Characteristics of Generic Dielectric Materials and Char as Bed Materials of a Dielectric Barrier Discharge Reactor under High Temperature and Wide Frequency Range

Abstract

1. Introduction

2. Present Literature

2.1. Solid Materials Intended to Be Used as the Bed in a DBD Reactor

2.2. Current “Know-How” on the Electrical Properties of Bed Materials

- The surface and volumetric behaviour of DBD bed materials with respect to the temperature and frequency.

- The typical characteristics of the char material and their temperature dependency.

3. Procedure

4. Sample Preparation and Test Cell

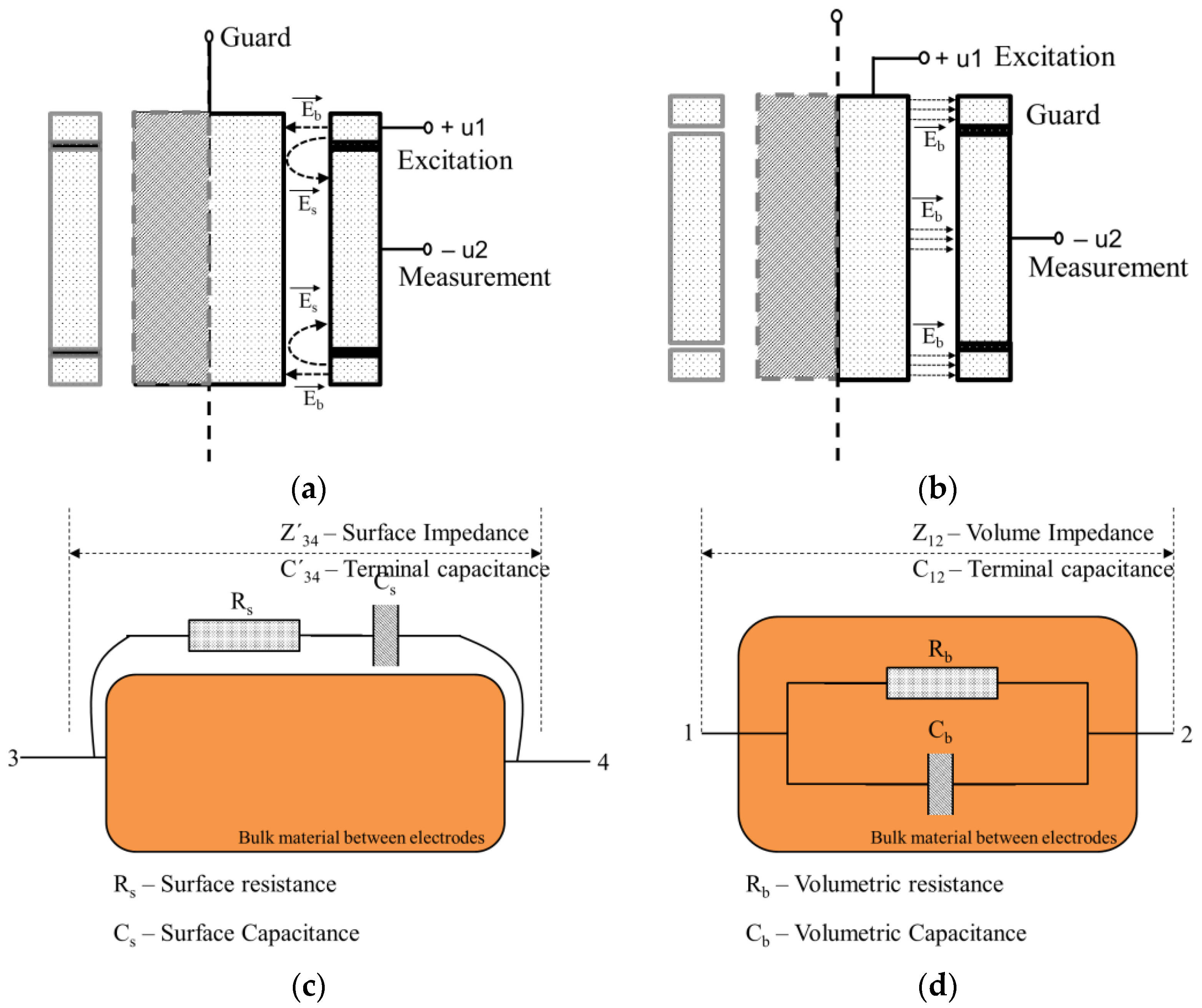

5. Measurement Principle

6. Experiments

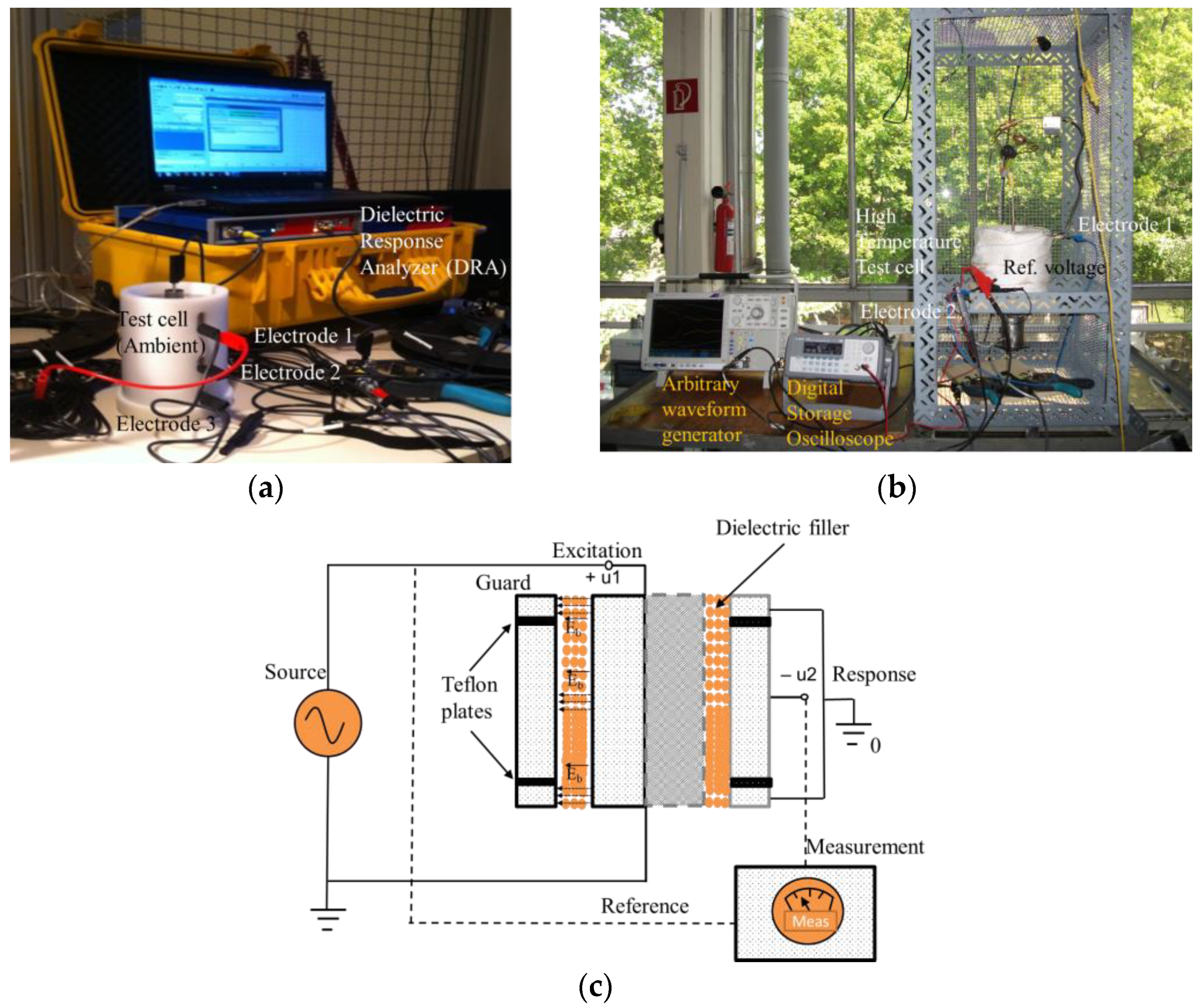

6.1. Frequency-Dependent Test Method

6.2. Measuring Electrical Properties under Ambient Temperature

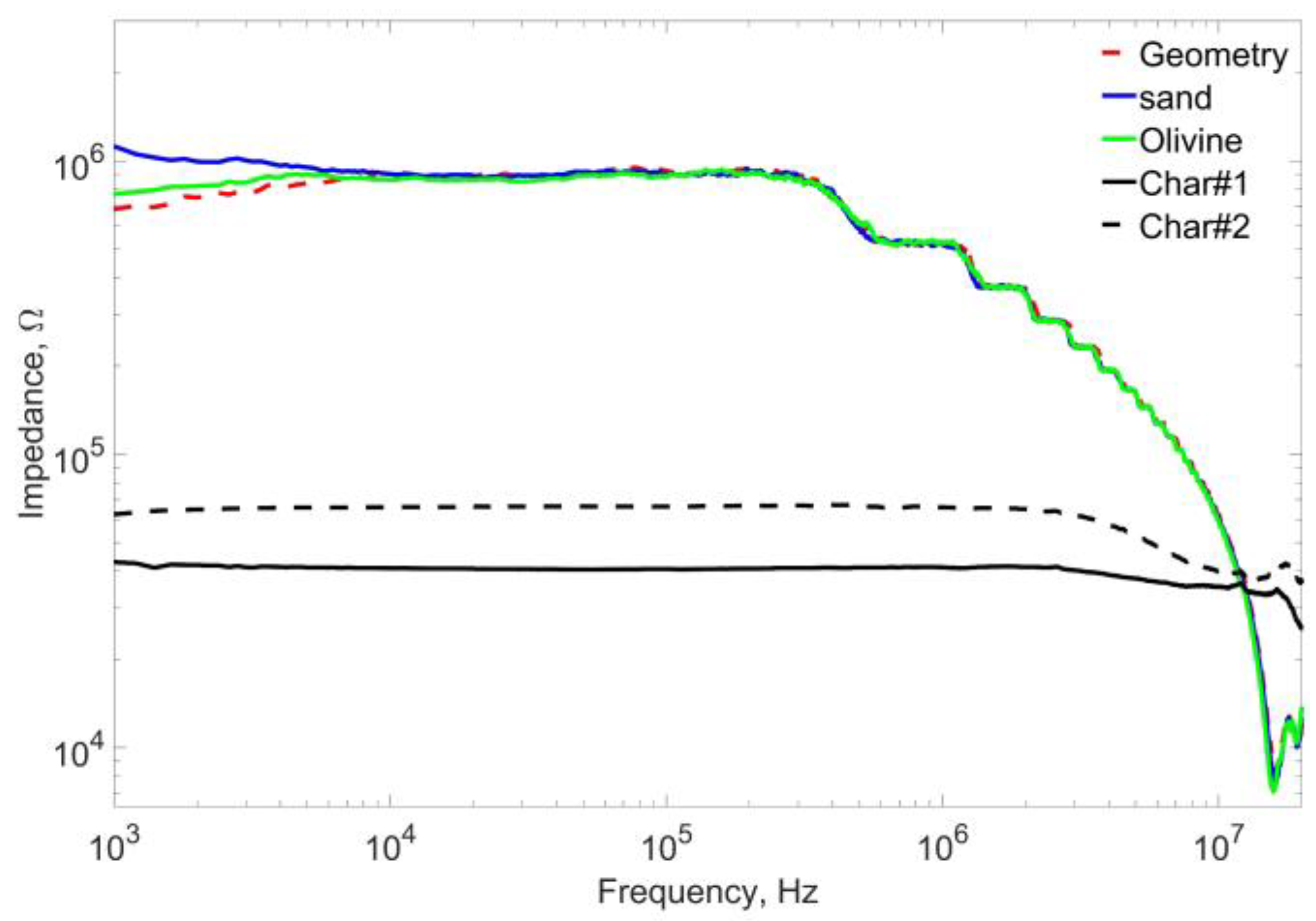

6.3. High-Frequency Impedance of the Char and Bed Materials at Ambient Temperature

6.4. Electrical Properties of Char as a Bed Material at a Higher Temperature

7. Inferences

