Long-Horizon Nonlinear Model Predictive Control of Modular Multilevel Converters

Abstract

:1. Introduction

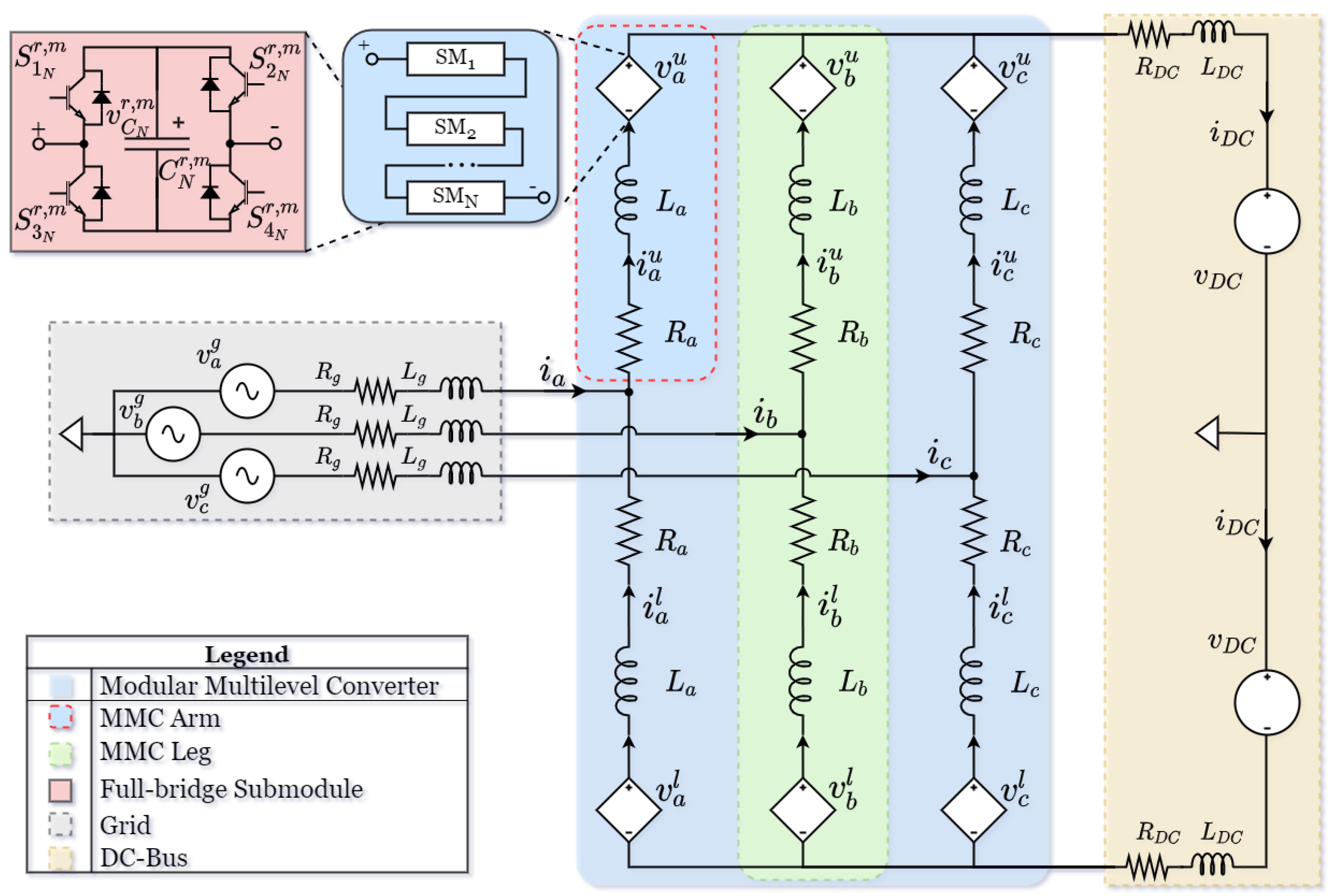

2. Modular Multilevel Converter Topology and Modeling

2.1. MMC Topology for Utra-Fast Charging Stations

