Automatic Risk Assessment for an Industrial Asset Using Unsupervised and Supervised Learning

Abstract

1. Introduction

1.1. Framework

1.2. Objectives

1.3. Contributions

1.4. Motivation and Innovation

1.5. Paper Structure

2. Theoretical Framework

2.1. Artificial Neural Networks

2.2. Data Grouping (Clustering)

2.3. K-Means

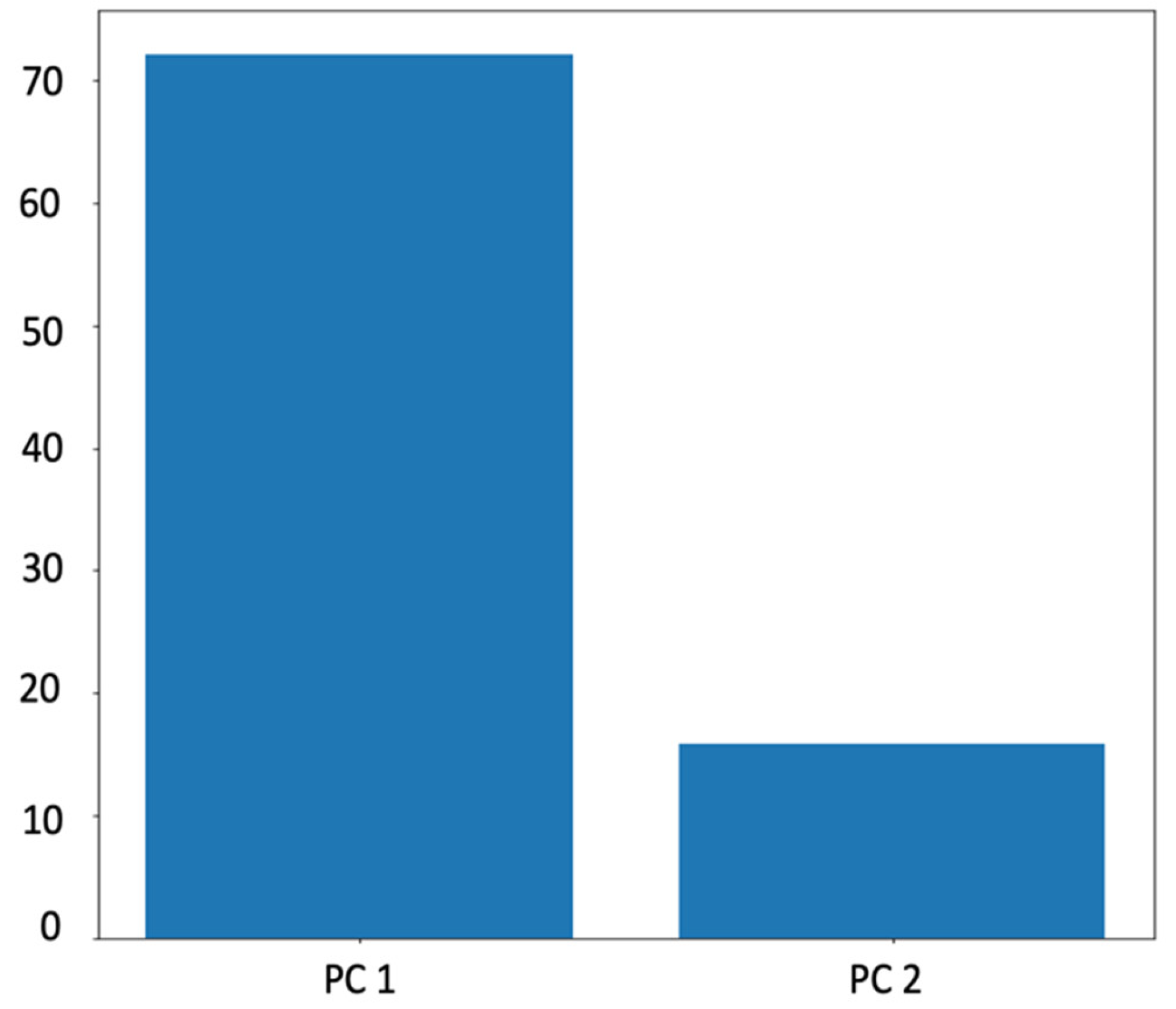

2.4. Principal Component Analysis (PCA)

