Geological Structure Features of Carbonate Formations and Their Impact on the Efficiency of Developing Hydrocarbon Deposits

Abstract

1. Introduction

- -

- Geological factors having a significant influence on the process of developing the object in question were identified;

- -

- The influence of the formed development system on the reserve recovery efficiency was established;

- -

- Reasons for the low efficiency of flooding were identified, and the direction to increase it for maintaining the optimal regime of oil displacement to the faces of producing wells was elaborated.

2. Materials and Methods

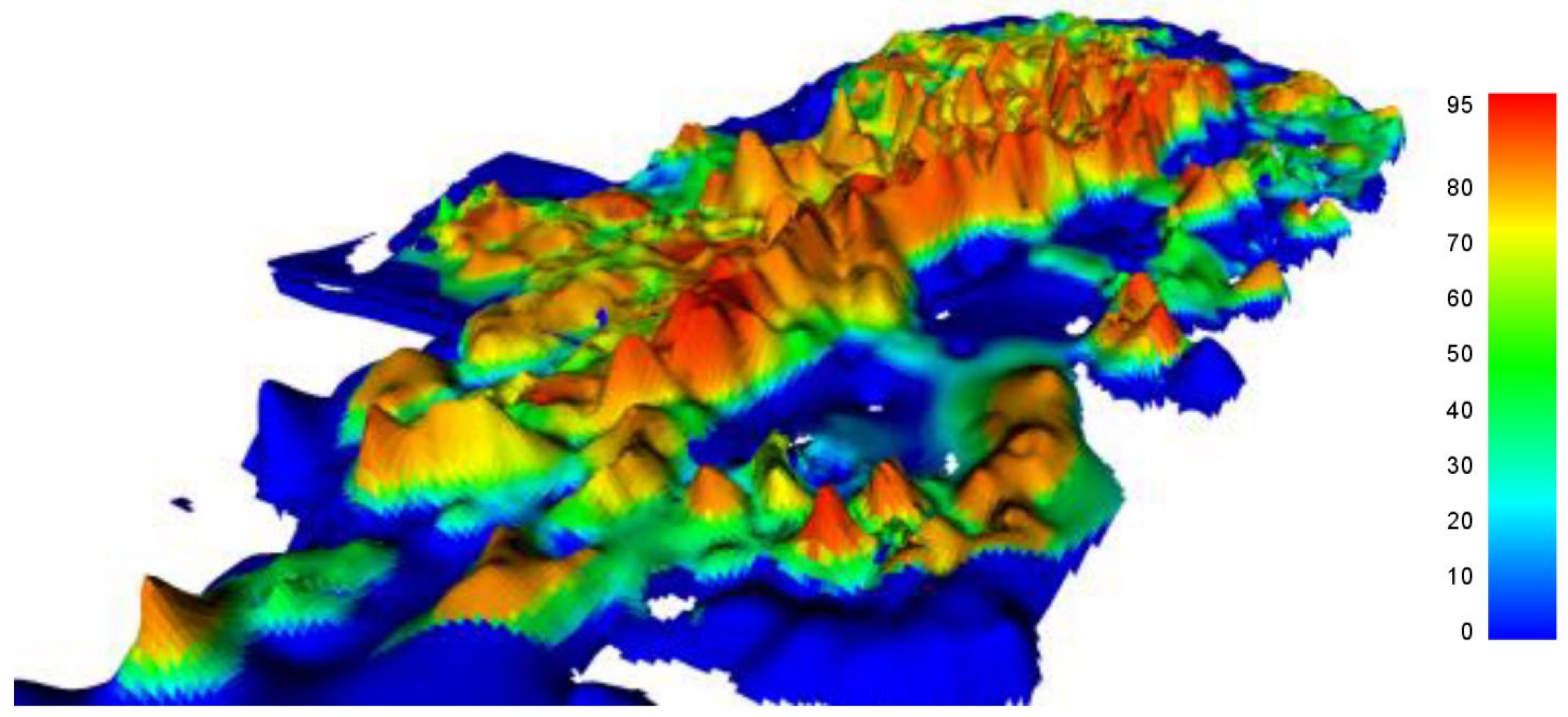

- At the first stage, the geological structure features that may influence the process of recovering hydrocarbon reserves were analyzed in detail.

