Numerical Investigation of a Fuel Cell-Powered Agricultural Tractor

Abstract

1. Introduction

2. Case Study Description

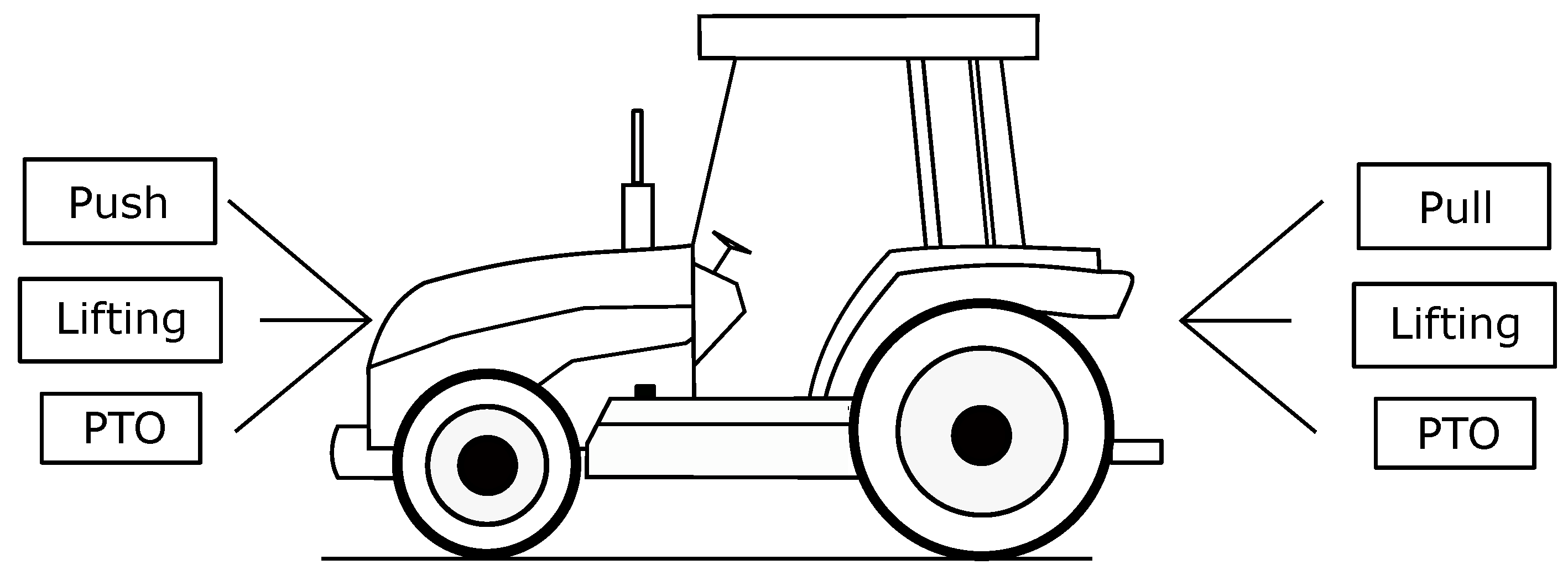

2.1. Conventional Diesel Tractor

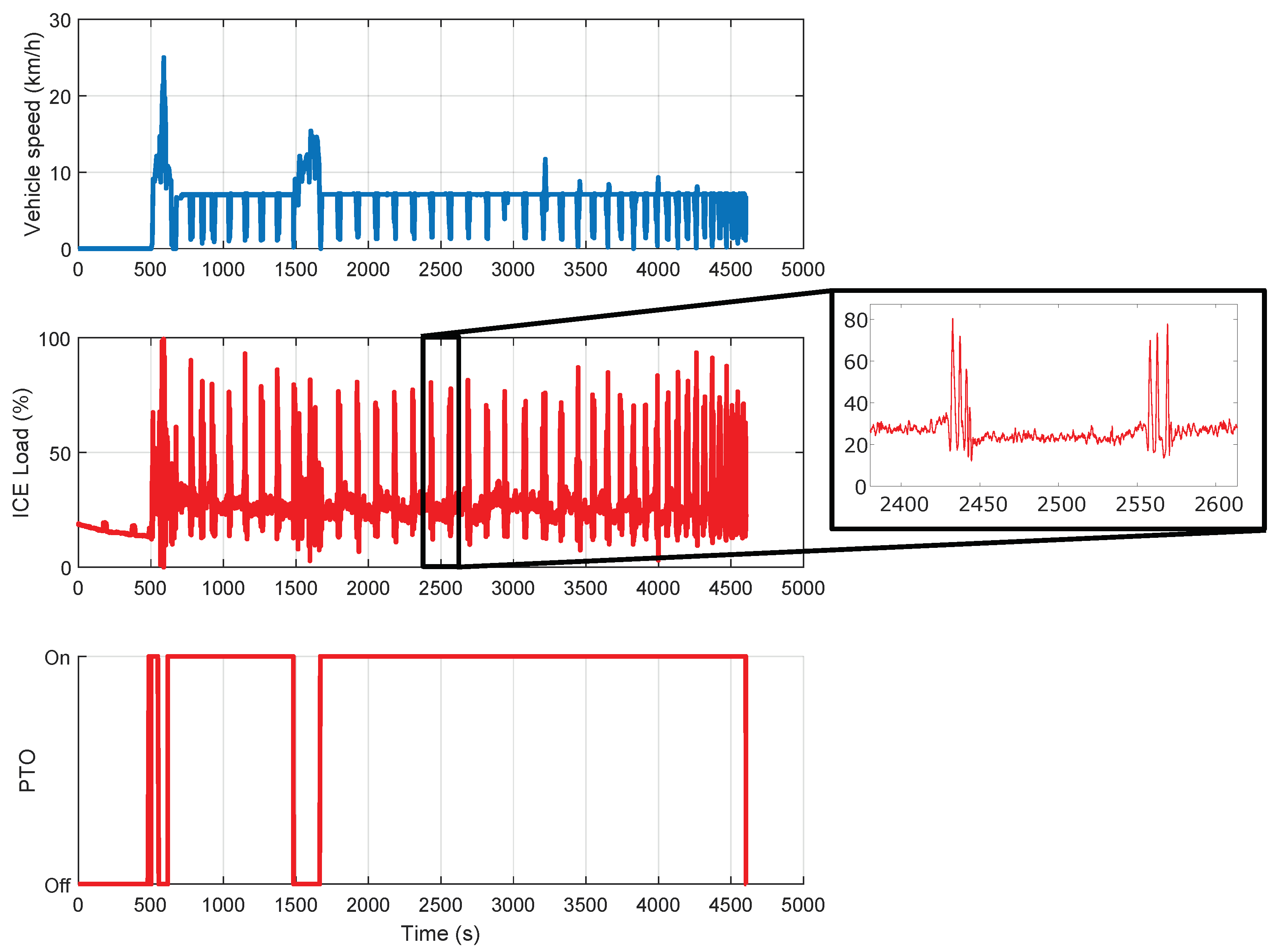

2.2. Experimental Definition of Mission Profiles

- Driver pedal signal as reference of the desired working speed.

- Engine rotational speed.

- Actual engine load as estimated by the vehicle control unit.

- Vehicle speed.

- PTO activation.

3. Numerical Modeling

3.1. Traditional Diesel Vehicle Numerical Model

- Vehicle dynamics.

- Gearbox and clutch.

- Engine power output and fuel consumption.

- PTO and auxiliaries (AUX) loads.

- a, b, and h represent the relative position of the center of gravity of the vehicle with respect to the front and rear axles.

- m is the tractor mass, g the acceleration of gravity.

- is the road slope angle.

- is the vehicle longitudinal speed.

- is the aerodynamic drag force as , with the air density, the drag coefficient and A the frontal cross-sectional area of the vehicle.

- and are the contact forces between the wheels and the ground on the longitudinal direction (front and rear axle).

- and are the normal contact forces between the wheels and the ground (front and rear axle).

- X is the normalized engine speed: .

- Y is the normalized brake torque: .

- Z is the normalized BSFC: .

- are the polynomial coefficients.

