Study on Inhibition Characteristics of Composite Structure with High-Temperature Heat Pipe and Metal Foam on Gas Explosion

Abstract

:1. Introduction

2. Mathematical Model of Gas Explosion

- 1.

- The pipeline is filled with uniform and static gas air mixture, and all gases in the process are ideal gases.

- 2.

- The explosion process is transient and the radiation heat transfer is ignored.

- 3.

- The influence of volume force is not considered.

- 4.

- Viscous dissipation, Soret effect, and Dufour effect are ignored.

- 5.

- The process of gas explosion belongs to one-step and one-way irreversible chemical reaction.

- 6.

- The specific heat capacity of mixed gas follows the mixing rule.

- 7.

- The pipe wall is rigid. The radiation and heat conduction between the mixed gas and the wall are ignored, and the convective heat transfer between the wall and the fluid is considered.

2.1. Governing Equation

- —Airflow density, kg/m3.

- —x-directional partial velocity, m/s.

- —y-directional partial velocity, m/s.

- —Pressure, Pa.

- —Bias stress, Pa.

- —Internal Energy, J.

- —Mass fraction of components.

- —Rate of chemical reaction generation of components, kmol/(m3/s).

- —Dynamic viscosity coefficient, kg/(m/s).

- —Empirical constants.

2.2. Turbulence Model

2.3. Combustion Model and Reaction Rate Model

2.4. Wall Function

2.5. Porous Media Model

3. Numerical Simulation Results and Analysis of Flame Wave and Shock Wave in Gas Explosion

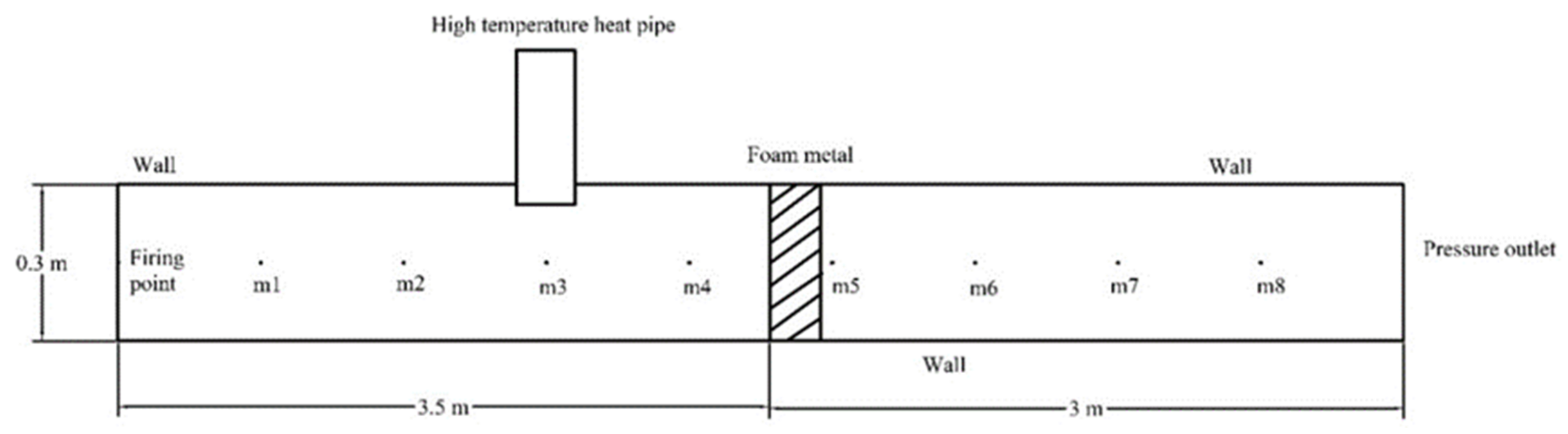

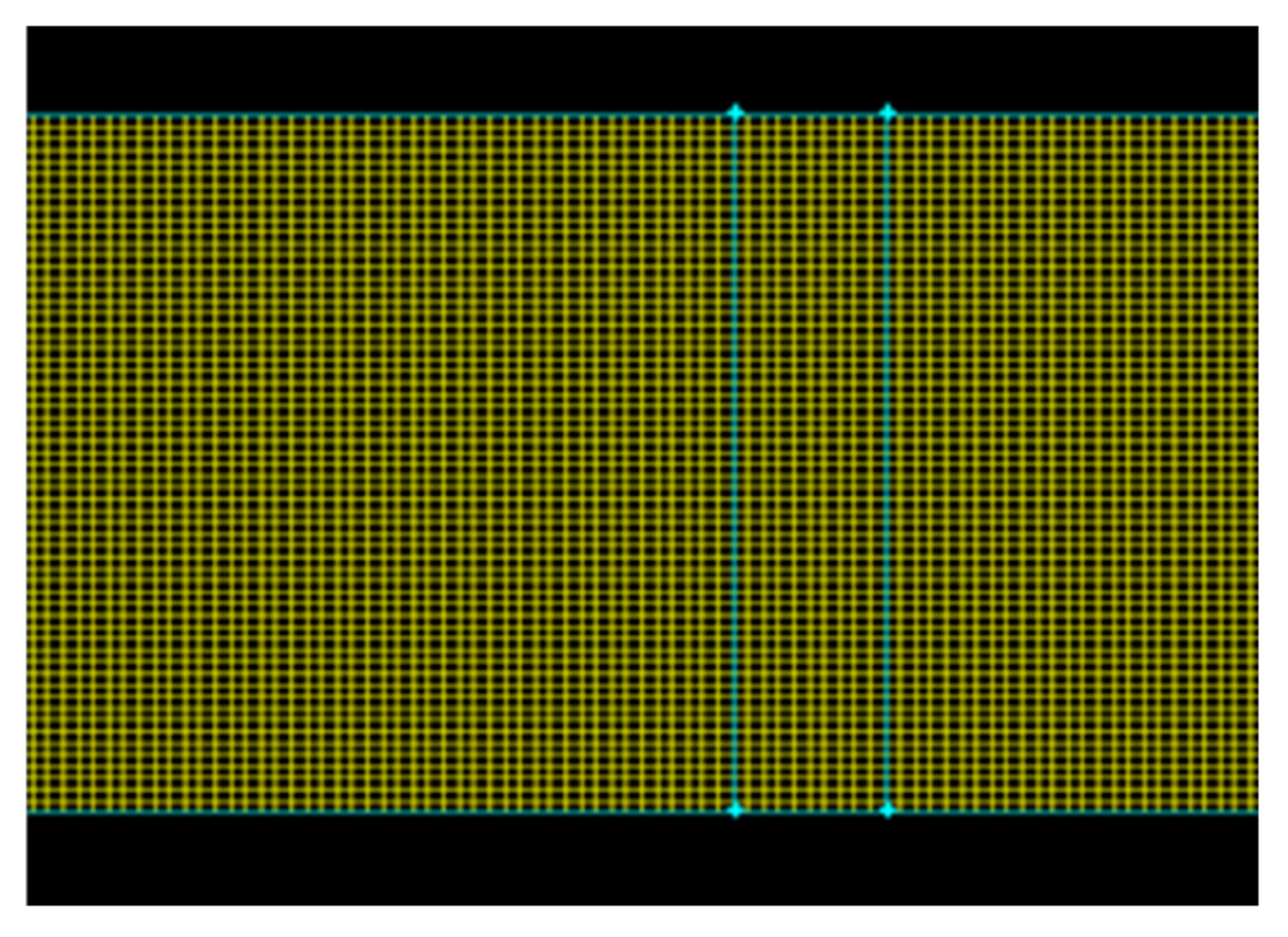

