Simulation Study of Solidification in the Shell-And-Tube Energy Storage System with a Novel Dual-PCM Configuration

Abstract

:1. Introduction

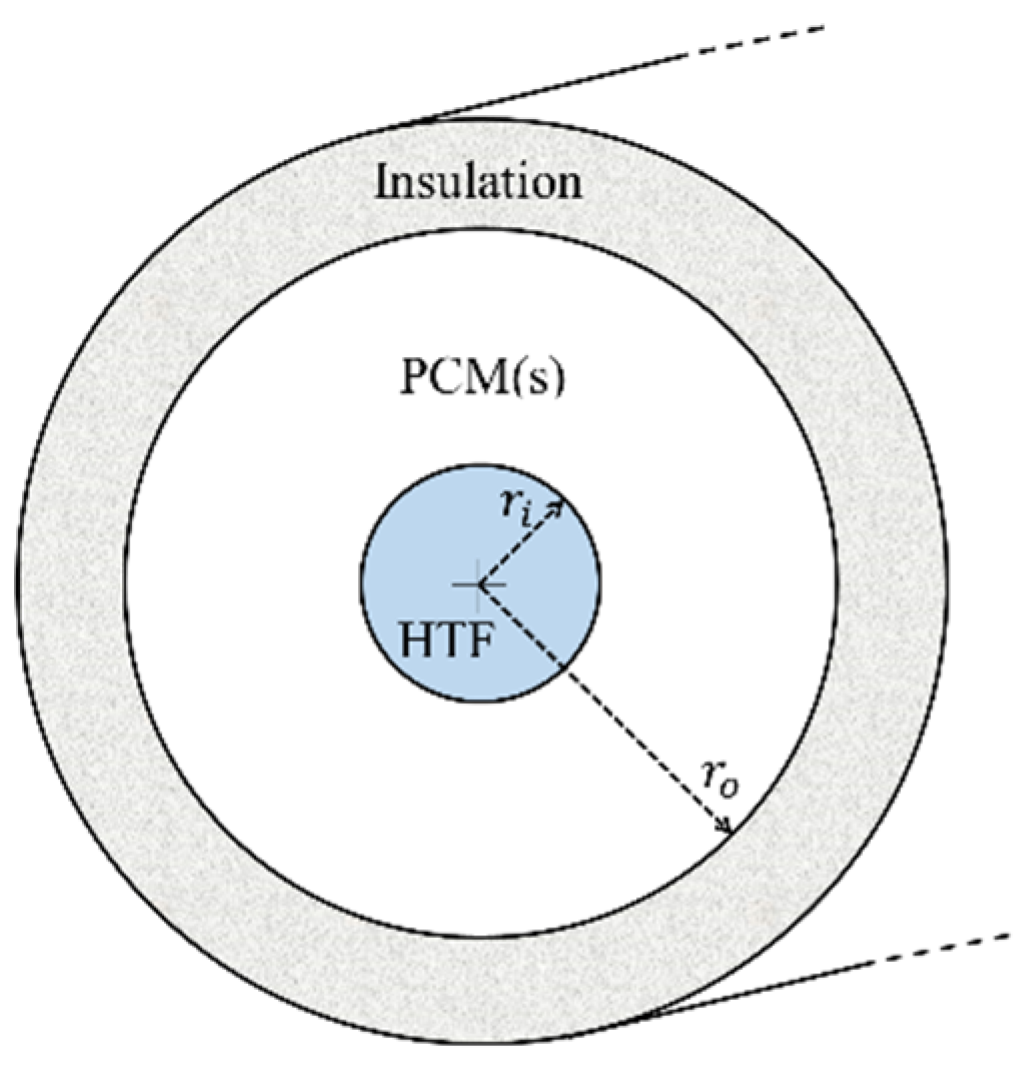

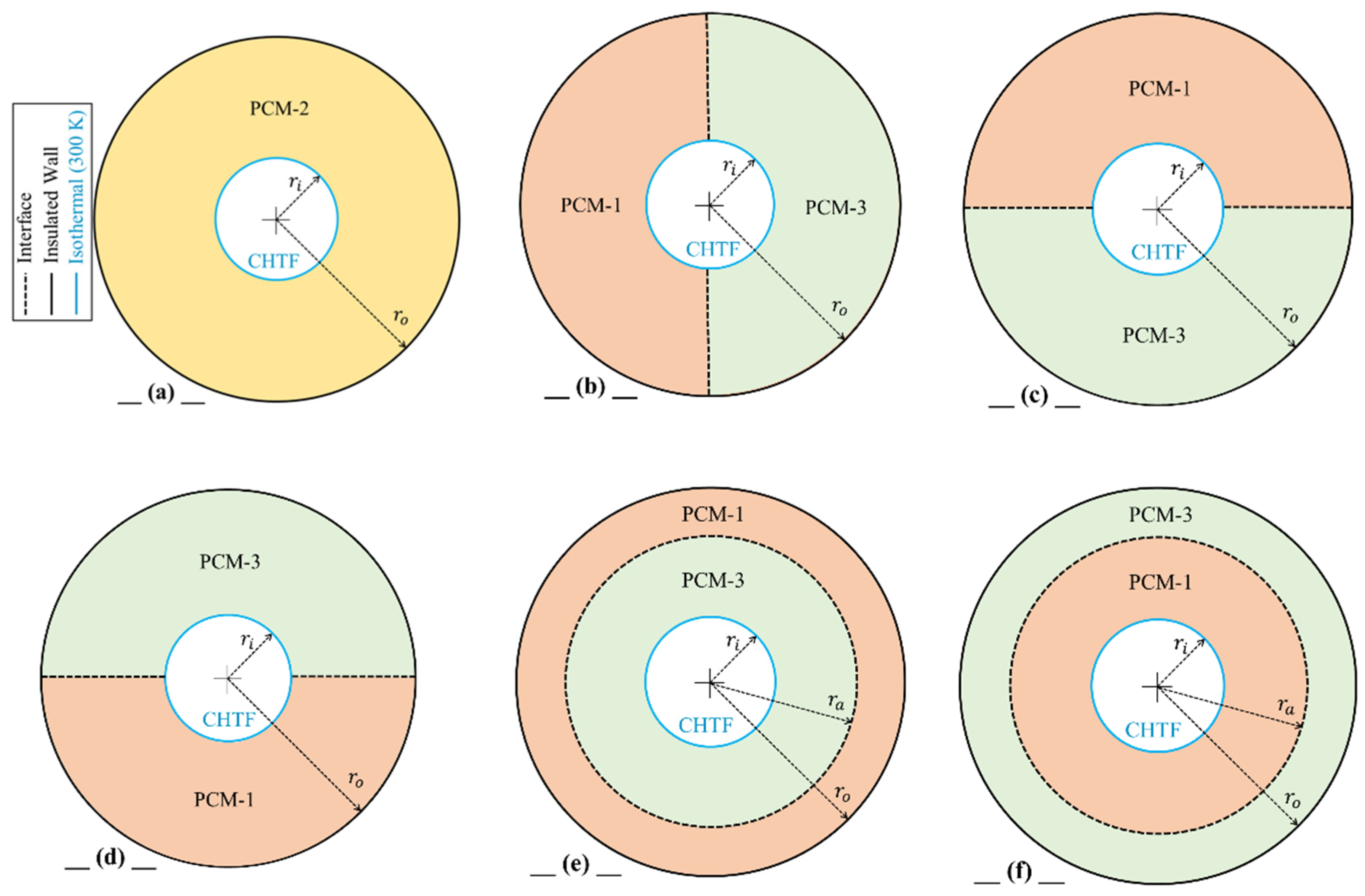

2. Problem Description

3. Numerical Method

3.1. Initial Boundary Conditions and Assumptions

- The liquid phase was laminar, incompressible, and Newtonian.

