Urban Hydrogen Production Model Using Environmental Infrastructures to Achieve the Net Zero Goal

Abstract

:1. Introduction

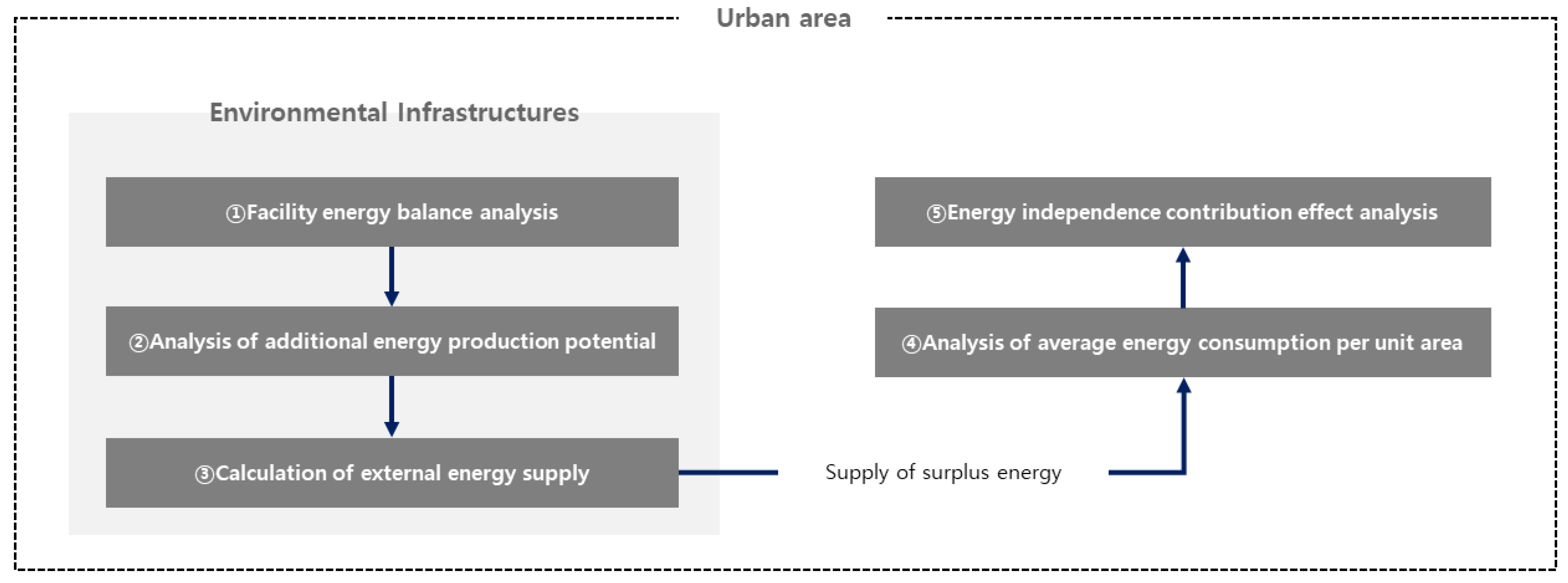

2. Materials and Methods

2.1. Research Methods

2.2. Analysis of Energy Consumption Characteristics in Seoul

2.3. Current Status of Seoul’s Environmental Infrastructure and Energy Production Capacity

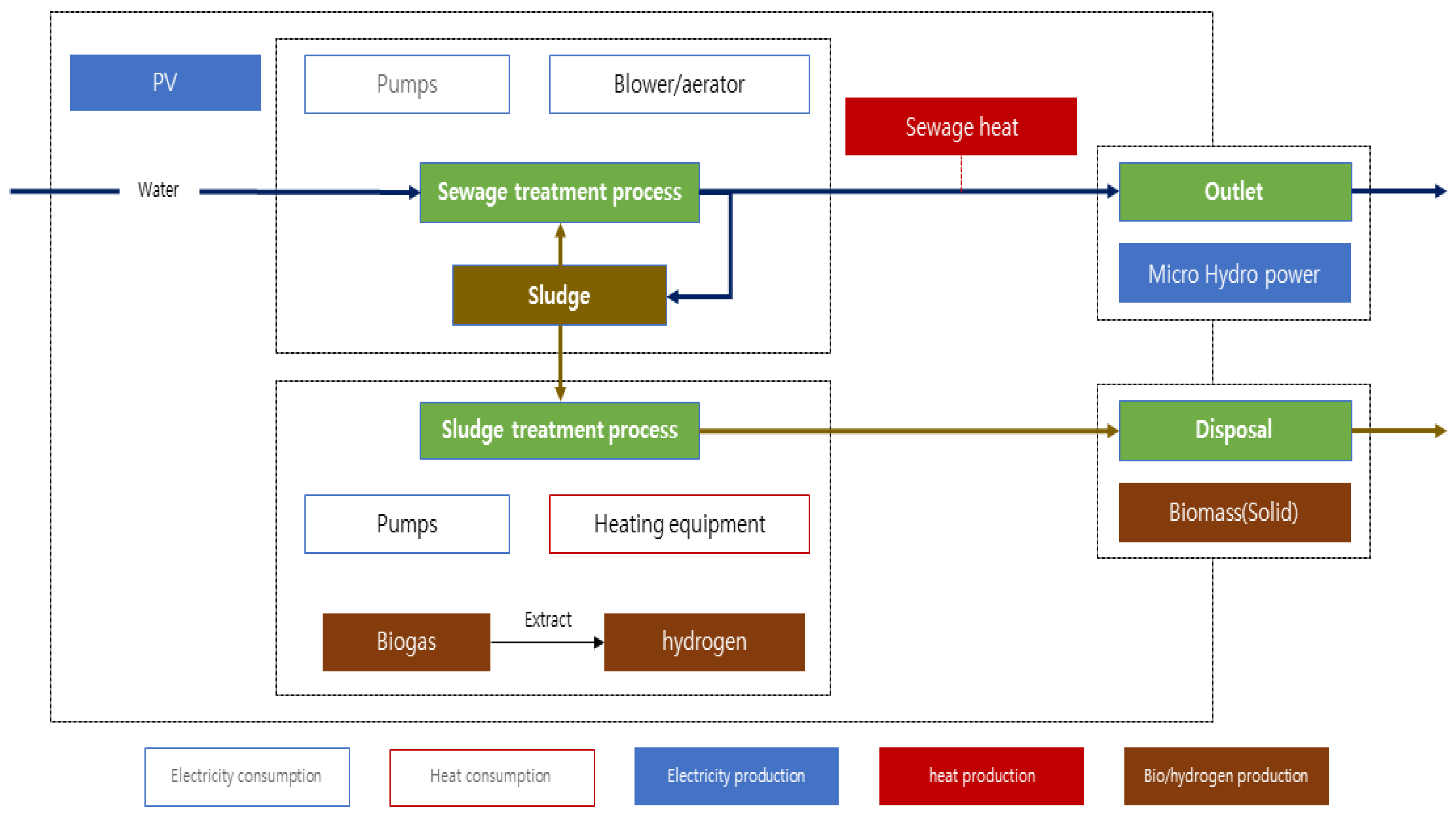

2.3.1. Sewage Treatment Plants

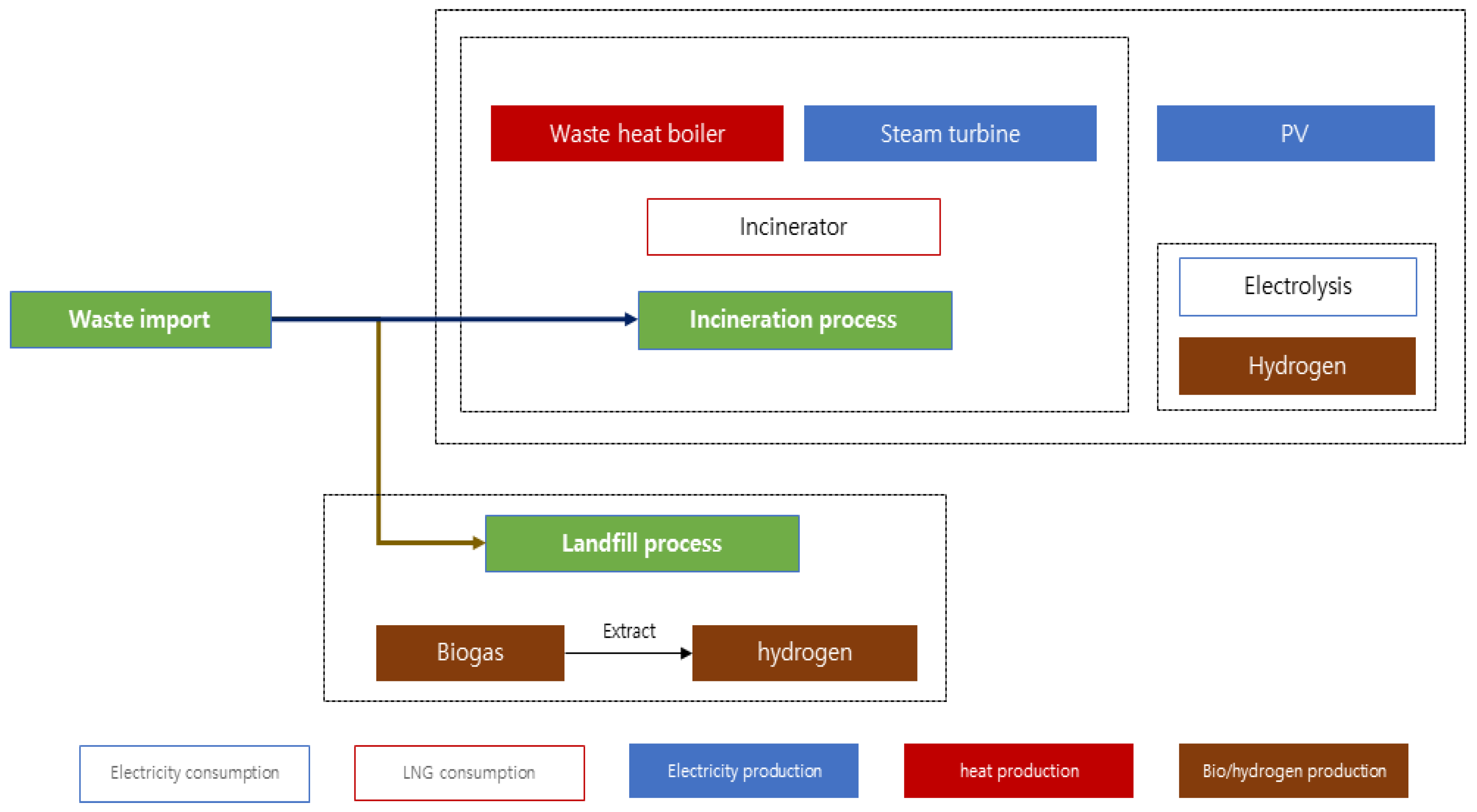

2.3.2. Incineration Plants

3. Results

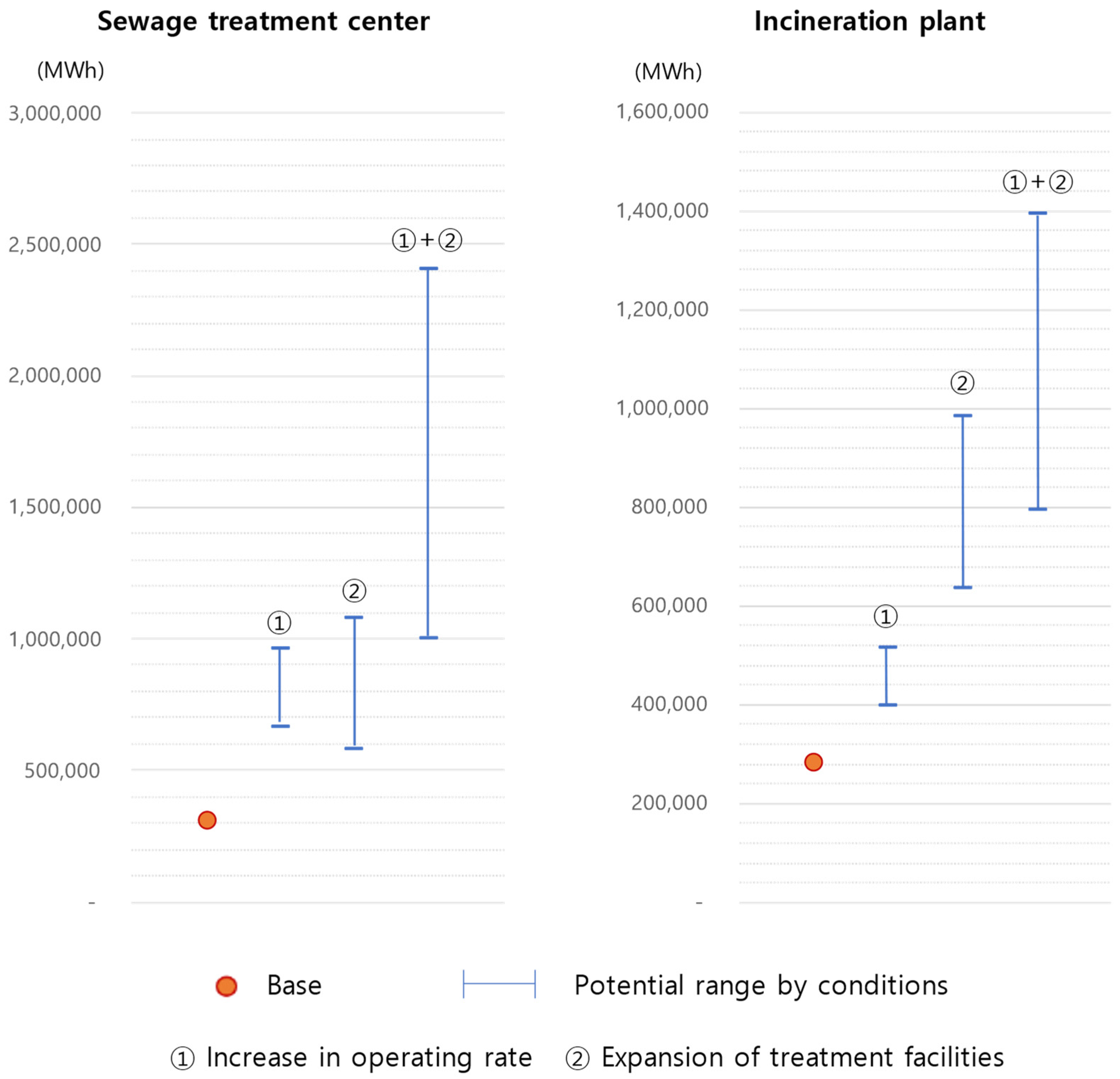

