Data-Driven Optimal Design of a CHP Plant for a Hospital Building: Highlights on the Role of Biogas and Energy Storages on the Performance

Abstract

:1. Introduction

- Proposes a bi-level optimal design for the integration of Biogas from Anaerobic Digestion (AD) and Energy Storage (ES) technologies (Thermal Energy Storage—TES and Battery Energy Storage System (BESS) for CHP applications;

- Uses the developed design and control algorithm on a real case study (the energy system of a hospital facility located in Rome) to evaluate the potential benefits arising from the innovative approach. Hospitals have in fact often used CHP power systems due to the relevant electric and thermal power consumed and the demands’ contemporaneity;

- Provides energy and environmental KPIs as a benchmark for a real case study for a hospital building.

2. Materials and Methods

2.1. System Layout

- The in situ cogeneration of electricity and heat is cheaper than the separated generation.

- Financial incentives are available in Italy (as in the rest of the EU) for the CHP units that achieve specific performance goals [37].

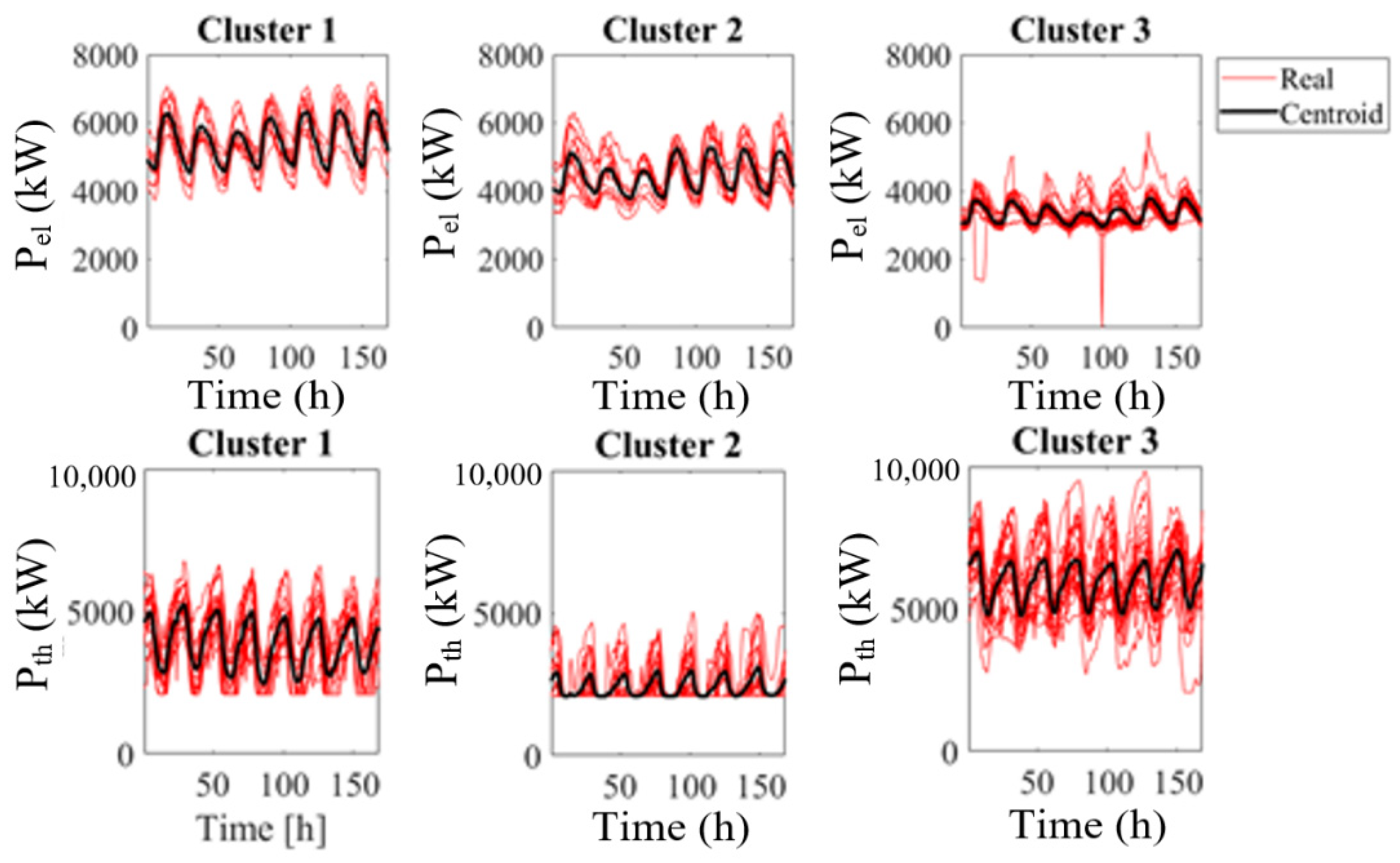

2.2. Modeling of Thermal and Electric Load

2.3. Optimal Design Method

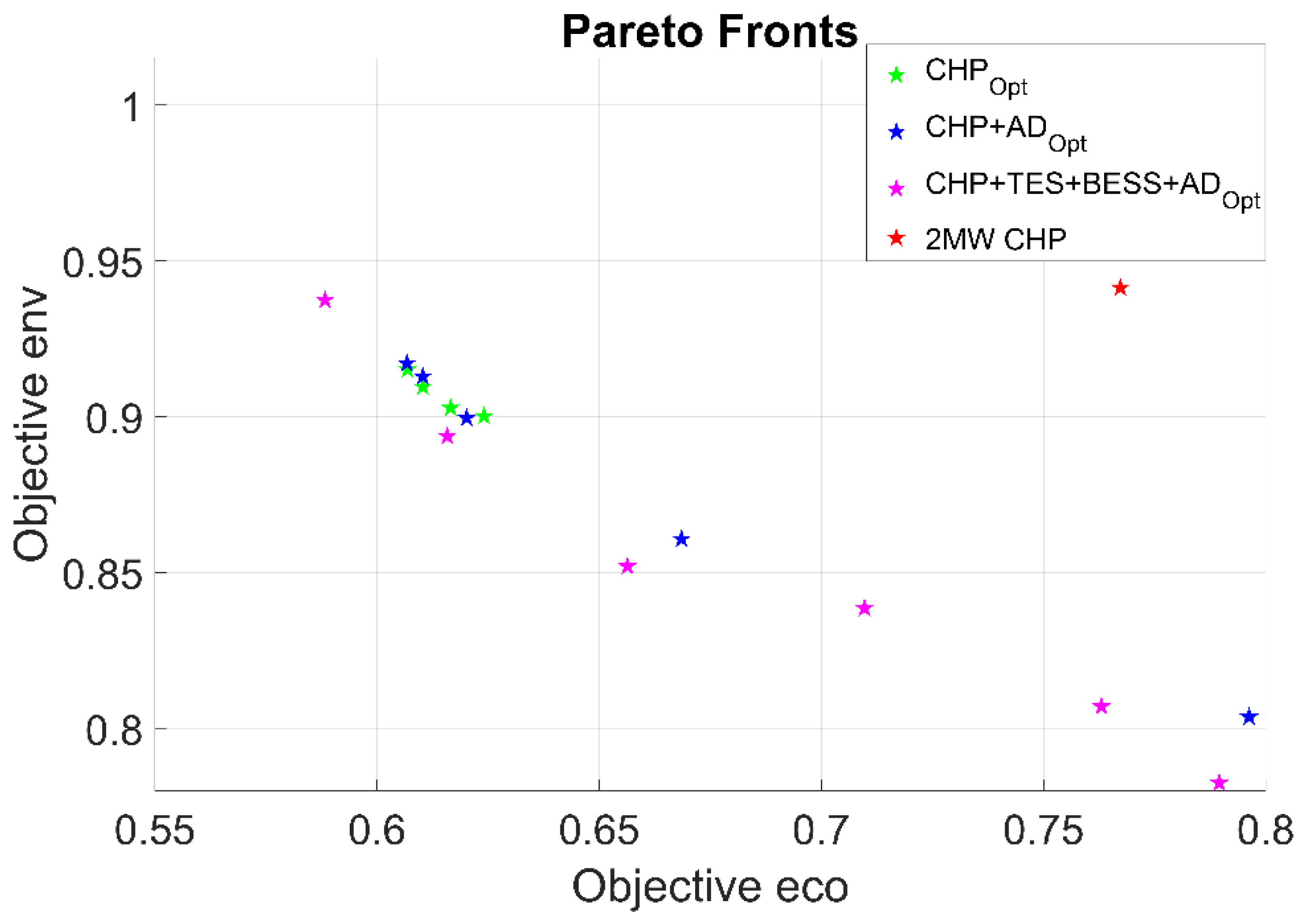

Optimal Solution through the Pareto Plot

3. Results

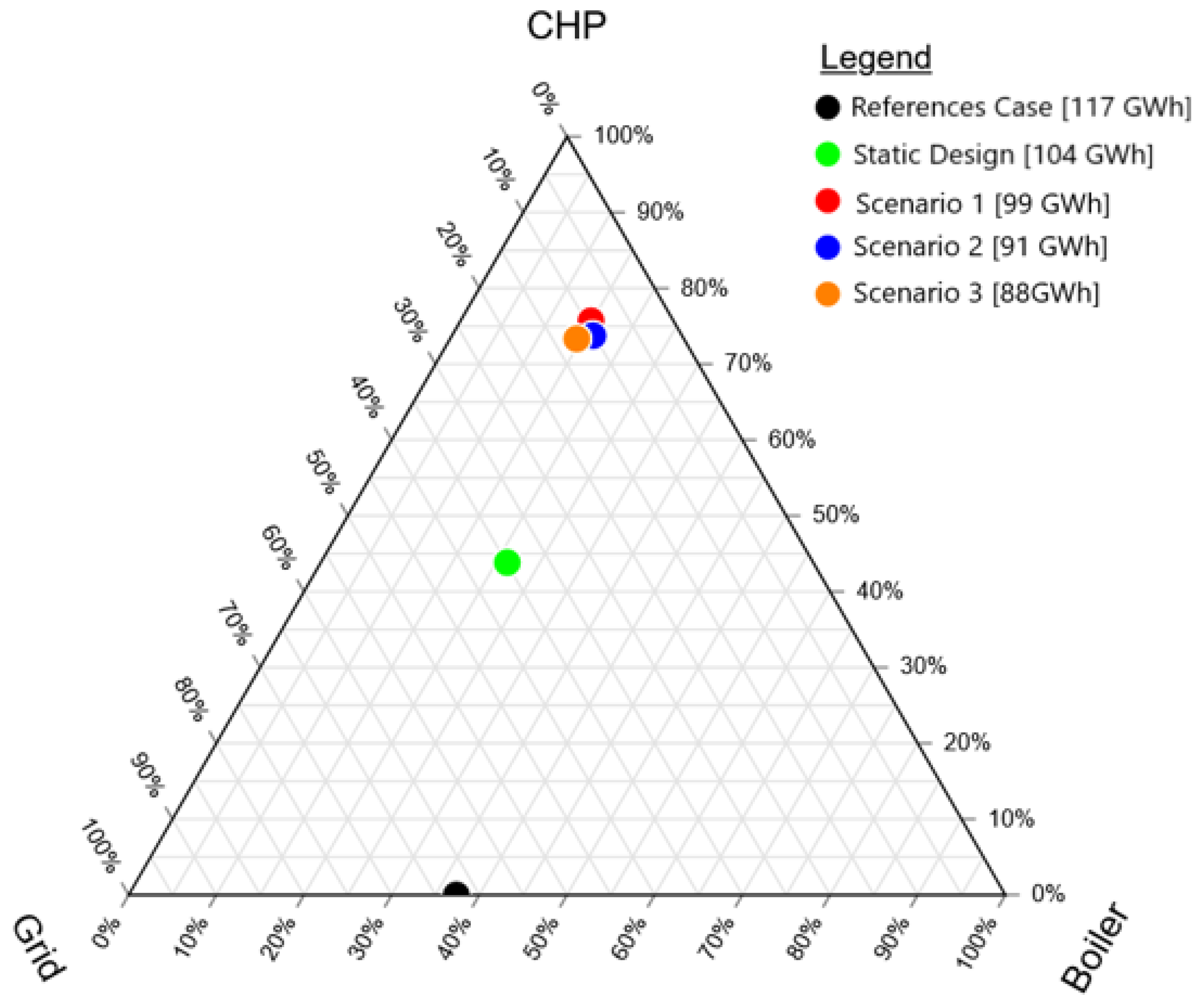

- SCENARIO 1—Optimal design of the CHP plant;

- SCENARIO 2—Optimal design of the CHP plant integrated with the AD reactor;

- SCENARIO 3—Optimal design of the CHP plant and the AD reactor, integrating TES and BESS.

