A Production Performance Model of the Cyclic Steam Stimulation Process in Multilayer Heavy Oil Reservoirs

Abstract

:1. Introduction

2. Model Assumption

3. Model Description

3.1. Heating Radius

3.1.1. The Heating Radius of the Steam Zone

3.1.2. The Heating Radius of the Hot Water Zone

3.2. The Temperature Variation and Distribution in the Heated Zone

3.2.1. The Temperature Variation of the Steam Zone

3.2.2. The Temperature Distribution and Variation of the Hot Water Zone

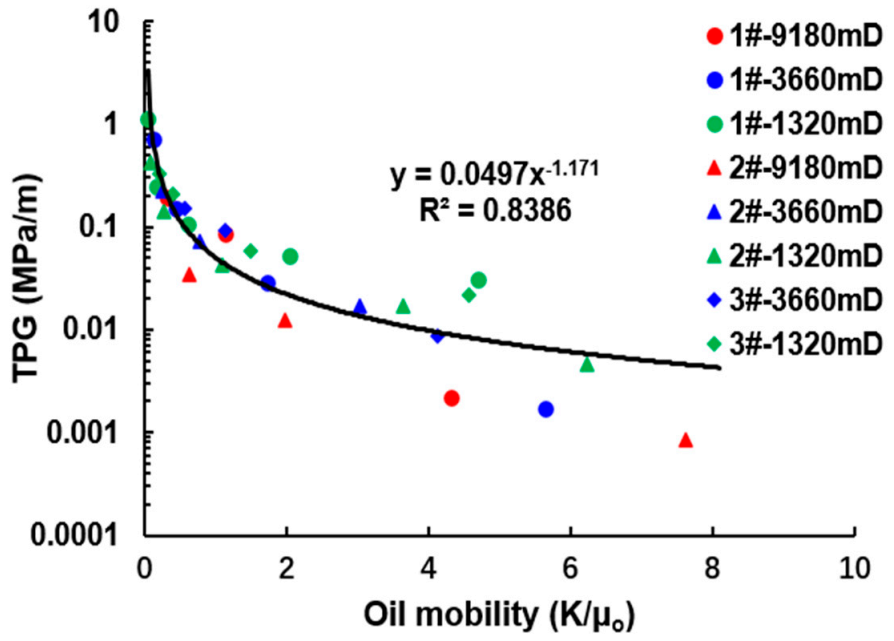

3.3. Threshold Pressure Gradient

3.4. Production Performance Model in a Multilayer Heavy Oil Reservoir

3.5. The Evolution of Reservoir Dynamic Parameters

3.5.1. Average Reservoir Pressure

3.5.2. Average Water Saturation

3.5.3. Cyclic Residual Heat

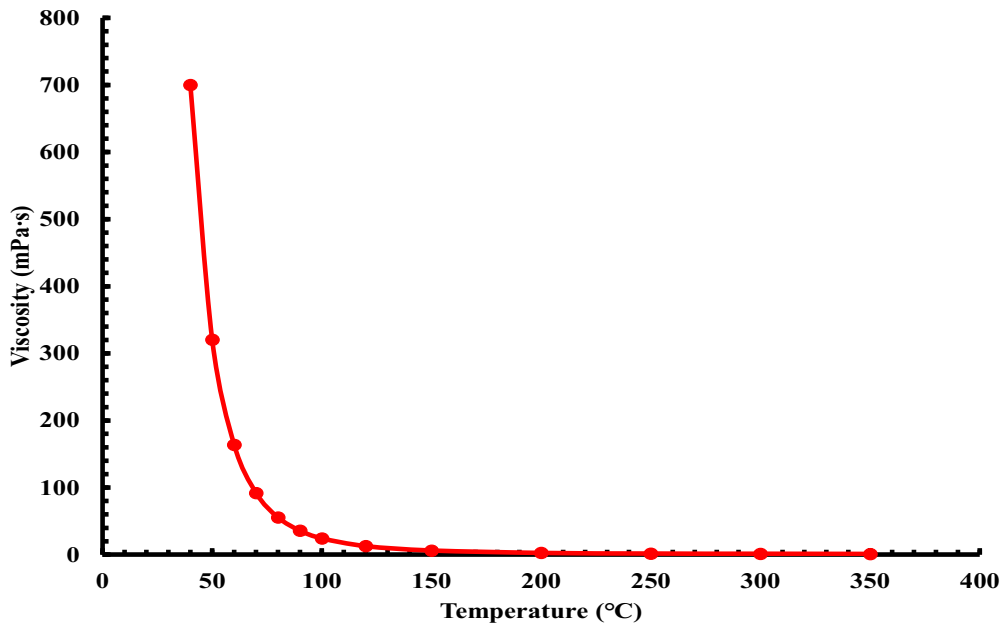

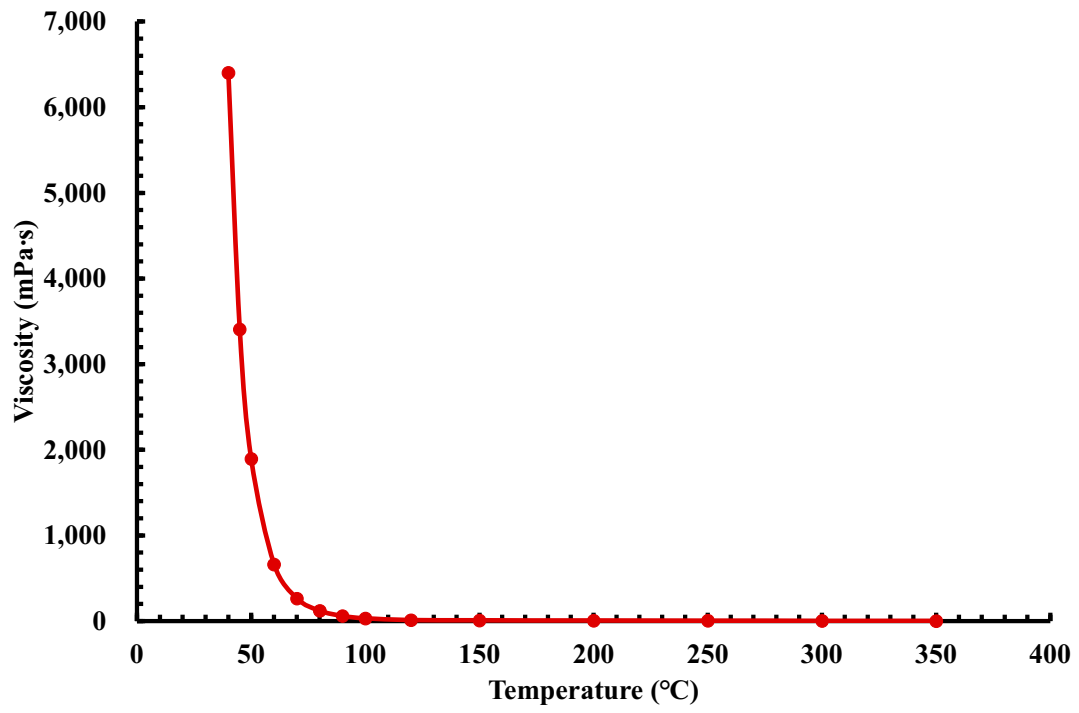

3.5.4. Oil Viscosity