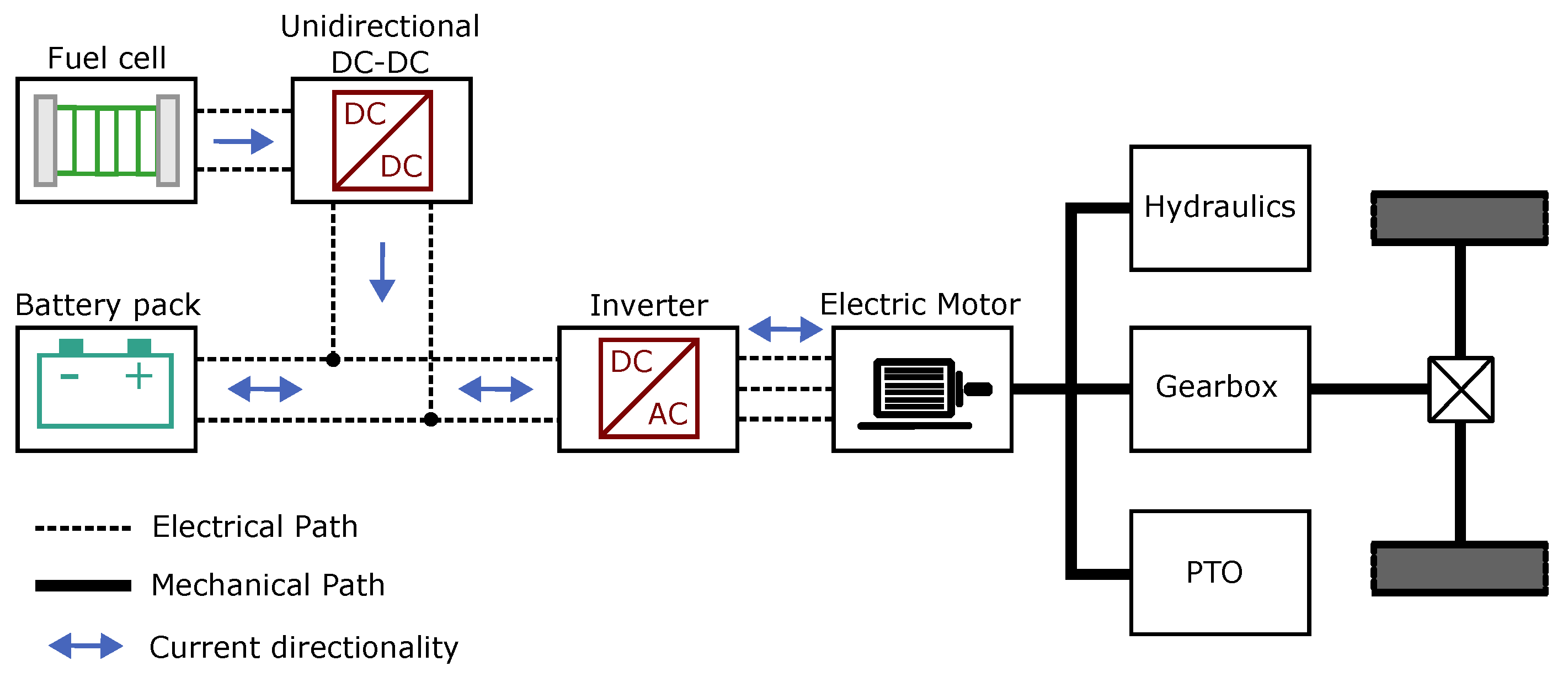

3.2. Hybrid Fuel-Cell/Battery Powertrain Numerical Model

3.2.1. Fuel-Cell Model

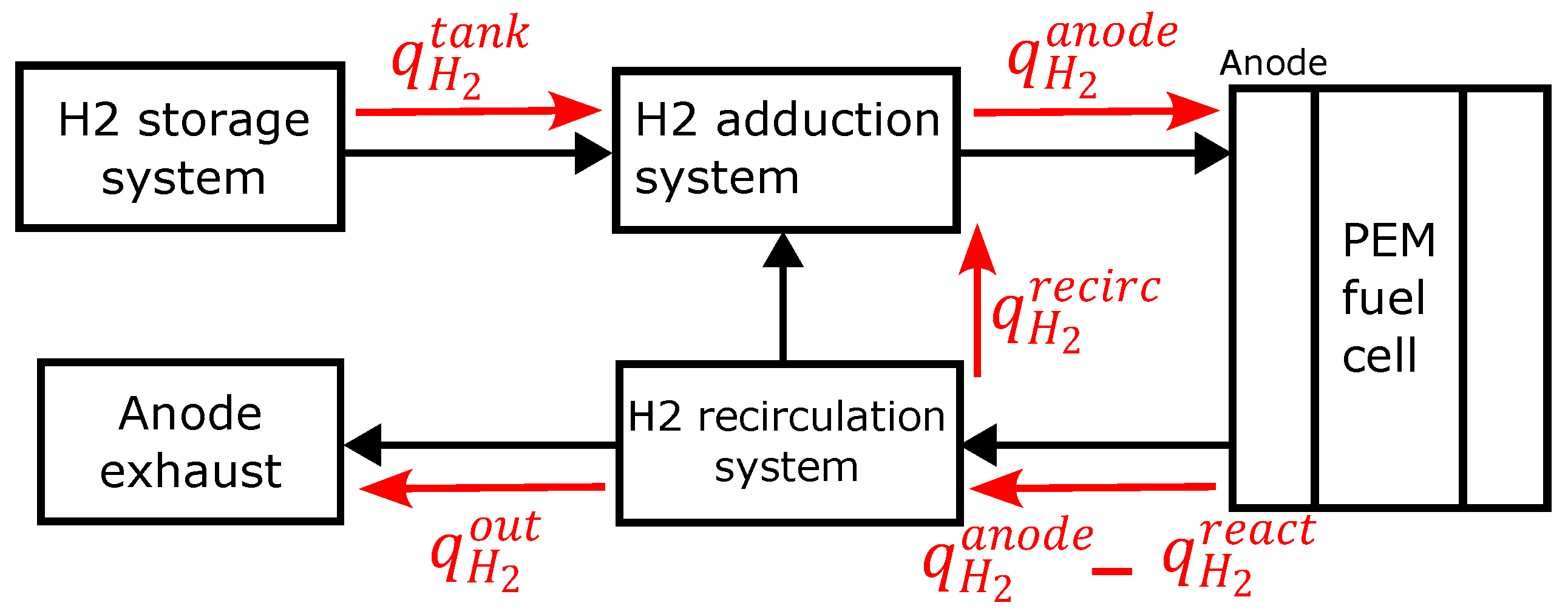

3.2.2. Adduction System Model

3.2.3. Oxygen Adduction System Model

