A Review of Research on Cavity Growth in the Context of Underground Coal Gasification

Abstract

1. Introduction

2. Research Progress of UCG and Cavity Growth

2.1. UCG Development History

2.2. Cavity Growth Mechanism

3. Current Status of Research Methods for Cavity Growth

3.1. Field Test

3.1.1. Direct Observation Method

3.1.2. Indirect Observation Method

3.2. Laboratory Experiment

3.2.1. Small Scale Experiments

3.2.2. Large Scale Experiments

3.3. Numerical Simulation

3.3.1. One-Dimensional Numerical Model

3.3.2. Two-Dimensional Numerical Model

3.3.3. Three-Dimensional Numerical Model

3.4. Chapter Summary

4. Influencing Factors of Cavity Growth

4.1. Geological factors

4.1.1. Coal Seam Physical Properties

4.1.2. Types of Coal

4.2. Operating Factors

4.2.1. The Temperature

4.2.2. The Pressure

4.2.3. The Composition of Gasification Agent

4.2.4. Flow Pattern of Gasification Agent

4.3. Chapter Summary

5. Existing Problems and Research Trends

5.1. Existing Problems

- (1)

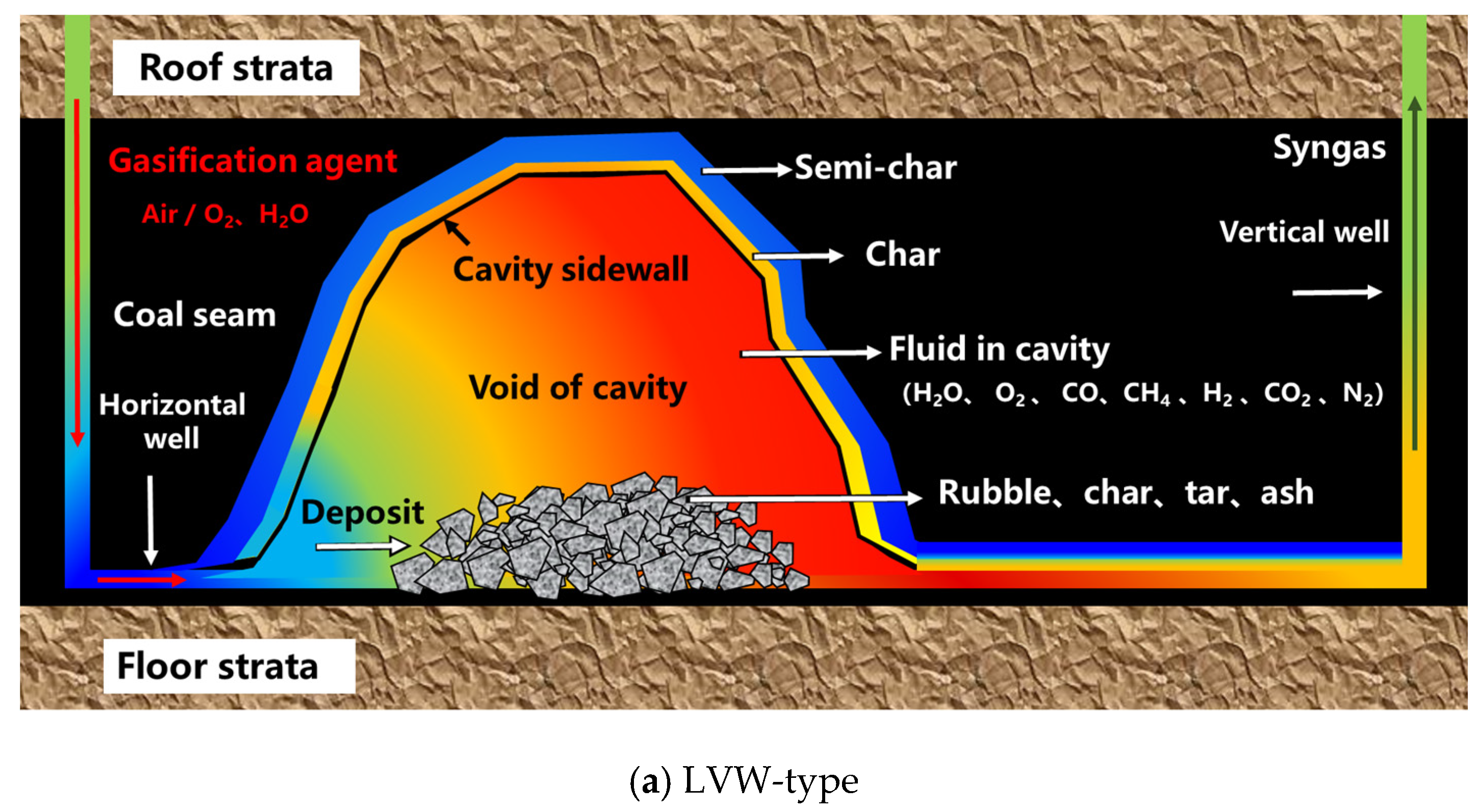

- Cavity growth is the result of the complex interaction of numerous physical and chemical fields. LVW-UCG is suitable for shallow coal seams, while CRIP-UCG is suitable for deep coal seams. The gasification agent flow patterns corresponding to the LVW and CRIP types are obviously different. Moreover, the thermophysical conditions of UCG in the deep coal seam have changed hugely. However, the current research results of UCG are mostly based on LVW type in shallow coal seam, which cannot effectively guide the production of a CRIP-UCG project in a deep coal seam.

- (2)

- The variation in moisture content and its distribution in the coal seam will act on heat balance and material balance in the cavity through a series of physical and chemical processes. This will make the movement and rupture behavior of the cavity side wall unknown in the process of gasification deformation, which seriously affects the quality of the UCG project. However, at present, the research results of the UCG cavity growth behavior under the condition of a water-bearing coal seam are few in number and mainly qualitative descriptions lacking quantitative analysis.

5.2. Research Trends

- (1)

