Abstract

The aim of this work is to develop a model of heat supply to buildings with almost zero energy consumption, indicating the significant importance of heat losses and gains in heating installations. The prepared model is to indicate the need for changes in the structure and topology of heating installations, resulting from the changing heat demand of buildings. The need to create a new model is heightened by changes that relate to tightening legal regulations related to energy consumption and demand, which must meet the standards of buildings in Poland from 2021. The article presents the assumptions and results of analyses of the use of energy installations in residential buildings that use renewable energy sources to balance energy consumption in various areas of its use. To achieve this goal, calculations were made using simulations of the impact of the use of installations using renewable energy sources on the energy performance of a building with different quality of partitions and improvement of energy efficiency in accordance with the Polish standard PN-EN 12831. The test results allow to choose the most advantageous, from the point of view of economic profitability, option of replacing installations in residential buildings, and they also allow to determine the possibilities of meeting national obligations in the field of final energy reduction and increasing the share of renewable energy sources in meeting its demand in accordance with the EU obligations imposed on Poland. Thermomodernization of buildings in the temperate climate zone allows for a reduction of 38% of energy demand over the entire life cycle of a building and a reduction of CO2 emissions by 99%.

1. Introduction

The electrification of heating systems in construction is becoming a necessity and an obligation under Polish law. This is the best way to reduce greenhouse gas emissions. One of the basic challenges of the modern world is to reduce energy consumption in residential construction. This is due to economic and ecological reasons. The higher the consumption, the higher the emission of pollutants into the atmosphere. Reducing consumption also contributes to increasing the world’s energy security. In countries with cool and temperate climates, construction is one of the largest energy consumers. A certain amount of energy is used to produce materials and build buildings, but much more energy is used to heat them. The value of the energy used for heating over the life of an average building is about twice the cost of constructing it. Building warm buildings is in the interest of all countries, as experience so far has shown that reducing energy consumption to space heating is one of the cheapest ways to reduce its deficit. Therefore, innovative design and construction solutions are constantly being developed to increase the thermal insulation requirements of buildings, which will contribute to reducing energy consumption for their heating. In recent years, the concept of energy-saving and passive construction has gained in popularity. One of the goals of building a building is to reduce the operating costs of a building, which can be achieved thanks to the proper design of the building. The development of the construction sector requires the introduction of low-energy solutions to the market. Currently, buildings erected in traditional technology consume about 40% of the total energy consumption. The trend of low-energy construction in the European Union, regarding the energy performance of buildings, assumes that buildings should be nearly zero-energy buildings [1]. The prerequisite for the creation of the above-mentioned directive was the need for actions aimed at a significant reduction in energy consumption, reducing the Union’s energy dependence and the need to reduce energy consumption from non-renewable sources aimed at reducing greenhouse gas emissions by at least 20%. The current construction law in Poland regulates the energy requirements for newly constructed buildings through the selection of appropriate building materials and compliance with construction requirements. Thanks to these regulations, the construction industry meets both legal, energy, and environmental requirements. While research on the reduction of CO2 emissions in transport has been widely conducted, and researchers propose a number of remedial solutions [2,3,4,5,6,7,8], buildings built before 2010 that do not meet energy efficiency requirements and that must undergo transformation remain a problem.

With this in mind, the article presents various variants of thermal modernization of these buildings, including research on the quality parameters of external partitions and the selection of an appropriate source of renewable energy heating installations. The results presented in the paper will allow future investors to make an informed decision in selecting the appropriate thermomodernization variant to meet the legal requirements for their building. The presented variants take into account various degrees of the achieved energy efficiency and aspects of the economic assessment of the incurred expenditure.

2. Review of the Literature

The building’s energy needs depend on the scope of its equipment with heating, ventilation and air-conditioning systems, hot water, and internal lighting. The preparation of the energy balance for the steady states allows to present the dependencies of the flow of individual energy levels in all separate aspects of its consumption in the building. The annual unit demand for non-renewable primary energy determines the total efficiency of the building and includes, apart from the final energy demand, additional inputs of non-renewable primary energy for supplying each used energy carrier to the building boundary [9]. The demand for utility energy contains important information about the energy quality of the building. It gives an image of the state of thermal insulation of external partitions, the degree of elimination of thermal bridges and their impact on heat losses and determines the type of ventilation used. From the amount of usable energy demand, it can additionally be deduced how the body of the building was designed and the benefits from solar radiation through transparent partitions that were used. The most important parameter for the user of the building is the final energy demand [10,11]. Activities rationalizing the demand for final energy in a building result from the optimization of the utility energy demand in a given field and the structure of its coverage by the installed energy systems. The annual amount of saved energy resources from non-renewable primary sources in a given area of its demand in a building is proportional to the amount of final energy used from renewable energy sources and supplied through an installation based on these resources, and to the difference in inputs of non-renewable primary energy resources for producing and providing a given type of carrier for that equivalent final energy that is consumed in a conventional or alternative installation [12,13]. Building energy quality, determined by the parameters thermal insulation of building partitions and the quality of energy systems, determined by the partial efficiency of carrier production, accumulation, transport, and regulation, has a significant impact on the size of devices and installations using renewable energy sources. The analysis of the profitability of using various renewable energy installations in single-family housing is presented in the works [14,15].

Greenhouse gas emissions in the construction sector are mainly related to the production of heat for heating and domestic hot water preparation based on fossil fuels, mainly hard coal. This applies to both system heat sources (boiler rooms, combined heat, and power plants) and local building heat sources. The key challenge in the process of achieving climate neutrality of the construction industry in Poland is so there is a shift away from coal in local heat sources in the first place. This process should be carried out by the end of 2030 at the latest. At the same time, the process of decarbonizing the heating sector and the electric power sector should be carried out, as electrification of heating will play a key role in the process of achieving climate neutrality. Therefore, the key challenge is to conduct an economically effective thermal modernization of the existing resources and to meet the energy needs of modernized renewable energy sources buildings. Achieving climate neutrality in Polish construction requires the government to link in practice the country’s energy policy with the policy of increasing energy efficiency and the use of renewable energy sources in construction, including ambitious goals for improving energy efficiency in documents such as the National Energy and Climate Plan and Poland’s Energy Policy until 2040. Therefore, both NECP, PEP2040, and similar documents require modification by the government so that they take into account the goals for zero-emission construction. Adopting a policy of maximum use of the renewable energy potential in construction, e.g., by the obligation to install a PV or solar heating installation in each building using an individual heat source, will also strengthen the achievement of the climate neutrality goal in 2050. It is necessary to combine the strategy of the “Clean Air” program with the energy efficiency policy and other related initiatives (including, in particular, those related to the support of renewable energy sources). It requires coordination of various support programs (renewable energy, thermal modernization, smog elimination, etc.) in order to effectively use funds for zero-emission construction. First of all, innovative technologies and solutions as well as additional activities, unprofitable from the investor’s point of view, but leading to the creation of low-emission buildings, should be subsidized.

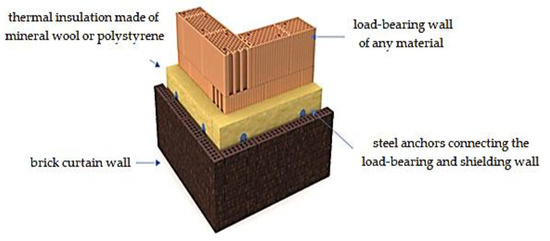

In an energy-efficient building, the proper design and construction of all external partitions has a fundamental influence on obtaining the proper thermal comfort of rooms [16,17]. The energy efficiency of a house is determined, among other things, by the heat transfer coefficient of each of its elements, such as the floor on the ground, walls, roof, windows, and doors. The lower the value of the heat transfer coefficient, the better the insulation properties the partition exhibits. According to the currently binding construction law, the heat transfer coefficient (U) cannot exceed 0.3 W/(m2·K) in the case of floors on the ground and ceilings above unheated cellars; 0.2 W/(m2·K) for external walls; 0.15 W/(m2·K) for roofs, flat roofs, and ceilings under unheated attics. The U value of the entire partition depends on the lambda thermal conductivity coefficient (λ) and the thickness of all its layers. The lower the value of this coefficient, the better the thermal insulation of the external partition by specific thickness. In construction, thermal insulation materials should be used that have λ within 0.03–0.05 W/(m·K) [18,19,20]. Walls are one of the most important elements of a home. They are exposed to unfavorable weather conditions such as rain, snow, wind, frost, and UV rays [21]. Therefore, they must be durable and, at the same time, provide good thermal insulation, tightness and soundproofing, be non-absorbent, and resistant to frost and color fading caused by the action of the sun [22,23,24,25]. Single-layer walls in an energy-saving house are rarely planned, although there are technologies that allow them to achieve the required thermal parameters, there are often construction problems that result in the lack of proper airtightness of partitions and the formation of thermal bridges. Three-layer walls (Figure 1) are the best type of partitions that ensure durability, tightness, thermal accumulation, and very good acoustic insulation of the house [26,27].

