Recycling of Lithium Batteries—A Review

Abstract

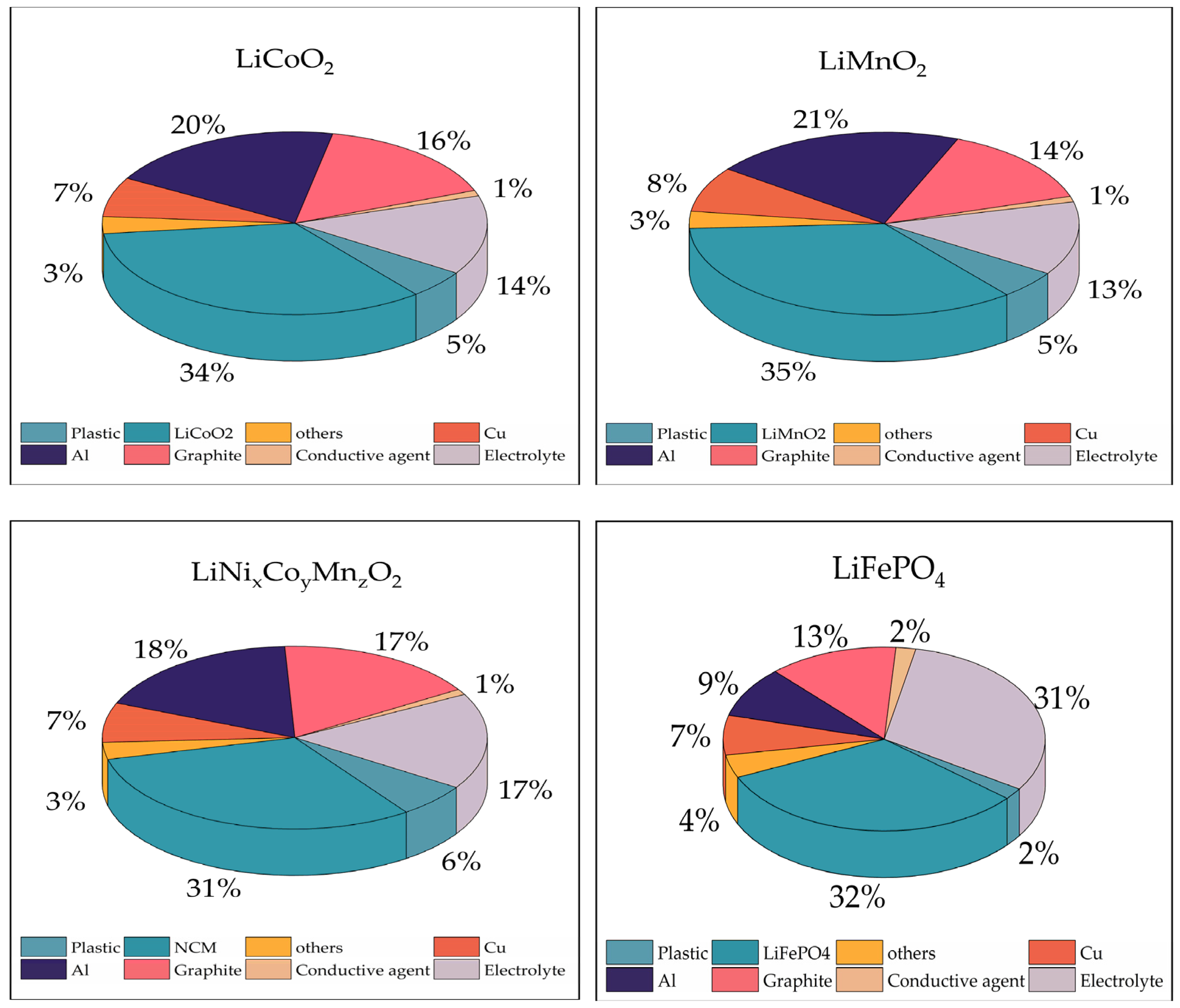

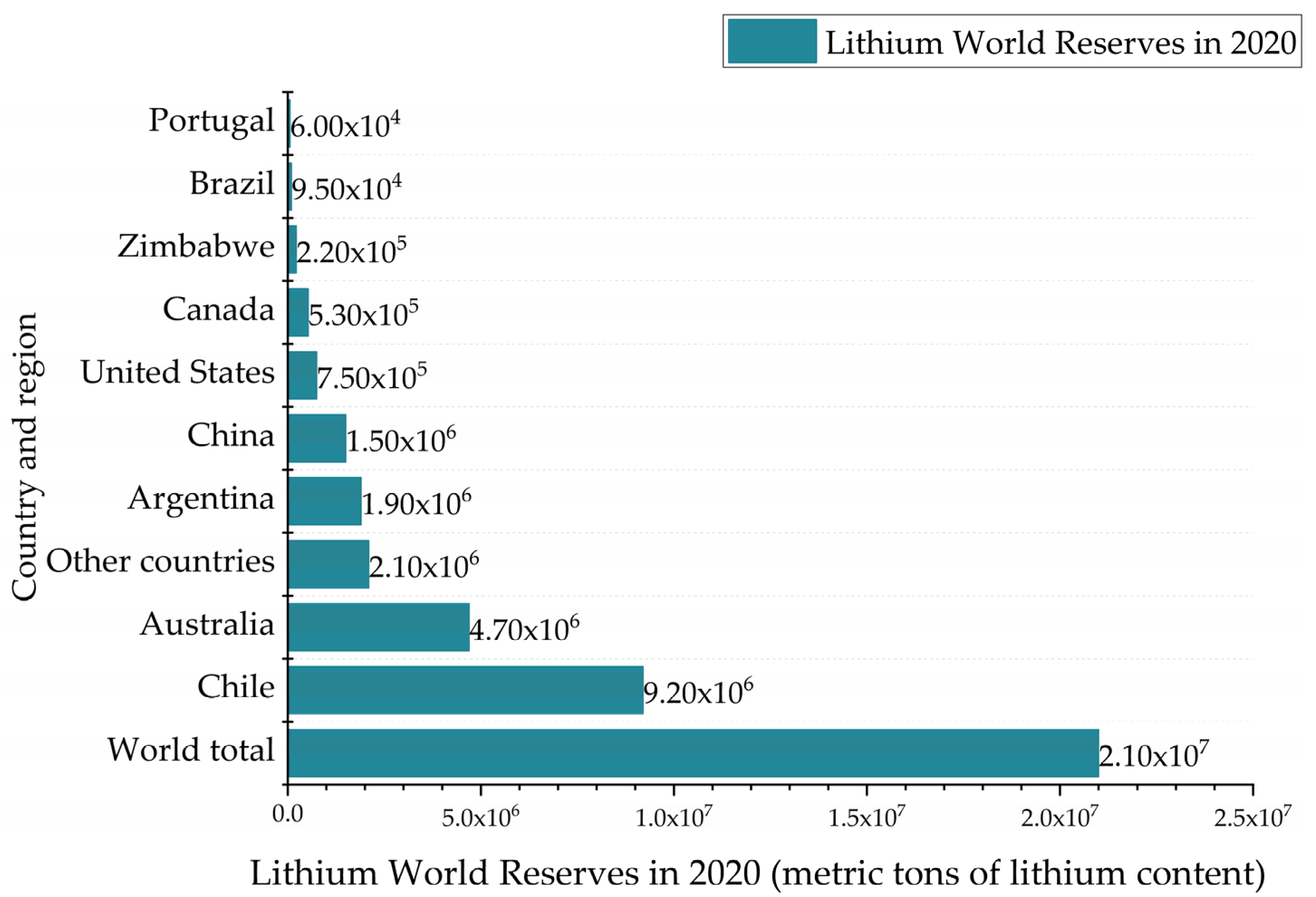

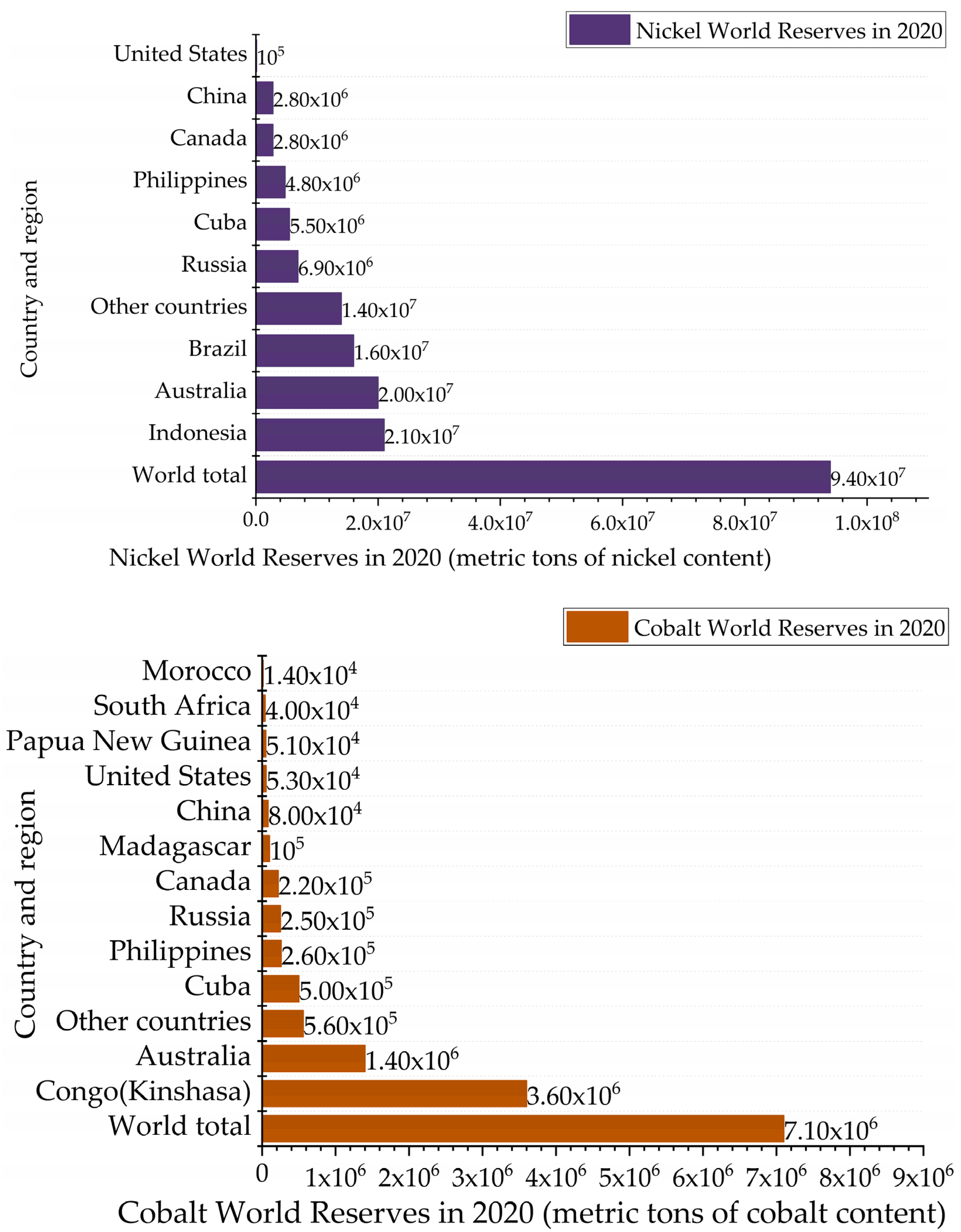

:1. Introduction

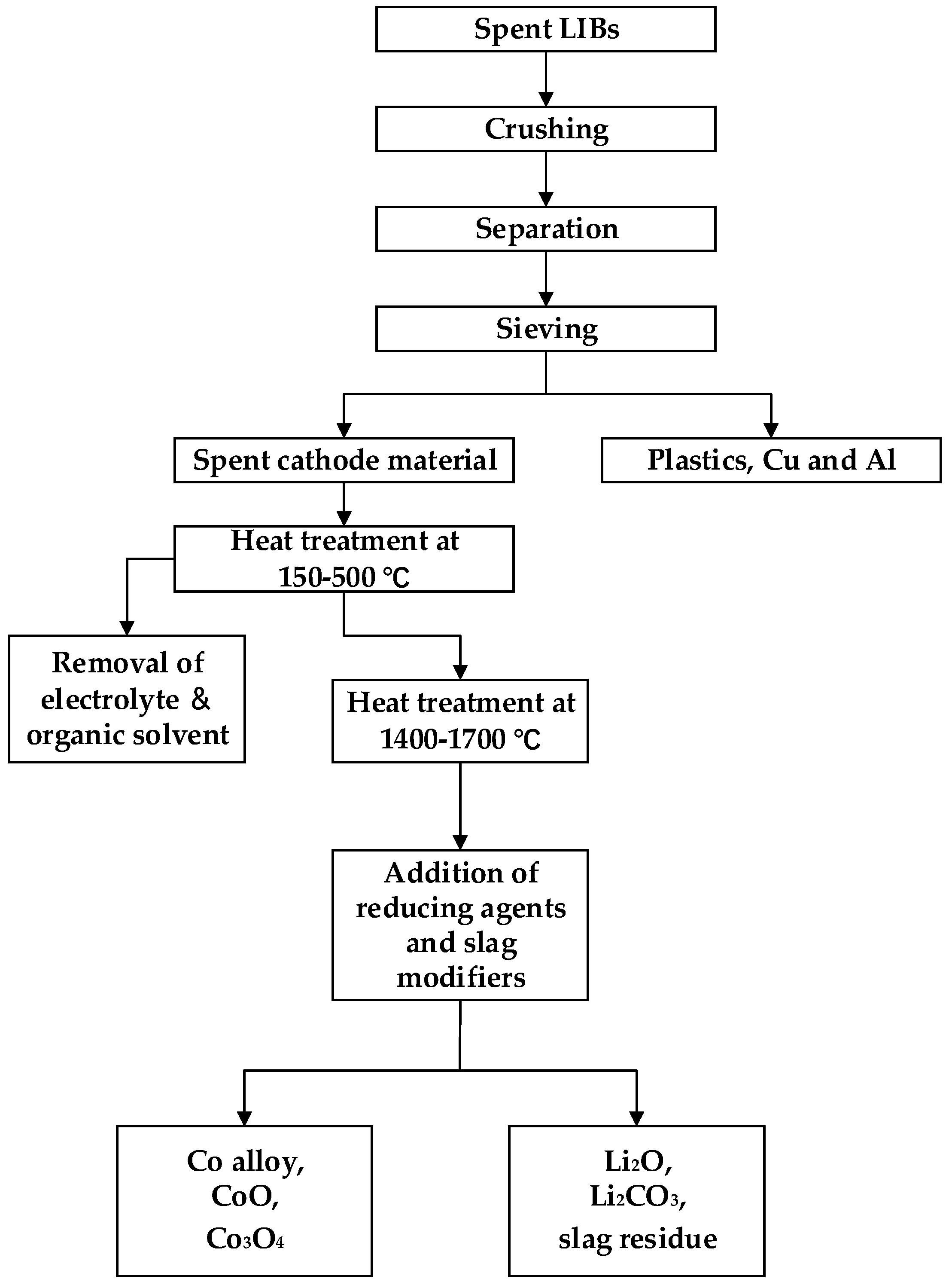

2. Pre-Treatments

2.1. Discharging Process

