Electric Vehicles: V2G for Rapid, Safe, and Green EV Penetration

Abstract

1. Introduction

2. Overview of Electric Vehicle (EV) Technology

3. The EV Market Potential

4. Potential EV Mass Market Challenges

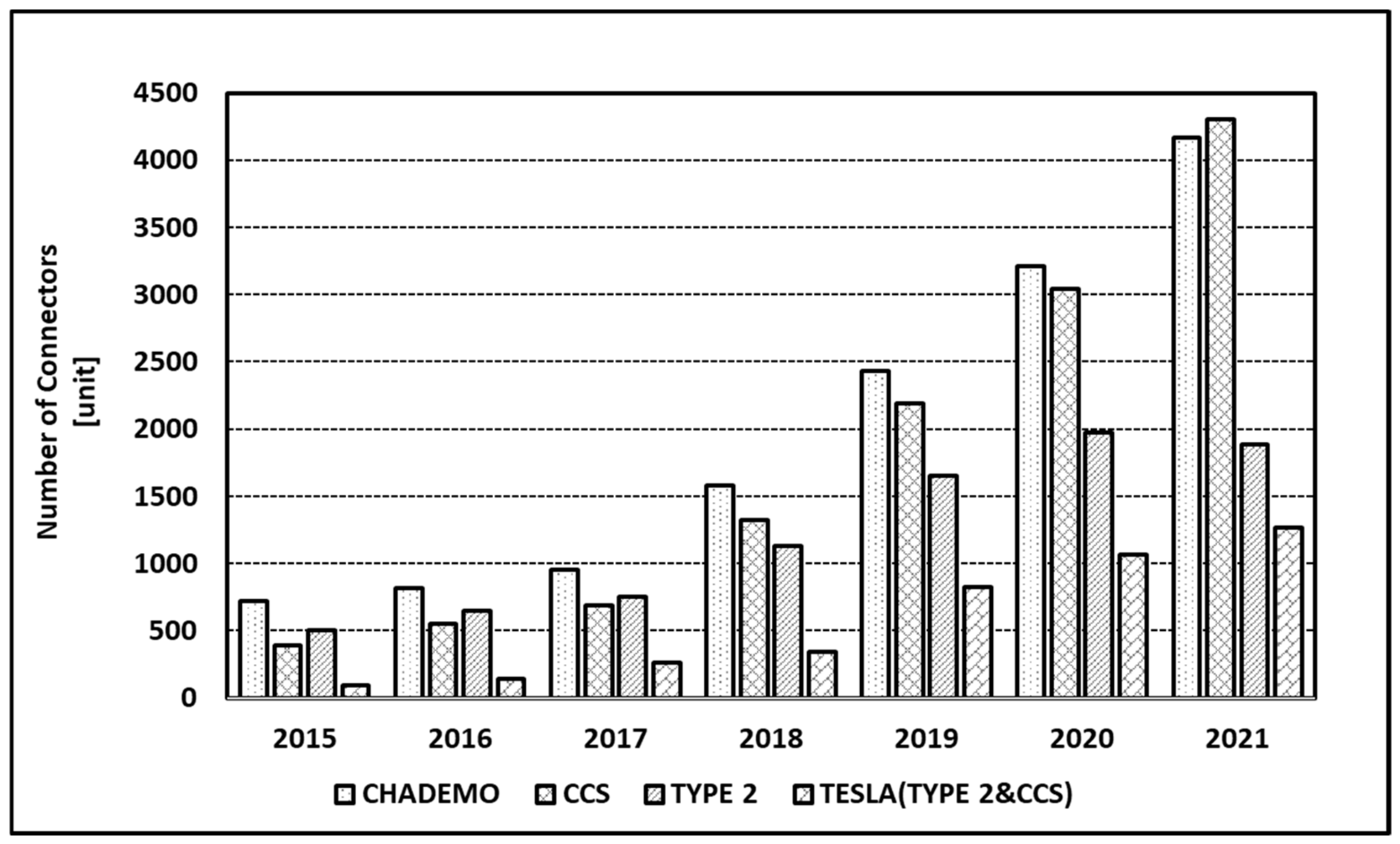

4.1. Charging Station Infrastructure

4.2. Recharging Time

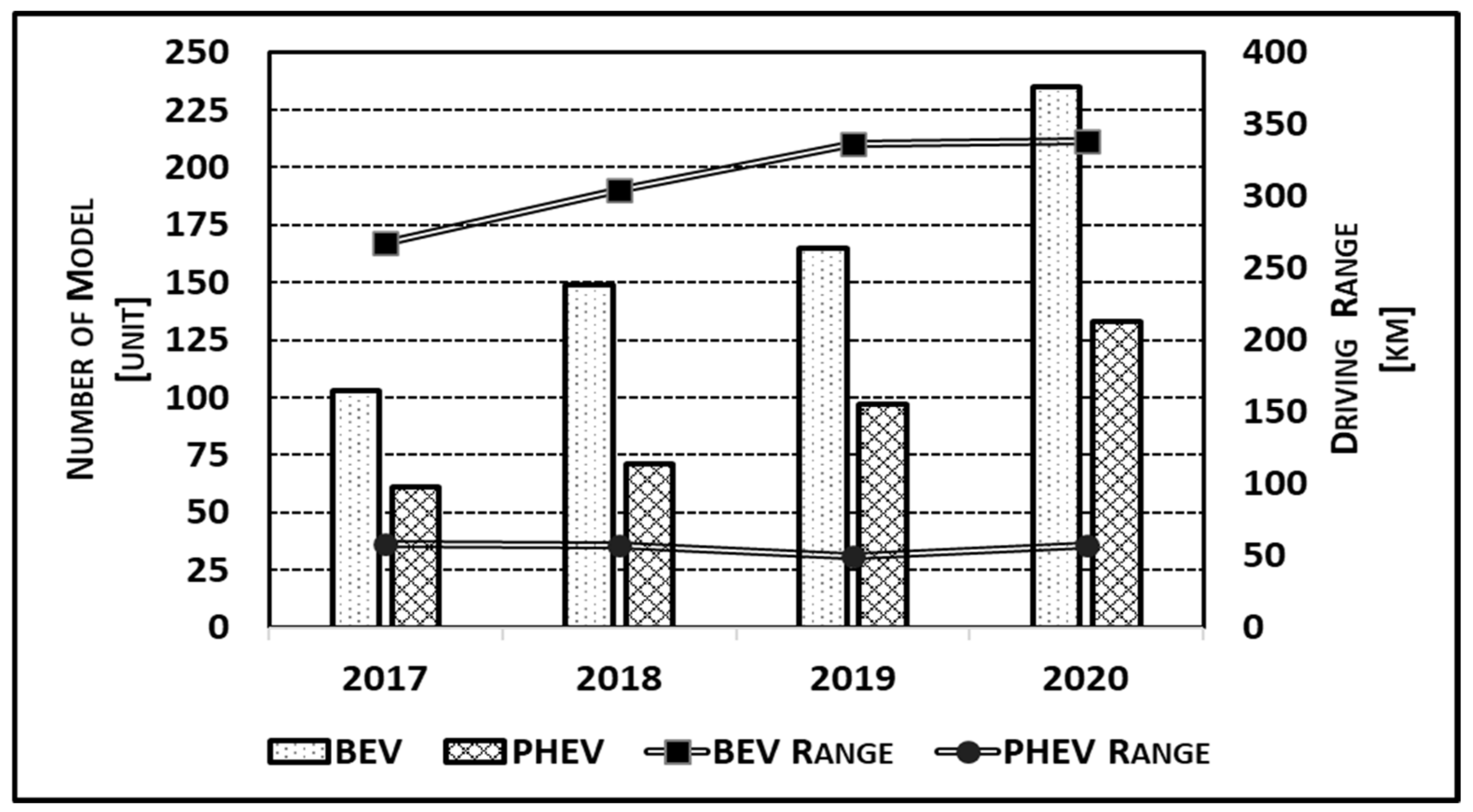

4.3. EVs Battery Development and Driving Rang

4.4. Cost and Affordability

4.5. Manufacturing and Recycling

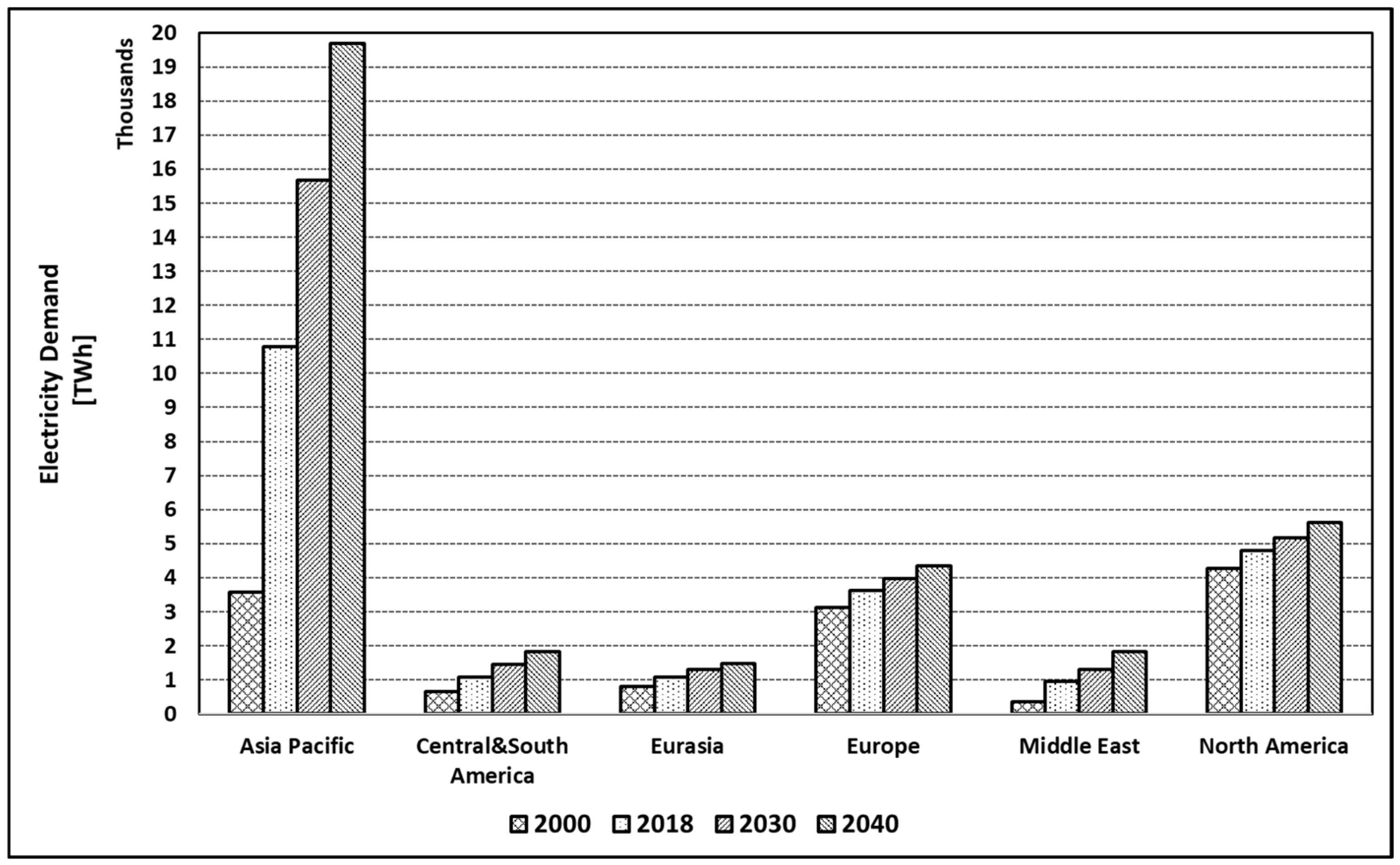

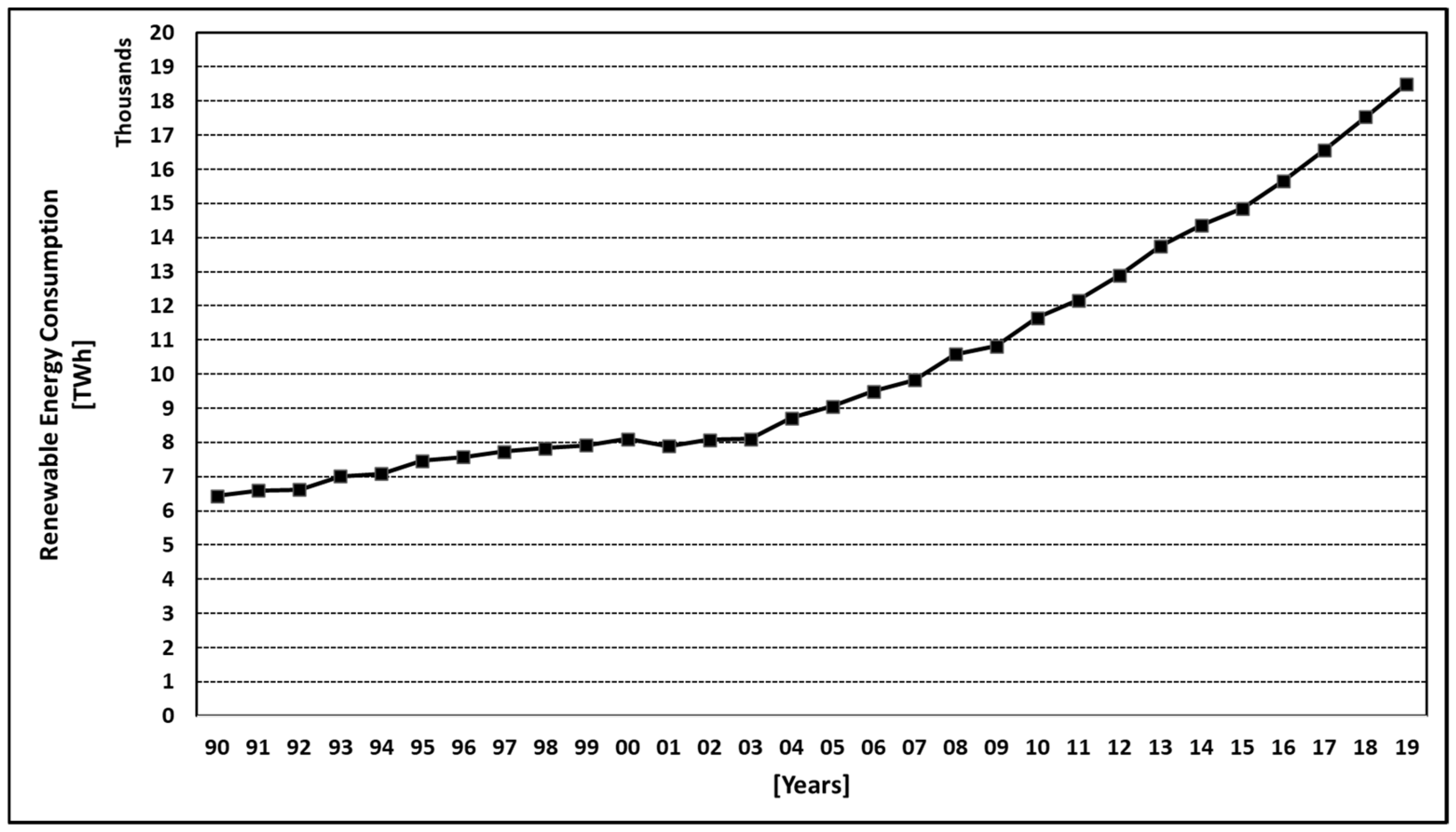

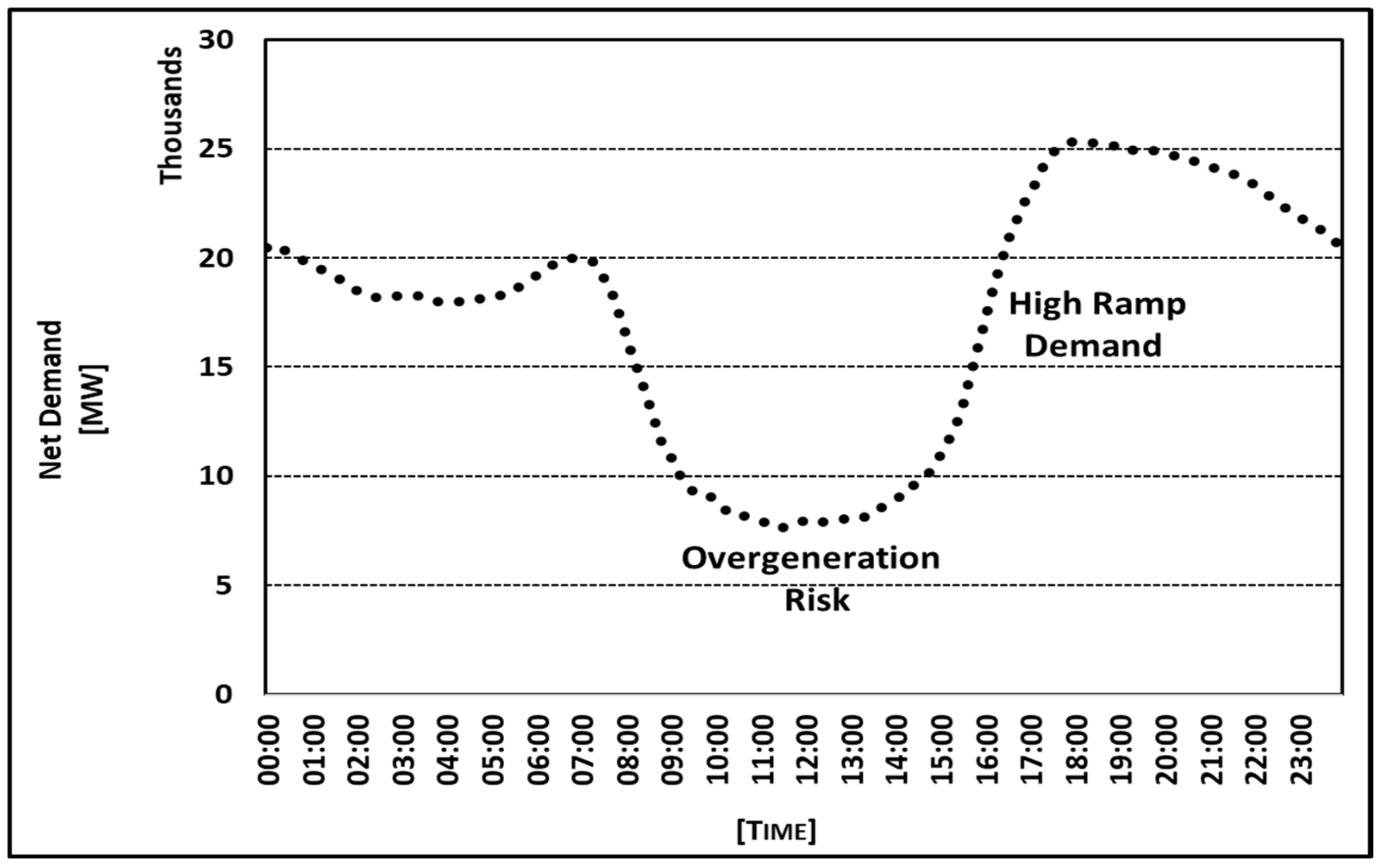

5. Impact of EVs Uptake on Power Grid Capacity