Figure 1.

Construction of a three-layer wall. Source: own study.

The calculation of the energy performance of a building is only accurate if the tightness of the building is measured [28,29]. It can be measured by various methods: theoretically [30,31], empirically [32,33,34,35,36], or by single-component models [37]. Relander et al. tested the tightness of connections between the basement wall and the wall with a wooden structure. They presented the results of their work in [38]. Hallik et al. conducted research on air leaks through various wooden joints filled with three different polyurethane foams [39]. Kalamees et al. measured air leakage levels for eight joints that were used for various sealing solutions in a prefabricated timber envelope structure [40]. Pinto et al. measured the air permeability through a set of window frames [41]. Langmans et al. investigated the influence of climatic conditions on the tightness of typical tape connections [42]. Research on air permeability in various types of structures carried out by the authors [43,44,45] allows to obtain information on how air passes through the various parts of the envelope. Usually 20–25% of the heat supplied to the building is lost through windows and external doors. In order to maintain an appropriate level of annual energy consumption in buildings and to enable the economically viable use of renewable energy sources, the building, depending on the construction technology, must meet the criteria presented in Table 1.

Table 1.

Criteria and standards for residential buildings—a list of parameters.

The energy balance is an important element in the design of low-energy and passive buildings. The purpose of this construction industry is to reduce the demand for heat from the central heating system or to eliminate it completely. The energy balance shows that losses in a traditional house are very large. In Polish climatic conditions, the largest component of the total energy consumption is the heating demand of buildings, therefore an energy-saving object is a building with low energy demand for heating purposes [46]. Table 2 presents the energy classification of buildings. In order to make a preliminary profitability analysis of the choice of renewable energy sources technology, it is therefore necessary to estimate the amount of energy necessary for a given facility to cover, among others, heat losses generated by external walls, roof, ceiling, floors on the ground or ceiling above an unheated basement, windows, and external doors. However, it is also necessary to take into account such systems as: lighting, hot water preparation utility, ventilation, air conditioning, etc.

Table 2.

Energy classification of buildings according to Association for Sustainable Development.

Thanks to the use of renewable energy sources, including solar panels, solar collectors, heat pumps, or the use of three-layer glazing in windows with a low heat transfer coefficient caused the intense development of construction with zero energy consumption in the world [47]. Research on low-energy buildings due to the ongoing climate change in the world and the desire to reduce the sources of emissions are still of interest to many scientists. Not only the tropical and hot climate is conducive to the development of low-emission and zero-emission construction technologies, but also more and more research works are taking up the topic of using this technology also in moderate climates. For example, Szejnwald et al. [48] stated during their research that thermal modernization of buildings is one of the best available techniques in economic terms, enabling the reduction of a significant amount of energy demand for the examined buildings. Researchers Yi et al. [49] in their research found that the impact of climate and the change of seasons has a significant impact on the energy demand of buildings. In turn, the results of the research carried out by Szalay and Zold [50] prove that the appropriate location of buildings in the area in terms of the shape of the structure has a significant impact on obtaining low heat transfer coefficients through the walls of buildings. Srinivasan et al. [51] presented the results on how energy produced from renewable sources in hot climates reduces the energy demand in buildings throughout their lifetime. Research by Robert and Kummert [52] using the “Morphing” method has shown how global warming has a significant impact on zero-energy buildings. Many researchers, including Zhou et al. [53], in their works indicate the advantages related to the selection of appropriate HVAC systems and related technologies for energy buildings. In turn, Pikas et al. [54] studied the energy costs of buildings energetic.

Despite these earlier works, while the issues related to new low-energy construction have been legally regulated and widely described in scientific studies, buildings built before 2010 remain a problem, which should be thermomodernized, preferably in such a way that they can use renewable energy sources to the maximum. Problems with the selection of an appropriate renewable heat source in Poland, its profitability and technical conditions of the building are still the subject of research and analysis. There is no work on the principles of selecting the appropriate renewable energy sources technology as part of the thermal modernization of buildings located in the temperate climate zone. In Poland, there is a small number of buildings that meet the concepts of low- and zero-energy buildings and zero-emission buildings. In a building where the energy demand for domestic hot water preparation constitutes 60% of the energy balance, it becomes necessary to look for solutions in innovative heat sources, taking into account renewable energy technologies. Therefore, the aim of this study is to evaluate and analyze the costs and energy consumption of thermomodernization of zero-energy, low-carbon residential buildings in temperate zones. This work, through the analyses and results obtained, allows investors to choose the most advantageous option in terms of economic profitability of the solution for the replacement of installations for residential buildings located in the temperate climate zone. The results showed that the thermal modernization of the building requires additional expenses estimated at 38% of the initial cost of the building. This will result in annual savings of €550 and an approximately 99% reduction in carbon dioxide emissions.

3. Materials and Methods

The article aims to show the methodology of selecting heat supplies to residential buildings located in the temperate climate zone, taking into account the economic application of various renewable energy technologies. The prepared model is to indicate a different alternative to the choice of renewable energy related to the mandatory thermal modernization of buildings, taking into account the construction parameters of buildings and their topology. The need to create a new model is intensified by changes that relate to tightening legal regulations related to energy consumption and demand, which must meet the standards of buildings in Poland from 2021. In order to achieve the goal, the article presents the assumptions and results of analyses of the use of energy installations in residential buildings that use renewable energy sources to balance energy consumption in various areas of its use, taking into account the location of the construction industry in moderate climate conditions. The impact of the use of the installation has been calculated using renewable energy sources for the energy performance of a building with different quality of partitions and improving energy efficiency. The research used weather data, simulations to determine energy consumption, and economic profitability of the investment.

3.1. Location and Climatic Data

This study was carried out in the south of Poland in Kraków, located in the temperate climate zone. The city has a very high social potential, which favors the development of renewable energy technologies. However, due to climatic conditions and low winter sun content, the country has less favorable conditions for the development of zero-energy targets in low-energy construction. However, Poland is undergoing important reforms to achieve zero energy and low carbon emissions by 2050. This study is intended to support this approach. According to the Köppen classification, Kraków is located in the oceanic climate zone (Cfb) with some features of a humid subtropical climate (Cfa). According to Wincenty Okołowicz’s classification, the city lies in the warm temperate climate zone. In the reference period 1991–2019, the annual mean temperature was 9.9 °C, the annual mean maximum temperature was 14.4 °C and the yearly mean minimum temperature was 5.4 °C. The highest recorded temperature is 38.8 °C and the lowest −26.8 °C. The hottest month is July with Wed. tmax 26 °C, avg. tavg 20.4 °C, and avg. tmin 14.9 °C, and the coldest January with an Wed. tmax 2.2 °C, avg. tavg −0.7 °C, and avg. tmin −3.6 °C. Wed tavg is above 10 °C for 7 months from April to October and above 0 °C for 11 months (only January has a slightly negative tavg). Maximum temperatures exceeding 20 °C may occur from mid-February to mid-December (the earliest was recorded on 23 February, at the latest on December 5), and temperatures exceeding 10 °C are common throughout year. A 24-h frost may occur from December to February (sporadically in November and March), but usually it occurs only a dozen or so days a year and is within the limits of moderate frost (e.g., in 2019 the lowest tmax was −5 °C). The meridional circulation, intensified by the fen effect (mountain wind), plays an important role, raising the temperature in winter to a dozen or so degrees above zero. The annual rainfall is 670 mm. The highest amounts of rainfall occur in June and May, and the lowest in December. The amount of rainfall in summer decreases with the change of climate, and it increases in spring and autumn. Snowfall is less and less frequent. Usually there are 30–40 days with snowfall, but only a dozen or so days with accumulation above 1 cm. Due to the small number of days with 24-h frost, snow usually falls at a mild plus temperature (0–2 °C) and melts quickly. The insolation in the latest available data ranged from 203 h in July to 32 h in December (ref. 1961–1990), but it has increased significantly recently. It is related to the approaching border of a humid subtropical climate and more and more often reaching the city’s regions of sunny southern European highlands. Krakow’s climate is one of the warmest in Poland, especially when it comes to maximum temperatures. In terms of average monthly temperatures, however, it loses in the winter to western Poland, which results from lower minimum temperatures than in western Poland (western Poland, closer to the ocean, has more clouds, so at night the temperature does not drop so much).