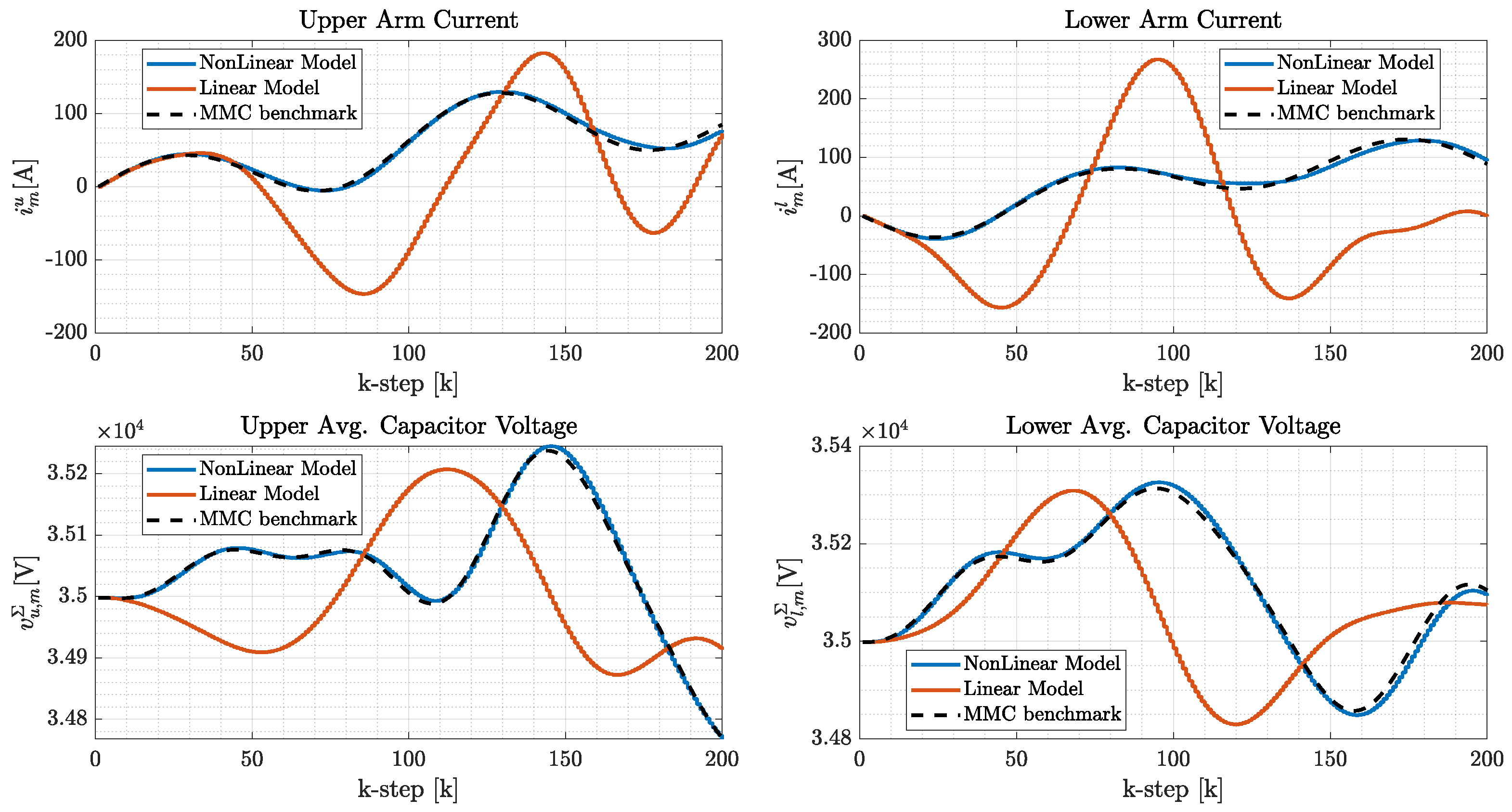

2.2. MMC Modeling for Predictive Control

3. MMC Control Problem Formulation

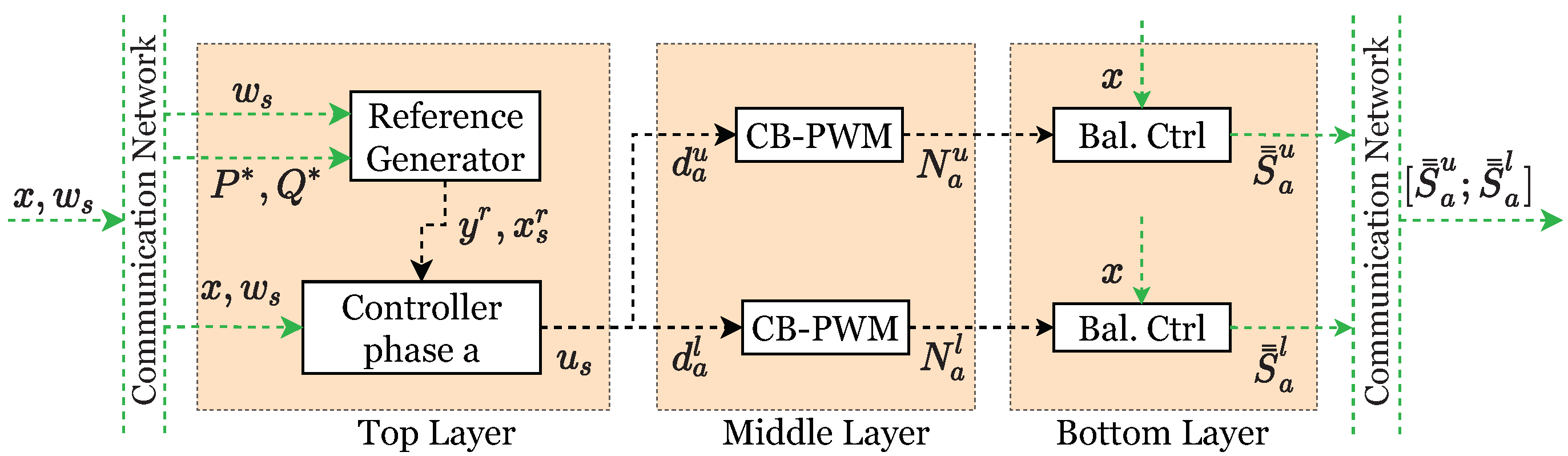

3.1. Standard Control Scheme for MMCs

3.2. Control Objectives

4. Nonlinear Model Predictive Control Design and Implementation