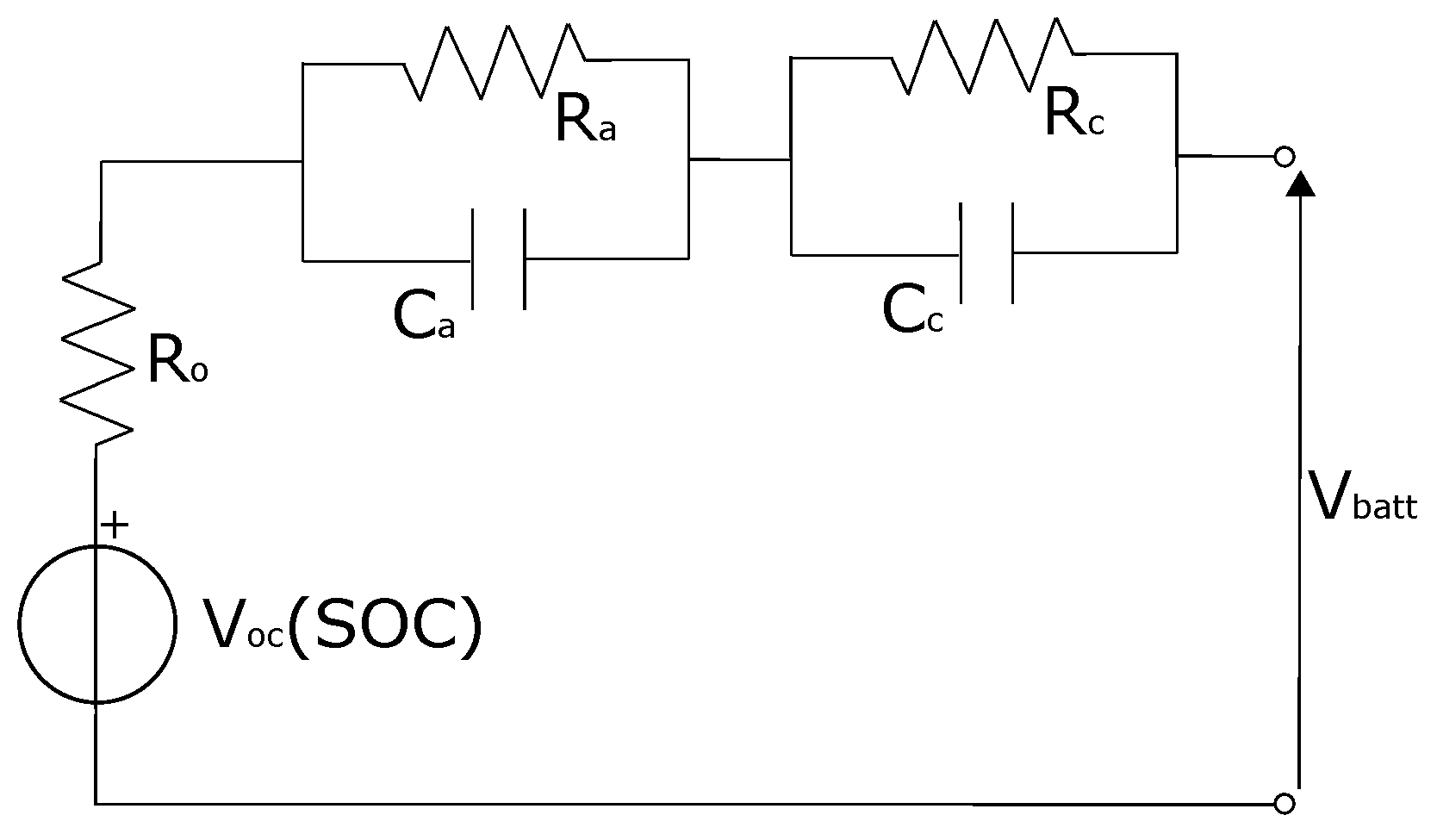

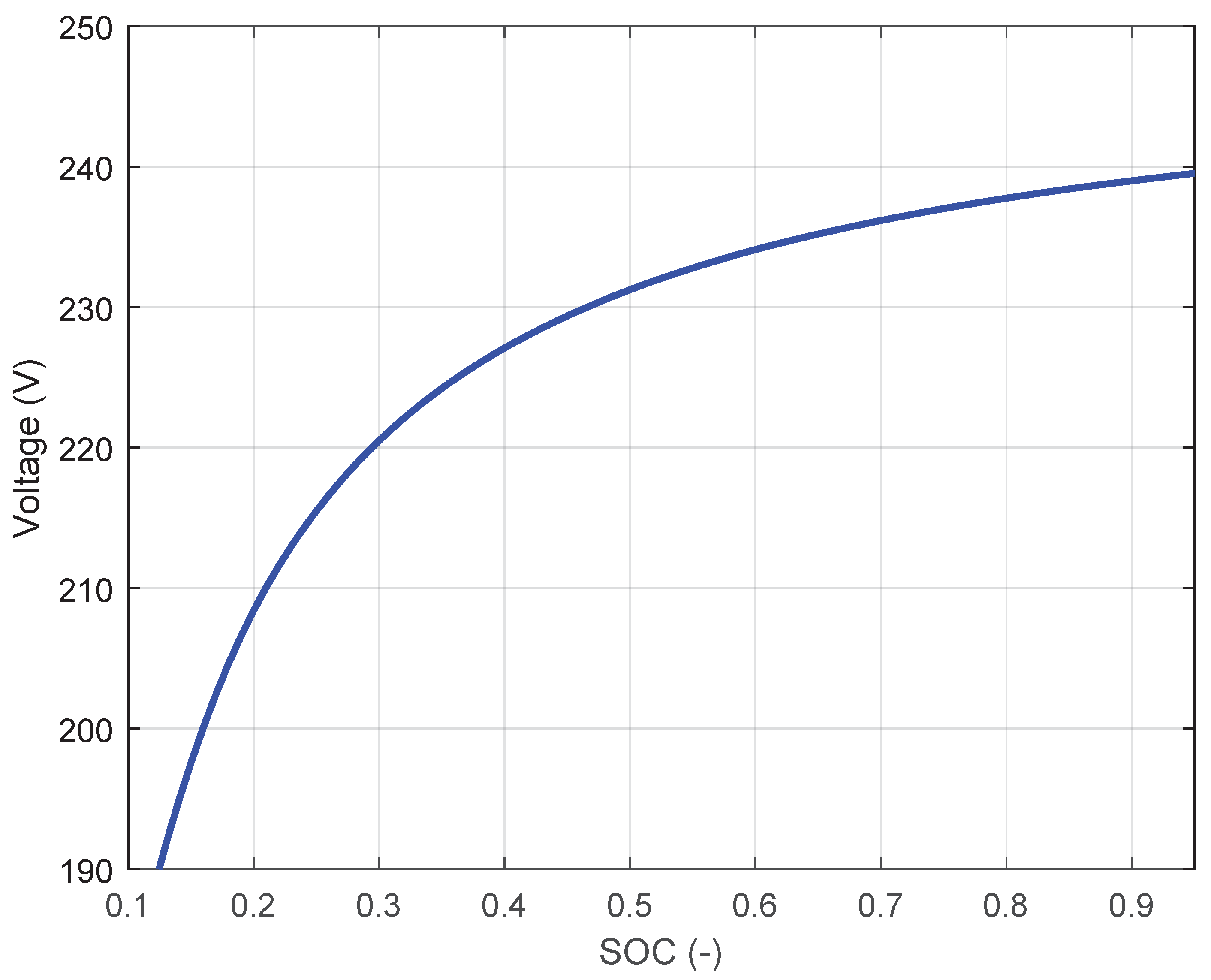

3.2.4. Battery Model

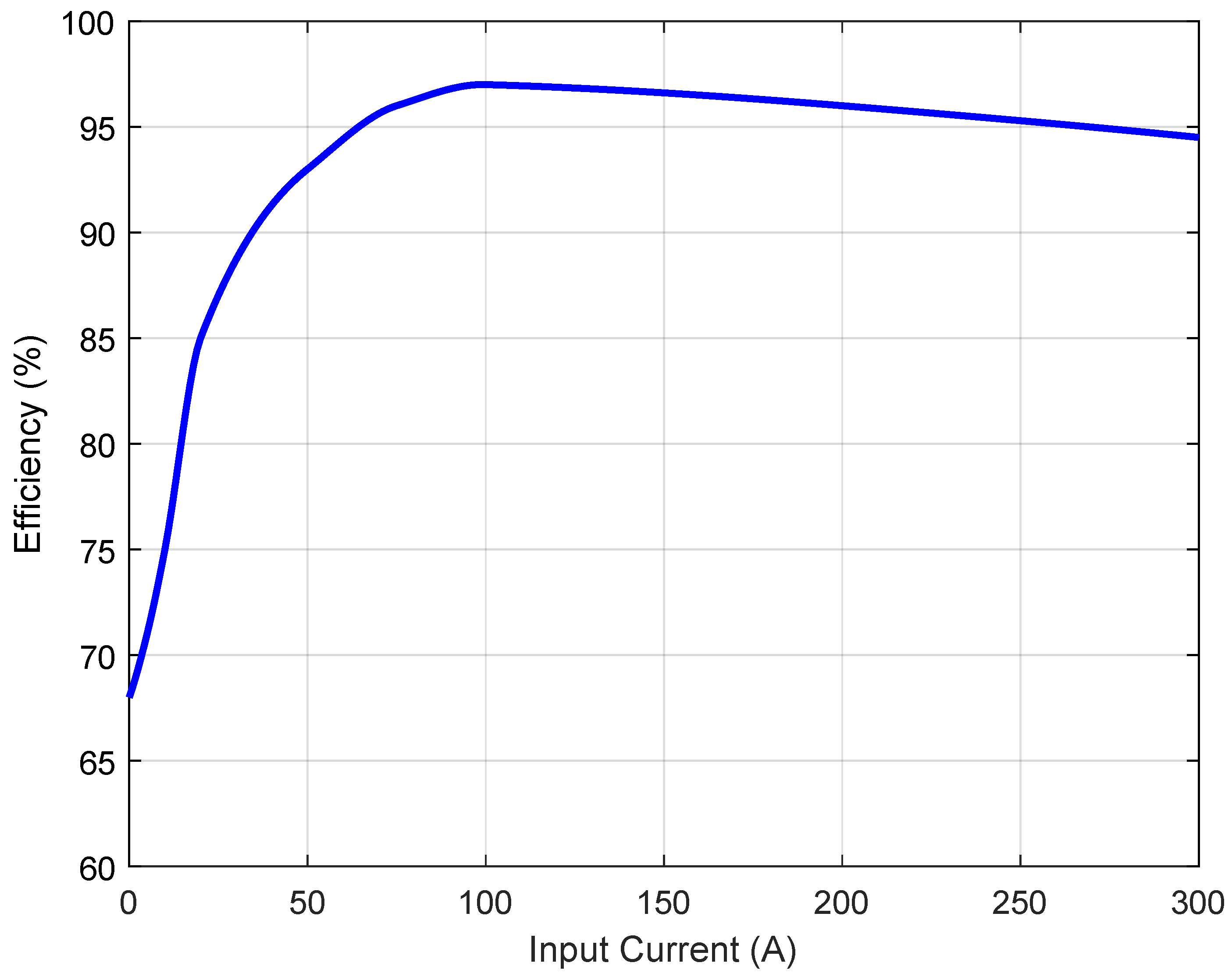

3.2.5. DC–DC Converter Model

4. Numerical Simulations

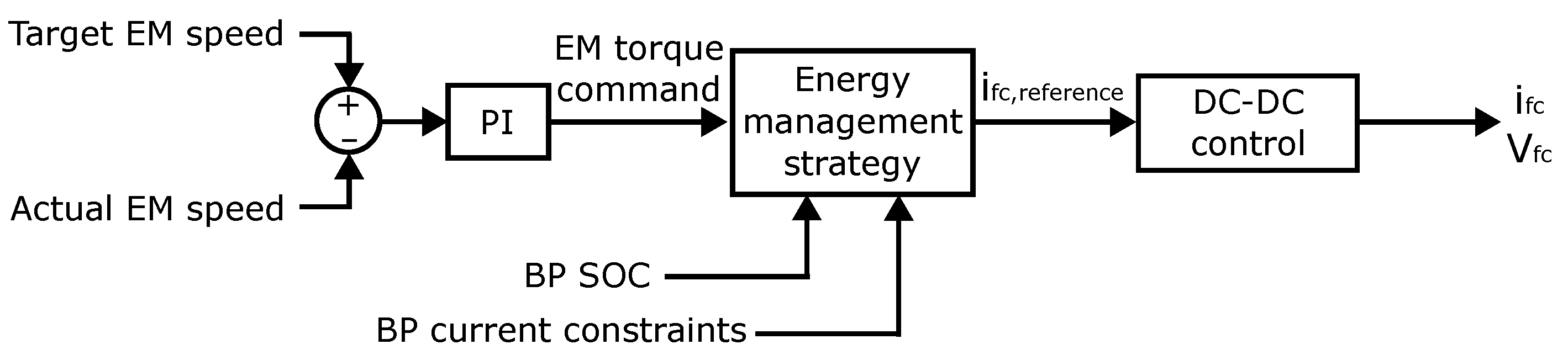

