1. Introduction

Unconventional oil and gas resources refer to oil and gas resources that are continuously distributed over a large area. Traditional technology cannot obtain natural industrial production capacity. New technologies are needed to improve reservoir permeability or fluidity for economic development. These include heavy oil, oil sands, tight oil and gas, shale oil and gas, coalbed methane, natural gas hydrate, and oil shale [

1]. Exploration and development practices and global new oil and gas resource evaluation have confirmed that unconventional oil and gas resources are abundant. According to the assessment of the International Energy Agency (IEA), the global recoverable oil resources are 9560 × 10

8 t, of which unconventional oil is 4210 × 10

8 t, and the global recoverable natural gas resources are 783.8 × 10

12 m

3, of which unconventional natural gas is 195 × 10

12 m

3 [

2]. According to IEA forecasts, global unconventional gas production will increase to 2.5 × 10

12 m

3 in 2040, accounting for about 42% of total natural gas production, of which shale gas is 1.7 × 1012 m

3 and tight gas is 0.46 × 10

12 m

3 [

2]. Oil production will increase to more than 10 × 10

8 t, accounting for about 20% of total crude oil production, of which tight oil and shale oil production is 5.1 × 10

8 t, and oil sands oil production is 3.4 × 10

8 t [

2]. The successful development of unconventional oil and gas has greatly increased the global oil and gas resources and promoted the growth of global oil and gas production.

However, unconventional petroleum resources such as heavy oil, oil sands, shale oil, and oil shale cannot be easily exploited through conventional methods. Among them, heavy oil and oil sands have high viscosity and poor fluidity, and it is difficult to achieve natural lift only by formation energy. The commonly used methods for viscosity reduction in heavy oil include thermal viscosity reduction, chemical viscosity reduction, mixing viscosity reduction, and microbial viscosity reduction. Among them, thermal viscosity reduction mainly includes steam stimulation (CSS), steam flooding (SF), gravity assisted oil drainage (SAGD), and combustion oil layers based on steam injection production [

3,

4]. For shale oil and oil shale, their main feature is the presence of undischarged liquid hydrocarbons and unconverted organic matter (kerogen) in the shale. To maximize the development of shale oil and oil shale resources, kerogen must be converted into oil and gas resources to improve oil and gas recovery [

5]. Investigations, tests, and field trials have shown that underground in situ heating is the best choice for large-scale development and utilization of shale oil. The main mining technologies include reactive heat heating, conduction heating, convection heating, and radiant heating. The basic principle is that by injecting heat into the formation, the kerogen-rich rock formation continues to heat up, causing a cracking process. Heavy oil, bitumen, and other organic matter are converted into light oil and natural gas on a large scale, leaving residual carbon and CO

2 and other pollutants underground, which is a clean and efficient mining method [

6,

7,

8,

9,

10,

11,

12]. It can be seen that heat injection is the most important method for the effective exploitation of heavy oil, oil sands, shale oil, oil shale, and other unconventional petroleum resources. Therefore, how to effectively inject heat into the formation is a problem that must be solved in the development of unconventional petroleum resources.