3.2. Case Study: Building Energy Parameters

| Building characteristics: | |

| Type and purpose | Residential building, single-family house |

| Standard | According to the regulations of 2002–2009 |

| Number of stories | 1 |

| The height of the story, m | 2.7 |

| Heated area, m2 | 120 |

| Roof | gable |

| Total area of the facade, m2 | 104 |

| Insulated facade surface, m2 | 104 |

| Total area of windows, m2 | 34 |

| Cubature, m3 | 247.07 |

| Location | Kraków, Poland |

| Insolation, kWh/m2 | 1080 |

| Airing, m/s | 17 |

| Climate zone, °C | I–7.7 |

| Heating system: | |

| Building heating system | Solid fuel boiler |

| Type | Old type (soot) |

| Heat distributor | Heater |

| Efficiency of the device, % | 60 |

| Efficiency of distribution and regulation, % | 62 |

| The temperature in the house, °C | 20 |

| Fuel | Coal |

| Calorific value, MJ/kg | 26 |

| Price 1 t, EUR | 197.8 |

| Cost 1 kWh, EUR | 0.12 |

| Max. power of the heating device, kW | 13.2 |

| Efficiency, % | 60 |

| Annual energy demand, kWh | 2900 |

| Building insulation parameters-roof: | |

| Material, λ = 0.042 | Mineral wool |

| Thickness, cm | 30 |

| U-factor, W/m2·K | 0.13 |

| Insulating parameters of the building–walls: | |

| U-factor of a wall without additional insulation | 1.25 |

| Material, λ = 0.045 | standard Styrofoam |

| Thickness, cm | 15 |

| U-factor, W/m2·K | 0.24 |

| Exterior doors, U | 1.3 |

| Insulating parameters of the building–floors: | |

| Material, λ = 0.045 | Styrofoam XPS |

| Thickness, cm | 10 |

| U-factor, W/m2·K | 0.19 |

| Foundations | Traditional insulated |

| Insulating parameters of the building–ventilation: | |

| Tightness | Airtight without recuperation |

| Trial n50 | 3 |

| Ventilation | Gravitational |

| Patency, % | 100 |

3.3. Simulation Tools

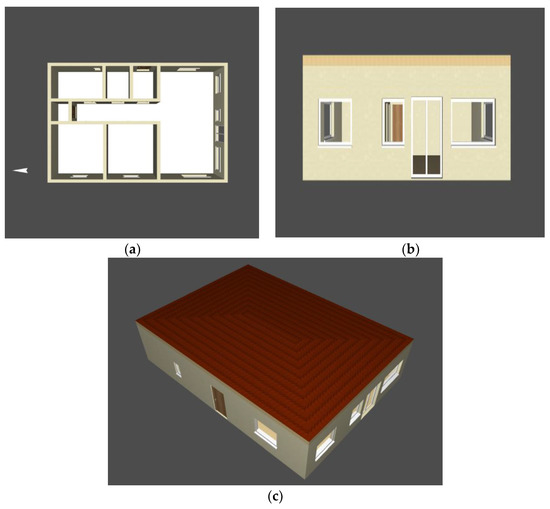

The single-family house used for the research was designed for the needs of the Engineering Project based on the study concerning the energy house (Figure 2). The object was spatially modeled in the Termocadia program by Intersoft, and then thermal calculations were carried out in the compatible ArCADia TERMOCAD 7.1 program in accordance with the PN-EN 12831 standard. This software is commonly used in simulation, optimization, and modeling and served as the basis for thousands of research works. For calculation purposes, in accordance with the requirements of energy construction, the building’s partitions were selected: windows, doors, flat roof, internal partitions, floor on the ground, and three variants of external walls were analyzed in detail. Subsequently, the renewable energy source devices necessary to determine the primary and final energy demand of the facility were selected, and the energy characteristics of the building were made.

Figure 2.

Analyzed building. (a) Building plan in 3D; (b) southern facade of the building; (c) 3D top view of the object. Source: own study.

3.4. Requirements for the Heat Transfer Coefficient Uc

The method of calculating the Uc heat transfer coefficient for external partitions in the tested facility was made in accordance with the standard PN-EN 12831-1:2017 [54]:

- Heat transfer coefficient Uc:

- —resistance to heat transfer of the partition, .

- Heat transfer coefficient resistance (thermal insulation) RT:

- —resistance to heat transfer on the inner surface of the partition, ;

- —design thermal resistance for the i-th layer of the partition, ;

- —resistance to heat transfer on the outer surface of the partition, .

For internal partitions, the resistance assumes the values . Computational thermal resistance for i-th layer of the partition :

where:

- —thickness of the i-th layer of the partition, [m];

- —heat conduction coefficient, .

3.5. The Use of Renewable Energy Sources in Buildings and Their Impact on Energy and Ecological Efficiency

In this part of the research, the impact of the use of selected renewable energy sources (i.e., heat pump, photovoltaic installation, induction boiler, mini wind farm) on the energy performance of the building was analyzed by making variant calculations of the demand for non-renewable primary energy for various options of equipping the building with heating installations using resources. In this part of the research, the impact of the use of selected renewable energy sources. The value of the EP index of the annual demand for non-renewable primary energy for a building is influenced by [55]:

- The amount of energy demand in individual areas of use;

- The amount of auxiliary energy demand;

- Efficiency of systems in individual areas of use;

- Values of the coefficients of input of non-renewable primary energy in and for the delivery of an energy carrier or a given type of energy to the building.

The use of renewable energy sources to supply buildings with heat allows, in most cases, to significantly reduce their EP indicators of the demand for non-renewable primary energy. For the analyzed building, the following variants of the application of renewable energy sources for energy supply for central heating were analyzed, and domestic hot water preparation was analyzed as well. In the calculations of energy characteristics, the values of heat transfer coefficients for external partitions and separating heated and unheated spaces were assumed, equal to the maximum values in force in the standards. The calculations were carried out for various values of heat transfer coefficients for external partitions, applicable in a given period of their construction.

4. Results and Discussion

Currently, dynamic simulation methods are gaining more and more popularity, supplementing or replacing the static calculations used so far. This paper presents the results of dynamic simulations adapted to typical single-family houses. The data analysis technique was based on the simulation methods of an example residential building located in a temperate climate zone. The analyses were based on simulation studies in which actual data and parameters of buildings built in Poland in the years 1950–2021 were applied. Information has been collected on the basis of data contained in the provisions of the construction law, technical standards, and energy certificates of buildings. Due to the changing climatic conditions, energy requirements, and EU regulations, buildings built in Poland in 1950–2021 are responsible for 38% of greenhouse gas emissions. Therefore, they should be thoroughly modernized to meet the applicable EU regulations and directives.