4.1. Powertrain Control Strategy

- Max current during continuous discharging equal to 3C.

- Max current during instantaneous discharging equal to 5C.

- Max current during continuous charging equal to C.

- Max current during instantaneous charging equal to 1.5C.

4.2. Simulations Results

4.2.1. Acceleration Test

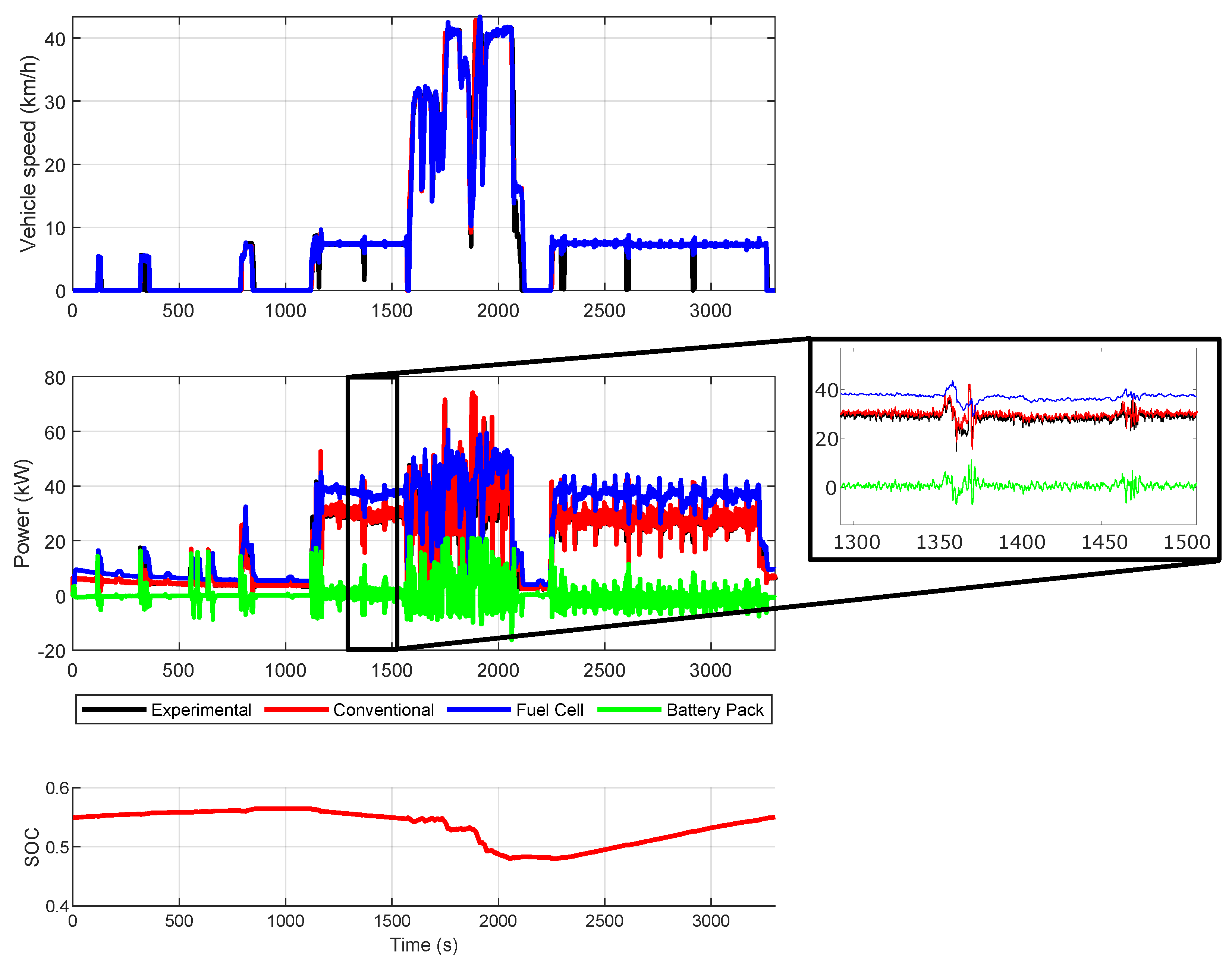

4.2.2. Work Cycle Simulation

4.2.3. GHG Emission Comparison

5. Conclusions

- Fuel cells produce no harmful products at the exhaust; the only chemical by-product of the reaction between and is water.

- Fuel cell-powered vehicles can be refueled with hydrogen in a few minutes, as traditional diesel vehicles.