- The radiation heat transfer was not considered in the system.

- Volume change of PCM during the solidification was neglected.

- Isotropic and homogeneous materials were considered for the tubes.

- The HTF was assumed to keep a constant temperature.

- The thickness of tubes was ignored due to the relatively higher thermal conductivity of the material.

- Viscous dissipation and slip velocity on the boundaries were ignored.

3.2. Governing Equations

3.3. Numerical Procedure

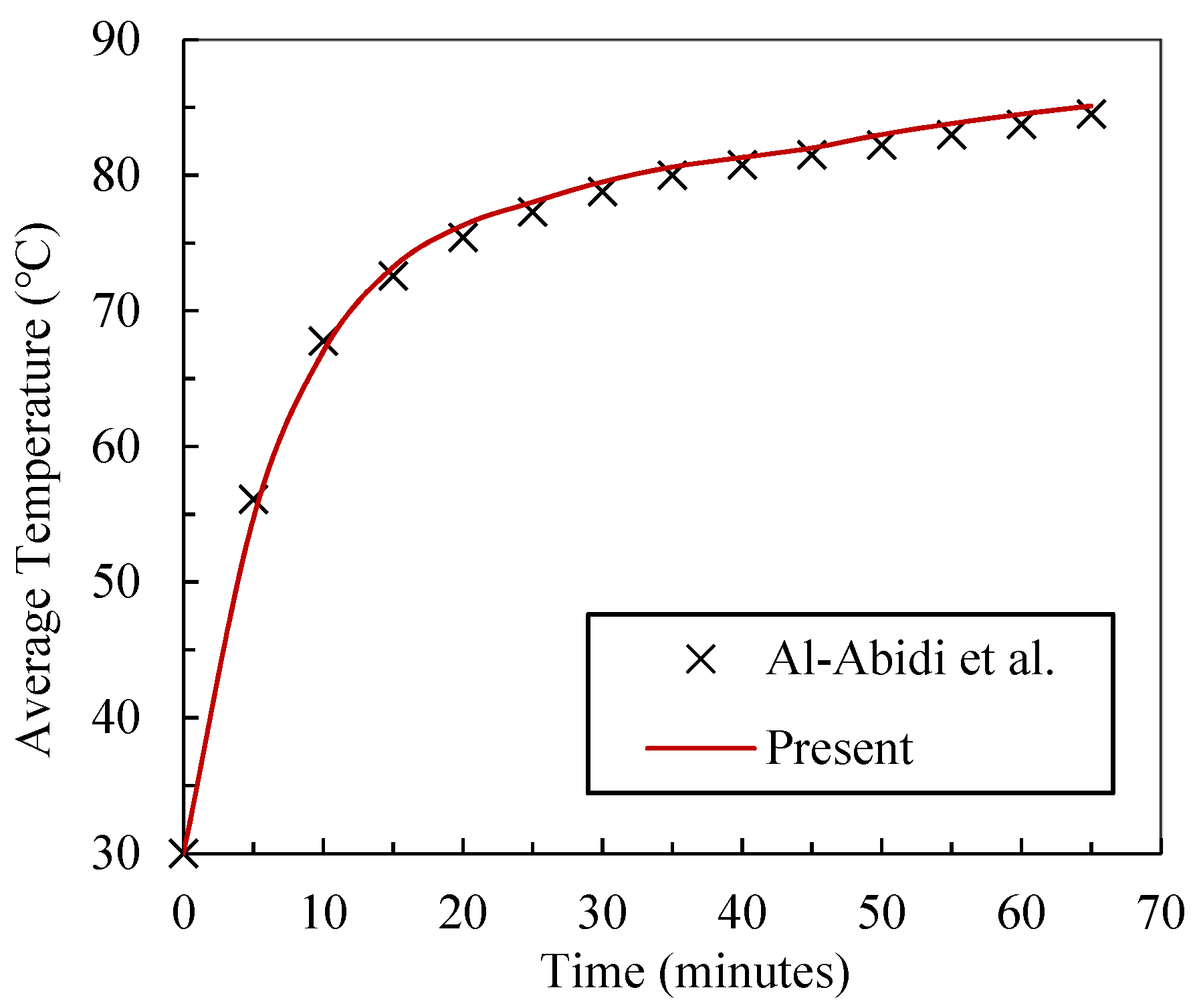

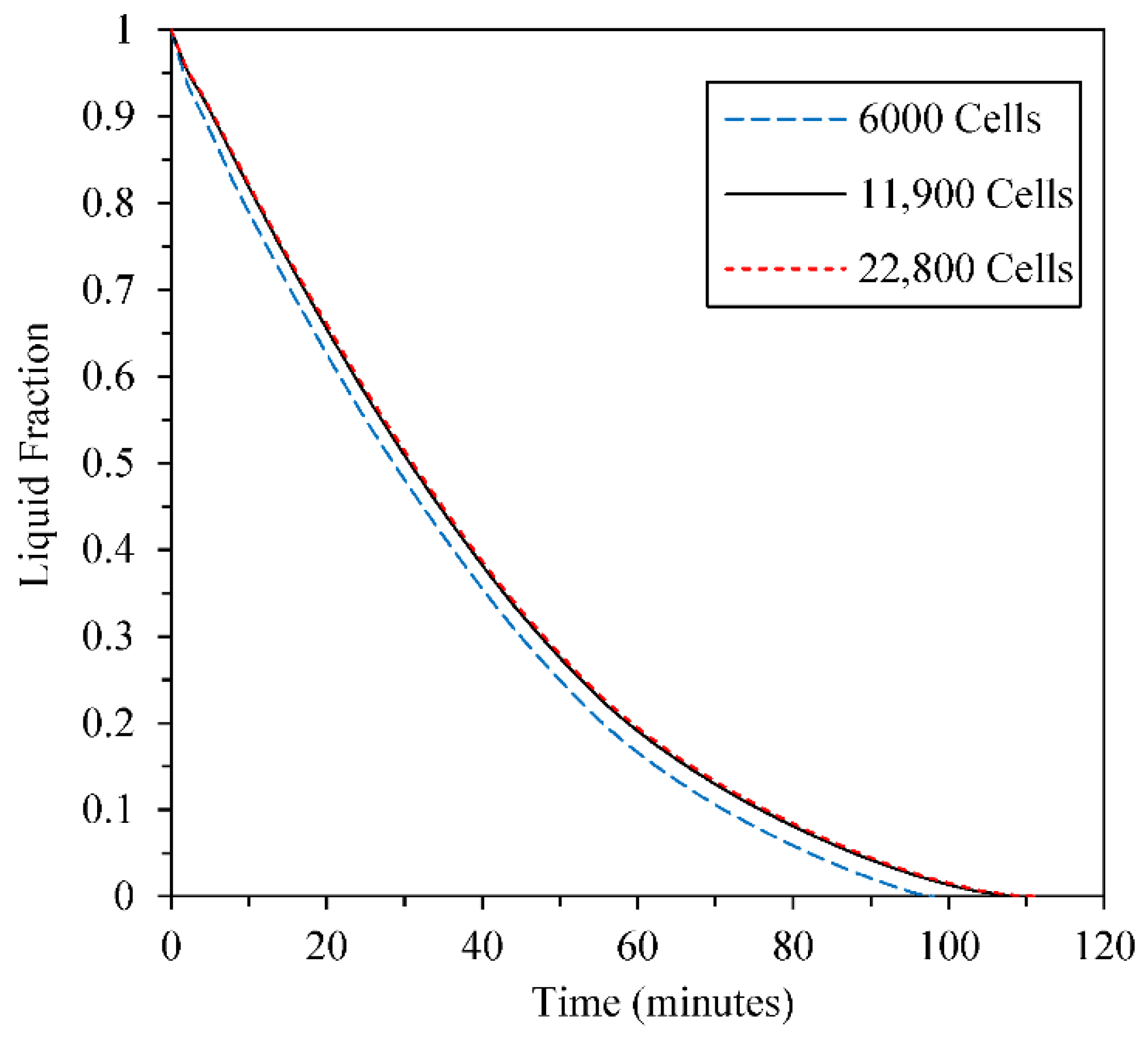

3.4. Validation and Verification

4. Results and Discussion