Cost Function and Optimization Problem

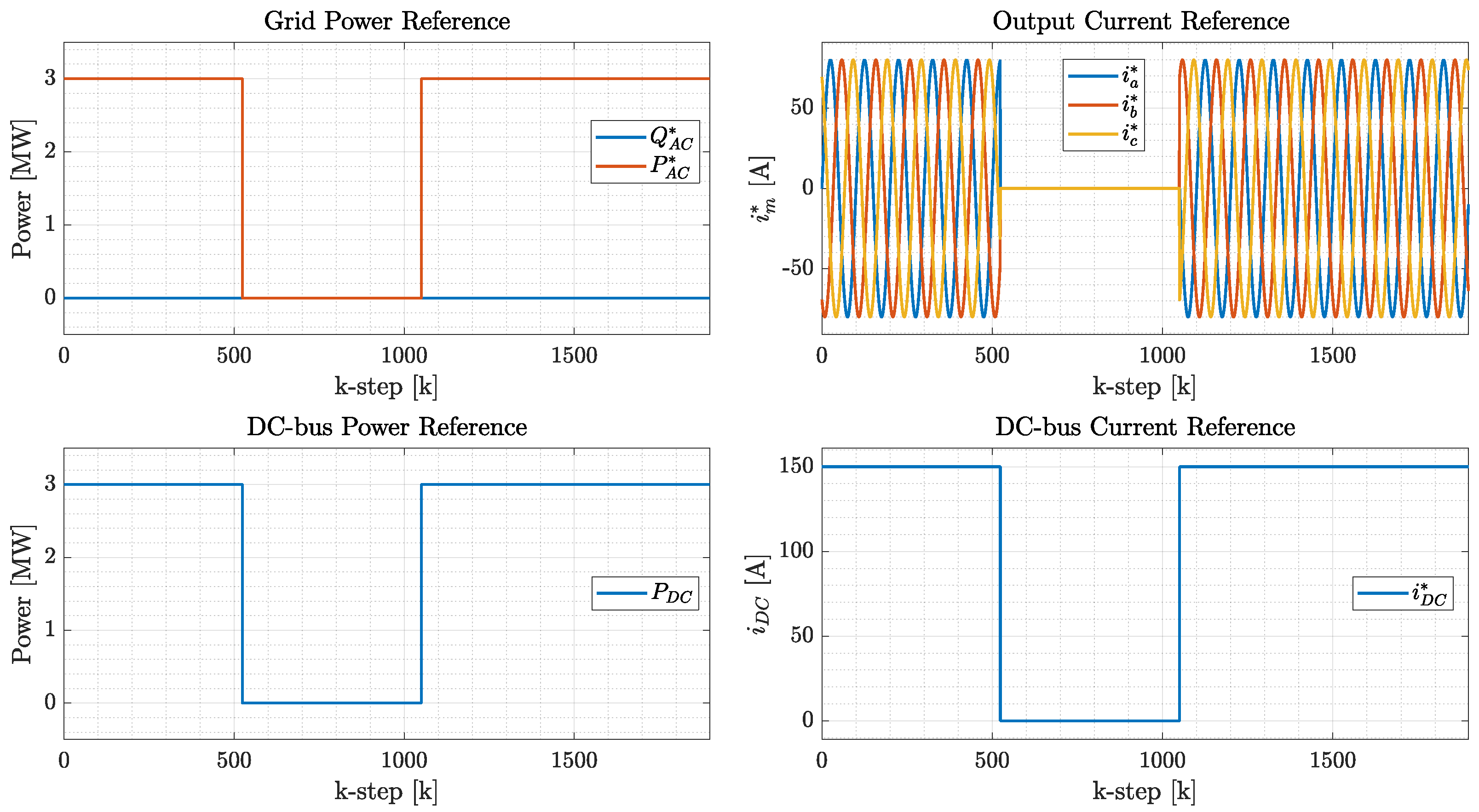

5. Case Study: Control of Modular Multilevel Converters for Ultra-Fast Charging Stations of Electric Vehicles

5.1. Ultra-Fast EV Charging Stations Topology

