A Grid-Connected Microgrid Model and Optimal Scheduling Strategy Based on Hybrid Energy Storage System and Demand-Side Response

Abstract

:1. Introduction

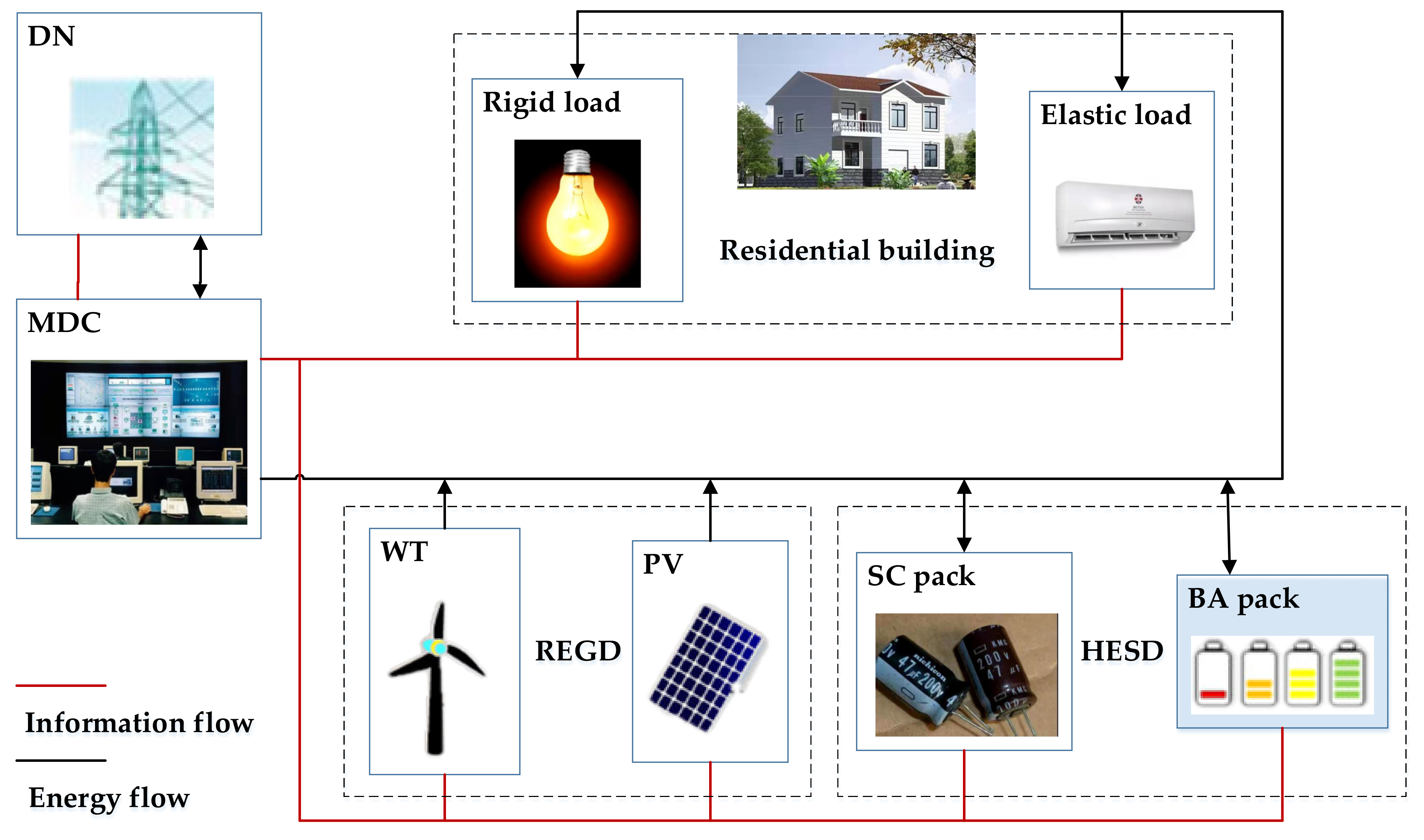

2. Overview of the Microgrid System

3. Methodology

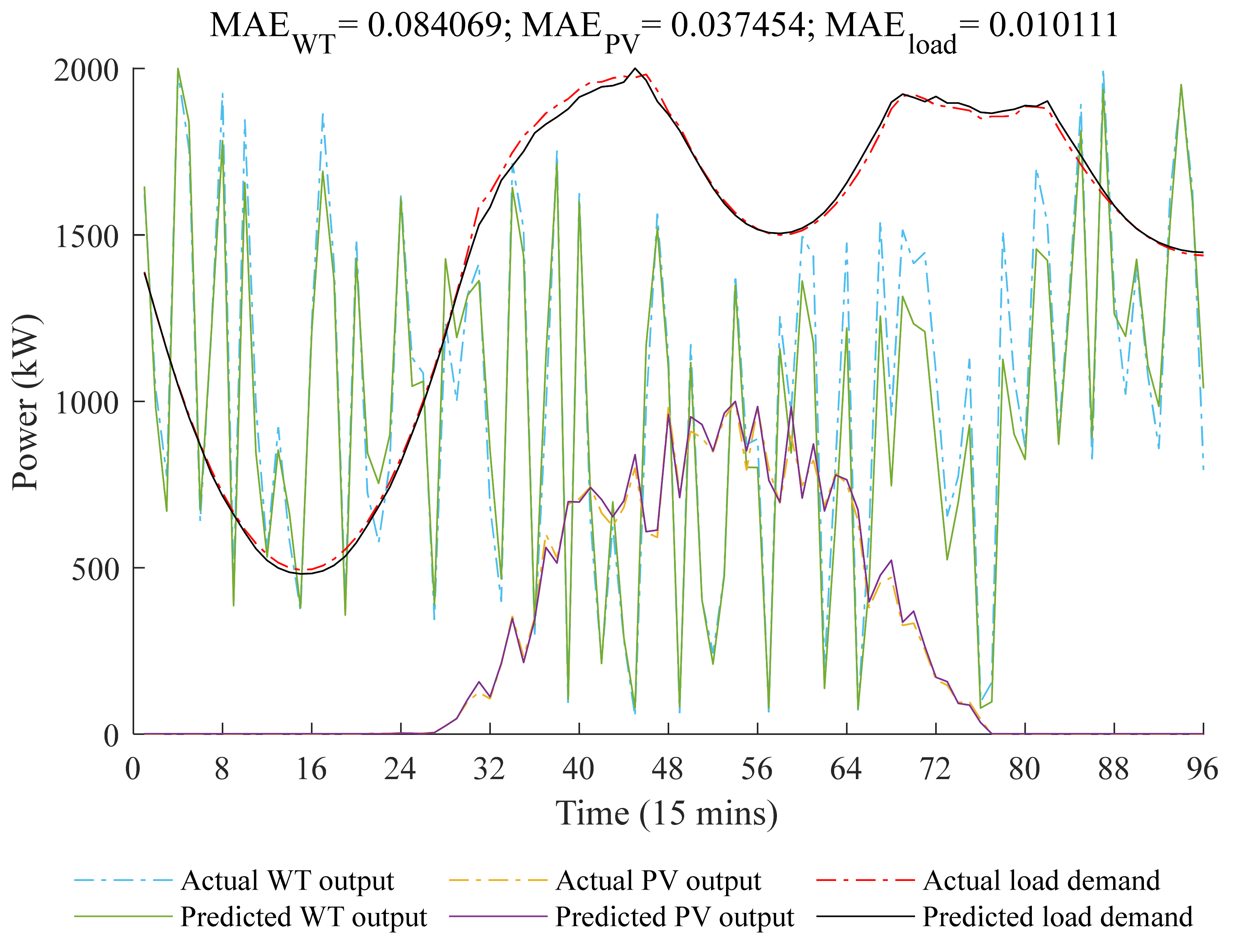

3.1. Power Prediction

3.2. Multi-Objective Optimization

3.2.1. Objective Functions

- Objective : Minimize the daily operation and maintenance cost of the lithium battery pack;

- Objective : Minimize the peak and valley difference of the daily load curve;

- Objective : Minimize the daily electricity cost of users;