6. Potential Solutions of EVs’ Uptake|Vehicle-to-Grid (V2G) Energy Carrier

6.1. V2G Concept

6.2. Financial Revenue Incentives of V2G

6.3. Effects of V2G on the EV Batteries’ Longivity

6.4. Effects of V2G on the Environment

6.5. Integration of RESs via V2G

7. Conclusions

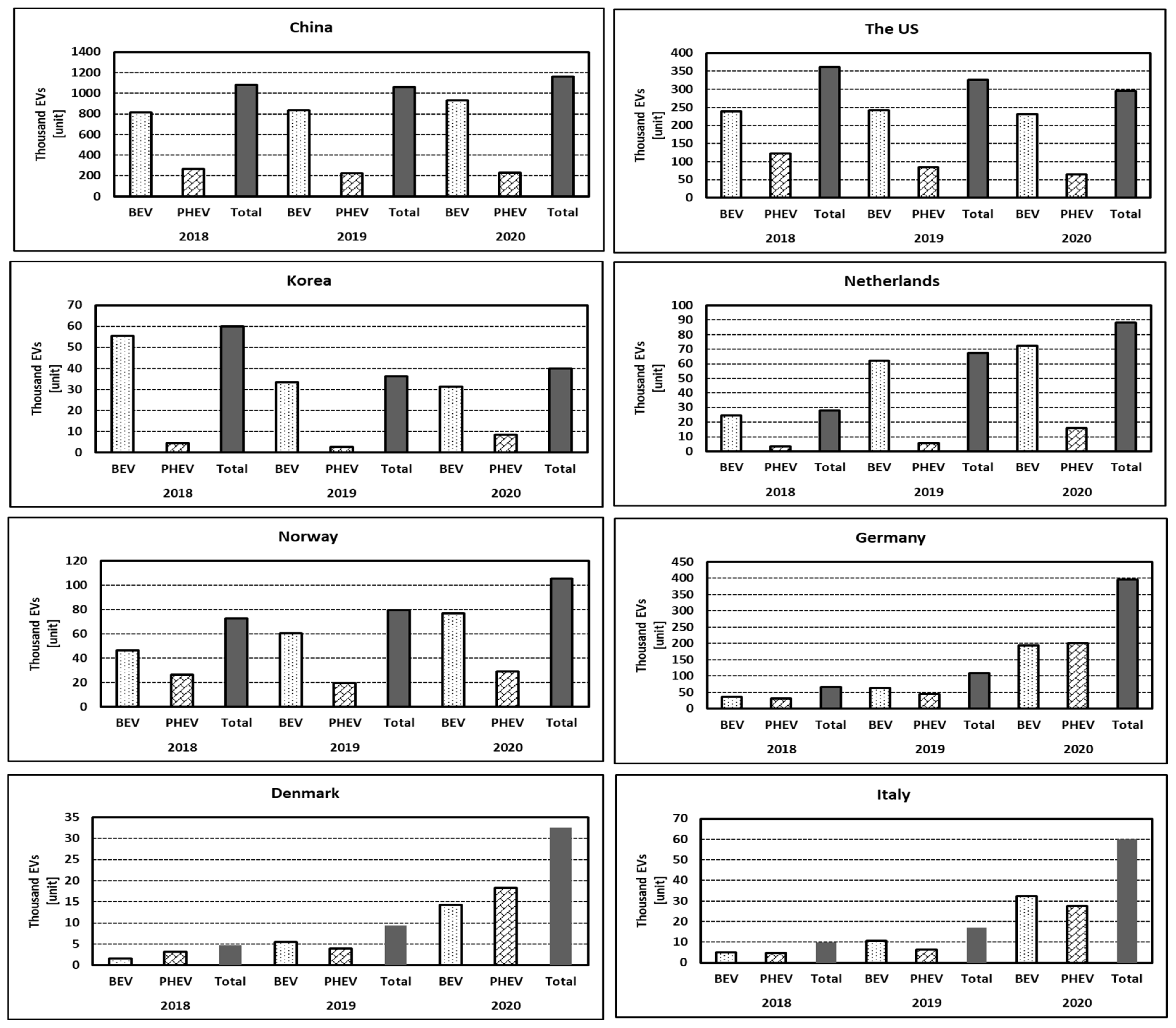

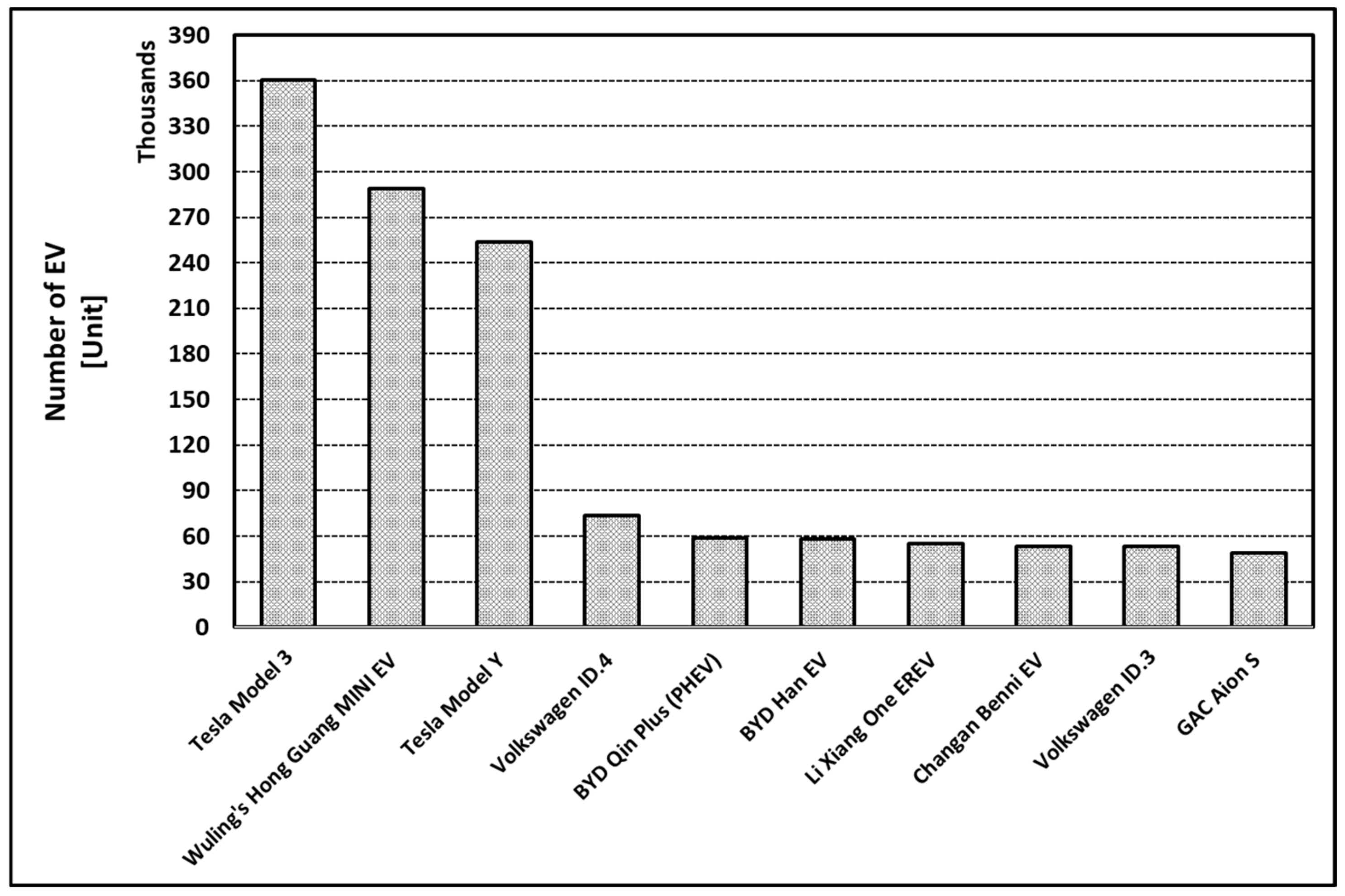

- The number of EVs sold is consistently increasing in many major economies of the world, thus displacing the process of ICE vehicles. To date, there are over 10 million EVs globally, of which BEVs and PHEVs are the best-selling types.

