Multimodal Carbonates: Distribution of Oil Saturation in the Microporous Regions of Arab Formations

Abstract

:1. Introduction

1.1. Petrophysical Properties of Multimodal Carbonates in the Ghawar

1.2. The Depositional Environment

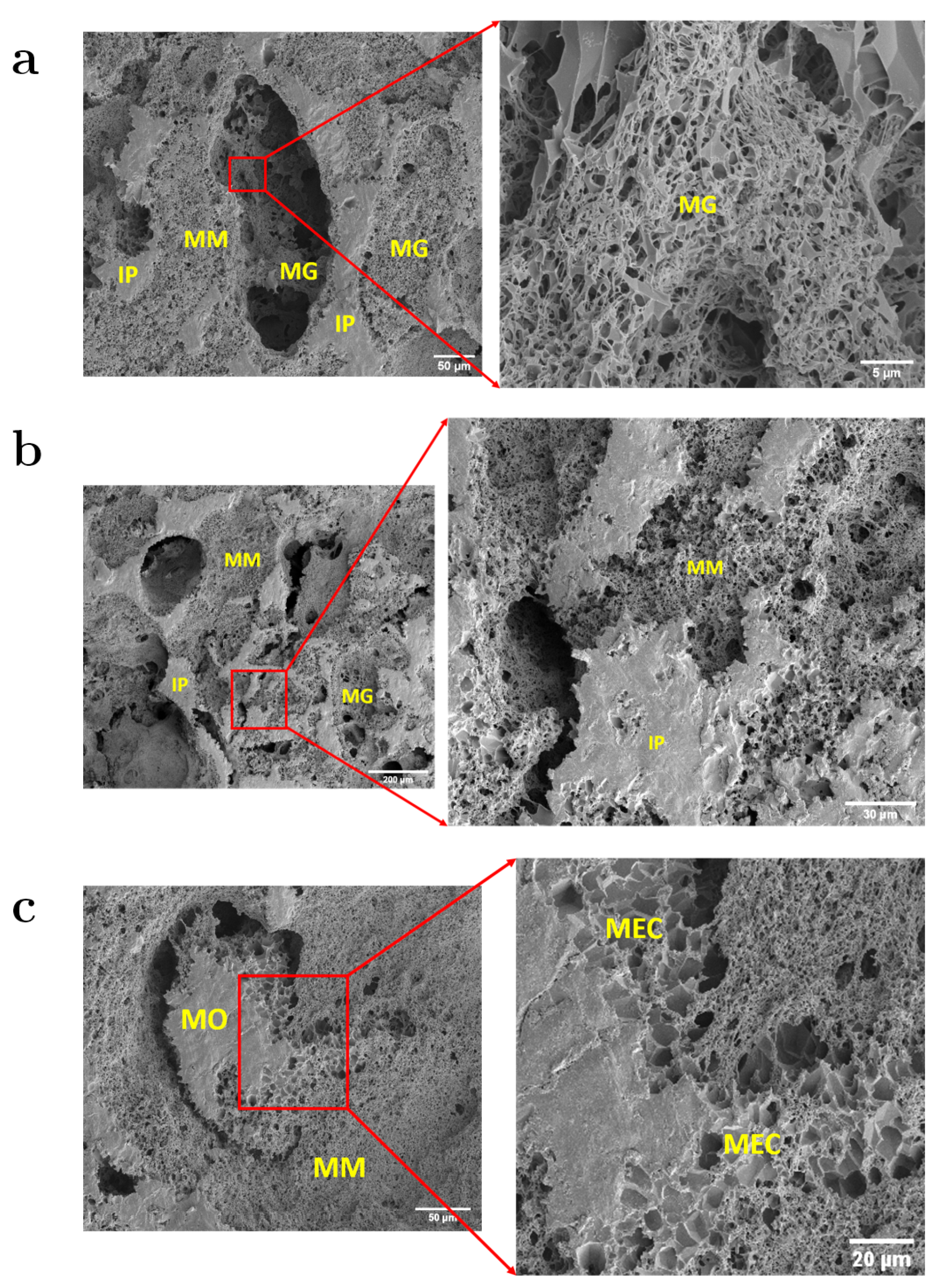

1.3. Classification of Macro- and Microporosity in the Carbonate Samples

- (1)

- The “connate” water saturation measured in a Hessler cell subjected to high-speed centrifugation to mimic the 700–1300 ft tall oil columns in the Arab D reservoirs ranges from 2.8% to 35%, with a majority of the saturations in the teens and twenties of porosity units, [31]. In the present day Ghawar, the oil column is 200–240 ft thick in the Upper Jubaila-Arab-D carbonates below the C-D anhydrite, [28].

- (2)

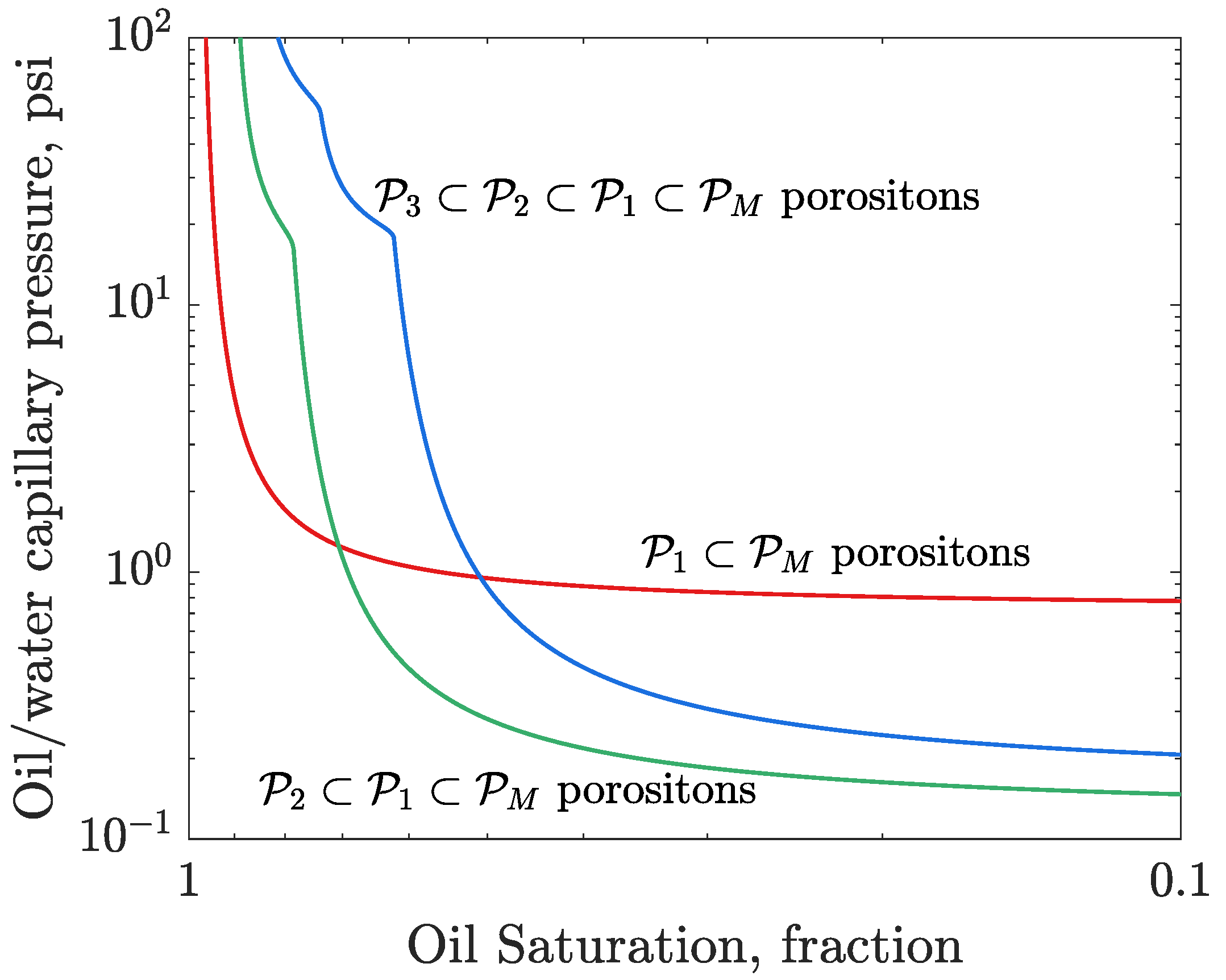

- The initial oil fill-up of the Arab D carbonates created oil columns in the macroporous rock. These columns could be several hundred feet in thickness () and could generate the buoyancy force (capillary pressure), that with time would drain the initially bypassed, water-filled microporous regions nested inside the oil-filled macroporosity.