3.2.2. Constraints

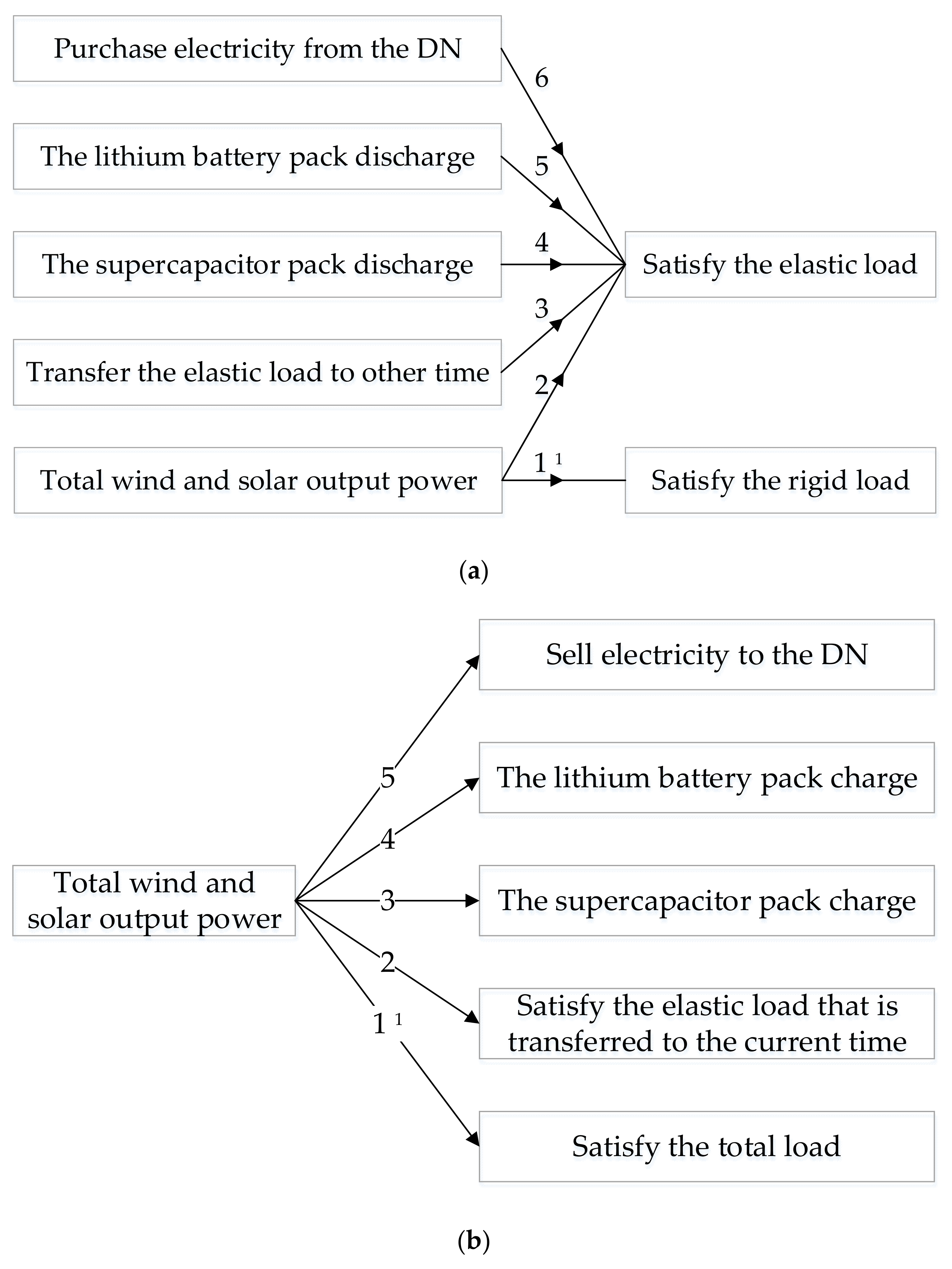

- Constraints of the supply order of the power and the satisfied order of the load;

- Constraints of power balance;

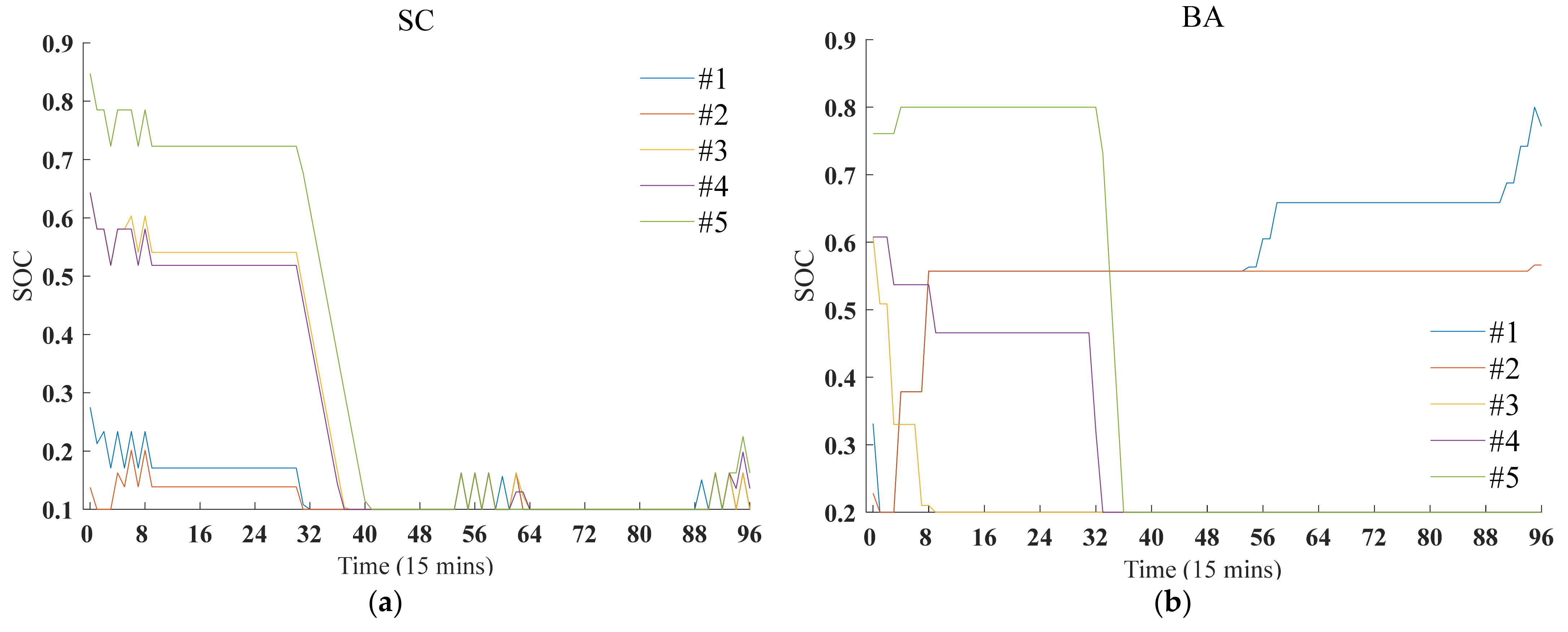

- Constraints of SOC and charge and discharge power of each energy storage unit;where and are the state of charge of the ith supercapacitor unit and the jth lithium battery unit at time t, respectively. and are the initial state of charge of the ith supercapacitor unit and the jth lithium battery unit, respectively. is the rated capacity of the supercapacitor unit. is the charge or discharge power of the ith supercapacitor unit, and is the charge or discharge power of the jth lithium battery unit. and are the upper and lower limits of the state of charge of the supercapacitor unit. and are the upper and lower limits of the state of charge of the lithium battery unit. and are the upper limits of the discharge power of the supercapacitor unit and the lithium battery unit, respectively. If the charge and discharge power of the energy storage unit is positive, it means discharging, and if it is negative, it means charging.