- China is the largest market for EVs, accounting for over 50% of global sales. However, Europe is emerging as the fastest-growing market with the most EV sales at the end of 2020.

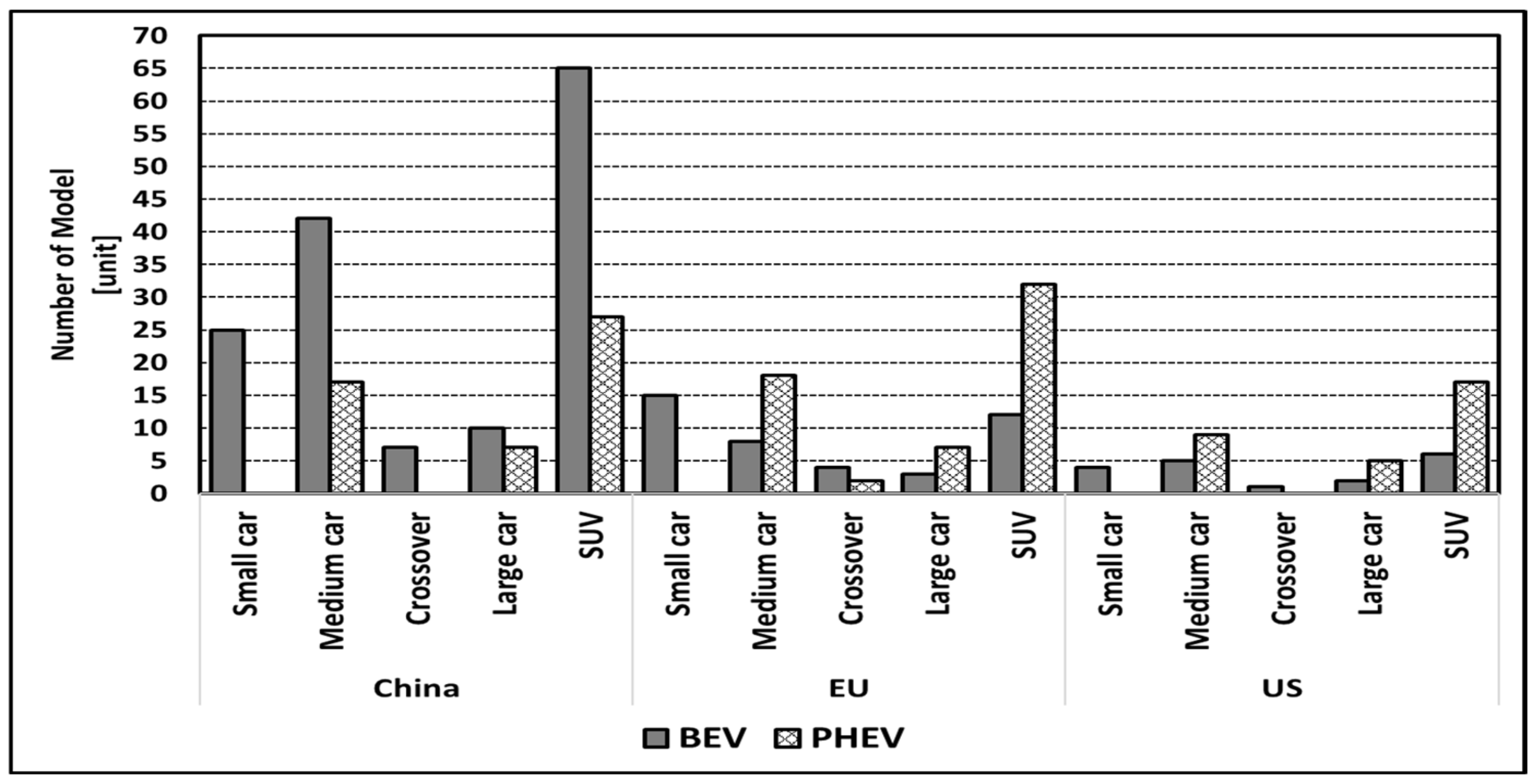

- All major automotive companies have committed to discontinuing the production of ICE cars in the next decade or soon after. They have also embarked on large investments, often supported by government grants, for research, development and manufacturing, a sign that the EV market is gaining momentum; for example, the number of available EV models increased by 40% at the end of 2020 compared to a year earlier.