Simulation studies on the basis of an example building with a standard usable area became the authors’ motivation to analyze the technologies used in construction, taking into account building partition coefficients since 1950, in terms of the possibility of using renewable energy sources in them. The simulation tests were supported by a computational methodology with the use of simulations of the impact of the use of installations using renewable energy sources on the energy performance of a building with different quality of partitions and the improvement of energy efficiency in accordance with the PN-EN 12831 standard. Correct planning and design of installations based on the use of renewable sources is of key importance to ensure their correct and effective operation [56]. The calculations of various variants of the thermomodernization project in the field of building partitions consisted of introducing an additional layer of external insulation of the building walls, additional insulation of the roof, and replacement of window and door joinery in accordance with the requirements of the standards. During the simulation tests, all possible cases were given, taking into account real data, the parameters of which were used for the final thermal calculations. For each of them, appropriate materials were selected, which enabled the calculation and achievement of the correct value of the heat transfer coefficient Uc for all three variants of possible partitions used in single-family housing in the years 1950–2021. In the research, due to the location of Poland in the zone of the temperate climate, the most common sources of renewable energy technologies to be used for this climate zone, which will make it possible to achieve the required final energy demand, were analyzed. These studies give a picture of the state of thermal insulation of external partitions, the degree of elimination of thermal bridges and their impact on heat losses, and the use of the best renewable energy source for the analyzed building in technical and economic terms. The analysis of the obtained results allows to conclude that the use of dynamic simulations at the design stage of renewable energy installations can significantly help in the selection of the appropriate technology for residential buildings and the elimination of many potential operational problems.

4.1. Building Energy Parameters–Calculations

The aim of this part of the work was to analyze and compare the installation costs of individual solutions using renewable energy sources along with their impact on the environment. Then, those that were both cheap and relatively easily available were selected.

- Usable energy demand during the year [56]:

- —annual demand for primary energy by the heating and ventilation system;

- —the annual primary energy requirement of the hot water system.

Four people live in the building, and if each of them consumes 35 dm3 of water at a temperature of 45 °C per day = 140 dm3 per day for four people. We assume that there are no residents at home for 14 days during the year (trips, holidays). So, they use hot water 351 days a year.

Heat the water to 45 °C. The water delivered to the house is at a temperature of 10 °C. Thus, the difference is 35 °C.

- Energy necessary to heat 1 dm3 of water by 1 °C = :

Annual primary energy demand for the heating and ventilation system QP,H. The house has an area of 120 m2. Its heat energy requirement is 150 (an older, insulated house).

Thus, the demand for primary energy during the year is:

where:

- —usable energy;

- —efficiency of the heating system.

Thus, the final energy demand is:

In order to determine the value of the primary energy, the amount of final energy should be multiplied by a factor appropriate for the given energy carrier. For hard coal, the coefficient is 1.1.

A coal-fired boiler with a capacity of B = 13.2 kW and a calorific value Qi = 26 MJ/kg has the following chemical composition: C = 65%; H = 4%; S = 1%; O = 1%; ash = 12%; total humidity = 8%.

During the 270-day heating period (1 September–31 May), the boiler will release to the atmosphere 28,123.20 kg CO2.

The final energy of Ek is 277.89 kWh/m2 per year. This value exceeds the maximum EA index given in the reference range (Table 2). Therefore, the analyzed building is highly energy-consuming and has an F energy class of over 250 kWh/m2. The planned energy purchase is: 33,346.20 [kWh/year], while the cost of energy purchase is 33,346.20 [kWh/year] 0.12 [EUR/ kWh] = 4001.55 [EUR/year].

4.2. Requirements for the Heat Transfer Coefficient Uc

The coefficients Rse, Rsi, and Uc,max were calculated based on the standard PN-EN 12831-1:2017 and presented in the Table 3 and Table 4.

Table 3.

Values of the coefficients Rse and Rsi.

Table 4.

Maximum values of the permeation coefficient warm Uc,max.

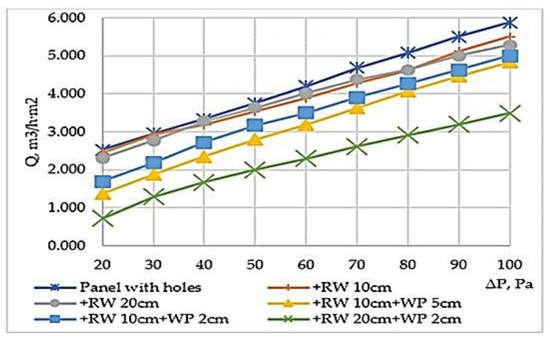

Figure 3 shows the measured dependencies of air permeability on the pressure difference with the use of different variants of insulation used in construction.

Figure 3.

The dependence of air permeability on the pressure difference when using different variants of insulation used in construction. Source: own study based on [28].

As can be seen from Figure 3, the thicker rock wool thermal insulation layer used without wind protection boards had a greater impact on the reduction of air permeability. A thicker rock wool thermal insulation layer and a lower air permeability of wind protection layer shows the lowest air permeability results for the whole structure. For the analyzed building, the values of thermomodernization parameters and material characteristics of all partitions were calculated, which will be used in the further part of the research to select the appropriate renewable energy source technology.

Ceiling: the design uses a flat roof, i.e., the ceiling above the last floor of the building, which also fulfills the role of a roof with the material characteristics presented in Table 5.

Table 5.

Characteristics of the partition-flat roof.

Calculation results of the coefficient values:

| Insulation thickness d, m | 0.45 |

| Total resistance RT, | 7.21 |

| Total permeation coefficient Uc, | 0.14 |

Ground on the ground: the design uses a multi-layer ground floor with the material characteristics presented in Table 6.

| On the ground floor: | |

| Insulation thickness d, m | 1.08 |

| Total resistance RT, | 6.42 |

| Total permeation coefficient Uc, | 0.16 |

| Exterior doors: | |

| Total resistance RT, | 6.42 |

| Total permeation coefficient Uc, | 0.16 |

| Interior doors: | |

| Total resistance RT, | 0.83 |

| Total permeation coefficient Uc, | 1.20 |

| Windows: | |

| Permeability coefficient b, % | 0.14 |

| Total resistance RT, | 0.83 |

| Total permeation coefficient Uc, | 1.20 |

| External walls: the material characteristics of the walls are shown in Table 7. | |

Table 6.

Characteristics of the partition-floor on the ground.

Table 7.

Characteristics of the partition-external walls.

Calculation results of the coefficient values:

| Insulation thickness d, m | 1.08 |

| Total resistance RT, | 1.09 |

| Total permeation coefficient Uc, | 0.91 |

4.3. The Use of Renewable Energy Sources in Buildings and Their Impact on Energy and Ecological Efficiency

Reducing energy consumption and the use of renewable energy in the residential building sector is a priority action in the Member States of the European Union. These activities allow for the effective and sustainable use of the potential of fossil fuels and for the reduction of gaseous and dust emissions resulting from the process of energy combustion of fuel. The constantly growing prices of energy carriers also force the necessity to improve the energy performance of a given building, in particular a newly erected building. The aim of this part of the research is to compare the energy needs of a single-family residential building with a specific cubature and heating area. The building’s energy consumption depends not only on the thermal insulation of building partitions, but also on the efficiency of the building’s technical systems. Therefore, in the calculations, several variants of heating systems were introduced, including those supported by energy from renewable sources. For those under consideration in cases, the total costs of energy supplied to the building were estimated, that is, the cost of heating, domestic hot water, and electricity.

- (a)

- Air Source Heat Pump

One of the solutions adopted for the research analysis is the use of the HEWALEX PCCO MONO 11 kW heat pump with a 3-kW heater with the technical parameters shown in Table 8. The data applies to the A7/W35 heating mode (temperature of the lower source 7 °C; temperature of the upper source 35 °C).

Table 8.

Heating system air-to-water heat pump.

The calculated rates of CO2 emissions in [kg/MWh] for end consumers of electricity are presented in Table 9.

Table 9.

Heating system air-to-water heat pump.

The CO2 emission is 0.719 kg CO2 /kWh

The energy parameters of the building after the application of the air-to-water heat pump are presented in Table 10.

Table 10.