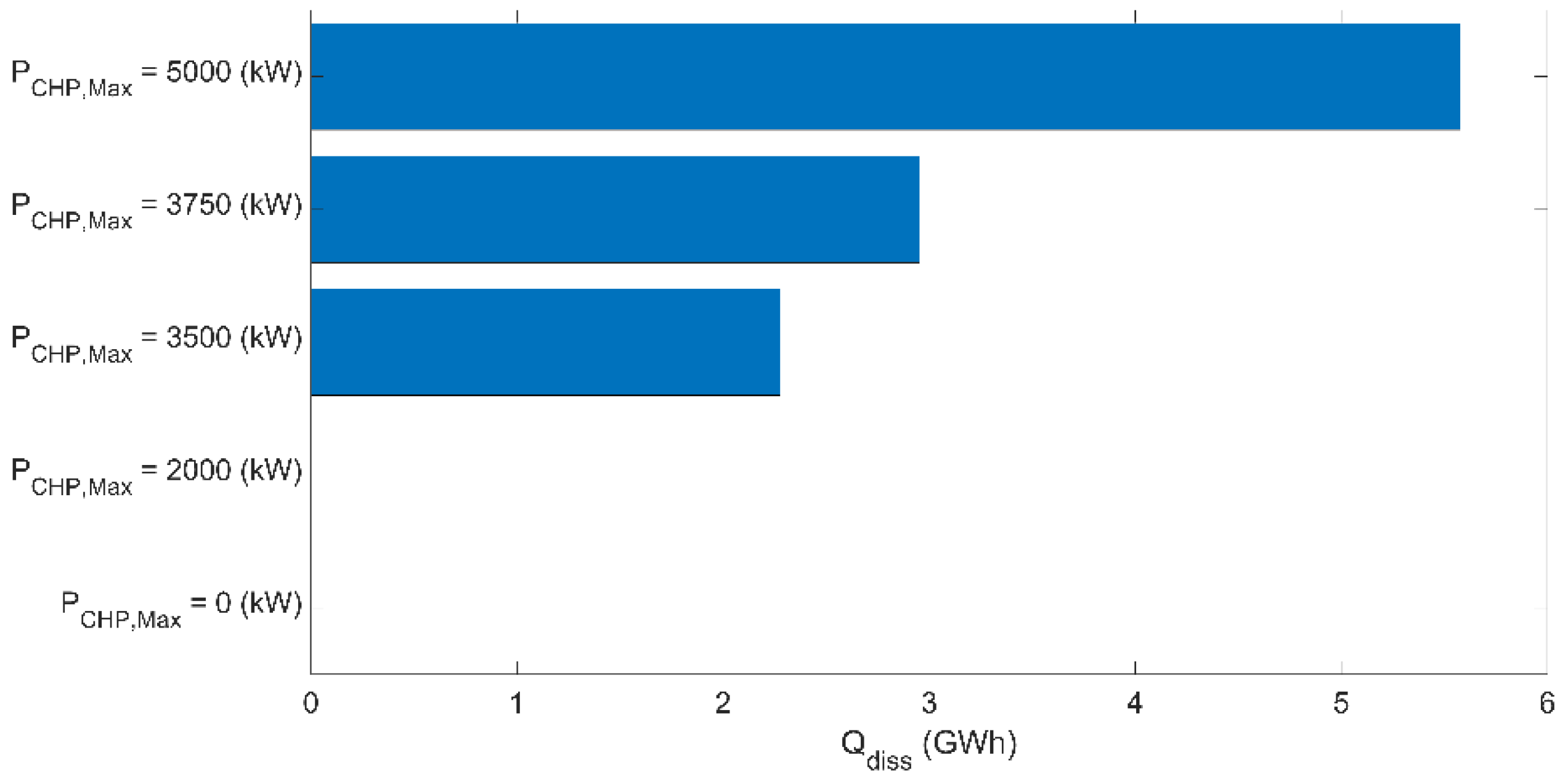

3.1. Scenario 1—CHP Optimal Design

- The loss of efficiency due to the waste heat occurring when electric and heat demands are not matched (Figure 5).

- The investment and maintenance costs that increase with the CHP size.