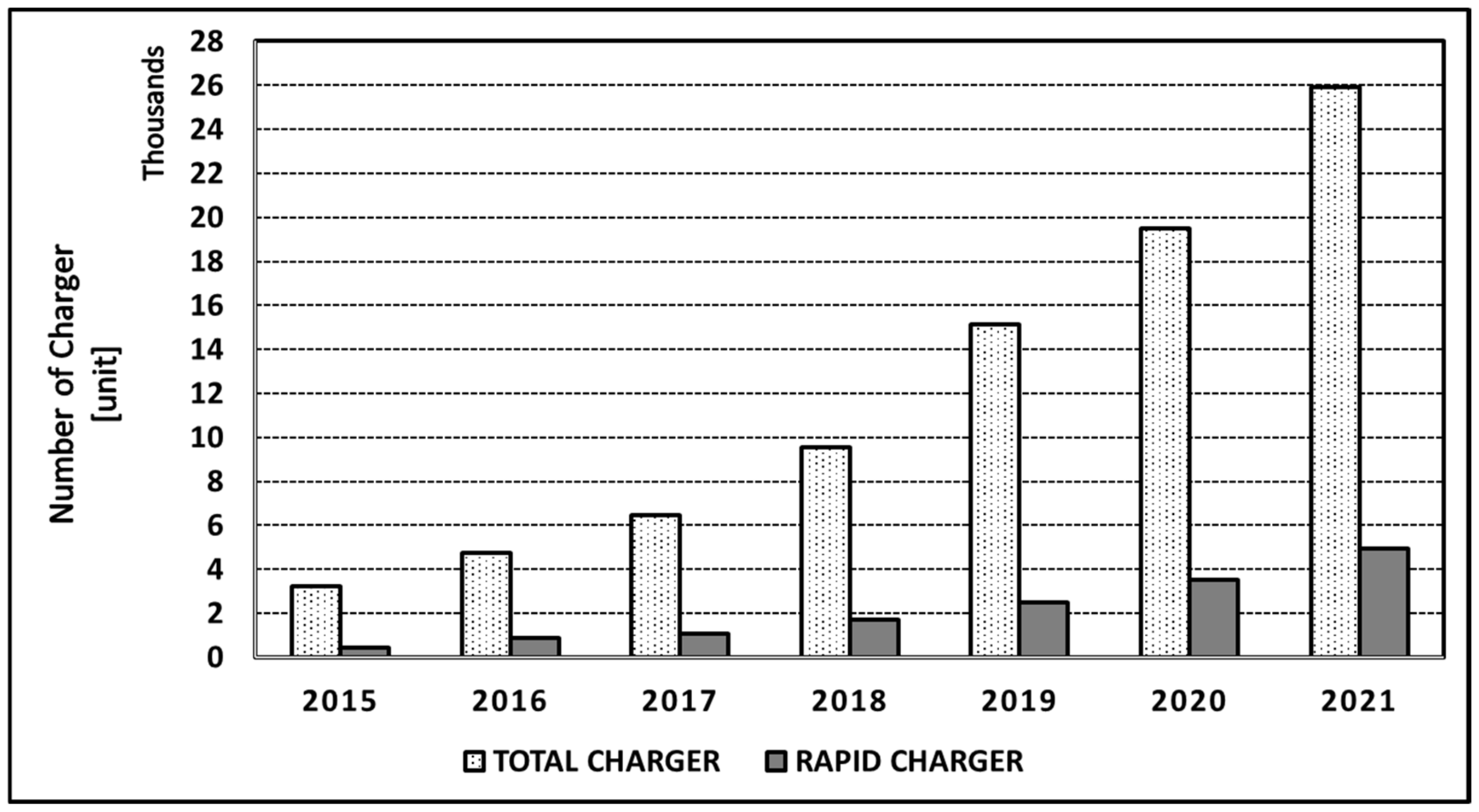

- However, the speed of market uptake will experience challenges, which could relate to both technology and affordability. For example, the number of plug-in charging installations is consistently increasing (currently at over 11 million chargers), but until this reaches a critical threshold to overcome users concerns about recharging, hesitancy will remain about switching to EVs. In addition, the development of rapid EV chargers will reduce the charging time, enabling EVs to compete with ICE vehicles.

- Concerns regarding range anxiety among potential users of EVs still needs to be addressed through the development of lighter and high energy density battery technology. However, any future technological advancement should consider the sustainability of sourcing rare earth materials, waste, and recycling issues.

- The deployment of the EV market will add significant pressure on grid infrastructure to increase both generation capacity and faster response times. However, EVs may also play a major role, in addition to their primary purpose of transportation, as an energy carrier supporting future smart power grids. V2G technology can, for example, be deployed through smart controllers to store electrical power generated from renewable sources at times of low demand, and discharge to the grid at times of peak demand. However, this still requires further research and development to address technical limitations, such as the impact on battery service life and users’ behaviour and acceptability.

- The mass market uptake of EVs will constitute a major global re-industrialisation, in conjunction with the shift to renewable energy power generation. These technological and social transformations will result in immense benefits, thus improving the quality of life and the environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Looney, B. BP Statistical Review of World Energy 2020, 69th ed.; British Petroleum Co.: London, UK, 2020; p. 66. [Google Scholar]

- Cozzi, L.; Gould, T.; Bouckaert, S.; Kim, T.Y.; McNamara, K.; Wanner, B.; Mcglade, C.; Olejarnik, P.; Adam, Z.; Sarazola, L.A.; et al. World Energy Outlook 2019; IEA: Paris, France, 2019. [Google Scholar]

- Cozzi, L.; Gould, T.; Bouckaert, S.; Crow, D.; Kim, T.Y.; Mcglade, C.; Olejarnik, P.; Wanner, B.; Wetzel, D.; Adam, Z.; et al. World Energy Outlook 2020; IEA: Paris, Frace, 2020. [Google Scholar]

- Chen, K.; Winter, R.C.; Bergman, M.K. Carbon dioxide from fossil fuels: Adapting to uncertainty. Energy Policy 1980, 8, 318–330. [Google Scholar] [CrossRef][Green Version]

- BGS. The Greenhouse Effect. Available online: https://www.bgs.ac.uk/discovering-geology/climate-change/how-does-the-greenhouse-effect-work/ (accessed on 25 November 2021).

- BBC. Climate Change—Impact of Human Activity. Available online: https://www.bbc.co.uk/bitesize/guides/zt6sfg8/revision/2 (accessed on 25 November 2021).

- BBC. Climate Change: Last Decade UK’s ‘Second Hottest in 100 Years’. 2020. Available online: https://www.bbc.co.uk/news/science-environment-50976909 (accessed on 25 November 2021).

- Sinsel, S.R.; Riemke, R.L.; Hoffmann, V.H. Challenges and solution technologies for the integration of variable renewable energy sources—A review. Renew. Energy 2020, 145, 2271–2285. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. Energy. 2020. Available online: https://ourworldindata.org/energy (accessed on 22 December 2021).

- Li, D.; Chiu, W.; Sun, H. Demand Side Management in Microgrid Control Systems. In Microgrid: Advanced Control Methods and Renewable Energy System Integration; Mahmoud, M.S., Ed.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 203–230. [Google Scholar]

- Strbac, G. Demand side management: Benefits and challenges. Energy Policy 2008, 36, 4419–4426. [Google Scholar] [CrossRef]

- Su, H.-I.; El Gamal, A. Modeling and analysis of the role of energy storage for renewable integration: Power balancing. IEEE Trans. Power Syst. 2013, 28, 4109–4117. [Google Scholar] [CrossRef]

- Muruganantham, B.; Gnanadass, R.; Padhy, N. Challenges with renewable energy sources and storage in practical distribution systems. Renew. Sustain. Energy Rev. 2017, 73, 125–134. [Google Scholar] [CrossRef]

- Teter, J.; Tattini, J.; Petropoulos, A. Tracking Transport 2020; IEA: Paris, France, 2020. [Google Scholar]

- McKerracher, C.; O’Donovan, A.; Albanese, N.; Soulopoulos, N.; Doherty, D.; Boers, M.; Fisher, R.; Cantor, C.; Frith, J.; Mi, S.; et al. Electric Vehicle Outlook (EVO) 2021; BloombergNEF (BNEF): London, UK, 2021. [Google Scholar]

- Borba, B.S.M.; Szklo, A.; Schaeffer, R. Plug-in hybrid electric vehicles as a way to maximize the integration of variable renewable energy in power systems: The case of wind generation in northeastern Brazil. Energy 2012, 37, 469–481. [Google Scholar] [CrossRef]

- Kempton, W.; Letendre, S.E. Electric vehicles as a new power source for electric utilities. Transp. Res. Part D Transp. Environ. 1997, 2, 157–175. [Google Scholar] [CrossRef]

- Kempton, W.; Tomić, J. Vehicle-to-grid power implementation: From stabilizing the grid to supporting large-scale renewable energy. J. Power Sources 2005, 144, 280–294. [Google Scholar] [CrossRef]

- Colmenar-Santos, A.; Muñoz-Gómez, A.M.; Rosales-Asensio, E.; López-Rey, Á. Electric vehicle charging strategy to support renewable energy sources in Europe 2050 low-carbon scenario. Energy 2019, 183, 61–74. [Google Scholar] [CrossRef]

- DfT. Annual Mileage of Cars by Ownership and Trip Purpose: England; Department for Transport (DfT) Statistics: London, UK, 2020.