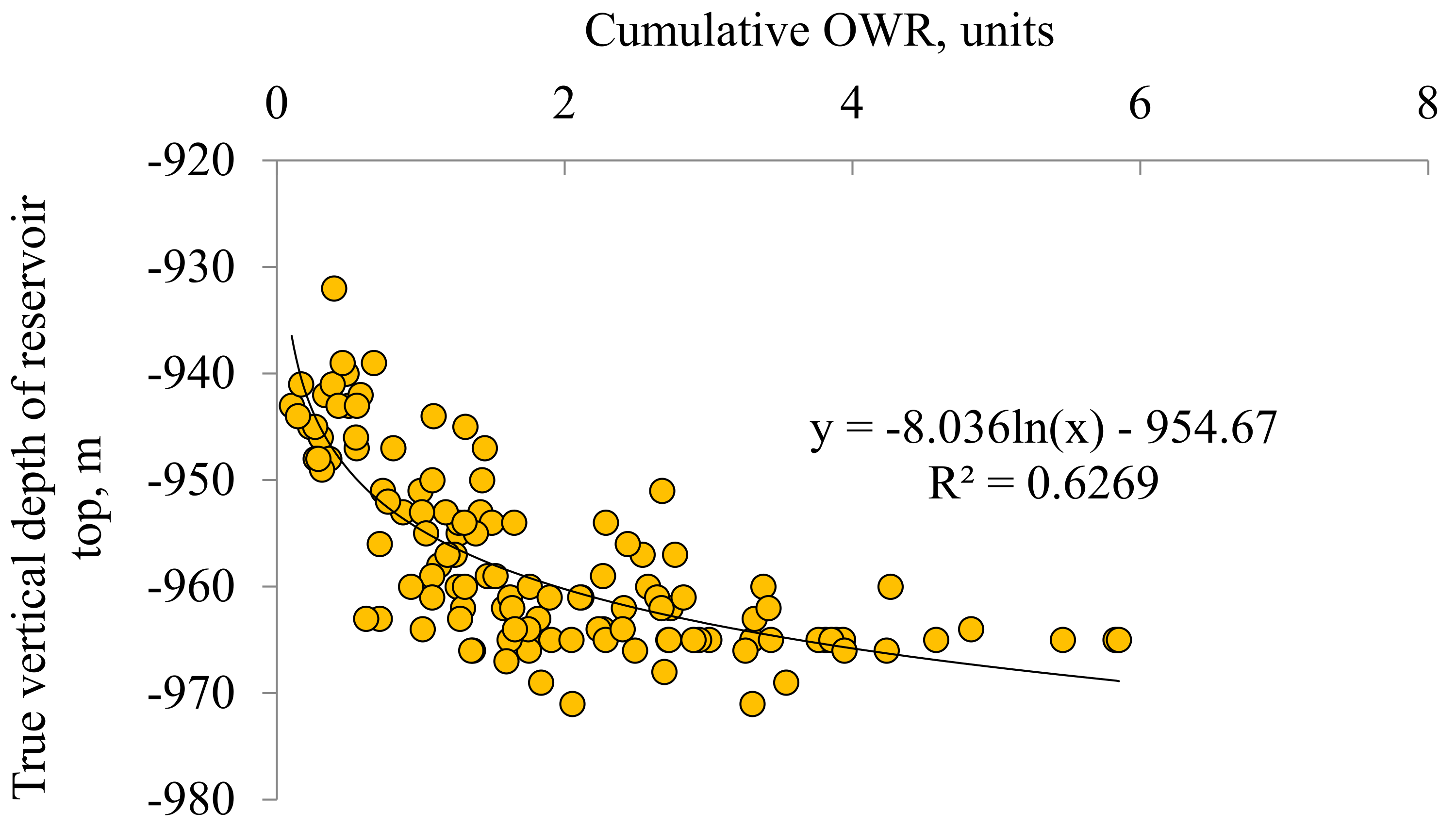

- Then, based on the operating characteristics of the well performance, the influence of a number of geological properties on the development indicators was confirmed.

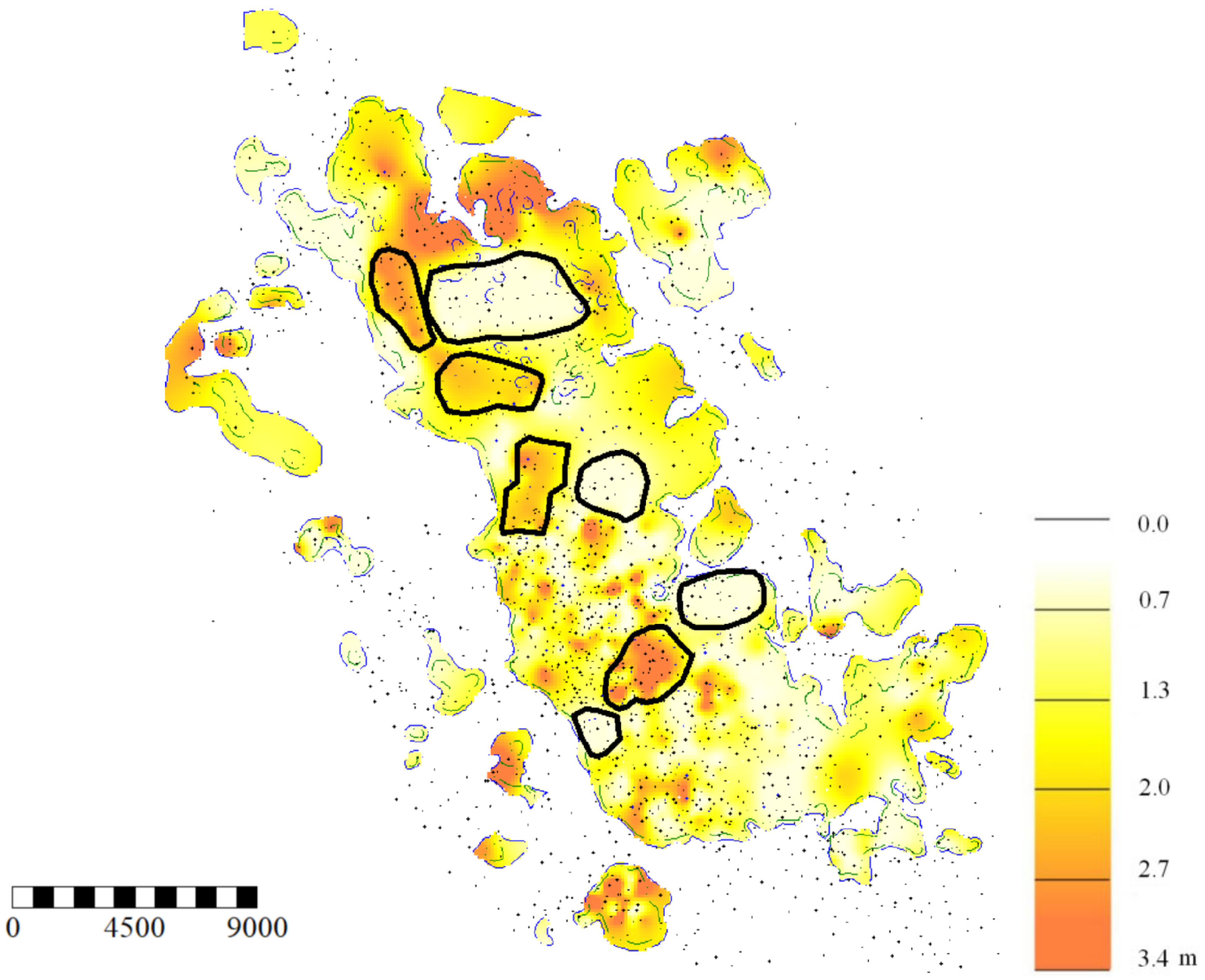

- Then, based on the complexation of the established influencing parameters, the entire area of the object under study was divided in terms of the potential efficiency of the development.