- The fuel-cell/battery powertrain was able to accomplish the same tasks as the traditional vehicle.

- The fuel-cell/battery powertrain showed peak power performance very close to the traditional vehicle.

- Compared to diesel-powered agricultural tractors and considering the actual state-of-the-art hydrogen production methods, the fuel-cell/battery powertrain showed a reduction of about 50% of the equivalent emissions accomplishing the same tasks, according to a WtW approach.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Platis, D.P.; Anagnostopoulos, C.D.; Tsaboula, A.D.; Menexes, G.C.; Kalburtji, K.L.; Mamolos, A.P. Energy Analysis, and Carbon and Water Footprint for Environmentally Friendly Farming Practices in Agroecosystems and Agroforestry. Sustainability 2019, 11, 1664. [Google Scholar] [CrossRef]

- European Parliament—Council of the European Union. Regulation (EU). 2016/1628 of the European Parliament and of the Council of 14 September 2016 on requirements relating to gaseous and particulate pollutant emission limits and type-approval for internal combustion engines for non-road mobile machinery, amending Regulations (EU) No 1024/2012 and (EU) No 167/2013, and amending and repealing Directive 97/68/EC. Off. J. Eur. Union 2016, 252, 53–117. [Google Scholar]

- Bacenetti, J.; Lovarelli, D.; Facchinetti, D.; Pessina, D. An environmental comparison of techniques to reduce pollutants emissions related to agricultural tractors. Biosyst. Eng. 2018, 171, 30–40. [Google Scholar] [CrossRef]

- Tomic, M.; Savin, L.; Simikic, M.; Kiss, F.; Keselj, K.; Ivanisevic, M.; Ponjican, O.; Zoranovic, M.; Sedlar, A. Effects of biodiesel on changes in IC engine performances: A long-term experiment with farm tractors. Fuel 2021, 292, 120300. [Google Scholar] [CrossRef]

- Owczuk, M.; Matuszewska, A.; Kruczyński, S.; Kamela, W. Evaluation of Using Biogas to Supply the Dual Fuel Diesel Engine of an Agricultural Tractor. Energies 2019, 12, 1071. [Google Scholar] [CrossRef]

- Venkatesan, V.; Nallusamy, N. Pine oil-soapnut oil methyl ester blends: A hybrid biofuel approach to completely eliminate the use of diesel in a twin cylinder off-road tractor diesel engine. Fuel 2020, 262, 116500. [Google Scholar] [CrossRef]

- Ettl, J.; Bernhardt, H.; Huber, G.; Thuneke, K.; Remmele, E.; Emberger, P. Evaluation of pure rapeseed oil as a renewable fuel for agricultural machinery based on emission characteristics and long-term operation behaviour of a fleet of 18 tractors. SN Appl. Sci. 2020, 2, 1711. [Google Scholar] [CrossRef]

- Matuszewska, A.; Owczuk, M.; Zamojska-Jaroszewicz, A.; Jakubiak-Lasocka, J.; Lasocki, J.; Orliński, P. Evaluation of the biological methane potential of various feedstock for the production of biogas to supply agricultural tractors. Energy Convers. Manag. 2016, 125, 309–319. [Google Scholar] [CrossRef]

- Simikic, M.; Tomic, M.; Savin, L.; Micic, R.; Ivanisevic, I.; Ivanisevic, M. Influence of biodiesel on the performances of farm tractors: Experimental testing in stationary and non-stationary conditions. Renew. Energy 2018, 121, 677–687. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. Analysis of a Parallel Hybrid Electric Tractor for Agricultural Applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V.; Somà, A. Comparative Analysis of Hybrid Electric Architectures for Specialized Agricultural Tractors. Energies 2022, 15, 1944. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V. Numerical Performance Investigation of a Hybrid eCVT Specialized Agricultural Tractor. Appl. Sci. 2022, 12, 2438. [Google Scholar] [CrossRef]

- Dalboni, M.; Santarelli, P.; Patroncini, P.; Soldati, A.; Concari, C.; Lusignani, D. Electrification of a Compact Agricultural Tractor: A Successful Case Study. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Novi, MI, USA, 19–21 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Mocera, F.; Martelli, S.; Costamagna, M. Dynamic behaviour of a battery pack for agricultural applications. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1214, 012032. [Google Scholar] [CrossRef]

- Vogt, H.H.; de Melo, R.R.; Daher, S.; Schmuelling, B.; Antunes, F.L.M.; dos Santos, P.A.; Albiero, D. Electric tractor system for family farming: Increased autonomy and economic feasibility for an energy transition. J. Energy Storage 2021, 40, 102744. [Google Scholar] [CrossRef]

- Melo, R.R.; Antunes, F.L.; Daher, S.; Vogt, H.H.; Albiero, D.; Tofoli, F.L. Conception of an electric propulsion system for a 9 kW electric tractor suitable for family farming. IET Electr. Power Appl. 2019, 13, 1993–2004. [Google Scholar] [CrossRef]

- Li, Y.; Taghizadeh-Hesary, F. The economic feasibility of green hydrogen and fuel cell electric vehicles for road transport in China. Energy Policy 2022, 160, 112703. [Google Scholar] [CrossRef]

- Duan, J.; He, Y.; Zhu, H.; Qin, G.; Wei, W. Research progress on performance of fuel cell system utilized in vehicle. Int. J. Hydrog. Energy 2019, 44, 5530–5537. [Google Scholar] [CrossRef]