Energy parameters of the building after using the air-to-water heat pump.

Purchase of energy to central heating and domestic hot water are: 4083.21 [kWh/year]. Energy purchase cost up to central heating and domestic hot water: 4083.21 [kWh/year]·0.14 [EUR/kWh] = 571.65 [EUR/year]. Purchase of energy to power household appliances and lighting the building: 2900 [kWh/year]. The cost of purchasing energy to power household appliances and lighting the building: 2900 [kWh/year] 0.14 [EUR/kWh] = 406 [EUR/year]. It is necessary to purchase energy for central heating, domestic hot water, and to power household appliances and building lighting: 4083.21 [kWh/year] +2900 [kWh/year] = 6983.21 [kWh/year]. Energy purchase cost up to central heating, domestic hot water, and to power household appliances and building lighting: 571.65 [EUR/year] + 406 [EUR/year] = 977.65 [EUR/year].

- (b)

- Ground Source Heat Pump

Similar calculations were made for the applicability of the ground heat pump for the analyzed building. The results are presented in Table 11.

Table 11.

Energy parameters of the building after using the brine-water heat pump.

Purchase of energy to central heating, domestic hot water: 4446.16 [kWh/year]. Energy purchase cost up to central heating: 4446.16 [kWh/year]·0.14 [EUR/kWh] = 622.47 [EUR/year]. Purchase of energy to power household appliances and lighting the building: 2900 [kWh/year]. The cost of purchasing energy to power household appliances and lighting the building: 2900 [kWh/year]·0.14 [EUR/kWh] = 406 [EUR/year]. Purchase of energy to central heating, domestic hot water, and to power household appliances and building lighting: 4446.16 [kWh/year] + 2900 [kWh/year] = 7346.16 [kWh/year]. Energy purchase cost up to central heating, domestic hot water, and to power household appliances and building lighting: 622.47 [EUR/year] + 406 [EUR/year] = 1028.47 [EUR/year].

- (c)

- Air Source Heat Pump and Solar Panels

A HEWALEX PCCO MONO 11kW heat pump with a 3-kW heater was used. Data refer to A7/W35 heating mode (heat source temperature 7 °C, heat source temperature 35 °C).

The annual electricity consumption of the heat pump is . It is assumed that by consuming 1000 kWh annually, a photovoltaic installation with a total capacity is needed 1 kWp.

In addition, devices that use electricity in the house (washing machine, dishwasher, etc.) and lighting should be supplied with electricity obtained from the photovoltaic installation. During the year, electricity consumption for these purposes is 2900 kWh/year.

Additionally, we install monocrystalline photovoltaic panels on the roof (SUNTECH STP370S-B60/WNH-370 Wp). The power of one module is 0.33 kWp. How many panels need to be installed to be produced is calculated below 5 kWp.

The efficiency of the photovoltaic installation is 20.3%. Dimensions of one module are 175 × 1039 × 35 mm3. The area required for the installation is 47.3 m2. The CO2 emission of the photovoltaic installation is 0.

The energy parameters of the building after the use of an air source heat pump an photovoltaic panels are shown in Table 12.

Table 12.

Building energy parameters after using an air heat pump and photovoltaic panels.

- (d)

- Induction Boiler and Solar Panels

The technical parameters of the heating boiler are presented in Table 13.

Table 13.

Heating system: induction boiler.

We supply electricity obtained from the photovoltaic installation to devices that use electricity at home (washing machine, dishwasher, etc.) and lighting. During the year, electricity consumption for these purposes is 2900 kWh/year. Electricity consumption is 20,007 kWh/year.

The power of one module is 0.33 kWp. How many panels need to be installed to be produced is calculated below 5 kWp.

To supply household appliances, lighting, and the energy demand of an induction boiler with electricity, you need a photovoltaic installation with a capacity of 28.7 kWp.

The efficiency of the photovoltaic installation is 20.3%. Dimensions of one module are 1756 × 1039 × 35 mm. The area required for the installation is 158.7 m2. The roof area of the building is 172 m2, and there are no roof windows, so the solar panels will fit on the roof. CO2 emission = 0. The energy parameters of the building with the use of an induction boiler are shown in Table 14.

Purchase of energy: 0 [kWh/year]

Energy purchase cost: 0 [kWh/year] × 0.14 [EUR/kWh] = 0 [EUR/year]

Table 14.

Building energy parameters after using an induction boiler.

- (e)

- Use of an Air Source Heat Pump and a Vertical swing wind turbine

Due to the location of the analyzed building in an area with good ventilation, the use of an air heat pump and a vertical line wind turbine were further analyzed. The technical parameters of the turbine are presented in Table 15. In order to supply the building with electricity needed for central heating and domestic hot water, the heat pump requires 4083.21 kWh.

Table 15.

Technical parameters of the turbine FLTXNY FH-2000.

- Pel—rated power of the wind farm: 2 kW,

- hn—height of the turbine mast: 9 m,

- V0—wind speed at height h0 = 30 m: 7 m/s.

If the turbine is to be installed at a height other than that at which the wind speed is known, the wind speed should be determined for the installation height of the turbine.

Reading from the standards, the power plant utilization factor for the rated wind speed adopted for the determination of the turbine power is equal to 7 m/s, and the wind speed at the height of 9 m is equal to 5.7 m/s; the factor amounts to 36%.

To supply the building with the electricity needed for central heating and domestic hot water, the heat pump requires 4083.21 kWh. The wind farm will produce 6307.20 kWh per year.

There is an overproduction of 2224 kWh/year. It can be used to supply electricity to domestic appliances and building lighting 2900 kWh/year.

After the building is supplied with electricity for purposes, central heating, domestic hot water, lighting, and electrical demand are lacking 676 kWh annually. The cost of purchasing the missing electricity is EUR 94.75 per year.

- (f)

- The use of an Induction Boiler and a Wind Turbine with a Vertical Rotation Line

In order to supply the building with electricity needed for central heating and domestic hot water, the induction boiler requires 21,000 kWh. The technical parameters of the turbine are shown in Table 16.

Table 16.

Technical parameters of the Spine + ARC 1500 turbine.

- Pel—rated power of the wind farm: 6 kW,

- hn—turbine rotor height: 12 m,

- V0—wind speed at height h0 = 30 m: 7 m/s.

The technical parameters of the Spine + ARC 1500 turbine are shown in Table 16.

If the turbine is to be installed at a height other than that at which the wind speed is known, the wind speed should be determined for the installation height of the turbine.

Reading from the standards, the power plant utilization factor for the rated wind speed adopted for the determination of the turbine power is equal to 7 m/s, and the wind speed at the height of 12 m is equal to 6 m/s; the factor amounts to 39%.

To supply the building with electricity needed for central heating and domestic hot water, the heat pump needs 20,007.72 kWh. The wind farm will produce 20,498.40 kWh annually.

There is an overproduction of 490.70 kWh/year. We can use it to supply electricity to domestic appliances and building lighting 2900 kWh/year.

After supplying the building with electricity for central heating, domestic hot water, lighting, and electrical appliances, it is necessary to buy an additional 2409.32 kWh per year. The purchase cost is:

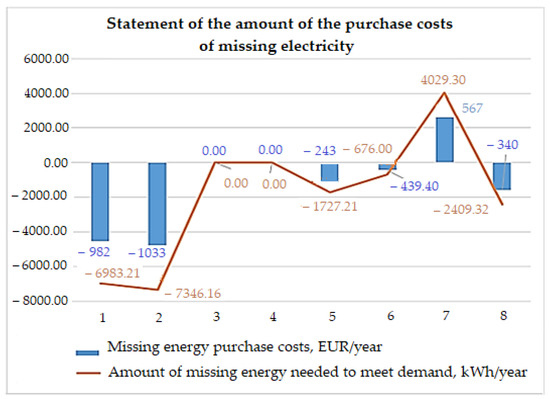

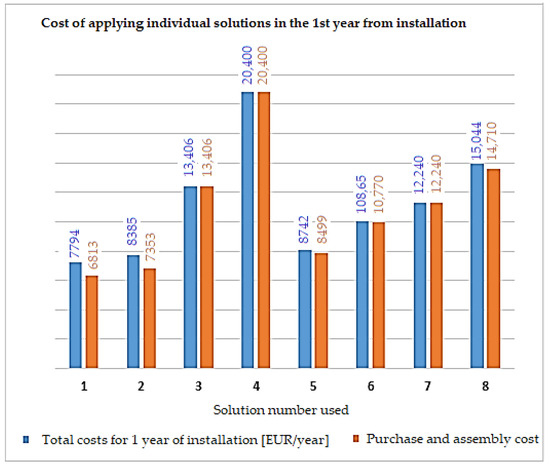

Table 17 shows the total purchase costs of the analyzed solutions. On the other hand, Figure 3 presents a summary of the quantity and costs of purchasing the missing electricity during the year.