3.2. Scenario 2—CHP and AD Optimal Design

3.3. Scenario 3—CHP, TES, BESS and AD Optimal Design

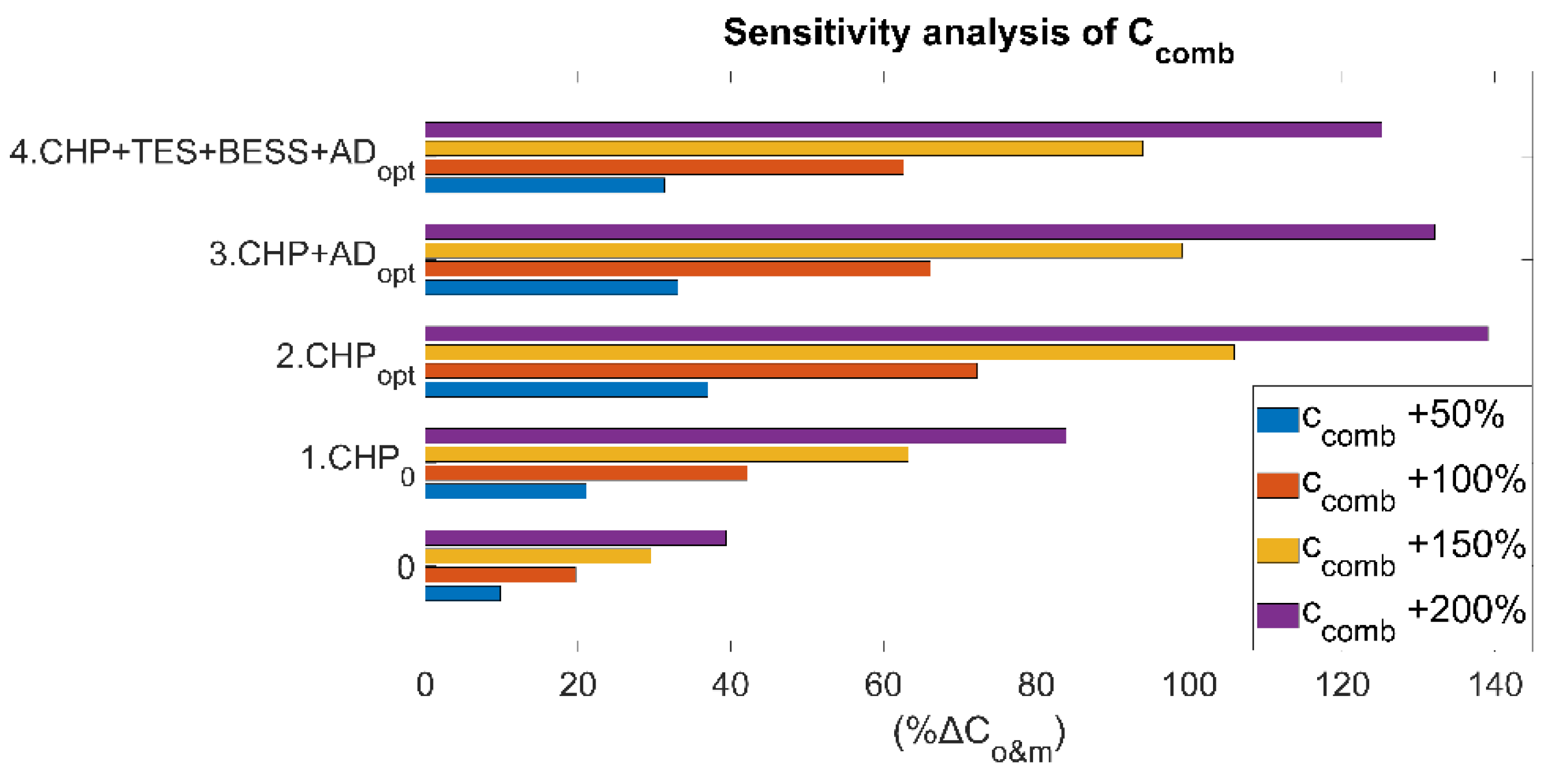

- The extension of the maximum benefits achievable (up to 42% and 22%, respectively, for costs and emissions reductions);

- The reduction in the carbon emissions at a given economic target.

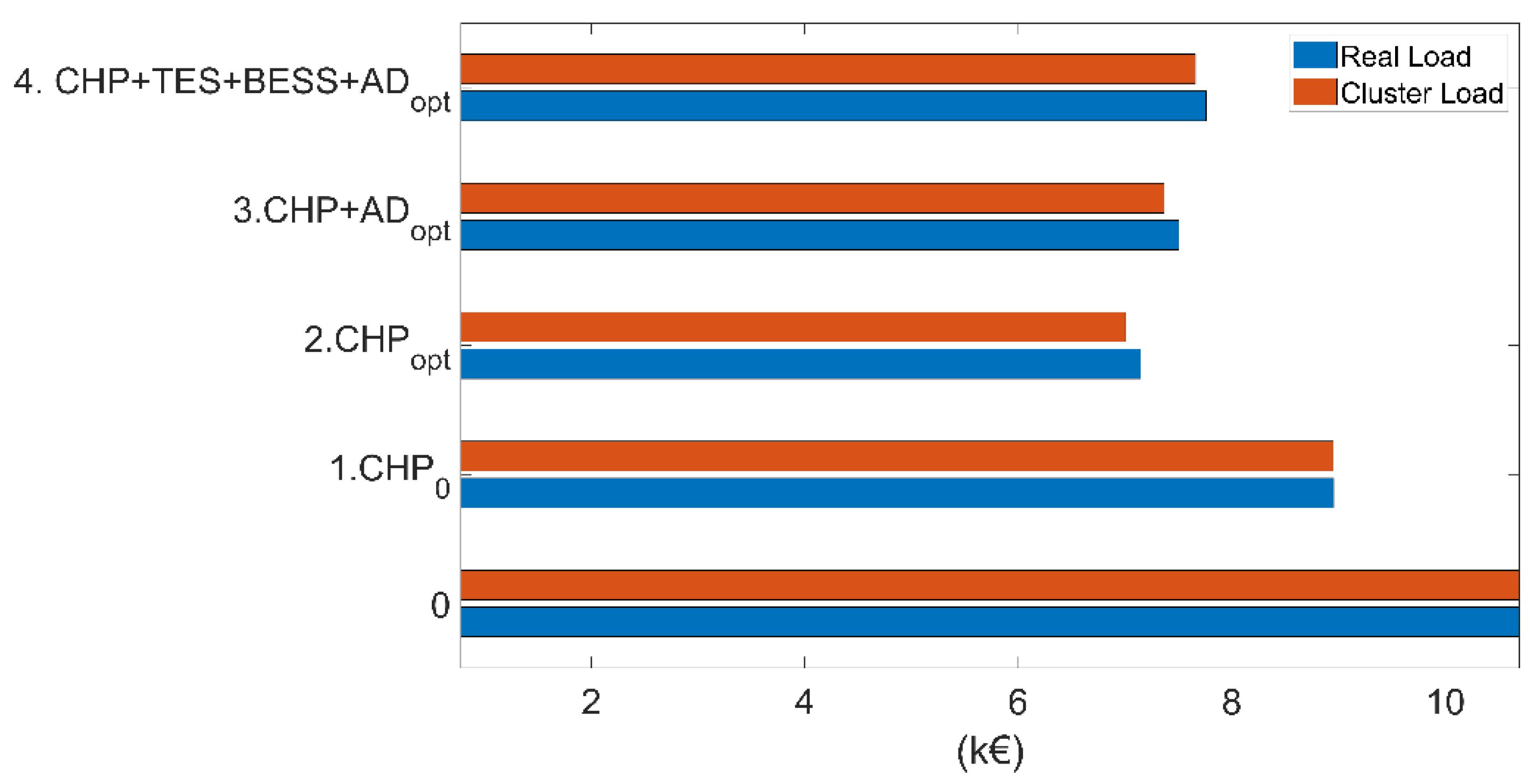

4. Discussion of the Results

5. Conclusions

- Compared with a static design, a dynamic procedure would allow for achieving better performance in terms of both economic and environmental perspectives.