- Constraints of continuous and deep charge and discharge of each unit in the lithium battery pack;

- Constraints of demand-side electricity price response;

3.2.3. Solution Algorithm

4. Results and Discussion

4.1. Data Explanation

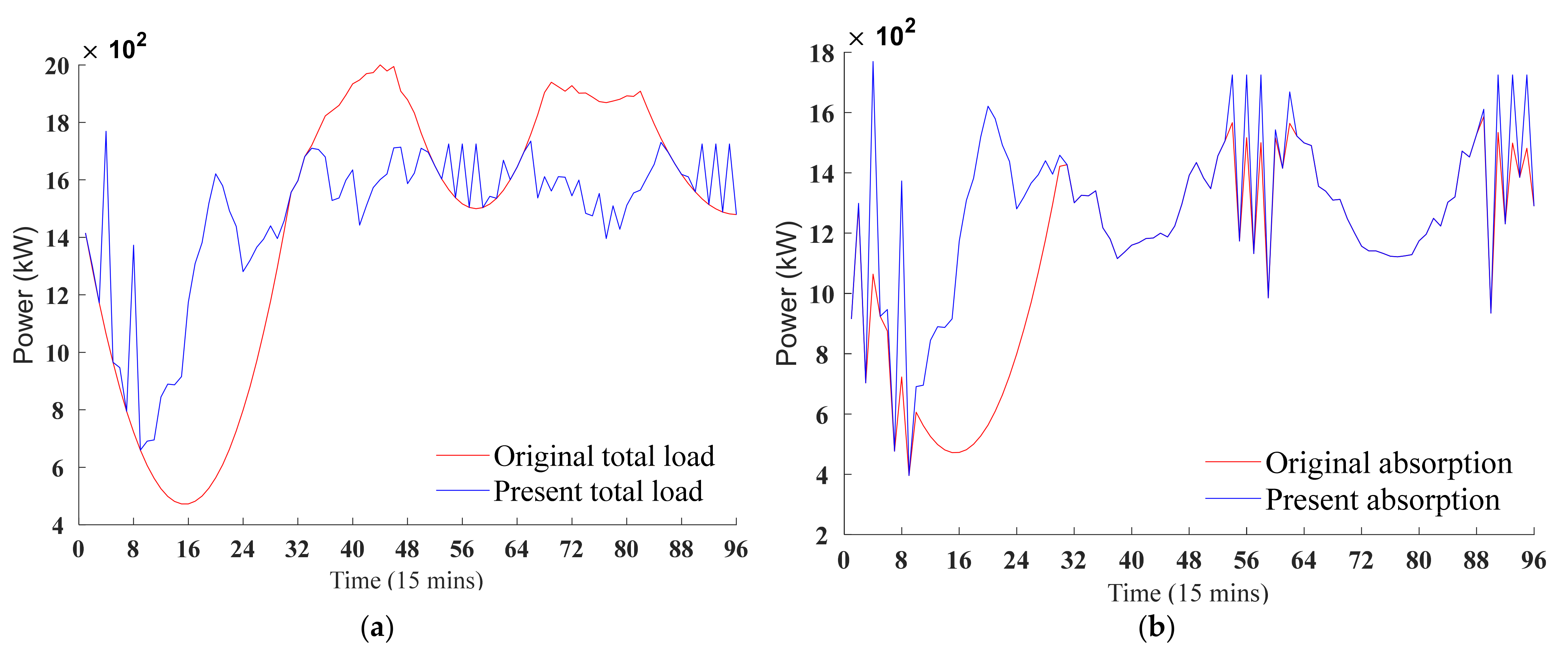

4.2. Optimal Scheduling Results

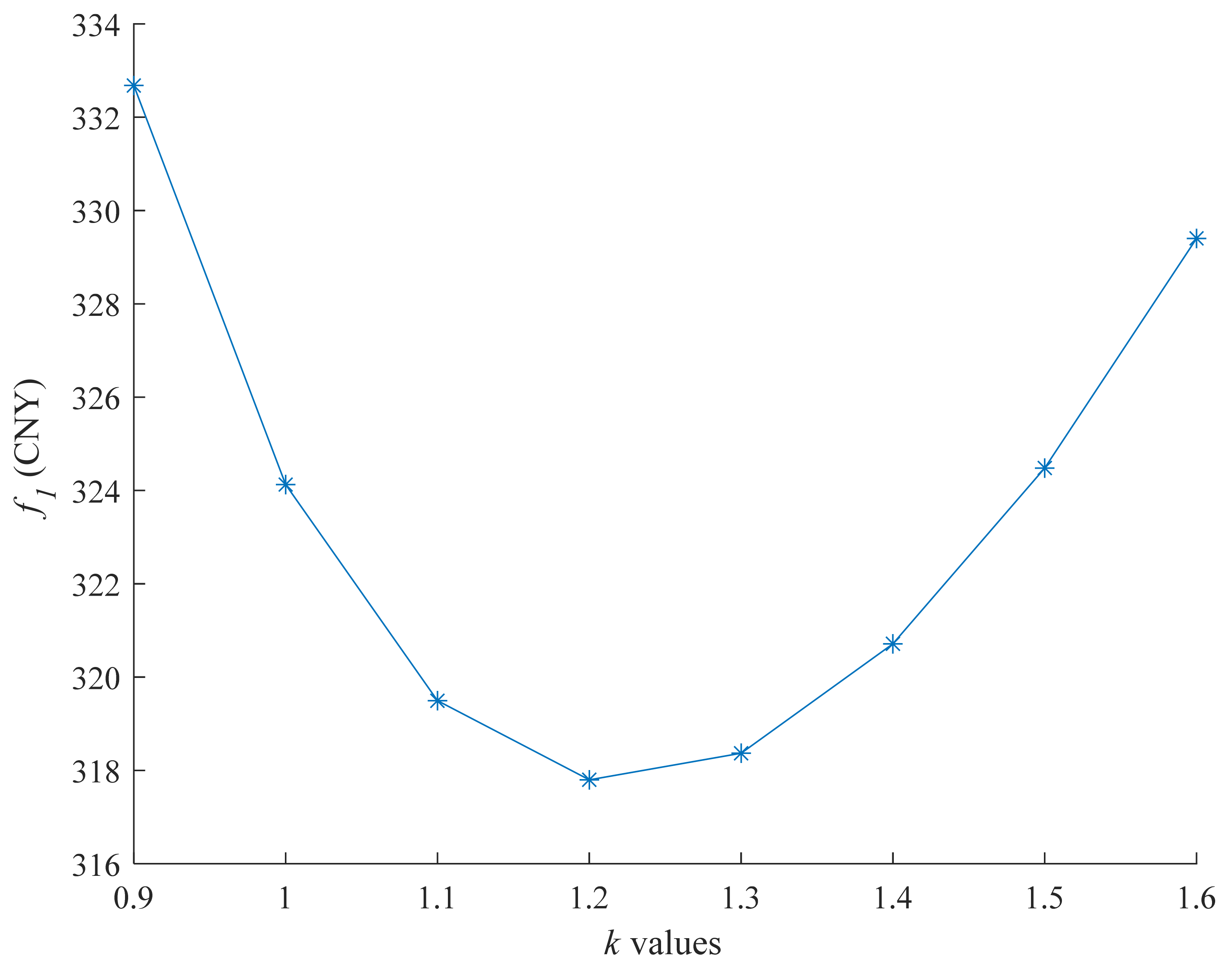

4.3. Sensitivity Analysis

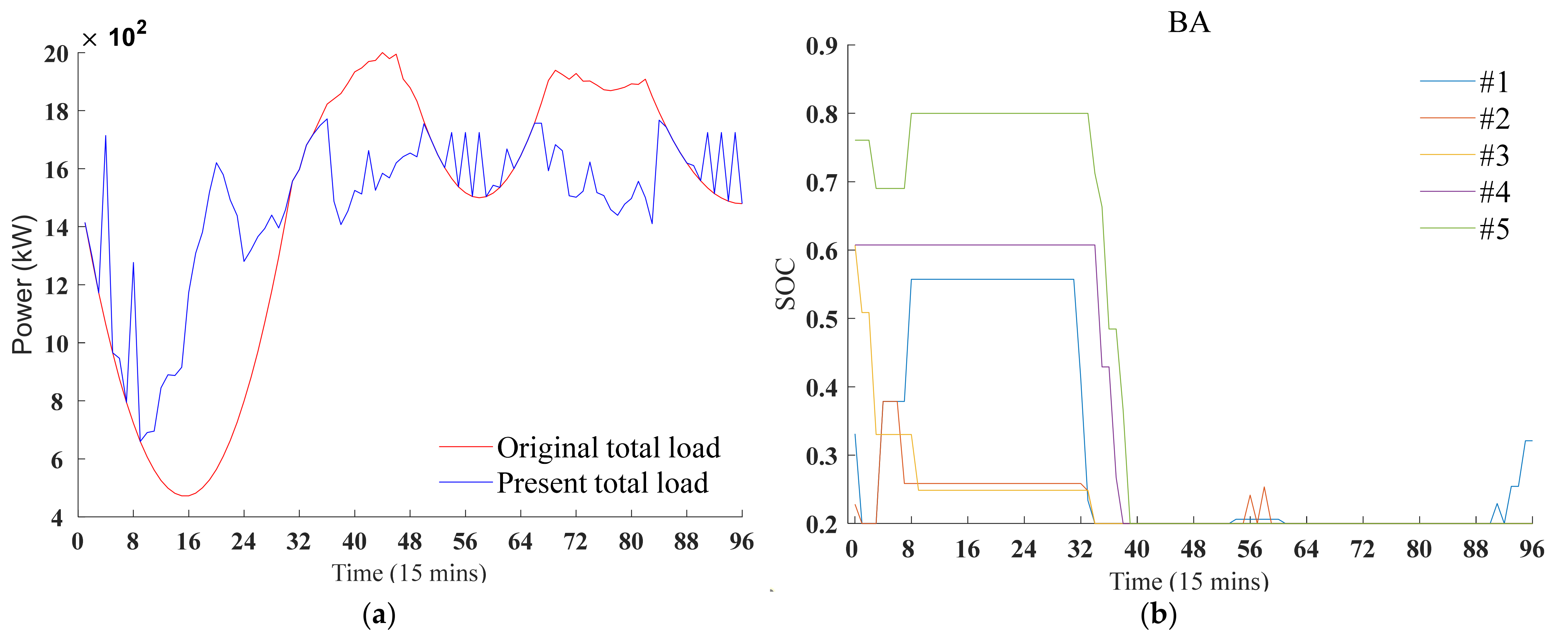

4.4. Comparative Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Sets | |

| Two different sets of time | |

| Indices | |

| t, s, q, L | The time point |

| i, j | The ith supercapacitor unit and the jth lithium battery unit, respectively |

| Superscript | |

| BP | Back Propagation |

| MAE | Mean absolute error |

| Variables | |

| The operation and maintenance cost per cycle period of the lithium battery pack | |

| k | The proportional coefficient in the demand-side electricity price response function |

| The real-time electricity price at time t | |

| The variance of the daily cycle times of lithium battery units | |

| The daily cycle times of the jth lithium battery unit | |

| The power purchased from the distribution network at the electricity price within the real-time electricity price ceiling at time t | |

| The remaining elastic load at time t | |

| The total load after peak shaving and valley filling at time t | |

| The elastic load power that is transferred from other time at time t | |

| The elastic load power that is transferred to other moments at time t | |

| The amount of the elastic load transfer from time s to time q | |

| The charge power of the supercapacitor pack and the lithium battery pack at time t, respectively | |

| The charge power of the ith supercapacitor unit and the jth lithium battery unit at time t, respectively | |