- Laboratory experimental research under conditions similar to actual coal seams. Study the cavity growth mechanism of CRIP-type in the deep coal seam. Focus on conducting large-scale coal gasification experimental research under high-pressure conditions. Furthermore, reveal the gasification mechanism of different operation regions (cavity sidewall, void space, and deposit), the cavity growth behaviors, and the influence of fractures on fluid flow. Meanwhile, improve the measurement method of the parameters required by the numerical model. Emphatically, study the influence mechanism of moisture content and its distribution in a coal seam on cavity growth. Elucidate the variation characteristics of heat and mass transfer in the cavity under the condition of water-bearing/non-water-bearing coal seams, determining the moisture content that can maintain the effective operation of the UCG reaction, clarifying the proper moisture content that can increase the hydrogen content in the syngas, and illustrating the effect of moisture content on the movement mechanism of the cavity side wall.

- (2)

- Numerical simulation research considering chemical reaction, thermal field propagation, complex fluid flow, coal rock deformation, and seepage field. It is meaningful to refine a single physical field model based on experimental results to obtain a more accurate expression. Moreover, one should establish a multi-field coupling numerical model of the CRIP-UCG, clarifying the heat and mass transfer characteristics of the cavity during the gasification process, as well as the movement mechanism of the cavity side wall. In order to improve the stability and convergence of the multi-field model, an advanced coupling algorithm is needed to solve the thermal–fluid flow–chemical–mechanical coupling problem. Moreover, utilizing machine learning to predict UCG data (such as syngas concentration, syngas calorific value, and underground temperature) is also promising for UCG projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Caineng, Z.O.U.; Xiong, B.; Huaqing, X.U.E.; Zheng, D.; Zhixin, G.E.; Ying, W.A.N.G.; Jiang, L.; Songqi, P.A.N.; Songtao, W.U. The role of new energy in carbon neutral. Pet. Explor. Dev. 2021, 48, 480–491. [Google Scholar]

- Ludwik-Pardała, M.; Stańczyk, K. Underground coal gasification (UCG): An analysis of gas diffusion and sorption phenomena. Fuel 2015, 150, 48–54. [Google Scholar] [CrossRef]