- Ehsani, M.; Gao, Y.; Longo, S.; Ebrahimi, K.M. Modern Electric, Hybrid Electric, And Fuel Cell Vehicles; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Standage, T. The Lost History of the Electric Car—And What It Tells Us about the Future of Transport. 2021. Available online: https://www.theguardian.com/technology/2021/aug/03/lost-history-electric-car-future-transport (accessed on 21 December 2021).

- NationalGrid. The (Surprisingly Long) History of Electric Vehicles. 2021. Available online: https://www.nationalgrid.com/stories/journey-to-net-zero-stories/surprisingly-long-history-electric-vehicles (accessed on 21 December 2021).

- Mui, S.; Shelby, M.; Chartier, D.; Ganss, D. Plug-In Hybrids: A Scenario Analysis; US Environmental Protection Agency: Washington, DC, USA, 2007.

- Qin, N.; Raissi, A.; Brooker, P. Analysis of Fuel Cell Vehicle Developments; The Florida Solar Energy Center (FSEC): Cocoa, FL, USA, 2014. [Google Scholar]

- Kebriaei, M.; Niasar, A.H.; Asaei, B. Hybrid electric vehicles: An overview. In Proceedings of the 2015 International Conference on Connected Vehicles and Expo (ICCVE), Shenzhen, China, 19–23 October 2015. [Google Scholar]

- Agarwal, O.P.; Jhunjhunwala, A.; Kaur, P.; Yadav, N.; Chakrabarty, S.; Kumar, P.; Pai, M.; Bhatt, A. A Guidance Document on Accelerating Electric Mobility in India; WRI India: Mumbai, India, 2019. [Google Scholar]

- Skoda. Types of Electric Vehicles—Do You Know THEM All? 2019. Available online: https://www.skoda-storyboard.com/en/skoda-world/innovation-and-technology/types-of-electric-vehicles-do-you-know-them-all/transport (accessed on 28 December 2021).

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.N.; Hossain, E. A comprehensive study of key electric vehicle (EV) components, technologies, challenges, impacts, and future direction of development. Energies 2017, 10, 1217. [Google Scholar] [CrossRef]

- Rao, H.S.; Hettige, H.; Singru, N.; Lumain, R.; Roldan, C. Reducing Carbon Emissions from Transport Projects. Evaluation Knowledge Brief; Dalkmann, H., Ed.; OECD: Paris, France, 2010; Available online: https://www.oecd.org/derec/adb/47170274.pdf (accessed on 10 January 2022).

- McKerracher, C.; Izadi-Najafabadi, A.; O’Donovan, A.; Albanese, N.; Soulopolous, N.; Doherty, D.; Boers, M.; Fisher, R.; Cantor, C.; Frith, J.; et al. Electric Vehicle Outlook (EVO) 2020; BloombergNEF (BNEF): London, UK, 2020. [Google Scholar]

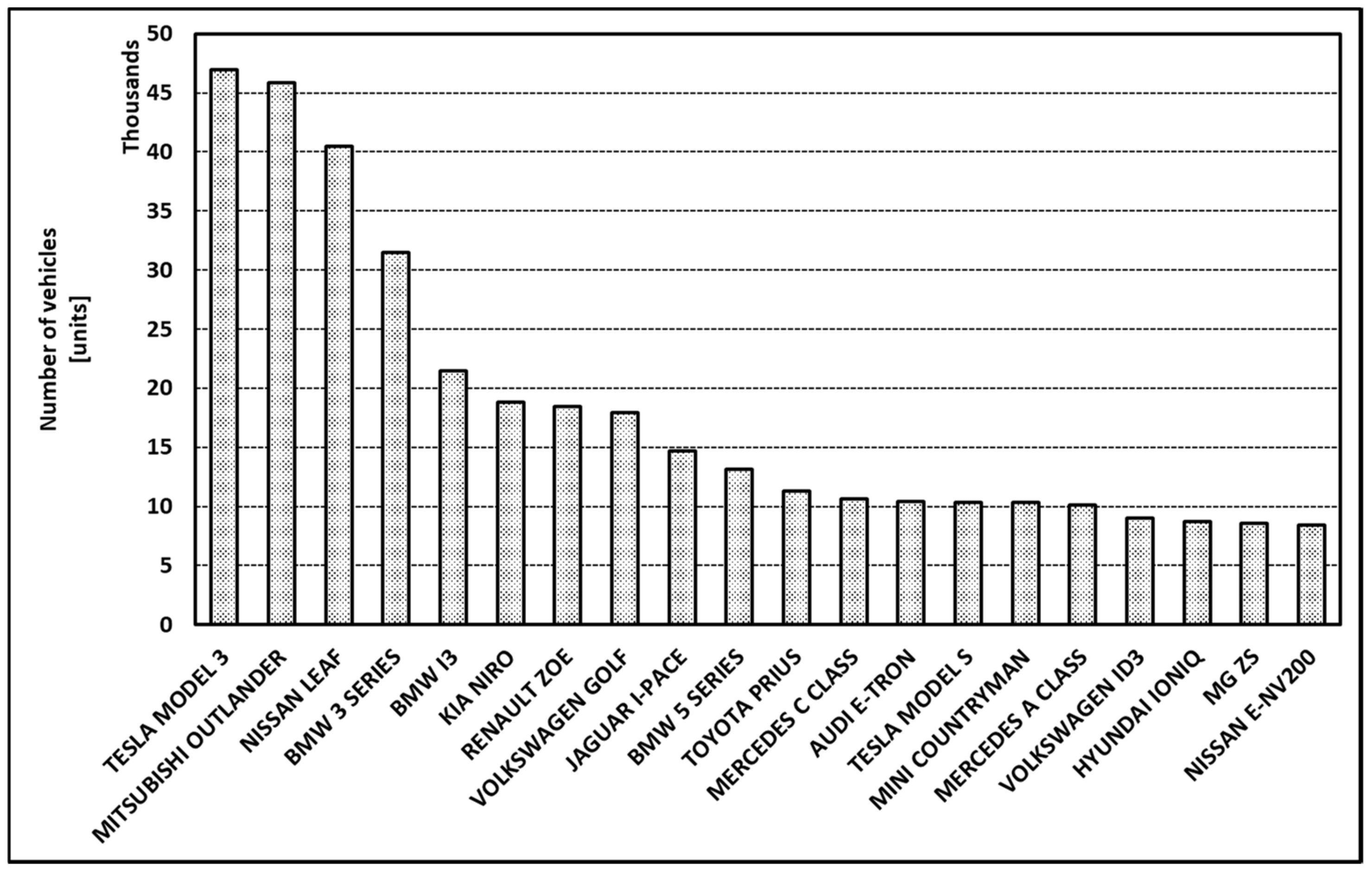

- Hirst, D.; Winnet, J.; Hinson, S. Electric Vehicles and Infrastructure; House of Commons Library: London, UK, 2021; pp. 5–10. [Google Scholar]

- Bigra, E.M.; Connelly, E.; Gorner, M.; Lowans, C.; Paoli, L.; Tattini, J.; Teter, J.; LeCroy, C.; MacDonnell, O.; Welch, D.; et al. Global EV Outlook 2021|Accelerating Ambitions Despite the Pandemic; IEA: Paris, France, 2021. [Google Scholar]

- Irle, R. Global EV Sales for 2021 H1. 2021. Available online: https://www.ev-volumes.com/country/total-world-plug-in-vehicle-volumes/ (accessed on 9 December 2021).

- Abergel, T.; Bunsen, T.; Gorner, M.; Leduc, P.; Pal, S.; Paoli, L.; Raghavan, S.; Tattini, J.; Teter, J.; Wachche, S.; et al. Global EV Outlook 2020|Entering the Decade of Electric Drive? IEA: Paris, France, 2020. [Google Scholar]

- IEA. Global EV Data Explorer. 2021. Available online: https://www.iea.org/articles/global-ev-data-explorer (accessed on 28 December 2021).

- DfT. Outcome and Response to Ending the Sale of New Petrol, Diesel and Hybrid Cars and Vans. 2021. Available online: https://www.gov.uk/government/consultations/consulting-on-ending-the-sale-of-new-petrol-diesel-and-hybrid-cars-and-vans/outcome/ending-the-sale-of-new-petrol-diesel-and-hybrid-cars-and-vans-government-response (accessed on 9 December 2021).

- Pickett, L.; Winnet, J.; Carver, D.; Bolton, P. Electric Vehicles and Infrastructure; House of Commons Library: London, UK, 2021. [Google Scholar]

- Wappelhorst, S. Update on Government Targets for Phasing out New Sales of Internal Combustion Engine Passenger Cars; International Council on Clean Transportation (ICCT): Washington, DC, USA, 2021. [Google Scholar]

- Carey, N.; Steitz, C. EU Proposes Effective Ban for New Fossil-Fuel Cars from 2035. 2021. Available online: https://www.reuters.com/business/retail-consumer/eu-proposes-effective-ban-new-fossil-fuel-car-sales-2035-2021-07-14/response (accessed on 7 January 2022).