| The discharge power of the supercapacitor pack and the lithium battery pack at time t, respectively | |

| The discharge power of the ith supercapacitor unit and the jth lithium battery unit at time t, respectively | |

| The power purchased from the distribution network at the punitive electricity price at time t | |

| A binary variable at time t | |

| The electricity the microgrid purchases from the distribution network at time t | |

| The electricity the microgrid sells to the distribution network at time t | |

| The state of charge of the ith supercapacitor unit and the jth lithium battery unit at time t, respectively | |

| The charge or discharge power of the ith supercapacitor unit at time t | |

| The charge or discharge power of the jth lithium battery unit at time t | |

| Parameters | |

| The number of test samples | |

| The actual value | |

| The predicted value | |

| The fixed operation and maintenance cost per cycle period | |

| The number of units contained in the lithium battery pack | |

| The investment cost per capacity of the lithium battery unit | |

| The rated capacity of the lithium battery unit | |

| The operation and maintenance cost coefficient | |

| The interest rate | |

| The theoretical service life | |

| The theoretical cycle times | |

| The rigid electricity price | |

| T | A day is divided into T periods |

| The original total load at time t | |

| The number of units contained in the supercapacitor pack | |

| The punitive electricity price | |

| Δt | The time interval |

| The power gap at time t | |

| The wind turbine and photovoltaic output power at time t, respectively | |

| The rigid load and elastic load at time t, respectively | |

| The proportion of the rigid load to the total load | |