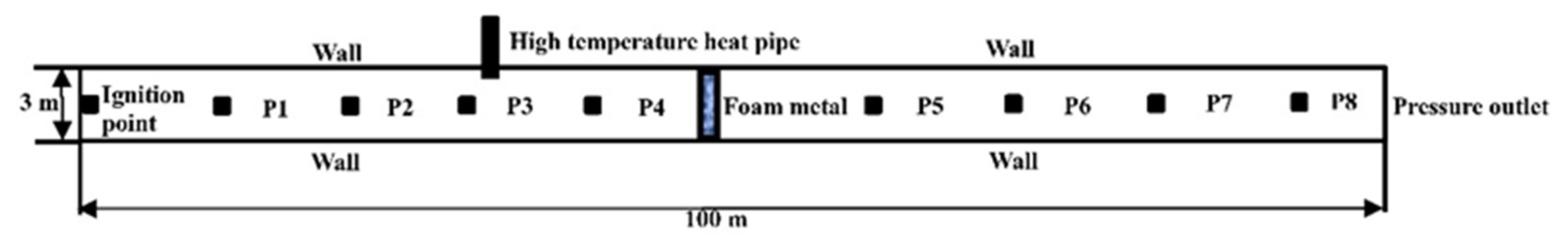

3.1. Geometric Model and Boundary Conditions

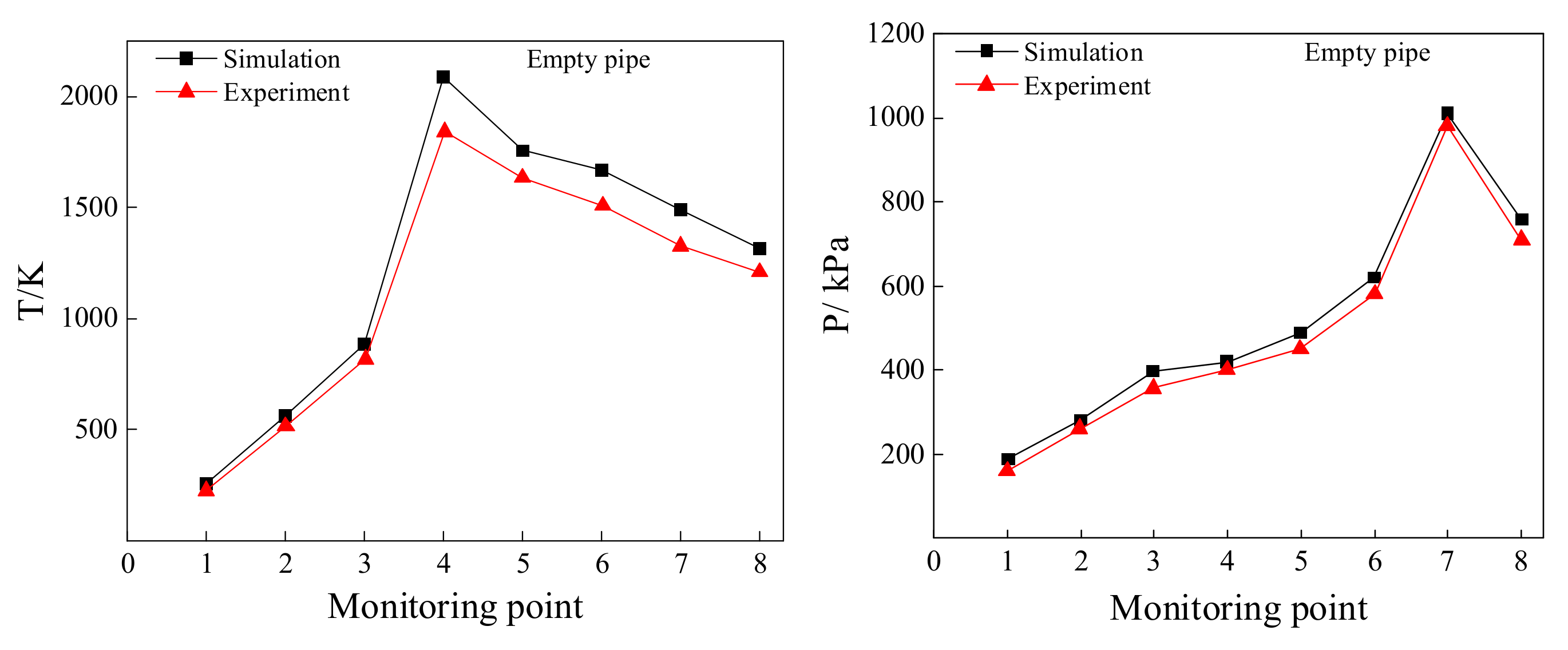

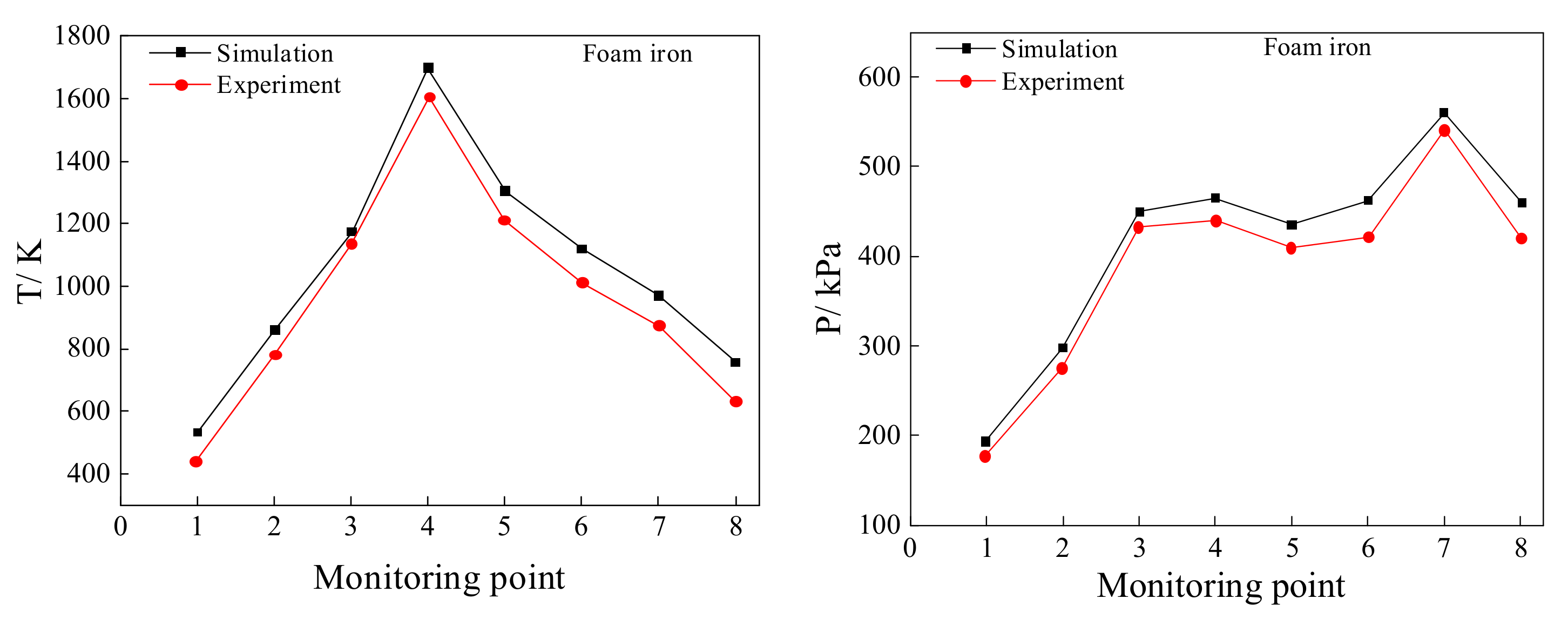

3.2. Verification of Numerical Simulation Results

4. Influence of Metal Foam Material on Gas Explosion Propagation

4.1. Geometric Model and Boundary Conditions

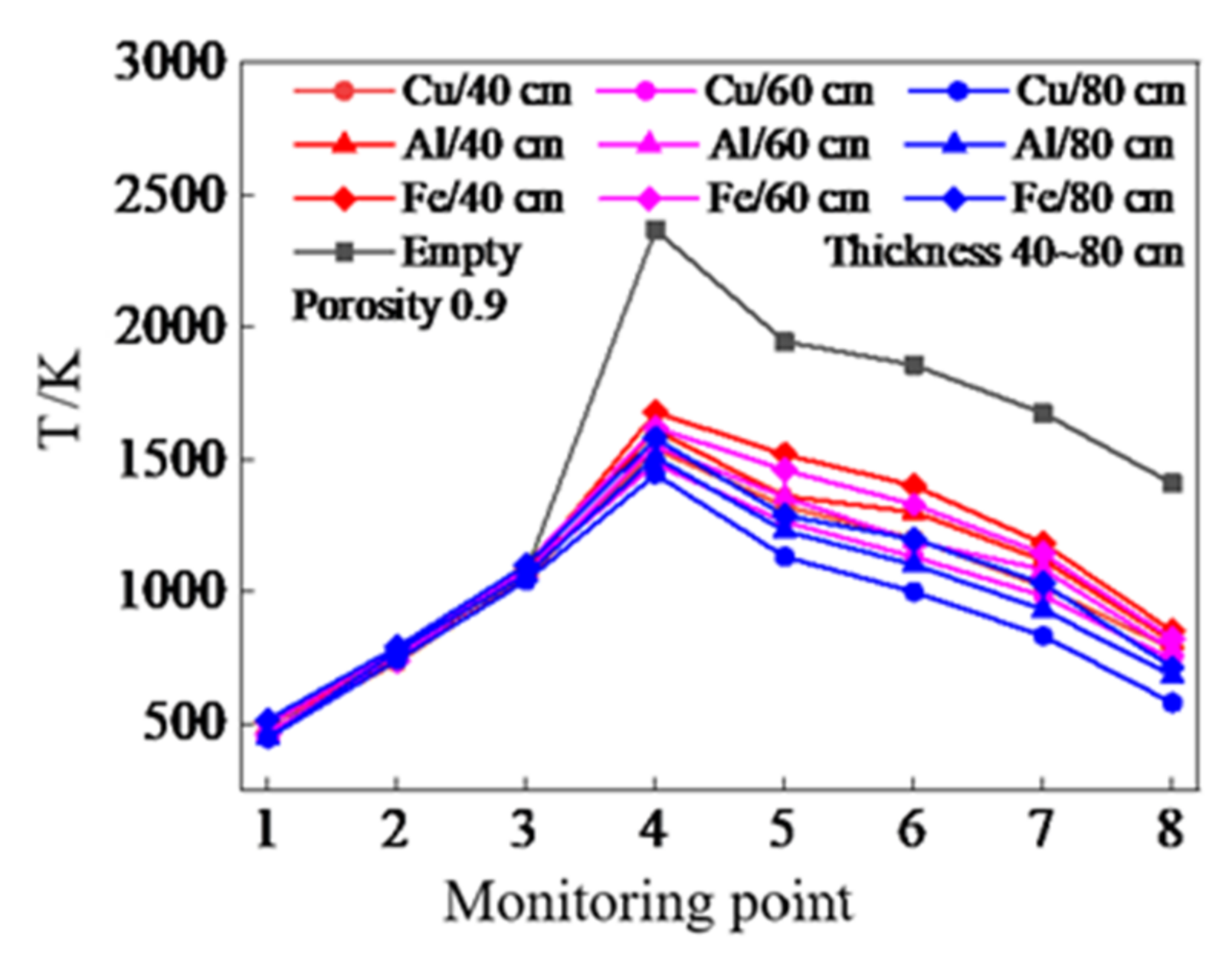

4.2. Influence of Thickness of Metal Foam on Propagation of Flame Wave in Gas Explosion

- 1.

- The foam copper with a thickness of 80 cm has the best effect to suppress the explosion flame. This is mainly because the greater the thickness, the stronger the heat storage capacity. Meanwhile, the increase of the thickness expands the distance of the flame, the flame is divided into small fire groups for a longer time, and the free radicals of collisional destruction increase in number. Therefore, the increase of thickness can effectively enhance the ability of metal foam to suppress the gas explosion flame wave.

- 2.

- The foam copper with a thickness of 80 cm has the best effect in suppressing the explosion shock wave. This is mainly due to the increase of thickness, making the metal foam have larger volume and specific surface area; colliding and rubbing with the shock wave, playing a better reflection and scattering effect; and ultimately converting the shock wave energy into the elastic, plastic, and internal energy of the material itself. Consequently, the increase of thickness can effectively enhance the ability of metal foam to suppress the blast wave of gas explosion.