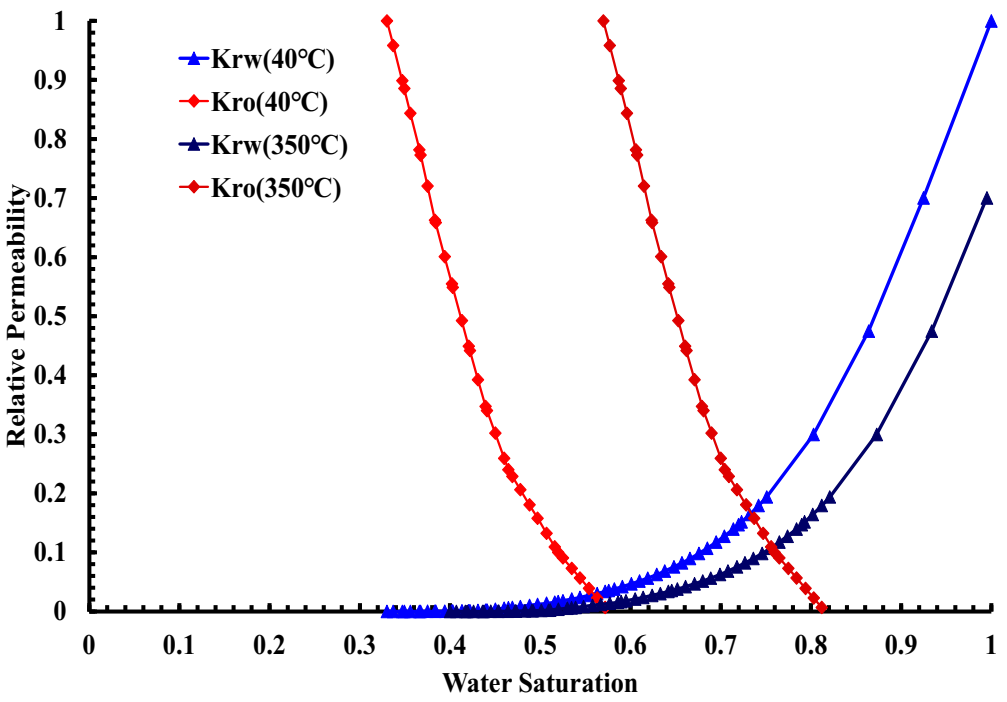

3.5.5. Oil-Water Relative Permeability Curve

3.6. Model Limitation

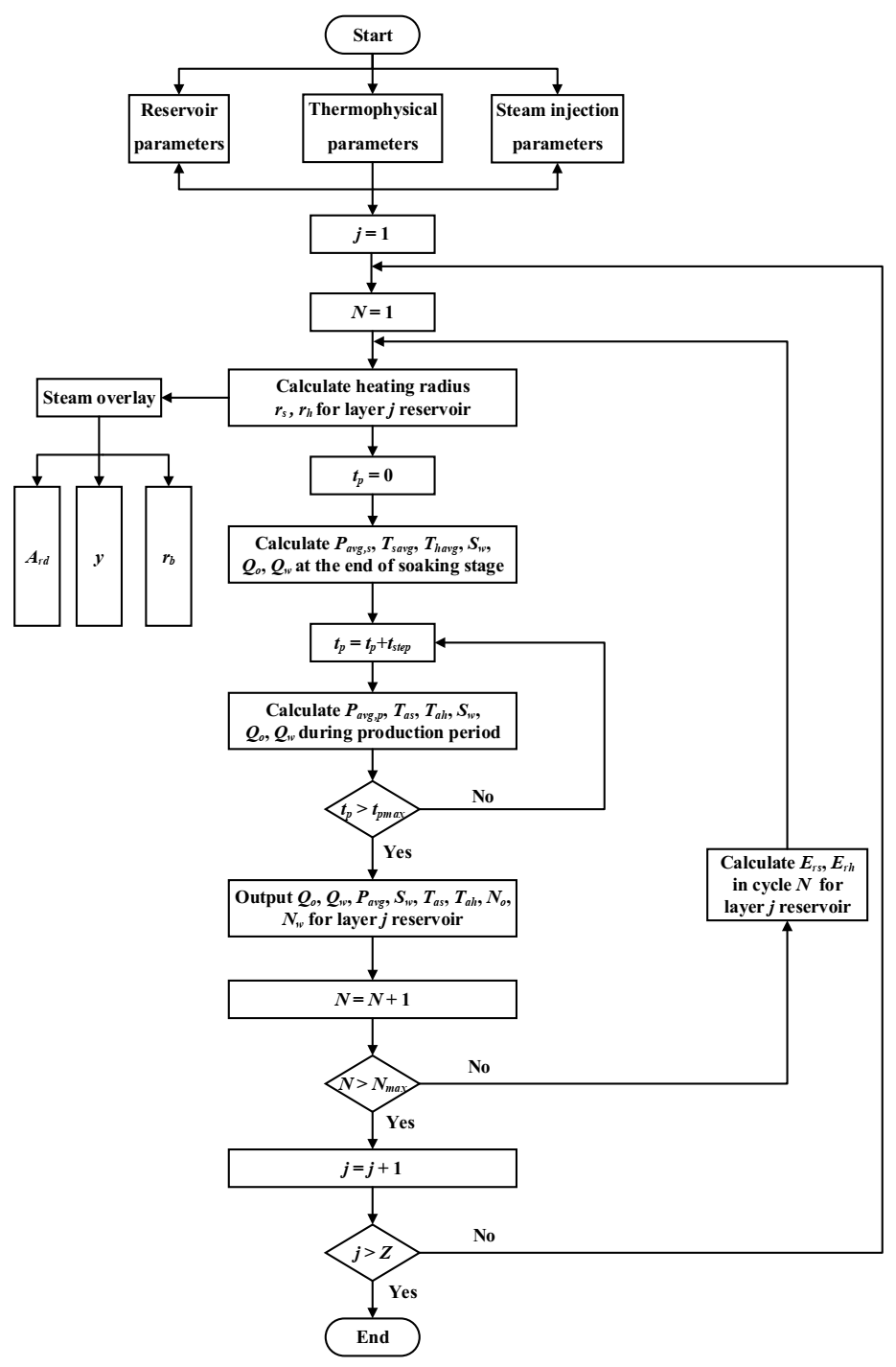

4. Calculation Procedure

5. Results and Discussion

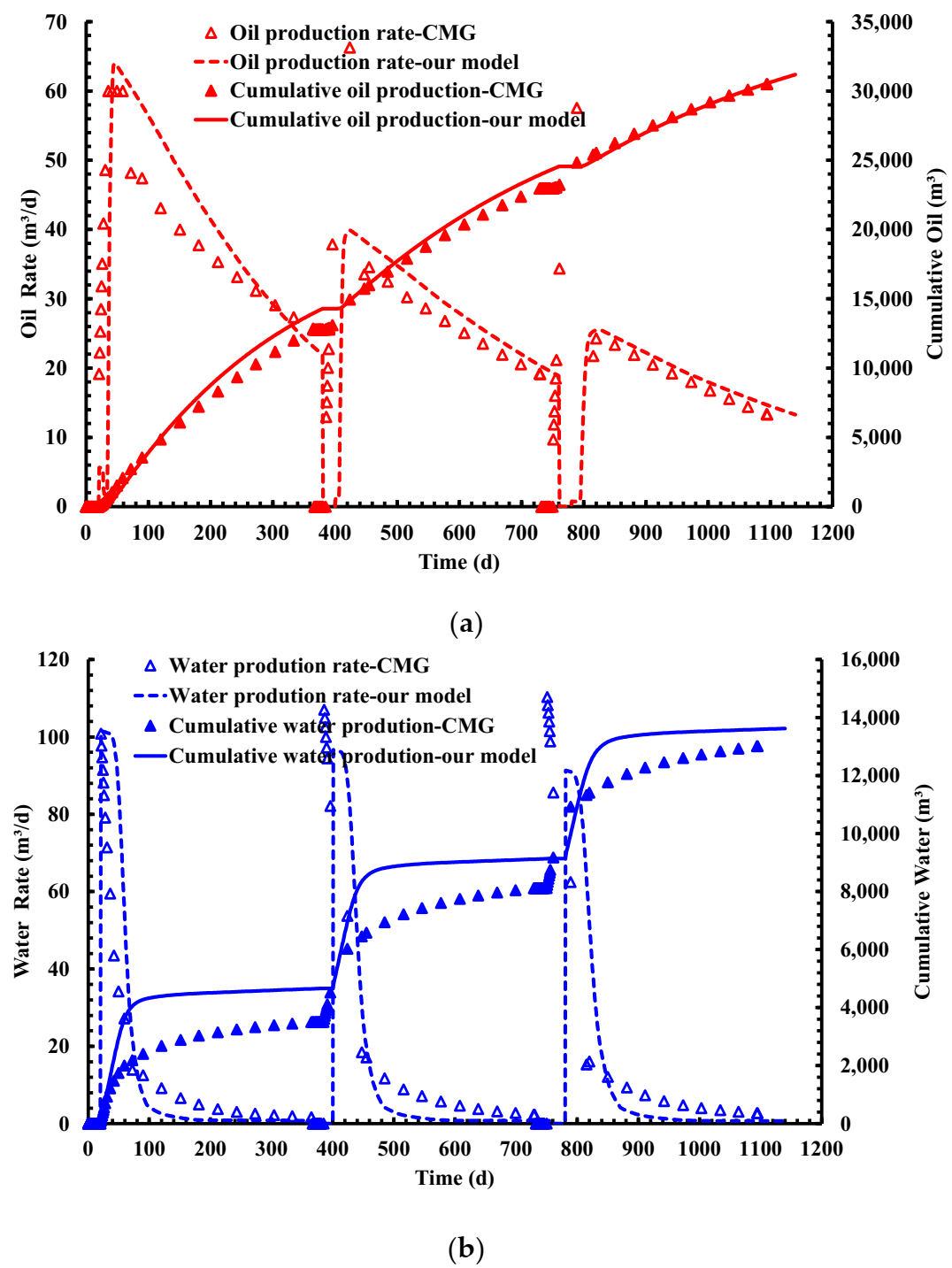

5.1. Model Validation

5.2. Sensitivity Analysis

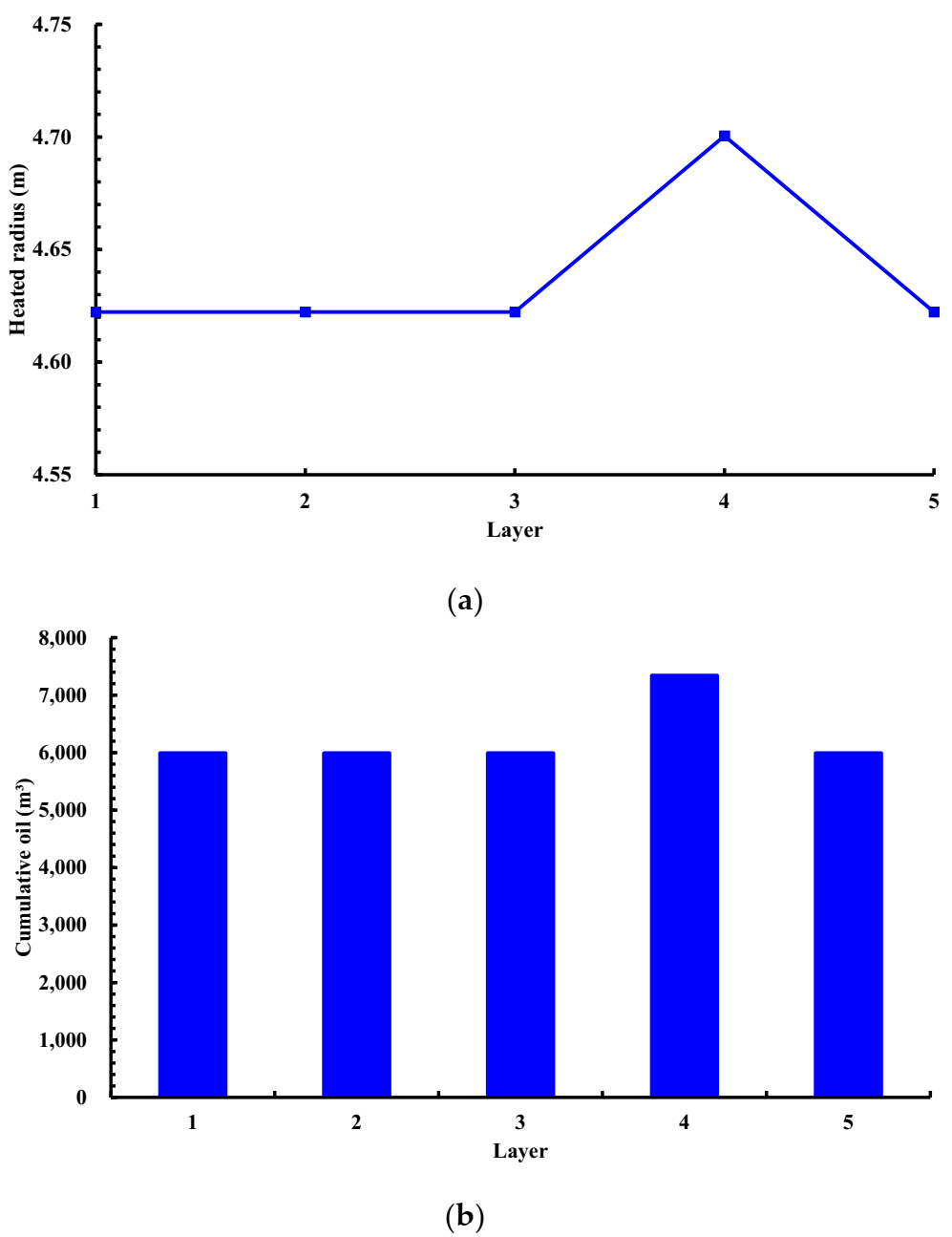

5.2.1. Effect of Formation Factor

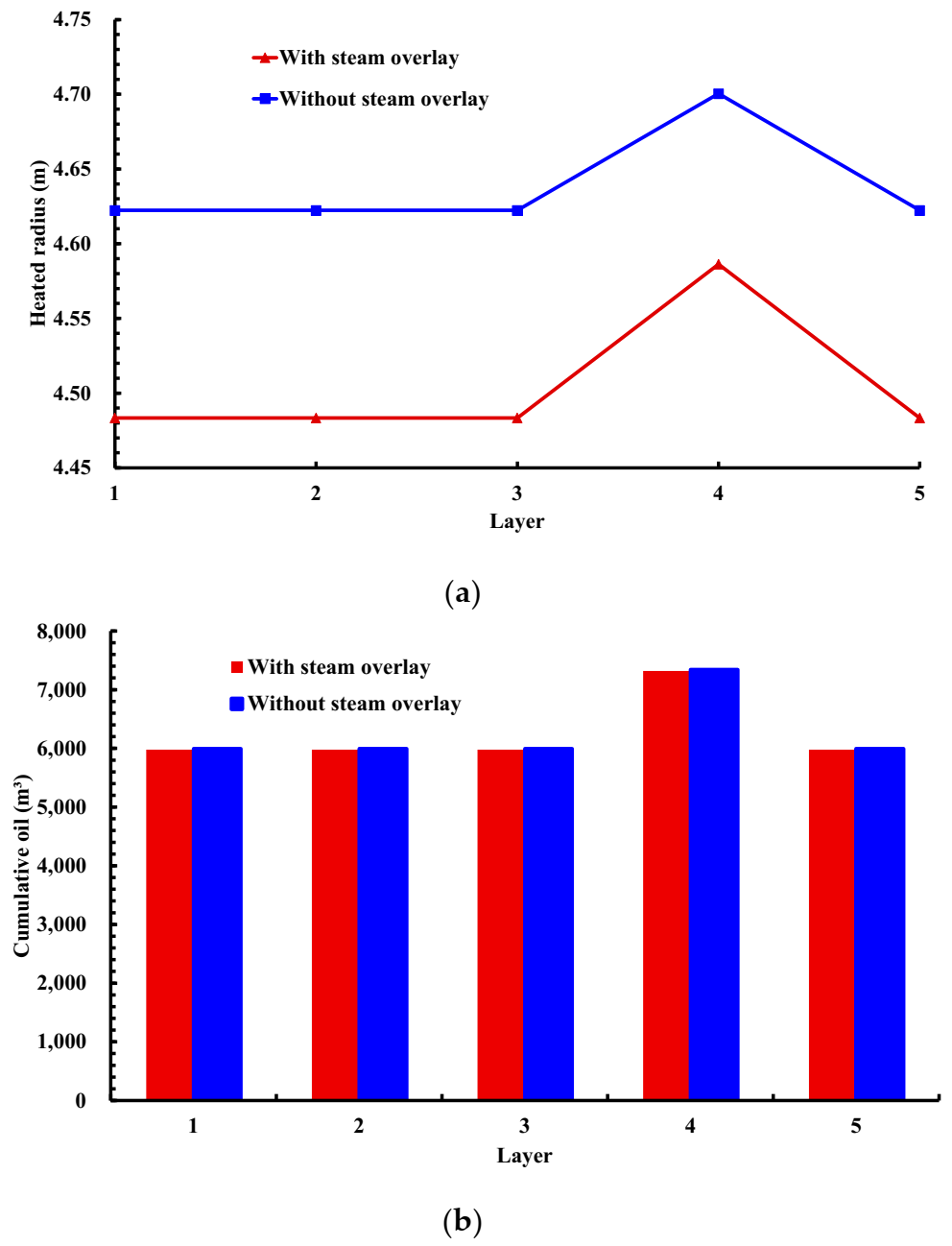

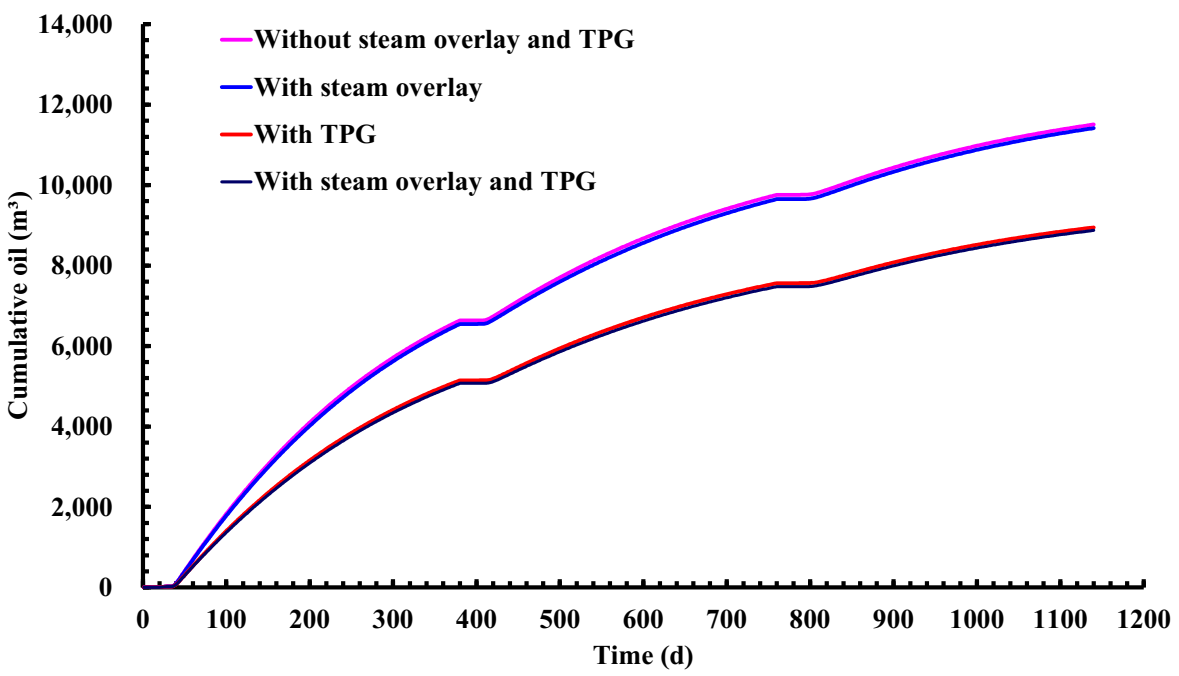

5.2.2. Effect of Steam Overlay

5.2.3. Effect of Threshold Pressure Gradient (TPG)

5.2.4. Effect of Bottom Hole Pressure

6. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ah | area of hot water zone, m2 |

| Ard | shape coefficient |

| As1, As2 | interlayer area of steam zone, m2 |

| Bo, Bw | volume factor |

| C, D | coefficient |

| Co, Cw, Cp, Ce | compressibility, MPa−1 |

| ds, do, dw | density of steam, oil, water kg/m3 |