| The initial state of charge of the ith supercapacitor unit and the jth lithium battery unit, respectively | |

| The rated capacity of the supercapacitor unit | |

| The upper and lower limits of the state of charge of the supercapacitor unit | |

| The upper and lower limits of the state of charge of the lithium battery unit | |

| The upper limits of the discharge power of the supercapacitor unit and the lithium battery unit, respectively | |

| The maximum multiple of the real-time electricity price relative to the rigid electricity price | |

| Weights of each sub-goal, i.e., , , and , respectively | |

| The minimum values of each sub-goal, i.e., , , and , respectively | |

| The maximum values of each sub-goal, i.e., , , and , respectively | |

| The maximum daily cycle times of the lithium battery unit | |

| The electricity cost of users at time t | |

| The total load exceeding the total wind and solar output at time t | |

| The electricity demarcation points of the step electricity price |

References

- Jeong, B.C.; Shin, D.H.; Im, J.B.; Park, J.-Y.; Kim, Y.-J. Implementation of Optimal Two-Stage Scheduling of Energy Storage System Based on Big-Data-Driven Forecasting-An Actual Case Study in a Campus Microgrid. Energies 2019, 12, 1124. [Google Scholar] [CrossRef] [Green Version]

- Nadeem, F.; Hussain, S.M.S.; Tiwari, P.K.; Goswami, A.K.; Ustun, T.S. Comparative Review of Energy Storage Systems, Their Roles, and Impacts on Future Power Systems. IEEE Access 2019, 7, 4555–4585. [Google Scholar] [CrossRef]

- Wu, T.; Ye, F.; Su, Y.; Wang, Y.; Riffat, S. Coordinated Control Strategy of DC Microgrid with Hybrid Energy Storage System to Smooth Power Output Fluctuation. Int. J. Low-Carbon Technol. 2020, 15, 46–54. [Google Scholar] [CrossRef] [Green Version]