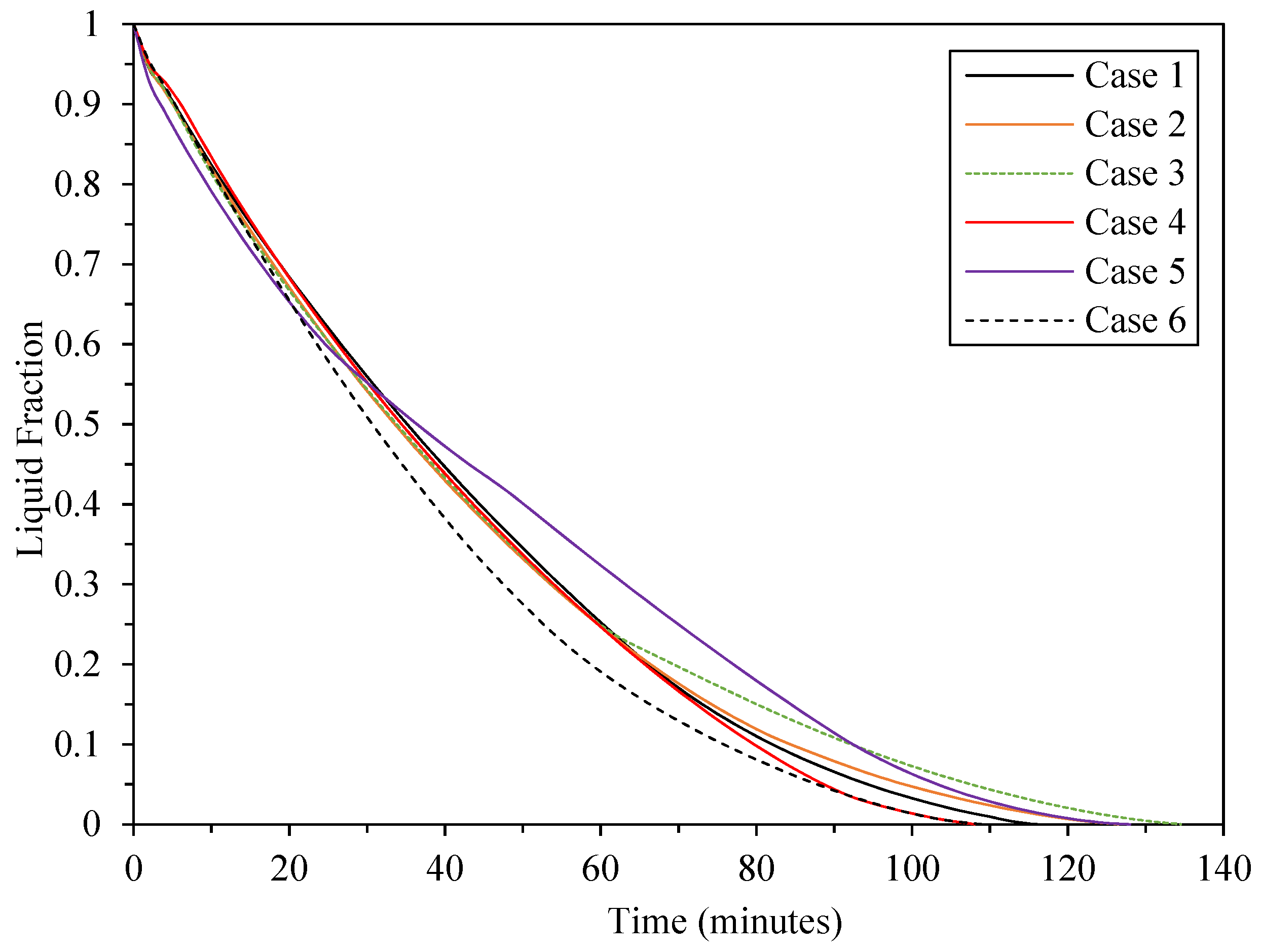

4.1. Comparison of the Configurations

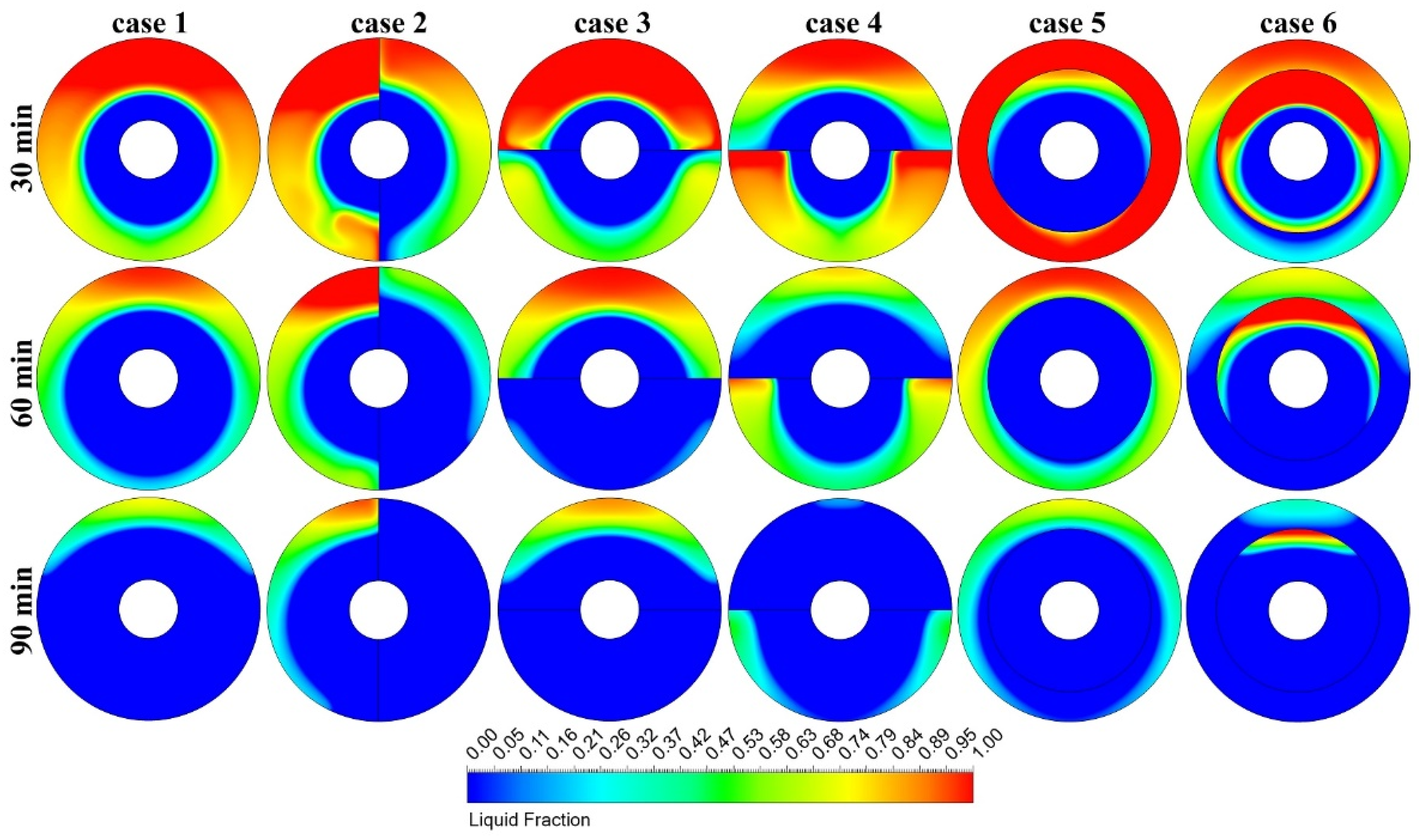

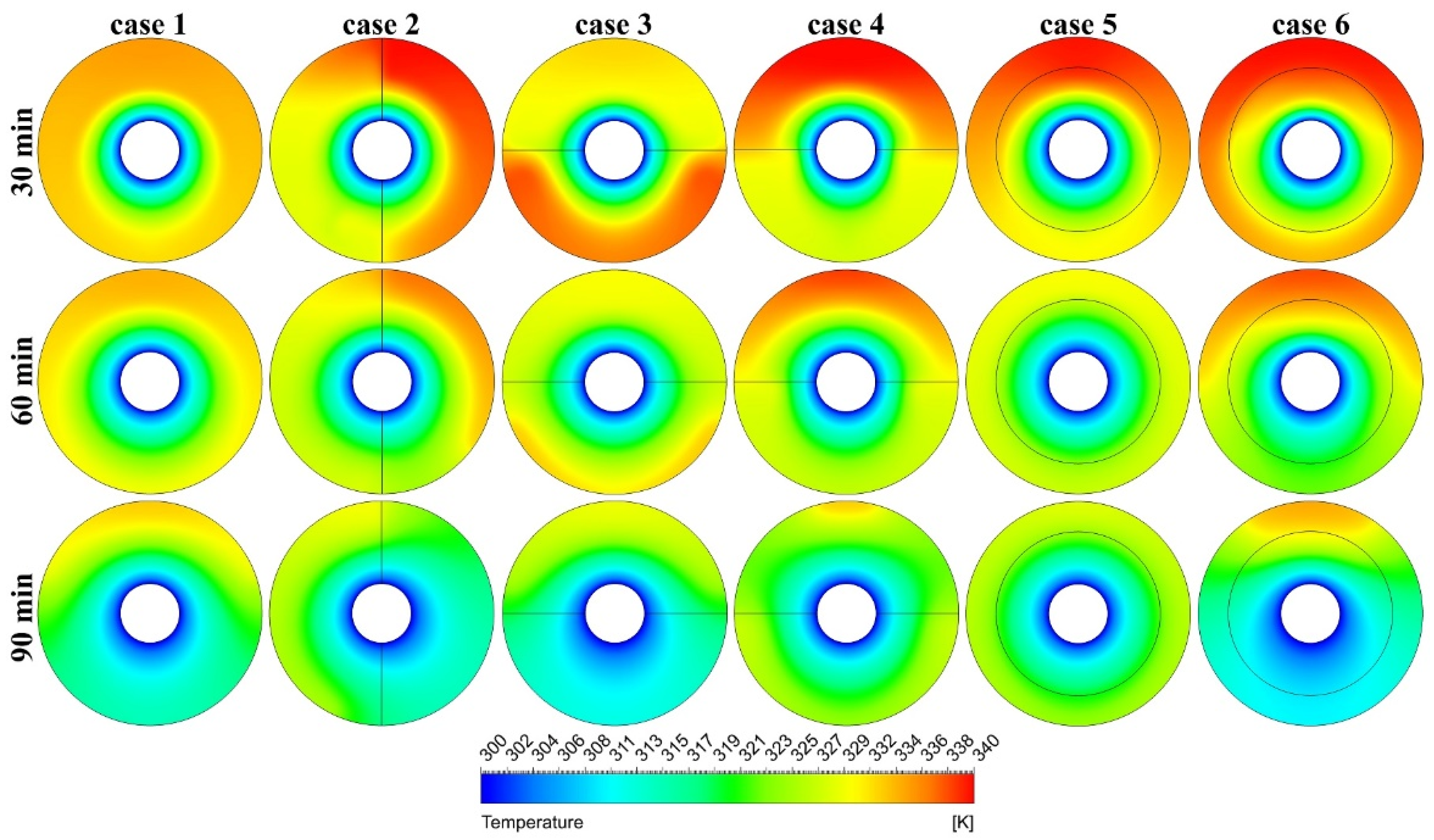

4.1.1. Liquid-Fraction and Temperature Analysis

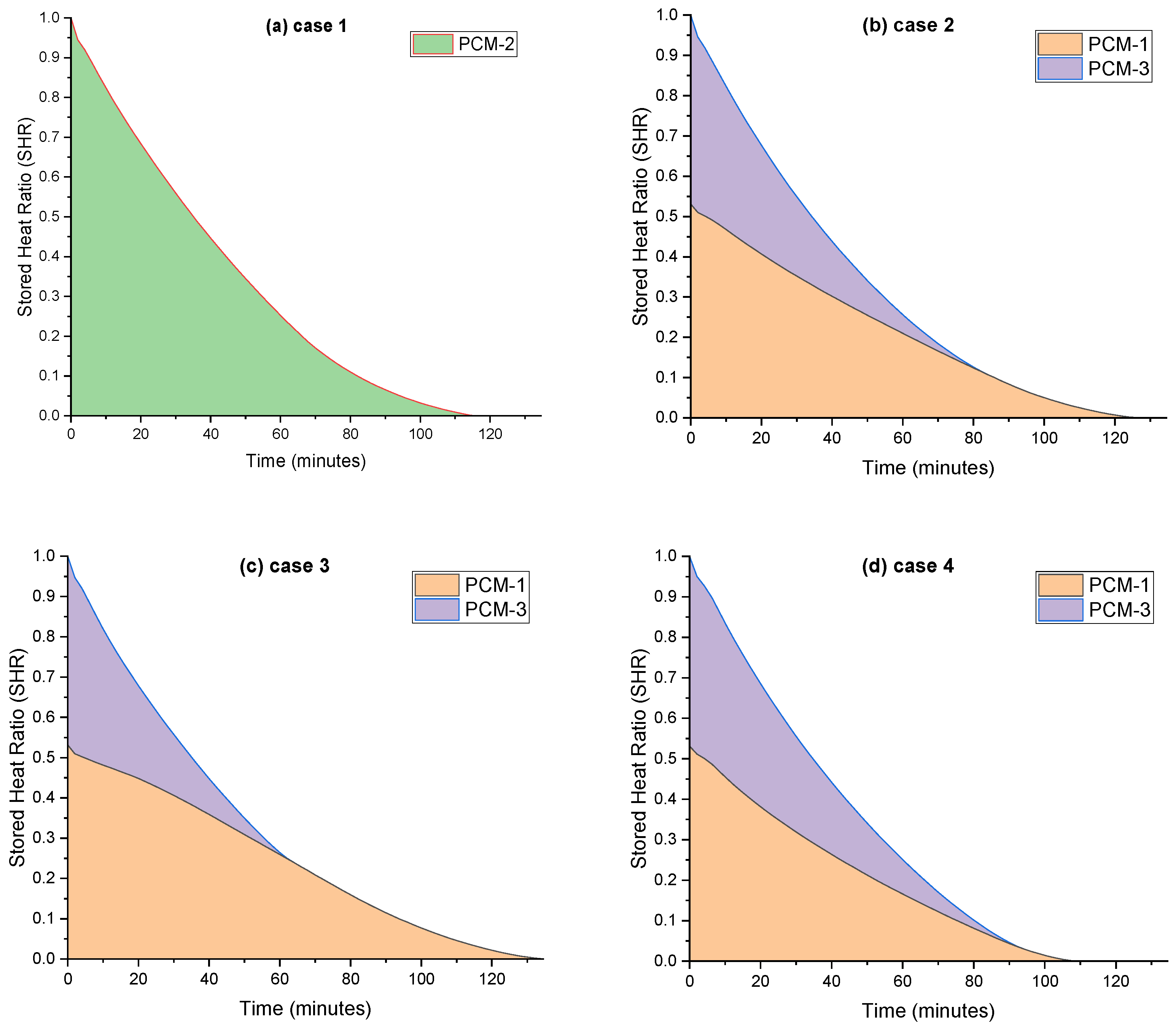

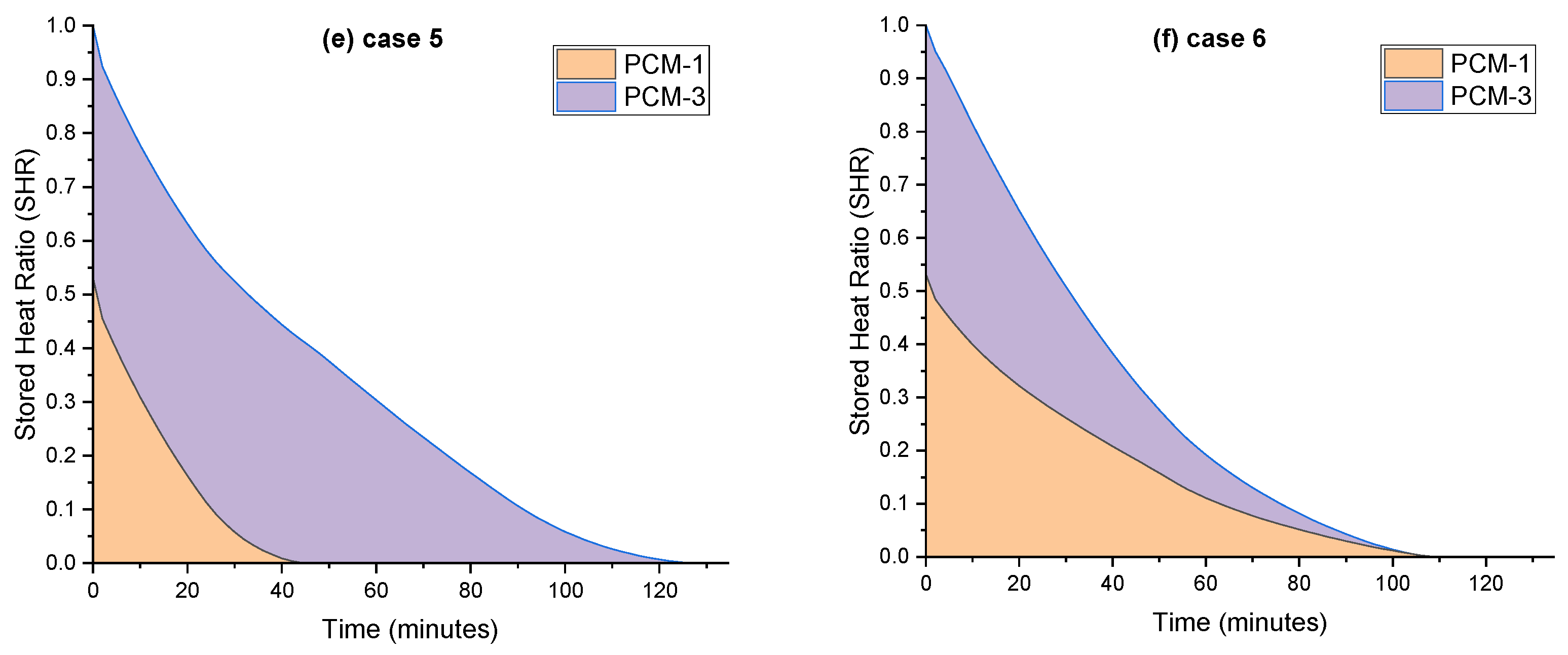

