Sintering of Industrial Uranium Dioxide Pellets Using Microwave Radiation for Nuclear Fuel Fabrication

Abstract

:1. Introduction

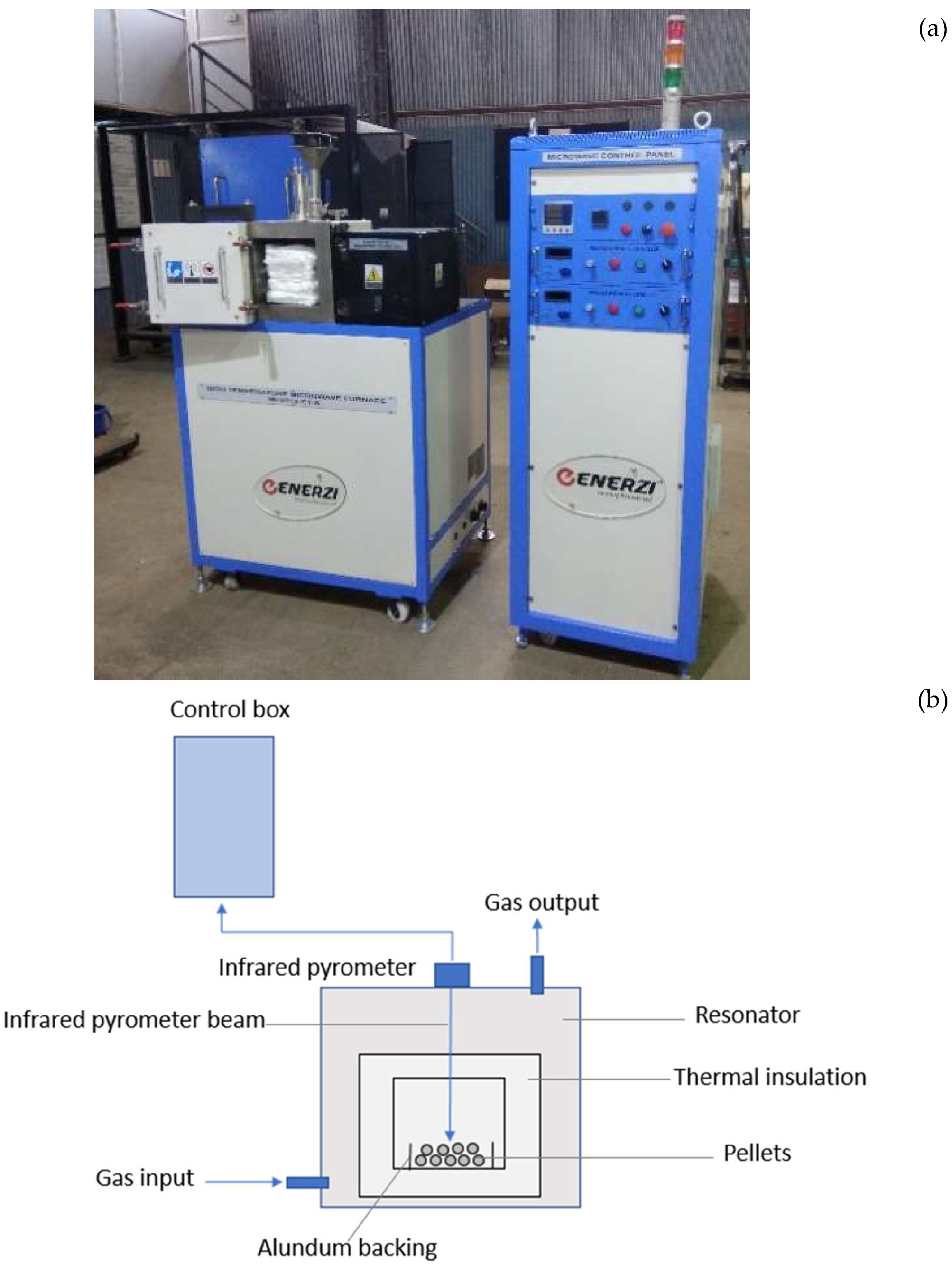