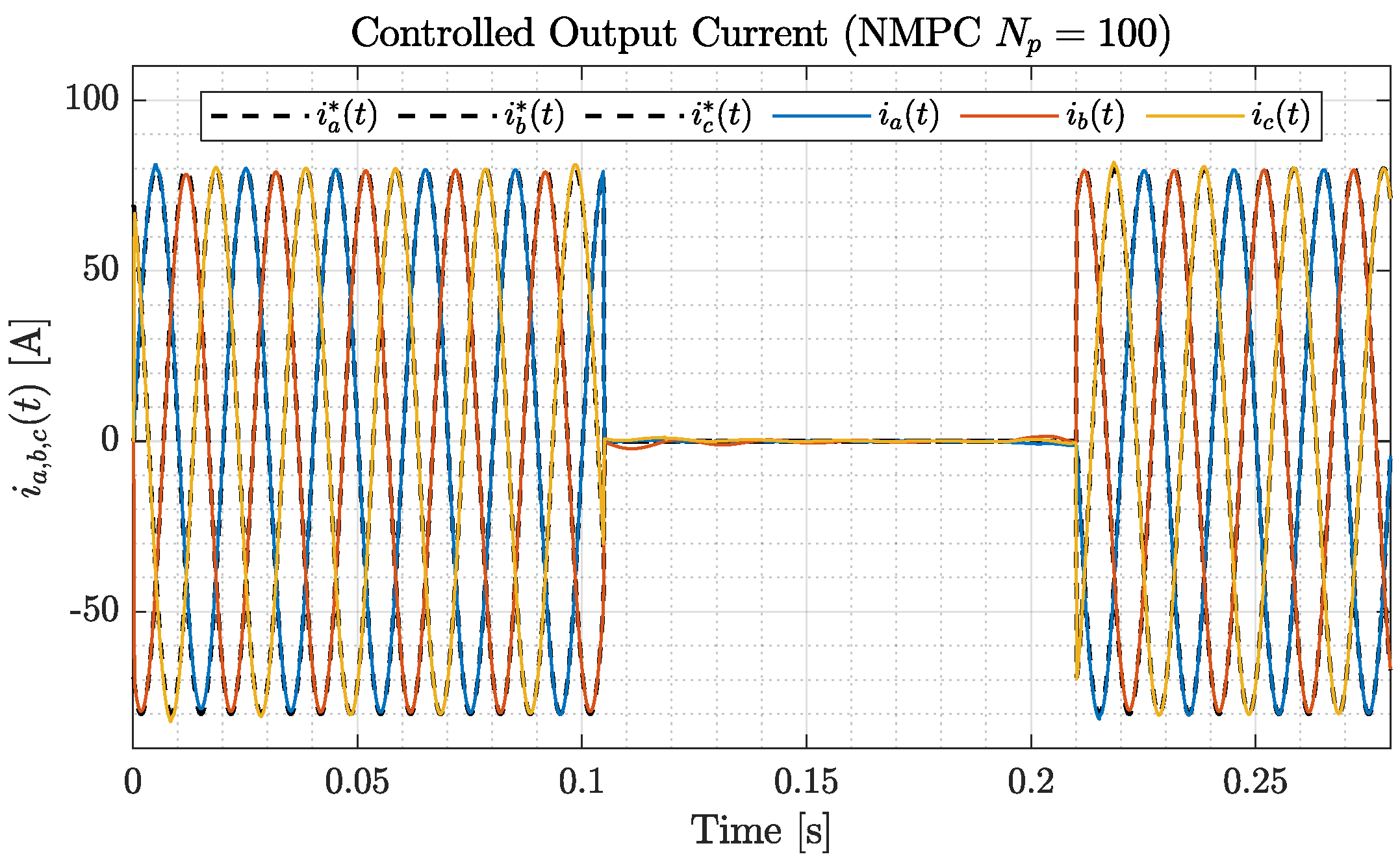

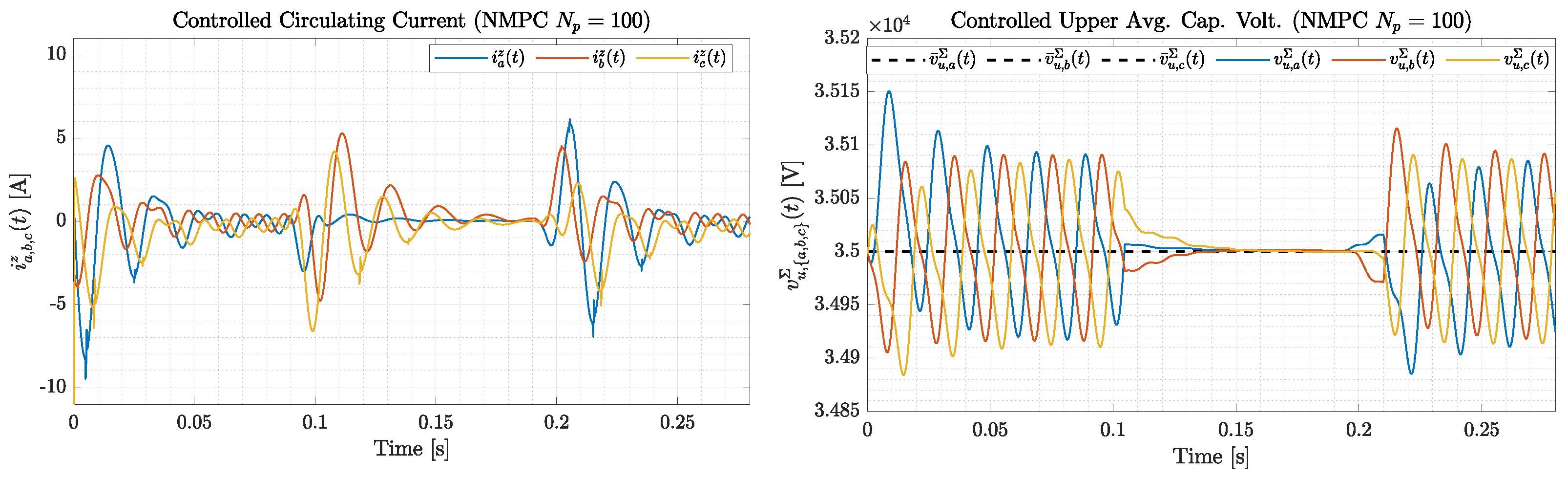

5.2. Results for NMPC with

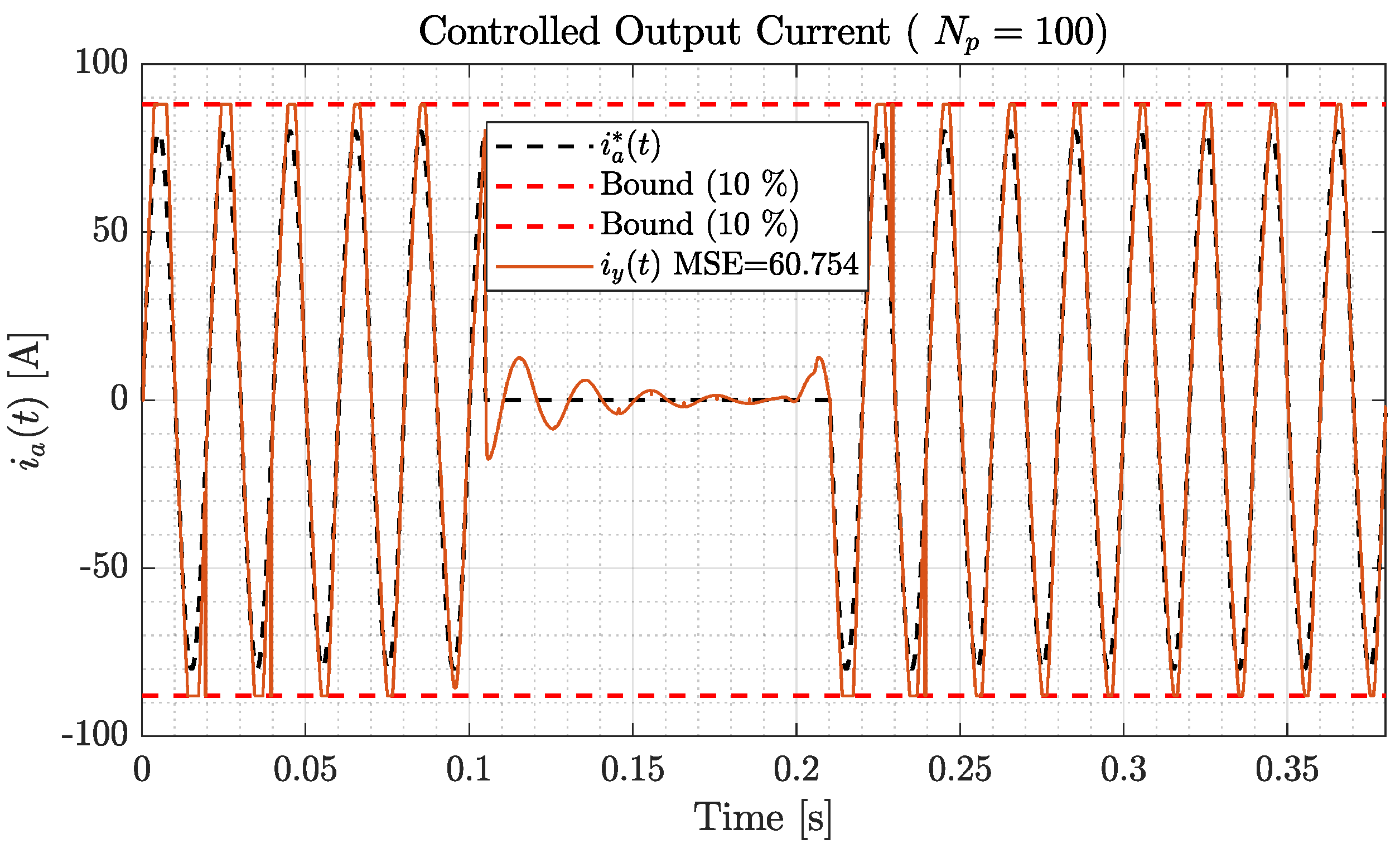

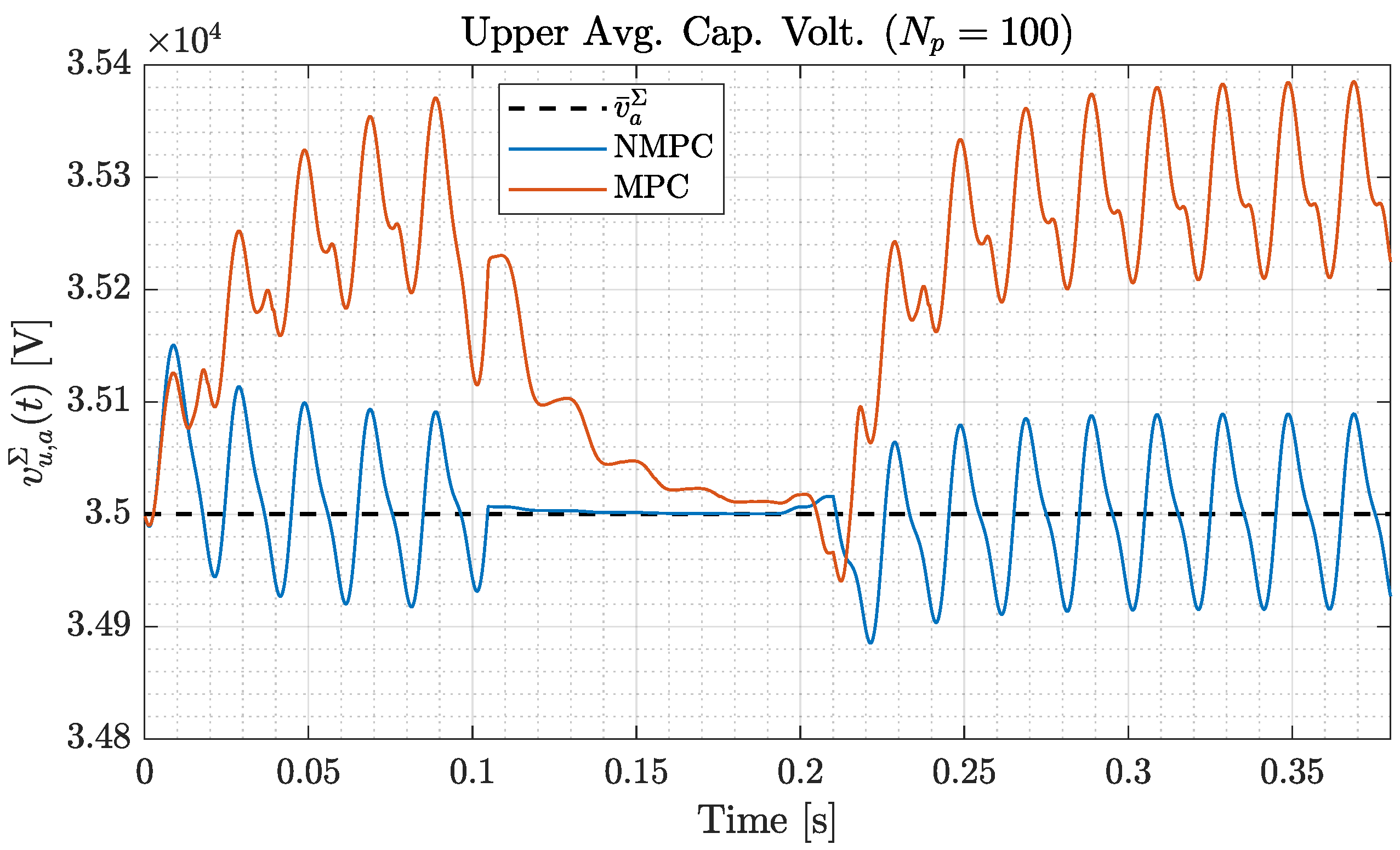

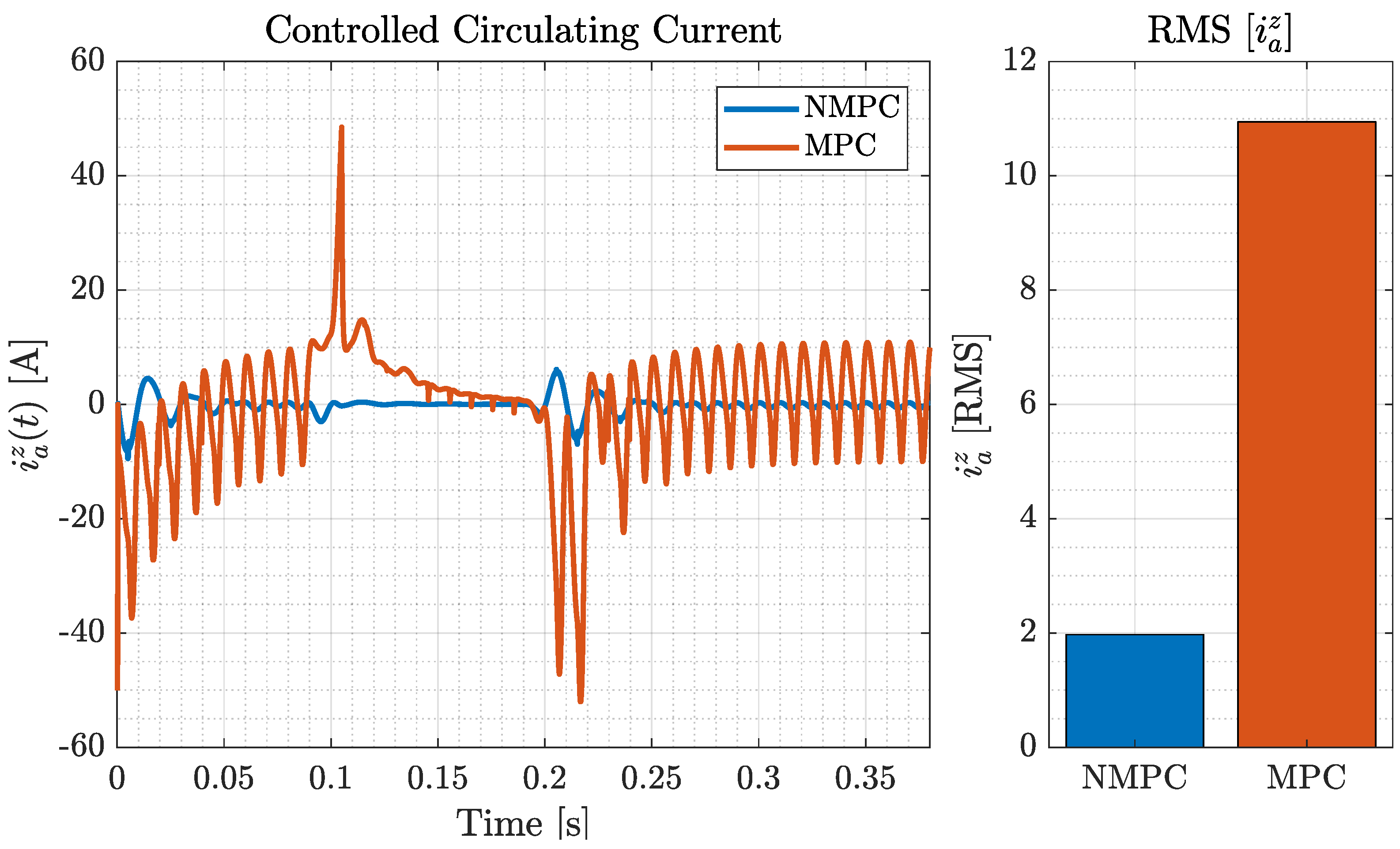