- The experimental results obtained give evidence that the loss factor measured at ambient temperature from the surface and volumetric parameters of the chosen DBD reactor bed materials manifested significant differences with the applied frequency. The surface and volumetric loss factor quantifies the energy lost in the material; the capacitances indicate the ability of the material to store charges; surface resistance provides information on the apparent material’s conductivity caused by the frequency-dependent polarisation. The surface parametric loss factor of the quartz sand and air emerged with lower values throughout the frequency span, thereby qualified as better materials. Comparatively, the capacitance of the surface of the test cell and quartz sand measured remained close to each other at higher frequencies. A further decrease in frequency caused a slight increase in the surface capacitance of the quartz sand, indicating a slightly better ability to store charges, contributed by the barriers and junctions formed by the quartz sand granules. Contrary to this, the surface parameter of the olivine material emerged with a higher loss factor at lower frequencies, which monotonically reduced with increasing frequency. The olivine with a higher dielectric constant manifested a higher ability to store charges on its surface at lower frequencies. As the frequency increased, the surface capacitance of the olivine decreased exponentially. Considering its surface resistance, which is lower than the quartz sand and air, it is possible to expect dominant conductivity in the olivine due to polarisation mechanism, making it higher in dielectric loss.

- The volumetric response of the chosen DBD reactor materials at ambient temperature remained more of less similar to that of the surface parametric measurements. The quartz sand and test cell (with air as the medium) emerged as better materials with a loss factor less than the olivine material. The pertinent volumetric response of the material indicated that the quartz sand and geometry of the test cell emerged with a loss factor lower than 1.0, while the same for the olivine was close to 10. Similar observations can be made from the volumetric capacitance, resistance, and impedance measured from the chosen DBD reactor materials. The volumetric capacitance of the olivine showed higher values at lower frequencies, indicating the ability of the bulk material to aid in storing charges in response to the applied voltage, which decreased exponentially with increasing frequency.

- The impedance measured at high frequencies collectively provided the overall response of the material. The measured impedance collectively described the typical behaviour of the frequency-dependent relaxation process containing several characteristic frequencies. The resistance and capacitive reactance of the impedance carry information regarding the characteristics of the material’s conductivity and its ability to store the charges due to its capacitive nature. The dielectric material’s conductivity was contributed by the polarisation mechanism (relaxation process), while the permittivity (or capacitance) indicated the ability of the material to store charges, thereby to confine an electric field within the desired location. It emerged from these experiments that the surface impedance of the chosen DBD materials manifested differences at lower frequencies, i.e., in the kHz range. A further increase in the frequency forced the surface impedances to match, which dropped to a lower value. At the same time, the volumetric impedance of the chosen materials remained the same throughout the frequency range.