3. Related Work

4. Data Processing

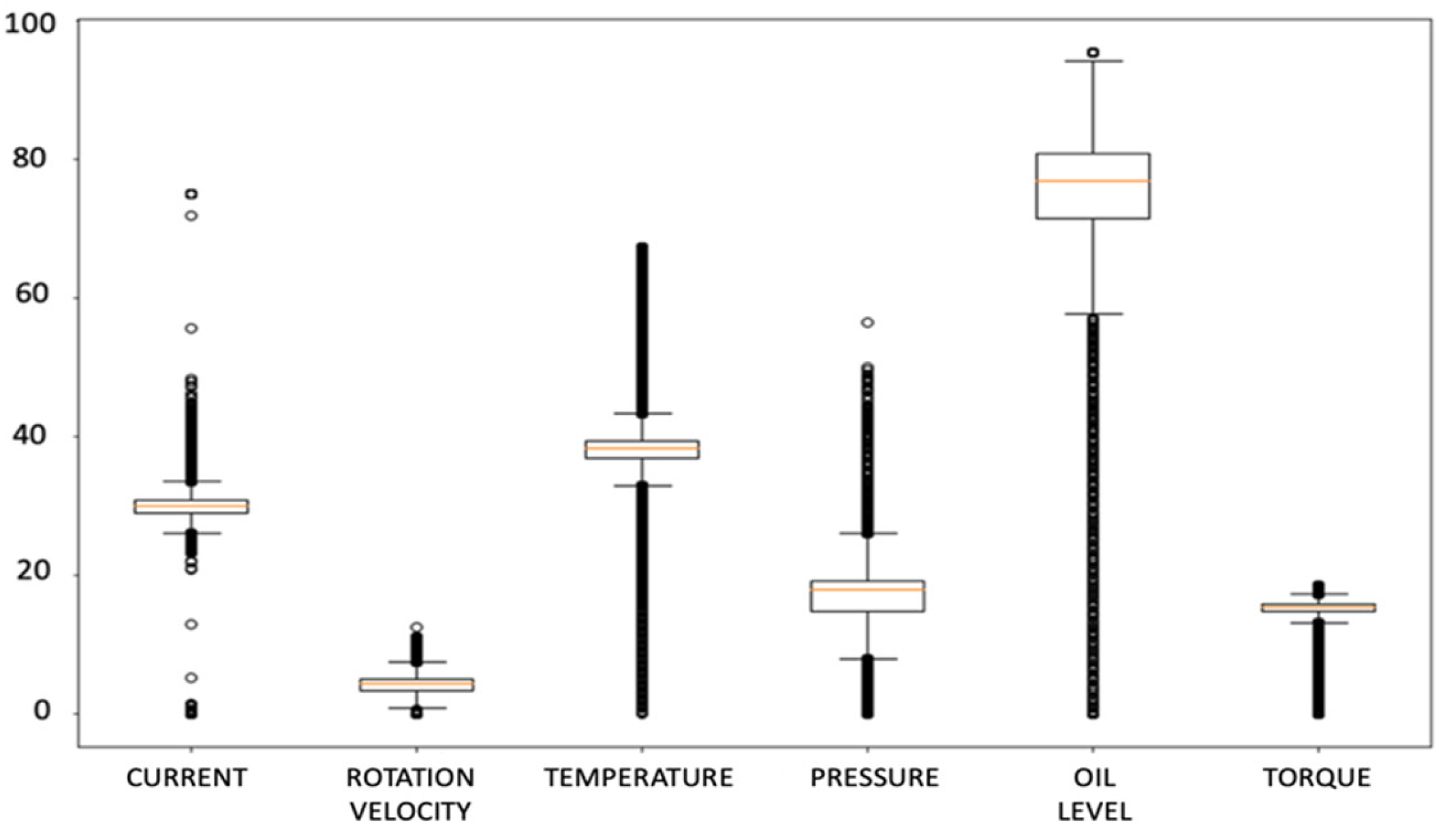

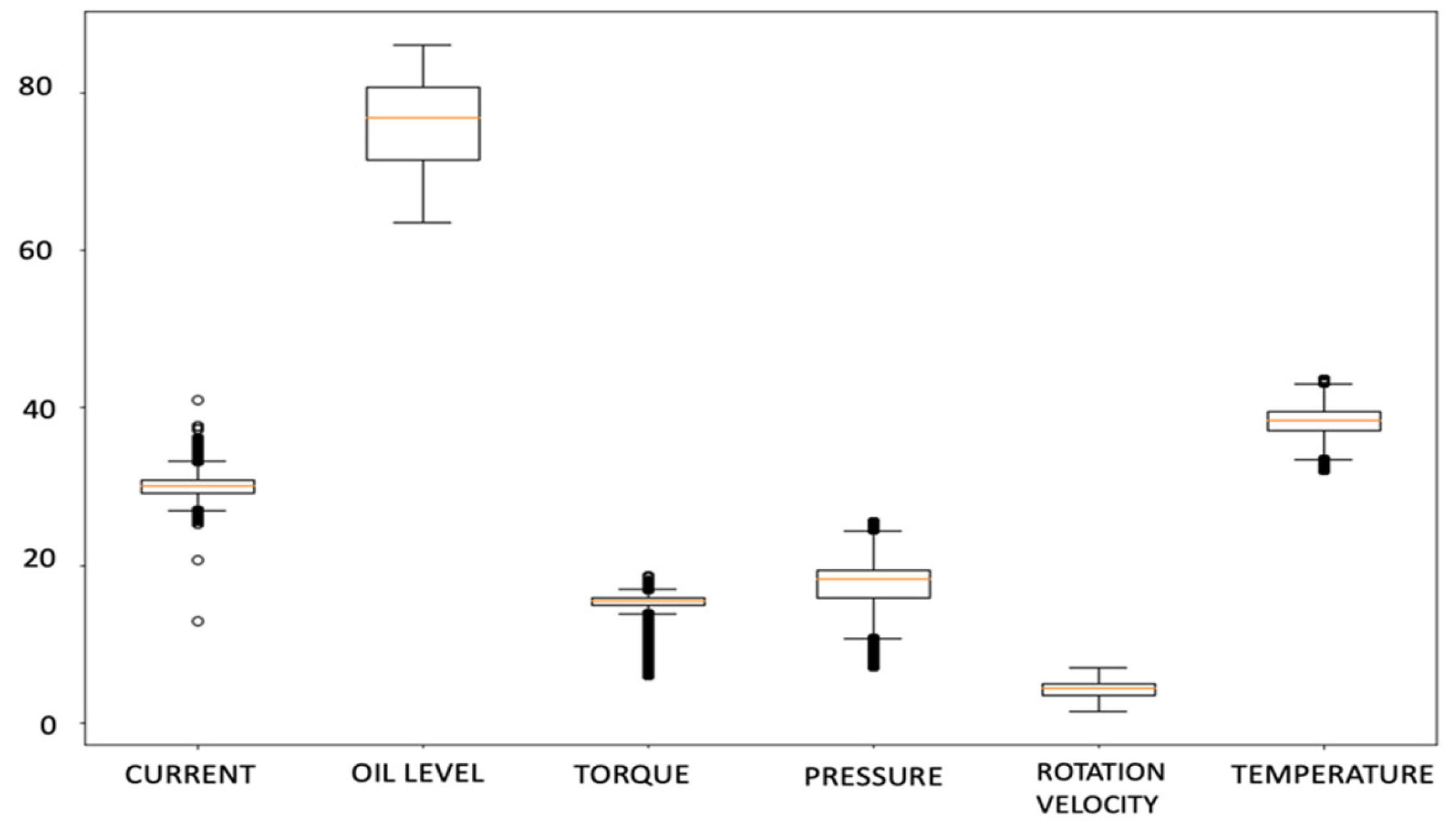

4.1. Sensor Data Collection

4.2. Data Enrichment

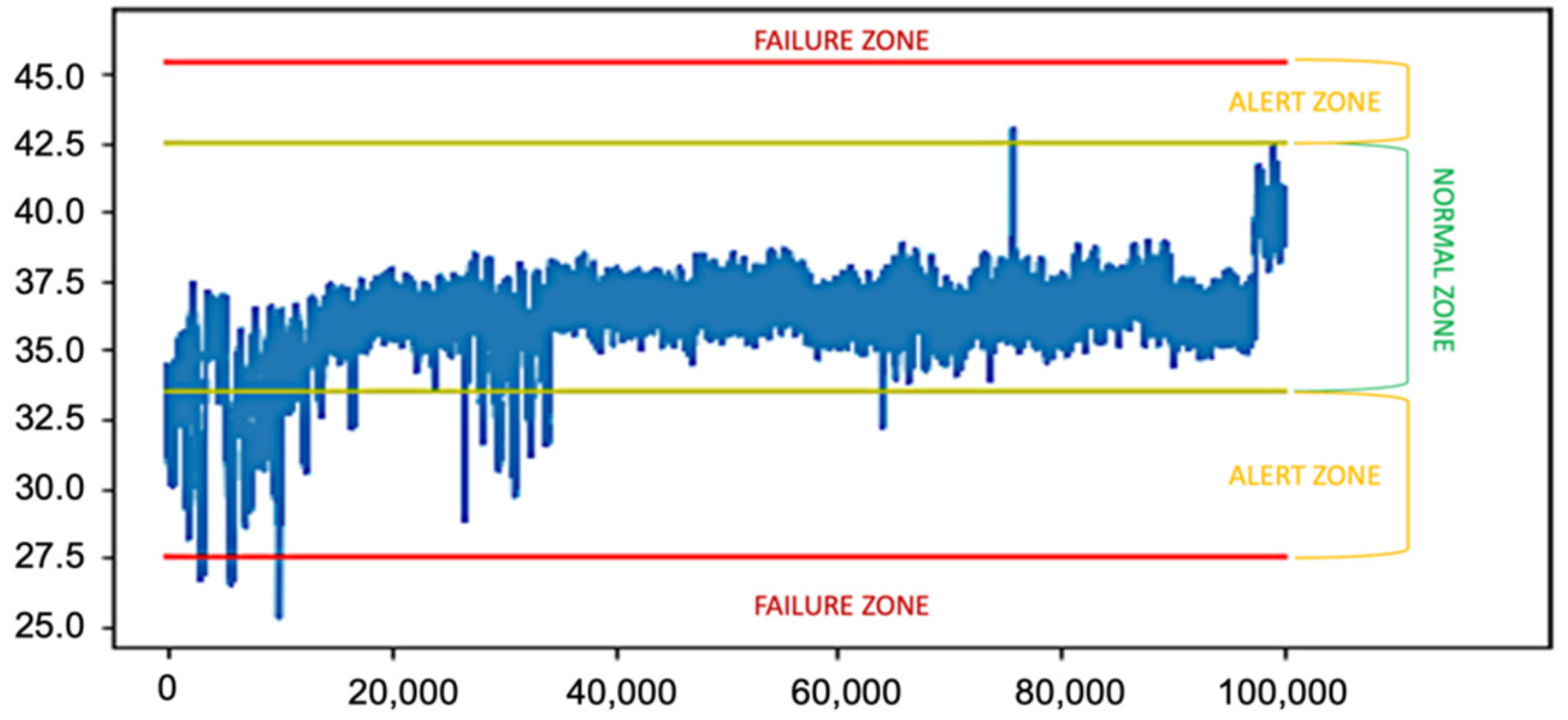

4.2.1. Equipment Nominal Operation Zones

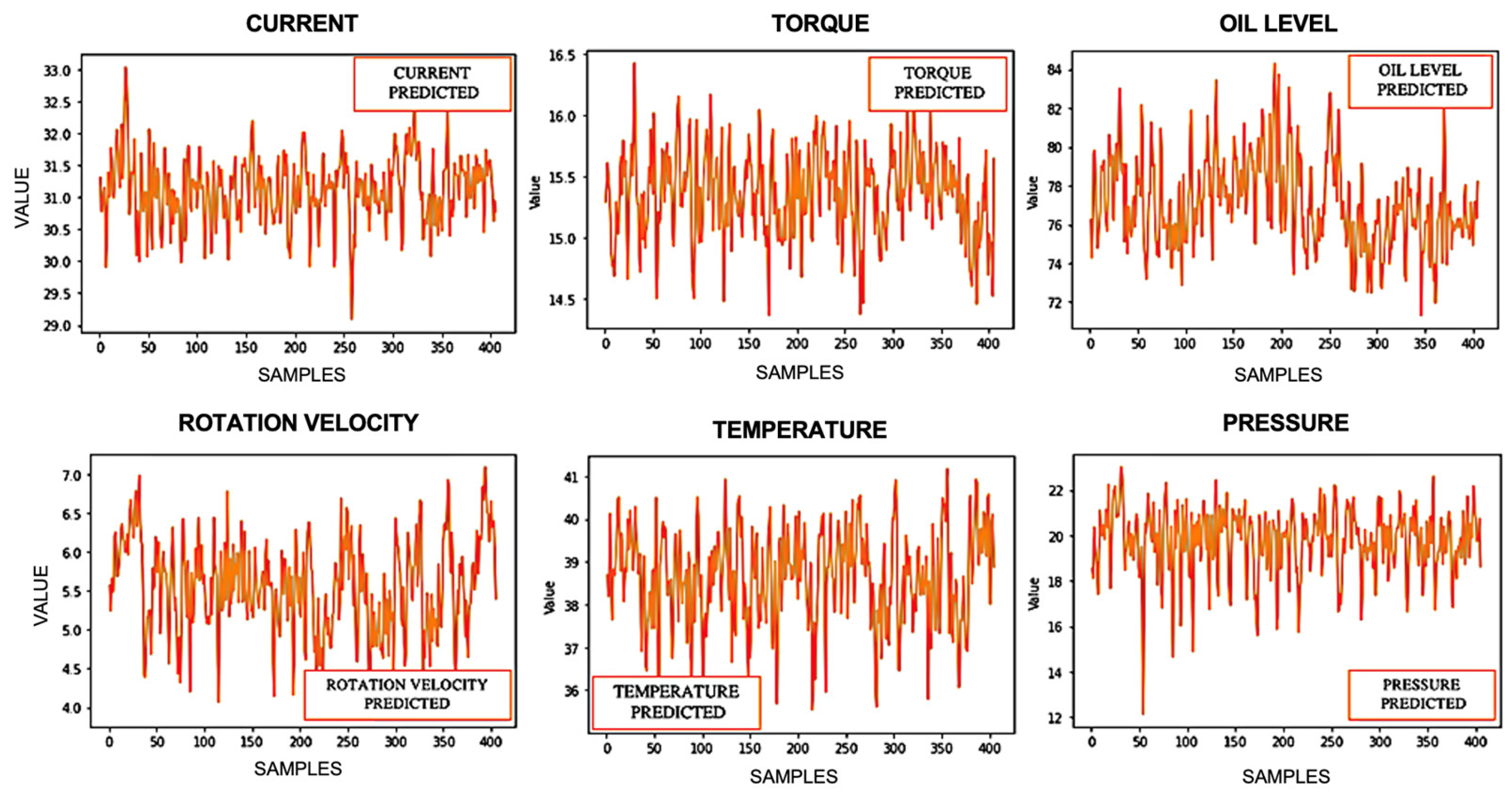

4.2.2. Sensor Values Predicted at 30 Days

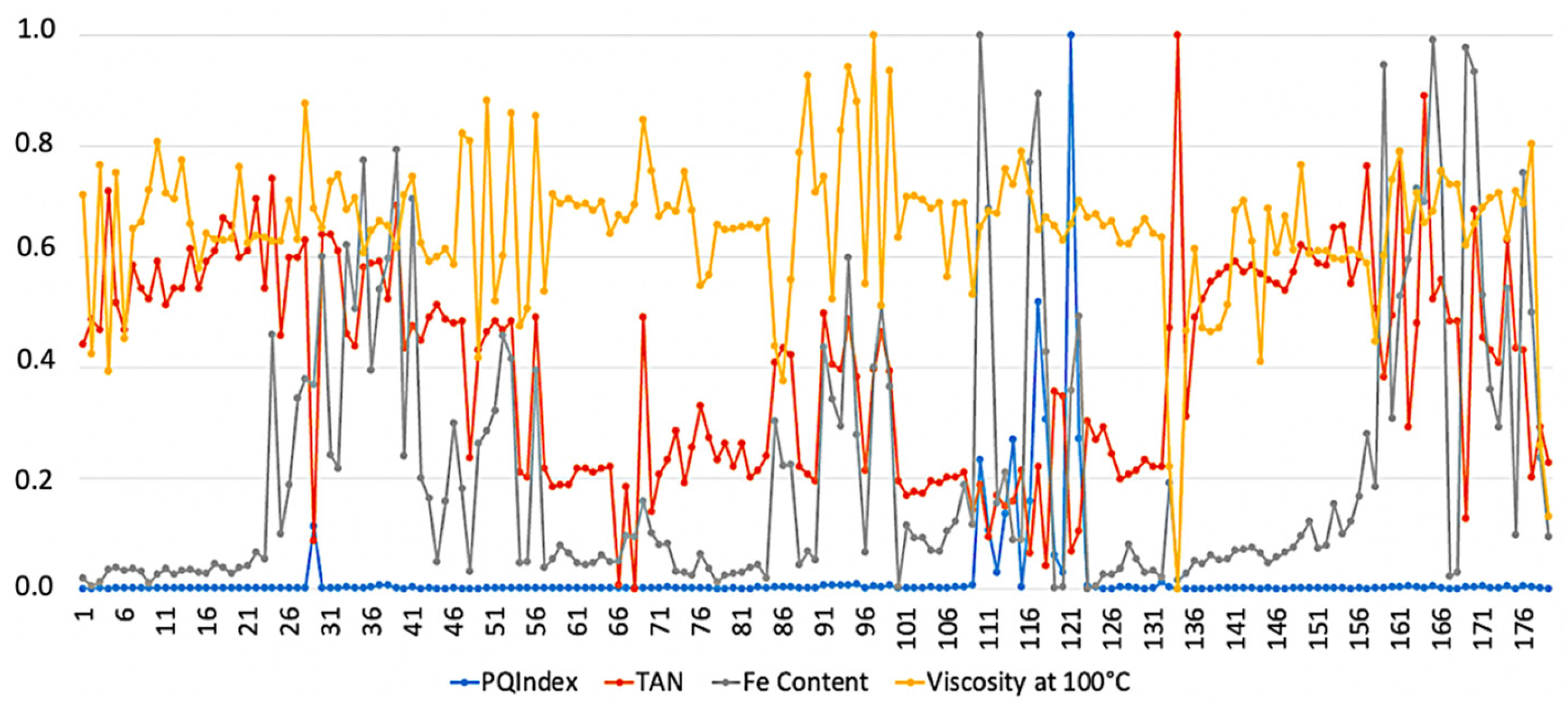

4.3. Lubricating Oil Database