3.1. Energy Production Potential of Environmental Infrastructure

3.1.1. Sewage Treatment Plant

3.1.2. Incineration Plant

3.2. Additional Utilization of Waste Resources and Contribution to Energy Self-Sufficiency

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| m2 | square meter |

| km2 | square kilometers |

| Nm3 | Normal cubic meter |

| kTOE | Kilo ton of oil equivalent |

| kcal | Kilocalorie |

| MW | Megawatt |

| MWh | Megawatt hour |

| t | metric ton = tonne = 1000 kg |

| MLE | Modified Ludzack Ettinger |

| A2O | Anaerobic anoxic aerobic |

| SRF | Solid refuse fuel |

| SOEC | Solid oxide electrolysis cell |

| LNG | Liquified natural gas |

References

- The World Bank. Available online: https://www.worldbank.org/en/topic/urbandevelopment/brief/climate-action-through-an-urban-lens (accessed on 14 September 2022).

- Day, J.W.; Hall, C. The Myth of Urban Self-Sufficiency: America’s Most Sustainable Cities and Regions; Copernicus: New York, NY, USA, 2016; pp. 25–36. [Google Scholar]

- Seto, K.C.; Dhakal, S.; Bigio, A.; Blanco, H.; Delgado, G.C.; Dewar, D.; Huang, L.; Inaba, A. Human settlements, infrastructure, and spatial planning. In Climate Change; Mitigation of Climate Change: Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014; Chapter 12; pp. 923–1000. [Google Scholar]

- IRENA. Rise of Renewables in Cities: Energy Solutions for the Urban Future; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- CEENERGYNEWS, Solving Three Problems at Once: Waste-to-Hydrogen Solutions and Their Contribution in CEE. Available online: https://ceenergynews.com/hydrogen/solving-three-problems-at-once-waste-to-hydrogen-solutions-and-their-contribution-in-cee/ (accessed on 19 September 2022).