5.3. NMPC vs. Linearization-Based MPC Comparison for

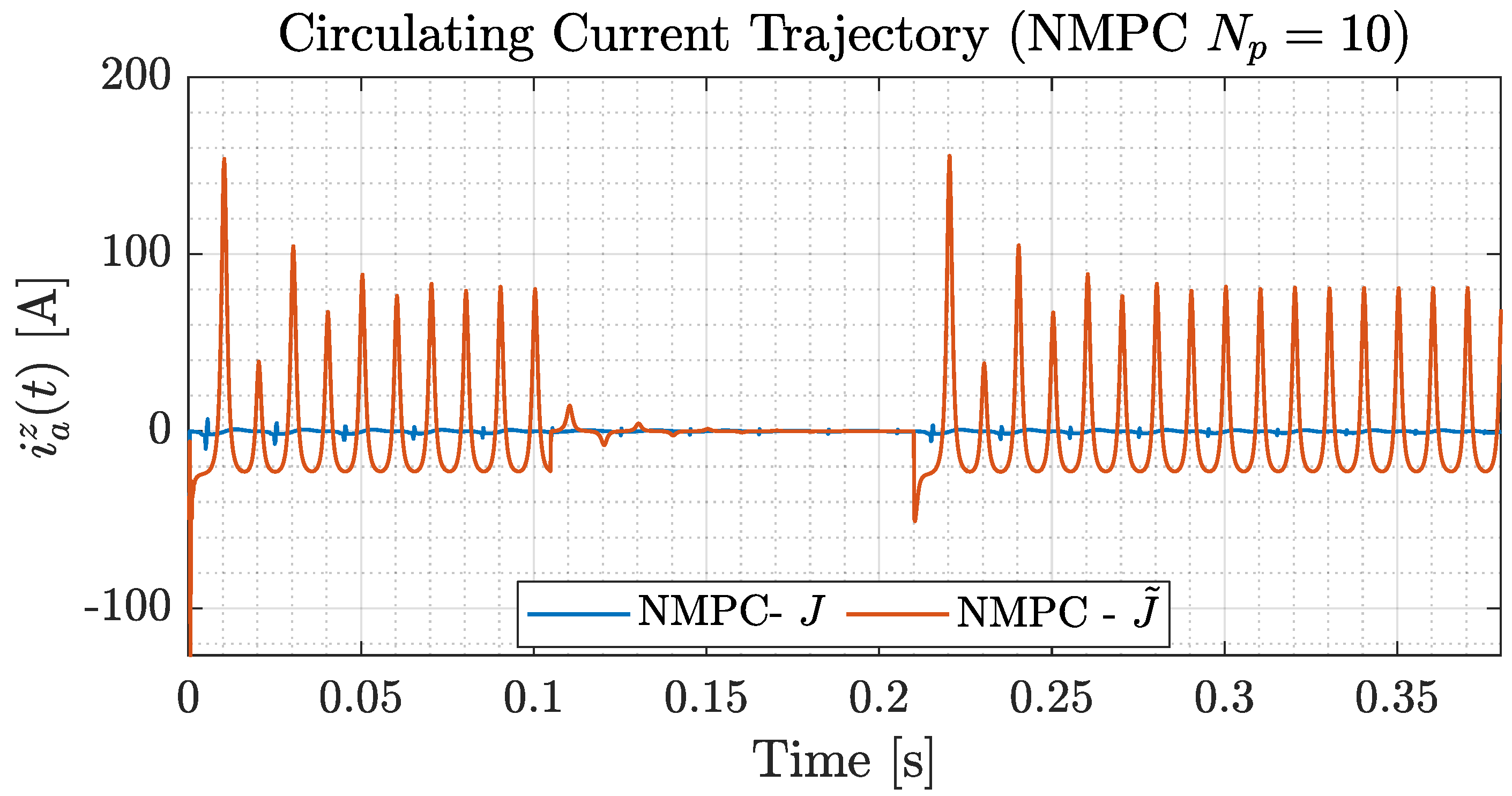

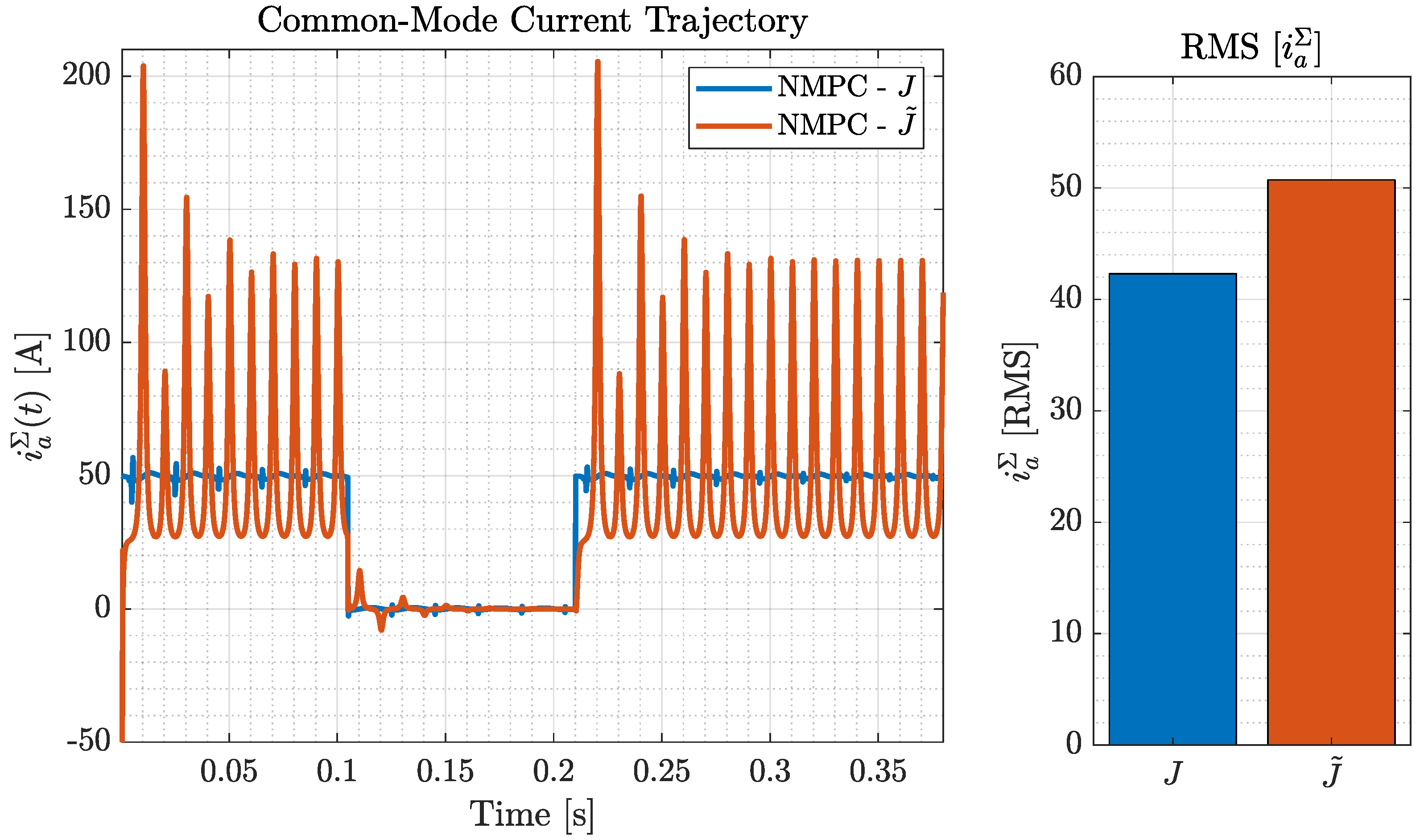

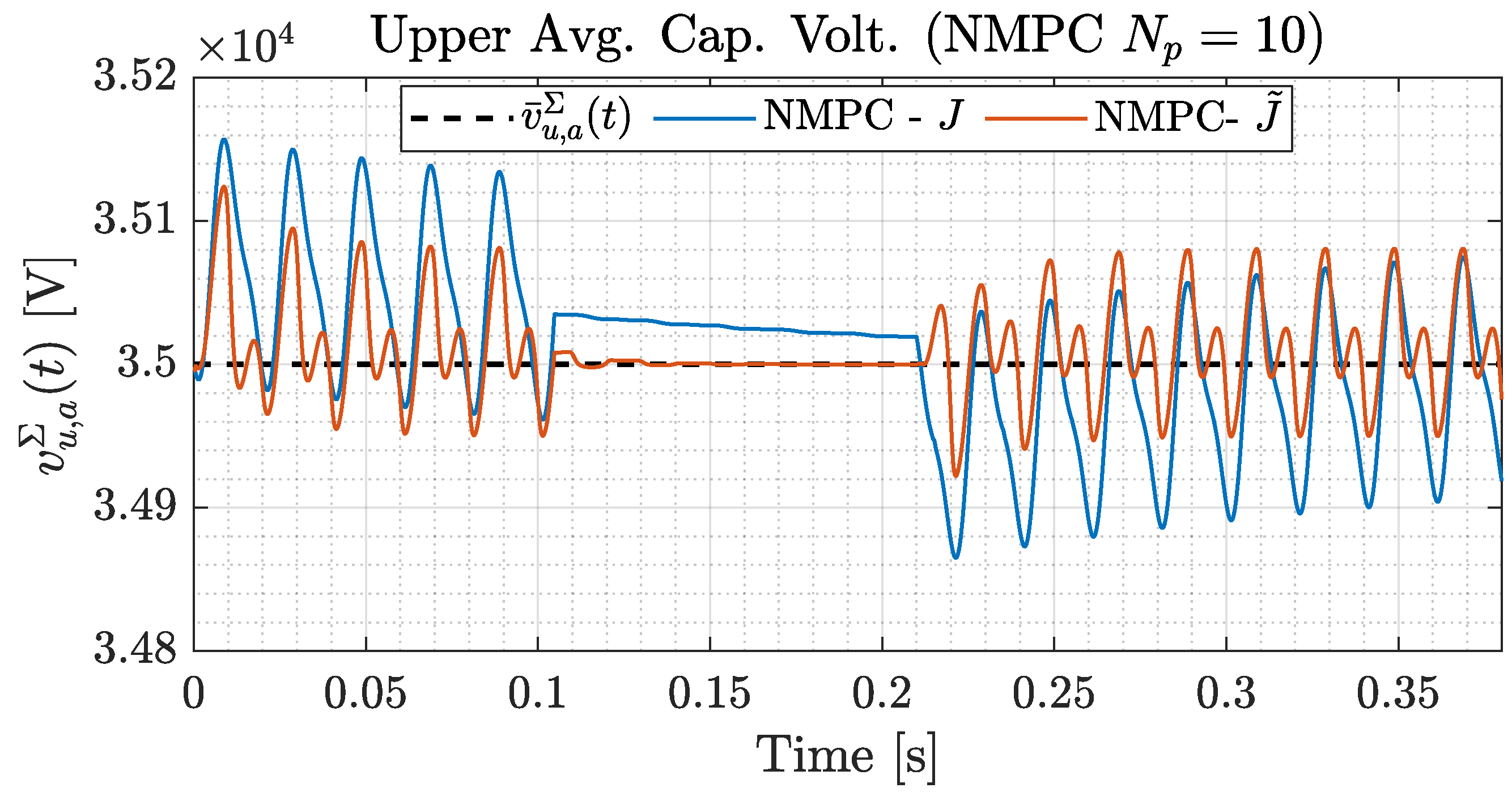

5.4. Evaluation of the NMPC Cost Function

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Lesnicar, A.; Marquardt, R. An innovative modular multilevel converter topology suitable for a wide power range. In Proceedings of the 2003 IEEE Bologna Power Tech Conference Proceedings, Bologna, Italy, 23–26 June 2003; pp. 272–277. [Google Scholar]