- Char, being a carbonaceous material, is predominantly conductive in nature. Therefore, the electrical property of char implies recording and characterising the surface and volumetric components of resistance and impedance at ambient and high temperature over a wide frequency range. It is understood through experiments that the surface of the char is more responsive than the bulk material. The resistance measured from the surface and volume of the char under ambient temperature remained constant with frequency. At the same time, the temperature dependency of the char seemed to be different. The temperature dependency of the surface and volumetric resistance seemed to be oscillatory at low frequencies. At lower frequencies, the surface and volumetric resistance increased with the temperature until a higher threshold value, beyond which, the same dropped until it reached a lower threshold value. A similar trend can be observed from the impedance function only at lower frequencies. At higher frequencies, the surface and volumetric resistance seemed to drop with temperature, reached a steady lower value, and remained at the same.

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Akdemir, M.; Hansu, F. Effect of Dielectric Barrier Discharges on the Elimination of Some Flue Gases. IEEE Trans. Plasma Sci. 2020, 48, 1030–1034. [Google Scholar] [CrossRef]

- Kogelschatz, U. Dielectric-barrier discharges: Their history, discharge physics, and industrial applications. Plasma. Chem. Plasma Process. 2003, 23, 1–46. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, Z.; Liu, F.; Wang, S. Study of NO/NOx removal from flue gas contained fly ash and water vapor by pulsed corona discharge. J. Electrost. 2005, 63, 155–164. [Google Scholar] [CrossRef]

- Ma, H.; Chen, P.; Zhang, M.; Lin, X.; Ruan, R. Study of SO2 removal using non-thermal plasma induced by dielectric barrier discharge (DBD). Plasma Chem. Plasma Process. 2002, 22, 239–254. [Google Scholar] [CrossRef]

- Ma, S.; Zhao, Y.; Yang, J.; Zhang, S.; Zhang, J.; Zheng, C. Research progress of pollutants removal from coal-fired flue gas using non-thermal plasma. Renew. Sustain. Energy Rev. 2017, 67, 791–810. [Google Scholar] [CrossRef]

- Arumugam, S.; Schröder, P.; Neubauer, Y.; Schoenemann, T. Dielectric and Partial Discharge Investigations on Ceramic Insulator Contaminated with Condensable Hydrocarbons. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2512–2524. [Google Scholar] [CrossRef]

- Schröder, P.; Arumugam, S.; Neubauer, Y. Application of Non-Thermal Plasma for Improving Producer Gas Quality. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; pp. 553–557. [Google Scholar]

- Parvulescu, V.I.; Magureanu, M.; Lukes, P. Plasma Chemistry and Catalysis in Gases, and Liquids; Wiley-VCH: Weinheim, Germany, 2012; ISBN 978-3-527-33006-5. [Google Scholar]

- Takaki, K.; Jani, M.A.; Fujiwara, T. Removal of nitric oxide in flue gases by multi-point to plane dielectric barrier discharge. IEEE Trans. Plasma Sci. 1999, 27, 1137–1145. [Google Scholar] [CrossRef]

- Anaghizi, S.J.; Talebizadeh, P.; Rahimzadeh, H.; Ghomi, H. The configuration effects of electrode on the performance of dielectric barrier discharge reactor for NOx removal. IEEE Trans. Plasma Sci. 2015, 43, 1944–1953. [Google Scholar] [CrossRef]

- Urashima, K.; Chang, J.-S.; Ito, T. Reduction of NOx from combustion flue gases by superimposed barrier discharge plasma reactors. IEEE Trans. Ind. Appl. 1997, 33, 879–886. [Google Scholar] [CrossRef]

- Sijia, N.I.; Yixi, C.A.I.; Yunxi, S.H.I.; Weikai, W.A.N.G.; Nan, Z.H.A.O.; Yirui, L.U. Effects of packing particles on the partial discharge behavior and the electrical characterization of oxygen PBRs. Plasma Sci. Technol. 2020, 23, 015405. [Google Scholar]