- IEA. Electrification Rates in Selected Countries and Regions in the New Policies Scenario, 2000–2030. Available online: https://www.iea.org/data-and-statistics/charts/electrification-rates-in-selected-countries-and-regions-in-the-new-policies-scenario-2000-2030 (accessed on 21 September 2022).

- The Climate Center. Available online: https://theclimatecenter.org/actions-by-countries-phase-out-gas/ (accessed on 1 September 2022).

- IEA. Heat Pumps; IEA: Paris, Italy, 2021; Available online: https://www.iea.org/reports/heat-pumps (accessed on 21 September 2022).

- Balta, M.Ö.; Balta, M.T. Development of a Sustainable Hydrogen City Concept and Initial Hydrogen City Projects. Energy Policy. 2022, 166, 113015. [Google Scholar] [CrossRef]

- Song, H.; Jung, H.S.; Uhn, S. Recent Progress for Hydrogen Production from Biogas and its Effective Applications. Appl. Chem. Eng. 2020, 31, 1–6. [Google Scholar] [CrossRef]

- Hong, G.I.H.; Song, H. Process Modeling and Economic Analysis of Hydrogen Production System on 500 kg-H2/d-Class Green Hydrogen Station Using Biogas. J. Kor. Inst. Gas 2021, 25, 19–26. [Google Scholar] [CrossRef]

- Park, S.; Ryu, J.Y.; Sohn, G. Techno-Economic Analysis (TEA) on Hybrid Process for Hydrogen Production Combined with Biomass Gasification Using Oxygen Released from the Water Electrolysis Based on Renewable Energy. J. Kor. Inst. Gas 2020, 24, 65–73. [Google Scholar] [CrossRef]

- Park, J.; Kim, C.-H.; Cho, H.s.; Kim, S.-K.; Cho, W.C. Techno-Economic Analysis of Green Hydrogen Production System based on Renewable Energy Sources. Trans. Korean Hydrog. New Energy Soc. 2020, 31, 337–344. [Google Scholar] [CrossRef]

- Yonsei University. Development of a Novel Process with Selective Pressure Control and Engineered Strain for Value-Added Hydrogen Production from Organic Waste. 2020. Available online: https://scienceon.kisti.re.kr/commons/util/originalView.do?cn=TRKO202000004145&dbt=TRKO&rn= (accessed on 14 September 2022).

- Kim, H.; Baek, Y. Wangyun won, Techno-Economic Analysis and Life-Cycle Assessment for the Production of Hydrogen from Biogas. Trans. Korean Hydrog. New Energy Soc. 2021, 32, 417–429. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, J.; Song, H. A Study on the Analysis of Risk Factors for Hydrogen Fuel Stations Based on Quantitative Risk Assessment. J. Kor. Inst. Gas 2020, 24, 70–76. [Google Scholar] [CrossRef]

- Ministry of the Environment. Basic Plan for Energy Independence at Wastewater Utility. 2010. Available online: https://www.korea.kr/common/download.do?fileId=199716&tblKey=EDN (accessed on 5 September 2022).

- Seoul, Seoul Information Communication Plaza. Available online: https://opengov.seoul.go.kr/sanction/17329818 (accessed on 1 August 2022).

- KEEI. Yearbook of Regional Energy Statistics; Korea Energy Statistical Information System; KEEI: Ulsan, Republic of Korea, 2021; Available online: http://www.kesis.net/sub/sub_0003.jsp (accessed on 15 August 2022).

- Seoul. Seoul Statistical [Yearbook]. 2021. Available online: https://lib.seoul.go.kr/search/detail/CATTOT000001460712?briefLink=/main/searchBrief?st=KWRD_A_si=TOTAL_A_q=%EC%84%9C%EC%9A%B8%ED%86%B5%EA%B3%84%EC%97%B0%EB%B3%B4+2020 (accessed on 17 August 2022).