- Darivianakis, G.; Geyer, T.; van der Merwe, W. Model predictive current control of modular multilevel converters. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 5016–5023. [Google Scholar]

- Priya, M.; Ponnambalam, P.; Muralikumar, K. Modular-multilevel converter topologies and applications—A review. IET Power Electron. 2019, 12, 170–183. [Google Scholar] [CrossRef]

- Ye, H.; Cao, W.; Chen, W.; Wu, H.; He, G.; Li, G.; Xi, Y.; Liu, Q. An AC Fault Ride Through Method for MMC-HVDC System in Offshore Applications Including DC Current-Limiting Inductors. IEEE Trans. Power Deliv. 2021. [Google Scholar] [CrossRef]

- Martinez-Rodrigo, F.; Ramirez, D.; Rey-Boue, A.; De Pablo, S.; Herrero-de Lucas, L. Modular Multilevel Converters: Control and Applications. Energies 2017, 10, 1709. [Google Scholar] [CrossRef] [Green Version]

- Marca, Y.P.; Roes, M.G.; Duarte, J.L.; Wijnands, K.G. Isolated MMC-based ac/ac stage for ultrafast chargers. In Proceedings of the 2021 IEEE 30th International Symposium on Industrial Electronics (ISIE), Kyoto, Japan, 20–23 June 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Pereira Marca, Y.; Duarte, J.; Roes, M.; Wijnands, C. Extended operating region of modular multilevel converters using full-bridge sub-modules. In Proceedings of the 23rd European Conference on Power Electronics and Application (EPE2021), Ghent, Belgium, 6–10 September 2021. [Google Scholar]

- Lopez, A.; Quevedo, D.E.; Aguilera, R.; Geyer, T.; Oikonomou, N. Reference design for predictive control of modular multilevel converters. In Proceedings of the 2014 4th Australian Control Conference (AUCC), Canberra, ACT, Australia, 17–18 November 2014; pp. 239–244. [Google Scholar] [CrossRef]

- Du, S.; Dekka, A.; Wu, B.; Zargari, N. Modular Multilevel Converter: Analysis, Control and Applications; Wiley: Hoboken, NJ, USA, 2018; p. 368. [Google Scholar]

- Sharifabadi, K.; Harnefors, L.; Nee, H.P.; Norrga, S.; Teodorescu, R. Design, Control and Application of Modular Multilevel Converters for HVDC Transmission Systems, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016. [Google Scholar]

- Böcker, J.; Freudenberg, B.; The, A.; Dieckerhoff, S. Experimental comparison of model predictive control and cascaded control of the modular multilevel converter. IEEE Trans. Power Electron. 2015, 30, 422–430. [Google Scholar] [CrossRef]

- Zhang, D.; Xue, H.; Chen, A.; Liu, T. Model-Predictive-Control-Based Circulating Current Reduction and Energy Balance for Modular Multilevel Converter Under Asymmetric Arm Impedance Conditions. In Proceedings of the 2020 IEEE 9th International Power Electronics and Motion Control Conference (IPEMC2020-ECCE Asia), Nanjing, China, 29 November–2 December 2020; pp. 704–709. [Google Scholar] [CrossRef]

- Majstorovic, M.; Rivera, M.; Ristic, L.; Wheeler, P. Comparative Study of Classical and MPC Control for Single-Phase MMC Based on V-HIL Simulations. Energies 2021, 14, 3230. [Google Scholar] [CrossRef]

- Dekka, A.; Wu, B.; Yaramasu, V.; Fuentes, R.L.; Zargari, N.R. Model Predictive Control of High-Power Modular Multilevel Converters—An Overview. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 168–183. [Google Scholar] [CrossRef]

- Yin, J.; Leon, J.I.; Perez, M.A.; Franquelo, L.G.; Marquez, A.; Vazquez, S. Model Predictive Control of Modular Multilevel Converters Using Quadratic Programming. IEEE Trans. Power Electron. 2021, 36, 7012–7025. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, X.; Chen, Y. Model Predictive Arm Current Control for Modular Multilevel Converter. IEEE Access 2021, 9, 54700–54709. [Google Scholar] [CrossRef]

- Shetgaonkar, A.; Lekić, A.; Rueda Torres, J.L.; Palensky, P. Microsecond Enhanced Indirect Model Predictive Control for Dynamic Power Management in MMC Units. Energies 2021, 14, 3318. [Google Scholar] [CrossRef]

- Geyer, T. Model Predictive Control of High Power Converters and Industrial Drives; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Karamanakos, P.; Liegmann, E.; Geyer, T.; Kennel, R. Model Predictive Control of Power Electronic Systems: Methods, Results, and Challenges. IEEE Open J. Ind. Appl. 2020, 1, 95–114. [Google Scholar] [CrossRef]

- Steckler, P.B.; Gauthier, J.Y.; Lin-Shi, X.; Wallart, F. Differential Flatness-Based, Full-Order Nonlinear Control of a Modular Multilevel Converter (MMC). IEEE Trans. Control Syst. Technol. 2021. [Google Scholar] [CrossRef]

- Wang, S.; Dragicevic, T.; Gao, Y.; Teodorescu, R. Neural Network Based Model Predictive Controllers for Modular Multilevel Converters. IEEE Trans. Energy Convers. 2021, 36, 1562–1571. [Google Scholar] [CrossRef]

- Houska, B.; Ferreau, H.; Diehl, M. ACADO Toolkit—An Open Source Framework for Automatic Control and Dynamic Optimization. Optim. Control Appl. Methods 2011, 32, 298–312. [Google Scholar] [CrossRef]

- Gros, S.; Zanon, M.; Quirynen, R.; Bemporad, A.; Diehl, M. From linear to nonlinear MPC: Bridging the gap via the real-time iteration. Int. J. Control 2020, 93, 62–80. [Google Scholar] [CrossRef]

- Sankar, D.; Syamala, L.; Ayyappan, B.C.; Kallarackal, M. FPGA-Based Cost-Effective and Resource Optimized Solution of Predictive Direct Current Control for Power Converters. Energies 2021, 14, 7669. [Google Scholar] [CrossRef]

- Vasiladiotis, M.; Rufer, A.; Beguin, A. Modular converter architecture for medium voltage ultra fast EV charging stations: Global system considerations. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, SC, USA, 4–8 March 2012. [Google Scholar] [CrossRef]