Table 17.

Purchase costs of the applied solutions.

Figure 4 shows the amount of electricity that was insufficient to meet the needs of the analyzed building and the costs that must be incurred for this purpose. Ensuring the independence of the house from the power grid means that the selected solution will cover the household’s demand for electricity necessary to power household appliances, lighting rooms, central heating, and hot water. The largest amount of electricity must be additionally purchased in the case of using a ground heat pump (7346.16 kWh/year; 1028.47 EUR/year). Similar values were observed for the installation of the air heat pump (6983.21 kWh/year; 977.65 EUR/year). The use of an air heat pump in the building in conjunction with a photovoltaic installation and an induction boiler in conjunction with a photovoltaic installation ensured that the total electricity demand was met and there was no need to purchase additional energy. There was also no overproduction of energy. Using a heat pump air-water in combination with a wind turbine with a vertical or horizontal axis of rotation, one should take into account the necessity to pay EUR 87–260 per year for the missing amount of electricity. A 2.2-kW horizontal swing turbine generates 20% less energy compared to a 2-kW vertical rotation turbine. This translates into almost EUR 152 higher costs of purchasing the missing energy. However, when using an induction boiler in combination with a wind turbine with a horizontal axis of rotation, after ensuring the self-sufficiency of the building from electricity, there was an overproduction of 4023.30 kWh/year. Additional energy can be used to power other devices that, for example, will appear on the farm after some time and have not been included in the demand. Then, you can save EUR 565.72 per year at the electricity price of EUR 0.14/kWh. Then, the research compared the total expenses that must be incurred in the first 12 months from the installation and purchase of a new one energy sources. These costs are shown in Figure 5.

Figure 4.

Summary of the quantity and costs of purchasing the missing electricity during the year: (1) 11.6 kW air-to-water heat pump; (2) ground source heat pump 12.5 kW; (3) 11.6 kW air-to-water heat pump + 8.4 kWp monocrystalline photovoltaic panels; (4) induction boiler 21 kW + 28.7 kWp monocrystalline photovoltaic panels; (5) 11.6 kW air-to-water heat pump + 2.2 kW wind turbine with a horizontal axis of rotation; (6) 11.6 kW air-to-water heat pump + 2 kW wind turbine with a vertical axis of rotation; (7) induction boiler 21 kW + wind turbine with a horizontal axis of rotation of 7.5 kW; (8) induction boiler 21 kW + wind turbine with a vertical axis of rotation 6 kW. Source: own study.

Figure 5.

The sum of the costs of applying individual solutions in the first year of installation: (1) 11.6 kW air-to-water heat pump; (2) ground source heat pump 12.5 kW; (3) 11.6 kW air-to-water heat pump + 8.4 kWp monocrystalline photovoltaic panels; (4) induction boiler 21 kW + 28.7 kWp monocrystalline photovoltaic panels; (5) 11.6 kW air-to-water heat pump + 2.2 kW wind turbine with a horizontal axis of rotation; (6) 11.6 kW air-to-water heat pump + 2 kW wind turbine with a vertical axis of rotation; (7) induction boiler 21 kW + wind turbine with a horizontal axis of rotation of 7.5 kW; (8) induction boiler 21 kW + wind turbine with a vertical axis of rotation 6 kW. Source: own study.

Figure 3 shows the total installation costs of a given device in the building (the cost of purchasing the device, the cost of assembly, the cost of purchasing additional elements necessary for the installation, and the cost of purchasing energy, which may have been insufficient to cover the household’s electricity demand). The highest costs (EUR 20,368.25) occurred with the use of a 21 kW induction boiler and 28.7 kWp monocrystalline photovoltaic panels. Such a high price is mainly due to the high power of the photovoltaic installation, and thus the need for more individual modules. In addition, the purchase of an induction boiler, which is not currently a popular solution, also involves a high cost. All three options with the use of an induction boiler are at the forefront of the presented options in terms of costs. The cheapest option is to choose one heat source: a heat pump. The costs for an air source heat pump or a ground source heat pump are similar level and amount to 7774–8206 EUR within the first year of installation. The solutions where only the purchase cost of the device itself and additional elements should be covered are:

- -

- 11.6 kW air source heat pump + 8.4 kWp monocrystalline photovoltaic panels;

- -

- 21 kW induction boiler + 28.7 kWp monocrystalline photovoltaic panels;

- -

- 21 kW induction boiler + 7.5 kW wind turbine with a horizontal axis of rotation.

The power of these devices has been selected so that there is no need to buy the missing energy and thus expose the consumer to additional costs.

Lowering the energy needs of a building by increasing the requirements for thermal insulation of its housing and introducing high-performance modern heating devices and energy-saving electrical devices translates into measurable ecological and economic benefits. Characteristics of energy demand in the analyzed residential building, in which the domestic hot water demand plays a dominant role, amounting to almost 60% of the energy balance, makes it practically impossible to achieve the required EP level without modifying the heat source. As can be seen on the basis of the analysis, the use of alternative energy sources may be more advantageous than conventional solutions, both in terms of the amount of investment outlays and costs in the life cycle. It therefore confirms that the level of requirements specified in the technical requirements for buildings can promote the widespread use of alternative energy sources.

5. Conclusions

Promoting and recommending the use of installations based on renewable energy resources in construction, in addition to improving the thermal insulation of building partitions, has a significant impact on increasing energy security and achieving the required standards inside buildings at a lower operating cost. Such a procedure gives optimal and economically profitable effects in the long-term effects of respecting the resources of non-renewable primary energy. Targeted and well-thought-out measures to rationalize the use of final energy for the needs of buildings should no longer pose a challenge but should be a necessary task in a sustainable low-carbon economy.

At the initial heat source (old-type solid fuel boiler), CO2 emissions to the atmosphere amounted to 28,123.2 kg during the 270-day heating period from 1 September to 31 May. This is a significant amount, considering that only one household releases so many harmful substances per year. It is also worth noting that the solid fuel boiler heated the rooms and hot water. Powering household appliances such as a washing machine or refrigerator as well as room lighting was associated with additional costs of about 410 EUR/year. The household’s demand for electricity necessary to power household appliances, lighting rooms, central heating, and hot water is 22,907.72 kWh/year. The presented solutions have been adjusted so as to fully or partially cover the building’s electricity needs. On the basis of the performed tests, the following conclusions were drawn:

- Even using traditional technologies, that is, two-layer walls of constructing external partitions, it is possible to obtain a heat transfer coefficient U through the partition, appropriate for an energy-saving building. The availability of materials on the market is not a problem.

- A three-layer wall is the most optimal solution for a single-family house built in energy-saving technology. Despite the higher investment costs, with such a solution the coefficient of demand for primary energy for heating is the lowest. Due to the cover layer, this solution is also the most durable and easy to maintain.

- When using a heat pump instead of a solid fuel boiler, the amount of CO2 released into the atmosphere is reduced by almost 90% per year and amounts to 2935.83 kg CO2/year with an air source heat pump and 3196.79 kg CO2/year with a ground source heat pump.

- “Zero emission” occurs in solutions where the consumer himself produces the electricity needed to power the heat pump or induction boiler. Variants with the generation of electricity by means of a turbine with a vertical and a horizontal axis of rotation, as well as with the use of a photovoltaic installation, were presented.