- Aguilar, P.; Groß, B. Battery electric vehicles and fuel cell electric vehicles, an analysis of alternative powertrains as a mean to decarbonise the transport sector. Sustain. Energy Technol. Assess. 2022, 53, 102624. [Google Scholar]

- Madheswaran, D.K.; Jayakumar, A.; Varuvel, E.G. Recent advancement on thermal management strategies in PEM fuel cell stack: A technical assessment from the context of fuel cell electric vehicle application. Energy Sources Part A 2022, 44, 3100–3125. [Google Scholar] [CrossRef]

- Ji, M.; Wang, J. Review and comparison of various hydrogen production methods based on costs and life cycle impact assessment indicators. Int. J. Hydrog. Energy 2021, 46, 38612–38635. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, Q.; Yu, D. The future of hydrogen energy: Bio-hydrogen production technology. Int. J. Hydrog. Energy 2022, 47, 33677–33698. [Google Scholar] [CrossRef]

- Das, A.; Peu, S.D. A Comprehensive Review on Recent Advancements in Thermochemical Processes for Clean Hydrogen Production to Decarbonize the Energy Sector. Sustainability 2022, 14, 11206. [Google Scholar] [CrossRef]

- Thounthong, P.; Rael, S.; Davat, B. Energy management of fuel cell/battery/supercapacitor hybrid power source for vehicle applications. J. Power Sources 2009, 193, 376–385. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, X.; Zhang, T.; Pei, P. The reactant starvation of the proton exchange membrane fuel cells for vehicular applications: A review. Energy Convers. Manag. 2019, 182, 282–298. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, L.; Zhou, Y.; Pan, B.; Wang, R.; Wang, L.; Yan, X. Energy management strategies for fuel cell hybrid electric vehicles: Classification, comparison, and outlook. Energy Convers. Manag. 2022, 270, 116179. [Google Scholar] [CrossRef]

- Ahluwalia, R.K.; Wang, X.; Star, A.G.; Papadias, D.D. Performance and cost of fuel cells for off-road heavy-duty vehicles. Int. J. Hydrog. Energy 2022, 47, 10990–11006. [Google Scholar] [CrossRef]

- Tritschler, P.J.; Bacha, S.; Rullière, E.; Husson, G. Energy Management Strategies for an embedded Fuel Cell System on Agricultural Vehicles. In Proceedings of the XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010. [Google Scholar]

- Yang, H.; Sun, Y.; Xia, C.; Zhang, H. Research on Energy Management Strategy of Fuel Cell Electric Tractor Based on Multi-Algorithm Fusion and Optimization. Energies 2022, 15, 6389. [Google Scholar] [CrossRef]

- Voss, W. A Comprehensible Guide to Controller Area Network; Copperhill Technologies Corporation: Greenfield, MA, USA, 2005. [Google Scholar]

- Voss, W. A Comprehensible Guide to J1939; Copperhill Technologies Corporation: Greenfield, MA, USA, 2008. [Google Scholar]

- Golverk, A.A. The Method for Development of a Diesel Engine Universal Performance Map. SAE Int. J. Fuels Lubr. 1994, 103, 1041–1048. [Google Scholar]

- Huang, Z.; Shen, J.; Chan, S.H.; Tu, Z. Transient response of performance in a proton exchange membrane fuel cell under dynamic loading. Energy Convers. Manag. 2020, 226, 113492. [Google Scholar] [CrossRef]

- Cruz Rojas, A.; Lopez Lopez, G.; Gomez-Aguilar, J.F.; Alvarado, V.M.; Sandoval Torres, C.L. Control of the Air Supply Subsystem in a PEMFC with Balance of Plant Simulation. Sustainability 2017, 9, 73. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Z.; Chen, Z. Energy management strategy for battery/supercapacitor/fuel cell hybrid source vehicles based on finite state machine. Appl. Energy 2019, 254, 113707. [Google Scholar] [CrossRef]

- Vergori, E.; Mocera, F.; Somà, A. Battery Modelling and Simulation Using a Programmable Testing Equipment. Computers 2018, 7, 20. [Google Scholar] [CrossRef]

- Wu, Z.; Xie, B.; Li, Z.; Chi, R.; Ren, Z.; Du, Y.; Inoue, E.; Mitsuoka, M.; Okayasu, T.; Hirai, Y. Modelling and verification of driving torque management for electric tractor: Dual-mode driving intention interpretation with torque demand restriction. Biosyst. Eng. 2019, 182, 65–83. [Google Scholar] [CrossRef]

- Vural, B.; Boynuegri, A.R.; Nakir, I.; Erdinc, O.; Balikci, A.; Uzunoglu, M.; Gorgun, H.; Dusmez, S. Fuel cell and ultra-capacitor hybridization: A prototype test bench based analysis of different energy management strategies for vehicular applications. Int. J. Hydrog. Energy 2010, 35, 11161–11171. [Google Scholar] [CrossRef]

- Di Ilio, G.; Di Giorgio, P.; Tribioli, L.; Bella, G.; Jannelli, E. Preliminary design of a fuel cell/battery hybrid powertrain for a heavy-duty yard truck for port logistics. Energy Convers. Manag. 2021, 243, 114423. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. Working Cycle requirements for an electrified architecture of a vertical feed mixer vehicle. Procedia Struct. Integr. 2018, 12, 213–223. [Google Scholar] [CrossRef]

- Mocera, F.; Vergori, E.; Soma, A. Battery Performance Analysis for Working Vehicle Applications. IEEE Trans. Ind. