamics, Reprinted; Oxford University Press: Oxford, UK, 1998; ISBN 0198565526. [Google Scholar]

- Transsolar Energietechnik GmbH; CSTB—Centre Scientifique et Technique du Bâtiment; TESS—Thermal Energy Systems Specialists. TRNSYS 18: Mathematical Reference; Solar Energy Laboratory, Univ. of Wisconsin-Madison: Madison, WI, USA, 2020; Volume 4. [Google Scholar]

- Verordnung über Energiesparenden Wärmeschutz und Energiesparende Anlagentechnik bei Gebäuden; EnEV: Berlin, Germany, 2015.

- Deutsches Institut für Normung e.V. DIN EN 16798-1:2015-07; Entwurf: Gesamtenergieeffizienz von Gebäuden—Teil 1: Eingangsparameter für das Innenraumklima zur Auslegung und Bewertung der Energieeffizienz von Gebäuden bezüglich Raumluftqualität, Temperatur, Licht und Akustik; Beuth Verlag GmbH: Berlin, Germany, 2015. [Google Scholar]

- Deutsches Institut für Normung e.V. DIN EN 12831-1:2017-09; Energetische Bewertung von Gebäuden—Verfahren zur Berechnung der Norm-Heizlast—Teil 1: Raumheizlast, Modul M3-3; Deutsche Fassung; Beuth Verlag GmbH: Berlin, Germany, 2017. [Google Scholar]

- Bettanini, E.; Gastaldello, A.; Schibuola, L. Simplified models to simulate part load performances of air conditioning equipments. In Proceedings of the 8th International IBPSA Conference, Eindhoven, The Netherlands, 11–14 August 2003. [Google Scholar]

- Deutsches Institut für Normung e.V. DIN V 18599-5; Energetische Bewertung von Gebäuden—Berechnung des Nutz-, End-und Primärenergiebedarfs für Heizung, Kühlung, Lüftung, Trinkwarmwasser und Beleuchtung—Teil 5: Endenergiebedarf von Heizsystemen; Beuth Verlag GmbH: Berlin, Germany, 2018. [Google Scholar]

- Bundesnetzagentur. Marktdaten für Jahr 2017. Available online: https://www.smard.de/home/downloadcenter/download-marktdaten#!?downloadAttributes=%7B%22selectedCategory%22:1,%22from%22:1483225200000,%22to%22:1514761199999,%22selectedFileType%22:%22XLS%22%7D (accessed on 11 February 2020).

- Entsoe, T.P. Generation Forecast-Day Ahead. Available online: https://transparency.entsoe.eu/generation/r2/dayAheadAggregatedGeneration/show (accessed on 26 February 2021).

- Schulz, M.; Hufendiek, K. Discussing the Actual Impact of Optimizing Cost and GHG Emission Minimal Charging of Electric Vehicles in Distributed Energy Systems. Energies 2021, 14, 786. [Google Scholar] [CrossRef]

- Khosravani, H.; Castilla, M.; Berenguel, M.; Ruano, A.; Ferreira, P. A Comparison of Energy Consumption Prediction Models Based on Neural Networks of a Bioclimatic Building. Energies 2016, 9, 57. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Zhang, X.; Shi, Y.; Xia, L.; Pan, S.; Wu, J.; Han, M.; Zhao, X. A review of data-driven approaches for prediction and classification of building energy consumption. Renew. Sustain. Energy Rev. 2018, 82, 1027–1047. [Google Scholar] [CrossRef]

- Breiman, L. Classification and Regression Trees, Repr; Chapman & Hall: Boca Raton, FL, USA, 1998; ISBN 0412048418. [Google Scholar]

- Quinlan, J.R. Induction of Decision Trees; Kluwer Academic Publishers: Boston, MA, USA, 1986. [Google Scholar]

- Rasmussen, C.; Williams, W. Gaussian Processes for Machine Learning; The MIT Press: Cambridge, MA, USA, 2006; ISBN 026218253X. [Google Scholar]

- Testreferenzjahre von Deutschland für Mittlere, Extreme und Zukünftige Witterungsverhältnisse; Bundesamt für Bauwesen und Raumordnung (BBR); Climate & Environment Consulting Potsdam GmbH und Deutscher Wetterdienst (Eds.) Climate & Environment Consulting Potsdam GmbH und Deutscher Wetterdienst: Offenbach, Germany, 2014. [Google Scholar]

- Deutscher Wetterdienst. Climate Data Center. Available online: https://opendata.dwd.de/climate_environment/CDC/ (accessed on 4 January 2020).