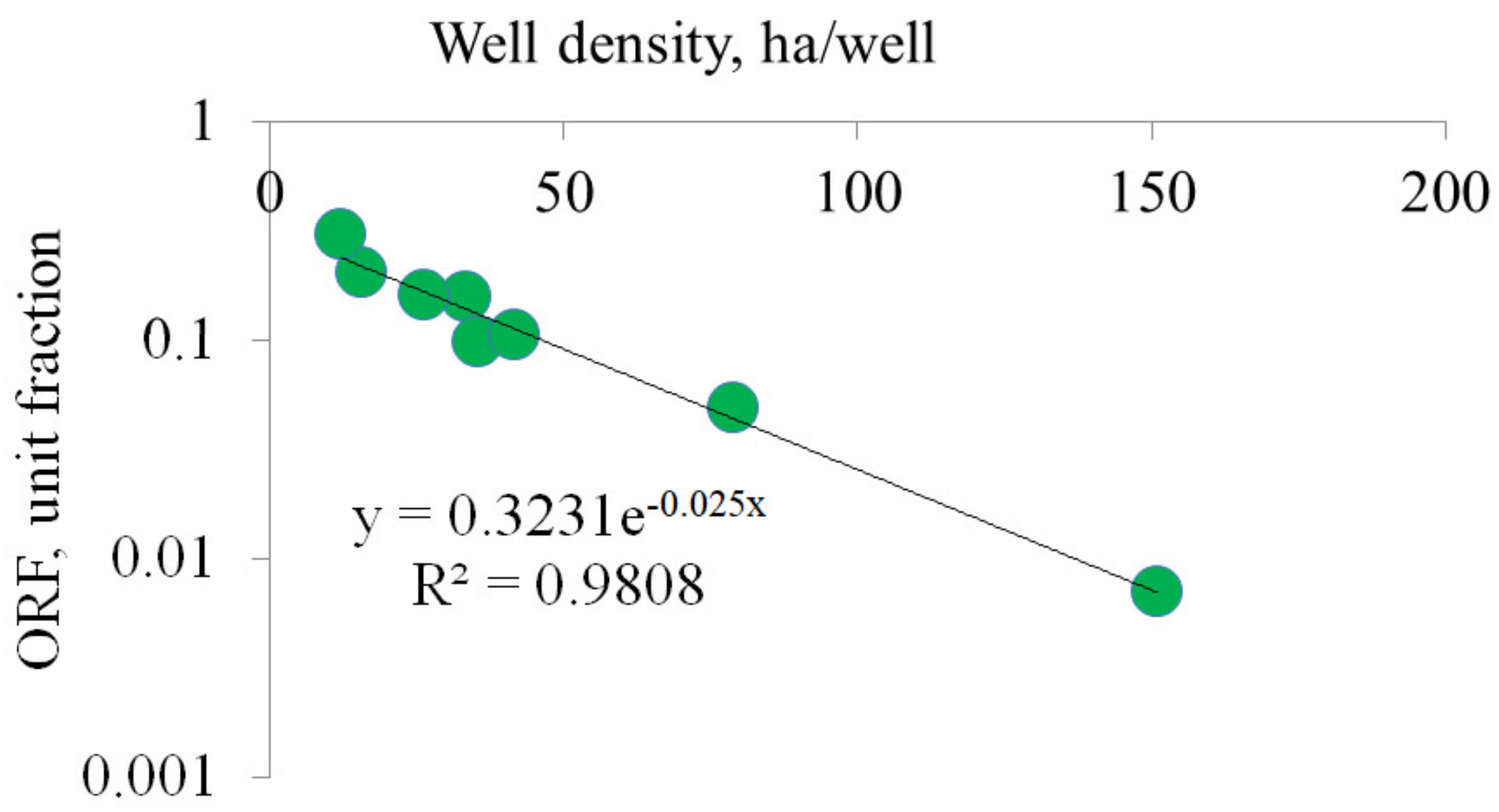

- At the next stage, the dependence of the predictive oil recovery factor on the well density grid was determined using the hydrodynamic modeling results. The results of items 3 and 4 above allow for determining the optimal system of well locations, taking into account its predictive efficiency.