- (3)

- As we show here, the oil ganglia 10–100 ft tall, flowing up by buoyancy, would create enough of the capillary pressure to invade some of the occluded microporous regions they were slowly passing by.

- (4)

- The oil–water capillary pressure would be highest at the top of the oil column, and the multimodal carbonates there be most fully drained of water. This is good news for the continuing or new oil recovery schemes in the Ghawar, which must be custom-designed to produce most of the oil in the microporous rock regions [17,18,19,20,21,32,33].

2. Methods

2.1. SEM Imaging of Pore Casts

2.2. The Lognormal and Generalized Extreme Value (GEV) Distributions

2.3. The Heights of Oil Columns Necessary to Drain the Ghawar Carbonates with Nested Microporous Porositons

3. Results and Discussion

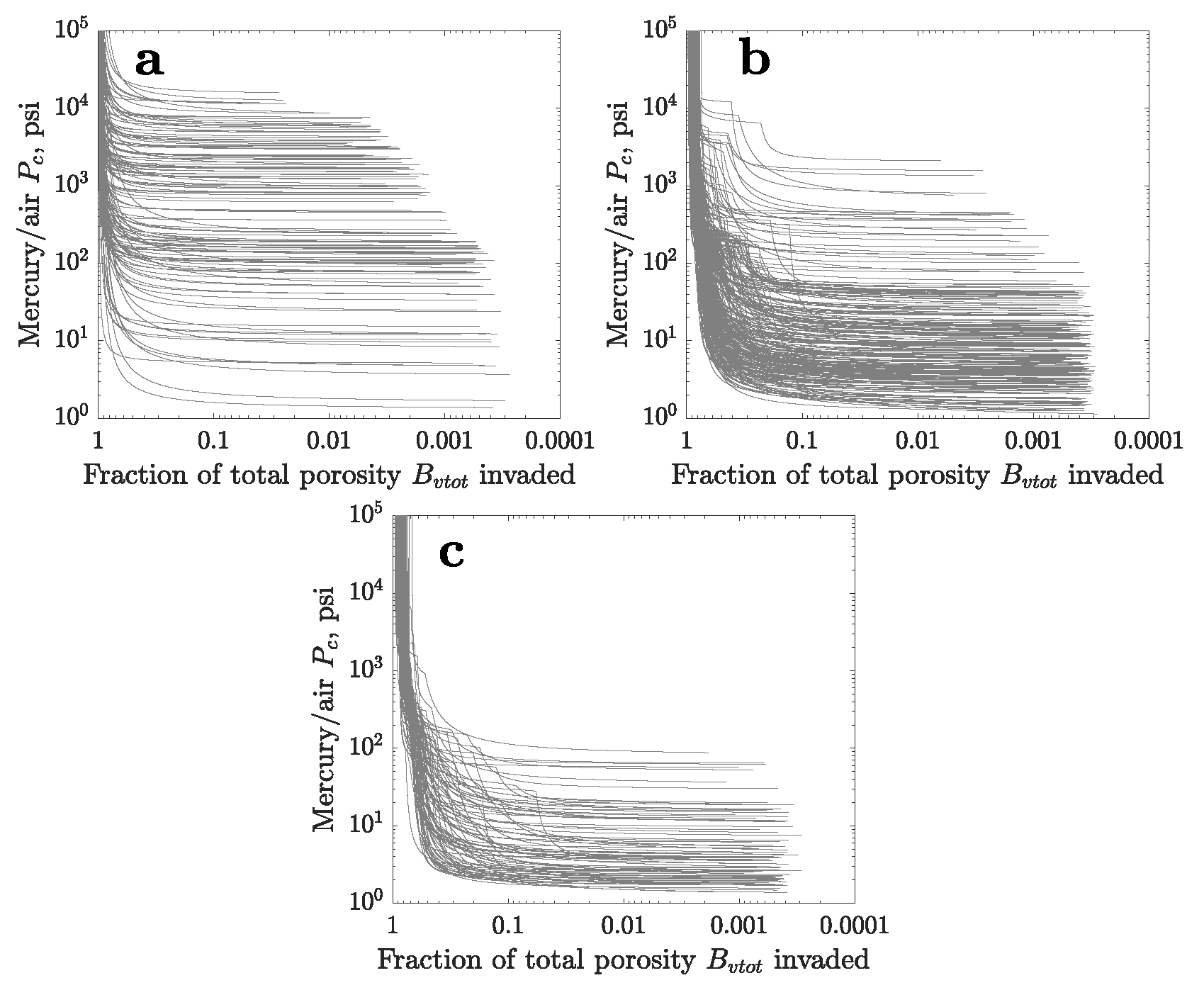

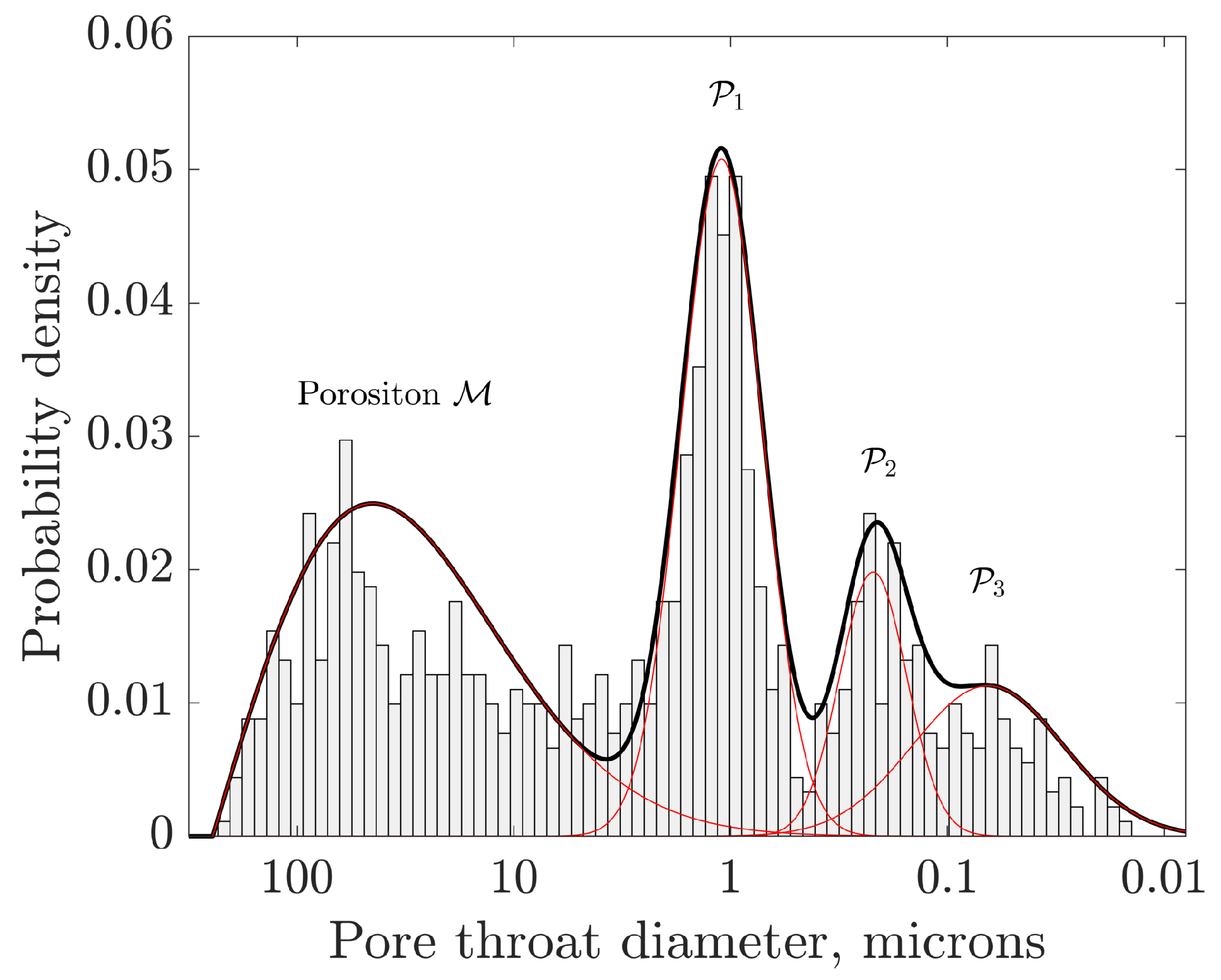

3.1. The Distribution of Pore Throat Diameters from the Capillary Entry Pressures

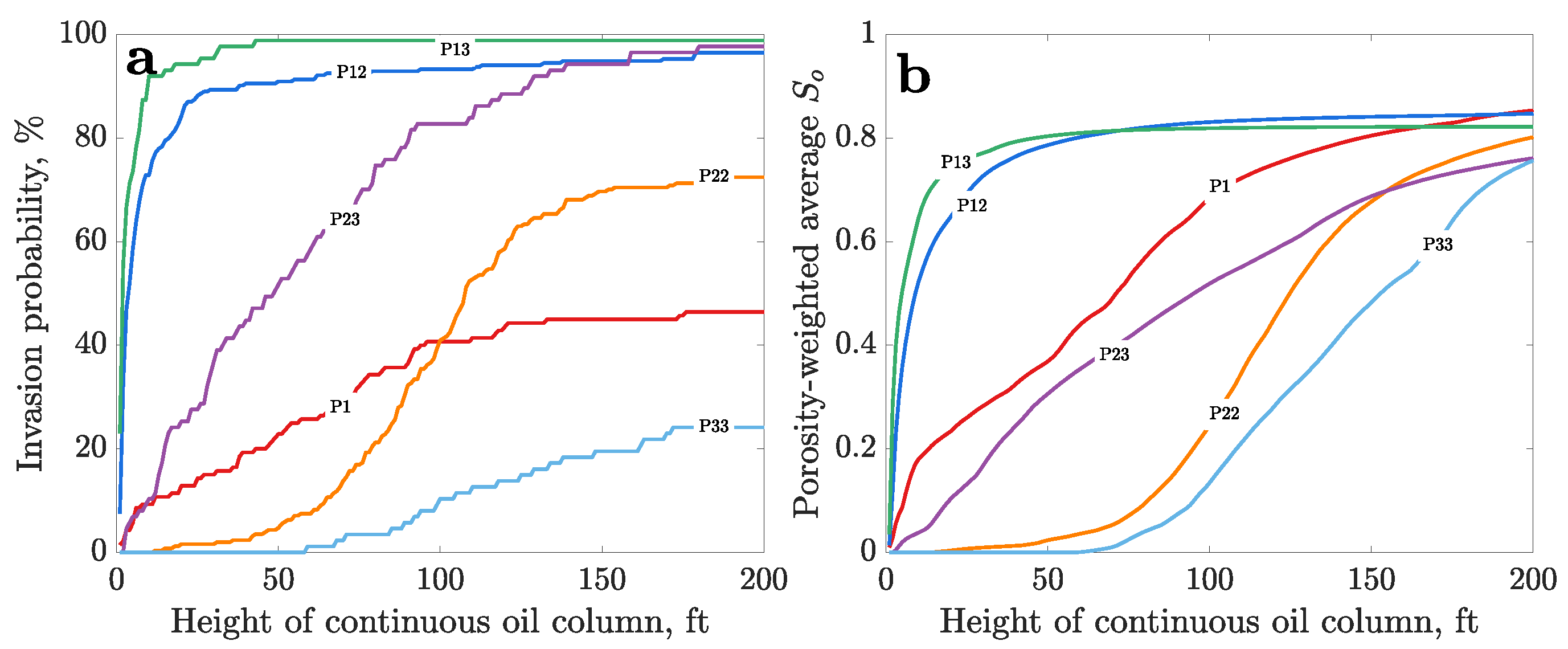

3.2. The Probability of Draining the Nested Porositons

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. The Lognormal and Generalized Extreme Value (GEV) Distributions

| Macroporosity | |||||

|---|---|---|---|---|---|

| GEV | |||||

| Macroporosity | Mode = 45 | Median = 33 | STD = 3.04 | m | |

| Gauss | |||||

| E = 1.06 | Mode = 1.01 | Median = 1.04 | STD = 0.20 | m | |

| Gauss | |||||

| E = 0.52 | Mode = 0.51 | Median = 0.52 | STD = 0.08 | m | |

| Gauss | |||||

| E = 0.32 | Mode = 0.27 | Median = 0.31 | STD = 0.12 | m |

Appendix B. The Heights of Oil Columns Necessary to Drain the Ghawar Carbonates with Nested Microporous Porositons