2.2. Mechanical Process

3. Pyrometallurgy Treatments

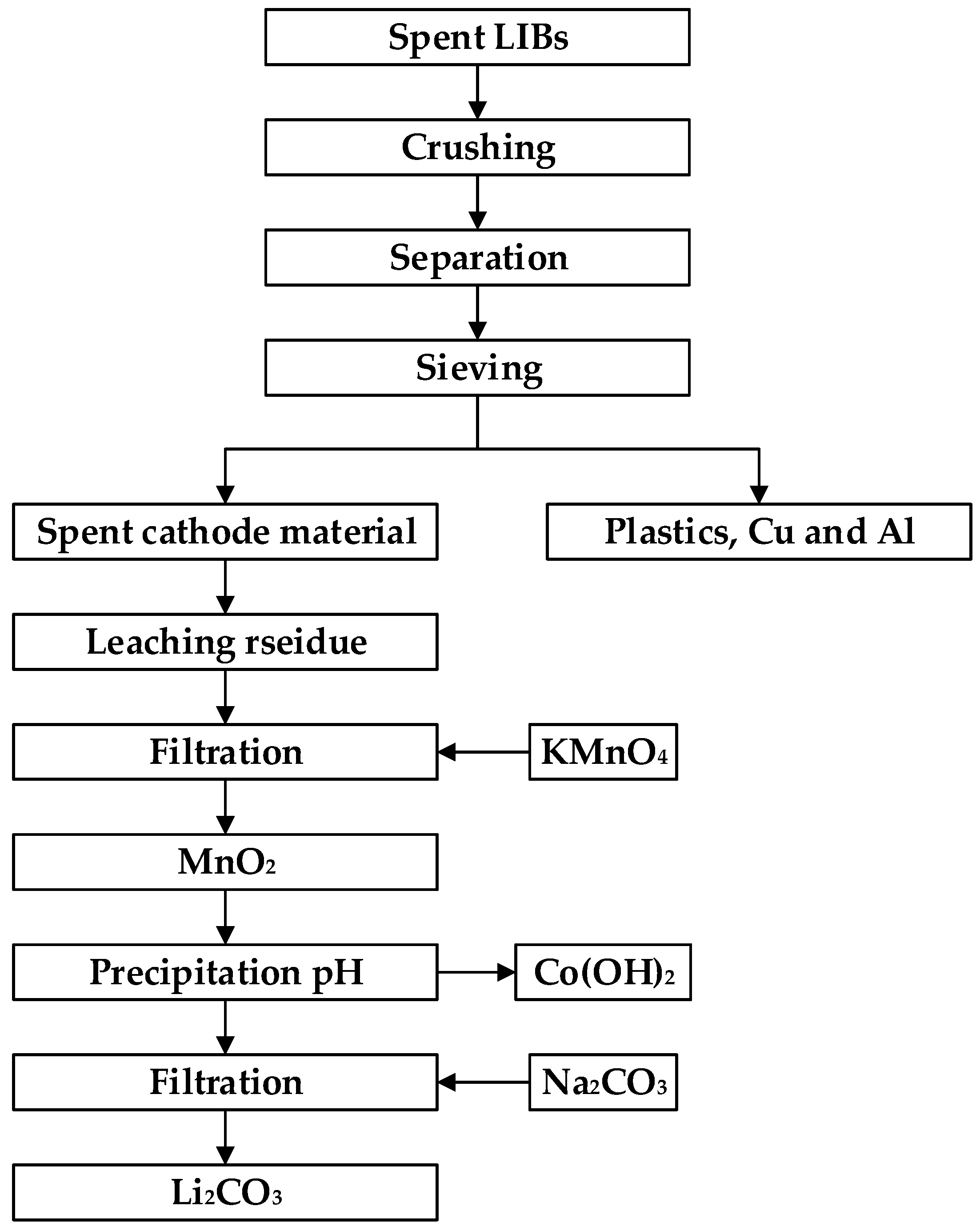

4. Hydrometallurgy

4.1. Acid Leaching

4.2. Chlorination Technology Process

4.3. Ammoniation Technology Process

4.4. Solvent Extraction

5. Biohydrometallurgy

6. Other Recycling Treatments

6.1. Closed-Loop LIBs Recycling Process

6.2. Electrochemical Methods

7. Conclusions: Future Perspective of the Research

- Understand the upstream and downstream materials of lithium battery production and clarify the target products of spent battery recycling.

- Build a closed-loop industrial chain, reuse reagents, minimize the use of chemical reagents and emissions, and reduce the pressure of spent liquid treatment.

- Understand the impurities that enter the recycling process, seek means to reduce the content of impurities, produce purer products, and improve the economic value and practicality of products.

- Develop the products of all by-products in the actual industrial chain to improve the economy of the whole chain.

- Research new processes that are more economical and environmentally friendly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Or, T.; Gourley, S.W.D.; Kaliyappan, K.; Yu, A.; Chen, Z. Recycling of mixed cathode lithium-ion batteries for electric vehicles: Current status and future outlook. Carbon Energy 2020, 2, 6–43. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Ma, X.; Chen, B.; Arsenault, R.; Karlson, P.; Simon, N.; Wang, Y. Recycling End-of-Life Electric Vehicle Lithium-Ion Batteries. Joule 2019, 3, 2622–2646. [Google Scholar] [CrossRef]

- Projection Total Lithium Demand Globally 2030|Statista. Available online: https://www.statista.com/statistics/452025/projected-total-demand-for-lithium-globally/ (accessed on 1 August 2020).

- Meng, F.; McNeice, J.; Zadeh, S.S.; Ghahreman, A. Review of Lithium Production and Recovery from Minerals, Brines, and Lithium-Ion Batteries. Miner. Processing Extr. Metall. Rev. 2021, 42, 123–141. [Google Scholar] [CrossRef]

- Salazar, K.; McNutt, M.K. Mineral Commodity Summaries US Geological Survey; U.S. Department of the Interior: Reston, VA, USA, 2012. [Google Scholar]

- Miao, Y.; Liu, L.; Zhang, Y.; Tan, Q.; Li, J. An overview of global power lithium-ion batteries and associated critical metal recycling. J. Hazard Mater. 2022, 425, 127900. [Google Scholar] [CrossRef] [PubMed]

- Joo, S.; Shin, D.J.; Oh, C.; Wang, J.; Senanayake, G.; Shin, S.M. Selective extraction and separation of nickel from cobalt, manganese and lithium in pre-treated leach liquors of ternary cathode material of spent lithium-ion batteries using synergism caused by Versatic 10 acid and LIX 84-I. Hydrometallurgy 2016, 159, 65–74. [Google Scholar] [CrossRef]

- Singh, U.K.; Kumar, B. Pathways of heavy metals contamination and associated human health risk in Ajay River basin, India. Chemosphere 2017, 174, 183–199. [Google Scholar] [CrossRef]

- Ordoñez, J.; Gago, E.J.; Girard, A. Processes and technologies for the recycling and recovery of spent lithium-ion batteries. Renew. Sustain. Energy Rev. 2016, 60, 195–205. [Google Scholar] [CrossRef]

- Gratz, E.; Sa, Q.; Apelian, D.; Wang, Y. A closed loop process for recycling spent lithium ion batteries. J. Power Sources 2014, 262, 255–262. [Google Scholar] [CrossRef]

- Zhao, J.; Qu, X.; Qu, J.; Zhang, B.; Ning, Z.; Xie, H.; Zhou, X.; Song, Q.; Xing, P.; Yin, H. Extraction of Co and Li2CO3 from cathode materials of spent lithium-ion batteries through a combined acid-leaching and electro-deoxidation approach. J. Hazard. Mater. 2019, 379, 120817. [Google Scholar] [CrossRef]

- Ma, X.; Azhari, L.; Wang, Y. Li-ion battery recycling challenges. Chem 2021, 7, 2843–2847. [Google Scholar] [CrossRef]

- Hanisch, C.; Loellhoeffel, T.; Diekmann, J.; Markley, K.J.; Haselrieder, W.; Kwade, A. Recycling of lithium-ion batteries: A novel method to separate coating and foil of electrodes. J. Clean. Prod. 2015, 108, 301–311. [Google Scholar] [CrossRef]

- Zhang, G.; Yuan, X.; He, Y.; Wang, H.; Zhang, T.; Xie, W. Recent advances in pretreating technology for recycling valuable metals from spent lithium-ion batteries. J. Hazard. Mater. 2021, 406, 124332. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Zhang, C.; Feng, P.; Yang, X.; Yang, X. A novel pulsated pneumatic separation with variable-diameter structure and its application in the recycling spent lithium-ion batteries. Waste Manag. 2021, 131, 20–30. [Google Scholar] [CrossRef] [PubMed]

- Yao, L.P.; Zeng, Q.; Qi, T.; Li, J. An environmentally friendly discharge technology to pretreat spent lithium-ion batteries. J. Clean. Prod. 2020, 245, 118820. [Google Scholar] [CrossRef]

- Wang, X.; Gaustad, G.; Babbitt, C.W. Targeting high value metals in lithium-ion battery recycling via shredding and size-based separation. Waste Manag. 2016, 51, 204–213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wuschke, L.; Jaeckel, H.; Leissner, T.; Peuker, U.A. Crushing of large Li-ion battery cells. Waste Manag. 2019, 85, 317–326. [Google Scholar] [CrossRef]

- Liu, J.; Bai, X.; Hao, J.; Wang, H.; Zhang, T.; Tang, X.; Wang, S.; He, Y. Efficient liberation of electrode materials in spent lithium-ion batteries using a cryogenic ball mill. J. Environ. Chem. Eng. 2021, 9, 106017. [Google Scholar] [CrossRef]

- Wang, M.; Tan, Q.; Huang, Q.; Liu, L.; Chiang, J.F.; Li, J. Converting spent lithium cobalt oxide battery cathode materials into high-value products via a mechanochemical extraction and thermal reduction route. J. Hazard. Mater. 2021, 413, 125222. [Google Scholar] [CrossRef]

- Xie, J.; Huang, K.; Nie, Z.; Yuan, W.; Wang, X.; Song, Q.; Zhang, X.; Zhang, C.; Wang, J.; Crittenden, J.C. An effective process for the recovery of valuable metals from cathode material of lithium-ion batteries by mechanochemical reduction. Resour. Conserv. Recycl. 2021, 168, 105261. [Google Scholar] [CrossRef]

- Thompson, D.; Hyde, C.; Hartley, J.M.; Abbott, A.P.; Anderson, P.A.; Harper, G.D.J. To shred or not to shred: A comparative techno-economic assessment of lithium ion battery hydrometallurgical recycling retaining value and improving circularity in LIB supply chains. Resour. Conserv. Recycl. 2021, 175, 105741. [Google Scholar] [CrossRef]

- Min, X.; Guo, M.; Liu, L.; Li, L.; Gu, J.; Liang, J.; Chen, C.; Li, K.; Jia, J.; Sun, T. Synthesis of MnO2 derived from spent lithium-ion batteries via advanced oxidation and its application in VOCs oxidation. J. Hazard. Mater. 2021, 406, 124743. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liang, G.; Yang, C.; Hu, J.; Chen, Y.; Wang, C. A breakthrough method for the recycling of spent lithium-ion batteries without pre-sorting. Green Chem. 2021, 23, 8434–8440. [Google Scholar] [CrossRef]

- Tao, R.; Xing, P.; Li, H.; Sun, Z.; Wu, Y. Recovery of spent LiCoO2 lithium-ion battery via environmentally friendly pyrolysis and hydrometallurgical leaching. Resour. Conserv. Recycl. 2022, 176, 105921. [Google Scholar] [CrossRef]

- Wang, D.; Li, W.; Rao, S.; Tao, J.; Duan, L.; Zhang, K.; Cao, H.; Liu, Z. Oxygen-free calcination for enhanced leaching of valuable metals from spent lithium-ion batteries without a reductant. Sep. Purif. Technol. 2021, 259, 118212. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, J.; Yu, B.; Huang, H.; Chen, Y.; Wang, C. Recovery of valuable metals from spent LiNixCoyMnzO2 cathode material via phase transformation and stepwise leaching. Sep. Purif. Technol. 2021, 267, 118609. [Google Scholar] [CrossRef]

- Xu, P.; Liu, C.; Zhang, X.; Zheng, X.; Lv, W.; Rao, F.; Yao, P.; Wang, J.; Sun, Z. Synergic Mechanisms on Carbon and Sulfur during the Selective Recovery of Valuable Metals from Spent Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2021, 9, 2271–2279. [Google Scholar] [CrossRef]

- Xiao, J.; Gao, R.; Niu, B.; Xu, Z. Study of reaction characteristics and controlling mechanism of chlorinating conversion of cathode materials from spent lithium-ion batteries. J. Hazard. Mater. 2021, 407, 124704. [Google Scholar] [CrossRef]

- Xiao, J.; Niu, B.; Xu, Z. Highly efficient selective recovery of lithium from spent lithium-ion batteries by thermal reduction with cheap ammonia reagent. J. Hazard. Mater. 2021, 418, 126319. [Google Scholar] [CrossRef]

- Makuza, B.; Yu, D.; Huang, Z.; Tian, Q.; Guo, X. Dry Grinding—Carbonated Ultrasound-Assisted Water Leaching of Carbothermally Reduced Lithium-Ion Battery Black Mass Towards Enhanced Selective Extraction of Lithium and Recovery of High-Value Metals. Resour. Conserv. Recycl. 2021, 174, 105784. [Google Scholar] [CrossRef]

- Qiu, R.; Huang, Z.; Zheng, J.; Song, Q.; Ruan, J.; Tang, Y.; Qiu, R. Energy models and the process of fluid-magnetic separation for recovering cobalt micro-particles from vacuum reduction products of spent lithium ion batteries. J. Clean. Prod. 2021, 279, 123230. [Google Scholar] [CrossRef]

- Hossain, R.; Kumar, U.; Sahajwalla, V. Selective thermal transformation of value added cobalt from spent lithium-ion batteries. J. Clean. Prod. 2021, 293, 126140. [Google Scholar] [CrossRef]

- Ma, Y.; Tang, J.; Wanaldi, R.; Zhou, X.; Wang, H.; Zhou, C.; Yang, J. A promising selective recovery process of valuable metals from spent lithium ion batteries via reduction roasting and ammonia leaching. J. Hazard. Mater. 2021, 402, 123491. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Qiu, K. Vacuum pyrolysis and hydrometallurgical process for the recovery of valuable metals from spent lithium-ion batteries. J. Hazard. Mater. 2011, 194, 378–384. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Zarcone, R.; Paiton, D.; Sohn, J.; Wan, W.; Olshausen, B.; Wong, H.P. Error-Resilient Analog Image Storage and Compression with Analog-Valued RRAM Arrays: An Adaptive Joint Source-Channel Coding Approach. In Proceedings of the 2018 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018; pp. 3.5.1–3.5.4. [Google Scholar]

- Zhang, P.W.; Yokoyama, T.; Itabashi, O.; Suzuki, T.M.; Inoue, K. Hydrometallurgical process for recovery of metal values from spent lithium-ion secondary batteries. Hydrometallurgy 1998, 47, 259–271. [Google Scholar] [CrossRef]

- Wang, R.; Lin, Y.; Wu, S. A novel recovery process of metal values from the cathode active materials of the lithium-ion secondary batteries. Hydrometallurgy 2009, 99, 194–201. [Google Scholar] [CrossRef]

- Cheng, J.; Lu, T.; Huang, S.; Li, G.; Wang, J.; Kong, F.; Cheng, Q.; Zhang, Y. Recovery of cobalt from spent lithium-ion batteries as the dopant of TiO2 photocatalysts for boosting ciprofloxacin degradation. J. Clean. Prod. 2021, 316, 128279. [Google Scholar] [CrossRef]

- Jiang, F.; Chen, Y.; Ju, S.; Zhu, Q.; Zhang, L.; Peng, J.; Wang, X.; Miller, J.D. Ultrasound-assisted leaching of cobalt and lithium from spent lithium-ion batteries. Ultrason. Sonochem. 2018, 48, 88–95. [Google Scholar] [CrossRef]

- Castillo, S.; Ansart, F.; Laberty-Robert, C.; Portal, J. Advances in the recovering of spent lithium battery compounds. J. Power Sources 2002, 112, 247–254. [Google Scholar] [CrossRef]

- Lee, C.K.; Rhee, K.I. Preparation of LiCoO2 from spent lithium-ion batteries. J. Power Sources 2002, 109, 17–21. [Google Scholar] [CrossRef]

- Lee, C.K.; Rhee, K.I. Reductive leaching of cathodic active materials from lithium ion battery wastes. Hydrometallurgy 2003, 68, 5–10. [Google Scholar] [CrossRef]

- Meng, Q.; Zhang, Y.; Dong, P. Use of glucose as reductant to recover Co from spent lithium ions batteries. Waste Manag. 2017, 64, 214–218. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Meng, Q.; Dong, P.; Duan, J.; Lin, Y. Use of grape seed as reductant for leaching of cobalt from spent lithium-ion batteries. J. Ind. Eng. Chem. 2018, 66, 86–93. [Google Scholar] [CrossRef]

- Zeba, G.T.C.; Paulino, J.F.; Afonso, J.C. Recovery of metals from electroactive components of spent Li-ion batteries after leaching with formic acid. Braz. J. Chem. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Lie, J.; Liu, J. Closed-vessel microwave leaching of valuable metals from spent lithium-ion batteries (LIBs) using dual-function leaching agent: Ascorbic acid. Sep. Purif. Technol. 2021, 266, 118458. [Google Scholar] [CrossRef]

- Esmaeili, M.; Rastegar, S.O.; Beigzadeh, R.; Gu, T. Ultrasound-assisted leaching of spent lithium ion batteries by natural organic acids and H2O2. Chemosphere 2020, 254, 126670. [Google Scholar] [CrossRef] [PubMed]

- Pindar, S.; Dhawan, N. Microwave processing of spent coin cells for recycling of metallic values. J. Clean. Prod. 2021, 280, 124144. [Google Scholar] [CrossRef]

- Tao, H.; Yang, Y.; Xu, S.; Liu, Q.; Huang, G.; Xu, Z. A lattice defect-inspired leaching strategy toward simultaneous recovery and separation of value metals from spent cathode materials. Waste Manag. 2021, 135, 40–46. [Google Scholar] [CrossRef]

- Liu, Y.; Lv, W.; Zheng, X.; Ruan, D.; Yang, Y.; Cao, H.; Sun, Z. Near-to-Stoichiometric Acidic Recovery of Spent Lithium-Ion Batteries through Induced Crystallization. ACS Sustain. Chem. Eng. 2021, 9, 3183–3194. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, X.; Yan, S.; Li, S.; Zhou, T. Pursuing green and efficient process towards recycling of different metals from spent lithium-ion batteries through Ferro-chemistry. Chem. Eng. J. 2021, 426, 131637. [Google Scholar] [CrossRef]

- Chan, K.H.; Anawati, J.; Malik, M.; Azimi, G. Closed-Loop Recycling of Lithium, Cobalt, Nickel, and Manganese from Waste Lithium-Ion Batteries of Electric Vehicles. ACS Sustain. Chem. Eng. 2021, 9, 4398–4410. [Google Scholar] [CrossRef]

- Xing, L.; Bao, J.; Zhou, S.; Qiu, Y.; Sun, H.; Gu, S.; Yu, J. Ultra-fast leaching of critical metals from spent lithium-ion batteries cathode materials achieved by the synergy-coordination mechanism. Chem. Eng. J. 2021, 420, 129593. [Google Scholar] [CrossRef]

- Yan, S.; Sun, C.; Zhou, T.; Gao, R.; Xie, H. Ultrasonic-assisted leaching of valuable metals from spent lithium-ion batteries using organic additives. Sep. Purif. Technol. 2021, 257, 117930. [Google Scholar] [CrossRef]

- Nayaka, G.P.; Pai, K.V.; Manjanna, J.; Keny, S.J. Use of mild organic acid reagents to recover the Co and Li from spent Li-ion batteries. Waste Manag. 2016, 51, 234–238. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Zhang, F. Innovative leaching of cobalt and lithium from spent lithium-ion batteries and simultaneous dechlorination of polyvinyl chloride in subcritical water. J. Hazard. Mater. 2016, 316, 19–25. [Google Scholar] [CrossRef] [PubMed]

- Nshizirungu, T.; Agarwal, A.; Jo, Y.T.; Rana, M.; Shin, D.; Park, J. Chlorinated polyvinyl chloride (CPVC) assisted leaching of lithium and cobalt from spent lithium-ion battery in subcritical water. J. Hazard. Mater. 2020, 393, 122367. [Google Scholar] [CrossRef]

- Nshizirungu, T.; Rana, M.; Jo, Y.T.; Park, J. Recycling of NCM cathode material from spent lithium-ion batteries via polyvinyl chloride and chlorinated polyvinyl chloride in subcritical water: A comparative study. J. Hazard. Mater. 2021, 414, 124575. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Huang, K.; Xiong, H.; Dong, H. Ammoniacal leaching process for the selective recovery of value metals from waste lithium-ion batteries. Environ. Technol. 2021, 1–15. [Google Scholar] [CrossRef]

- Li, D.; Zhang, B.; Ou, X.; Zhang, J.; Meng, K.; Ji, G.; Li, P.; Xu, J. Ammonia leaching mechanism and kinetics of LiCoO2 material from spent lithium-ion batteries. Chin. Chem. Lett. 2021, 32, 2333–2337. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, N.; Hu, F.; Ye, L.; Xi, Y.; Yang, S. Thermal treatment and ammoniacal leaching for the recovery of valuable metals from spent lithium-ion batteries. Waste Manag. 2018, 75, 469–476. [Google Scholar] [CrossRef] [PubMed]

- Keller, A.; Hlawitschka, M.W.; Bart, H.J. Manganese recycling of spent lithium-ion batteries via solvent extraction. Sep. Purif. Technol. 2021, 275, 119166. [Google Scholar] [CrossRef]

- Vakylabad, A.B.; Darezereshki, E.; Hassanzadeh, A. Selective Recovery of Cobalt and Fabrication of Nano-Co3S4 from Pregnant Leach Solution of Spent Lithium-Ion Batteries. J. Sustain. Metall. 2021, 7, 1027–1044. [Google Scholar] [CrossRef]

- Choubey, P.K.; Dinkar, O.S.; Panda, R.; Kumari, A.; Jha, M.K.; Pathak, D.D. Selective extraction and separation of Li, Co and Mn from leach liquor of discarded lithium ion batteries (LIBs). Waste Manag. 2021, 121, 452–457. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Chen, J.; Li, H.; Li, K. An integrated process for the separation and recovery of valuable metals from the spent LiNi0.5Co0.2Mn0.3O2 cathode materials. Sep. Purif. Technol. 2020, 245, 116869. [Google Scholar] [CrossRef]

- Viet, N.H.N.; Lee, M.S. Improvement of metal separation process from synthetic hydrochloric acid leaching solution of spent lithium ion batteries by solvent extraction and ion exchange. Physicochem. Probl. Miner. Process. 2021, 57, 1–17. [Google Scholar]

- Wu, H.; Ting, Y. Metal extraction from municipal solid waste (MSW) incinerator fly ash—Chemical leaching and fungal bioleaching. Enzym. Microb. Tech. 2006, 38, 839–847. [Google Scholar] [CrossRef]

- Bahaloo-Horeh, N.; Mousavi, S.M.; Baniasadi, M. Use of adapted metal tolerant Aspergillus niger to enhance bioleaching efficiency of valuable metals from spent lithium-ion mobile phone batteries. J. Clean. Prod. 2018, 197, 1546–1557. [Google Scholar] [CrossRef]

- Mishra, D.; Kim, D.; Ralph, D.E.; Ahn, J.; Rhee, Y. Bioleaching of metals from spent lithium ion secondary batteries using Acidithiobacillus ferrooxidans. Waste Manag. 2008, 28, 333–338. [Google Scholar] [CrossRef]