| dwi | initial density of water, kg/m3 |

| Ers, Erh | residual heat, kJ |

| Gw | total volume of cyclic injected steam, m3 |

| h | reservoir thickness, m |

| Hfs, Hfh | heat flux carried by produced fluids, kJ/d |

| hwr | hot water enthalpy, kJ/kg |

| hws | saturated steam enthalpy, kJ/kg |

| I | total steam injection rate, kg/d |

| is | steam injection rate, kg/d |

| K | reservoir permeability, mD |

| Kroc, Kroh, Kros | oil relative permeability |

| ks | effective permeability of steam, mD |

| Lv | latent heat of vaporization, kJ/kg |

| M | cycle of steam stimulation |

| MR | reservoir heat capacity, kJ/(m3 °C) |

| N | total geological reserves, m3 |

| Nos, Noh | geological reserves, m3 |

| Nw, No | cumulative production, m3 |

| Ors, Orh | radial dimensionless time |

| Os, Oh | correction coefficient for temperature drop |

| Ozs, Ozh | vertical dimensionless time |

| Pavg | average reservoir pressure, MPa |

| Pavg,p | average reservoir pressure (production), MPa |

| Pavg,s | average reservoir pressure (soaking), MPa |

| Pi | initial reservoir pressure, MPa |

| Pwf | bottom hole pressure, MPa |

| Qo, Qw | production rate, m3/d |

| r | the distance from wellbore, m |

| rb | bottom radius of steam zone, m |

| re | equivalent radius of drainage area, m |

| rh | radius of hot water zone, m |

| the distance corresponding to , m | |

| Ro, Rw | flow resistance, (MPa·d)/m3 |

| rs | equivalent radius of steam zone, m |

| S | skin factor |

| Swi, Soi | initial saturation |

| t | injection time, d |

| T | temperature, °C |

| Tas, Tah | average temperature (production), °C |

| tb | soaking time, d |

| tD | dimensionless time |

| Tf | front temperature of hot water zone, °C |

| Th | temperature of hot water zone, °C |