2. Materials and Methods

3. Results and Discussion

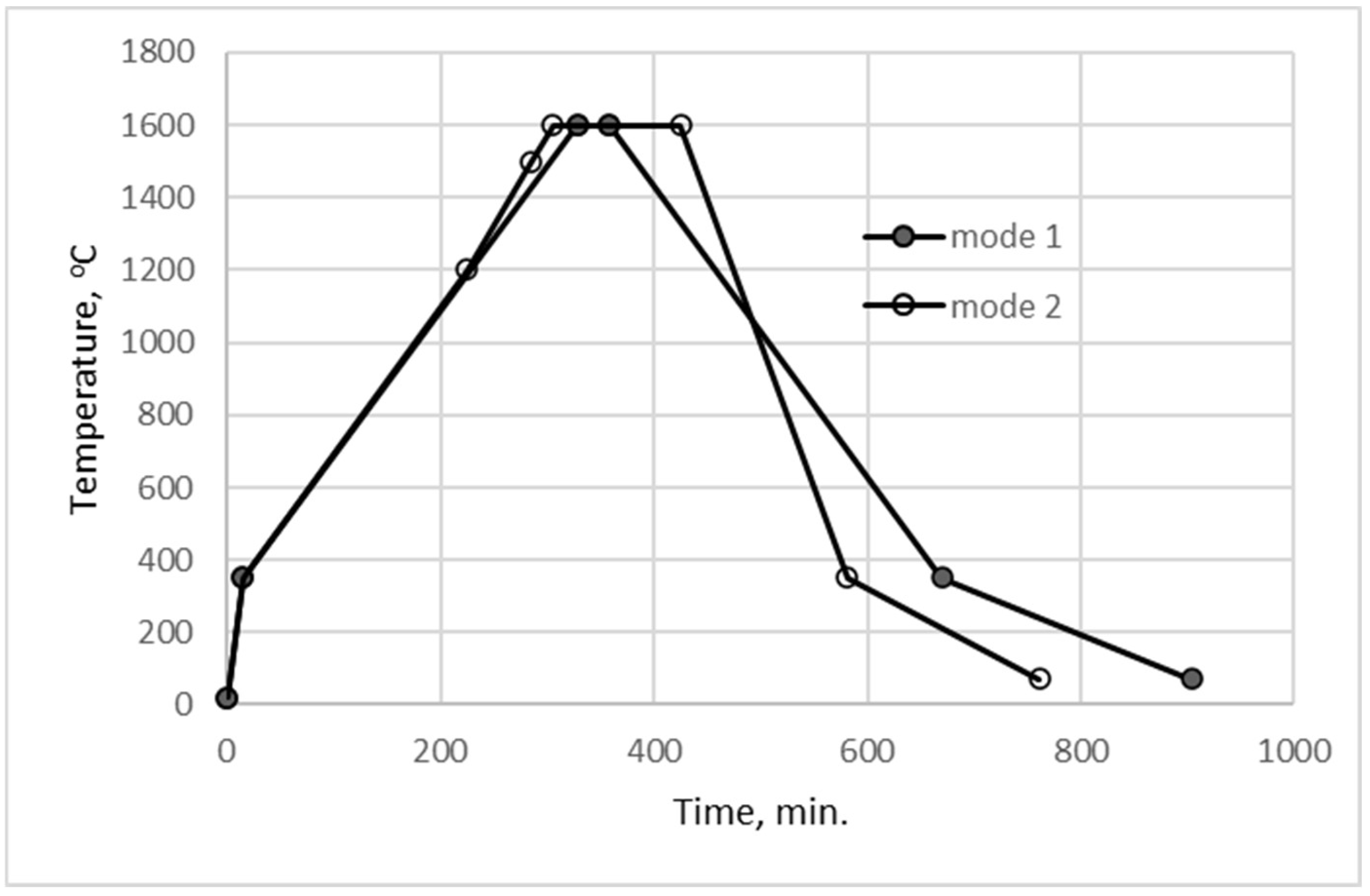

3.1. Selection of the Microwave Sintering Mode for Fuel Pellets