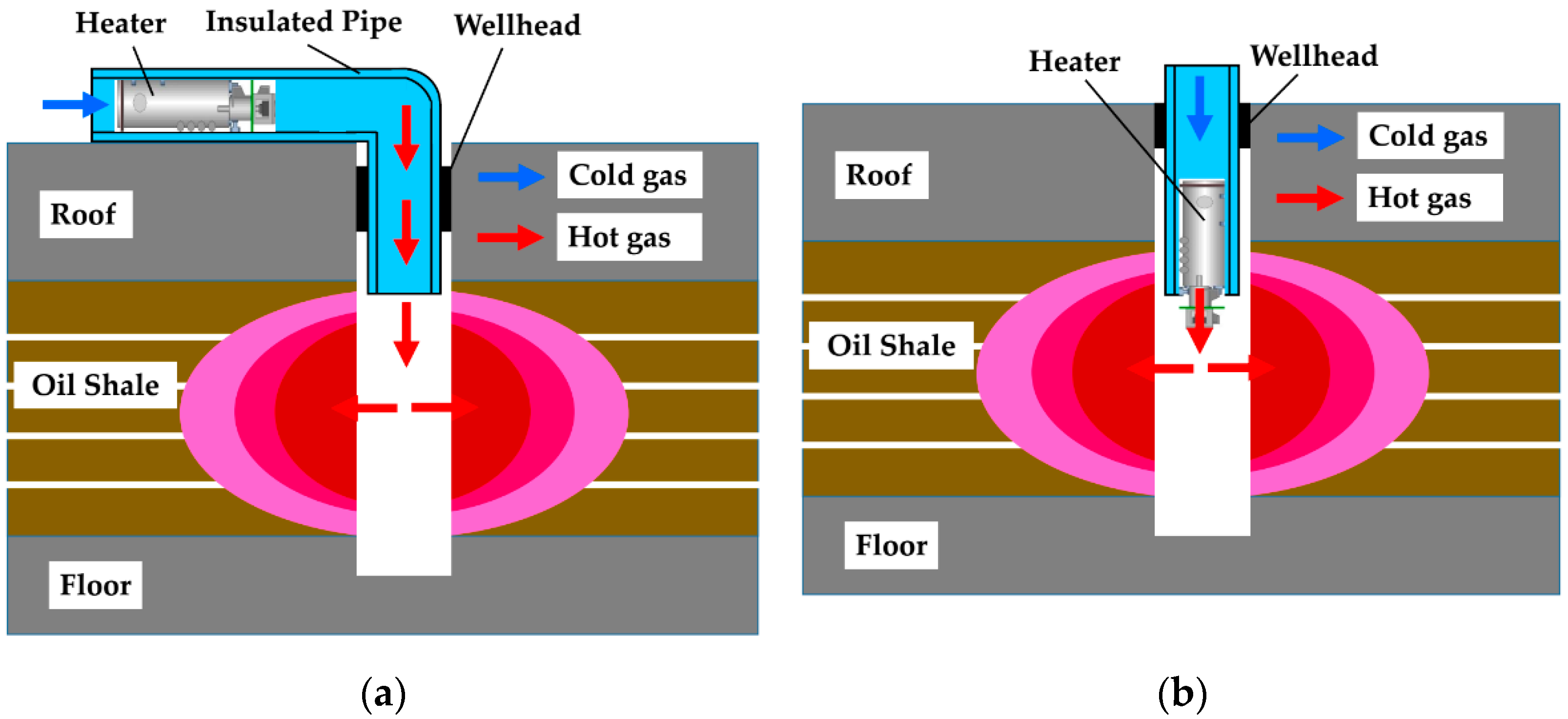

Heat injection methods for the exploitation of unconventional oil and gas resources can be divided into surface heating and downhole heating. Surface heating technology means that the high-temperature heat carrier generator is placed on the surface, the low-temperature heat carrier is transported to the surface heater through the gas injection pipeline, and the generated high-temperature heat carrier is transported to the target reservoir through the insulated pipeline, and the reservoir is heated to the cracking temperature, as shown in

Figure 1a. The surface heating technology is mature, but the high-temperature heat carrier produces a large amount of heat loss during the process of injecting into the oil shale layer. Even after the heat-insulating pipe string is insulated, the heat loss of the high-temperature gas in the “transportation section” is still as high as 13.5 K/m. It can be seen that for the in situ mining of oil shale resources in the middle and deep layers, in order to improve the efficiency of heat injection and avoid the huge heat loss of the high-temperature heat carrier on the transmission path, it is necessary to develop heating technology for in situ mining of the oil shale resources in the middle and deep layers. Downhole heating technology involves placement of the high-temperature heat carrier generator downhole, and the low-temperature heat carrier is transported to the downhole heater through the heat injection pipeline. The high-temperature heat carrier produced by the downhole heater directly heats the target oil shale layer and heats the oil shale to cracking, as shown in

Figure 1b. Downhole heating technology has fast heating speed, high energy utilization rate, and the prospect of large-scale commercial development. The downhole heater is the key equipment of this technology [

13].

According to the source of heat, the downhole heater can be divided into two heating methods: electric heating and combustion heating. The heat source of the electric heating method is electric energy. The electric heating wire is used to convert the electric energy into heat energy to heat the oil shale by heat conduction, or the electric energy is converted into heat energy through the electromagnetic induction effect of the excitation coil to produce high-temperature fluid in the form of thermal convection, heating oil shale. Previous research on downhole electric heaters mainly focused on the study of the influence of heaters with different structures (electric heating rods) and heater materials on heater performance [

14,

15,

16,

17,

18]. The heat transfer area of the electric heating rod is small, and the low thermal conductivity of the oil shale makes the heating efficiency of heating the oil shale by heat conduction lower, and the cost is higher, which is not suitable for large-scale applications. Electric heating downhole electric heaters that generate high-temperature fluids with resistance heat have no enhanced heat transfer structure on the surface of the heating body, which tends to produce local high-temperature areas, resulting in short heater life and poor stability. The heat source of combustion and heating is the combustion reaction heat of fossil fuels (oil or gas), and the high-temperature gas produced directly heats the oil shale layer by means of thermal convection, or the high-temperature gas generates a high-temperature heat carrier through the heat exchange structure to heat the oil shale layer. The combustion heater device does not have high requirements itself, so it has better stability [

19,

20].