4.1.2. Heat Transfer Analysis

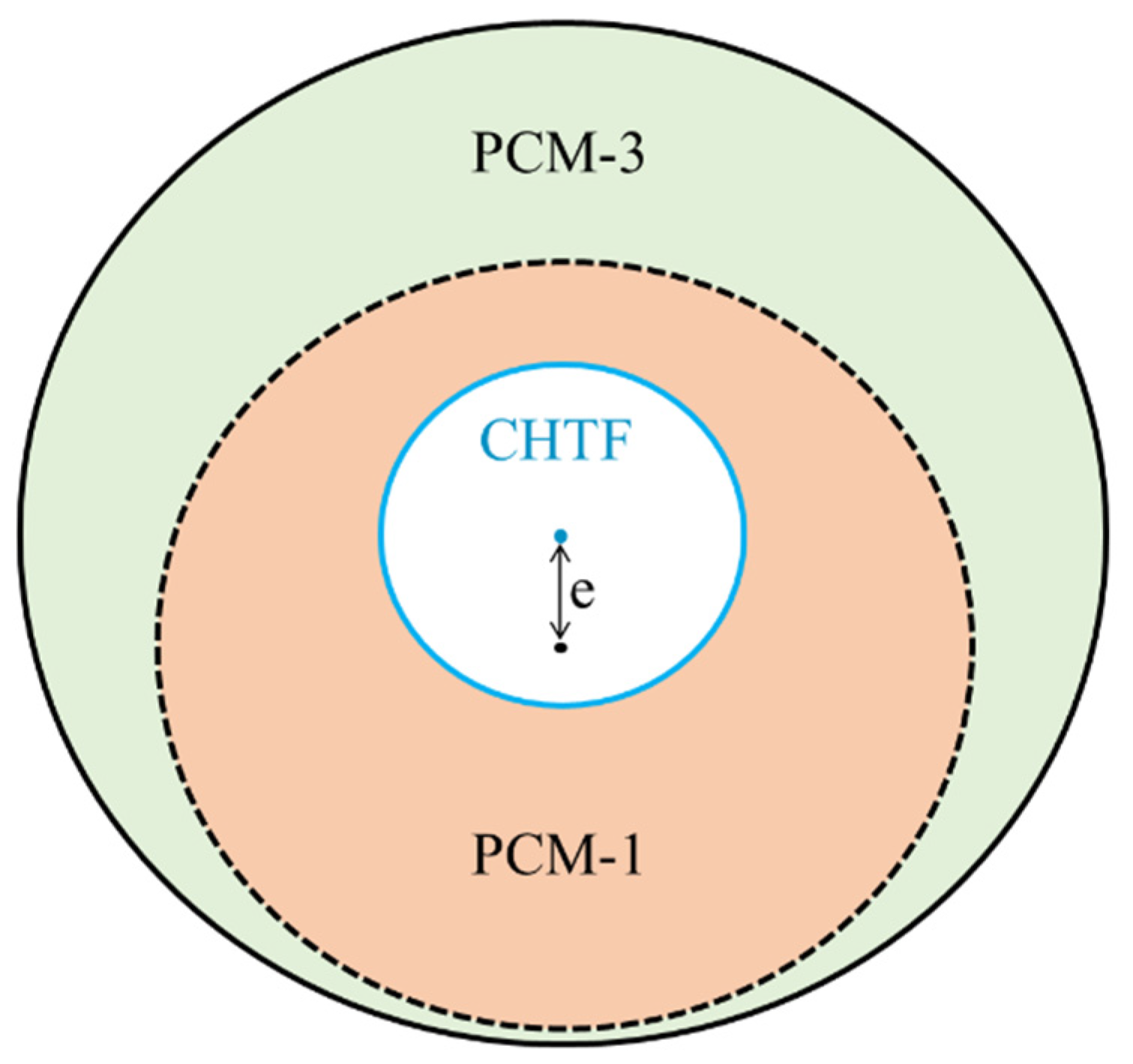

4.2. Optimum Configuration of Dual-PCM

- Arrangement of PCMs in the radial direction, such that PCM with lower solidus point is placed around the cold tube.

- Filling the upper half of the unit with the PCM with a higher solidus point.