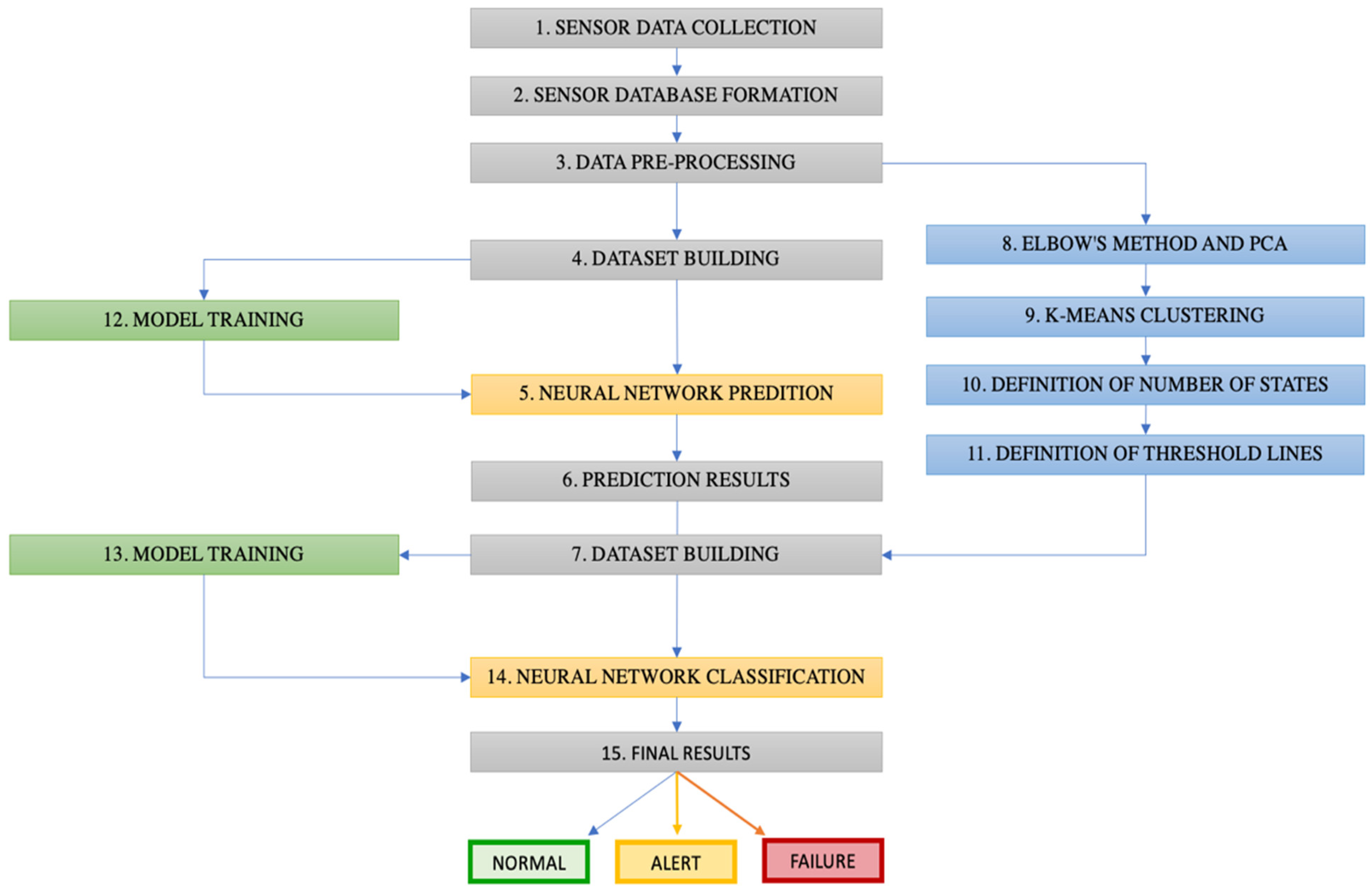

5. Data Processing

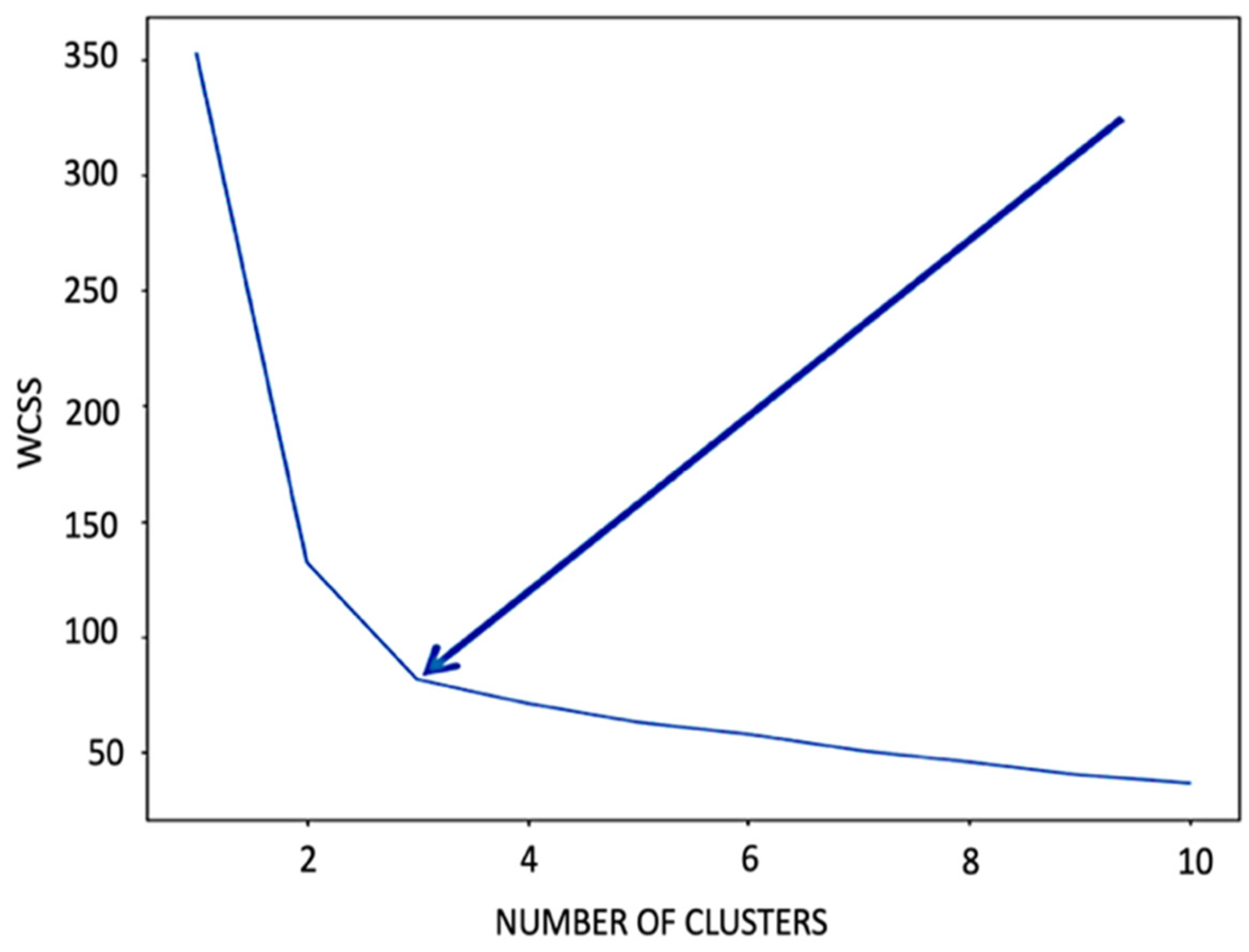

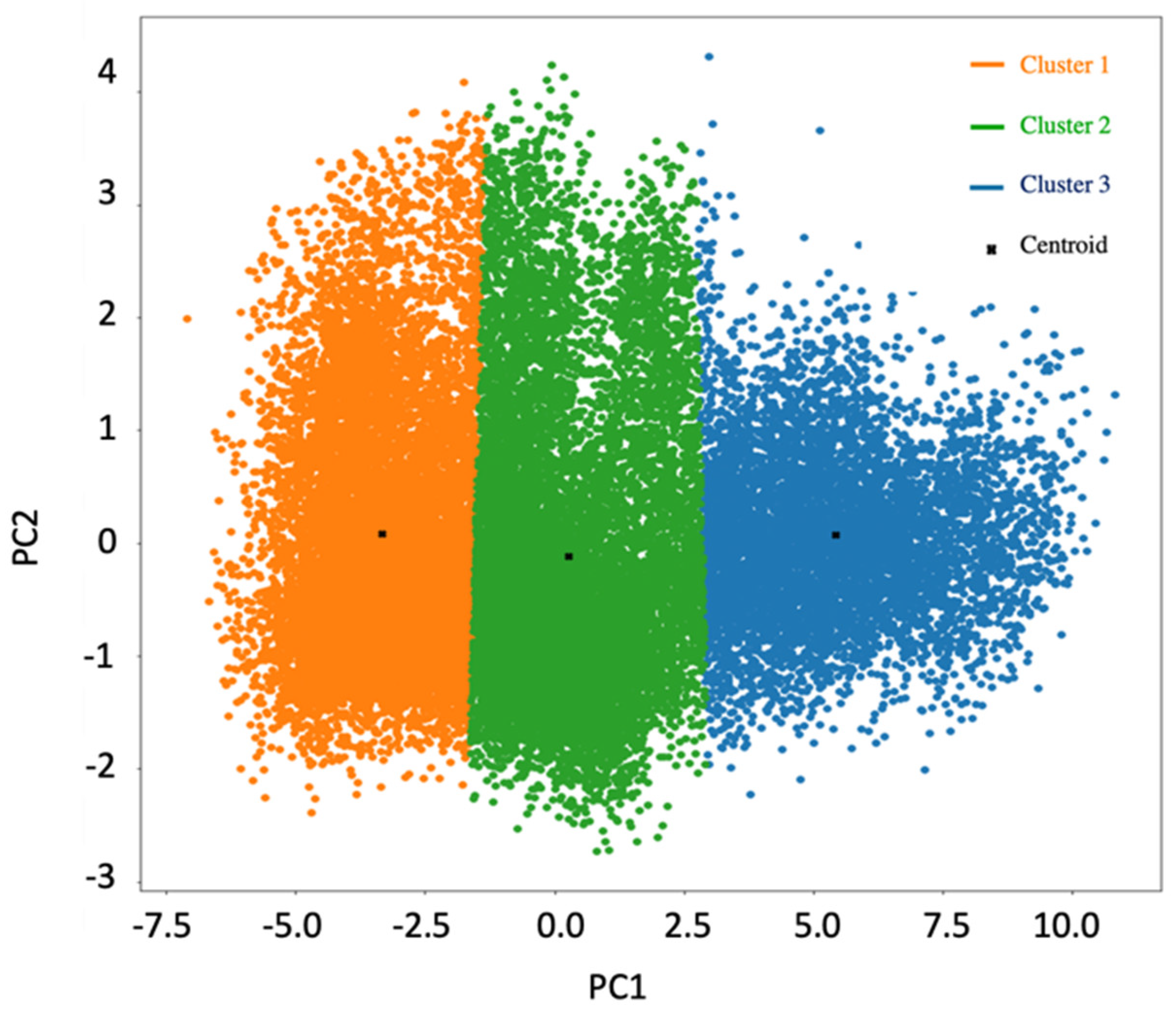

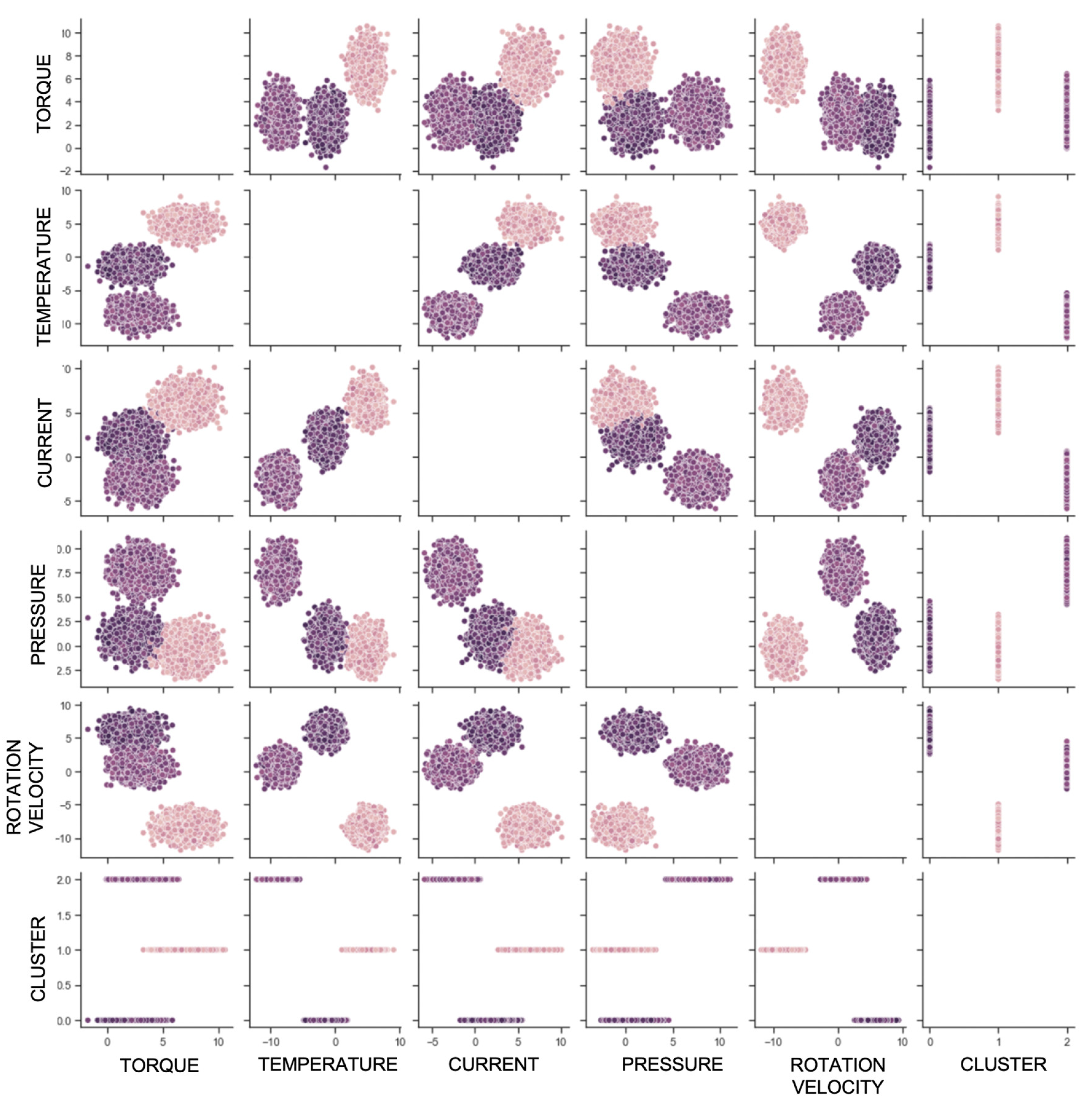

6. Clustering (Operating States)

- a.

- Application of the K-means method described for different K values between 1 and 10;

- b.

- Specifying the number of clusters K;

- c.

- Initialization of the centroids of each cluster, randomly selecting, without repetition, a data point for each of the centroids of the K clusters;

- d.

- Calculation of the square of the distance between each of the remaining data points and each of the K centroids;

- e.

- Assignment of each of these data points to the cluster whose centroid is closest;

- f.

- Calculation of the new position of the centroids of each cluster according to the average position of all data points belonging to each cluster;

- g.

- Repetition of the last three steps, until the position of the centroids no longer changes;

- h.

- Determining the optimal number of clusters based on the elbow method [35];

- i.

- Use of PCA to reduce the number of variables to two and, thus, be able to view the data points classified according to the cluster to which they belong.