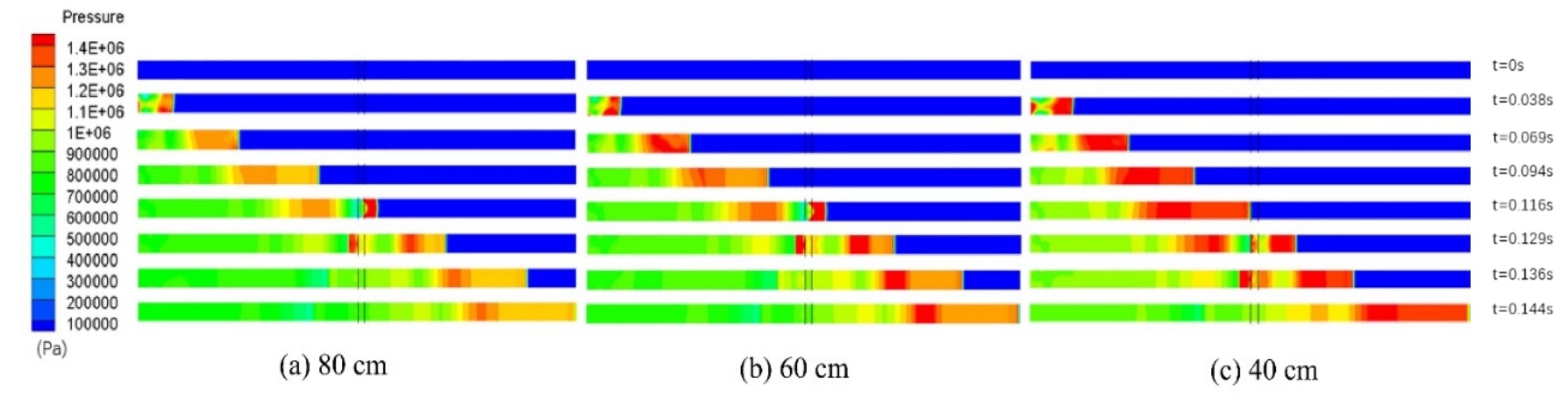

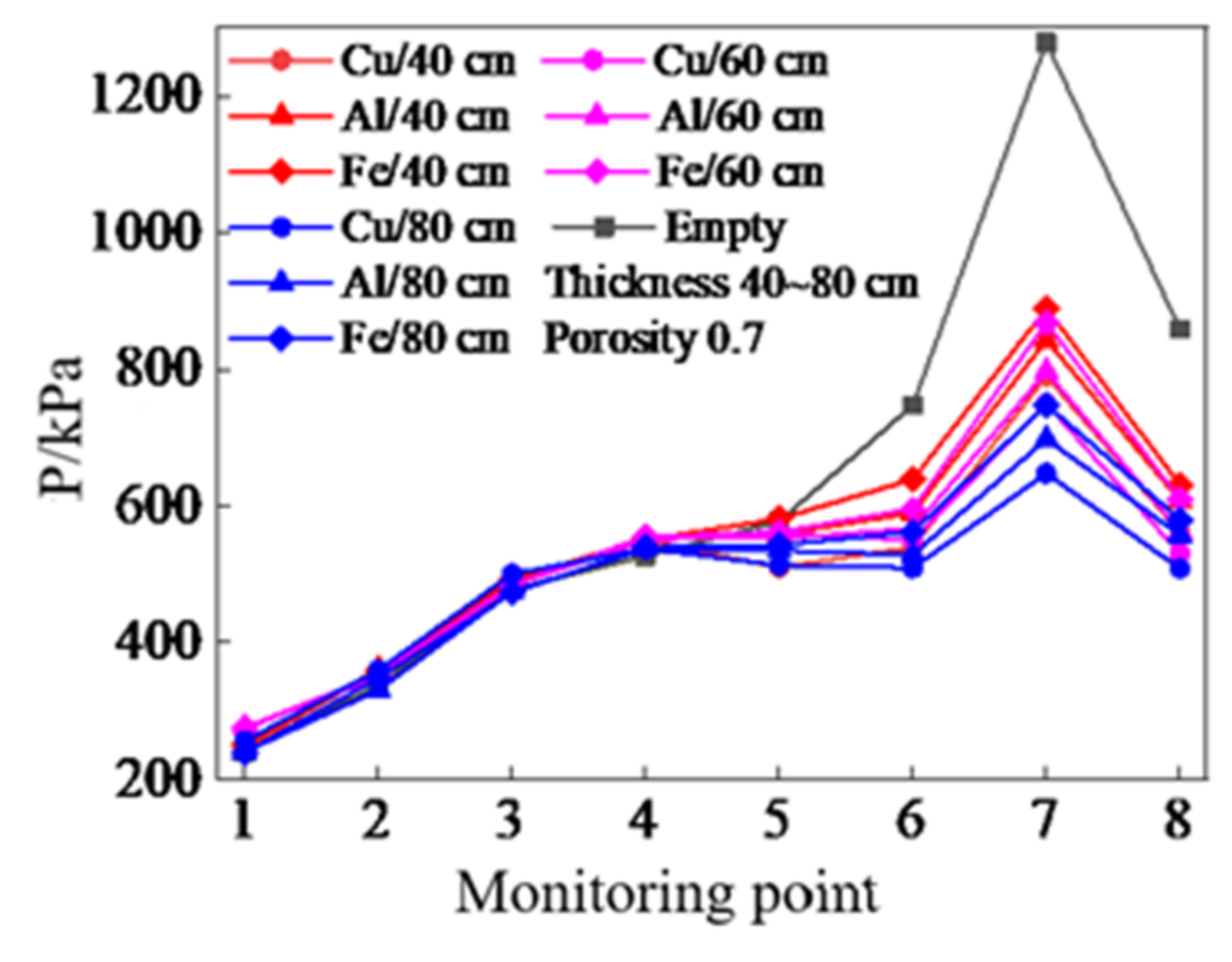

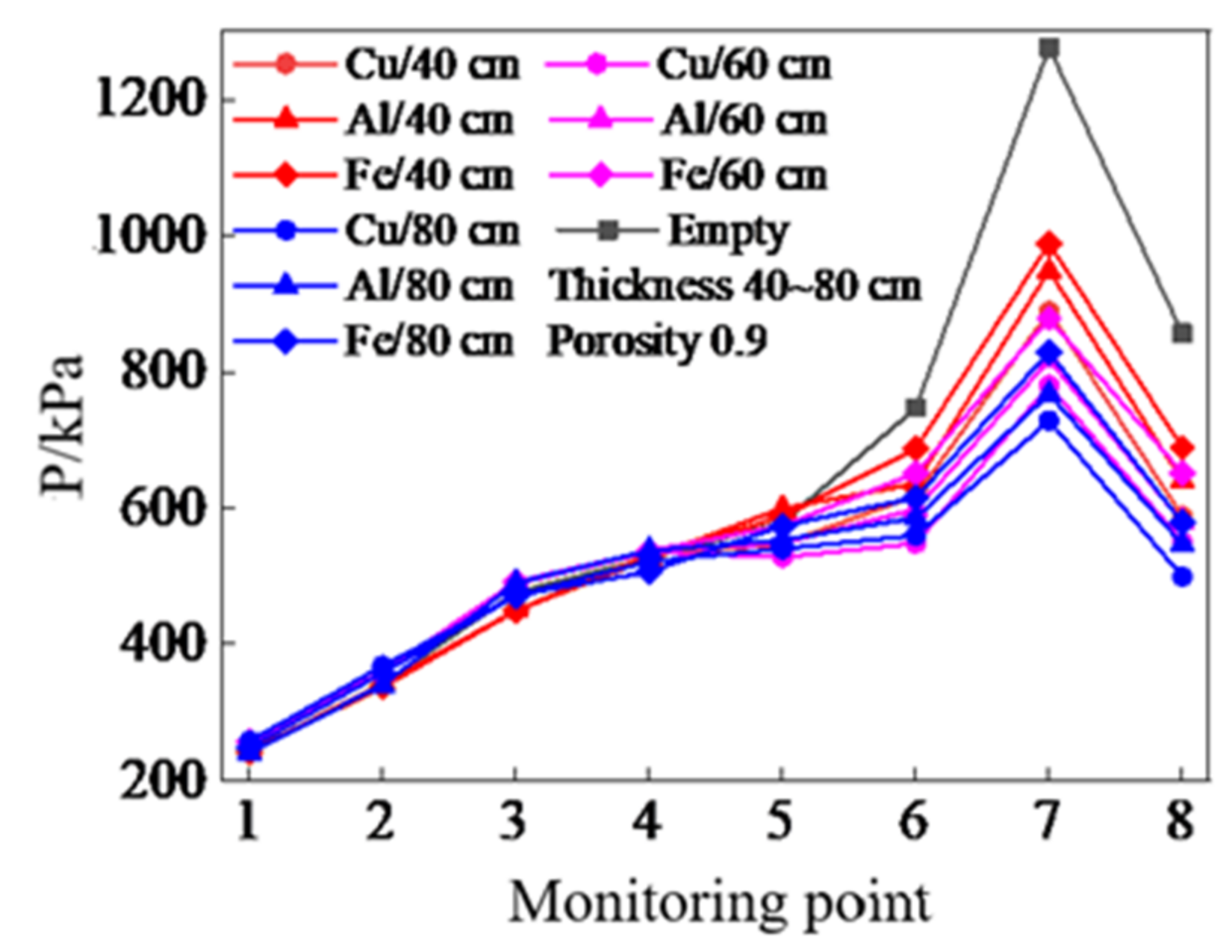

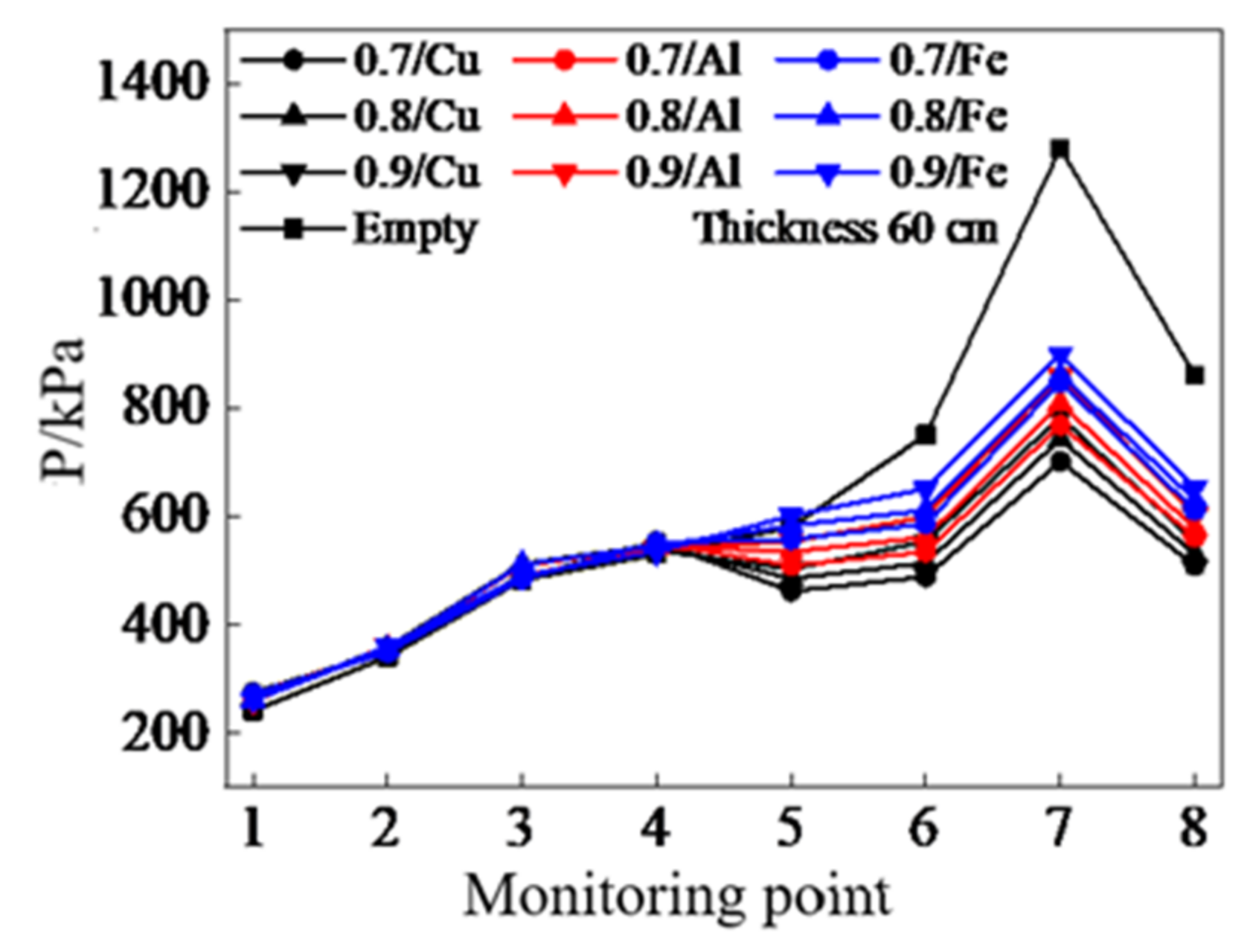

4.3. Influence of Thickness of Metal Foam on Shock Wave Propagation of Gas Explosion

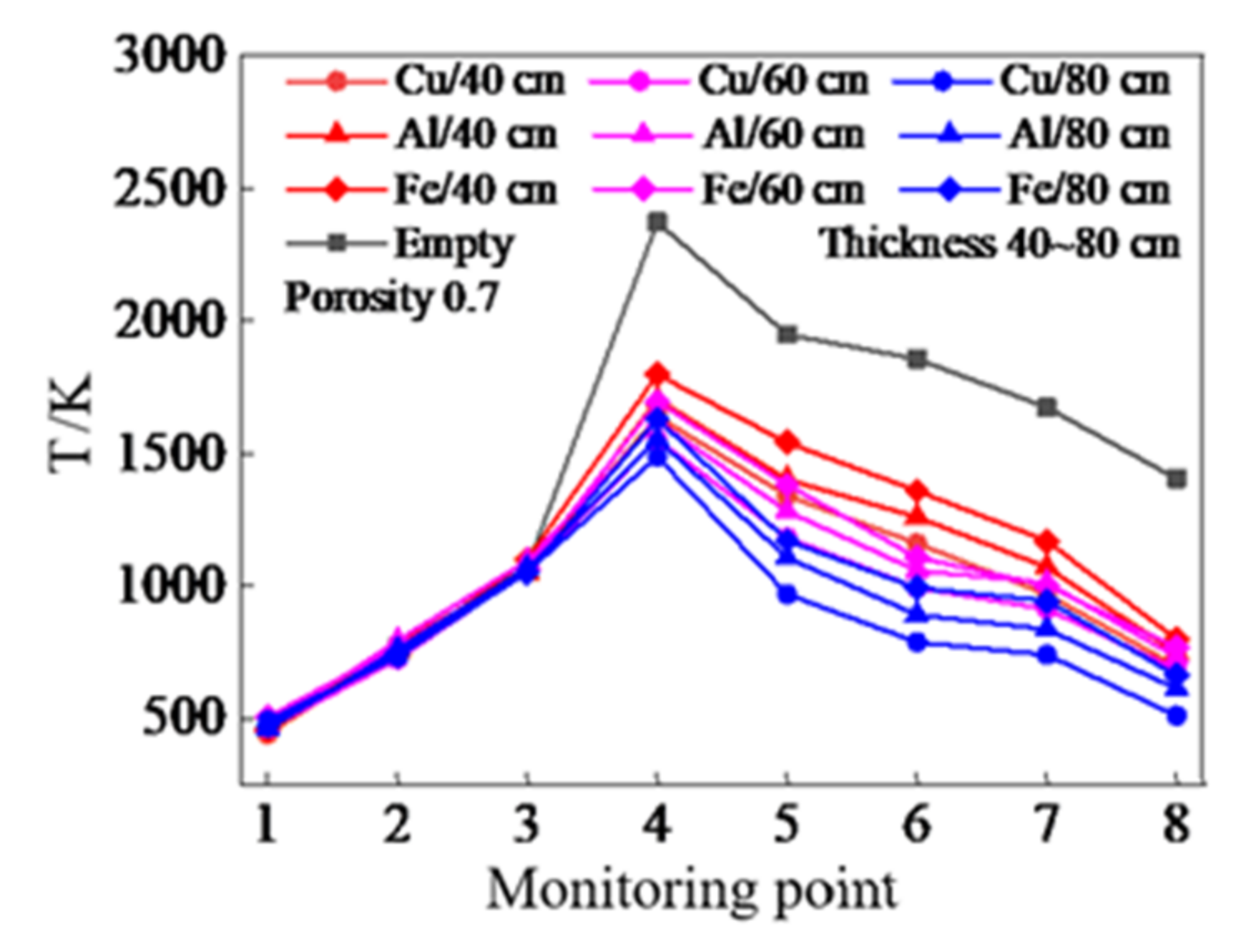

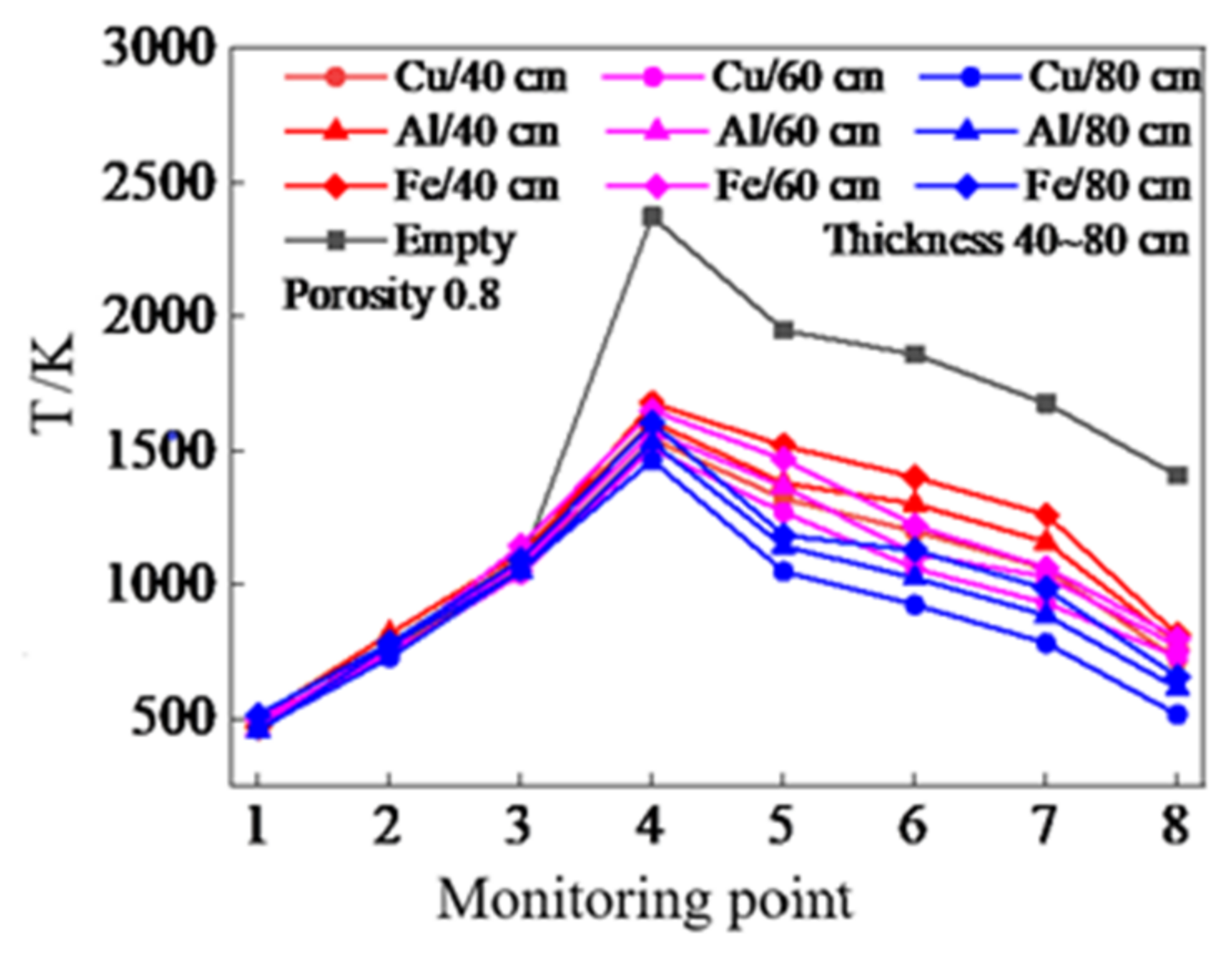

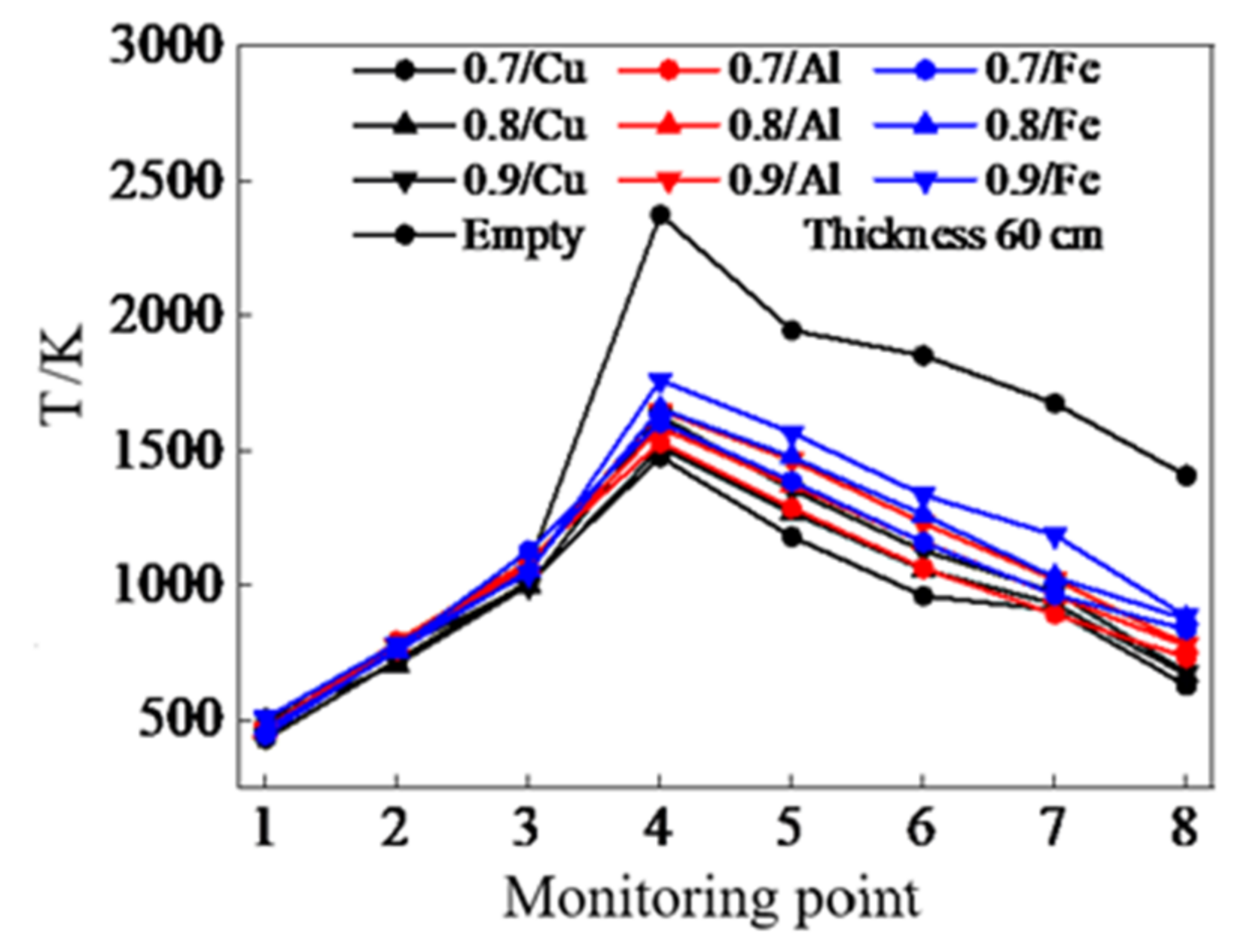

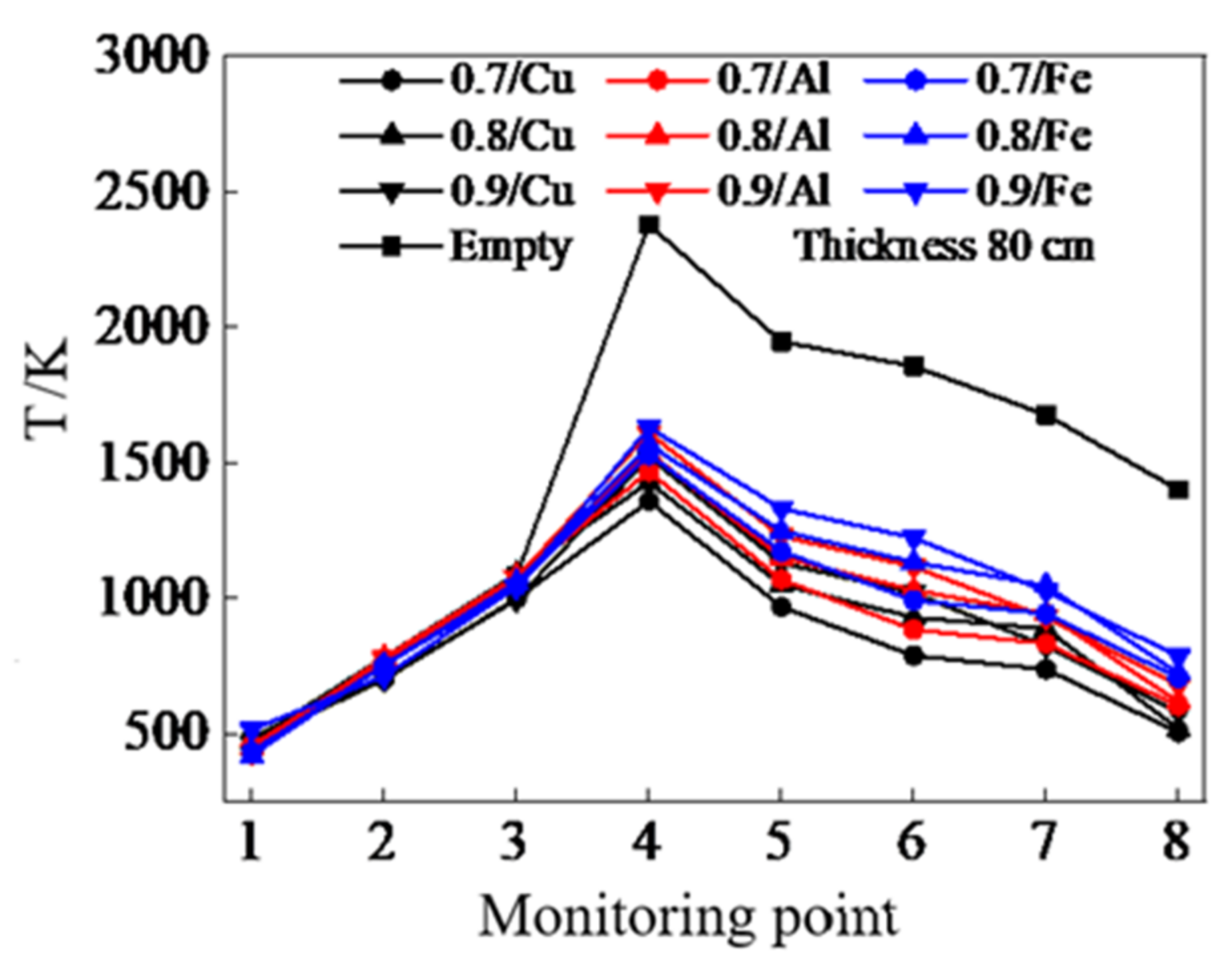

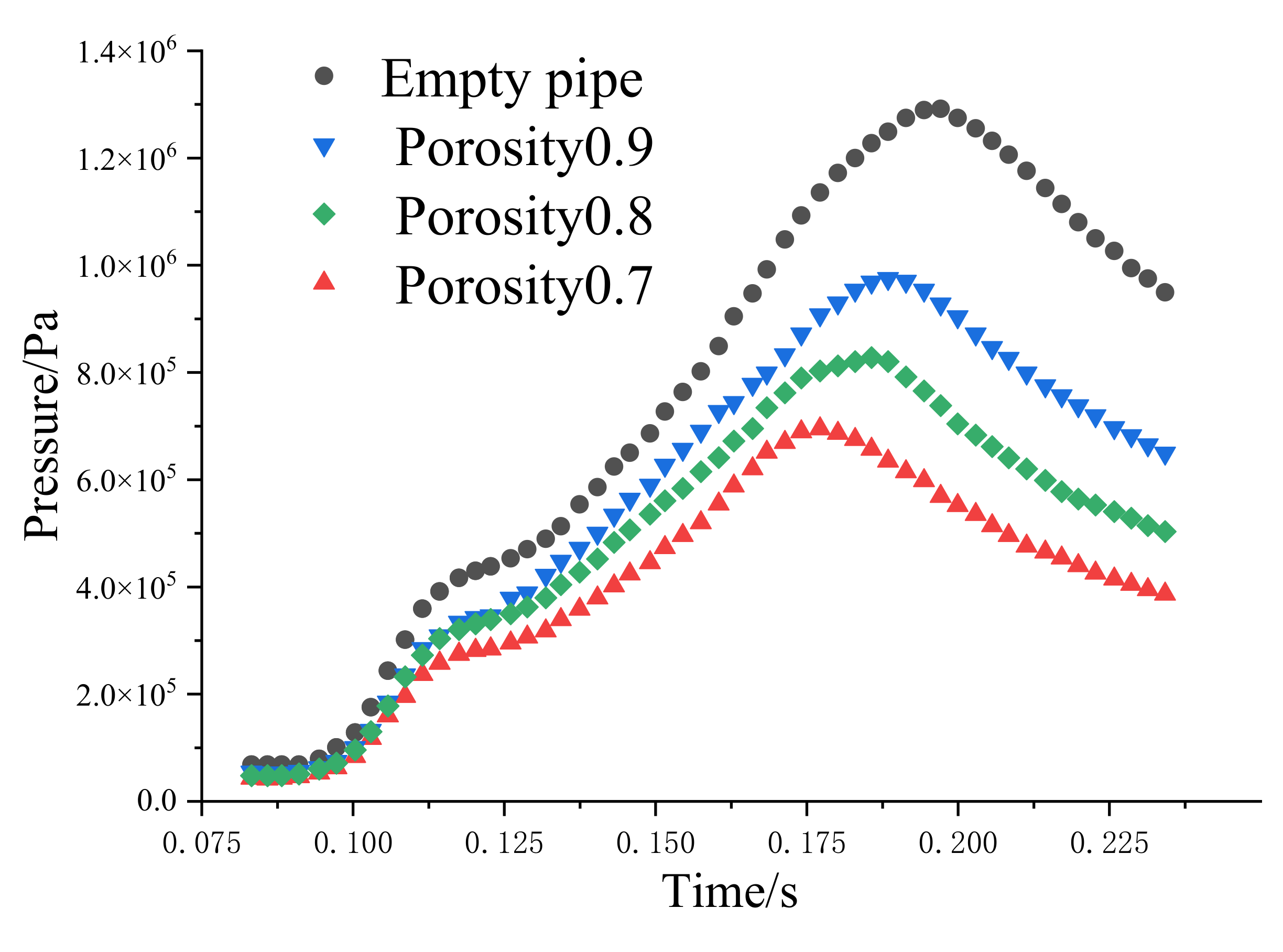

4.4. Influence of Porosity of Metal Foam on Propagation of Flame Wave in Gas Explosion

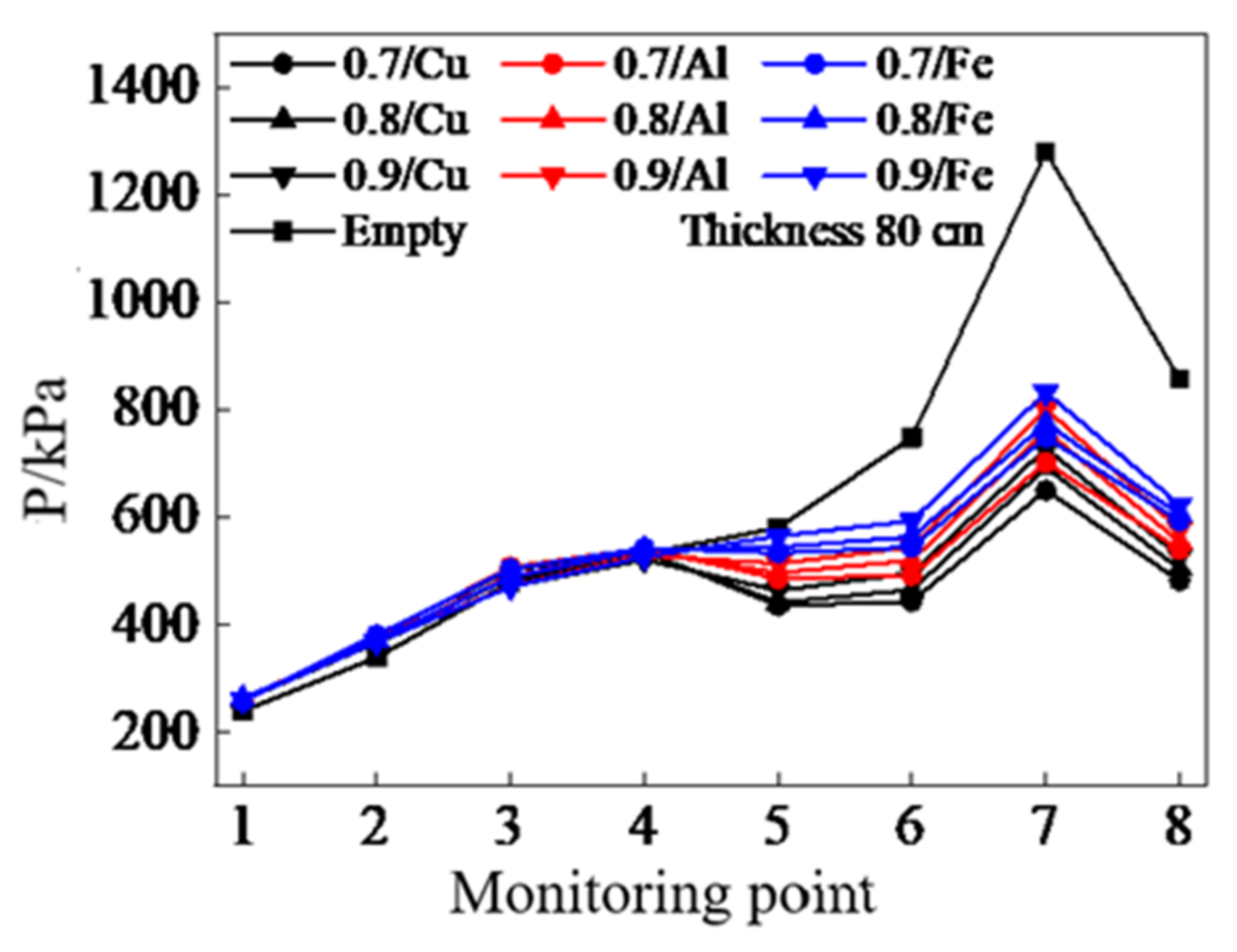

- 1.

- The metal foam with a porosity of 0.7 has the best effect to suppress the explosion flame. The smaller the porosity is, the more metallic the material is and the smaller the pore size in the metal foam is, which enhances the heat conduction and heat storage performance, and the ability to separate and extinguish the explosion flame is better. Therefore, the smaller the porosity, the stronger the ability of metal foam to suppress the gas explosion flame wave.

- 2.

- The metal foam with a porosity of 0.7 is the best to suppress the blast shock wave. The smaller the porosity, the more metal content exists and smaller pore size in the metal foam is. Thence, the higher the material strength, the higher the energy required to suppress the elastoplastic deformation when the blast wave is applied, and the better the effect of absorbing the energy of the blast wave. Thus, the smaller porosity, the stronger the ability of metal foam to suppress gas explosion shock wave.

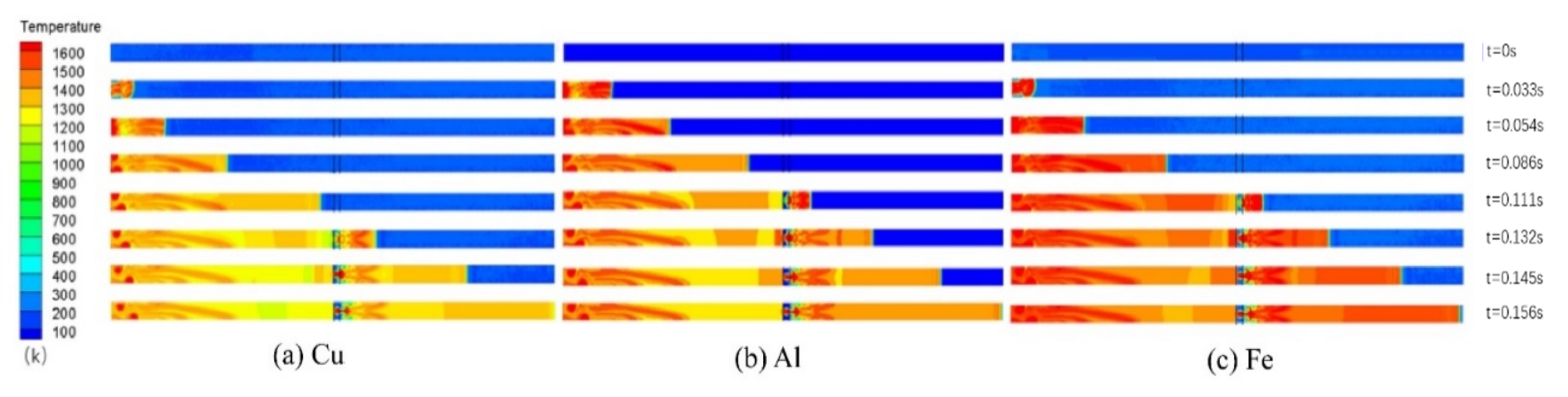

- 1.

- Compared with iron and aluminum, the foam material with copper foam is the best way to suppress the explosion flame. The thermal conductivity of the material has certain effect on its ability to suppress the gas explosion flame wave. The material with better thermal conductivity can lead the heat of the gas explosion flame faster and weaken the gas explosion intensity.

- 2.

- Compared with iron and aluminum, the foam material with copper foam is the best way to suppress the blast wave. The energy of the gas explosion shock wave is provided by the flame after the wave. The material has good thermal conductivity and strong ability to suppress the gas explosion flame wave, thereby weakening the energy source of the blast shock wave and ultimately effectively attenuating the gas explosion shock wave.