References

- Liang, Y.; Tan, Y.; Wang, F.; Luo, Y.; Zhao, Z. Improving permeability of coal seams by freeze-fracturing method: The characterization of pore structure changes under low-field NMR. Energy Rep. 2020, 6, 550–561. [Google Scholar] [CrossRef]

- Chichinina, T.; Martyushev, D. Specific Anisotropy Properties of Fractured Reservoirs: Research on Thomsen’s Anisotropy Parameter Delta. Geomodel 2021, 2021, 1–5. [Google Scholar] [CrossRef]

- Zeng, Y.; Du, S.; Zhang, X.; Zhang, B.; Liu, H. The crucial geometric distinctions of microfractures as the indispensable transportation channels in hydrocarbon-rich shale reservoir. Energy Rep. 2020, 6, 2056–2065. [Google Scholar] [CrossRef]

- Gou, B.; Zhan, L.; Guo, J.; Zhang, R.; Zhou, C.; Wu, L.; Ye, J.; Zeng, J. Effect of different types of stimulation fluids on fracture propagation behavior in naturally fractured carbonate rock through CT scan. J. Pet. Sci. Eng. 2021, 201, 108529. [Google Scholar] [CrossRef]

- Martyushev, D.A.; Yurikov, A. Evaluation of opening of fractures in the Logovskoye carbonate reservoir, Perm Krai, Russia. Pet. Res. 2021, 6, 137–143. [Google Scholar] [CrossRef]

- Ponomarev, A.; Zavatsky, M.; Nurullina, T.; Kadyrov, M.; Galinsky, K.; Tugushev, O. Application of core X-ray microtomography in oilfield geology. Georesources 2021, 23, 34–43. [Google Scholar] [CrossRef]

- Khirevich, S.; Patzek, T.W. Three-dimensional simulation of tracer transport dynamics in formations with high-permeability channels or fractures: Estimation of oil saturation. Phys. Fluids 2019, 31, 113604. [Google Scholar] [CrossRef]

- Lucia, F.J.; Kerans, C.; Jennings, J.W. Carbonate reservoir characterization. J. Pet. Technol. 2003, 55, 70–72. [Google Scholar] [CrossRef]

- Nehring, R. Giant Oil Fields and World Oil Resources. 1978. Available online: https://www.rand.org/content/dam/rand/pubs/reports/2006/R2284.pdf (accessed on 2 January 2022).

- Ivanhoe, L.; Leckie, G. Global oil, gas fields, sizes tallied, analyzed. Oil Gas J. 1993, 91. Available online: www.ogj.com/home/article/17223313/global-oil-gas-fieldssizes-tallied-analyzed (accessed on 2 January 2022).

- Gaswirth, S.B.; French, K.L.; Pitman, J.K.; Marra, K.R.; Mercier, T.J.; Leathers-Miller, H.M.; Schenk, C.J.; Tennyson, M.E.; Woodall, C.A.; Brownfield, M.E.; et al. Assessment of Undiscovered Continuous Oil and Gas Resources in the Wolfcamp Shale and Bone Spring Formation of the Delaware Basin, Permian Basin Province, New Mexico and Texas, 2018; U.S. Geological Survey: Denver, CO, USA, 2018. [CrossRef]

- Saputra, W.; Kirati, W.; Patzek, T. Forecast of Economic Tight Oil and Gas Production in Permian Basin. Energies 2022, 15, 43. [Google Scholar] [CrossRef]

- Saputra, W.; Kirati, W.; Patzek, T. Generalized Extreme Value Statistics, Physical Scaling and Forecasts of Oil Production from All Vertical Wells in the Permian Basin. Energies 2022, 1, 904. [Google Scholar] [CrossRef]