- The combination of two solutions using renewable energy sources is characterized by higher costs than that with one source of energy, but then the household becomes energy self-sufficient and is not affected by increases in electricity prices and power cuts.

- Taking into account the co-financing programs, the most cost-effective solution for the analyzed single-family building is to install a heat pump in combination with photovoltaic panels. Then, it is possible to obtain funding of up to EUR 6480 under a government program called the “Clean Air Program” [57] for the replacement of the current high-emission furnace with an environmentally friendly device and for the installation of photovoltaic panels. In the event that the consumer decides not to introduce photovoltaics, the surcharge may amount to a maximum of EUR 5400. Currently, there is a huge selection of photovoltaic panels on the market. The popularity of this solution is constantly growing, and the programs of subsidies or tax deductions for purchase costs encourage more people to install photovoltaics in their home. The aforementioned heat pump is also relatively popular.

- By using two solutions using renewable energy sources from a highly energy-consuming building with energy class F, a house has become passive with energy class A+. The household is then energy self-sufficient and is not affected by possible increases in energy prices or power outages.

In order to encourage building owners to use renewable energy sources, it is necessary for the state to create a broader support system and to modify the existing regulations enabling them to conduct prosumer activity on the electricity and heat market. Renewable energy installations, as an alternative to conventional systems, should become a standard in the design of nearly zero-energy buildings.

This type of research is necessary to generate more detailed scientific information that architectural engineers can use to design these types of buildings. Additional studies should be carried out to develop more complex models with external weather data as input data and to explore the benefits of passive technologies in different climatic regions. In addition, the algorithms for assessing the impact of thermomodernization of heating installations with the use of systems based on RES resources on the energy performance of the building and its certificate should be examined.

Author Contributions

Conceptualization, M.N.; methodology, M.N.; software, M.N.; validation, M.N.; formal analysis, M.N. and P.W.; investigation, M.N. and P.W.; resources, M.N.; data curation, M.N. and P.W.; writing—original draft preparation, M.N. and P.W.; writing—review and editing, P.W.; visualization, M.N.; supervision, P.W.; project administration, M.N. and P.W.; funding acquisition, M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC (Text with EEA relevance). Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/?uri=celex%3A32009L0028 (accessed on 15 December 2021).

- Wróblewski, P.; Lewicki, W. A Method of Analyzing the Residual Values of Low-Emission Vehicles Based on a Selected Expert Method Taking into Account Stochastic Operational Parameters. Energies 2021, 14, 6859. [Google Scholar] [CrossRef]

- Wróblewski, P. Analysis of Torque Waveforms in Two-Cylinder Engines for Ultralight Aircraft Propulsion Operating on 0W-8 and 0W-16 Oils at High Thermal Loads Using the Diamond- Like Carbon Composite Coating. SAE Int. J. Engines 2021, 15, 2022. [Google Scholar] [CrossRef]

- Dziubak, T.; Bąkała, L.; Karczewski, M.; Tomaszewski, M. Numerical research on vortex tube separator for special vehicle engine inlet air filter. Sep. Purif. Technol. 2020, 237, 116463. [Google Scholar] [CrossRef]

- Dziubak, T.; Dziubak, S.D. Experimental Study of Filtration Materials Used in the Car Air Intake. Materials 2020, 13, 3498. [Google Scholar] [CrossRef] [PubMed]

- Dziubak, T.; Bąkała, L. Computational and Experimental Analysis of Axial Flow Cyclone Used for Intake Air Filtration in Internal Combustion Engines. Energies 2021, 14, 2285. [Google Scholar] [CrossRef]

- Wróblewski, P.; Koszalka, G. An Experimental Study on Frictional Losses of Coated Piston Rings with Symmetric and Asymmetric Geometry. SAE Int. J. Engines 2021, 14, 853. [Google Scholar] [CrossRef]

- Wróblewski, P. An Innovative Approach to Data Analysis in the Field of Energy Consumption and Energy Conversion Efficiency in Vehicle Drive Systems—The Impact of Operational and Utility Factors. In Proceedings of the 37th International Business Information Management Association (IBIMA), Cordoba, Spain, 1–2 April 2021; ISBN 978-0-9998551-6-4. [Google Scholar]

- Kubińska-Jabcoń, E.; Kubiński, W.; Niekurzak, M. Analysis of the Economical, Ecological and Quality Advantages Consequent Resulting from Initiation of Technology Integrated in Metallurgy. J. Mech. Eng. Autom. 2015, 5, 549–553. [Google Scholar] [CrossRef]

- Janoś, K. Polski Prąd Najdroższy w UE już 7 m-c z Rzędu. Tak Drogo Może być 15 Lat. Available online: https://www.money.pl/gospodarka/polski-prad-najdrozszy-w-ue-juz-7-miesiecy-z-rzedu-tak-drogo-moze-byc-15-lat-6576934583294752a.html (accessed on 12 December 2021).

- Olczak, P.; Matuszewska, D.; Kryzia, D. “Mój Prąd” as an example of the photovoltaic one off grant program in Poland. Energy Policy J. 2020, 23, 123–138. Available online: https://epj.min-pan.krakow.pl/-Moj-Prad-as-an-example-of-the-photovoltaic-one-off-grant-program-in-Poland,122482,0,2.html (accessed on 15 October 2021). [CrossRef]

- Niekurzak, M. The Potential of Using Renewable Energy Sources in Poland Taking into Account the Economic and Ecological Conditions. Energies 2021, 14, 7525. [Google Scholar] [CrossRef]

- Eurostat Statistics Explained, Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Electricity_price_statistics (accessed on 10 December 2021).

- Niekurzak, M.; Mikulik, J. Modeling of Energy Consumption and Reduction of Pollutant Emissions in a Walking Beam Furnace Using the Expert Method—Case Study. Energies 2021, 14, 8099. [Google Scholar] [CrossRef]

- Niekurzak, M.; Kubińska-Jabcoń, E. Analysis of the Return on Investment in Solar Collectors on the Example of a Household: The Case of Poland. Front. Energy Res. 2021, 9, 224. [Google Scholar] [CrossRef]

- Olczak, P.; Olek, M.; Kryzia, D. The Ecological Impact of Using Photothermal and Photovoltaic Installations for DHW Preparation. Polityka Energetyczna. Energy Policy J. 2020, 23, 65–74. [Google Scholar] [CrossRef]

- Olczak, P.; Olek, M.; Matuszewska, D.; Dyczko, A.; Mania, T. Monofacial and Bifacial Micro PV Installation as Element of Energy Transition-The Case of Poland. Energies 2021, 14, 499. [Google Scholar] [CrossRef]

- Borowski, P. Adaptation strategy on regulated markets of power companies in Poland. Energy Environ. 2019, 30, 3–26. [Google Scholar] [CrossRef]

- Kochanek, E. Wielowymiarowość Interesów Energetycznych w Dobie Transformacji Systemowej; WAT: Warsaw, Poland, 2021. [Google Scholar]

- Polityka Energetyczna Polski 2040, Załącznik do Uchwały nr 22/2021 Rady Ministrów z Dnia 2 Lutego 2021 r; Ministerstwo Klimatu i Środowiska: Warsaw, Poland, 2021.

- Wiśniewski, G. Europejskie Centrum Energii Odnawialnej, Ekonomiczne i Prawne Aspekty Wykorzystania Odnawialnych Zródeł Energii w Polsce; Ministerstwa Środowiska: Warsaw, Poland, 2000; Available online: http://www.pga.org.pl/prawo/ekonomiczne_i_prawne_aspekty.pdf (accessed on 10 December 2021).

- Szczerbowski, R. The forecast of Polish power production sector development by 2050—Coal scenario. Energy Policy J. 2018, 19, 5–18. [Google Scholar]

- Młynarski, T.; Tarnawski, M. Źródła Energii i ich Znaczenie dla Bezpieczeństwa Energetycznego w XXI Wieku; Difin: Warsaw, Poland, 2016. [Google Scholar]

- Wnioski z Analiz Prognostycznych na Potrzeby Polityki Energetycznej Polski do 2050 Roku, Załącznik 2; Ministerstwo Klimatu i Środowiska: Warsaw, Poland, 2021.