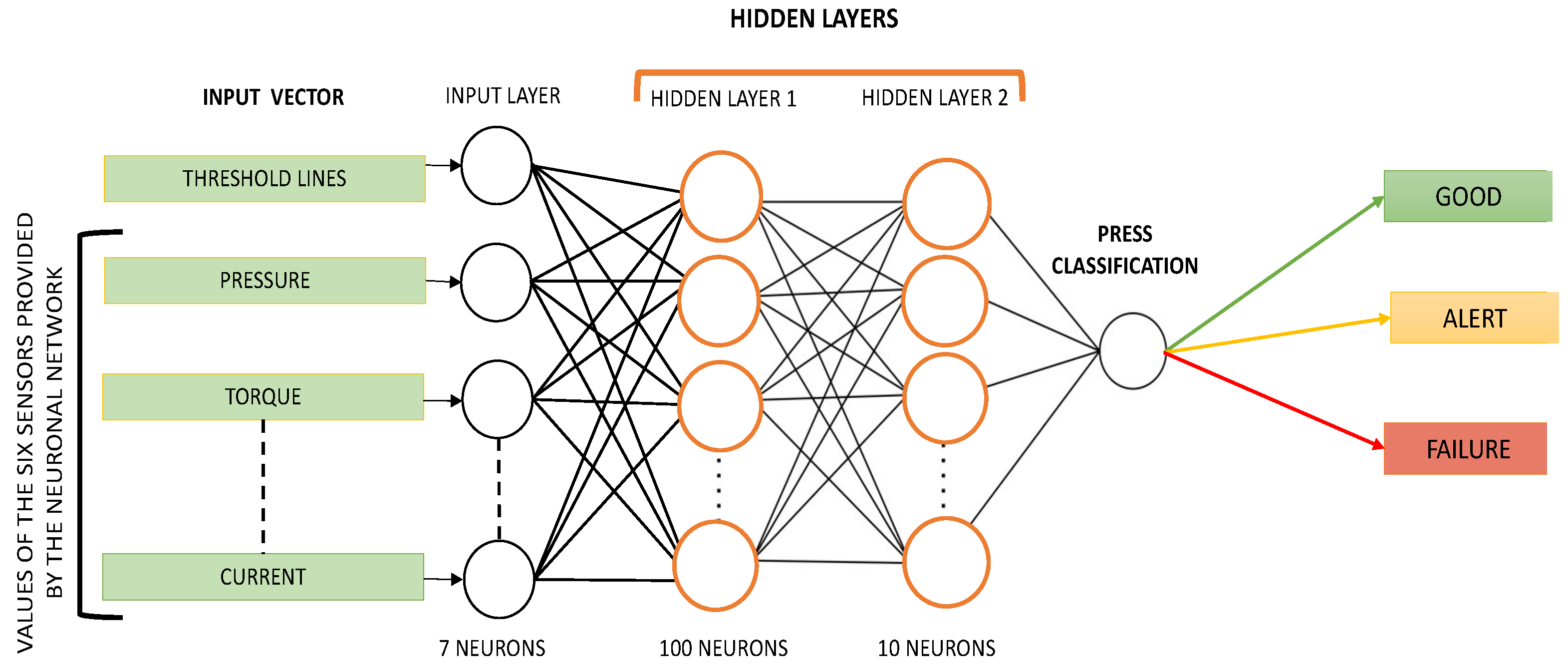

7. Neural Networks Architecture

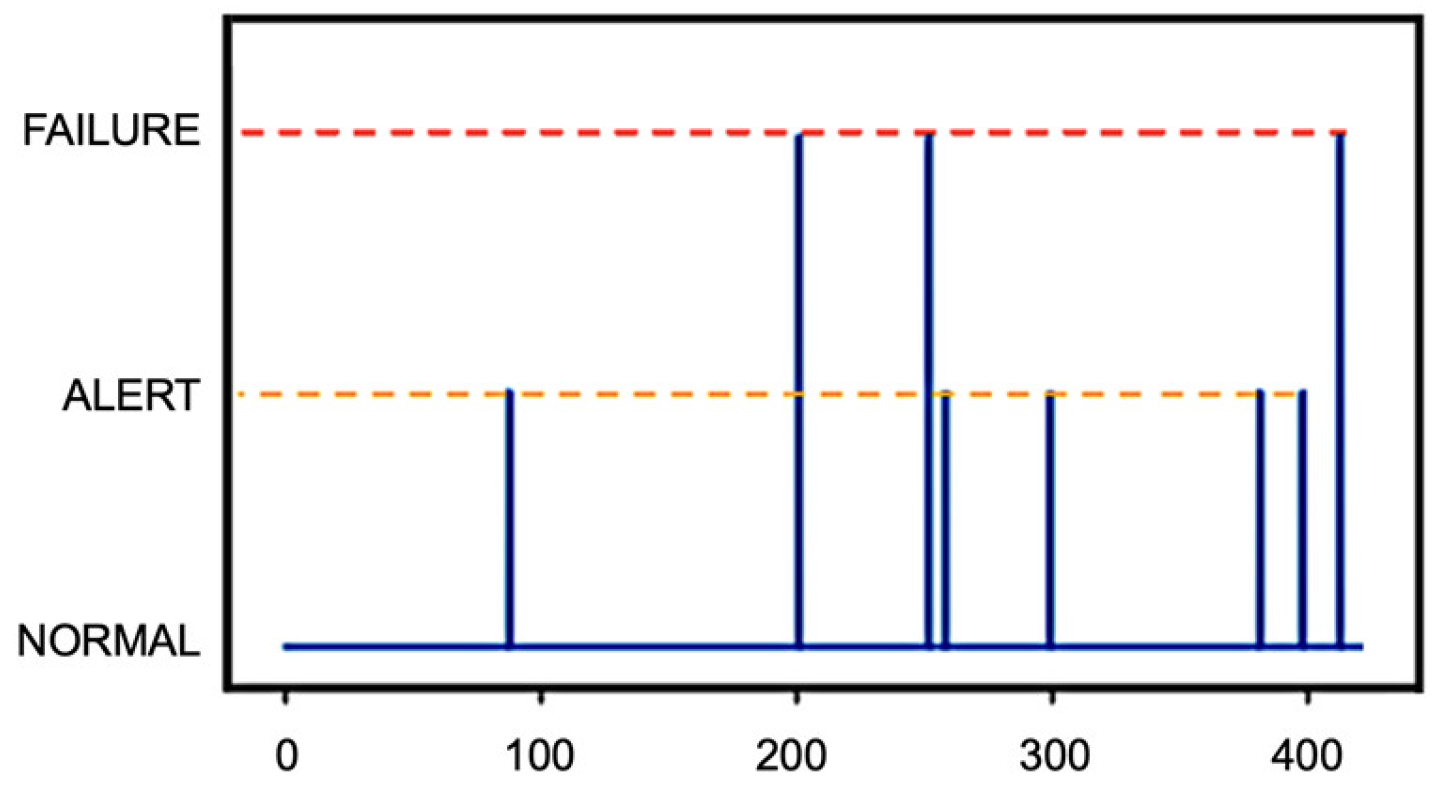

7.1. Network Classification for the State of the Paper Press

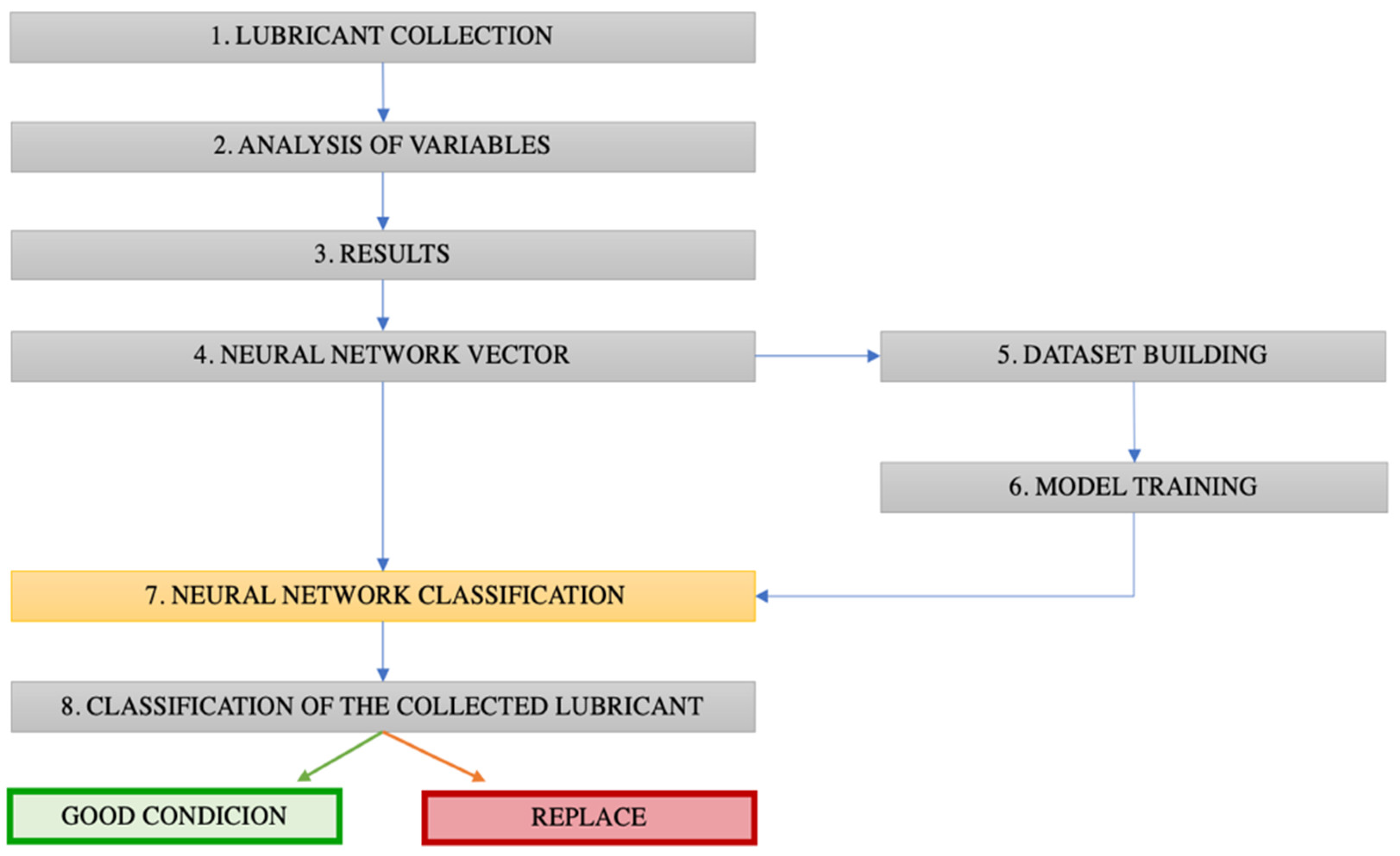

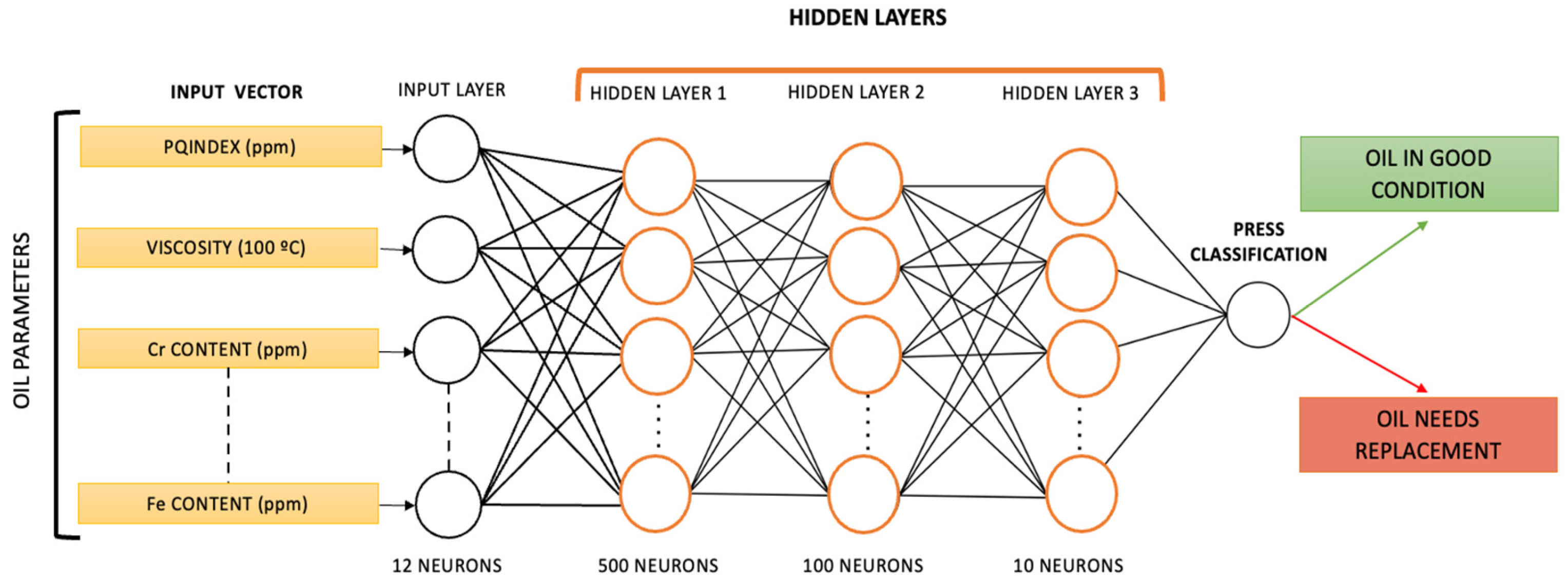

7.2. Neural Network for Press Lubricant Classification

7.3. Evaluation Models

8. Press State Classification Results

9. Lubricating Oil Classification Results

10. Limitations

11. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Network |

| AVG | Average |

| FF | Feed Forward |

| ITER | Iterations |

| MAPE | Mean Absolute Percentage Error |

| MLP | Multi-Layer Perceptron |

| MSE | Mean Square Error |

| PC | Principal Component |

| PCA | Principal Component Analysis |

| PCI | Principal Component Index |

| RF | Random Forest |

| RNN | Recurrent Neural Network |

| TAN | Total Acid Number |

| TPR | True Positive Rate |

References

- Kumar, U.; Galar, D.; Parida, A.; Stenström, C.; Berges, L. Maintenance Performance Metrics: A State-of-the-art Review. J. Qual. Maint. Eng. 2013, 19, 233–277. [Google Scholar] [CrossRef]

- Selcuk, S. Manutenção Preditiva, Sua Implementação e Últimas Tendências. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1670–1679. [Google Scholar] [CrossRef]

- Martins, A.; Fonseca, I.; Farinha, J.; Reis, J.; Cardoso, A.J.M. Maintenance Prediction through Sensing Using Hidden Markov Models-A Case Study. Appl. Sci. 2021, 11, 7685. [Google Scholar] [CrossRef]

- Uygun, Y. Industry 4.0: Principles, Effects and Challenges—Nova Science Publishers; Nova Science Publishers: Hauppauge, NY, USA, 2020; ISBN 1-5361-8423-3. [Google Scholar]

- Cachada, A.; Barbosa, J.; Leitño, P.; Gcraldcs, C.A.S.; Deusdado, L.; Costa, J.; Teixeira, C.; Teixeira, J.; Moreira, A.H.J.; Moreira, P.M.; et al. Maintenance 4.0: Intelligent and Predictive Maintenance System Architecture. In Proceedings of the 2018 IEEE 23rd International Conference on Emerging Technologies and Factory Automation (ETFA), Turin, Italy, 4–7 September 2018; Volume 1, pp. 139–146. [Google Scholar]

- Rodrigues, J.; Torres Farinha, J.; Marques Cardoso, A. Predictive Maintenance Tools—A Global Survey. WSEAS Trans. Syst. Control 2021, 16, 96–109. [Google Scholar] [CrossRef]

- de-Almeida-e-Pais, J.E.; Raposo, H.; Farinha, J.; Cardoso, A.J.M.; Marques, P. Optimizing the Life Cycle of Physical Assets through an Integrated Life Cycle Assessment Method. Energies 2021, 2021, 6128. [Google Scholar] [CrossRef]