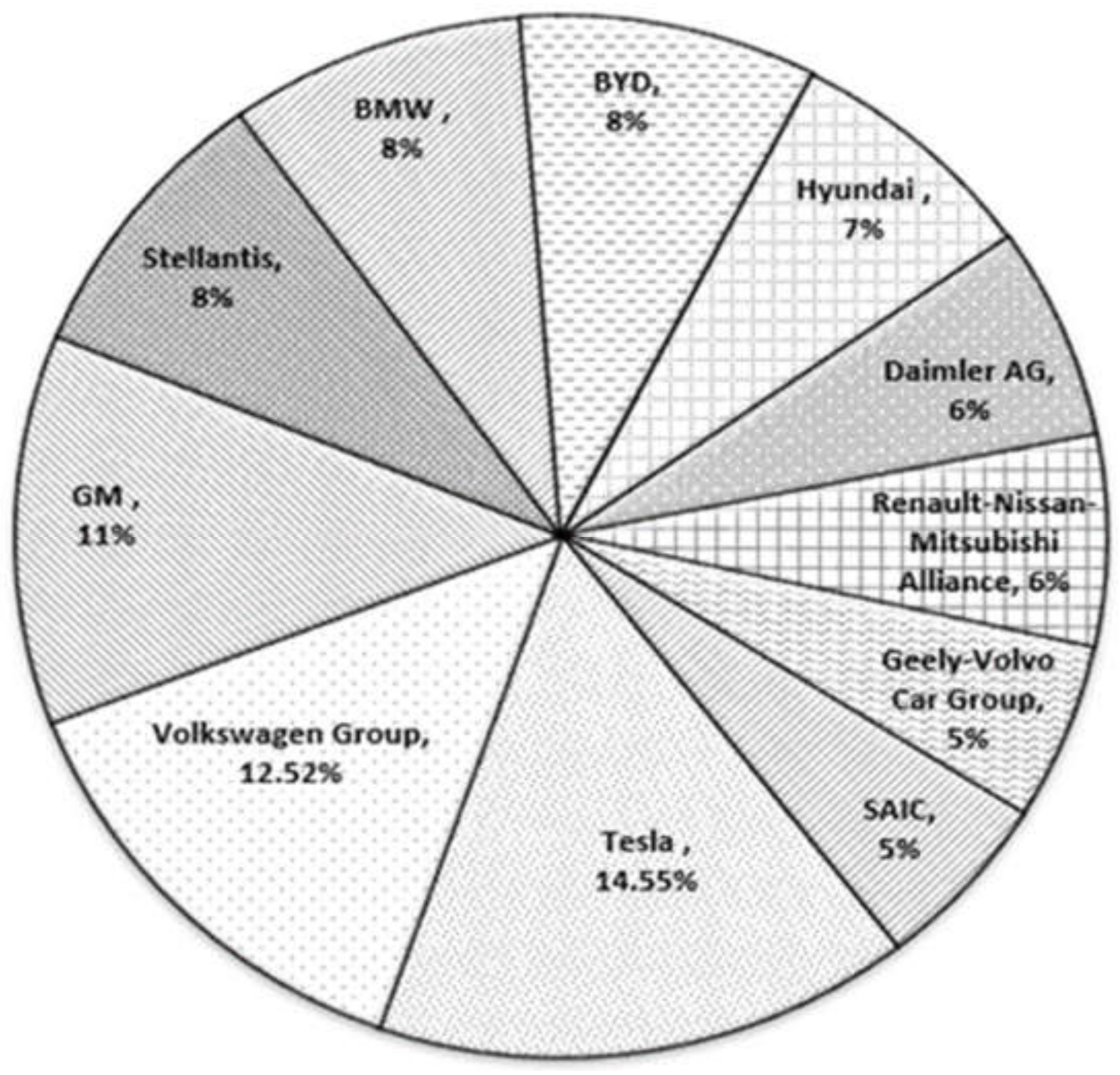

- EV-Volumes. Global Plug-In Electric Vehicle Market Share in the First Half of 2021, by Main Producer. 2021. Available online: https://www.statista.com/statistics/541390/global-sales-of-plug-in-electric-vehicle-manufacturers/ (accessed on 22 December 2021).

- TESLA. Investor Relations|Tesla Releases Third Quarter 2021 Financial Results. 2021. Available online: https://ir.tesla.com/#tab-quarterly-disclosure (accessed on 23 December 2021).

- Kane, M. Global Plug-In Car Sales September 2021: Doubled To A New Record. 2021. Available online: https://insideevs.com/news/544743/global-plugin-car-sales-september2021/ (accessed on 23 December 2021).

- VOLKSWAGEN. E-Mobility. 2021. Available online: https://www.volkswagenag.com/en/group/e-mobility.html (accessed on 23 December 2021).

- VOLKSWAGEN. Volkswagen Group Doubles Deliveries of Pure E-Vehicles in Third Quarter. 2021. Available online: https://www.volkswagen-newsroom.com/en/press-releases/volkswagen-group-doubles-deliveries-of-pure-e-vehicles-in-third-quarter-7569 (accessed on 23 December 2021).

- Taylor, C. Volkswagen Wants Half of Its Vehicle Sales to Be Electric by 2030. 2021. Available online: https://www.cnbc.com/2021/07/13/volkswagen-wants-half-of-its-vehicle-sales-to-be-electric-by-2030.html (accessed on 23 December 2021).

- Riley, C. The Great Electric Car Race is Just Beginning. 2019. Available online: https://edition.cnn.com/interactive/2019/08/business/electric-cars-audi-volkswagen-tesla/ (accessed on 7 March 2021).

- GM. GM Commits Full Support to SGMW’s NEV Development. 2020. Available online: https://media.gm.com/media/cn/en/gm/news.detail.html/content/Pages/news/cn/en/2020/Dec/1214-GM.html (accessed on 23 December 2021).

- DfT. Licensed Ultra Low Emission Vehicles by Body Type and Propulsion or Fuel Type; Department for Transport (DfT) Statistics: London, UK, 2021.

- DfT. Electric Vehicle Charging Device Statistics: October 2021; Department for Transport (DfT) Statistics: London, UK, 2021.

- ZAP-MAP. 2021. Available online: https://www.zap-map.com/ (accessed on 23 December 2021).

- Lilly, C. EV Connector Types. 2020. Available online: https://www.zap-map.com/charge-points/connectors-speeds/ (accessed on 28 December 2021).

- ZAP-MAP. EV Charging Stats 2021. 2021. Available online: https://www.zap-map.com/statistics/ (accessed on 24 December 2021).

- Chen, T.; Zhan, X.; Wang, J.; Li, J.; Wu, C.; Hu, M.; Bian, H. A review on electric vehicle charging infrastructure development in the UK. J. Mod. Power Syst. Clean Energy 2020, 8, 193–205. [Google Scholar] [CrossRef]

- DfT. Electric Vehicle Charging in Residential and Non-Residential Buildings; Department for Transport (DfT): London, UK, 2019.

- BSI. PAS 1878 Energy Smart Appliances—System Functionality and Architecture. 2021. Available online: https://www.bsigroup.com/en-GB/about-bsi/uk-national-standards-body/about-standards/Innovation/energy-smart-appliances-programme/pas-1878/ (accessed on 10 December 2021).

- Zhao, H.; Wang, L.; Chen, Z.; He, X. Challenges of fast charging for electric vehicles and the role of red phosphorous as anode material. Energies 2019, 12, 3897. [Google Scholar] [CrossRef]

- Zhang, C.; Wei, Y.L.; Cao, P.F.; Lin, M.C. Energy storage system: Current studies on batteries and power condition system. Renew. Sustain. Energy Rev. 2018, 82, 3091–3106. [Google Scholar] [CrossRef]

- Mirzaeian, M.; Abbas, Q.; Hunt, M.R.C.; Galeyeva, A.; Raza, R. Na-Ion Batteries. Adv. Funct. Mater. 2021, 23, 947–958. [Google Scholar]

- Wang, Y.; Satoh, M.; Arao, M.; Matsumoto, M.; Imai, H.; Nishihara, H. High-energy, Long-cycle-life Secondary Battery with electrochemically pre-doped Silicon Anode. Sci. Rep. 2020, 10, 3208. [Google Scholar] [CrossRef]

- Almarzooqi, A.; Mnatsakanyan, A.; Muruaga, E. Management of Used Lithium Ion Batteries of EV in Dubai. In Proceedings of the 2019 IEEE International Smart Cities Conference (ISC2), Casablanca, Morocco, 14–17 October 2019. [Google Scholar]

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A review of battery fires in electric vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- Pinnangudi, B.; Kuykendal, M.; Bhadra, S. Smart Grid Energy Storage. In The Power Grid; D’Andrade, B.A., Ed.; Academic Press: Boston, MA, USA, 2017; pp. 93–135. [Google Scholar]

- Kurzweil, P.; Garche, J. Overview of Batteries for Future Automobiles. In Lead-Acid Batteries for Future Automobiles; Elsevier: Amsterdam, The Netherlands, 2017; pp. 27–96. [Google Scholar]

- Fiorello, D.; Zani, L. EU Survey on Issues Related to Transport and Mobility; JRC Science and Policy Report: Sevile, Spain, 2015. [Google Scholar]

- Singer, M. Consumer Views on Plug-in Electric Vehicles—National Benchmark Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016.

- Electiric Vehicle Database (EV-Database). All Electric Vehicles. Available online: https://ev-database.uk/#sort:path~type~order=.erange_real~number~desc|range-slider-range:prev~next=0~600|range-slider-bijtelling:prev~next=0~600|range-slider-acceleration:prev~next=2~23|range-slider-fastcharge:prev~next=0~1100|range-slider-lease:prev~next=150~2500|range-slider-topspeed:prev~next=60~260|paging:currentPage=0|paging:number=9 (accessed on 10 January 2022).

- Fishman, T.; Myers, R.J.; Rios, O.; Graedel, T.E. Implications of emerging vehicle technologies on rare earth supply and demand in the United States. Resources 2018, 7, 9. [Google Scholar] [CrossRef]

- Schwarzer, S. Challenges for the Growth of the Electric Vehicle Market; The United Nations Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- Swiss Resource Capital AG. Battery Metals Report 2019: Everything You Need to Know about the Battery Metals Lithium, Cobalt, Nickel and Vanadium; Swiss Resource Capital AG: Herisau, Switzerland, 2019. [Google Scholar]

- EEA. EEA Greenhouse Gases Data Viewer|Greenhouse Gas Emission Intensity of Electricity Generation. 2022. Available online: https://www.eea.europa.eu/data-and-maps/daviz/co2-emission-intensity-6/#tab-googlechartid_googlechartid_chart_111_filters=%7B%22rowFilters%22%3A%7B%7D%3B%22columnFilters%22%3A%7B%22pre_config_date%22%3A%5B2018%3B2019%5D%7D%3B%22sortFilter%22%3A%5B%22index_2018%22%5D%7D (accessed on 10 January 2022).

- IEA. IEA Data Browser|Electricity. 2022. Available online: https://www.iea.org/fuels-and-technologies/electricity (accessed on 10 January 2021).

- Hoehne, C.G.; Chester, M.V. Optimizing plug-in electric vehicle and vehicle-to-grid charge scheduling to minimize carbon emissions. Energy 2016, 115, 646–657. [Google Scholar] [CrossRef]

- Lin, B.; Wu, W. The impact of electric vehicle penetration: A recursive dynamic CGE analysis of China. Energy Econ. 2021, 94, 105086. [Google Scholar] [CrossRef]

- Sato, F.E.K.; Nakata, T. Energy consumption analysis for vehicle production through a material flow approach. Energies 2020, 13, 2396. [Google Scholar] [CrossRef]

- Knobloch, F.; Hanssen, S.V.; Lam, A.; Pollitt, H.; Salas, P.; Chewpreecha, U.; Huijbregts, M.A.; Mercure, J.F. Net emission reductions from electric cars and heat pumps in 59 world regions over time. Nat. Sustain. 2020, 3, 437–447. [Google Scholar] [CrossRef] [PubMed]

- Cox, B.; Mutel, C.L.; Bauer, C.; Mendoza Beltran, A.; Van Vuuren, D.P. Uncertain environmental footprint of current and future battery electric vehicles. Environ. Sci. Technol. 2018, 52, 4989–4995. [Google Scholar] [CrossRef] [PubMed]

- Kurland, S.D. Energy use for GWh-scale lithium-ion battery production. Environ. Res. Commun. 2019, 2, 012001. [Google Scholar]

- Hall, D.; Lutsey, N. Effects of Battery Manufacturing on Electric Vehicle Life-Cycle Greenhouse Gas Emissions; The Internal Council on Clean Transportation (ICCT): Washington, DC, USA, 2018. [Google Scholar]

- Bieker, G. A global comparison of the life-cycle greenhouse gas emissions of combustion engine and electric passenger cars. Communications 2021, 49, 847129-102. [Google Scholar]

- IEA. Amount of Spent Lithium-Ion Batteries from Electric Vehicles and Storage in the Sustainable Development Scenario, 2020–2040. 2021. Available online: https://www.iea.org/data-and-statistics/charts/amount-of-spent-lithium-ion-batteries-from-electric-vehicles-and-storage-in-the-sustainable-development-scenario-2020-2040 (accessed on 9 January 2022).

- Saiyid, A. Threefold Increase in Recycling Needed to Help Meet 2030 Demand for Lithium-Ion EV Batteries. 2021. Available online: https://cleanenergynews.ihsmarkit.com/research-analysis/threefold-increase-in-recycling-needed-to-help-meet-2030-deman.html (accessed on 9 January 2022).

- Gaines, L.; Richa, K.; Spangenberger, J. Key issues for Li-ion battery recycling. MRS Energy Sustain. 2018, 5, E14. [Google Scholar] [CrossRef]

- Rohr, S.; Wagner, S.; Baumann, M.; Müller, S.; Lienkamp, M. A techno-economic analysis of end of life value chains for lithium-ion batteries from electric vehicles. In Proceedings of the 2017 Twelfth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 11–13 April 2017. [Google Scholar]

- Clement-Nyns, K.; Haesen, E.; Driesen, J. The impact of charging plug-in hybrid electric vehicles on a residential distribution grid. IEEE Trans. Power Syst. 2009, 25, 371–380. [Google Scholar] [CrossRef]

- Kapustin, N.O.; Grushevenko, D.A. Long-term electric vehicles outlook and their potential impact on electric grid. Energy Policy 2020, 137, 111103. [Google Scholar] [CrossRef]

- Kim, S.; Hur, J. A Probabilistic Modeling Based on Monte Carlo Simulation of Wind Powered EV Charging Stations for Steady-States Security Analysis. Energies 2020, 13, 5260. [Google Scholar] [CrossRef]

- Mu, Y.; Wu, J.; Jenkins, N.; Jia, H.; Wang, C. A spatial–temporal model for grid impact analysis of plug-in electric vehicles. Appl. Energy 2014, 114, 456–465. [Google Scholar] [CrossRef]

- Qian, K.; Zhou, C.; Allan, M.; Yuan, Y. Modeling of load demand due to EV battery charging in distribution systems. IEEE Trans. Power Syst. 2010, 26, 802–810. [Google Scholar] [CrossRef]

- Qian, K.; Zhou, C.; Allan, M.; Yuan, Y. Load model for prediction of electric vehicle charging demand. In Proceedings of the 2010 International Conference on Power System Technology, Hangzhou, China, 24–28 October 2010. [Google Scholar]

- Wang, S.; Zhang, N.; Li, Z.; Shahidehpour, M. Modeling and impact analysis of large scale V2G electric vehicles on the power grid. In Proceedings of the IEEE PES Innovative Smart Grid Technologies, Tianjin, China, 21–24 May 2012. [Google Scholar]

- Papadopoulos, P.; Akizu, O.; Cipcigan, L.M.; Jenkins, N.; Zabala, E. Electricity demand with electric cars in 2030: Comparing Great Britain and Spain. Proc. Inst. Mech. Eng. Part A J. Power Energy 2011, 225, 551–566. [Google Scholar] [CrossRef]

- Ueckerdt, F.; Kempener, R. From Baseload to Peak: Renewables Provide a Reliable Solution; International Renewable Energy Agency (IREA): Abu Dhabi, United Arab Emirates, 2015. [Google Scholar]

- National Grid ESO. Future Energy Scenarios (FES) 2021; National Grid ESO: Warwick, UK, 2021. [Google Scholar]

- Toniato, E.; Mehta, P.; Marinkovic, S.; Tiefenbeck, V. Peak load minimization of an e-bus depot: Impacts of user-set conditions in optimization algorithms. Energy Inform. 2021, 4, 23. [Google Scholar] [CrossRef]

- Fathabadi, H. Novel wind powered electric vehicle charging station with vehicle-to-grid (V2G) connection capability. Energy Convers. Manag. 2017, 136, 229–239. [Google Scholar] [CrossRef]

- Kempton, W.; Tomić, J. Vehicle-to-grid power fundamentals: Calculating capacity and net revenue. J. Power Sources 2005, 144, 268–279. [Google Scholar] [CrossRef]

- Noori, M.; Zhao, Y.; Onat, N.C.; Gardner, S.; Tatari, O. Light-duty electric vehicles to improve the integrity of the electricity grid through Vehicle-to-Grid technology: Analysis of regional net revenue and emissions savings. Appl. Energy 2016, 168, 146–158. [Google Scholar] [CrossRef]

- Ginigeme, K.; Wang, Z. Distributed optimal vehicle-to-grid approaches with consideration of battery degradation cost under real-time pricing. IEEE Access 2020, 8, 5225–5235. [Google Scholar] [CrossRef]

- Peterson, S.B.; Whitacre, J.; Apt, J. The economics of using plug-in hybrid electric vehicle battery packs for grid storage. J. Power Sources 2010, 195, 2377–2384. [Google Scholar] [CrossRef]

- Kiaee, M.; Cruden, A.; Sharkh, S. Estimation of cost savings from participation of electric vehicles in vehicle to grid (V2G) schemes. J. Mod. Power Syst. Clean Energy 2015, 3, 249–258. [Google Scholar] [CrossRef]

- Hidrue, M.K.; Parsons, G.R. Is there a near-term market for vehicle-to-grid electric vehicles? Appl. Energy 2015, 151, 67–76. [Google Scholar] [CrossRef]

- Cicconi, P.; Landi, D.; Morbidoni, A.; Germani, M. Feasibility analysis of second life applications for Li-Ion cells used in electric powertrain using environmental indicators. In Proceedings of the 2012 IEEE International Energy Conference and Exhibition (ENERGYCON), Florence, Italy, 9–12 September 2012. [Google Scholar]

- Ahmadian, A.; Sedghi, M.; Mohammadi-ivatloo, B.; Elkamel, A.; Golkar, M.A.; Fowler, M. Cost-benefit analysis of V2G implementation in distribution networks considering PEVs battery degradation. IEEE Trans. Sustain. Energy 2017, 9, 961–970. [Google Scholar] [CrossRef]

- Xiong, S. A Study of the Factors That Affect Lithium Ion Battery Degradation. Master’s Thesis, University of Missouri, Columbia, MI, USA, May 2019. [Google Scholar]

- Peterson, S.B.; Apt, J.; Whitacre, J. Lithium-ion battery cell degradation resulting from realistic vehicle and vehicle-to-grid utilization. J. Power Sources 2010, 195, 2385–2392. [Google Scholar] [CrossRef]

- Bishop, J.D.; Axon, C.J.; Bonilla, D.; Tran, M.; Banister, D.; McCulloch, M.D. Evaluating the impact of V2G services on the degradation of batteries in PHEV and EV. Appl. Energy 2013, 111, 206–218. [Google Scholar] [CrossRef]

- Guo, J.; Yang, J.; Cao, W.; Serrano, C. Evaluation of EV battery degradation under different charging strategies and V2G schemes. In Proceedings of the 8th Renewable Power Generation Conference (RPG 2019), Shanghai, China, 24–25 October 2019. [Google Scholar]

- Uddin, K.; Jackson, T.; Widanage, W.D.; Chouchelamane, G.; Jennings, P.A.; Marco, J. On the possibility of extending the lifetime of lithium-ion batteries through optimal V2G facilitated by an integrated vehicle and smart-grid system. Energy 2017, 133, 710–722. [Google Scholar] [CrossRef]

- Zhou, C.; Qian, K.; Allan, M.; Zhou, W. Modeling of the cost of EV battery wear due to V2G application in power systems. IEEE Trans. Energy Convers. 2011, 26, 1041–1050. [Google Scholar] [CrossRef]

- BEIS. 2020 UK Greenhouse Gas Emissions, Provisional Figures; Department for Business, Energy and Industrial Strategy (BEIS): London, UK, 2021.

- Buekers, J.; Van Holderbeke, M.; Bierkens, J.; Panis, L.I. Health and environmental benefits related to electric vehicle introduction in EU countries. Transp. Res. Part D Transp. Environ. 2014, 33, 26–38. [Google Scholar] [CrossRef]

- Turton, H.; Moura, F. Vehicle-to-grid systems for sustainable development: An integrated energy analysis. Technol. Forecast. Soc. Chang. 2008, 75, 1091–1108. [Google Scholar] [CrossRef]

- Jiao, Z.; Yin, Y.; Ran, L.; Gao, Z. Integrating Vehicle-to-Grid Contract Design with Power Dispatching Optimization: Managerial Insights, and Carbon Footprints Mitigation. Int. J. Prod. Res. 2021, 1–26. [Google Scholar] [CrossRef]

- Ali, H.; Hussain, S.; Khan, H.A.; Arshad, N.; Khan, I.A. Economic and Environmental Impact of Vehicle-to-Grid (V2G) Integration in an Intermittent Utility Grid. In Proceedings of the 2020 2nd International Conference on Smart Power & Internet Energy Systems (SPIES), Bangkok, Thailand, 15–18 September 2020. [Google Scholar]

- Bamisile, O.; Obiora, S.; Huang, Q.; Okonkwo, E.C.; Olagoke, O.; Shokanbi, A.; Kumar, R. Towards a sustainable and cleaner environment in China: Dynamic analysis of vehicle-to-grid, batteries and hydro storage for optimal RE integration. Sustain. Energy Technol. Assess. 2020, 42, 100872. [Google Scholar] [CrossRef]

- Zhao, Y.; Noori, M.; Tatari, O. Vehicle to Grid regulation services of electric delivery trucks: Economic and environmental benefit analysis. Appl. Energy 2016, 170, 161–175. [Google Scholar] [CrossRef]

- Sioshansi, R.; Denholm, P. Emissions impacts and benefits of plug-in hybrid electric vehicles and vehicle-to-grid services. Environ. Sci. Technol. 2009, 43, 1199–1204. [Google Scholar] [CrossRef]

- California ISO (CAISO). Today’s Outlook|Net Demand Trend. 2022. Available online: http://www.caiso.com/TodaysOutlook/Pages/default.aspx#section-net-demand-trend (accessed on 6 January 2022).