- Gabryś, H. Elektroenergetyka w Polsce 2020. Energetyka 2020, 8, 365–373. [Google Scholar]

- Robaina, M.; Neves, A. Complete decomposition analysis of CO2 emissions intensity in the transport sector in Europe. Res. Transp. Econ. 2021, 87, 101074. [Google Scholar] [CrossRef]

- Polski Sektor Energetyczny 2050. 4 Scenariusze; Forum Energii: Warsaw, Poland, 2018. [Google Scholar]

- Šadauskienė, J.; Seduikyte, L.; Paukštys, V.; Banionis, K.; Gailius, A. The role of air tightness in assessment of building energy performance: Case study of Lithuania. Energy Sustain. Dev. 2016, 32, 31–39. [Google Scholar] [CrossRef]

- Cardoso, V.E.M.; Pereira, P.F.; Ramos, N.M.M.; Almeida, R. The Impacts of Air Leakage Paths and Airtightness Levels on Air Change Rates. Buildings 2020, 10, 55. [Google Scholar] [CrossRef]

- Ziółkowski, J.; Żurek, J.; Małachowski, J.; Oszczypała, M.; Szkutnik-Rogoż, J. Method for Calculating the Required Number of Transport Vehicles Supplying Aviation Fuel to Aircraft during Combat Tasks. Sustainability 2022, 14, 1619. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Q. Validation of a Coupled Multizone-CFD Program for Building Airflow and Contaminant Transport Simulations. HvacR Res. 2007, 13, 267–281. [Google Scholar] [CrossRef]

- Chan, W.R.; Joh, J.; Sherman, M.H. Analysis of air leakage measurements of US houses. Energy Build. 2013, 66, 616–625. [Google Scholar] [CrossRef]

- Montoya, M.I.; Pastor, E.; Carrié, F.R.; Guyot, G.; Planas, E. Air leakage in Catalan dwellings: Developing an airtightness model and leakage airflow predictions. Build. Environ. 2010, 45, 1458–1469. [Google Scholar] [CrossRef]

- Pan, W. Relationships between air-tightness and its influencing factors of post-2006 new-build dwellings in the UK. Build. Environ. 2010, 45, 2387–2399. [Google Scholar] [CrossRef]

- Fernández-Agüera, J.; Domínguez-Amarillo, S.; Sendra, J.J.; Suarez, R. An approach to modelling envelope airtightness in multi-family social housing in Mediterranean Europe based on the situation in Spain. Energy Build. 2016, 128, 236–253. [Google Scholar] [CrossRef]

- Bramiana, C.; Entrop, A.; Halman, J. Relationships between Building Characteristics and Airtightness of Dutch Dwellings. Energy Procedia 2016, 96, 580–591. [Google Scholar] [CrossRef][Green Version]

- Szkutnik-Rogoż, J.; Ziółkowski, J.; Małachowski, J.; Oszczypała, M. Mathematical Programming and Solution Approaches for Transportation Optimisation in Supply Network. Energies 2021, 14, 7010. [Google Scholar] [CrossRef]

- Relander, T.-O.; Heiskel, B.; Tyssedal, J.S. The influence of the joint between the basement wall and the wood-frame wall on the airtightness of wood-frame houses. Energy Build. 2011, 43, 1304–1314. [Google Scholar] [CrossRef]

- Hallik, J.; Gustavson, H.; Kalamees, T. Air Leakage of Joints Filled with Polyurethane Foam. Buildings 2019, 9, 172. [Google Scholar] [CrossRef]

- Kalamees, T.; Alev, Ü.; Pärnalaas, M. Air leakage levels in timber frame building envelope joints. Build. Environ. 2017, 116, 121–129. [Google Scholar] [CrossRef]

- Pinto, M.; Viegas, J.; De Freitas, V. Air permeability measurements of dwellings and building components in Portugal. Build. Environ. 2011, 46, 2480–2489. [Google Scholar] [CrossRef]

- Langmans, J.; Desta, T.Z.; Alderweireldt, L.; Roels, S. Durability of self-adhesive tapes for exterior air barrier applications: A laboratory investigation. Int. J. Vent. 2016, 16, 30–41. [Google Scholar] [CrossRef]

- Ziółkowski, J.; Oszczypała, M.; Małachowski, J.; Szkutnik-Rogoż, J. Use of Artificial Neural Networks to Predict Fuel Consumption on the Basis of Technical Parameters of Vehicles. Energies 2021, 14, 2639. [Google Scholar] [CrossRef]

- Fokin, K.F. Cmpoumeльнaя Tenлomexнuкa Oгpaждaющux Чacmeй Здaнuй [Building Heat Engineering Enclosing Parts of Buildings]; ABOK-ΠPECC: Moscow, Russia, 2006. [Google Scholar]

- Hens, S.L.C.H. Building Physics-Heat, Air and Moisture 3e Fundamentals and Engineering Methods with Examples and Exercises; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 135–141. [Google Scholar]

- Niekurzak, M. Determining the Unit Values of the Allocation of Greenhouse Gas Emissions for the Production of Biofuels in the Life Cycle. Energies 2021, 14, 8394. [Google Scholar] [CrossRef]

- Shaw-Williams, D.; Susilawati, C.; Walker, G.; Varendorff, J. Towards net-zero energy neighbourhoods utilising high rates of residential photovoltaics with battery storage: A techno-economic analysis. Int. J. Sustain. Energy 2020, 39, 190–206. [Google Scholar] [CrossRef]

- Brown, H.S.; Vergragt, P.J. Bounded socio-technical experiments as agents of systemic change: The case of a zero-energy residential building. Technol. Forecast. Soc. Chang. 2008, 75, 107–130. [Google Scholar] [CrossRef]

- Yi, H.; Srinivasan, R.S.; Braham, W.W.; Tilley, D.R. An ecological understanding of net-zero energy building: Evaluation of sustainability based on emergy theory. J. Clean. Prod. 2017, 143, 654–671. [Google Scholar] [CrossRef]

- Szalay, Z.; Zöld, A. Definition of nearly zero-energy building requirements based on a large building sample. Energy Policy 2014, 74, 510–521. [Google Scholar] [CrossRef]

- Srinivasan, R.; Braham, W.W.; Campbell, D.E.; Curcija, C.D. Re (De) fining Net Zero Energy: Renewable Energy balance in environmental building design. Build. Environ. 2012, 47, 300–315. [Google Scholar] [CrossRef]

- Robert, A.; Kummert, M. Designing net-zero energy buildings for the future climate, not for the past. Build. Environ. 2012, 55, 150–158. [Google Scholar] [CrossRef]

- Zhou, Z.; Feng, L.; Zhang, S.; Wang, C.; Chen, G.; Du, T.; Li, Y.; Zuo, J. The operational performance of “net zero energy building”: A study in China. Appl. Energy 2016, 177, 716–728. [Google Scholar] [CrossRef]

- Pikas, E.; Thalfeldt, M.; Kurnitski, J. Cost optimal and nearly zero energy building solutions for office buildings. Energy Build. 2014, 74, 30–42. [Google Scholar] [CrossRef]

- Nematchoua, M.K.; Tchinda, R.; Orosa, J.A. Adaptation and comparative study of thermal comfort in naturally ventilated classrooms and buildings in the wet tropical zones. Energy Build 2014, 85, 321–328. [Google Scholar] [CrossRef]

- Strzeszewski, M.; Wereszczyński, P. Norma PN-EN 12831-3:2017-08E Nowa Metoda Obliczania Projektowego Obciążenia Ceiplnego. Poradnik. Warszawa. 2009. Available online: https://www.purmo.com/docs/Poradnik-Purmo-nowa-metoda-obliczania_12831_01_2012.pdf (accessed on 8 December 2021).

- Ministerstwo Klimatu i Środowiska, Program Czyste Powietrze, Warsaw, Poland. 2022. Available online: https://czystepowietrze.gov.pl (accessed on 10 January 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).