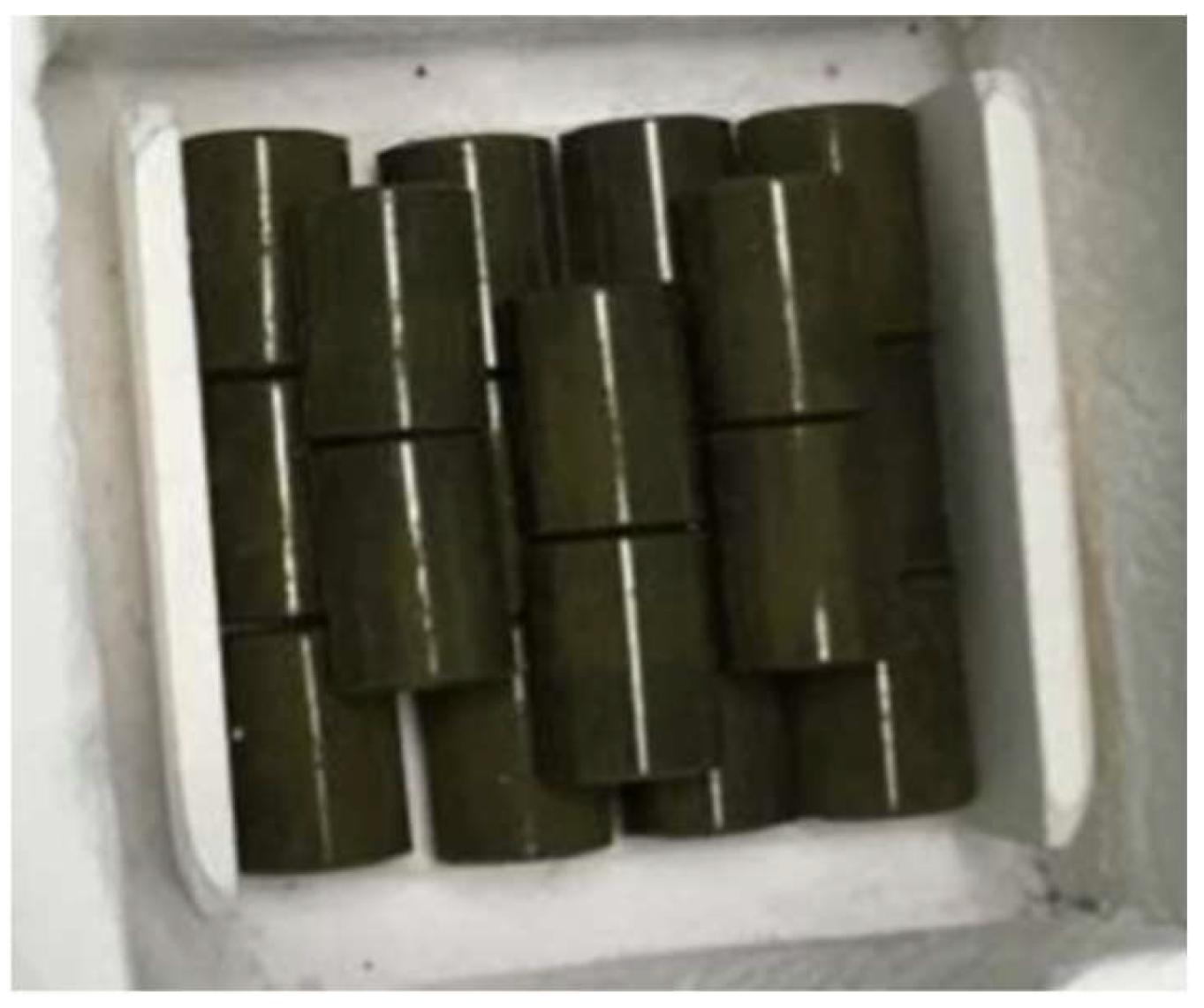

3.2. Selection of the Geometry of the Placement of “Raw” Tablets in the Substrate during Sintering in a Pilot Microwave Setup