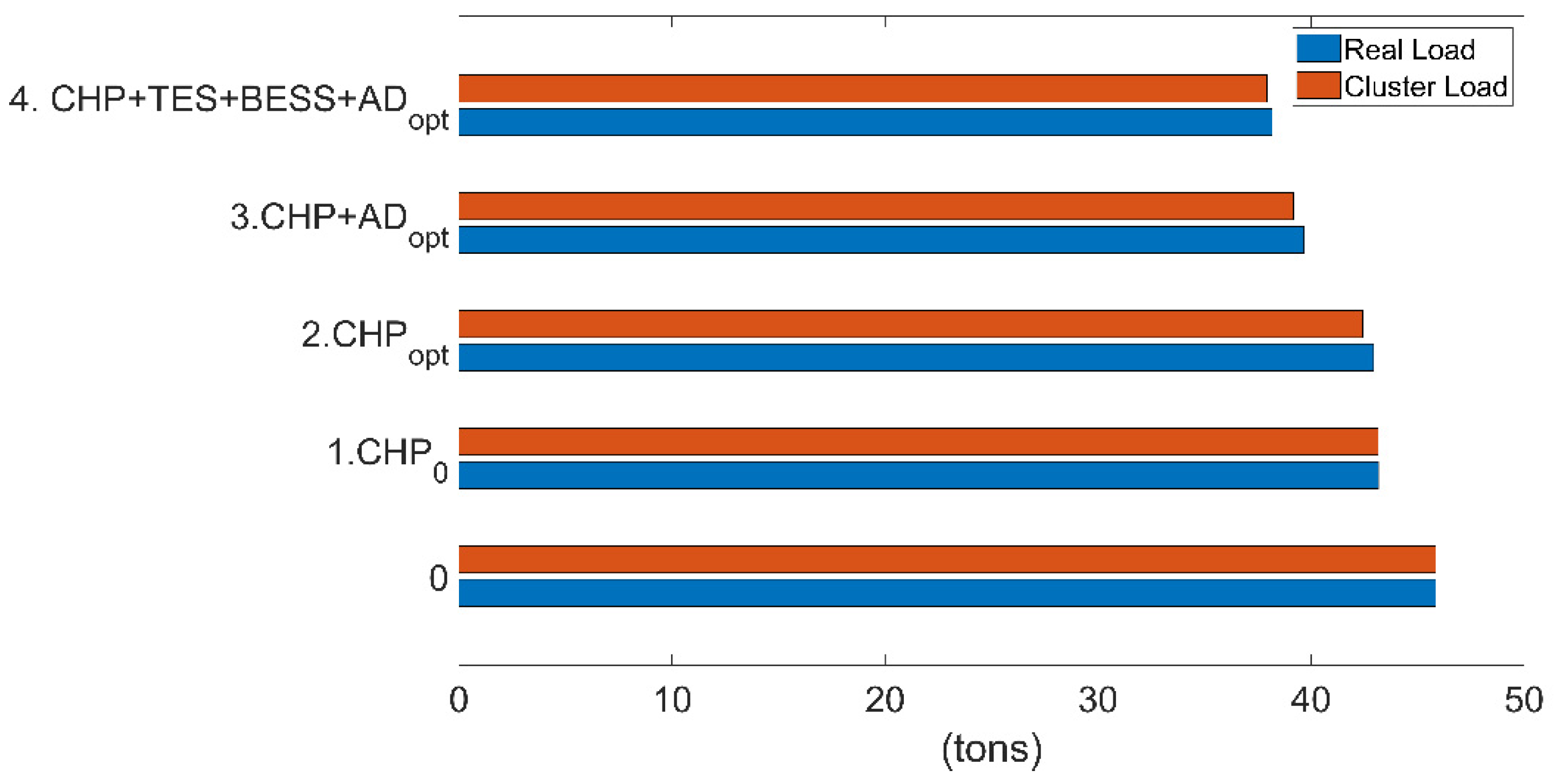

- The minimum total energy cost per bed is achieved for the optimized CHP plant at about 7 kEUR/per bed, whereas to achieve the best performance in terms of CO2 emissions, the integration of the AD process and ES technologies is needed, allowing to reduce the carbon foot print up to about 38 tons/per bed.

- The introduction of biogas from SCG AD helps to extend the positive influence on CO2 emissions (saving up to 20% with respect to the reference case), but it negatively affects the economic performance due to the high costs of transportation.

- Further benefits both in terms of economic and environmental targets can be achieved through a proper design of the Thermal and Battery Energy Storages—with maximum obtainable savings up to 42% and 22%, respectively, increasing costs and the emission weighing factor.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Element | Description |

| AD | Anaerobic Digestion |

| BESS | Battery Energy Storage System |

| CHP | Combined Heat and Power |

| CRF | Actualization Factor |

| ES | Energy Storage |

| FPEC | Fossil Primary Energy Consumption |

| GA | Genetic Algorithm |

| GHG | Greenhouse Gas |

| HE-CHP | high-efficiency incentives |

| ICE | Internal Combustion Engine |

| MESs | Multi Energy Systems |

| PES | Primary Energy Saving |

| PHR | Power to Heat Ratio |

| PV | Photovoltaic |

| PTV | Policlinico Tor Vergata |

| SCG | Spent Coffee Ground |

| TES | Thermal Energy Storage |

| Economic weight | |

| Environmental weight | |

| Economic Objective | |

| Environmental Objective | |

| Electric efficiency of CHP unit | |

| Thermal efficiency of CHP unit | |

| Reference efficiencies for standalone electric energy conversion | |

| Reference efficiencies for standalone thermal energy conversion |

Appendix A

- HRT: 28 days

- CMPHRT: 0.314 lCH4/gVS;

- TREACTOR: 35 °C.

Appendix B

| # | Lower Limit | Upper Limit | ||

|---|---|---|---|---|

| 1 | 0 | 7000 | (kW) | |

| 2 | 0 | 45,000 | (kWh) | |

| 3 | 0 | 6000 | (kWh) | |

| 4 | 0 | 2000 | (kWh) |

| Element | Description |

|---|---|

| cc | High Efficiency incentives (EUR/kWh) |

| Electricity cost (EUR/kWhel) | |

| Natural Gas cost (EUR/kWhth) | |

| Battery Energy Storage System Capacity (kWh) | |

| Thermal Energy Storage Capacity (kWh) | |

| Capital cost of ES (EUR) | |

| Capital cost of Thermal Anaerobic Digestion System (EUR) | |

| Capital cost of Battery Energy Storage System (EUR/kWh) | |

| Annual Capital cost of CHP unit (EUR/kWh) | |

| Capital cost of Thermal Energy Storage (EUR/kWh) | |

| Maintenance cost of CHP unit (EUR/kWhth) | |

| Operation and Maintenance cost of the system (EUR) | |

| Total Transport, Operation and Maintenance cost of the Anaerobic Digestion System (EUR) | |

| Operation and Maintenance cost of the Battery Energy Storage System (EUR/kWh) | |

| Operation and Maintenance cost of PV (EUR/kWh) | |

| Operation and Maintenance cost of the Thermal Energy Storage (EUR/kWh) | |

| Hourly production of methane form Anaerobic Digestion (kWh) | |

| Carbon Footprint due to the SCG transportation (tCO2) | |

| Carbon Footprint due to the grid (tCO2) | |

| Carbon Footprint due to the NG consumption (tCO2) | |

| Emission factor of the electric grid (gCO2/kWhel) | |

| Emission factor of the natural gas (gCO2/kWhth) | |

| Charging energy of the Battery Energy Storage System at time step k of week i (kWh) | |

| Thermal energy of the boiler at time step k of week i (kWh) | |

| Electric energy of the CHP at time step k of week i (kWh) | |

| Dissipated Thermal Energy of the CHP unit (thermal energy not used in CHP mode) at time step k of week i (kWh) | |

| Electric energy from the grid at time step k of week i (kWh) | |

| Electric energy produced by PV at time step k of week i (kWh) | |

| Thermal energy from the TES at time step k of week i (kWh) | |

| number of hours in a week (168) | |

| number of weeks in a year (52) | |

| Maximum Power of the CHP Unit | |

| Self-discharge index of the Electric Energy Storage | |

| Self-discharge index of the Thermal Energy Storage | |

| Round-trip efficiency of Battery Energy Storage System | |

| Boiler efficiency | |

| Electric conversion efficiency of the CHP Unit | |

| Thermal conversion efficiency of the CHP unit | |

| Reference electric efficiency | |

| Reference thermal efficiency | |

| Round-trip efficiency of Thermal Energy Storage |

References

- Available online: https://www.un.org/development/desa/en/news/population/world-population-prospects-2019.html (accessed on 13 December 2021).

- Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-glasgow-climate-pact-key-outcomes-from-cop26 (accessed on 13 December 2021).

- Jiang, P.; Van Fan, Y.; Klemeš, J.J. Impacts of COVID-19 on energy demand and consumption: Challenges, lessons and emerging opportunities. Appl. Energy 2021, 285, 116441. [Google Scholar] [CrossRef] [PubMed]

- European Commission. A Clean Planet for All. A European Long-Term Strategic Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52018DC0773&from=EN (accessed on 15 December 2021).

- European Parliament and the Council. Directive 2008/98/EC of the European Parliament and of the Council. In Fundamental Texts On European Private Law; European Parliament and The Council: Strasbourg, France, 2020; pp. 3–30. [Google Scholar]

- Available online: https://www.ieabioenergy.com/blog/task/biorefining-sustainable-processing-of-biomass-into-a-spectrum-of-marketable-biobased-products-and-bioenergy/ (accessed on 14 December 2021).

- Kirk, N.K.; Navarrete, C.; Juhl, J.E.; Martínez, J.L.; Procentese, A. The “zero miles product” concept applied to biofuel production: A case study. Energies 2021, 14, 565. [Google Scholar] [CrossRef]

- Park, S.; Jeong, H.-R.; Shin, Y.-A.; Kim, S.-J.; Ju, Y.-M.; Oh, K.-C.; Cho, L.-H.; Kim, D. Performance optimisation of fuel pellets comprising pepper stem and coffee grounds through mixing ratios and torrefaction. Energies 2021, 14, 4667. [Google Scholar] [CrossRef]

- Brunerová, A.; Roubik, H.; Brožek, M.; Haryanto, A.; Hasanudin, U.; Iryani, D.A.; Herak, D. Valorization of bio-briquette fuel by using spent coffee ground as an external additive. Energies 2019, 13, 54. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://www.bio-bean.com/ (accessed on 10 December 2021).

- Massaya, J.; Pereira, A.P.; Mills-Lamptey, B.; Benjamin, J.; Chuck, C.J. Conceptualization of a spent coffee grounds biorefinery: A review of existing valorisation approaches. Food Bioprod. Process. 2019, 118, 149–166. [Google Scholar] [CrossRef]

- Battista, F.; Zanzoni, S.; Strazzera, G.; Andreolli, M.; Bolzonella, D. The cascade biorefinery approach for the valorization of the spent coffee grounds. Renew. Energy 2020, 157, 1203–1211. [Google Scholar] [CrossRef]

- Atabani, A.E.; Al-Muhtaseb, A.H.; Kumar, G.; Saratale, G.D.; Aslam, M.; Khan, H.A.; Sid, Z.; Mahmoud, E. Valorization of spent coffee grounds into biofuels and value-added products: Pathway towards integrated bio-refinery. Fuel 2019, 254, 115640. [Google Scholar] [CrossRef]

- Rajesh Banu, J.; Kavitha, S.; Kannah, R.Y.; Kumar, M.D.; Preethi Atabani, A.E.; Kumar, G. Biorefinery of spent coffee grounds waste: Viable pathway towards circular bioeconomy. Bioresour. Technol. 2020, 302, 122821. [Google Scholar] [CrossRef]

- Mayson, S.; Williams, I.D. Applying a circular economy approach to valorize spent coffee grounds. Resour. Conserv. Recycl. 2021, 172, 105659. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.; Baek, G.; Lee, C. Anaerobic co-digestion of spent coffee grounds with different waste feedstocks for biogas production. Waste Manag. 2017, 60, 322–328. [Google Scholar] [CrossRef]

- Rivera, X.C.S.; Gallego-Schmid, A.; Najdanovic-Visak, V.; Azapagic, A. Life cycle environmental sustainability of valorisation routes for spent coffee grounds: From waste to resources. Resour. Conserv. Recycl. 2020, 157, 104751. [Google Scholar] [CrossRef]

- Van Keulen, M.; Kirchherr, J. The implementation of the circular economy: Barriers and enablers in the coffee value chain. J. Clean. Prod. 2021, 281, 125033. [Google Scholar] [CrossRef]

- Matrapazi, V.K.; Zabaniotou, A. Experimental and feasibility study of spent coffee grounds upscaling via pyrolysis towards proposing an eco-social innovation circular economy solution. Sci. Total Environ. 2020, 718, 137316. [Google Scholar] [CrossRef] [PubMed]

- Vakalis, S.; Moustakas, K.; Benedetti, V.; Cordioli, E.; Patuzzi, F.; Loizidou, M.; Beratieri, M. The “COFFEE BIN” concept: Centralized collection and torrefaction of spent coffee grounds. Environ. Sci. Pollut. Res 2019, 26, 35473–35481. [Google Scholar] [CrossRef] [PubMed]

- Vicidomini, M.; Wang, Q.; Chu, W.; Calise, F.; Duić, N. Recent Advances in technology, strategy and application of sustainable energy systems. Energies 2020, 13, 5229. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency. 2012. Available online: https://www.legislation.gov.uk/eudr/2012/27/contents (accessed on 3 December 2021).

- Calise, F.; Vicidomini, M.; Costa, M.; Wang, Q.; Østergaard, P.A.; Duić, N. Toward an efficient and sustainable use of energy in industries and cities. Energies 2019, 12, 3150. [Google Scholar] [CrossRef] [Green Version]

- Paine, S.; James, P.; Bahaj, A.B. Evaluating CHP management and outputs using simple operational data. Int. J. Low-Carbon Technol. 2018, 13, 109–115. [Google Scholar] [CrossRef] [Green Version]

- Vialetto, G.; Noro, M. An innovative approach to design cogeneration systems based on big data analysis and use of clustering methods. Energy Convers. Manag. 2020, 214, 112901. [Google Scholar] [CrossRef]

- Testi, D.; Conti, P.; Schito, E.; Urbanucci, L.; D’Ettorre, F. Synthesis and optimal operation of smart microgrids serving a cluster of buildings on a campus with centralized and distributed hybrid renewable energy units. Energies 2019, 12, 745. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Yu, H.; Yong, M.; Huang, Y.; Zhang, F.; Wang, X. Optimal scheduling of integrated energy systems with combined heat and power generation, photovoltaic and energy storage considering battery lifetime loss. Energies 2018, 11, 1360. [Google Scholar] [CrossRef] [Green Version]

- Kaffash, M.; Ceusters, G.; Deconinck, G. Interval optimization to schedule a multi-energy system with data-driven PV uncertainty representation†. Energies 2021, 14, 2739. [Google Scholar] [CrossRef]

- Alavijeh, N.M.; Steen, D.; Norwood, Z.; Tuan, L.A.; Agathokleous, C. Cost-effectiveness of carbon emission abatement strategies for a local multi-energy system—A case study of chalmers university of technology campus. Energies 2020, 13, 1626. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Lu, Y.; Ju, L.; Wang, T.; Tan, Q.; Wang, J.; Tan, Z. A Multi-objective scheduling optimization model for hybrid energy system connected with wind-photovoltaic-conventional gas turbines, CHP Considering heating storage mechanism. Energies 2019, 12, 425. [Google Scholar] [CrossRef] [Green Version]

- Ghiasi, M.; Niknam, T.; Dehghani, M.; Siano, P.; Alhelou, H.H.; Al-Hinai, A. Optimal multi-operation energy management in smart microgrids in the presence of ress based on multi-objective improved de algorithm: Cost-emission based optimization. Appl. Sci. 2021, 11, 3661. [Google Scholar] [CrossRef]

- Bartolucci, L.; Cordiner, S.; Mulone, V.; Santarelli, M.; Lombardi, P.; Arendarski, B. Towards net zero energy factory: A multi-objective approach to optimally size and operate industrial flexibility solutions. Int. J. Electr. Power Energy Syst. 2021, 137, 107796. [Google Scholar] [CrossRef]

- Bartolucci, L.; Cordiner, S.; Mulone, V.; Pasquale, S.; Sbarra, A. Design and management strategies for low emission building-scale Multi Energy Systems. Energy 2022, 239, 122160. [Google Scholar] [CrossRef]

- Wu, C.; Gu, W.; Xu, Y.; Jiang, P.; Lu, S.; Zhao, B. Bi-level optimization model for integrated energy system considering the thermal comfort of heat customers. Appl. Energy 2018, 232, 607–616. [Google Scholar] [CrossRef]

- Carrasqueira, P.; Alves, M.J.; Antunes, C.H. Bi-level particle swarm optimization and evolutionary algorithm approaches for residential demand response with different user profiles. Inf. Sci. 2017, 418, 405–420. [Google Scholar] [CrossRef] [Green Version]

- Morvaj, B.; Evins, R.; Carmeliet, J. Bi-level optimisation of distributed energy systems incorporating non-linear power flow constraints. In Proceedings of the International Conference CISBAT 2015 Future Buildings and Districts Sustainability from Nano to Urban Scale, Lausanne, Switzerland, 9–11 September 2015; pp. 859–864. [Google Scholar]

- Gestore dei Servizi Energetici (GSE). Guida alla cogenerazione ad alto rendimento. Aggiorn. Ed. 2018, 6, 1–18. [Google Scholar]

- Available online: https://aprireunbar.com/2017/03/13/quante-tazzine-prepara-in-media-un-bar-e-quanto-costa-una-tazzina-di-caffe-in-italia/ (accessed on 3 December 2021).