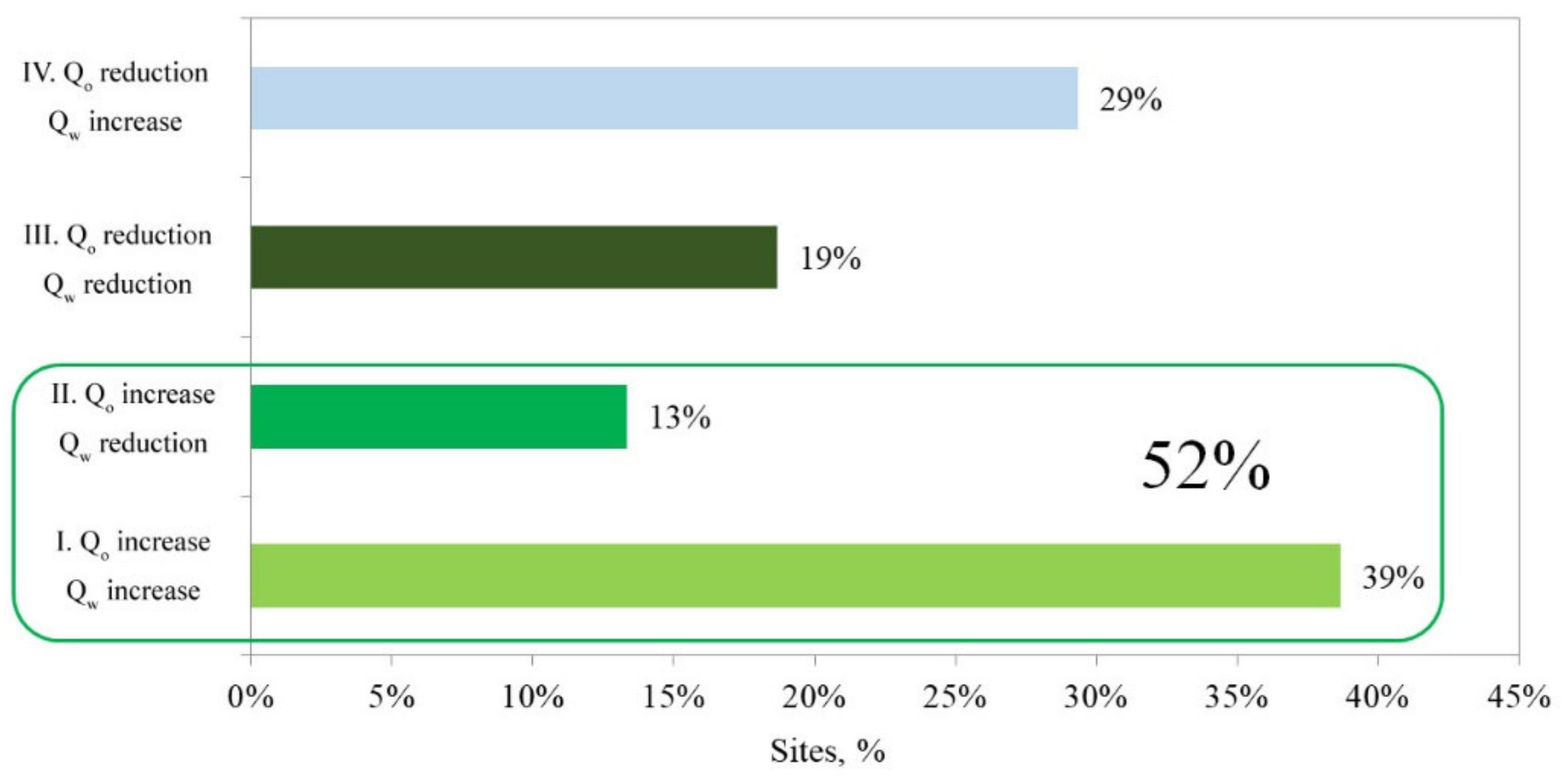

- At the final stage, the results of the research and field studies of water-injection wells were summarized, which allowed the establishment of the pattern efficiency in general, factors influencing this efficiency, and determining methods for improving its productivity.

3. Results

4. Conclusions

- -

- The main geological feature of the considered deposits of the Tournaisian stage is the presence of fracturing, which provides a hydrodynamic connectivity between oil and water-saturated formations;

- -

- The shale barrier thickness between the beds, determined by logging, affects the initial water cut;

- -

- The structural factor has a significant impact on the change in the cumulative oil-water ratio;

- -

- In order to determine the most promising areas in planning priority measures to intensify the development of reserves, it is necessary to build maps that take into account the barrier thickness, the structural factor and the potential productivity of the area;

- -

- Well density significantly affects the oil recovery factor, and the resulting regression equation can be used to estimate the ORF for the undeveloped areas, as well as for other fields with similar geological conditions;