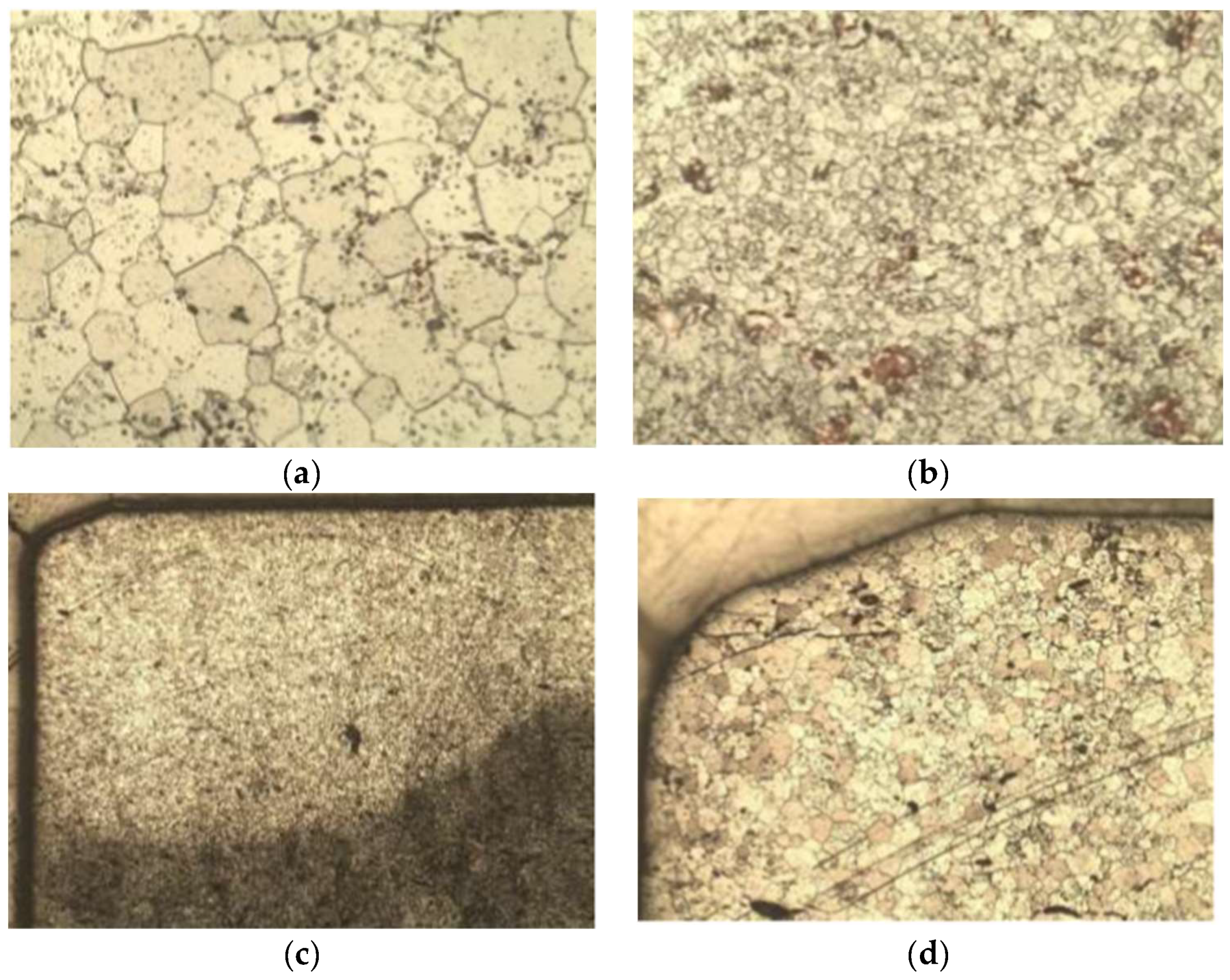

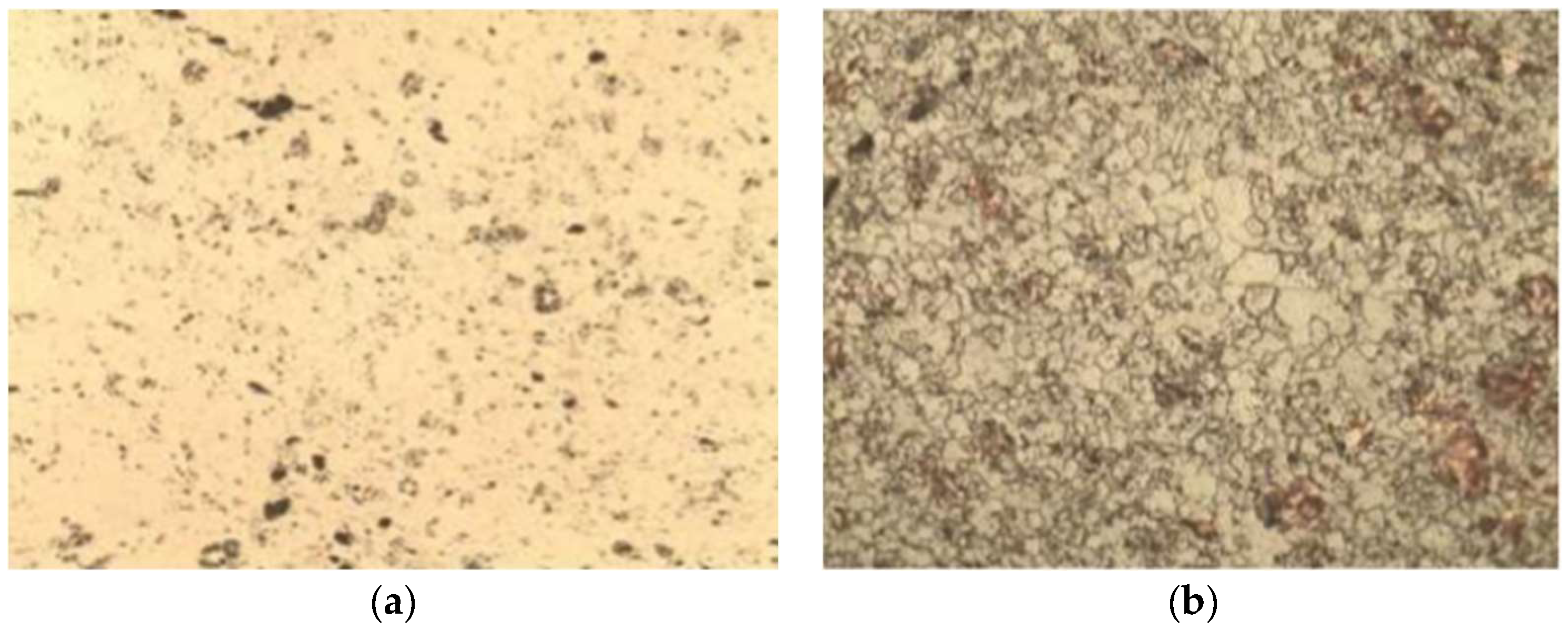

3.3. Microstructure, Chemical Composition and Re-Sintering of Ceramic Fuel Pellets Produced Using Microwave Radiation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kutty, T.R.G.; Hegde, P.V.; Khan, K.B.; Basak, U.; Pillai, S.N.; Sengupta, A.K.; Jain, G.C.; Majumdar, S.; Kamath, H.S.; Purushotham, D.S.C. Densification behaviour of UO2 in six different atmospheres. J. Nucl. Mater. 2022, 305, 159–168. [Google Scholar] [CrossRef]

- Karimov, O.K.; Daminev, R.R.; Kasyanova, L.Z.; Karimo, E.K. Application of Microwave Radiation For Preparation Metal Oxide Catalysts. E.P.Patent A1/No. 1693106, 23 August 2006. [Google Scholar]

- LG Electronics. Method for preparing catalysts for partial oxidation of propylene and iso-butylene. U.S. Patent No. 7329628, 12 February 2008. [Google Scholar]

- Kulyako, Y.M.; Trofimov, T.I.; Samsonov, M.D.; Vinokurov, S.E.; Myasoedov, B.F. Preparation of powdered uranium oxides by microwave heating of substandard ceramic pellets of oxide nuclear fuel. Radiochemistry 2015, 57, 127–130. [Google Scholar] [CrossRef]

- Kulyako, Y.M.; Trofimov, T.I.; Perevalov, S.A.; Malikov, D.A.; Vinokurov, S.E.; Samsonov, M.D.; Myasoedov, B.F.; Travnikov, S.S.; Dvoeglazov, K.N.; Shadrin, A.Y. Preparation of uranium oxides by reductive denitration of uranyl nitrate under microwave heating. Radiochemistry 2015, 57, 251–254. [Google Scholar] [CrossRef]

- Myasoedov, B.F.; Kulyako, Y.M.; Trofimov, T.I.; Perevalov, S.A.; Vinokurov, S.E.; Samsonov, M.D.; Fedoseev, A.M.; Bessonov, A.A.; Shadrin, A.Y. Preparation of Np, Pu, and U dioxides in nitric acid solutions in the presence of hydrazine hydrate. Radiochemistry 2013, 55, 574–580. [Google Scholar] [CrossRef]