- Takaki, K.; Urashima, K.; Chang, J. Ferro-electric pellet shape effect on C2F6 removal by a packed-bed-type nonthermal plasma reactor. IEEE Trans. Plasma Sci. 2004, 32, 2175–2183. [Google Scholar] [CrossRef]

- Chen, M.; Jin, L.; Liu, Y.; Guo, X.; Chu, J. Decomposition of NO in automobile exhaust by plasma–photocatalysis synergy. Environ. Sci. Pollut. Res. 2014, 21, 1242–1247. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Sun, B.-M. Effects of O2 and H2O on SO2 removal by dielectric barrier discharge at various temperatures. Jpn. J. Appl. Phys. 2014, 53, 046201. [Google Scholar] [CrossRef]

- Pham, H.-C.; Kim, K.-S. Effect of TiO2 thin film thickness on NO and SO2 removals by dielectric barrier discharge-photocatalyst hybrid process. Ind. Eng. Chem. Res. 2013, 52, 5296–5301. [Google Scholar] [CrossRef]

- Pang, Y.; Bahr, L.; Fendt, P.; Zigan, L.; Will, S.; Hammer, T.; Baldauf, M.; Fleck, R.; Müller, D.; Karl, J. Plasma-Assisted Biomass Gasification with Focus on Carbon Conversion and Reaction Kinetics Compared to Thermal Gasification. Energies 2018, 11, 1302. [Google Scholar] [CrossRef]

- Roland, U.; Holzer, F.; Kopinke, F.-D. Combination of non-thermal plasma and heterogeneous catalysis for oxidation of volatile organic compounds: Part 2. Ozone decomposition and deactivation of γ-Al2O3. Appl. Catal. B Environ. 2005, 58, 217–226. [Google Scholar] [CrossRef]

- Pekarek, S. Experimental study of surface dielectric barrier discharge in air and its ozone production. J. Phys. D Appl. Phys. 2012, 45, 075201. [Google Scholar] [CrossRef]

- Dwivedi, C.; Toley, M.A.; Dey, G.R.; Das, T.N. Ozone Generation from Argon-Oxygen Mixtures in Presence of Different Packing Materials within Dielectric Barrier Discharge Gap. Ozone Sci. Eng. 2015, 35, 134–145. [Google Scholar] [CrossRef]

- Huang, W.; Ren, T.; Xia, W. Ozone Generation by Hybrid Discharge Combined with Catalysis. Ozone Sci. Eng. 2013, 29, 107–112. [Google Scholar] [CrossRef]

- Kostov, K.G.; Honda, R.Y.; Kayama, M.E.; Alves, L.S.M. Characteristics of dielectric barrier discharge reactor for material treatment. Braz. J. Phys. 2009, 39, 322–325. [Google Scholar] [CrossRef]

- Liu, L.-J.; Li, X.-X.; Wang, H.; Xue, B.; Zheng, X.-M.; Chen, M. Application of combined plasma-catalytic method for carbon particulate matter (PM) removal. Royal Soc. Adv. 2015, 5, 40012–40017. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Nguyen, D.B.; Heo, I.; Mok, Y.S. Plasma-Assisted Selective Catalytic Reduction for Low-Temperature Removal of NOx and Soot Simulant. Catalysts 2019, 9, 853. [Google Scholar] [CrossRef]

- Ray, D.; Chawdhury, P.; Subrahmanyam, C. A facile method to decompose CO2 using a g-C3N4-assisted DBD plasma reactor. Environ. Res. 2020, 183, 109286. [Google Scholar] [CrossRef] [PubMed]

- Ray, D.; Subrahmanyam, C. CO2 decomposition in a packed DBD plasma reactor: Influence of packing materials. Royal Sci. Chem. Adv. 2016, 6, 39492–39499. [Google Scholar]

- Mei, D.; Zhu, X.; He, Y.L.; Yan, J.D.; Tu, X. Plasma-assisted conversion of CO2 in a dielectric barrier discharge reactor: Understanding the effect of packing materials. Plasma Sources Sci. Technol. 2015, 24, 015011. [Google Scholar] [CrossRef]