The ignition temperature of methane is 538 °C, and the flame temperature is as high as 2861 °C, far exceeding the heating temperature required for heavy oil, oil sands, shale oil, and oil shale production, such as shale oil and organic matter conversion in oil shale. The temperature of oil and gas is between 300 °C and 500 °C. Excessive temperature leads to carbonization of organic matter, which is not conducive to oil production. Therefore, it is necessary to effectively reduce the ignition temperature and combustion temperature of methane by means of catalytic combustion. The use of catalysts enables flameless combustion of CH

4 in air below the autoignition temperature of CH

4 in air (595 °C) and can exceed the flammability limit (4.4 vol.% 16.5 vol.% in air) [

21]. This leads to a double safety application and safe operation of the reactor. The total oxidation of CH

4 is an exothermic reaction with a release of about 803 kJ/mol. Since the decomposition of CH

4 hydrate requires +52 kJ/mol, the in situ combustion method is used to thermally increase production [

22]. Under the action of the catalyst, methane can be burned at a lower air concentration and lower temperature. While ensuring the efficient conversion of methane, the temperature of the exhaust gas can be controlled by controlling the methane reaction. Methane catalytic combustion technology is relatively mature. At present, common methane combustion catalysts mainly include noble metal catalysts (Pd, Pt, Au, Rh, Ru, etc.) [

5] and non-precious metal catalysts (transition metal oxides, perovskites, spinel, and other metal oxides) such as stone and hexaaluminate [

23,

24]. Under the action of noble metal catalysts, methane is decomposed and adsorbed into methyl (CH

3) or methylene (CH

2). The adsorbed oxygen directly generates CO

2 and H

2O or formaldehyde (HCHO), which then reacts with the noble-metal-adsorbed oxygen to generate CO

2 and H

2O [

25]. Catalysis can reduce the ignition temperature and combustion peak temperature of methane and generate exhaust gas with different temperatures to meet the different process requirements of unconventional petroleum resources.

At present, the research on catalytic combustion of methane mainly focuses on coal mine tail gas treatment, Micro-Electro-Mechanical System, and other fields. The main focus is on how to improve the conversion efficiency of low-concentration methane in coal mine exhaust gas, and how to reduce the emission of nitrogen oxides (NOx) including nitrogen monoxide, nitrogen dioxide, and nitrous oxide and reduce air pollution [

26,

27,

28,

29]. A large number of studies have been carried out on the catalytic combustion efficiency of methane and the exhaust gas composition of methane catalytic combustion. However, for the in situ extraction of unconventional oil and gas resources, in addition to the catalytic combustion efficiency of methane, whether the temperature of the exhaust gas produced by combustion can meet the heat injection requirements of in situ extraction is also the main parameter of concern. In addition, the in situ mining of unconventional oil and gas resources is usually carried out at a depth of several hundred meters underground, so the high pressure of the formation must be overcome when high-temperature gas is injected into the formation. Under high pressure underground, the density of the gas, the contact area, and the reaction characteristics of the mixture on the catalyst surface are all affected. The effect of these changes on the downhole catalytic combustion process is unclear. Therefore, this the means of numerical simulation were adopted in this study to analyze the influence of high-pressure environment on methane catalytic combustion by comparing the methane catalytic combustion process under two different working conditions, atmospheric pressure and underground high pressure. A reference is provided for the selection of downhole catalytic combustion heating process parameters.

3. Numerical Simulation Method

3.1. Physical Model

The heater consists of a large number of porous media coated with platinum catalyst on the inner wall. The loading density is 2.72 × 10

−9 mol/cm

2. The porous medium material is foamed alumina, which has the advantages of reduced pressure, large specific surface area, and high mechanical strength. It has a diameter of Φ150 mm and a length of 30 mm, and the single pore diameter of the porous medium is about Φ1 mm. The simulated combustion process is the same as the working steps of the downhole catalytic combustion heater. First, a certain temperature is applied to the porous aluminum foam supporting the catalyst to cause the catalytic combustion reaction to occur. The methane-air mixture enters the pores from one side of the reactor and is preheated by the solid substrate to the catalytic reaction temperature. Under the action of the catalyst coated on the inner wall of the pore, a catalytic reaction occurs on the wall. The flue gas generated after the reaction exits the reactor through the vent outlet. Since the structure, internal flow and reaction of each channel are the same, the characteristics of the entire catalyst were selected in this study as the simulation object, as shown in

Figure 4. The inner diameter is Φ1 mm, and the length is 30 mm.

3.2. Method

In the combustion process of porous media, the flow, heat transfer, and chemical reaction processes involved are quite complicated, and it is difficult to simulate the detailed process completely. Therefore, the combustion process must be simplified. The simplified assumptions involved in this study were:

- ①

The porous medium is isotropic and the porosity is constant,

- ②

The chemical reaction occurring on the surface of the catalyst is uniform,

- ③

The dispersion effect of gas in porous media is ignored,

- ④

The influence of gravity is negligible,

- ⑤

The solid wall surface is a radiant gray body.

The control equation used is as follows [

30,

31].

Component conservation equation:

ρg is the gas density,

u is the lateral velocity,

p is the pressure,

T is the temperature,

v is the longitudinal velocity,

μ is the dynamic viscosity,

Jl is the mass flow,

Sh,r are the chemical reaction sources,

hl is the enthalpy of each component,

Yl is the mass fraction of the component, and

Rl is the net production rate of the component. The flow model in the article is a low-pressure laminar flow model. The component transport model is selected for the combustion model, and the chemical reaction rate follows Arrheniu’s law. For the detailed surface chemical reaction mechanism, the authoritative mechanism of methane catalytic reaction on the Pt surface proposed by Deutschmann is selected, which includes 7 adsorption reactions, 11 surface reactions, and 5 desorption reactions, as shown in

Table 1 [

32]. Since the space in the hole is extremely small, the temperature in the combustion chamber is not high, the fuel residence time is short, and the spatial reaction is ignored [

33].

3.3. Boundary Conditions

The inlet of the mixed gas was set as the velocity inlet, the flow rate is set to 0.5, 1, 1.5, 2, 2.5, and 3 m/s, and the initial methane concentration was set to 3%, 4%, 5%, 6%, 7%, and 8%. The outlet was set as a pressure outlet, and the outlet pressure was set as normal pressure, 2 and 4 MPa. The hole wall was set as the wall, the loading density was 2.72 × 10−9 mol/cm2, and the initial temperature was 1500 K. The velocity inlet boundary conditions, the pressure outlet, and the inner wall were non-slip boundary conditions, and the wall had adiabatic boundary conditions. The simulated single pore was a pore in the porous medium, and the outside of this pore was the other identical pore. There was no temperature difference between the pore channels, and no heat exchange occurred between them. Therefore, the outer wall of a single channel was approximately adiabatic.

3.4. Validation of the Grid Independence

Grid independence research involves changing the number of grids and observing the influence of the number of grids on the calculation results. In order to ensure that the mesh can not only fully reflect the physical process of exhaust gas flow but also achieve good convergence, a mesh-independent study must be carried out. The quality of meshing directly affects the speed of convergence and even the success or failure of the solution. Quadrilateral grids were mainly used in this study, and the number of grids was: 750, 3000, 12,000, 27,000, 48,000, 75,000, and 108,000.

The grid independence is studied by comparing the variation of exhaust gas temperature of catalytic combustion under conditions of different grid numbers. The results show that the exhaust gas temperature changes significantly with the increase in grid number, and when the grid number increases to a certain value, the temperature remains relatively stable. The results are shown in

Table 1. As the number of grids increases, the exhaust gas temperature decreases sharply. When the number of grids reaches 48,000, the temperature remains basically stable. Thus, the total number of grids used for the calculation is 48,000. The specific division of the grid is shown in

Figure 5.

The SIMPLE algorithm was adopted for the model, and steady state calculations were used. The second-order upwind style was utilized for the discrete format, and the single-precision coupled solver was used to solve the control equations. The conversion rate of methane was calculated using the following formula:

min is the methane inlet mass concentration, and

mout is the methane outlet mass concentration.