- -

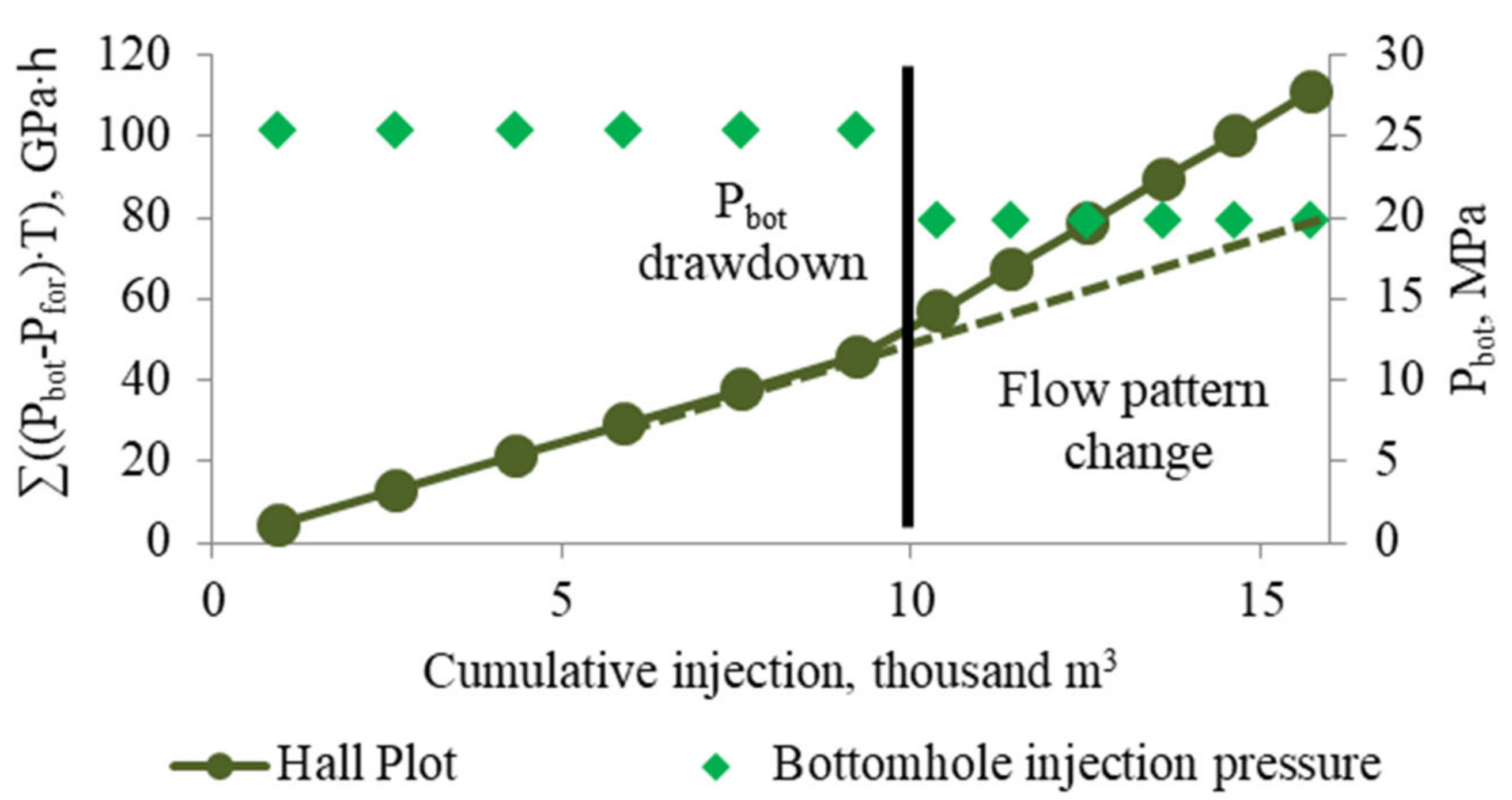

- The injection efficiency of the object is also influenced by secondary cavernosity, which causes the inter formational cross flows confirmed by the data of various studies and analytical assessment methods;

- -

- In order to improve waterflooding efficiency, it is necessary to reduce the pressure on the barrier to reduce the leakage of the injected water. Organization of additional waterflooding sites with a more stringent development system in terms of the ratio of production and injection wells should be planned.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suchkov, B.M. Oil Production from Carbonate Reservoirs. In Regular and Chaotic Dynamics; Izhevsk: Moscow, Russia, 2005; 688p. [Google Scholar]

- Dmitrievsky, A.N.; Eremin, N.A. Modern scientific-technical revolution (STR) and the shift of paradigm of hydrocarbon resources development. Equip. Technol. Oil Gas Complex 2015, 6, 10–16. [Google Scholar]

- Khisamov, R.S.; Khabibrakhmanov, A.G.; Podavalov, V.B.; Kemaeva, Y.P.; Mironova, L.M. Geological features and prospects for development of low-permeability carbonate reservoirs of Rodveryuskoye oil field. Oil Ind. 2016, 11, 84–87. [Google Scholar]

- Long, H.; Thang, V.T.; Truong, H.T.; Quy, M.N.; Ngoc, Q.P.; Hien, H.D.; Linh, H. Study and apply the advanced analysis algorithm to screen the optimal enhanced oil recovery solution for oil and gas fields in Viet Nam. J. Min. Earth Sci. 2021, 62, 17–29. [Google Scholar] [CrossRef]

- Piantanida, M.; Bonamini, E.; Caborni, C.; Bergero, F.; Staar, P.; Dolfi, M.; Auer, C.; Saturnino, V. Using knowledge graphs to navigate through geological concepts extracted from documents. In Proceedings of the 15th OMC Med Energy Conference and Exhibition, Ravena, Italy, 28–30 September 2021; pp. 1–10. [Google Scholar]

- Yuanjun, L.; Robello, S. Reservoir ranking map sketching for selection of infill and replacement drilling locations using machine learning technique. In Proceedings of the Abu Dhabi International Petroleum Exhibithion and Conference, Abu Dhabi, United Arab Emirates, 12–15 November 2018. [Google Scholar] [CrossRef]