- Zeng, G.; Deng, X.; Luo, S.; Luo, X.; Zou, J. A copper-catalyzed bioleaching process for enhancement of cobalt dissolution from spent lithium-ion batteries. J. Hazard. Mater. 2012, 199, 164–169. [Google Scholar] [CrossRef]

- Roy, J.J.; Madhavi, S.; Cao, B. Metal extraction from spent lithium-ion batteries (LIBs) at high pulp density by environmentally friendly bioleaching process. J. Clean. Prod. 2021, 280, 124242. [Google Scholar] [CrossRef]

- Sadeghabad, M.S.; Bahaloo-Horeh, N.; Mousavi, S.M. Using bacterial culture supernatant for extraction of manganese and zinc from waste alkaline button-cell batteries. Hydrometallurgy 2019, 188, 81–91. [Google Scholar] [CrossRef]

- Cai, X.; Tian, L.; Chen, C.; Huang, W.; Yu, Y.; Liu, C.; Yang, B.; Lu, X.; Mao, Y. Phylogenetically divergent bacteria consortium from neutral activated sludge showed heightened potential on bioleaching spent lithium-ion batteries. Ecotoxicol. Environ. Saf. 2021, 223, 112592. [Google Scholar] [CrossRef] [PubMed]

- Heydarian, A.; Mousavi, S.M.; Vakilchap, F.; Baniasadi, M. Application of a mixed culture of adapted acidophilic bacteria in two-step bioleaching of spent lithium-ion laptop batteries. J. Power Sources 2018, 378, 19–30. [Google Scholar] [CrossRef]

- Dolker, T.; Pant, D. Chemical-biological hybrid systems for the metal recovery from waste lithium ion battery. J. Environ. Manag. 2019, 248, 109270. [Google Scholar] [CrossRef] [PubMed]

- Xin, Y.; Guo, X.; Chen, S.; Wang, J.; Wu, F.; Xin, B. Bioleaching of valuable metals Li, Co, Ni and Mn from spent electric vehicle Li-ion batteries for the purpose of recovery. J. Clean. Prod. 2016, 116, 249–258. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, W.; Li, G.; Zhu, H.; Huang, J.; He, W. Ultrasonic renovating and coating modifying spent lithium cobalt oxide from the cathode for the recovery and sustainable utilization of lithium-ion battery. J. Clean. Prod. 2020, 257, 120510. [Google Scholar] [CrossRef]

- Peng, D.; Zhang, J.; Zou, J.; Ji, G.; Ye, L.; Li, D.; Zhang, B.; Ou, X. Closed-loop regeneration of LiFePO4 from spent lithium-ion batteries: A “feed three birds with one scone” strategy toward advanced cathode materials. J. Clean. Prod. 2021, 316, 128098. [Google Scholar] [CrossRef]

- Ribeiro, J.S.; Freitas, M.B.J.G.; Freitas, J.C.C. Recycling of graphite and metals from spent Li-ion batteries aiming the production of graphene/CoO-based electrochemical sensors. J. Environ. Chem. Eng. 2021, 9, 104689. [Google Scholar] [CrossRef]

- Fan, X.; Tan, C.; Li, Y.; Chen, Z.; Li, Y.; Huang, Y.; Pan, Q.; Zheng, F.; Wang, H.; Li, Q. A green, efficient, closed-loop direct regeneration technology for reconstructing of the LiNi0.5Co0.2Mn0.3O2 cathode material from spent lithium-ion batteries. J. Hazard. Mater. 2021, 410, 124610. [Google Scholar] [CrossRef]

- Xing, L.; Lin, S.; Yu, J. Novel Recycling Approach to Regenerate a LiNi0.6Co0.2Mn0.2O2 Cathode Material from Spent Lithium-Ion Batteries. Ind. Eng. Chem. Res. 2021, 60, 10303–10311. [Google Scholar] [CrossRef]

- Chu, W.; Zhang, Y.; Chen, X.; Huang, Y.; Cui, H.; Wang, M.; Wang, J. Synthesis of LiNi0.6Co0.2Mn0.2O2 from mixed cathode materials of spent lithium-ion batteries. J. Power Sources 2020, 449, 227567. [Google Scholar] [CrossRef]

- Fan, M.; Chang, X.; Guo, Y.; Chen, W.; Yin, Y.; Yang, X.; Meng, Q.; Wan, L.; Guo, Y. Increased residual lithium compounds guided design for green recycling of spent lithium-ion cathodes. Energy Environ. Sci. 2021, 14, 1461–1468. [Google Scholar] [CrossRef]

- Sa, Q.; Gratz, E.; He, M.; Lu, W.; Apelian, D.; Wang, Y. Synthesis of high performance LiNi1/3Mn1/3Co1/3O2 from lithium ion battery recovery stream. J. Power Sources 2015, 282, 140–145. [Google Scholar] [CrossRef]

- Ma, X.; Chen, M.; Zheng, Z.; Bullen, D.; Wang, J.; Harrison, C.; Gratz, E.; Lin, Y.; Yang, Z.; Zhang, Y.; et al. Recycled cathode materials enabled superior performance for lithium-ion batteries. Joule 2021, 5, 2955–2970. [Google Scholar] [CrossRef]

- Ji, G.; Ou, X.; Zhao, R.; Zhang, J.; Zou, J.; Li, P.; Peng, D.; Ye, L.; Zhang, B.; He, D. Efficient utilization of scrapped LiFePO4 battery for novel synthesis of Fe2P2O7/C as candidate anode materials. Resour. Conserv. Recycl. 2021, 174, 105802. [Google Scholar] [CrossRef]

- Schiavi, P.G.; Altimari, P.; Zanoni, R.; Pagnanelli, F. Full recycling of spent lithium ion batteries with production of core-shell nanowires//exfoliated graphite asymmetric supercapacitor. J. Energy Chem. 2021, 58, 336–344. [Google Scholar] [CrossRef]

- Zou, W.; Feng, X.; Wang, R.; Wei, W.; Luo, S.; Zheng, R.; Yang, D.; Mi, H.; Chen, H. High-efficiency core-shell magnetic heavy-metal absorbents derived from spent-LiFePO4 Battery. J. Hazard. Mater. 2021, 402, 123583. [Google Scholar] [CrossRef]

- Suarez, D.S.; Pinna, E.G.; Rosales, G.D.; Rodriguez, M.H. Synthesis of Lithium Fluoride from Spent Lithium Ion Batteries. Minerals 2017, 7, 81. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Hu, J.; Liu, Y.; Jing, Q.; Yang, C.; Chen, Y.; Wang, C. Sustainable and Facile Method for the Selective Recovery of Lithium from Cathode Scrap of Spent LiFePO4 Batteries. ACS Sustain. Chem. Eng. 2019, 7, 5626–5631. [Google Scholar] [CrossRef]