- MathWorks. Optimization Toolbox: User’s Guide; MathWorks: Natick, MA, USA, 2021. [Google Scholar]

- Arteconi, A.; Hewitt, N.J.; Polonara, F. Domestic demand-side management (DSM): Role of heat pumps and thermal energy storage (TES) systems. Appl. Therm. Eng. 2013, 51, 155–165. [Google Scholar] [CrossRef]

- Chuang, J.; Lien, H.-L.; Den, W.; Iskandar, L.; Liao, P.-H. The relationship between electricity emission factor and renewable energy certificate: The free rider and outsider effect. Sustain. Environ. Res. 2018, 28, 422–429. [Google Scholar] [CrossRef]

- Drosihn, D. Übersicht zur Entwicklung der Energiebedingten Emissionen und Brennstoffeinsätze in Deutschland 1990–2018: Unter Verwendung von Berechnungsergebnissen der Nationalen Koordinierungsstelle Emissionsberichterstattung Umweltbundesamt; Dessau-Roßlau, 2020, ISBN 1862-4359. Available online: https://www.umweltbundesamt.de/publikationen/energiebedingte-emissionen-brennstoffe-2018 (accessed on 24 January 2022).

| Parameter | Range of Values | Unit |

|---|---|---|

| Weekday | Mo…Fr | - |

| Hour of the day | 0…24 | h |

| Presence of users | 0…1 | - |

| Set temperature | 16…20 | °C |

| Outdoor temperature | −12…35 | °C |

| Solar radiation | 0…928 | W/m2 |

| Daily heat load | 0…28 | kW |

| Typical Day | Temperature | Appearance Frequency |

|---|---|---|

| Cold day | −15 °C to −5 °C | 10 days |

| Cool day | −5 °C to 5 °C | 88 days |

| Moderate day | 5 °C to 15 °C | 162 days |

| Month | ||||||

|---|---|---|---|---|---|---|

| (kWh) | (kWh) | (kWh) | (kWh) | (kWh) | (%) | |

| Jan | 311.6 | 272.3 | 10.7 | 30.0 | −1.4 | 87.4 |

| Feb | 80.0 | 56.7 | 8.1 | 10.7 | 4.5 | 70.9 |

| Mar | 15.2 | 4.8 | 9.6 | 1.7 | −0.9 | 31.4 |

| Apr | 11.3 | 0.0 | 11.0 | 0.2 | 0.1 | 0.4 |

| May | 7.0 | 0.0 | 9.1 | 0.1 | −2.3 | 0.0 |

| Jun | 7.2 | 0.0 | 6.5 | 0.1 | 0.6 | 0.0 |

| Jul | 5.3 | 0.0 | 6.3 | 0.1 | −1.0 | 0.0 |

| Aug | 6.8 | 0.0 | 6.1 | 0.1 | 0.6 | 0.0 |

| Sep | 9.8 | 0.0 | 8.8 | 0.1 | 0.8 | 0.0 |

| Oct | 13.1 | 0.0 | 9.3 | 0.1 | 3.6 | 0.3 |

| Nov | 80.3 | 64.6 | 8.7 | 10.9 | −4.0 | 80.5 |

| Dec | 157.4 | 128.8 | 8.2 | 73.8 | 1.4 | 81.8 |

| Sum | 704.9 | 527.2 | 102.5 | 127.9 | 2.0 | 74.8 |

| Month | ||||||

|---|---|---|---|---|---|---|

| (kWh) | (kWh) | (kWh) | (kWh) | (kWh) | (%) | |

| Jan | 276.6 | 245.7 | 7.2 | 25.5 | −1.9 | 88.9 |

| Feb | 67.4 | 52.8 | 5.8 | 6.1 | 2.7 | 78.4 |

| Mar | 9.3 | 4.3 | 5.8 | 1.0 | −1.8 | 45.7 |

| Apr | 7.5 | 0.0 | 6.3 | 0.4 | 0.9 | 0.5 |

| May | 1.6 | 0.0 | 3.7 | 0.2 | −2.2 | 0.1 |

| Jun | 3.6 | 0.0 | 2.4 | 0.4 | 0.8 | 0.0 |