- Fathy, D.; Wagreich, M.; Sami, M. Geochemical evidence for photic zone euxinia during greenhouse climate in the Tethys Sea, Egypt. In Advances in Geophysics, Tectonics and Petroleum Geosciences; Springer: Cham, Switzerland, 2022; pp. 373–374. [Google Scholar] [CrossRef]

- Abouhenidi, M.; Fadul, R.; Tadamarry, F.; Rahdi, Y. Streamlining and automating geological requirements for development wells. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 18–21 March 2019. [Google Scholar] [CrossRef]

- Lianhua, H.; Zhichao, Y.; Xia, L.; Senhu, L.; Zhongying, Z.; Zhi, Y.; Songtao, W.; Jingwei, C.; Lijun, Z. Key geological factors controlling the estimated ultimate recovery of shale oil and gas: A case study of the Eagle Ford shale, Gulf Coast Basin, USA. Pet. Explor. Dev. 2021, 48, 762–774. [Google Scholar] [CrossRef]

- Grishchenko, V.A.; Gareev, R.R.; Tsiklis, I.M.; Mukhametshin, V.V.; Yakupov, R.F. Expanding the amount of preferential royalty facilities with hard-to-recover oil reserves. SOCAR Proc. 2021, 2, 8–18. [Google Scholar] [CrossRef]

- Khisamiev, T.R.; Bashirov, I.R.; Mukhametshin, V.S.; Kuleshova, L.S.; Yakupov, R.F.; Vagizov, A.M. Results of the development system optimization and increasing the efficiency of carbonate reserves extraction of the turney stage of the Chetyrmansky deposit. SOCAR Proc. 2021, 2, 131–142. [Google Scholar] [CrossRef]

- Setya Wardhana, B.A.; Titaley, G.S.; Purwatiningsih, N. An integrated geological approach for a successful waterflood implementations and EOR planning: Lesson learned from T field development, Barito Basin, Indonesia. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Bali, Indonesia, 29–31 October 2019. [Google Scholar] [CrossRef]

- Feder, J. Artificial Intelligence-Driven Timelines Help Optimize Well Life Cycle. J. Pet. Technol. 2020, 72, 50–51. [Google Scholar] [CrossRef]

- Tanzharykov, P.A.; Sarabekova, U.Z.; Tulegen, A.E. Risk assessment in oil and gas production. Oil Gas 2021, 1, 95–107. [Google Scholar] [CrossRef] [PubMed]

- Mardashov, D.V.; Rogachev, M.K.; Zeigman, Y.V.; Mukhametshin, V.V. Well killing technology before workover operation in complicated conditions. Energies 2021, 14, 654. [Google Scholar] [CrossRef]

- Zoveidavianpoor, M.; Samsuri, A.; Shadizadeh, S.R. Development of a fuzzy system model for candidate-well selection for hydraulic fracturing in a carbonate reservoir. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 28–30 March 2012; 25p. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Belkina, E.Y.; Khasanov, M.M.; Pavlov, V.A.; Tarasov, P.A. Quantitative approach of using of analogs in exploration and field development. Oil Ind. 2015, 4, 43–47. [Google Scholar]

- Khuzin, R.R.; Bakhtizin, R.N.; Andreev, V.E.; Kuleshova, L.S.; Mukhametshin, V.V.; Sultanov, S.K. Oil recovery enhancement by reservoir hydraulic compression technique employment. SOCAR Proc. 2021, 1, 98–108. [Google Scholar] [CrossRef]

- Muslimov, R.K. A new strategy for the development of oil fields in modern Russi—Optimization of production and maximization of KIN. Oil Gas. Innov. 2016, 4, 8–17. [Google Scholar]

- Minnikhanov, R.N.; Maganov, N.U.; Khisamov, R.S. On creation of research and testing facilities to promote study of nonconventional oil reserves in Tatarstan. Oil Ind. 2016, 8, 60–63. [Google Scholar]

- Mukhametshin, V.S.; Khakimzyanov, I.N.; Bakhtizin, R.N.; Kuleshova, L.S. Differentiation and grouping of complex-structured oil reservoirs in carbonate reservoirs in development management problems solving. SOCAR Proc. 2021, 1, 88–97. [Google Scholar] [CrossRef]

- Zakaria, A.S.; Nasr-El-Din, H.A. A novel polymer-assisted emulsified-acid system improves the efficiency of carbonate matrix acidizing. SPE J. 2016, 21, 14. [Google Scholar] [CrossRef]