- Christen, D.; Jauch, F.; Biela, J. Ultra-fast charging station for electric vehicles with integrated split grid storage. In Proceedings of the 2015 17th European Conference on Power Electronics and Applications (EPE’15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015; pp. 1–11. [Google Scholar] [CrossRef]

- Zhang, F.; Li, W.; Joós, G. A Voltage-Level-Based Model Predictive Control of Modular Multilevel Converter. IEEE Trans. Ind. Electron. 2016, 63, 5301–5312. [Google Scholar] [CrossRef]

- Carrara, G.; Gardella, S.; Marchesoni, M.; Salutari, R.; Sciutto, G. A new multilevel PWM method: A theoretical analysis. IEEE Trans. Power Electron. 1992, 7, 497–505. [Google Scholar] [CrossRef]

- Engel, S.; Doncker, R.W. Control of the Modular Multi-Level Converter for minimized cell capacitance. In Proceedings of the 14th European Conference on Power Electronics and Applications, Birmingham, UK, 30 August–1 September 2011; pp. 1–10. [Google Scholar]

- Vasiladiotis, M.; Cherix, N.; Rufer, A. Accurate voltage ripple estimation and decoupled current control for modular multilevel converters. In Proceedings of the 15th International Power Electronics and Motion Control Conference and Exposition, EPE-PEMC 2012 ECCE Europe, Novi Sad, Serbia, 4–6 September 2012. [Google Scholar] [CrossRef]

- Zeilinger, M.N.; Jones, C.N.; Morari, M. Robust stability properties of soft constrained MPC. In Proceedings of the IEEE Conference on Decision and Control, Atlanta, GA, USA, 15–17 December 2010; pp. 5276–5282. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, M.H.; Kwak, S. Simplified Indirect Model Predictive Control Method for a Modular Multilevel Converter. IEEE Access 2018, 6, 62405–62418. [Google Scholar] [CrossRef]

- Ricker, N.; Subrahmanian, T.; Sim, T. Case studies of model-predictive control in pulp and paper production. IFAC Proc. Vol. 1988, 21, 13–22. [Google Scholar] [CrossRef]

- Boggs, P.T.; Tolle, J.W. Sequential Quadratic Programming. Acta Numer. 1995, 4, 1–51. [Google Scholar] [CrossRef] [Green Version]

- Ferreau, H.; Bock, H.; Diehl, M. An online active set strategy to overcome the limitations of explicit MPC. Int. J. Robust Nonlinear Control 2008, 18, 816–830. [Google Scholar] [CrossRef]

- Jerez, J.L.; Ling, K.V.; Constantinides, G.A.; Kerrigan, E.C. Model predictive control for deeply pipelined field-programmable gate array implementation: Algorithms and circuitry. IET Control Theory Appl. 2011, 6, 1029–1041. [Google Scholar] [CrossRef] [Green Version]

- Hausberger, T.; Kugi, A.; Eder, A.; Kemmetmuller, W. High-Speed Nonlinear MPC with Long Prediction Horizon for Interleaved Switching AC/DC-Converters. In Proceedings of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; pp. 723–730. [Google Scholar] [CrossRef]

- Geyer, T.; Merwe, W.V.D.; Spudic, V.; Darivianakis, G. Model Predictive Control of a Modular Multilevel Converter. U.S. Patent 10,074,978 B2, 11 September 2018. [Google Scholar]

- Aydiner, E.; Müller, M.A.; Allgöwer, F. Periodic reference tracking for nonlinear systems via model predictive control. In Proceedings of the 2016 European Control Conference, ECC 2016, Aalborg, Denmark, 29 June–1 July 2016; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; pp. 2602–2607. [Google Scholar] [CrossRef]

- Köhler, J.; Müller, M.A.; Allgöwer, F. MPC for nonlinear periodic tracking using reference generic offline computations. IFAC-PapersOnLine 2018, 51, 556–561. [Google Scholar] [CrossRef]

- Limon, D.; Pereira, M.; Muñoz de la Peña, D.; Alamo, T.; Jones, C.N.; Zeilinger, M.N. MPC for Tracking Periodic References. IEEE Trans. Autom. Control 2016, 61, 1123–1128. [Google Scholar] [CrossRef] [Green Version]

- Grüne, L. NMPC without terminal constraints. IFAC Proc. Vol. 2012, 45, 1–13. [Google Scholar] [CrossRef] [Green Version]

| Switching Positions | Switching Signals | Terminal Voltage | ||||

|---|---|---|---|---|---|---|

| States | ||||||

| 1 | 0 | 0 | 1 | 1 | ON-Positive | |

| 0 | 0 | 1 | 1 | 0 | OFF-Bypassed | 0 |

| 1 | 1 | 0 | 0 | 0 | OFF-Bypassed | 0 |

| 0 | 1 | 1 | 0 | −1 | ON-Negative | |

| MAE | |||||

|---|---|---|---|---|---|

| k-Step | Model | ||||

| 10 | NPM | 0.096 | 0.17 | 0.099 | 0.71 |

| 10 | LPM | 0.031 | 0.36 | 1.89 | 2.52 |

| 100 | NPM | 1.80 | 2.45 | 2.84 | 7.14 |

| 100 | LPM | 85.03 | 112.21 | 105.67 | 108.47 |

| Component | Parameter | Symbol | SI Value |

|---|---|---|---|

| Grid | Frequency | 50 Hz | |

| Grid | Peak phase voltage | 25 kV | |

| Grid | Nominal active power | 3 MW | |

| DC Bus | DC Voltage | 10 kV | |

| MMC | Arm resistance | 50 m | |

| MMC | Arm inductance | 3 mH | |

| MMC | Capacitance | C | 4 mF |

| MMC | Number of SMs | N | 4 |

| Variable | ||||

|---|---|---|---|---|

| Limit | ||||

| Upper | 1.1 | 1.2 | 1 | |

| Lower | −1.1 | 0.8 | −1 | |

| Computational Time [ms] | ||||||

|---|---|---|---|---|---|---|

| THD [%] | [s] | Mean | Std | Max | Min | |

| 0.46 | ≈0.35 | 0.11 | 0.02 | 0.25 | 0.092 | |

| 0.21 | ≈0.22 | 0.13 | 0.021 | 0.22 | 0.109 | |

| 0.053 | ≈0.17 | 0.28 | 0.036 | 0.49 | 0.23 | |

| 0.036 | ≈0.1 | 1.3 | 0.156 | 2.2 | 1.09 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reyes Dreke, V.D.; Lazar, M. Long-Horizon Nonlinear Model Predictive Control of Modular Multilevel Converters. Energies 2022, 15, 1376. https://doi.org/10.3390/en15041376

Reyes Dreke VD, Lazar M. Long-Horizon Nonlinear Model Predictive Control of Modular Multilevel Converters. Energies. 2022; 15(4):1376. https://doi.org/10.3390/en15041376

Chicago/Turabian StyleReyes Dreke, Victor Daniel, and Mircea Lazar. 2022. "Long-Horizon Nonlinear Model Predictive Control of Modular Multilevel Converters" Energies 15, no. 4: 1376. https://doi.org/10.3390/en15041376

APA StyleReyes Dreke, V. D., & Lazar, M. (2022). Long-Horizon Nonlinear Model Predictive Control of Modular Multilevel Converters. Energies, 15(4), 1376. https://doi.org/10.3390/en15041376