- Dvoeglazov, K.; Kulyako, Y.; Vinokurov, S.; Myasoedov, B.; Dmitriev, M.; Ushakov, O.; Mochalov, Y.; Shadrin, A.; Smolkin, P. Synthesis of Mixed Actinide Oxides Using Microwave Radiation. Energies 2022, 15, 6618. [Google Scholar] [CrossRef]

- Subramanian, T.; Venkatesh, P.; Nagarajan, K.; Vasudeva, P.R. A novel method of sintering UO2 pellets by microwave heating. Mater. Lett. 2000, 46, 120–124. [Google Scholar] [CrossRef]

- Yang, J.H.; Song, K.W.; Lee, Y.W.; Kim, J.H.; Kang, K.W.; Kim, K.S.; Jung, Y.H. Microwave process for sintering of uranium dioxide. J. Nucl. Mater. 2004, 325, 210–216. [Google Scholar] [CrossRef]

- Croquesel, J.; Meunier, C.; Petit, C.; Valdivieso, F.; Pillon, S.; Robisson, A.C.; Martinez, J.; Lemont, F. Design of an instrumented microwave multimode cavity for sintering of nuclear ceramics. Mater. Des. 2021, 204, 109638. [Google Scholar] [CrossRef]

- Petit, C.; Meunier, C.; Valdivieso, F.; Croquesel, J.; Pillon, S.; Robisson, A.C.; Martinez, J.; Lemont, F. Densification of UO2 pellets by microwave sintering using an instrumented multimode cavity. Ceram. Int. 2021, 47, 30610–30615. [Google Scholar] [CrossRef]

- Pilyushenko, K.S.; Kulyako, Y.M.; Trofimov, T.I.; Perevalov, S.A.; Savel’ev, B.V.; Vinokurov, S.E.; Myasoedov, B.F. Use of microwave radiation for denitration of uranyl nitrate solution and subsequent sintering of uranium dioxide fuel pellets. Russ. J. Appl. Chem. 2021, 94, 317–322. [Google Scholar] [CrossRef]

| Parameters | Position of Pellets During Microwave Sintering | Parameter Requirements | |

|---|---|---|---|

| Vertical | Horizontal | ||

| Oxygen coefficient | 2.0007 | 2.0024 | 2.00–2.01 |

| Hydrogen concentration, ppm | 0.29 | 0.35 | Not more than 0.60 |

| Density of Sintered Pellets, g/cm3 | Density of Pellets after Re-Sintering, g/cm3 | Change in Density, % |

|---|---|---|

| 10.42 10.52 | 10.49 10.57 | 0.7 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pilyushenko, K.S.; Dmitriyev, M.S.; Vinokurov, S.E.; Trofimov, T.I.; Saveliyev, B.V.; Kuznetsov, A.I.; Uvarov, A.A.; Myasoedov, B.F. Sintering of Industrial Uranium Dioxide Pellets Using Microwave Radiation for Nuclear Fuel Fabrication. Energies 2022, 15, 9193. https://doi.org/10.3390/en15239193

Pilyushenko KS, Dmitriyev MS, Vinokurov SE, Trofimov TI, Saveliyev BV, Kuznetsov AI, Uvarov AA, Myasoedov BF. Sintering of Industrial Uranium Dioxide Pellets Using Microwave Radiation for Nuclear Fuel Fabrication. Energies. 2022; 15(23):9193. https://doi.org/10.3390/en15239193

Chicago/Turabian StylePilyushenko, Konstantin S., Maxim S. Dmitriyev, Sergey E. Vinokurov, Trofim I. Trofimov, Boris V. Saveliyev, Alexander I. Kuznetsov, Alexander A. Uvarov, and Boris F. Myasoedov. 2022. "Sintering of Industrial Uranium Dioxide Pellets Using Microwave Radiation for Nuclear Fuel Fabrication" Energies 15, no. 23: 9193. https://doi.org/10.3390/en15239193

APA StylePilyushenko, K. S., Dmitriyev, M. S., Vinokurov, S. E., Trofimov, T. I., Saveliyev, B. V., Kuznetsov, A. I., Uvarov, A. A., & Myasoedov, B. F. (2022). Sintering of Industrial Uranium Dioxide Pellets Using Microwave Radiation for Nuclear Fuel Fabrication. Energies, 15(23), 9193. https://doi.org/10.3390/en15239193