- Marzec, A.; Czaijkowska, S.; Moszynski, J. Electrical resistivity of carbonized coals. Energy Fuels 1994, 8, 1296–1303. [Google Scholar] [CrossRef]

- Challa, S.; Little, W.E.; Cha, C.Y. Measurement of the dielectric properties of char at 2.45 GHz. J. Microw. Power Electromagn. Energy 1994, 29, 131–137. [Google Scholar] [CrossRef]

- Eidem, P.A. Electrical Resistivity of Coke Beds. Ph.D. Thesis, Norwegian University, Trondheim, Norway, 2008. [Google Scholar]

- Duba, A.G. Electrical conductivity of coal and coal char. Fuel 1977, 56, 441–443. [Google Scholar] [CrossRef]

- Koei, N.A.; Hata, T.; Ishihara, S. Mechanism and clarification of electrical conduction through wood charcoal. Wood Res. 1995, 82, 34–36. [Google Scholar]

- Lucas, J. Bestimmung des spezifischen elektrischen Widerstands mit einer speziellen Messzelle. Tech. Sicherh. Bd 2011, 1, 33–36. [Google Scholar]

- Teipel, U.; Wolf, S.; Schreiber, A. Durchgangswiderstand von partikulären Systemen. Chem. Ing. Tech. 2020, 92, 229–237. [Google Scholar] [CrossRef]

- Arumugam, S. Theoretical Considerations While Applying Frequency Response Analysis Method in Determining the Inter-Winding Capacitance of Power Transformers at Higher Frequencies. Eng. Rep. 2019, 1, e12036. [Google Scholar]

- Panda, N. Complex impedance spectroscopy for monitoring frequency response to the electrical properties of polycrystalline materials. Int. J. Intellig. Comp. Appl. Sci. 2016, 4, 14–19. [Google Scholar]

| Dielectric Material Filling in Cell | Frequency | Surface Parameter | |||

|---|---|---|---|---|---|

| Loss Factor | Capacitance | Resistance | Impedance | ||

| Hz | p.u. | pF | GΩ | MΩ | |

| Air | 1 | 0.0199 | 160.820 | 49.797 | 989.451 |

| 50 | 0.0122 | 154.714 | 1.690 | 20.573 | |

| 103 | 0.0039 | 153.022 | 0.268 | 1.040 | |

| Quartz Sand | 1 | 0.2128 | 178.258 | 4.196 | 873.285 |

| 50 | 0.0359 | 154.817 | 0.572 | 20.547 | |

| 103 | 0.0075 | 150.655 | 0.140 | 1.056 | |

| Olivine | 1 | 26.486 | 267.437 | 11.881 | 22.453 |

| 50 | 0.7328 | 197.961 | 21.943 | 12.970 | |

| 103 | 0.0738 | 181.434 | 11.881 | 0.875 | |

| Dielectric Material Filling in Cell | Frequency | Volume Parameter | |||

|---|---|---|---|---|---|

| Loss Factor | Capacitance | Resistance | Impedance | ||

| Hz | p.u. | pF | GΩ | MΩ | |

| Air | 1 | 0.2380 | 14.376 | 46.251 | 10,770.0 |

| 50 | 0.1741 | 7.459 | 2.4510 | 420.413 | |

| 103 | 0.0365 | 6.574 | 0.6630 | 24.194 | |

| Quartz Sand | 1 | 1.4802 | 51.245 | 2.0980 | 1739.0 |

| 50 | 0.4465 | 16.736 | 0.4259 | 425.920 | |

| 103 | 0.1033 | 11.864 | 0.1298 | 129.859 | |

| Olivine | 1 | 9.3966 | 246.705 | 68.655 | 68.269 |

| 50 | 0.7711 | 86.173 | 47.90 | 29.251 | |

| 103 | 0.2269 | 63.285 | 11.085 | 2.453 | |

| Material | Frequencies Ranging 1 Hz to 103 Hz | Frequency 103 Hz to 106 Hz | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Surface Impedance (ZL) | Volume Impedance (ZL) | Surface (ZV) | Volume (ZV) | |||||||