- Caineng, Z.O.U.; Yanpeng, C.H.E.N.; Lingfeng, K.O.N.G.; Fenjin, S.; Shanshan, C.; Zhen, D. Underground coal gasification and its strategic significance to the development of natural gas industry in China. Pet. Explor. Dev. 2019, 46, 205–215. [Google Scholar]

- Lingfeng, K.; Zhongxun, Z.; Binggang, Z. Feasibility analysis on rebuilding coal-mine gas storage by using underground coal gasification (UCG) technology. Nat. Gas Ind. 2016, 36, 99–107. (In Chinese) [Google Scholar]

- Yang, D.; Koukouzas, N.; Green, M.; Sheng, Y. Recent development on underground coal gasification and subsequent CO2 storage. J. Energy Inst. 2016, 89, 469–484. [Google Scholar] [CrossRef]

- Najafi, M.; Jalali, S.M.E.; KhaloKakaie, R.; Forouhandeh, F. Prediction of cavity growth rate during underground coal gasification using multiple regression analysi. Int. J. Coal Sci. Technol. 2015, 2, 318–324. [Google Scholar] [CrossRef]

- Yuewu, L.; Huijun, F.; Longlong, L.; Tengze, G.; Taiyi, Z.; Danlu, L.; Jiuge, D. Recent progress on numerical research of key mechanical problems during underground coal gasification. Chin. J. Theor. Appl. Mech. 2022, 54, 1–17. (In Chinese) [Google Scholar]

- Klimenko, A.Y. Early developments and inventions in underground coal gasification. In Underground Coal Gasification and Combustion; Woodhead Publishing: Sawston, UK, 2018; pp. 11–24. [Google Scholar]

- Perkins, G. Underground coal gasification—Part I: Field demonstrations and process performance. Prog. Energy Combust. Sci. 2018, 67, 158–187. [Google Scholar] [CrossRef]

- Perkins, G. Mathematical modelling of in situ combustion and gasification. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 56–73. [Google Scholar] [CrossRef]

- Perkins, G. Underground coal gasification—Part II: Fundamental phenomena and modeling—ScienceDirect. Prog. Energy Combust. Sci. 2018, 67, 234–274. [Google Scholar] [CrossRef]

- Perkins, G.; du Toit, E.; Cochrane, G.; Bollaert, G. Overview of underground coal gasification operations at Chinchilla, Australia. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 3639–3646. [Google Scholar] [CrossRef]

- Upadhye, R.S.; Field, J.E.; Fields, D.B.; Britten, J.A.; Thorsness, C.B. Experimental Investigation of Coal Spalling; Lawrence Livermore National Lab.: Livermore, CA, USA, 1986. [Google Scholar]

- Gao, W.; Zagorščak, R.; Thomas, H.R. Insights into solid-gas conversion and cavity growth during Underground Coal Gasification (UCG) through Thermo-Hydraulic-Chemical (THC) modelling. Int. J. Coal Geol. 2021, 237, 103711. [Google Scholar] [CrossRef]

- Laouafa, F.; Farret, R.; Vidal-Gilbert, S.; Kazmierczak, J.B. Overview and modeling of mechanical and thermomechanical impact of underground coal gasification exploitation. Mitig. Adapt. Strateg. Glob. Change 2016, 21, 547–576. [Google Scholar] [CrossRef]

- Bhutto, A.W.; Bazmi, A.A.; Zahedi, G. Underground coal gasification: From fundamentals to applications. Prog. Energy Combust. Sci. 2013, 39, 189–214. [Google Scholar] [CrossRef]

- Bhaskaran, S.; Samdani, G.; Aghalayam, P.; Ganesh, A.; Singh, R.P.; Sapru, R.K.; Jain, P.K.; Mahajani, S. Experimental studies on spalling characteristics of Indian lignite coal in context of underground coal gasification. Fuel 2015, 154, 326–337. [Google Scholar] [CrossRef]

- Niu, S.; Zhao, Y.; Hu, Y. Experimental ivestigation of the temperature and pore pressure effect on permeability of lignite under the in situ condition. Transp. Porous Media 2014, 101, 137–148. [Google Scholar] [CrossRef]

- Stephens, D.R. Hoe Creek Experiments: LLNL’s Underground Coal-Gasification Project in Wyoming; Lawrence Livermore National Lab.: Livermore, CA, USA, 1981. [Google Scholar]

- Hill, R.W.; Thorsness, C.B. Large block experiments in underground coal gasification. ACS Symp. Ser. 1983, 79, 226. [Google Scholar]

- Blinderman, M.S.; Klimenko, A.Y. Underground Coal Gasification and Combustion; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Thorsness, C.B. 3.4 an underground coal gasification cavity simulator with solid motion. Fossil Energy 1983. Available online: https://digital.library.unt.edu/ark:/67531/metadc1065489/m2/1/high_res_d/5295596.pdf (accessed on 1 November 2022).