| Jul | 3.0 | 0.0 | 2.7 | 0.3 | 0.0 | 0.0 |

| Aug | 3.3 | 0.0 | 3.3 | 0.2 | −0.2 | 0.0 |

| Sep | 4.9 | 0.0 | 4.0 | 0.3 | 0.5 | 0.0 |

| Oct | 10.1 | 0.0 | 4.7 | 0.4 | 5.0 | 0.3 |

| Nov | 70.7 | 61.4 | 6.8 | 6.7 | −4.2 | 86.8 |

| Dec | 147.0 | 125.7 | 6.5 | 55.5 | 0.2 | 85.5 |

| Sum | 605.0 | 490.0 | 59.3 | 96.9 | −0.3 | 81.0 |

| Size | PDH | Insufficient Energy | CDE | |||

|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (kWh/(m2∙a)) | (kWh/(m2∙a)) | (EUR/(m2∙a)) | (kg/(m2∙a)) |

| −50 | 0.3 | 0.78 | 15.22 | 8.35 | 0.336 | 4.42 |

| 0 | 0.2 | 0.61 | 15.55 | 7.43 | 0.274 | 3.95 |

| 50 | 0.3 | 0.55 | 16.08 | 7.46 | 0.271 | 3.98 |

| Tank Size | G(t) = I | G(t) = II | G(t) = III | Relative Electricity Utilization in % |

|---|---|---|---|---|

| −50% | 72% | 27% | 3% | 82 |

| Baseline | 84% | 15% | 1% | 73 |

| 50% | 86% | 13% | 1% | 73 |

| Variations of Heat Pump | Nominal Dimension | 75% of Nominal Dimension | 60% of Nominal Dimension | |||

|---|---|---|---|---|---|---|

| Reference | XMPC | Reference | XMPC | Reference | XMPC | |

| (kWh/(m2∙a)) | 13.99 | 15.55 | 13.99 | 15.60 | 13.99 | 15.56 |

| (kWh/(m2∙a)) | 10.19 | 7.43 | 9.43 | 7.61 | 9.01 | 7.99 |

| CDE (kg/m2∙a) | 5.40 | 3.95 | 5.00 | 4.08 | 4.79 | 4.30 |

| (EUR /m2∙a) | 0.51 | 0.27 | 0.47 | 0.28 | 0.45 | 0.30 |

| SCOP | 1.38 | 2.11 | 1.49 | 2.07 | 1.57 | 1.97 |

| PDH (%) | -- | 0.21 | -- | 0.20 | -- | 0.20 |

| Insufficient Energy (%) | -- | 0.61 | -- | 0.57 | -- | 0.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eydner, M.; Wan, L.; Henzler, T.; Stergiaropoulos, K. Real-Time Grid Signal-Based Energy Flexibility of Heating Generation: A Methodology for Optimal Scheduling of Stratified Storage Tanks. Energies 2022, 15, 1793. https://doi.org/10.3390/en15051793

Eydner M, Wan L, Henzler T, Stergiaropoulos K. Real-Time Grid Signal-Based Energy Flexibility of Heating Generation: A Methodology for Optimal Scheduling of Stratified Storage Tanks. Energies. 2022; 15(5):1793. https://doi.org/10.3390/en15051793

Chicago/Turabian StyleEydner, Matthias, Lu Wan, Tobias Henzler, and Konstantinos Stergiaropoulos. 2022. "Real-Time Grid Signal-Based Energy Flexibility of Heating Generation: A Methodology for Optimal Scheduling of Stratified Storage Tanks" Energies 15, no. 5: 1793. https://doi.org/10.3390/en15051793

APA StyleEydner, M., Wan, L., Henzler, T., & Stergiaropoulos, K. (2022). Real-Time Grid Signal-Based Energy Flexibility of Heating Generation: A Methodology for Optimal Scheduling of Stratified Storage Tanks. Energies, 15(5), 1793. https://doi.org/10.3390/en15051793