| Th,p(r) | temperature distribution (production), °C |

| Th,s(r) | temperature distribution (soaking), °C |

| average temperature (injection), °C | |

| Ti | initial reservoir temperature, °C |

| tp | production time, d |

| TPG | threshold pressure gradient, MPa/m |

| Ts | injection temperature, °C |

| Tsavg, Thavg | average temperature (soaking), °C |

| Vo, Vw | specific heat capacity, kJ/(kg·°C) |

| Vrs, Vrh | radial thermal loss coefficient |

| Vzs, Vzh | vertical thermal loss coefficient |

| x | steam quality |

| y | radius ratio of overburden to underburden |

| Z | total layers of reservoir |

| Greek symbols | |

| α | thermal diffusion coefficient of reservoir, m2/d |

| βo, βw, βr, βe | thermal expansion coefficient, °C−1 |

| δ | time corresponding to heated area front, d |

| λ | heat capacity ratio of reservoir to interlayer |

| λe | thermal conductivity of reservoir, kJ/(d·m·°C) |

| μs, μo | viscosity of steam, oil, mPa·s |

| φ | porosity |

| Subscripts | |

| c, h, s | cold zone, hot water zone, steam zone |

| j | a certain layer |

| o, w, r/p | oil phase, water phase, rock/rock pores |

| 1, 2 | top and bottom of reservoir |

References

- Liu, H. Thermal Recovery Principle and Method; Petroleum Industry Press: Beijing, China, 2013. [Google Scholar]

- Dong, X.; Liu, H.; Chen, Z.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Thomas, S. Enhanced oil recovery-an overview. Oil Gas Sci. Technol. Rev. IFP 2008, 63, 9–19. [Google Scholar] [CrossRef] [Green Version]

- Hou, J.; Sun, J. Thermal Recovery Techniques; China University of Petroleum Press: Dongying, China, 2013. [Google Scholar]

- Somerton, W.H.; Keese, J.A.; Chu, S.L. Thermal behavior of unconsolidated oil sands. SPE J. 1974, 14, 513–521. [Google Scholar] [CrossRef]