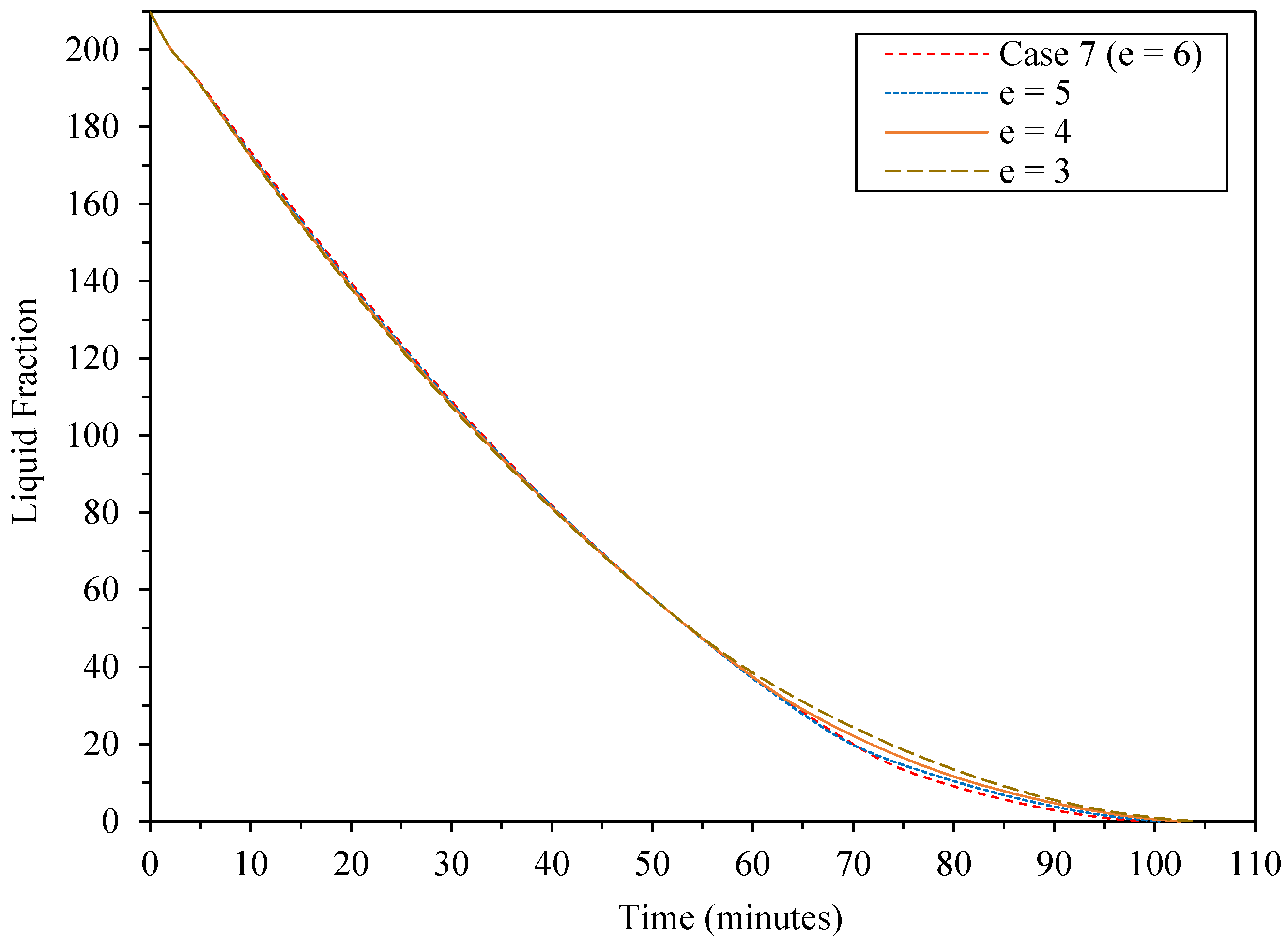

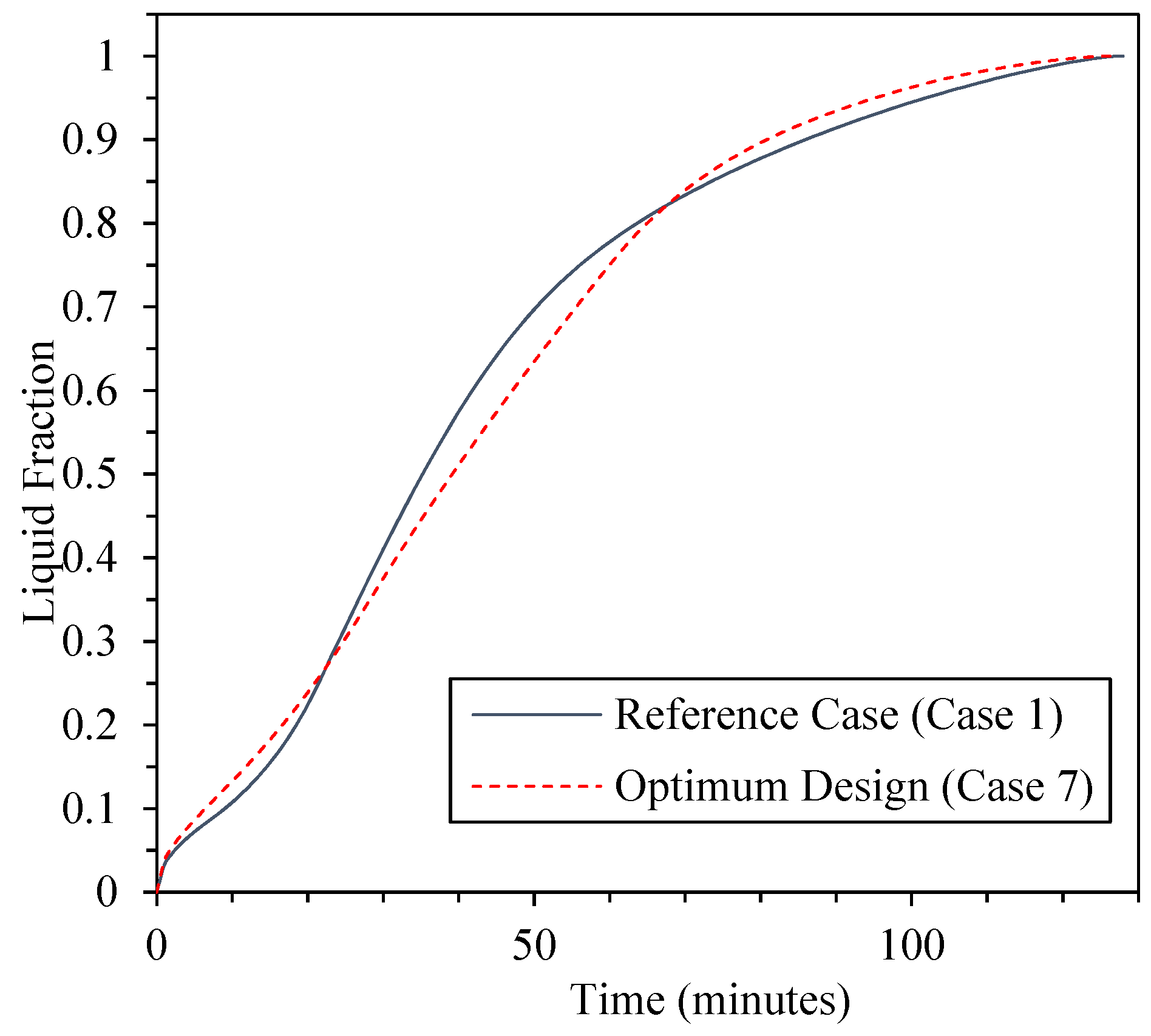

4.3. Melting Performance of the New Design

5. Conclusions

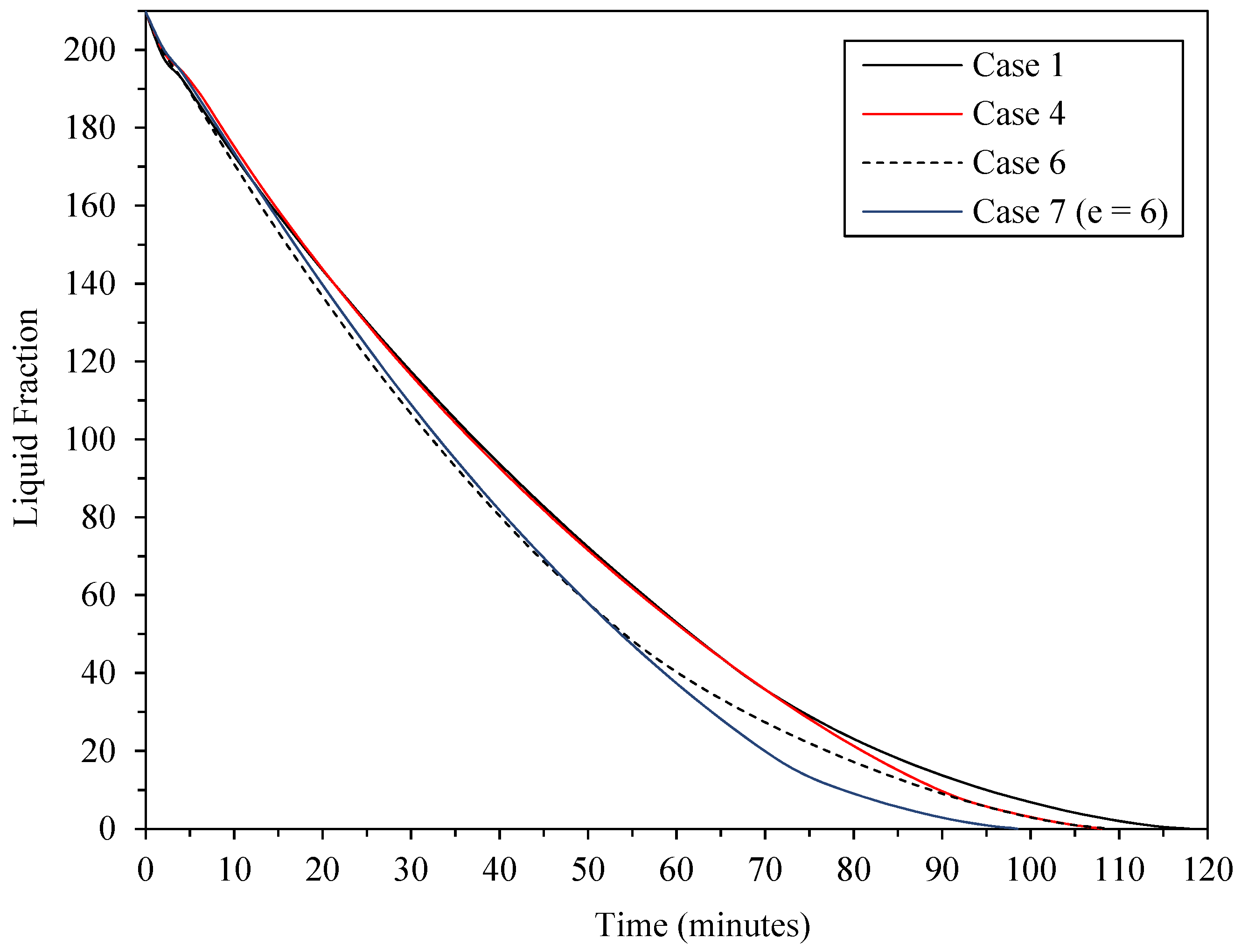

- Applying dual-PCM configurations instead of a single-PCM configuration does not necessarily improve the solidification performance inside a horizontal TES system, but effective arrangements of PCMs with different solidus points could improve the energy recovery performance.

- Placement of a PCM with a higher solidus point at the upper half and a PCM with a lower solidus point at the lower half of the system could significantly accelerate the solidification time (case-4), up to 6.89% compared with the reference case (case-1 with a single-PCM).

- When dual-PCMs were radially arranged in the storage unit (annulus-shaped sections) such that the PCM with a lower solidus point is placed around the cold tube (case-6), the energy recovery time improved up to 6.03% compared with the reference case.

- A better recovery response in the TES system could be achieved when both design advantages of case-4 and case-6 are taken into account by applying a downward eccentricity to the sector tube of the radial configuration. Therefore, a novel design with 6 mm eccentricity was introduced to accelerate the solidification time up to 15.09%, 8.51%, and 9.36% compared with cases 1, 4, and 6, respectively.

- Although this paper was focused only on solidification performance of the PCMs in a shell-and-tube storage unit, evaluation of the melting process showed a slight storage improvement for the new design compared with the reference case.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| C | Mushy zone constant |

| Specific heat (J/kg·K) | |

| d | Diameter |

| g | Gravity acceleration (m/s²) |

| h | Specific enthalpy (J/kg) |

| k | Thermal conductivity (W/m·K) |

| L | Latent heat of fusion (J/kg) |

| P | Pressure (Pa) |

| S | Momentum source term (N/m³) |

| t | Time (s) |

| T | Temperature (K) |

| Liquidus temperature (K) | |