- Gu, S.; Zhang, J. Two-Stage Stochastic Scheduling Method for Microgrid Based on Price-Based Demand Response. J. North China Electr. Power Univ. 2018, 45, 39–46. (In Chinese) [Google Scholar]

- Jin, S.; Mao, Z.; Li, H. Economic Operation Optimization of Smart Micro Grid Considering the Uncertainty. Control Theory Appl. 2018, 35, 1357–1370. (In Chinese) [Google Scholar]

- Jin, S.; Mao, Z.; Li, H.; Qi, W. Dynamic Operation Management of a Renewable Microgrid Including Battery Energy Storage. Math. Probl. Eng. 2018, 2018, 5852309. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Guo, L.; Wang, C. Economic Dispatch of Microgrid Based on Two Stage Robust Optimization. Proc. CSEE 2018, 38, 4013–4022. (In Chinese) [Google Scholar]

- Liu, B.; Zhou, S.; Chen, Y.; Yang, P. Optimal Energy Dispatching Strategy for Microgrid Considering Multi-Scale Demand Response Resources. Electr. Power Constr. 2018, 39, 9–17. (In Chinese) [Google Scholar]

- Wang, L.; Wang, X.; Hu, X. Optimal Scheduling of Demand-Side Time-of-Use Pricing Based on the MAS Microgrid. Inf. Control 2020, 49, 429–435. (In Chinese) [Google Scholar]

- He, J.; Shi, C.; Ma, M. Bi-Level Optimal Configuration Method of Hybrid Energy Storage System Based on Meta Model Optimization Algorithm. Electr. Power Autom. Equip. 2020, 40, 157–167. (In Chinese) [Google Scholar]

- Xu, G.; Shang, C.; Fan, S.; Hu, X.; Cheng, H. A Hierarchical Energy Scheduling Framework of Microgrids with Hybrid Energy Storage Systems. IEEE Access 2018, 6, 2472–2483. [Google Scholar] [CrossRef]

- Li, J.; Xiong, R.; Mu, H.; Cornélusse, B.; Vanderbemden, P.; Ernst, D.; Yuan, W. Design and Real-Time Test of a Hybrid Energy Storage System in the Microgrid with the Benefit of Improving the Battery Lifetime. Appl. Energy 2018, 218, 470–478. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Wei, Q.; Huang, J.; Zhou, W.; Yu, J. Collaboration Strategy and Optimization Model of Wind Farm-Hybrid Energy Storage System for Mitigating Wind Curtailment. Energy Sci. Eng. 2019, 7, 3255–3273. [Google Scholar] [CrossRef]

- Wei, M.; Zhou, Q.; Zhou, H.; Cai, S.; Jiang, L.; Lu, L.; Liang, W.; Shen, L.; Li, Q. Economic Dispatch of Microgrid in Southwest China Based on Two-Stage Robust Optimization. Electr. Power 2019, 52, 2–18. (In Chinese) [Google Scholar]

- Xu, F.; Liu, J.; Lin, S.; Dai, Q.; Li, C. A Multi-Objective Optimization Model of Hybrid Energy Storage System for Non-Grid-Connected Wind Power: A Case Study in China. Energy 2018, 163, 585–603. [Google Scholar] [CrossRef]

- Wang, D.; Qiu, J.; Reedman, L.; Meng, K.; Lai, L.L. Two-Stage Energy Management for Networked Microgrids with High Renewable Penetration. Appl. Energy 2018, 226, 39–48. [Google Scholar] [CrossRef]

- Cao, Z.; Han, Y.; Wang, J.; Zhao, Q. Two-Stage Energy Generation Schedule Market Rolling Optimisation of Highly Wind Power Penetrated Microgrids. Int. J. Electr. Power Energy Syst. 2019, 112, 12–27. [Google Scholar] [CrossRef]

- Gao, H.-C.; Choi, J.-H.; Yun, S.-Y.; Lee, H.-J.; Ahn, S.-J. Optimal Scheduling and Real-Time Control Schemes of Battery Energy Storage System for Microgrids Considering Contract Demand and Forecast Uncertainty. Energies 2018, 11, 1371. [Google Scholar] [CrossRef] [Green Version]

- Kazemi, M.; Zareipour, H. Long-Term Scheduling of Battery Storage Systems in Energy and Regulation Markets Considering Battery’s Lifespan. IEEE Trans. Smart Grid 2018, 9, 6840–6849. [Google Scholar] [CrossRef]

- Fan, S.; Qian, A.; Piao, L. Hierarchical Energy Management of Microgrids Including Storage and Demand Response. Energies 2018, 11, 1111. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Ma, R.; Wang, S.; Zhang, Y.; Li, B.; Fang, C. Operation Control Strategy for Energy Storage Station after Considering Battery Life in Commercial Park. High Volt. Eng. 2020, 46, 62–70. (In Chinese) [Google Scholar]

- Wei, F.; Sui, Q.; Lin, X.; Li, Z.; Chen, L. Optimized Energy Control Strategy about Daily Operation of Islanded Microgrid with Wind/Photovoltaic/Diesel/Battery under Consideration of Transferable Load Efficiency. Proc. CSEE 2018, 38, 1045–1053. (In Chinese) [Google Scholar]