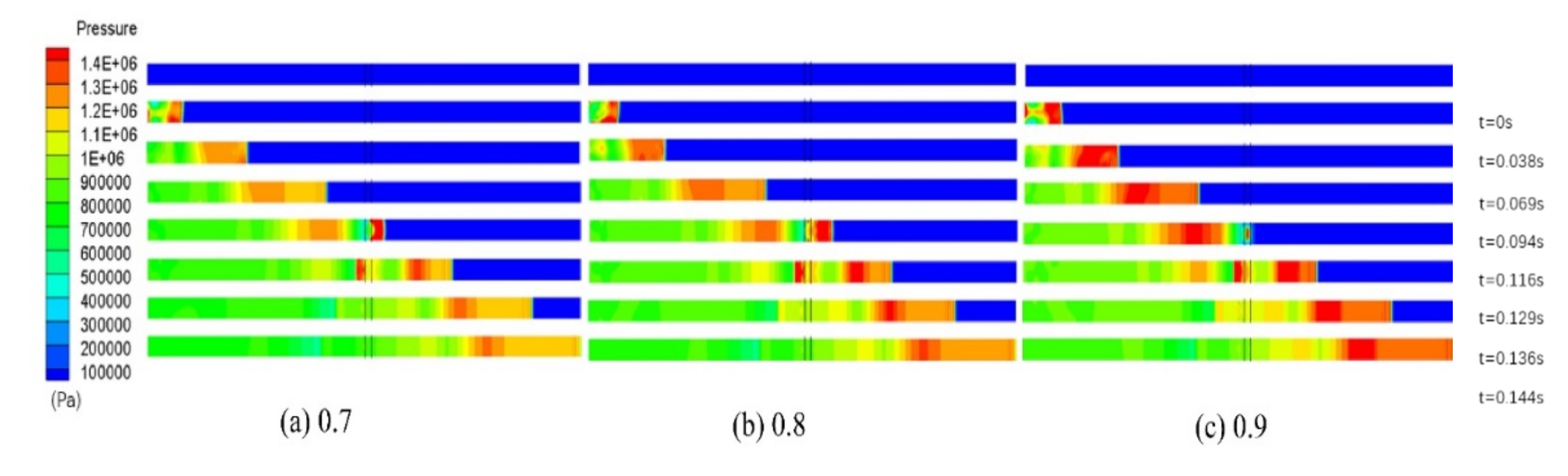

4.5. Influence of Porosity of Metal Foam on Shock Wave Propagation of Gas Explosion

5. Numerical Simulation Analysis of High-Temperature Heat Pipe Metal Foam Composite Structure to Restrain Gas Explosion in Roadway

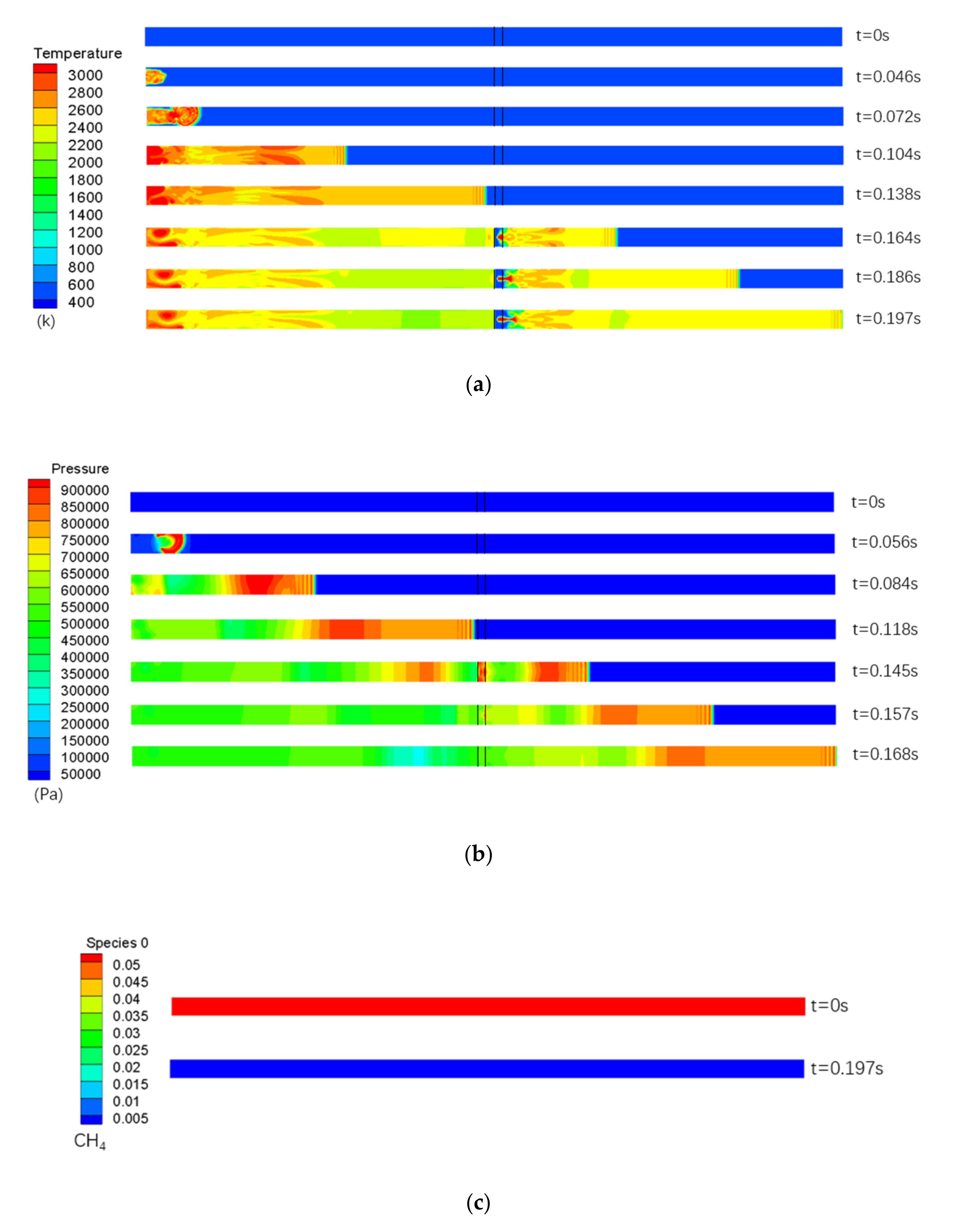

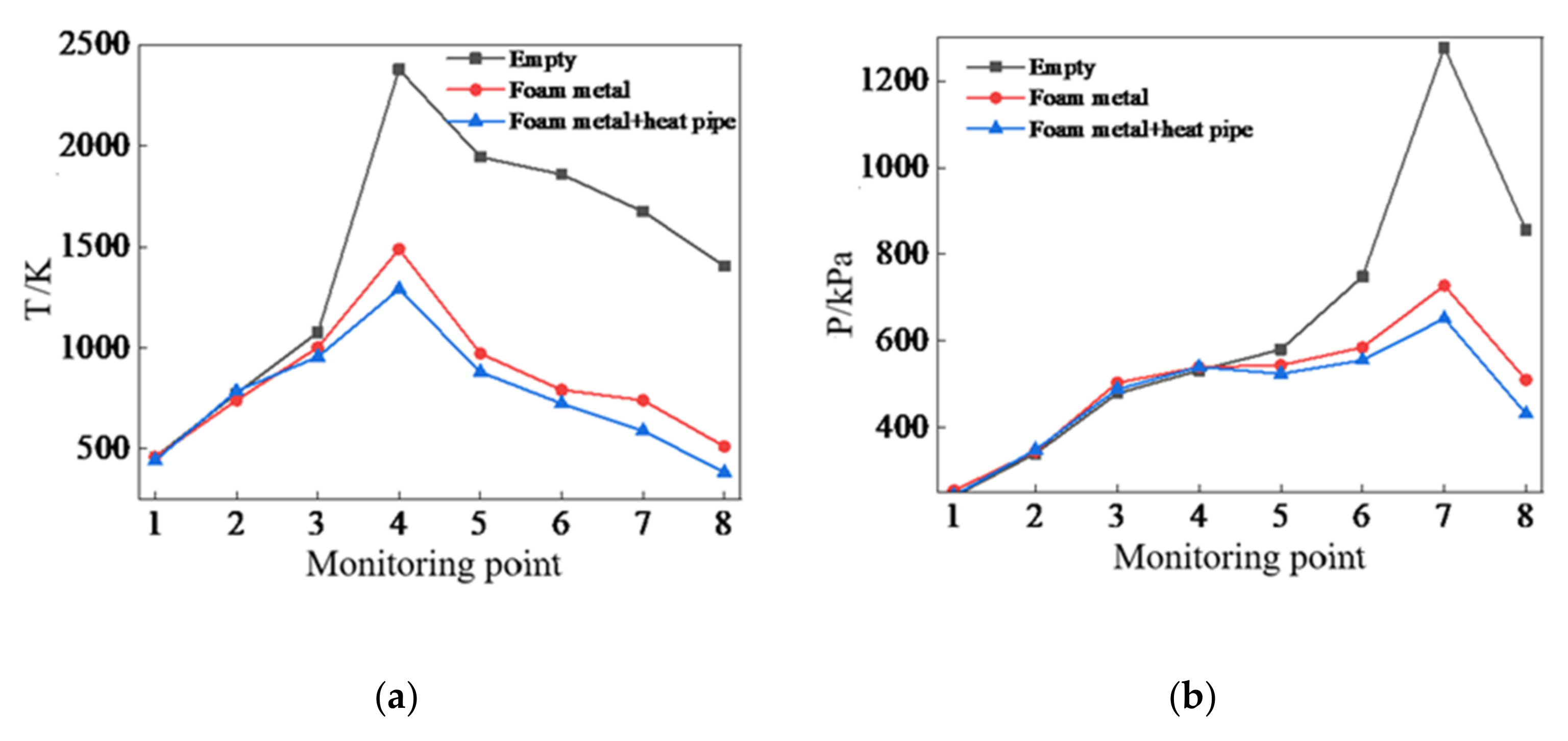

- 1.

- After ignition, a semicircular laminar flame is formed near the left wall of the roadway, and the propagation speed is slow. With the development of combustion reaction, the wall effect gradually appears. The flame velocity at the upper and lower walls of the roadway slows down, the flame velocity at the central axis of the roadway is the fastest, and the flame front develops into an ellipse as a whole. With the continuous advancement of the flame, the flame skirt is in constant contact with the wall, resulting in the reduction of the flame surface area and the gradual flattening of the flame front. When the flame front is also near the high-temperature heat pipe area, the high-temperature heat pipe rapidly transfers heat to the outside of the pipeline in the form of gas-liquid phase change, and the flame finally makes contact with the metal foam material. After some obstruction, the flame passes through the metal foam material. The metal foam material has good quenching properties and a certain degree of thermal conductivity. From the color of the cloud map, we can see that the temperature of the flame after the metal foam is significantly reduced, and the overall reaction time is longer than that of the tunnel without the high-temperature heat pipe metal foam composite structure to 0.197 s.

- 2.