- Chu, W.; Zhang, Y.; Chen, L.; Wu, K.; Huang, Y.; Jia, Y. Comprehensive recycling of Al foil and active materials from the spent lithium-ion battery. Sep. Purif. Technol. 2021, 269, 118704. [Google Scholar] [CrossRef]

- Meng, Q.; Zhang, Y.; Dong, P. Use of electrochemical cathode-reduction method for leaching of cobalt from spent lithium-ion batteries. J. Clean. Prod. 2018, 180, 64–70. [Google Scholar] [CrossRef]

- Lv, W.; Ruan, D.; Zheng, X.; Li, L.; Cao, H.; Wang, Z.; Zhang, Y.; Sun, Z. One-step recovery of valuable metals from spent Lithium-ion batteries and synthesis of persulfate through paired electrolysis. Chem. Eng. J. 2021, 421, 129908. [Google Scholar] [CrossRef]

- Li, J.; He, Y.; Fu, Y.; Xie, W.; Feng, Y.; Alejandro, K. Hydrometallurgical enhanced liberation and recovery of anode material from spent lithium-ion batteries. Waste Manag. 2021, 126, 517–526. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Huang, Z.; Song, Q.; Tang, Y.; Qiu, R.; Ruan, J. Recovery nano-flake (100 nm thickness) of zero-valent manganese from spent lithium-ion batteries. J. Clean. Prod. 2021, 278, 123867. [Google Scholar] [CrossRef]

| Methodology | Advantage | Disadvantage |

|---|---|---|

| Pyrometallurgy |

|

|

| Hydrometallurgy |

|

|

| Biohydrometallurgy |

|

|

| Active Ingredients | Recycling and Disposal Methods | Parameter Conditions | Leach Efficiency (%) | Ref. | |||

|---|---|---|---|---|---|---|---|

| Li | Co | Mn | Ni | ||||

| LCO | pyrometallurgy | LCO to H2SO4 ratio 2:1, 20% carbon content, heating temperature of 873 K, holding time 120 min | 92 | 100 | [28] | ||

| NCM | pyrometallurgy | NCM mixed with NH4Cl in a ratio of 1:3, roast at 623 K for 20 min | 100 | 100 | 100 | [29] | |

| LCO | pyrometallurgy | LCO to urea ratio of 1:2, temperature 823 K, holding time 20 min | 99.9 | [30] | |||

| LCO LMO LNO | pyrometallurgy, ultrasound assist | heating temperature of 873 K, holding time 30 min, 4 mol/L H2SO4 leaching | 99 | 99 | 99 | 99 | [31] |

| NCM | pyrometallurgy | 1:1 mix of cathode and anode materials, heating temperature of 573 K, holding time 10 min | 99.2 | 97.9 | [32] | ||

| LCO | thermal disengagement, thermal transformation | 5:1 mix of cathode and anode materials, heating temperature of 1673 K, holding time 20 min | 96 | [33] | |||

| NCM | 19:1 mix of cathode and anode materials, heating temperature of 923 K, holding time 60 min | 82.2 | 99.1 | 97.1 | [34] | ||

| LCO | vacuum pyrolysis | heating temperature of 973 K, holding time 30 min | 99 | 99 | [35] | ||

| Leaching Treatment | Auxiliary Means | Leach Temp | Leach Efficiency (%) | Reference | |||

|---|---|---|---|---|---|---|---|

| Inorganic Leaching Agent | Reducing Agent | Li | Co | Mn | |||

| 4 mol/L HCl | 80 °C | 99 | 99 | [37] | |||

| 4 mol/L HCl | 80 °C | 99 | 99 | 99 | [38] | ||

| 2 mol/L H2SO4 | 76 | 76 | [35] | ||||

| 2 mol/L H2SO4 | H2O2 | 80 °C | 99 | 99 | [35] | ||

| 2 mol/L H2SO4 | H2O2 | 99.9 | [39] | ||||

| 4 mol/L H2SO4 | H2O2 | 70 °C | 99 | 99 | 100 | [23] | |

| 2 mol/L H2SO4 | H2O2 | ultrasound | 30 °C | 98.6 | 94.6 | [40] | |

| 1 mol/L HNO3 | 75 °C | 75 | 40 | [41] | |||

| 1 mol/L HNO3 | 75 °C | 75 | 40 | [42] | |||

| 1 mol/L HNO3 | H2O2 | 75 °C | 95 | 95 | [43] | ||

| 1.5 mol/L H3PO4 | C6H12O6 | 80 °C | 98 | 100 | [44] | ||

| 1.5 mol/L malic acid | grape seed | 80 °C | 99 | 92 | [45] | ||

| 10 mol/L HCOOH | H2O2 | 80 °C | 99.5 | [46] | |||

| 0.5 mol/L ascorbic acid | microwave | 125 °C | 100 | 100 | 100 | [47] | |

| 57.8% (v/v) lemon juice | H2O2 | ultrasound | 40 °C | 100 | 96 | 96 | [48] |

| citric acid | microwave | 94 | [49] | ||||

| H2C2O4-H3PO4 | 100 | 98.2 | 100 | [50] | |||

| H2SO4-FePO4·2H2O | 80 °C | 96 | 96 | 96 | [51] | ||

| 0.5 mol/L HCl-0.5 mol/L ascorbic acid | 90 °C | 97.72 | 97.25 | [52] | |||

| 0.5 mol/L CH3COOH-0.2 mol/L ascorbic acid | bagasse pith | ultrasound | 50 °C | 98 | 98 | 98 | [53] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, X.; Zhu, W.; Ruan, Z.; Xie, M.; Chen, J.; Ren, X. Recycling of Lithium Batteries—A Review. Energies 2022, 15, 1611. https://doi.org/10.3390/en15051611

Duan X, Zhu W, Ruan Z, Xie M, Chen J, Ren X. Recycling of Lithium Batteries—A Review. Energies. 2022; 15(5):1611. https://doi.org/10.3390/en15051611

Chicago/Turabian StyleDuan, Xiaowei, Wenkun Zhu, Zhongkui Ruan, Min Xie, Juan Chen, and Xiaohan Ren. 2022. "Recycling of Lithium Batteries—A Review" Energies 15, no. 5: 1611. https://doi.org/10.3390/en15051611

APA StyleDuan, X., Zhu, W., Ruan, Z., Xie, M., Chen, J., & Ren, X. (2022). Recycling of Lithium Batteries—A Review. Energies, 15(5), 1611. https://doi.org/10.3390/en15051611