- California ISO (CASIO). What the Duck Curve Tells Us about Managing a Green Grid. Available online: https://www.caiso.com/documents/flexibleresourceshelprenewables_fastfacts.pdf (accessed on 10 January 2022).

- Atia, R.; Yamada, N. More accurate sizing of renewable energy sources under high levels of electric vehicle integration. Renew. Energy 2015, 81, 918–925. [Google Scholar] [CrossRef]

- McPherson, M.; Ismail, M.; Hoornweg, D.; Metcalfe, M. Planning for variable renewable energy and electric vehicle integration under varying degrees of decentralization: A case study in Lusaka, Zambia. Energy 2018, 151, 332–346. [Google Scholar] [CrossRef]

- Shi, R.; Li, S.; Zhang, P.; Lee, K.Y. Integration of renewable energy sources and electric vehicles in V2G network with adjustable robust optimization. Renew. Energy 2020, 153, 1067–1080. [Google Scholar] [CrossRef]

- Sharifi, P.; Banerjee, A.; Feizollahi, M.J. Leveraging owners’ flexibility in smart charge/discharge scheduling of electric vehicles to support renewable energy integration. Comput. Ind. Eng. 2020, 149, 106762. [Google Scholar] [CrossRef]

- Child, M.; Nordling, A.; Breyer, C. Scenarios for a sustainable energy system in the Åland Islands in 2030. Energy Convers. Manag. 2017, 137, 49–60. [Google Scholar] [CrossRef]

- Schuller, A.; Flath, C.M.; Gottwalt, S. Quantifying load flexibility of electric vehicles for renewable energy integration. Appl. Energy 2015, 151, 335–344. [Google Scholar] [CrossRef]

- Richardson, D.B. Electric vehicles and the electric grid: A review of modeling approaches, Impacts, and renewable energy integration. Renew. Sustain. Energy Rev. 2013, 19, 247–254. [Google Scholar] [CrossRef]

- Nguyen, H.N.; Zhang, C.; Mahmud, M.A. Optimal coordination of G2V and V2G to support power grids with high penetration of renewable energy. IEEE Trans. Transp. Electrif. 2015, 1, 188–195. [Google Scholar] [CrossRef]

- Pfeifer, A.; Dobravec, V.; Pavlinek, L.; Krajačić, G.; Duić, N. Integration of renewable energy and demand response technologies in interconnected energy systems. Energy 2018, 161, 447–455. [Google Scholar] [CrossRef]

- Šare, A.; Krajačić, G.; Pukšec, T.; Duić, N. The integration of renewable energy sources and electric vehicles into the power system of the Dubrovnik region. Energy Sustain. Soc. 2015, 5, 27. [Google Scholar] [CrossRef]

- Schetinger, A.M.; Dias, D.H.N.; Borba, B.S.M.C.; Pimentel da Silva, G.D. Techno-economic feasibility study on electric vehicle and renewable energy integration: A case study. Energy Storage 2020, 2, e197. [Google Scholar] [CrossRef]

- Freire, R.; Delgado, J.; Santos, J.M.; De Almeida, A.T. Integration of renewable energy generation with EV charging strategies to optimize grid load balancing. In Proceedings of the 13th International IEEE Conference on Intelligent Transportation Systems, Funchal, Portugal, 19–22 September 2010. [Google Scholar]

- Zhang, Q.; Tezuka, T.; Ishihara, K.N.; Mclellan, B.C. Integration of PV power into future low-carbon smart electricity systems with EV and HP in Kansai Area, Japan. Renew. Energy 2012, 44, 99–108. [Google Scholar] [CrossRef]

- Ekman, C.K. On the synergy between large electric vehicle fleet and high wind penetration–An analysis of the Danish case. Renew. Energy 2011, 36, 546–553. [Google Scholar] [CrossRef]

- Hassan, A.S.; Marmaras, C.E.; Xydas, E.S.; Cipcigan, L.M.; Jenkins, N. Integration of Wind Power Using V2G as a Flexible Storage. In Proceedings of the IET Conference on Power in Unity: A Whole System Approach, London, UK, 16–17 October 2013. [Google Scholar]

| EV Type | BEVs | PHEVs | HEVs | FCEVs |

|---|---|---|---|---|

| Strength | No emission or very low emission | Lower emission than HEVs | Lower emission than ICE vehicles | No emission or very low emission |

| High energy efficiency | High fuel efficiency | High fuel efficiency | High efficiency | |

| Independent from oil/Low engine noise | Fuel diversity/No range anxiety | No charging station problem | Independent from electricity | |

| Weakness | High purchase and battery cost | Complex technology | Complex technology/Higher cost | High fuel cell cost |

| Charging station problems | Management of the energy sources | Management of the energy sources | Technical challenge and cost issue | |

| Battery replacement requirement | Heavier/Tail-pipe emissions | Dependence on fossil fuel/Tail-pipe emissions/Heavier | Problems of H2 generation |

| Canada | China | France | Germany | Japan | United States | |

|---|---|---|---|---|---|---|

| EV Fleets [units] | Total: 209,171 BEVs: 127,487 PHEVs: 81,588 FCEVs: 96 | Total: 4,514,114 BEVs: 3,512,477 PHEVs: 996,191 FCEVs: 5446 | Total: 416,585 BEVs: 281,603 PHEVs: 134,607 FCEVs: 375 | Total: 634,236 BEVs: 330,780 PHEVs: 302,644 FCEVs: 812 | Total: 297,181 BEVs: 136,700 PHEVs: 156,381 FCEVs: 4100 | Total: 1,787,221 BEVs: 1,138,654 PHEVs: 639,432 FCEVs: 9135 |

| EV Sales Share [%] | 4.2% of the new cars | 5.7% of the new cars | 11.3% of the new cars | 13.5% of the new cars | 0.6% of the new cars | 2.0% of the new cars |

| Canada | China | France | Germany | Japan | United States | |

|---|---|---|---|---|---|---|

| Targets to Ban ICE Vehicle Sales | Not available in all states | - | ✓ | ✓ | - | Not available in all states |

| Targets for Low Carbon Transport | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Vehicle Purchase Incentives | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Charger Regulations | Not available in all regions | Not available in all regions | ✓ | ✓ | No building side regulation | Not available in all states |

| Charger Installation Incentives | ✓ | ✓ | ✓ | ✓ | ✓ | Not available in all states |

| Canada | China | France | Germany | Japan | United States |

|---|---|---|---|---|---|

| [Unit] | [Unit] | [Unit] | [Unit] | [Unit] | [Unit] |

| Total: 13,194 | Total: 807,000 | Total: 46,045 | Total: 44,669 | Total: 29,855 | Total: 103,021 |

| 1 F & R: 2258 | F & R: 309,000 | F & R: 4045 | F & R: 7456 | F & R: 7939 | F & R: 16,718 |

| Slow: 10,936 | Slow: 498,000 | Slow: 42,000 | Slow: 37,213 | Slow: 21,916 | Slow: 82,263 |

| Charger Type | Charge Mode | Power Rating | Connector Type | Charging Time | |

|---|---|---|---|---|---|

| Slow Charger | - | Mode 2 | 3–6 kW | 3-Pin | |

| Type 1 | 8–10 h | ||||

| Type 2 | |||||

| Commando | |||||

| Fast Charger | - | Mode 3 | 7 kW/11 kW/22 kW | Type 1 | |

| Type 2 | 3–4 h | ||||

| Commando | |||||

| Rapid Charger | AC Rapid | Mode 3 | 43 kW | Type 2 | 30–60 min |

| DC Rapid | Mode 4 | 50 kW | CHAdeMO/ | ||

| CCS | |||||

| DC ultra-Rapid | Mode 4 | 100–350 kW | CHAdeMO | ||

| CCS | |||||

| Tesla Supercharger | - | Mode 4 | Up to 250 kW | Tesla CCS | |

| Type 2 | |||||

| CCS | |||||

| CHAdeMO |

| BEVs | Battery Capacity | Specific Energy Consumption | Range |

|---|---|---|---|

| [kWh] | [Wh/mi] | [mi] | |

| Hyundai Kona Electric | 64 | 0.26 | 245 |

| Tesla Model 3 Long Range | 70 | 0.245 | 285 |

| Polestar 2 | 75 | 0.305 | 245 |

| Tesla Model 3 Performance | 76 | 0.265 | 285 |

| Volkswagen ID.3 Pro S | 77 | 0.275 | 280 |

| Volkswagen ID.4 | 77 | 0.31 | 245 |

| Mercedes EQC 400 | 80 | 0.345 | 230 |

| Porsche Taycan 4S Plus | 83.7 | 0.31 | 270 |

| Porsche Taycan Turbo | 83.7 | 0.34 | 245 |

| Audi e-tron Sportback | 86.5 | 0.375 | 230 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dik, A.; Omer, S.; Boukhanouf, R. Electric Vehicles: V2G for Rapid, Safe, and Green EV Penetration. Energies 2022, 15, 803. https://doi.org/10.3390/en15030803

Dik A, Omer S, Boukhanouf R. Electric Vehicles: V2G for Rapid, Safe, and Green EV Penetration. Energies. 2022; 15(3):803. https://doi.org/10.3390/en15030803

Chicago/Turabian StyleDik, Abdullah, Siddig Omer, and Rabah Boukhanouf. 2022. "Electric Vehicles: V2G for Rapid, Safe, and Green EV Penetration" Energies 15, no. 3: 803. https://doi.org/10.3390/en15030803

APA StyleDik, A., Omer, S., & Boukhanouf, R. (2022). Electric Vehicles: V2G for Rapid, Safe, and Green EV Penetration. Energies, 15(3), 803. https://doi.org/10.3390/en15030803