- Cena, R.J.; Britten, J.A.; Thorsness, C.B. Excavation of the Partial Seam CRIP Underground Coal Gasification Test Site; Lawrence Livermore National Lab.: Livermore, CA, USA, 1987. [Google Scholar]

- Stephens, D.R.; Cena, R.J.; Hill, R.W.; Thorsness, C.B. The Centralia partial seam CRIP underground coal gasification experiment. [Controlled retracting injection point]. In Proceedings of the AIChE Annual Meeting, San Francisco, CA, USA, 25 November 1984; American Institute of Chemical Engineers: New York, NY, USA, 1985. [Google Scholar]

- Cena, R.J.; Hill, R.W.; Stephens, D.R.; Thorsness, C.B. Summary Results of the Centralia Partial Seam CRIP Underground Coal Gasification Field Test; Lawrence Livermore National Lab.: Livermore, CA, USA, 1984. [Google Scholar]

- Kühnel, R.A.; Schmit, C.R.; Eylands, K.E.; McCarthy, G.J. Comparison of the pyrometamorphism of clayey rocks during underground coal gasification and firing of structural ceramics. Appl. Clay Sci. 1993, 8, 129–146. [Google Scholar] [CrossRef]

- Oliver, R.L.; Lindblom, S.R.; Covell, J.R. Results of Phase 2 Postburn Drilling, Coring, and Logging: Rocky Mountain 1 Underground Coal Gasification Test, Hanna, Wyoming; Western Research Institute: Laramie, WY, USA, 1991. [Google Scholar]

- Cena, R.J.; Thorsness, C.B.; Britten, J.A. Assessment of the CRIP (Controlled Retracting Injection Point) Process for Underground Coal Gasification: The Rocky Mountain I Test; Lawrence Livermore National Lab.: Livermore, CA, USA, 1988. [Google Scholar]

- Kapusta, K.; Stańczyk, K.; Wiatowski, M.; Chećko, J. Environmental aspects of a field-scale underground coal gasification trial in a shallow coal seam at the Experimental Mine Barbara in Poland. Fuel 2013, 113, 196–208. [Google Scholar] [CrossRef]

- Daggupati, S.; Mandapati, R.N.; Mahajani, S.M.; Ganesh, A.; Mathur, D.K.; Sharma, R.K.; Aghalayam, P. Laboratory studies on combustion cavity growth in lignite coal blocks in the context of underground coal gasification. Energy 2010, 35, 2374–2386. [Google Scholar] [CrossRef]

- Daggupati, S.; Mandapati, R.N.; Mahajani, S.M.; Ganesh, A.; Sapru, R.K.; Sharma, R.K.; Aghalayam, P. Laboratory studies on cavity growth and product gas composition in the context of underground coal gasification. Energy 2011, 36, 1776–1784. [Google Scholar] [CrossRef]

- Prabu, V.; Jayanti, S. Simulation of cavity formation in underground coal gasification using bore hole combustion experiments. Energy 2011, 36, 5854–5864. [Google Scholar] [CrossRef]

- Kapusta, K.; Stańczyk, K. Pollution of water during underground coal gasification of hard coal and lignite. Fuel 2011, 90, 1927–1934. [Google Scholar] [CrossRef]

- Kapusta, K.; Wiatowski, M.; Stańczyk, K. An experimental ex-situ study of the suitability of a high moisture ortho-lignite for underground coal gasification (UCG) process. Fuel 2016, 179, 150–155. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, Y.; Hou, T.; Jin, Y.; Wang, C.; Liang, J. Large-scale laboratory study on the evolution law of temperature fields in the context of underground coal gasification. Chin. J. Chem. Eng. 2020, 28, 3126–3135. [Google Scholar] [CrossRef]