- Lei, M.; Hua, Y.; Zhao, H.; Xu, B. Strategy of Electric Vehicles Participating Peak Load Regulation of Power Grid Considering Battery Life. Mod. Electr. Power 2020, 37, 510–517. (In Chinese) [Google Scholar]

- Mohsenian-Rad, H. Optimal Bidding, Scheduling, and Deployment of Battery Systems in California Day-Ahead Energy Market. IEEE Trans. Power Syst. 2016, 31, 442–453. [Google Scholar] [CrossRef] [Green Version]

- Global Sustainable Energy Solutions Pty Ltd. Battery Characteristics. In Grid-Connected PV Systems with Battery Storage; China Electric Power Research Institute, Ed.; China Water & Power Press: Beijing, China, 2017; p. 23. [Google Scholar]

- He, S.; Gao, H.; Liu, J.; Liu, J. Distributionally Robust Optimal DG Allocation Model Considering Flexible Adjustment of Demand Response. Proc. CSEE 2019, 39, 2253–2264. (In Chinese) [Google Scholar]

- Wang, H.; Fang, H.; Yu, X.; Liang, S. How Real Time Pricing Modifies Chinese Households’ Electricity Consumption. J. Clean. Prod. 2018, 178, 776–790. [Google Scholar] [CrossRef]

- Wu, N.; Wang, H.; Yin, L.; Yuan, X.; Leng, X. Application Conditions of Bounded Rationality and a Microgrid Energy Management Control Strategy Combining Real-Time Power Price and Demand-Side Response. IEEE Access 2020, 8, 227327–227339. [Google Scholar] [CrossRef]

- Krishnamoorthy, M.; Periyanayagam, A.D.V.R. Integrated Energy Management System Employing Pre-Emptive Priority Based Load Scheduling (PEPLS) Approach at Residential Premises. Energy 2019, 186, 115815. [Google Scholar]

- Krishnamoorthy, M.; Periyanayagam, A.D.V.R.; Kumar, C.S.; Kumar, B.P.; Srinivasan, S.; Kathiravan, P. Optimal Sizing, Selection, and Techno-Economic Analysis of Battery Storage for PV/BG-based Hybrid Rural Electrification System. IETE J. Res. 2020, 1, 1–16. [Google Scholar] [CrossRef]

- Samuelson, P.A.; Nordhaus, W.D. Cost Analysis. In Economics, 18th ed.; Xiao, C., Ed.; Posts & Telecom Press: Beijing, China, 2008; p. 113. [Google Scholar]

- Zhang, X.; Yuan, Y.; Cao, Y. Modeling and Scheduling for Battery Energy Storage Station with Consideration of Wearing Costs. Power Syst. Technol. 2017, 41, 1541–1547. (In Chinese) [Google Scholar]

- Hu, Y. Practical Multi-Objective Optimization; Shanghai Scientific & Technical Publishers: Shanghai, China, 1987; pp. 60–64. [Google Scholar]

- The Step Electricity Price. Available online: https://baike.so.com/doc/5636603-5849230.html (accessed on 1 September 2021).

- Wu, T.; Shi, X.; Liao, L.; Zhou, C.; Zhou, H.; Su, Y. A Capacity Configuration Control Strategy to Alleviate Power Fluctuation of Hybrid Energy Storage System Based on Improved Particle Swarm Optimization. Energies 2019, 12, 642. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Values |

|---|---|

| 5 and 5 | |

| (kW) | 30 and 250 |

| (kWh) | 120 and 350 |

| 0.9 and 0.8 | |

| 0.1 and 0.2 | |

| (0.27, 0.13, 0.64, 0.64, 0.84) and (0.33, 0.22, 0.60, 0.60, 0.76) |

| Various Power | F 1 | F crit |

|---|---|---|

| Wind power | 0.004481 | 3.890867 |

| PV power | 3.16 × 10−7 | 3.890867 |

| Total load | 0.003616 | 3.890867 |

| The judgment method is: when F > F crit, the F value is considered to be significant at the level of α = 0.05. | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, Y.; Wang, H.; Hu, Y.; Li, C. A Grid-Connected Microgrid Model and Optimal Scheduling Strategy Based on Hybrid Energy Storage System and Demand-Side Response. Energies 2022, 15, 1060. https://doi.org/10.3390/en15031060

Jing Y, Wang H, Hu Y, Li C. A Grid-Connected Microgrid Model and Optimal Scheduling Strategy Based on Hybrid Energy Storage System and Demand-Side Response. Energies. 2022; 15(3):1060. https://doi.org/10.3390/en15031060

Chicago/Turabian StyleJing, Yaqian, Honglei Wang, Yujie Hu, and Chengjiang Li. 2022. "A Grid-Connected Microgrid Model and Optimal Scheduling Strategy Based on Hybrid Energy Storage System and Demand-Side Response" Energies 15, no. 3: 1060. https://doi.org/10.3390/en15031060

APA StyleJing, Y., Wang, H., Hu, Y., & Li, C. (2022). A Grid-Connected Microgrid Model and Optimal Scheduling Strategy Based on Hybrid Energy Storage System and Demand-Side Response. Energies, 15(3), 1060. https://doi.org/10.3390/en15031060