- Ministry of the Environment. Road Map for Expanding Bio and Water Energy Using Environmental Facilities. 2022. Available online: http://www.me.go.kr/home/web/board/read.do?boardMasterId=1&boardId=1532140&menuId=10525 (accessed on 5 August 2022).

- Ministry of the Environment. Sewer Statistics. 2021. Available online: https://me.go.kr/home/web/policy_data/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=&searchValue=&menuId=10264&orgCd=&condition.toInpYmd=null&condition.code=A5&condition.fromInpYmd=null&condition.orderSeqId=6430&condition.rnSeq=110&condition.deleteYn=N&condition.deptNm=null&seq=7809 (accessed on 5 August 2022).

- Seoul. Sewage Treat. Plants Vis.; 3.0 Plan. 2019. Available online: https://news.seoul.go.kr/env/files/2021/03/policy-waterrotate-2021.pdf (accessed on 28 August 2022).

- Reliable Ministry of Government legislation, Korean law information center, Waste Management Act Enforcement Rules, <2021.7.6.>. Available online: https://www.law.go.kr/lsEfInfoP.do?lsiSeq=90900# (accessed on 1 September 2022).

- Seoul.go.kr. Seoul Incineration Plants. Available online: https://rrf.seoul.go.kr/content/bcrea211.do (accessed on 1 September 2022).

- Bloom Energy, Applications Electrolyzers. Available online: https://www.bloomenergy.com/bloomelectrolyzer/ (accessed on 11 August 2022).

- Carbon Neutrality and Green Growth Commission. Opinion from the Industry and Local Governments (Renewable Energy) Related to the Draft 2050 Carbon-Neutral Scenario. 2021. Available online: https://www.2050cnc.go.kr/base/board/read?boardManagementNo=4&boardNo=43&searchCategory=&page=2&searchType=&searchWord=&menuLevel=2&menuNo=15 (accessed on 11 September 2022).

- MFG Magazine, Energy-Saving Measures to Recover Energy from Small-Scale Hydroelectric Power Generation. Available online: www.ei.co.kr/content/view.asp?idx=13738/ (accessed on 13 August 2022).

- Ministry of the Environment. The 5th National Waste Statistical Survey. 2017. Available online: https://www.recycling-info.or.kr/rrs/stat/envStatDetail.do?menuNo=M13020302&pageIndex=1&bbsId=BBSMSTR_000000000002&s_nttSj=KEC011&nttId=867&searchBgnDe=&searchEndDe= (accessed on 11 September 2022).

- Boroomandnia, A.; Rismanchi, B.; Wu, W. A Review of Micro Hydro Systems in Urban Areas: Opportunities and Challenges. Renew. Sustain. Energy Rev. 2022, 169, 112866. [Google Scholar] [CrossRef]

- Yonhap News Agency, Seoul to Supply District Heating Using Sewage Heat from SEONAM Water Recycling Center. Available online: https://www.yna.co.kr/view/AKR20150610163500004/ (accessed on 13 August 2022).

- Osaka Gas. By Technology Classification. Available online: https://www.osakagas.co.jp/en/rd/technical/1198859_6995.html#anchor2 (accessed on 15 August 2022).

- Bnetech. Development of Pretreatment System for High Added Value of Biogas. 2012. Available online: https://scienceon.kisti.re.kr/commons/util/originalView.do?cn=TRKO201300025199&dbt=TRKO&rn= (accessed on 20 September 2022).

- Gim, B.; Yoon, W.L.; Seo, D.J. Analysis of the Economy of Scale for Domestic Steam Methane: Reforming Hydrogen Refueling Stations Utilizing the Scale Factor. Trans. Korean Hydrog. New Energy Soc. 2019, 30, 251–259. [Google Scholar] [CrossRef]

- Macedo, L.V.; Bellezoni, R.A.; de Oliveira, J.A.P.; Salehi, P.; Currie, P.; Jones, A. Innovating in Urban Green and Blue Infrastructure to Improve the Food Water Energy Nexus: An Implementation Guide for Cities and Subnational Governments. 2022. Available online: https://iclei.org/wp-content/uploads/2022/08/IFWEN-Implementation-Guide_2022_FINAL.pdf (accessed on 20 September 2022).