- Winslow, A.M. Numerical model of coal gasification in a packed bed. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1977; Volume 16, pp. 503–513. [Google Scholar]

- Tsang, T.H.T. Modeling of Heat and Mass Transfer during Coal Block Gasification; The University of Texas at Austin: Austin, TX, USA, 1980. [Google Scholar]

- Massaquoi JG, M.; Riggs, J.B. Mathematical modeling of combustion and gasification of a wet coal slab—I: Model development and verification. Chem. Eng. Sci. 1983, 38, 1747–1756. [Google Scholar] [CrossRef]

- Massaquoi JG, M.; Riggs, J.B. Mathematical modeling of combustion and gasification of a wet coal slab—II: Mode of combustion, steady state multiplicities and extinction. Chem. Eng. Sci. 1983, 38, 1757–1766. [Google Scholar] [CrossRef]

- Park, K.Y.; Edgar, T.F. Modeling of early cavity growth for underground coal gasification. Ind. Eng. Chem. Res. 1987, 26, 237–246. [Google Scholar] [CrossRef]

- Perkins, G.; Sahajwalla, V. A mathematical model for the chemical reaction of a semi-infinite block of coal in underground coal gasification. Energy Fuels 2005, 19, 1679–1692. [Google Scholar] [CrossRef]

- Perkins, G.; Sahajwalla, V. A numerical study of the effects of operating conditions and coal properties on cavity growth in underground coal gasification. Energy Fuels 2006, 20, 596–608. [Google Scholar] [CrossRef]

- Perkins, G.; Sahajwalla, V. Steady-state model for estimating gas production from underground coal gasification. Energy Fuels 2008, 22, 3902–3914. [Google Scholar] [CrossRef]

- Luo, Y.; Coertzen, M.; Dumble, S. Comparison of UCG cavity growth with CFD model predictions. In Proceedings of the Seventh International Conference on CFD in the Minerals and Process Industries (CSIRO), Melbourne, Australia, 9–11 December 2009. [Google Scholar]

- Samdani, G.; Aghalayam, P.; Ganesh, A.; Sapru, R.K.; Lohar, B.L.; Mahajani, S. A process model for underground coal gasification–Part-I: Cavity growth. Fuel 2016, 181, 690–703. [Google Scholar] [CrossRef]

- Samdani, G.; Aghalayam, P.; Ganesh, A.; Sapru, R.K.; Lohar, B.L.; Mahajani, S. A process model for underground coal gasification–Part-II growth of outflow channel. Fuel 2016, 181, 587–599. [Google Scholar] [CrossRef]

- Samdani, G.; Aghalayam, P.; Ganesh, A.; Mahajani, S. A process model for underground coal gasification–Part-III: Parametric studies and UCG process performance. Fuel 2018, 234, 392–405. [Google Scholar] [CrossRef]

- Xin, L.; Wang, Z.; Huang, W.; Kang, G.; Lu, X.; Zhang, P.; Wang, J. Temperature field distribution of burnt surrounding rock in UCG stope. Int. J. Min. Sci. Technol. 2014, 24, 573–580. [Google Scholar] [CrossRef]

- Jowkar, A.; Sereshki, F.; Najafi, M. A new model for evaluation of cavity shape and volume during Underground Coal Gasification process. Energy 2018, 148, 756–765. [Google Scholar] [CrossRef]

- Nourozieh, H.; Kariznovi, M.; Chen, Z.; Abedi, J. Simulation study of underground coal gasification in Alberta reservoirs: Geological structure and process modeling. Energy Fuels 2010, 24, 3540–3550. [Google Scholar] [CrossRef]

- Sarraf Shirazi, A.; Karimipour, S.; Gupta, R. Numerical simulation and evaluation of cavity growth in in situ coal gasification. Ind. Eng. Chem. Res. 2013, 52, 11712–11722. [Google Scholar] [CrossRef]

- Seifi, M.; Chen, Z.; Abedi, J. Numerical simulation of underground coal gasification using the CRIP method. Can. J. Chem. Eng. 2011, 89, 1528–1535. [Google Scholar] [CrossRef]