- Thanh, H.V.; Sugai, Y.; Nguele, R.; Sasaki, K. Robust optimization of CO2 sequestration through a water alternating gas process under geological uncertainties in Cuu Long Basin, Vietnam. J. Nat. Gas Sci. Eng. 2020, 76, 103208. [Google Scholar] [CrossRef]

- Li, B.; Zhang, J.; Kang, X.; Zhang, F.; Wang, S.; Zhao, W.; Wang, X.; Wei, Z. Review and prospect of the development and field application of China offshore chemical EOR technology. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar]

- Tang, X.; Ma, Y.; Sun, Y. Research and field test of complex thermal fluid huff and puff technology for offshore viscous oil recovery. China Offshore Oil Gas 2011, 23, 185–188. [Google Scholar]

- Li, P.; Liu, Z.; Zou, J.; Liu, H.; Yu, J.; Fan, Y. Injection and production project of pilot test on steam huff-puff in oilfield LD27-2 Bohai Sea. Acta Pet Sin. 2016, 37, 242–247. [Google Scholar]

- Li, X.; Zhang, F.; Huang, K.; Cui, D.; Huang, Y.; Miao, F. Discussion about the thermal recovery of NB35-2 offshore heavy oilfield. Reserv. Eval. Dev. 2011, 1, 61–63. [Google Scholar]

- Boberg, T.C.; Lantz, R.B. Calculation of the production rate of a thermally stimulated well. J. Pet. Technol. 1966, 18, 1613–1623. [Google Scholar] [CrossRef]

- He, C.G.; Mu, L.X.; Xu, A.Z.; Fang, S.D. A new model of steam soaking heating radius and productivity prediction for heavy oil reservoirs. Acta Pet. Sin. 2015, 36, 1564–1570. [Google Scholar]

- Marx, J.W.; Langenheim, R.H. Reservoir heating by hot fluid injection. Trans. AIME 1959, 216, 312–315. [Google Scholar] [CrossRef]

- Willman, B.T.; Valleroy, V.V.; Runberg, G.W.; Cornelius, A.J.; Powers, L.W. Laboratory studies of oil recovery by steam injection. J. Pet. Technol. 1961, 13, 681–690. [Google Scholar] [CrossRef]

- Mandl, G.; Volek, C.W. Heat and mass transport in steam-drive processes. SPE J. 1969, 9, 59–79. [Google Scholar] [CrossRef]

- Jones, J. Cyclic steam reservoir model for viscous oil, pressure depleted gravity drainage reservoirs. In Proceedings of the SPE 6544, paper presented at California Regional Meeting, Bakersfield, CA, USA, 13–15 April 1977. [Google Scholar]

- Gros, R.P.; Pope, G.A.; Lake, L.W. Steam soak predictive model. In Proceedings of the SPE Annual Technical Conference and Exhibition, Las Vegas, NV, USA, 22–26 September 1985. [Google Scholar]

- Li, C.; Yang, B. Non-isothermal productivity predicting model of heavy crude oil exploited with huff and puff. Oil Drill. Prod. Technol. 2003, 25, 89–90. [Google Scholar]

- Hou, J.; Wei, B.; Du, Q.; Wang, J.; Wang, Q.; Zhang, G. Production prediction of cyclic multi-thermal fluid stimulation in a horizontal well. J. Pet. Sci. Eng. 2016, 146, 949–958. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, H.; Kang, X.; Liu, Y.; Dong, X.; Wang, Y.; Liu, S.; Li, G. An investigation of production performance by cyclic steam stimulation using horizontal well in heavy oil reservoirs. Energy 2021, 218, 119500. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, H.; Zhang, Z.; Wang, X. A novel model and sensitive analysis for productivity estimate of nitrogen assisted cyclic steam stimulation in a vertical well. Int. J. Heat Mass Transf. 2018, 126, 391–400. [Google Scholar] [CrossRef]

- Van Lookeren, J. Calculation methods for linear and radial steam flow in oil reservoirs. SPE J. 1983, 23, 427–439. [Google Scholar] [CrossRef]

- Hou, J.; Chen, Y. An improved steam soak predictive model. Pet. Explor. Dev. 1997, 24, 53–56. [Google Scholar]

- Lai, L.; Pan, T.; Qin, Y. A calculation method for heat loss considering steam overlap in steam flooding. J. Northwest Univ. 2014, 44, 104–110. [Google Scholar]

- Tian, Y.; Ju, B.; Hu, J. A productivity prediction model for heavy oil steam huff and puff considering steam override. Pet. Drill. Tech. 2018, 46, 100–116. [Google Scholar]

- Sun, F.; Li, C.; Cheng, L.; Huang, S.; Zou, M.; Sun, Q.; Wu, X. Production performance analysis of heavy oil recovery by cyclic superheated steam stimulation. Energy 2017, 121, 356–371. [Google Scholar] [CrossRef]

- He, C.; Xu, A.; Fan, Z.; Zhao, L.; Zhang, A.; Shan, F.; He, J. An integrated heat efficiency model for superheated steam injection in heavy oil reservoirs. Oil Gas Sci. Technol. Rev. IFP Energ. Nouv. 2019, 74. [Google Scholar] [CrossRef]

- Thomas, L.K.; Katz, D.L.; Tek, M.R. Threshold pressure phenomena in porous media. SPE J. 1968, 8, 174–184. [Google Scholar] [CrossRef]

- Wu, Y.; Pruess, K.; Witherspoon, P.A. Flow and displacement of Bingham non-Newtonian fluids in porous media. SPE Reserv. Eng. 1992, 7, 369–376. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Huang, Y.; Civan, F. Experimental and theoretical investigation of the Zaoyuan field heavy oil flow through porous media. J. Pet. Sci. Eng. 2006, 50, 83–101. [Google Scholar] [CrossRef]