- Saputra, W.; Kirati, W.; Patzek, T. Generalized Extreme Value Statistics, Physical Scaling and Forecasts of Oil Production in the Bakken Shale. Energies 2019, 12, 3641. [Google Scholar] [CrossRef] [Green Version]

- Saputra, W.; Kirati, W.; Patzek, T. Physical Scaling of Oil Production Rates and Ultimate Recovery from All Horizontal Wells in the Bakken Shale. Energies 2020, 13, 2052. [Google Scholar] [CrossRef] [Green Version]

- Patzek, T.W.; Saputra, W.; Kirati, W. A Simple Physics-Based Model Predicts Oil Production from Thousands of Horizontal Wells in Shales. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar]

- Yousef, A.A.; Al-Saleh, S.; Al-Jawfi, M.S. Improved/Enhanced Oil Recovery from Carbonate Reservoirs by Tuning Injection Water Salinity and Ionic Content. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2012. [Google Scholar] [CrossRef]

- Hu, X.; Yutkin, M.P.; Hassan, S.; Wu, J.; Prausnitz, J.M.; Radke, C.J. Calcium Ion Bridging of Aqueous Carboxylates Onto Silica: Implications for Low-Salinity Waterflooding. Energy Fuels 2018, 33, 127–134. [Google Scholar] [CrossRef]

- Hassan, S.; Kamireddy, S.; Yutkin, M.; Radke, C.; Patzek, T. Adsorption of Charged Surfactants onto Calcium Carbonate. In Proceedings of the IOR 2019-20th European Symposium on Improved Oil Recovery, Pau, France, 8–10 April 2019. [Google Scholar] [CrossRef]

- Yutkin, M.; Radke, C.; Patzek, T. Chemical Compositions in Salinity Waterflooding of Carbonate Reservoirs: Theory. Transp. Porous Med. 2021, 136, 411–429. [Google Scholar] [CrossRef]

- Yutkin, M.; Radke, C.; Patzek, T. Chemical Compositions in Salinity Waterflooding of Carbonate Reservoirs: Experiment. Transp. Porous Med. 2022, 141. [Google Scholar] [CrossRef]

- Sorkhabi, R. Ghawar, Saudi Arabia: The King of Giant Fields. 2010. Available online: www.geoexpro.com/articles/2010/04/-the-king-of-giant-fields (accessed on 2 January 2022).

- Cantrell, D.L.; Hagerty, R.M. Microporosity in arab formation carbonates, Saudi Arabia. GeoArabia 1999, 4, 129–154. [Google Scholar] [CrossRef]

- Clerke, E.A.; Mueller, H.W., III; Phillips, E.C.; Eyvazzadeh, R.Y.; Jones, D.H.; Ramamoorthy, R.; Srivastava, A. Application of Thomeer Hyperbolas to decode the pore systems, facies and reservoir properties of the Upper Jurassic Arab D Limestone, Ghawar field, Saudi Arabia: A “Rosetta Stone” approach. GeoArabia 2008, 13, 113–160. [Google Scholar]

- Thomeer, J. Introduction of a pore geometrical factor defined by the capillary pressure curve. J. Pet. Technol. 1960, 12, 73–77. [Google Scholar] [CrossRef]

- Thomeer, J. Air permeability as a function of three pore-network parameters. J. Pet. Technol. 1983, 35, 809–814. [Google Scholar] [CrossRef]

- Mitchell, J.; Lehmann, P.; Cantrell, D.; Al-Jallal, I.; Al-Thagafy, M. Lithofacies, Diagenesis and Depositional Sequence; Arab-D Member, Ghawar Field, Saudi Arabia; SEPM Society for Sedimentary Geology: Tulsa, OK, USA, 1988. [Google Scholar]

- AAOC Staff. Ghawar oil field, Saudi Arabia. AAPG Bull. 1959, 43, 434–454. [Google Scholar]

- Hassan, A.; Chandra, V.; Yutkin, M.P.; Patzek, T.W.; Espinoza, D. Imaging and characterization of microporous carbonates using confocal and electron microscopy of epoxy pore casts. SPE J. 2019, 24, 1220–1233. [Google Scholar] [CrossRef]