- Bischi, A.; Taccari, L.; Martelli, E.; Amaldi, E.; Manzolini, G.; Silva, P.; Campanari, S.; Macchi, E. A rolling-horizon optimization algorithm for the long term operational scheduling of cogeneration systems. Energy 2019, 184, 73–90. [Google Scholar] [CrossRef]

- Alhuyi Nazari, M.; Maleki, A.; El Haj Assad, M.; Rosen, M.A.; Haghighu, A.; Sharabaty, H.; Chen, L. A review of nanomaterial incorporated phase change materials for solar thermal energy storage. Sol. Energy 2020, 228, 725–743. [Google Scholar] [CrossRef]

- Gazzetta Ufficiale dell’Unione Europea. Direttiva (UE) 2018/2002 del Parlamento Europeo e Del Consiglio. Available online: https://eur-lex.europa.eu/legal-content/IT/TXT/PDF/?uri=CELEX:32018L2002&from=EN (accessed on 13 December 2021).

- Atelge, M.R.; Atabani, A.E.; Abut, S.; Kaya, M.; Eskicioglu, C.; Semaan, G.; Lee, C.; Yildiz, Y.S.; Unalan, S.; Mohanasundraram, R.; et al. Anaerobic co-digestion of oil-extracted spent coffee grounds with various wastes: Experimental and kinetic modeling studies. Bioresour. Technol. 2020, 322, 124470. [Google Scholar] [CrossRef] [PubMed]

- Vítěz, T.; Koutný, T.; Šotnar, M.; Chovanec, J. On the spent coffee grounds biogas production. Acta Univ. Agric. Silvic. Mendel. Brun. 2016, 64, 1279–1282. [Google Scholar] [CrossRef] [Green Version]

- Zepter, J.M.; Engelhardt, J.; Gabderakhmanova, T.; Marinelli, M. Empirical validation of a biogas plant simulation model and analysis of biogas upgrading potentials. Energies 2021, 14, 2424. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Fresh food sustainable distribution: Cost, delivery time and carbon footprint three-objective optimization. J. Food Eng. 2016, 174, 56–67. [Google Scholar] [CrossRef]

- EPA. U.S. Environmental Protection Agency Combined Heat and Power Partnership. 2017. Available online: https://www.epa.gov/chp (accessed on 3 December 2021).

- Banzato, D. Analisi Economica Degli Impianti di Digestione Anaerobica. 2016. Available online: http://levicases.unipd.it/wp-content/uploads/2016/11/Banzato-modalità-compatibilità.pdf (accessed on 3 December 2021).

| #Combination | αeco | αenv |

|---|---|---|

| 1 | 1 | 0 |

| 2 | 0.75 | 0.25 |

| 3 | 0.5 | 0.5 |

| 4 | 0.25 | 0.75 |

| 5 | 0 | 1 |

| # | αeco | αenv | SizeCHP | Distance from Ideal |

|---|---|---|---|---|

| 1 | 1 | 0 | 5000 | 0.606715 |

| 2 | 0.75 | 0.25 | 4750 | 0.696809 |

| 3 | 0.5 | 0.5 | 3750 | 0.773042 |

| 4 | 0.25 | 0.75 | 3500 | 0.839668 |

| 5 | 0 | 1 | 3500 | 0.90013 |

| # | αeco | αenv | SizeCHP (kWel) | SizeAD (kWth) | Distance from Ideal |

|---|---|---|---|---|---|

| 1 | 1 | 0 | 5000 | 0 | 0.606715 |

| 2 | 0.75 | 0.25 | 5000 | 250 | 0.696498604 |

| 3 | 0.5 | 0.5 | 3750 | 850 | 0.768223141 |

| 4 | 0.25 | 0.75 | 3750 | 1950 | 0.800594604 |

| 5 | 0 | 1 | 3500 | 2000 | 0.804014218 |

| # | αeco | αenv | SizeCHP (kWel) | SizeAD (kWth) | SizeTES (kWhth) | SizeBESS (kWhel) | Distance from Ideal |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 5750 | 0 | 35,000 | 0 | 0.588610647 |

| 2 | 0.75 | 0.25 | 5750 | 0 | 35,000 | 0 | 0.692419719 |

| 3 | 0.5 | 0.5 | 3500 | 900 | 30,000 | 3000 | 0.760299511 |

| 4 | 0.25 | 0.75 | 4000 | 2000 | 35,000 | 3000 | 0.784488196 |

| 5 | 0 | 1 | 3500 | 2000 | 25,000 | 6000 | 0.78281029 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartolucci, L.; Cordiner, S.; De Maina, E.; Mulone, V. Data-Driven Optimal Design of a CHP Plant for a Hospital Building: Highlights on the Role of Biogas and Energy Storages on the Performance. Energies 2022, 15, 858. https://doi.org/10.3390/en15030858

Bartolucci L, Cordiner S, De Maina E, Mulone V. Data-Driven Optimal Design of a CHP Plant for a Hospital Building: Highlights on the Role of Biogas and Energy Storages on the Performance. Energies. 2022; 15(3):858. https://doi.org/10.3390/en15030858

Chicago/Turabian StyleBartolucci, Lorenzo, Stefano Cordiner, Emanuele De Maina, and Vincenzo Mulone. 2022. "Data-Driven Optimal Design of a CHP Plant for a Hospital Building: Highlights on the Role of Biogas and Energy Storages on the Performance" Energies 15, no. 3: 858. https://doi.org/10.3390/en15030858

APA StyleBartolucci, L., Cordiner, S., De Maina, E., & Mulone, V. (2022). Data-Driven Optimal Design of a CHP Plant for a Hospital Building: Highlights on the Role of Biogas and Energy Storages on the Performance. Energies, 15(3), 858. https://doi.org/10.3390/en15030858