- Back, M.J.; Kirk, G. An integrated portfolio management approach for more effective business planning. In Proceedings of the SPE Hydrocarbon Economics and Evaluation Symposium, Calgary, AL, Canada, 24–25 September 2012; p. 12. [Google Scholar] [CrossRef]

- Rogachev, M.K.; Mukhametshin, V.V. Control and regulation of the hydrochloric acid treatment of the bottomhole zone based on field-geological data. J. Min. Inst. 2018, 231, 275–280. [Google Scholar] [CrossRef]

- Husein, N.; Malyavko, E.; Novikov, I.; Drobot, A.; Buyanov, A.; Potapova, E.; Upadhye, V. Recovery improvement using geological, technical and operational factors of field development that influence the character of inflow profiles in horizontal laterals. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Virtual, 28 November–1 December 2021. [Google Scholar] [CrossRef]

- Economides, J.M.; Nolte, K.I. Reservoir Stimulation; John Wiley and Sons: West Sussex, UK, 2000; 856p. [Google Scholar]

- Nurov, S.R.; Yakupov, R.F.; Mukhametshin, V.V.; Gareev, A.T.; Kuleshova, L.S.; Faizov, I.A. Increasing the efficiency management of carbonate oil deposits development in the Kashiro-Podolsk deposits of the Birsk saddle. SOCAR Proc. 2022, 1, 91–99. [Google Scholar] [CrossRef]

| Indicator | Value |

|---|---|

| Average net oil thickness, m | 6.3 |

| Porosity, unit fraction | 0.1 |

| Oil content, unit fraction | 0.76 |

| permeability, 10−3 µm2 | 8.0 |

| Net sand, unit fraction | 0.6 |

| Sand-to-shale ratio | 2.5 |

| Parameter | Area | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | Other | |

| Initial oil in place, thousand tons | 2078 | 8349 | 13,148 | 7018 | 7293 | 4778 | 7775 |

| Initial recoverable reserves, thousand tons | 384 | 2120 | 3563 | 1902 | 1896 | 1099 | 1938 |

| Remaining recoverable reserves, thousand tons | 374 | 963 | 524 | 1304 | 1519 | 701 | 1681 |

| Cumulative oil production, thousand tons | 10 | 1157 | 3039 | 598 | 377 | 398 | 257 |

| Cumulative fluid production, thousand tons | 89 | 3093 | 8314 | 1729 | 1112 | 1107 | 760 |

| Water cut, % | 76 | 72.8 | 74.9 | 68.4 | 76.5 | 74.8 | 76.3 |

| Current ORF, unit fraction | 0.005 | 0.139 | 0.231 | 0.085 | 0.052 | 0.083 | 0.033 |

| Recovery of initial recoverable reserves (IRR), % | 3 | 55 | 85 | 31 | 20 | 36 | 13 |

| Cumulative injection, thousand m3 | - | 9657 | 17,973 | 4256 | 2383 | 773.6 | 852 |

| Exhausted production/injection well stock, number of wells | 11/- | 205/39 | 349/63 | 66/9 | 93/12 | 71/6 | 61/3 |

| Well density, ha/well | 150.9 | 15.5 | 12 | 33.5 | 35.4 | 41.6 | 79 |

| Predicted ORF by HDM, unit fraction | 0.007 | 0.203 | 0.304 | 0.156 | 0.097 | 0.106 | 0.048 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grishchenko, V.A.; Mukhametshin, V.S.; Rabaev, R.U. Geological Structure Features of Carbonate Formations and Their Impact on the Efficiency of Developing Hydrocarbon Deposits. Energies 2022, 15, 9002. https://doi.org/10.3390/en15239002

Grishchenko VA, Mukhametshin VS, Rabaev RU. Geological Structure Features of Carbonate Formations and Their Impact on the Efficiency of Developing Hydrocarbon Deposits. Energies. 2022; 15(23):9002. https://doi.org/10.3390/en15239002

Chicago/Turabian StyleGrishchenko, Vadim Aleksandrovich, Vyacheslav Sharifullovich Mukhametshin, and Ruslan Uralovich Rabaev. 2022. "Geological Structure Features of Carbonate Formations and Their Impact on the Efficiency of Developing Hydrocarbon Deposits" Energies 15, no. 23: 9002. https://doi.org/10.3390/en15239002

APA StyleGrishchenko, V. A., Mukhametshin, V. S., & Rabaev, R. U. (2022). Geological Structure Features of Carbonate Formations and Their Impact on the Efficiency of Developing Hydrocarbon Deposits. Energies, 15(23), 9002. https://doi.org/10.3390/en15239002