- Hassan, A.; Yutkin, M.; Chandra, V.; Patzek, T. Quality Evaluation of Epoxy Pore Casts Using Silicon Micromodels: Application to Confocal Imaging of Carbonate Samples. Appl. Sci. 2021, 11, 5557. [Google Scholar] [CrossRef]

- Verma, M.K.; Boucherit, M.; Bouvier, L. Evaluation of residual oil saturation after waterflood in a carbonate reservoir. SPE Reserv. Eng. 1994, 9, 247–253. [Google Scholar] [CrossRef]

- Yutkin, M.P.; Mishra, H.; Patzek, T.W.; Lee, J.; Radke, C.J. Bulk and Surface Aqueous Speciation of Calcite: Implications for Low-Salinity Waterflooding of Carbonate Reservoirs. SPE J. 2018, 23, 084–101. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Yutkin, M.P.; Hassan, S.; Wu, J.; Prausnitz, J.M.; Radke, C.J. Asphaltene Adsorption From Toluene Onto Silica Through Thin Water Layers. Langmuir 2018, 35, 428–434. [Google Scholar] [CrossRef]

- Patzek, T.W. Verification of a complete pore network simulator of drainage and imbibition. Spe J. 2001, 6, 144–156. [Google Scholar] [CrossRef] [Green Version]

- Yousef, A.A.; Al-Saleh, S.; Al-Kaabi, A.; Al-Jawfi, M. Laboratory investigation of the impact of injection-water salinity and ionic content on oil recovery from carbonate reservoirs. SPE Reserv. Eval. Eng. 2011, 14, 578–593. [Google Scholar] [CrossRef]

- Alotaibi, M.; Yousef, A. The impact of dissolved species on the reservoir fluids and rock interactions in carbonates. In Proceedings of the SPE Saudi Arabia Section Annual Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 21–23 April 2015. [Google Scholar]

- Salathiel, R. Oil recovery by surface film drainage in mixed-wettability rocks. J. Pet. Technol. 1973, 25, 1216–1224. [Google Scholar] [CrossRef]

- Kovscek, A.; Wong, H.; Radke, C. A pore-level scenario for the development of mixed wettability in oil reservoirs. AIChE J. 1993, 39, 1072–1085. [Google Scholar] [CrossRef] [Green Version]

- Blunt, M.J. Pore level modeling of the effects of wettability. SPE J. 1997, 2, 494–510. [Google Scholar] [CrossRef]

- Freer, E.; Svitova, T.; Radke, C. The role of interfacial rheology in reservoir mixed wettability. J. Pet. Sci. Eng. 2003, 39, 137–158. [Google Scholar] [CrossRef]

- Saad, A.M.; Aime, S.; Mahavadi, S.C.; Song, Y.Q.; Patzek, T.W.; Weitz, D. Interfacial Viscoelasticity in Crude Oil-Water Systems to Understand Incremental Oil Recovery. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 5–7 October 2020. [Google Scholar]

| Microporosity Type | Description |

|---|---|

| Type I | Microporous grain (MG) |

| Type II | Microporous matrix (MM) |

| Type III | Microporous equant intercrystalline between cement crystals (MEC) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patzek, T.W.; Saad, A.M.; Hassan, A. Multimodal Carbonates: Distribution of Oil Saturation in the Microporous Regions of Arab Formations. Energies 2022, 15, 1243. https://doi.org/10.3390/en15031243

Patzek TW, Saad AM, Hassan A. Multimodal Carbonates: Distribution of Oil Saturation in the Microporous Regions of Arab Formations. Energies. 2022; 15(3):1243. https://doi.org/10.3390/en15031243

Chicago/Turabian StylePatzek, Tadeusz W., Ahmed M. Saad, and Ahmed Hassan. 2022. "Multimodal Carbonates: Distribution of Oil Saturation in the Microporous Regions of Arab Formations" Energies 15, no. 3: 1243. https://doi.org/10.3390/en15031243

APA StylePatzek, T. W., Saad, A. M., & Hassan, A. (2022). Multimodal Carbonates: Distribution of Oil Saturation in the Microporous Regions of Arab Formations. Energies, 15(3), 1243. https://doi.org/10.3390/en15031243