| Coal | Oil | Gas | Electricity | Heat | Renewables & Others | Total | |

|---|---|---|---|---|---|---|---|

| Industry | 0 | 904 | 19 | 129 | 0 | 3 | 1055 |

| Transportation | 0 | 2900 | 250 | 130 | 0 | 77 | 3357 |

| Residential & Commercial | 42 | 339 | 3724 | 3320 | 477 | 39 | 7941 |

| Public & Others | 0 | 419 | 0 | 359 | 9 | 178 | 964 |

| Total | 42 | 4561 | 3993 | 3938 | 485 | 297 | 13,316 |

| Name | Extent (m2) | Sewage Treatment Volume | Sewage Disposal | Biogas Production and Utilization | ||||

|---|---|---|---|---|---|---|---|---|

| Incineration | Drying | Selling | Electricity Generation (Ton/Day) | Self-Utilization (Ton/Day) | Surplus (Discard) | |||

| Nanji | 929,084 | 557.2 | 130.1 | 119.2 | 11.3 | 0 | 11.0 | 14.2 |

| Jungnang | 501,000 | 1136.6 | 0 | 459.5 | 19.1 | 0 | 48.8 | 1.5 |

| Seonam | 1,032,423 | 1456.5 | 123.6 | 192.3 | 31.9 | 0.2 | 16.9 | 4.0 |

| Tancheon | 393,000 | 752.3 | 0 | 126.7 | 0 | 2.3 | 19.6 | 2.6 |

| Name | Population | Extent | Total Input | Incineration | Rate of Operation | Water Usage |

|---|---|---|---|---|---|---|

| (m2) | (Ton/Year) | (%) | m3/year | |||

| Gangnam | 1,649,169 | 63,818 | 253,193 | 247,907 | 89 | 209,139 |

| Nowon | 1,052,194 | 46,307 | 170,229 | 175,034 | 71 | 196,368 |

| Mapo | 575,102 | 58,435 | 175,550 | 172,573 | 76 | 149,239 |

| Yangcheon | 632,329 | 16,914 | 99,114 | 100,296 | 85 | 47,824 |

| Self-Production | External Supply | Total | |||||

|---|---|---|---|---|---|---|---|

| Electricity | Heat | Biogas | Electricity | Oil | LNG | ||

| Nanji | 35 | 38,275 | 45,581 | 68,422 | 364 | 0 | 152,678 |

| Jungnang | 519 | 42,664 | 101,479 | 180,759 | 1630 | 27 | 327,077 |

| Seonam | 7032 | 28,151 | 44,224 | 146,541 | 269 | 252 | 226,470 |

| Tancheon | 3264 | 11,091 | 51,240 | 68,984 | 52 | 278 | 134,909 |

| Solar Power 1 | Micro-Hydropower 2 | Biomass 3 | Sewage Heat 4 | Biogas 5 | Hydrogen 6 | Total | |

|---|---|---|---|---|---|---|---|

| Nanji | 24,663 | 885 | 98,027 | 236,497 | 25,045 | 68,667 | 453,785 |

| Jungnang | 13,299 | 2008 | 204,668 | 536,289 | 42,229 | 136,894 | 935,387 |

| Seonam | 27,406 | 2554 | 149,595 | 682,075 | 70,507 | 57,629 | 989,766 |

| Tancheon | 10,432 | 1196 | 55,194 | 319,326 | 11,145 | 52,993 | 450,286 |

| Energy Sales | Utility Usage | Total | |||

|---|---|---|---|---|---|

| Waste Heat | Electricity | LNG | Electricity | ||

| Gangnam | 550,638 | 0 | 4268 | 25,685 | 580,591 |

| Nowon | 319,210 | 0 | 1820 | 17,122 | 338,152 |

| Mapo | 357,369 | 307 | 2085 | 19,438 | 379,199 |

| Yangcheon | 194,866 | 2219 | 10,582 | 9252 | 216,919 |

| Self-Consumption | Production and Supply | ||

|---|---|---|---|

| Facility Operation | Water Electrolysis | Heat | Hydrogen |

| 90,252 | 332,402 | 1,754,485 | 284,204 |

| Current Status | (1) Increased Utilization (Duration of Stay) | (2) Expansion of Processing Facilities | |||||

|---|---|---|---|---|---|---|---|

| 30 | 25 | 20 | 50% | 100% | 150% | ||

| Nanji | 68,667 | 99,738 | 99,738 | 113,688 | 118,410 | 168,153 | 217,896 |

| Jungnang | 136,894 | 204,259 | 245,110 | 306,388 | 231,323 | 325,753 | 420,183 |

| Seonam | 57,629 | 247,573 | 297,087 | 371,359 | 129,825 | 202,021 | 274,217 |

| Tancheon | 52,993 | 114,282 | 137,138 | 171,423 | 100,060 | 133,414 | 166,767 |

| Total | 316,183 | 665,851 | 779,073 | 962,857 | 579,619 | 829,341 | 1,079,063 |

| Current Status | (1) Increased Utilization (Duration of Stay) | (2) Expansion of Incineration Treatment (Reduction of Landfill Ratio) | |||

|---|---|---|---|---|---|

| 90% | 100% | −50% | −100% | ||

| Gangnam | 83,787 | 87,517 | 124,819 | 208,974 | 334,161 |

| Nowon | 89,840 | 152,567 | 185,581 | 178,228 | 266,616 |

| Mapo | 68,997 | 111,569 | 141,977 | 156,142 | 243,288 |

| Yangcheon | 41,580 | 49,481 | 65,283 | 92,228 | 142,875 |

| Total | 284,204 | 401,133 | 517,660 | 635,572 | 986,940 |

| Coal | Oil | Gas | Electricity | Thermal Energy | Renewables & etc. | Total |

|---|---|---|---|---|---|---|

| 798.7 | 87,576.3 | 76,668.4 | 75,608.5 | 9320.0 | 5698.8 | 255,671 |

| Category | Name | Extent (km2) | Self-Consumption (MWh) | External Supply (MWh) | Additional Areas Where Energy Self-Sufficiency Achieved (km2) | ||

|---|---|---|---|---|---|---|---|

| Minimum | Maximum | Minimum | Maximum | ||||

| Sewage treatment plants | Nanji | 0.929 | 152,678 | 301,107 | 516,659 | 1.18 | 2.02 |

| Jungnang | 0.501 | 327,077 | 608,311 | 1,237,386 | 2.38 | 4.84 | |

| Seonam | 1.032 | 226,470 | 763,296 | 1,634,064 | 2.99 | 6.39 | |

| Tancheon | 0.393 | 146,054 | 315,377 | 690,941 | 1.23 | 2.70 | |

| Incineration plants | Gangnam | 0.063 | 29,953 | 732,421 | 881,155 | 2.86 | 3.45 |

| Nowon | 0.046 | 18,942 | 514,126 | 942,821 | 2.01 | 3.69 | |

| Mapo | 0.058 | 21,523 | 507,064 | 805,584 | 1.98 | 3.15 | |

| Yangcheon | 0.016 | 19,834 | 285,078 | 400,187 | 1.12 | 1.57 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, H.; Lee, H.; Kim, B.; Kim, Y. Urban Hydrogen Production Model Using Environmental Infrastructures to Achieve the Net Zero Goal. Energies 2022, 15, 9293. https://doi.org/10.3390/en15249293

Moon H, Lee H, Kim B, Kim Y. Urban Hydrogen Production Model Using Environmental Infrastructures to Achieve the Net Zero Goal. Energies. 2022; 15(24):9293. https://doi.org/10.3390/en15249293

Chicago/Turabian StyleMoon, Hyodong, Hyoeun Lee, Boram Kim, and Yunsung Kim. 2022. "Urban Hydrogen Production Model Using Environmental Infrastructures to Achieve the Net Zero Goal" Energies 15, no. 24: 9293. https://doi.org/10.3390/en15249293

APA StyleMoon, H., Lee, H., Kim, B., & Kim, Y. (2022). Urban Hydrogen Production Model Using Environmental Infrastructures to Achieve the Net Zero Goal. Energies, 15(24), 9293. https://doi.org/10.3390/en15249293