- Kasani, H.A.; Chalaturnyk, R.J. Coupled reservoir and geomechanical simulation for a deep underground coal gasification project. J. Nat. Gas Sci. Eng. 2017, 37, 487–501. [Google Scholar] [CrossRef]

- Jiang, L.; Chen, S.; Chen, Y.; Chen, Z.; Sun, F.; Dong, X.; Wu, K. Underground coal gasification modelling in deep coal seams and its implications to carbon storage in a climate-conscious world. Fuel 2023, 332, 126016. [Google Scholar] [CrossRef]

- Mathy, B. Flow modeling in an underground gasifier at great depth by the boundary element method. Fuel Energy Abstr. 1995, 4, 254. [Google Scholar]

- Pang, X.L.; Chen, F. Model test research on the temperature field of underground coal gasification with water influx and oxygen-enriched. J. China Coal Soc. 2011, 36, 151–155. (In Chinese) [Google Scholar]

- Verma, R.P.; Mandal, R.; Chaulya, S.K.; Singh, P.K.; Singh, A.K.; Prasad, G.M. Contamination of groundwater due to underground coal gasification. Int. J. Water Resour. Environ. Eng. 2014, 6, 303–311. [Google Scholar]

- Liu, S.; Liang, J.; Yu, X.; Lu, L. Characteristics of underground gasification of different kinds of coal. J. China Univ. Min. Technol. 2003, 32, 624–628. (In Chinese) [Google Scholar]

- Li, H.; Guo, G.; Zheng, N. Influence of coal types on overlying strata movement and deformation in underground coal gasification without shaft and prediction method of surface subsidence. Process Saf. Environ. Prot. 2018, 120, 302–312. [Google Scholar] [CrossRef]

- Liu, X.; Guo, G.; Li, H. Study on the propagation law of temperature field in surrounding rock of underground coal gasification (UCG) combustion cavity based on dynamic thermal parameters. Results Phys. 2019, 12, 1956–1963. [Google Scholar] [CrossRef]

- Liu, S.Q.; Wang, Y.Y.; Ke, Z.; Ning, Y.A.N.G. Enhanced-hydrogen gas production through underground gasification of lignite. Min. Sci. Technol. 2009, 19, 389–394. [Google Scholar] [CrossRef]

- Jiang, L.; Chen, Z.; Ali SM, F. Thermal-hydro-chemical-mechanical alteration of coal pores in underground coal gasification. Fuel 2020, 262, 116543. [Google Scholar] [CrossRef]

- Wall, T.F.; Liu, G.S.; Wu, H.W.; Roberts, D.G.; Benfell, K.E.; Gupta, S.; Lucas, J.A.; Harris, D.J. The effects of pressure on coal reactions during pulverised coal combustion and gasification. Prog. Energy Combust. Sci. 2002, 28, 405–433. [Google Scholar] [CrossRef]

- Kariznovi, M.; Nourozieh, H.; Abedi, J.; Chen, Z. Simulation study and kinetic parameter estimation of underground coal gasification in Alberta reservoirs. Chem. Eng. Res. Des. 2013, 91, 464–476. [Google Scholar] [CrossRef]

- MacNeil, S.; Basu, P. Effect of pressure on char combustion in a pressurized circulating fluidized bed boiler. Fuel 1998, 77, 269–275. [Google Scholar] [CrossRef]

- Makino, M.; Toda, Y. Factors affecting methane evolution on pyrolysis of coal under pressure. Fuel 1979, 58, 231–234. [Google Scholar] [CrossRef]

- Shirazi, A.S. CFD Simulation of Underground Coal Gasification. In Masters Abstracts International; University Microfilms International: Edmonton, AB, Canada, 2012; Volume 51. [Google Scholar]

- Jowkar, A.; Sereshki, F.; Najafi, M. Numerical simulation of UCG process with the aim of increasing calorific value of syngas. Int. J. Coal Sci. Technol. 2020, 7, 196–207. [Google Scholar] [CrossRef]