- The explosion of premixed gas produces a strong shock wave, which rapidly advances towards the opening direction. Due to the existence of wall roughness, the shock wave quickly develops into a plane wave. Due to the heat conduction of the high-temperature heat pipe, the flame temperature decreases, the explosion overpressure decreases to a certain extent, and the propagation speed also slows down. The shock wave then passes through the metal foam area, and the intensity and velocity is again attenuated. The reflection effect of explosive shock wave on the surface of metal foam consumes part of the energy of the shock wave, the internal pore structure is also compressed by force, and the impact energy is transformed into plastic property. The shock wave entering the metal foam causes elastic deformation of the pore structure of the material pore structure and can transform part of the shock wave energy into the elastic property. When the shock wave enters the pore structure, it collides with the wall of the pore structure at various angles, resulting in reflection and scattering at various angles, and the energy of the shock wave is gradually consumed. Under the action of shock wave, metal foam also undergoes shear failure. The impact and friction between the pores and matrix further consume the energy of shock wave.

- 3.

- It can be seen from the gas concentration cloud diagram that after the reaction, the methane concentration in the pipeline is basically zero, which indicates that the combustion reaction is sufficient; all CH4 have participated in the reaction; and, finally, water and carbon dioxide are generated.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bei, P.; Li, J.; Wang, Y.; Wen, X.; Gao, M. Synergistic inhibition effect on methane/air explosions by N2-twin-fluid water mist containing sodium chloride additive. Fuel 2019, 253, 361–368. [Google Scholar]

- Li, X.; Zhang, H.; Yang, C.; Zhao, J.; Long, Y. Effect of Water on the Chain Reaction Characteristics of Gas Explosion. ACS Omega 2021, 6, 12513–12521. [Google Scholar] [CrossRef] [PubMed]

- Jiao, Y.; Duan, Y.L.; Zhou, X.Q.; Wang, H.Y. Temporal and spatial distribution of air temperature in tunnel after gas explosion in tunneling. J. Chongqing Univ. 2011, 34, 95–101. [Google Scholar]

- Sun, Y.R.; Yuan, B.; Chen, X.; Li, K.; Wang, L.; Yun, Y.; Ao, F. Suppression of methane/air explosion by kaolinite-based multi-component inhibitor. Powder Technol. 2019, 343, 279–286. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Z.; Cao, X.; Cui, Y.; Sun, P.; Qian, C. Interaction mechanism of wire mesh inhibition and ducted venting on methane explosion. Fuel 2021, 304, 121343. [Google Scholar] [CrossRef]

- Nie, B.; Yang, L.; Wang, J. Experiments and Mechanisms of Gas Explosion Suppression with Foam Ceramics. Combust. Sci. Technol. 2016, 188, 2117–2127. [Google Scholar] [CrossRef]

- Ywab, C.; Sja, D.; Zw, A.; Hao, S.; Kai, W.; Lei, W. Study on the inhibition influence on gas explosions by metal foam based on its density and coal dust—Science Direct. J. Loss Prevent. Proc. 2018, 56, 451–457. [Google Scholar]

- Zhang, Y.M.; Wang, Y.; Zheng, L.G.; Yang, T.; Gao, J.; Li, Z. Effect of Pristine Palygorskite Powders on Explosion Characteristics of Methane-Air Premixed Gas. Energies 2018, 11, 2496. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Feng, H.; Zhang, Y.M.; Lin, C.; Han, X. Suppression Effects of Hydroxy Acid Modified Montmorillonite Powders on Methane Explosions. Energies 2019, 12, 4068. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.H.; Chen, W.; Wen, X.P.; Zhao, W.L.; Liu, Z.C. Numerical simulation and mechanism analysis of gas explosion suppression by ultrasonic water mist. Energy Source Part A 2019, 41, 2821–2833. [Google Scholar] [CrossRef]

- Wang, F.H.; Yu, M.G.; Wen, X.P.; Deng, H.X.; Pei, B. Suppression of methane/air explosion in pipeline by water mist. J. Loss Prevent. Proc. 2017, 49, 791–796. [Google Scholar] [CrossRef]

- Song, Y.F.; Zhang, Q. Quantitative research on gas explosion inhibition by water mist. J. Hazard. Mater. 2019, 363, 16–25. [Google Scholar] [CrossRef]

- Edwards, K.L.; Norris, M.J. Materials and constructions used in devices to prevent the spread of flames in pipelines and vessels. Mater. Des. 1999, 20, 245–252. [Google Scholar] [CrossRef]

- Jing, Q.; Wang, D.; Liu, Q.M.; Chen, X.; Zhong, Y. Inhibition effect and mechanism of ultra-fine water mist on CH4/air detonation: Quantitative research based on CFD technology. Process Saf. Environ. 2021, 148, 75–92. [Google Scholar] [CrossRef]

- Lu, C.; Wang, H.B.; Pan, R.K.; Zhang, Y.P.; Yu, M.G. Preventing the propagation of gas explosion in ducts using spurted nitrogen. Process Saf. Environ. 2019, 123, 11–23. [Google Scholar] [CrossRef]

- Li, R.; Zhang, Z.; Si, R.; Wang, L.; Ren, W. Experimental Study on Injuries to Animals Caused by a Gas Explosion in a Large Test Laneway. Shock Vib. 2021, 151, 1–9. [Google Scholar] [CrossRef]

- Zhu, Y.F.; Wang, D.M.; Shao, Z.L.; Zhu, X.; Zhang, Y. Investigation on the overpressure of methane-air mixture gas explosions in straight large-scale tunnels. Process Saf. Environ. 2020, 135, 101–112. [Google Scholar] [CrossRef]

- Yu, M.; Liu, M.; Wen, X.; Zhao, W.; Pei, B. Experimental study on suppression of methane explosion by porous media and ultra-fine water mist. Fire Saf. Sci. 2010, 19, 51–59. [Google Scholar] [CrossRef]

- Jiang, H.; Bi, M.; Huang, L.; Zhou, L.; Gao, W. Suppression mechanism of ultrafine water mist containing phosphorus compounds in methane/coal dust explosions. Energy 2021, 239, 121987. [Google Scholar] [CrossRef]

- Abhishek, K.S.; Royb, A.K. Numerical Investigation of Mixed Convection Flows with Variable Viscosity and Prandtl Number and Validation Using ANSYS FLUENT. J. Appl. Comput. Math-Bak 2021, 10, 51–53. [Google Scholar]

- Jia, B.S.; Jin, K.; Hu, R.X.; Li, C.M.; Li, Z.X.; Li, S.G. Inhibitory Effect of Porous Media Materials on Characteristics of Gas Explosion in Confined Space. World Sci. Technol. Res. Dev. 2015, 37, 473–476. [Google Scholar]

- Wei, C.R. Porous Materials Inhibition on Gas Explosion Degree; Harbin Institute of Technology: Harbin, China, 2012. [Google Scholar]

| Number of monitoring point | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Distance from ignition point (m) | 10 | 20 | 30 | 40 | 60 | 70 | 80 | 90 |

| Material | Porosity | Thickness/cm | Maximum Temperature Attenuation Rate/% | Maximum Pressure Attenuation Rate/% |

|---|---|---|---|---|

| Cu | 0.7 | 80/60 | 19.2% | 8.6% |

| 60/40 | 13.4% | 7.1% | ||

| 0.8 | 80/60 | 17.3% | 8.3% | |

| 60/40 | 16.8% | 9.1% | ||

| 0.9 | 80/60 | 14.7% | 6.3% | |

| 60/40 | 13.6% | 9.3% | ||

| Al | 0.7 | 80/60 | 17.6% | 6.8% |

| 60/40 | 16.1% | 7.3% | ||

| 0.8 | 80/60 | 16.4% | 6.2% | |

| 60/40 | 15.1% | 10.4% | ||

| 0.9 | 80/60 | 15.5% | 5.8% | |

| 60/40 | 12.1% | 9.4% | ||

| Fe | 0.7 | 80/60 | 15.2% | 8.4% |

| 60/40 | 14.8% | 6.2% | ||

| 0.8 | 80/60 | 16.9% | 8.1% | |

| 60/40 | 14.3% | 7.7% | ||

| 0.9 | 80/60 | 15.8% | 8.1% | |

| 60/40 | 12.7% | 8.3% | ||

| Cu | 40 | 0.7/0.8 | 7.6% | 5.2% |

| 0.8/0.9 | 6.8% | 4.3% | ||

| 60 | 0.7/0.8 | 6.3% | 5.1% | |

| 0.8/0.9 | 7.8% | 4.8% | ||

| 80 | 0.7/0.8 | 10.3% | 3.7% | |

| 0.8/0.9 | 4.1% | 4.2% | ||

| Al | 40 | 0.7/0.8 | 7.4% | 6.7% |

| 0.8/0.9 | 8.1% | 3.4% | ||

| 60 | 0.7/0.8 | 6.6% | 5.7% | |

| 0.8/0.9 | 5.4% | 4.9% | ||

| 80 | 0.7/0.8 | 8.9% | 7.3% | |

| 0.8/0.9 | 5.3% | 3.5% | ||

| Fe | 40 | 0.7/0.8 | 6.1% | 5.8% |

| 0.8/0.9 | 5.8% | 4.6% | ||

| 60 | 0.7/0.8 | 7.1% | 2.3% | |

| 0.8/0.9 | 8.9% | 4.5% | ||

| 80 | 0.7/0.8 | 8.7% | 3.1% | |

| 0.8/0.9 | 5.1% | 7.1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gui, X.; Xue, H.; Zhu, J.; Zhan, X.; Zhao, F. Study on Inhibition Characteristics of Composite Structure with High-Temperature Heat Pipe and Metal Foam on Gas Explosion. Energies 2022, 15, 1135. https://doi.org/10.3390/en15031135

Gui X, Xue H, Zhu J, Zhan X, Zhao F. Study on Inhibition Characteristics of Composite Structure with High-Temperature Heat Pipe and Metal Foam on Gas Explosion. Energies. 2022; 15(3):1135. https://doi.org/10.3390/en15031135

Chicago/Turabian StyleGui, Xiaohong, Haiteng Xue, Junwei Zhu, Xingrui Zhan, and Fupeng Zhao. 2022. "Study on Inhibition Characteristics of Composite Structure with High-Temperature Heat Pipe and Metal Foam on Gas Explosion" Energies 15, no. 3: 1135. https://doi.org/10.3390/en15031135

APA StyleGui, X., Xue, H., Zhu, J., Zhan, X., & Zhao, F. (2022). Study on Inhibition Characteristics of Composite Structure with High-Temperature Heat Pipe and Metal Foam on Gas Explosion. Energies, 15(3), 1135. https://doi.org/10.3390/en15031135