| 1 | 50 | 103 | 1 Hz | 50 Hz | 103 | 104 | 104 | 104 | 104 | |

| MΩ | MΩ | MΩ | MΩ | MΩ | MΩ | MΩ | MΩ | MΩ | MΩ | |

| Air | 989.451 | 20.573 | 1.040 | 10,770.0 | 420.413 | 24.194 | 0.8881 | 0.5283 | 1.024 | 0.9532 |

| $ Sand | 873.285 | 20.547 | 1.056 | 1739.0 | 425.920 | 129.859 | 0.9041 | 0.5201 | 0.8742 | 0.8738 |

| Olivine | 22.453 | 12.970 | 0.875 | 68.269 | 29.251 | 2.453 | 0.8623 | 0.5265 | 0.9038 | 0.9174 |

| Char1 | – | – | – | – | – | – | 0.0660 | 0.0659 | 0.0332 | 0.0338 |

| Char2 | – | – | – | – | – | – | 0.0409 | 0.0412 | 0.0327 | 0.336 |

| Temperature | Low Frequency 100–103 Hz | High Frequency 104–106 Hz | ||||

|---|---|---|---|---|---|---|

| Surface Parameter | Volume Parameter | Surface | Volume | |||

| Resistance | Impedance | Resistance | Impedance | Impedance | Impedance | |

| θ | RSL | ZSL | RVL | ZVL | ZSH | ZVH |

| °C | Ω | Ω | Ω | Ω | Ω | Ω |

| 20 | 9.972 | 9.958 | 4.355 | 4.323 | 105.3 | 28.78 |

| 120 | 36.075 | 36.071 | 25.494 | 255.489 | 12.86 | 10.2 |

| 220 | 59.227 | 59.225 | 31.674 | 31.670 | 4.628 | 7.956 |

| 400 | 24.712 | 24.707 | 10.068 | 10.068 | 15.930 | 4.652 |

| 500 | 12.230 | 12.217 | 6.962 | 6.985 | – | – |

| 555 | 8.126 | 8.109 | 5.326 | 5.326 | – | 2.6 |

| 650 | 25.098 | 25.091 | 12.116 | 12.116 | – | 2.211 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arumugam, S.; Schröder, P.; Schoenemann, T.; Neubauer, Y. Characteristics of Generic Dielectric Materials and Char as Bed Materials of a Dielectric Barrier Discharge Reactor under High Temperature and Wide Frequency Range. Energies 2022, 15, 9241. https://doi.org/10.3390/en15239241

Arumugam S, Schröder P, Schoenemann T, Neubauer Y. Characteristics of Generic Dielectric Materials and Char as Bed Materials of a Dielectric Barrier Discharge Reactor under High Temperature and Wide Frequency Range. Energies. 2022; 15(23):9241. https://doi.org/10.3390/en15239241

Chicago/Turabian StyleArumugam, Saravanakumar, Philipp Schröder, Thomas Schoenemann, and York Neubauer. 2022. "Characteristics of Generic Dielectric Materials and Char as Bed Materials of a Dielectric Barrier Discharge Reactor under High Temperature and Wide Frequency Range" Energies 15, no. 23: 9241. https://doi.org/10.3390/en15239241

APA StyleArumugam, S., Schröder, P., Schoenemann, T., & Neubauer, Y. (2022). Characteristics of Generic Dielectric Materials and Char as Bed Materials of a Dielectric Barrier Discharge Reactor under High Temperature and Wide Frequency Range. Energies, 15(23), 9241. https://doi.org/10.3390/en15239241