- Javed, S.B.; Uppal, A.A.; Bhatti, A.I.; Samar, R. Prediction and parametric analysis of cavity growth for the underground coal gasification project Thar. Energy 2019, 172, 1277–1290. [Google Scholar] [CrossRef]

- Daggupati, S.; Mandapati, R.N.; Mahajani, S.M.; Ganesh, A.; Pal, A.K.; Sharma, R.K.; Aghalayam, P. Compartment modeling for flow characterization of underground coal gasification cavity. Ind. Eng. Chem. Res. 2011, 50, 277–290. [Google Scholar] [CrossRef]

- Prabu, V.; Jayanti, S. Laboratory scale studies on simulated underground coal gasification of high ash coals for carbon-neutral power generation. Energy 2012, 46, 351–358. [Google Scholar] [CrossRef]

| No. | Set | Equation |

|---|---|---|

| 1 | Conservation of mass | |

| 2 | Conservation of species | |

| 3 | Conservation of momentum | |

| 4 | Conservation of energy | |

| 5 | Conservation of turbulent kinetic energy | |

| 6 | Conservation of energy dissipation | |

| 7 | Conservation of species at wall | |

| 8 | Stress tensor for each phase β | |

| 9 | Source term for phase β | |

| 10 | Source term for species i phase β | |

| 11 | Interphase constraint | |

| 12 | Reaction source for species i phase β | |

| 13 | Mass transfer of matter |

| Country | Test Site | Year | Seam Depth (m) | Technique |

|---|---|---|---|---|

| U.S.S.R | Podmoskova | 1940–1962 | 40 | LVW |

| Shatskaya | 1959 | 50 | LVW | |

| Angrenskaja | 1961 | 150 | LVW | |

| USA | Hanna series tests | 1973–1977 | 85–120 | LVW |

| Hoe Creek series tests | 1976–1979 | 40 | LVW | |

| Rawlins series tests | 1979 | 105–180 | ||

| Pricetown | 1979 | 270 | LVW | |

| Centralia series tests | 1984–1985 | 75 | LVW/CRIP | |

| Rocky Mountain | 1987–1988 | 110 | LVW/CRIP | |

| France | Bruayen Artois | 1979–1981 | 1170 | Drilling-type |

| Haute-Duele | 1985–1986 | 880 | ||

| Belgium | Thulin | 1982–1984 | 860 | LVW |

| Spain | El Tremedal | 1997 | 500–700 | CRIP |

| Australia | Chinchilla series tests | 2000–2013 | 130 | CRIP |

| Bloodwood Ck series tests | 2009–2011 | 200 | CRIP | |

| South Africa | Majuba test | 2007–2011 | 250–380 | Drilling-type |

| Poland | Wieczorek | 2014 | 464 | |

| China | Xinwen, Xuzhou, Tangshan, Gansu | 1985–2010 | 80–200 | Shaft type |

| Ulanqab | 2007–2012 | 285 | Drilling-type | |

| Canada | Swan Hills | 2007–2012 | 1400 | CRIP |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, H.; Liu, Y.; Ge, T.; Zheng, T.; Yu, Y.; Liu, D.; Ding, J.; Li, L. A Review of Research on Cavity Growth in the Context of Underground Coal Gasification. Energies 2022, 15, 9252. https://doi.org/10.3390/en15239252

Fang H, Liu Y, Ge T, Zheng T, Yu Y, Liu D, Ding J, Li L. A Review of Research on Cavity Growth in the Context of Underground Coal Gasification. Energies. 2022; 15(23):9252. https://doi.org/10.3390/en15239252

Chicago/Turabian StyleFang, Huijun, Yuewu Liu, Tengze Ge, Taiyi Zheng, Yueyu Yu, Danlu Liu, Jiuge Ding, and Longlong Li. 2022. "A Review of Research on Cavity Growth in the Context of Underground Coal Gasification" Energies 15, no. 23: 9252. https://doi.org/10.3390/en15239252

APA StyleFang, H., Liu, Y., Ge, T., Zheng, T., Yu, Y., Liu, D., Ding, J., & Li, L. (2022). A Review of Research on Cavity Growth in the Context of Underground Coal Gasification. Energies, 15(23), 9252. https://doi.org/10.3390/en15239252