- de-Almeida-e-Pais, J.E.; Farinha, J.; Cardoso, A.J.M.; Raposo, H. Optimizing the Life Cycle of Physical Assets -a Review. WSEAS Trans. Syst. Control 2020, 15, 417–430. [Google Scholar] [CrossRef]

- Jain, A.K.; Murty, M.N.; Flynn, P.J. Data Clustering: A Review. ACM Comput. Surv. 1999, 31, 264–323. [Google Scholar] [CrossRef]

- Xie, J.; Jiang, S.; Xie, W.; Gao, X. An Efficient Global K-Means Clustering Algorithm. JCP 2011, 6, 271–279. [Google Scholar] [CrossRef]

- Bala, R.; Kumar, D.D. Classification Using ANN: A Review. Int. J. Comput. Intell. Res. 2017, 13, 10. [Google Scholar]

- Rodrigues, J.; Farinha, J.; Mendes, M.; Mateus, R.; Cardoso, A.J.M. Short and Long Forecast to Implement Predictive Maintenance in a Pulp Industry. Eksploat. Niezawodn.-Maint. Reliab. 2021, 24, 33–41. [Google Scholar] [CrossRef]

- Shenbagarajan, A.; Ramalingam, V.; Balasubramanian, C.; Palanivel, S. Tumor Diagnosis in MRI Brain Image Using ACM Segmentation and ANN-LM Classification Techniques. Indian J. Sci. Technol. 2016, 9. [Google Scholar] [CrossRef]

- Rajab, S.; Sharma, V. Performance Evaluation of ANN and Neuro-Fuzzy System in Business Forecasting. In Proceedings of the 2015 2nd International Conference on Computing for Sustainable Global Development (INDIACom), New Delhi, India, 11–13 March 2015; pp. 749–754. [Google Scholar]

- Agatonovic-Kustrin, S.; Beresford, R. Basic Concepts of Artificial Neural Network (ANN) Modeling and Its Application in Pharmaceutical Research. J. Pharm. Biomed. Anal. 2000, 22, 717–727. [Google Scholar] [CrossRef] [PubMed]

- Paul, A.K.; Das, D.; Kamal, M.M. Bangla Speech Recognition System Using LPC and ANN. In Proceedings of the 2009 Seventh International Conference on Advances in Pattern Recognition, Kolkata, India, 4–6 February 2009; pp. 171–174. [Google Scholar]

- Wahyuni, E.S. Arabic Speech Recognition Using MFCC Feature Extraction and ANN Classification. In Proceedings of the 2017 2nd International conferences on Information Technology, Information Systems and Electrical Engineering (ICITISEE), Yogyakarta, Indonesia, 1–3 November 2017; pp. 22–25. [Google Scholar]

- Sinaga, K.P.; Yang, M.-S. Unsupervised K-Means Clustering Algorithm. IEEE Access 2020, 8, 80716–80727. [Google Scholar] [CrossRef]

- Kurita, T. Principal Component Analysis (PCA). In Computer Vision: A Reference Guide; Springer International Publishing: Cham, Switzerland, 2019; pp. 1–4. ISBN 978-3-030-03243-2. [Google Scholar]