| Solidus temperature (K) | |

| u | Velocity in r direction (m/s) |

| v | Velocity in θ direction (m/s) |

| r | Radial coordinate |

| Greek symbols | |

| ρ | Density (kg/m³) |

| β | Thermal expansion coefficient () |

| μ | Dynamic viscosity (kg/ms) |

| θ | Angular coordinate |

| δ | Constant small number |

| λ | Liquid fraction |

| Φ | Volume fraction |

| Subscripts | |

| i | Inner tube |

| init | Initial |

| l | Liquid PCM |

| o | Outer shell |

| ref | Reference |

| s | Solid PCM |

| Acronyms | |

| CFD | Computational fluid dynamics |

| FVM | Finite volume method |

| HTF | Heat transfer fluid |

| LTES | Latent thermal energy storage |

| PCM | Phase change materials |

| PRESTO | Pressure staggering option |

| SIMPLE | Semi-implicit method for pressure linked equations |

| TES | Thermal energy storage |

References

- Kolosok, S.; Bilan, Y.; Vasylieva, T.; Wojciechowski, A.; Morawski, M. A Scoping Review of Renewable Energy, Sustainability and the Environment. Energies 2021, 14, 4490. [Google Scholar] [CrossRef]

- Alva, G.; Liu, L.; Huang, X.; Fang, G. Thermal energy storage materials and systems for solar energy applications. Renew. Sustain. Energy Rev. 2017, 68, 693–706. [Google Scholar] [CrossRef]

- Mozafari, M.; Lee, A.; Cheng, S. A novel dual-PCM configuration to improve simultaneous energy storage and recovery in triplex-tube heat exchanger. Int. J. Heat Mass Transf. 2022, 186, 122420. [Google Scholar] [CrossRef]

- Chaturvedi, R.; Islam, A.; Sharma, K. A review on the applications of PCM in thermal storage of solar energy. Mater. Today Proc. 2021, 43, 293–297. [Google Scholar] [CrossRef]

- Tao, Y.; He, Y.-L. A review of phase change material and performance enhancement method for latent heat storage system. Renew. Sustain. Energy Rev. 2018, 93, 245–259. [Google Scholar] [CrossRef]

- Ghoneim, A. Comparison of theoretical models of phase-change and sensible heat storage for air and water-based solar heating systems. Sol. Energy 1989, 42, 209–220. [Google Scholar] [CrossRef]