- Tian, J.; Xu, J.; Cheng, L. The method of characterization and physical simulation of TPG for ordinary heavy oil. J. Southwest Pet. Univ. Sci. Technol. Ed. 2009, 31, 158–162. [Google Scholar]

- Liu, H.; Wang, J.; Xie, Y.; Ma, D.; Shi, X. Flow characteristics of heavy oil through porous media. Energy Sources Part A Recovery Util. Environ. Eff. 2011, 34, 347–359. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Wang, Q.; Pang, Z.; Wang, C. Non-Newtonian flow characterization of heavy crude oil in porous media. J. Pet. Explor. Prod. Technol. 2013, 3, 43–53. [Google Scholar] [CrossRef] [Green Version]

- Huang, T.; Ning, Z.; Liu, H.; Zhang, S.; Xiao, L. Experiment investigation on mobility characteristics of different components of heavy oil. Sci. Technol. Eng. 2013, 13, 6851–6854. [Google Scholar]

- Sun, J. Experimental Study on Single Phase Flow in Block Zheng 411 of Shengli Ultra Heavy Oil Reservoir. Drill. Pet. Tech. 2011, 39, 86–90. [Google Scholar]

- Zhang, D.; Peng, J.; Gu, Y.; Leng, Y. Experimental study on threshold pressure gradient of heavy oil reservoir. Xinjiang Pet. Geol. 2012, 33, 201–204. [Google Scholar]

- Yang, J.; Li, X.; Chen, Z.; Tian, J.; Huang, L.; Liu, X. A productivity prediction model for cyclic steam stimulation in consideration of non-Newtonian characteristics of heavy oil. Acta Pet. Sin. 2017, 38, 84–90. [Google Scholar]

- Huang, S.; Kang, B.; Cheng, L.; Zhou, W.; Chang, S. Quantitative characterization of interlayer interference and productivity prediction of directional wells in the multilayer commingled production of ordinary offshore heavy oil reservoirs. Pet. Explor. Dev. 2015, 42, 533–540. [Google Scholar] [CrossRef]

- Shen, F.; Cheng, L.; Sun, Q.; Huang, S. Evaluation of the vertical producing degree of commingled production via waterflooding for multilayer offshore heavy oil reservoirs. Energies 2018, 11, 2428. [Google Scholar] [CrossRef] [Green Version]

- Dong, X.; Liu, H.; Chen, Z. Hybrid Enhanced Oil Recovery Processes for Heavy Oil Reservoirs. In Developments in Petroleum Science; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

| Stage | Parameters | Value |

|---|---|---|

| Basic parameters | Reservoir thickness, m | 7.5 * 3 + 10 + 7.5 |

| Porosity, decimal | 0.28 | |

| Permeability, mD | 1200 | |

| Initial reservoir pressure, MPa | 10 | |

| Initial reservoir temperature, °C | 40 | |

| Initial water saturation, decimal | 0.33 | |

| Reservoir compressibility, MPa−1 | 0.0055 | |

| Wellbore radius, m | 0.1 | |

| Bottom hole pressure, MPa | 6 | |

| Thermal conductivity of reservoir, kJ/(d·m·°C) | 163.4 | |

| Thermal conductivity of interlayers, kJ/(d·m·°C) | 105.5 | |

| Heat capacity of reservoir, kJ/(m3·°C) | 2575 | |

| Heat capacity of interlayers, kJ/(m3·°C) | 2200 | |

| Oil thermal expansion coefficient, °C−1 | 0.00045 | |

| Water thermal expansion coefficient, °C−1 | 0.00015 | |

| Oil specific heat capacity, kJ/(kg·°C) | 2.1 | |

| Water specific heat capacity, kJ/(kg·°C) | 4.2 | |

| Steam injection parameters | Injection time, d | 15 |

| Soaking time, d | 5 | |

| Production time, d | 360 | |

| CSS cycles, dless | 3 | |

| Steam injection rate, t/d | 300 | |

| Injection temperature, ·°C | 340 | |

| Steam quality, decimal | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, T.; Xu, W.; Zheng, W.; Jiang, W.; Jiang, X.; Wang, T.; Dong, X. A Production Performance Model of the Cyclic Steam Stimulation Process in Multilayer Heavy Oil Reservoirs. Energies 2022, 15, 1757. https://doi.org/10.3390/en15051757

Fan T, Xu W, Zheng W, Jiang W, Jiang X, Wang T, Dong X. A Production Performance Model of the Cyclic Steam Stimulation Process in Multilayer Heavy Oil Reservoirs. Energies. 2022; 15(5):1757. https://doi.org/10.3390/en15051757

Chicago/Turabian StyleFan, Tingen, Wenjiang Xu, Wei Zheng, Weidong Jiang, Xiuchao Jiang, Taichao Wang, and Xiaohu Dong. 2022. "A Production Performance Model of the Cyclic Steam Stimulation Process in Multilayer Heavy Oil Reservoirs" Energies 15, no. 5: 1757. https://doi.org/10.3390/en15051757

APA StyleFan, T., Xu, W., Zheng, W., Jiang, W., Jiang, X., Wang, T., & Dong, X. (2022). A Production Performance Model of the Cyclic Steam Stimulation Process in Multilayer Heavy Oil Reservoirs. Energies, 15(5), 1757. https://doi.org/10.3390/en15051757