- Seal, A.; Karlekar, A.; Krejcar, O.; Herrera-Viedma, E. Performance and Convergence Analysis of Modified C-Means Using Jeffreys-Divergence for Clustering. IJIMAI 2021, 7, 141. [Google Scholar] [CrossRef]

- Karlekar, A.; Seal, A.; Krejcar, O.; Gonzalo-Martin, C. Fuzzy K-Means Using Non-Linear S-Distance. IEEE Access 2019, 7, 55121–55131. [Google Scholar] [CrossRef]

- Sharma, K.K.; Seal, A.; Yazidi, A.; Krejcar, O. A New Adaptive Mixture Distance-Based Improved Density Peaks Clustering for Gearbox Fault Diagnosis. IEEE Trans. Instrum. Meas. 2022, 71, 1–16. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Wang, K.-S. Wind Turbine Fault Detection Based on SCADA Data Analysis Using ANN. Adv. Manuf. 2014, 2, 70–78. [Google Scholar] [CrossRef]

- Ertunc, H.M.; Ocak, H.; Aliustaoglu, C. ANN- and ANFIS-Based Multi-Staged Decision Algorithm for the Detection and Diagnosis of Bearing Faults. Neural Comput. Appl. 2013, 22, 435–446. [Google Scholar] [CrossRef]

- Rodrigues, J.; Cost, I.; Farinha, J.T.; Mendes, M.; Margalho, L. Predicting Motor Oil Condition Using Artificial Neural Networks and Principal Component Analysis. Eksploat. Niezawodn. 2020, 22, 440–448. [Google Scholar] [CrossRef]

- Le, V.T.; Lim, C.P.; Mohamed, S.; Nahavandi, S.; Yen, L.; Gallasch, G.E.; Baker, S.; Ludovici, D.; Draper, N.; Wickramanayake, V. Condition Monitoring of Engine Lubrication Oil of Military Vehicles: A Machine Learning Approach. AIAC 2017, 8. [Google Scholar]

- Kittisupakorn, P.; Thitiyasook, P.; Hussain, M.A.; Daosud, W. Neural Network Based Model Predictive Control for a Steel Pickling Process. J. Process Control 2009, 19, 579–590. [Google Scholar] [CrossRef]

- Gajewski, J.; Vališ, D. The Determination of Combustion Engine Condition and Reliability Using Oil Analysis by MLP and RBF Neural Networks. Tribol. Int. 2017, 115, 557–572. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, B.; Wood, J. Predict Failures in Production Lines: A Two-Stage Approach with Clustering and Supervised Learning. In Proceedings of the 2016 IEEE International Conference on Big Data (Big Data), Washington, DC, USA, 5–8 December 2016; pp. 2070–2074. [Google Scholar]

- Mazumder, R.K.; Salman, A.M.; Li, Y. Failure Risk Analysis of Pipelines Using Data-Driven Machine Learning Algorithms. Struct. Saf. 2021, 89, 102047. [Google Scholar] [CrossRef]

- Mateus, B.C.; Mendes, M.; Farinha, J.T.; Cardoso, A.M. Anticipating Future Behavior of an Industrial Press Using LSTM Networks. Appl. Sci. 2021, 11, 6101. [Google Scholar] [CrossRef]

- Mateus, B.; Farinha, J.T.; Mendes, M.; Martins, A.B.; Cardoso, A.M. Data Analysis for Predictive Maintenance Using Time Series and Deep Learning Models—A Case Study in a Pulp Paper Industry. 2021. Available online: https://www.researchgate.net/publication/363646966_Data_Analysis_for_Predictive_Maintenance_Using_Time_Series_and_Deep_Learning_Models-A_Case_Study_in_a_Pulp_Paper_Industry (accessed on 1 December 2022).

- Rodrigues, J.A.; Farinha, J.T.; Mendes, M.; Mateus, R.J.G.; Cardoso, A.J.M. Comparison of Different Features and Neural Networks for Predicting Industrial Paper Press Condition. Energies 2022, 15, 6308. [Google Scholar] [CrossRef]

- Rodrigues, J.A.; Farinha, J.T.; Cardoso, A.M.; Mendes, M.; Mateus, R. Prediction of Sensor Values in Paper Pulp Industry Using Neural Networks. In Proceedings of IncoME-VI and TEPEN 2021; Zhang, H., Feng, G., Wang, H., Gu, F., Sinha, J.K., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 281–291. [Google Scholar]

- Thorndike, R.L. Who Belongs in the Family? Psychometrika 1953, 18, 267–276. [Google Scholar] [CrossRef]

- Sklearn.Neural_network.MLPClassifier. Available online: https://scikit-learn/stable/modules/generated/sklearn.neural_network.MLPClassifier.html (accessed on 1 December 2022).

| Units | Mean | Min | Max | Var | Std | |

|---|---|---|---|---|---|---|

| TAN (Total Acid Number) | mgKOH/g | 1.26 | 0.18 | 2.85 | 0.26 | 0.52 |

| PQIndex | ppm | 131.78 | 0.00 | 6732.00 | 396,718.55 | 631.63 |

| Al Content | ppm | 1.30 | 0.00 | 15.00 | 8.00 | 2.84 |

| Cr Content | ppm | 5.59 | 0.00 | 2.00 | 34.02 | 5.85 |

| Cu Content | ppm | 9.16 | 0.00 | 243.00 | 815.87 | 28.65 |

| Fe Content | ppm | 260.17 | 2.00 | 1231.00 | 91,004.30 | 302.55 |

| Na Content | ppm | 5.21 | 0.00 | 38.00 | 25.82 | 5.10 |

| Ni Content | ppm | 4.20 | 0.00 | 26.00 | 17.16 | 4.16 |

| Pb Content | ppm | 0.51 | 0.00 | 30.00 | 6.25 | 2.51 |

| Si Content | ppm | 2.39 | 0.00 | 22.00 | 8.10 | 2.85 |

| Sn Content | ppm | 1.07 | 0.00 | 8.00 | 2.62 | 1.62 |

| Viscosity at 100 °C | m2/s | 3035.76 | 954.40 | 4146.20 | 168,647.64 | 436.90 |

| Classification | Precision | Recall | F1-Score |

|---|---|---|---|

| Normal | 0.96 | 1.00 | 0.98 |

| Alert | 0.98 | 0.85 | 0.91 |

| Failure | 1.00 | 0.90 | 0.94 |

| Accuracy | 0.96 | ||

| Macro AVG | 0.98 | 0.91 | 0.94 |

| Weighted AVG | 0.96 | 0.96 | 0.96 |

| Classification | Precision | Recall | F1-Score | Support |

|---|---|---|---|---|

| Oil in good Condition | 0.96 | 1.00 | 0.98 | 27 |

| Replace the oil | 1.00 | 0.94 | 0.97 | 18 |

| Accuracy | 0.98 | 45 | ||

| Macro AVG | 0.98 | 0.97 | 0.98 | 45 |

| Weighted AVG | 0.98 | 0.98 | 0.98 | 45 |

| Predictive Value | |||

|---|---|---|---|

| Oil in Good Condition | Replace the Oil | ||

| Real | Oil in good Condition | 27 | 0 |

| Replace the oil | 1 | 17 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, J.A.; Martins, A.; Mendes, M.; Farinha, J.T.; Mateus, R.J.G.; Cardoso, A.J.M. Automatic Risk Assessment for an Industrial Asset Using Unsupervised and Supervised Learning. Energies 2022, 15, 9387. https://doi.org/10.3390/en15249387

Rodrigues JA, Martins A, Mendes M, Farinha JT, Mateus RJG, Cardoso AJM. Automatic Risk Assessment for an Industrial Asset Using Unsupervised and Supervised Learning. Energies. 2022; 15(24):9387. https://doi.org/10.3390/en15249387

Chicago/Turabian StyleRodrigues, João Antunes, Alexandre Martins, Mateus Mendes, José Torres Farinha, Ricardo J. G. Mateus, and Antonio J. Marques Cardoso. 2022. "Automatic Risk Assessment for an Industrial Asset Using Unsupervised and Supervised Learning" Energies 15, no. 24: 9387. https://doi.org/10.3390/en15249387

APA StyleRodrigues, J. A., Martins, A., Mendes, M., Farinha, J. T., Mateus, R. J. G., & Cardoso, A. J. M. (2022). Automatic Risk Assessment for an Industrial Asset Using Unsupervised and Supervised Learning. Energies, 15(24), 9387. https://doi.org/10.3390/en15249387