- Qiu, L.; Ouyang, Y.; Feng, Y.; Zhang, X. Review on micro/nano phase change materials for solar thermal applications. Renew. Energy 2019, 140, 513–538. [Google Scholar] [CrossRef]

- Kumar, A.; Tiwari, A.K.; Said, Z. A comprehensive review analysis on advances of evacuated tube solar collector using nanofluids and PCM. Sustain. Energy Technol. Assess. 2021, 47, 101417. [Google Scholar] [CrossRef]

- Saffari, M.; De Gracia, A.; Fernández, C.; Cabeza, L.F. Simulation-based optimization of PCM melting temperature to improve the energy performance in buildings. Appl. Energy 2017, 202, 420–434. [Google Scholar] [CrossRef] [Green Version]

- Jia, J.; Liu, B.; Ma, L.; Wang, H.; Li, D.; Wang, Y. Energy saving performance optimization and regional adaptability of prefabricated buildings with PCM in different climates. Case Stud. Therm. Eng. 2021, 26, 101164. [Google Scholar] [CrossRef]

- Park, J.H.; Berardi, U.; Chang, S.J.; Wi, S.; Kang, Y.; Kim, S. Energy retrofit of PCM-applied apartment buildings considering building orientation and height. Energy 2021, 222, 119877. [Google Scholar] [CrossRef]

- Mozafari, M.; Lee, A.; Mohammadpour, J. Thermal Management of Single and Multiple PCMs based Heat Sinks for Electronics Cooling. Therm. Sci. Eng. Prog. 2021, 23, 100919. [Google Scholar] [CrossRef]

- Mozafari, M.; Lee, A.; Cheng, S. Improvement on the cyclic thermal shock resistance of the electronics heat sinks using two-objective optimization. J. Energy Storage 2022, 46, 103923. [Google Scholar] [CrossRef]

- Mozafari, M.; Akhavan-Behabadi, M.; Qobadi-Arfaee, H.; Hanafizadeh, P.; Fakoor-Pakdaman, M. Experimental study on condensation flow patterns inside inclined U-bend tubes. Exp. Therm. Fluid Sci. 2015, 68, 276–287. [Google Scholar] [CrossRef]

- Senthil, R. Effect of position of heat transfer fluid tube on the melting of phase change material in cylindrical thermal energy storage. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 1–11. [Google Scholar] [CrossRef]

- Kadivar, M.; Moghimi, M.; Sapin, P.; Markides, C. Annulus eccentricity optimisation of a phase-change material (PCM) horizontal double-pipe thermal energy store. J. Energy Storage 2019, 26, 101030. [Google Scholar] [CrossRef]

- Alnakeeb, M.A.; Salam, M.A.A.; Hassab, M.A. Eccentricity optimization of an inner flat-tube double-pipe latent-heat thermal energy storage unit. Case Stud. Therm. Eng. 2021, 25, 100969. [Google Scholar] [CrossRef]

- Gong, Z.-X.; Mujumdar, A. A new solar receiver thermal store for space-based activities using multiple composite phase-change materials. J. Sol. Energy Eng. 1995, 117, 215–220. [Google Scholar] [CrossRef]

- Wang, J.; Ouyang, Y.; Chen, G. Experimental study on charging processes of a cylindrical heat storage capsule employing multiple-phase-change materials. Int. J. Energy Res. 2001, 25, 439–447. [Google Scholar] [CrossRef]

- Al Siyabi, I.; Khanna, S.; Mallick, T.; Sundaram, S. Multiple phase change material (PCM) configuration for PCM-based heat sinks—an experimental study. Energies 2018, 11, 1629. [Google Scholar] [CrossRef] [Green Version]

- Farid, M.M.; Kanzawa, A. Thermal performance of a heat storage module using PCM’s with different melting temperatures: Mathematical modeling. J. Sol. Energy Eng. 1989, 111, 152–157. [Google Scholar] [CrossRef]

- Farid, M.M.; Kim, Y.; Kansawa, A. Thermal performance of a heat storage module using PCM’s with different melting temperature: Experimental. J. Sol. Energy Eng. 1990, 112, 125–131. [Google Scholar] [CrossRef]

- Al Siyabi, I.; Khanna, S.; Mallick, T.; Sundaram, S. Experimental and numerical study on the effect of multiple phase change materials thermal energy storage system. J. Energy Storage 2021, 36, 102226. [Google Scholar] [CrossRef]

- Thonon, M.; Fraisse, G.; Zalewski, L.; Pailha, M. Analytical modelling of PCM supercooling including recalescence for complete and partial heating/cooling cycles. Appl. Therm. Eng. 2021, 190, 116751. [Google Scholar] [CrossRef]

- Tan, P.; Lindberg, P.; Eichler, K.; Löveryd, P.; Johansson, P.; Kalagasidis, A.S. Effect of phase separation and supercooling on the storage capacity in a commercial latent heat thermal energy storage: Experimental cycling of a salt hydrate PCM. J. Energy Storage 2020, 29, 101266. [Google Scholar] [CrossRef]

- Rubitherm GmbH. Available online: https://www.rubitherm.eu. (accessed on 28 November 2021).

- Khodadadi, J.M.; Hosseinizadeh, S.F. Nanoparticle-enhanced phase change materials (NEPCM) with great potential for improved thermal energy storage. Int. Commun. Heat Mass Transf. 2007, 34, 534–543. [Google Scholar] [CrossRef]

- Brent, A.; Voller, V.R.; Reid, K. Enthalpy-porosity technique for modeling convection-diffusion phase change: Application to the melting of a pure metal. Numer. Heat Transf. Part A Appl. 1988, 13, 297–318. [Google Scholar]

- Leonard, B.P. A stable and accurate convective modelling procedure based on quadratic upstream interpolation. Comput. Methods Appl. Mech. Eng. 1979, 19, 59–98. [Google Scholar] [CrossRef]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; Taylor & Francis: Abingdon, UK, 2018. [Google Scholar]

- Al-Abidi, A.A.; Mat, S.; Sopian, K.; Sulaiman, M.; Mohammad, A.T. Experimental study of melting and solidification of PCM in a triplex tube heat exchanger with fins. Energy Build. 2014, 68, 33–41. [Google Scholar] [CrossRef]

| Material | ||||||||

|---|---|---|---|---|---|---|---|---|

| PCM-1 (RT-55) | 0.2 | 2 | 170 | 324 | 330 | 770 | 0.0005 | 0.0264 |

| PCM-2 (RT-60) | 0.2 | 2 | 160 | 328 | 334 | 770 | 0.0005 | 0.0288 |

| PCM-3 (RT-65) | 0.2 | 2 | 150 | 331 | 338 | 770 | 0.0005 | 0.03 |

| Copper | 400 | 0.38 | --- | --- | --- | 8920 | --- | --- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mozafari, M.; Lee, A.; Cheng, S. Simulation Study of Solidification in the Shell-And-Tube Energy Storage System with a Novel Dual-PCM Configuration. Energies 2022, 15, 832. https://doi.org/10.3390/en15030832

Mozafari M, Lee A, Cheng S. Simulation Study of Solidification in the Shell-And-Tube Energy Storage System with a Novel Dual-PCM Configuration. Energies. 2022; 15(3):832. https://doi.org/10.3390/en15030832

Chicago/Turabian StyleMozafari, Moslem, Ann Lee, and Shaokoon Cheng. 2022. "Simulation Study of Solidification in the Shell-And-Tube Energy Storage System with a Novel Dual-PCM Configuration" Energies 15, no. 3: 832. https://doi.org/10.3390/en15030832

APA StyleMozafari, M., Lee, A., & Cheng, S. (2022). Simulation Study of Solidification in the Shell-And-Tube Energy Storage System with a Novel Dual-PCM Configuration. Energies, 15(3), 832. https://doi.org/10.3390/en15030832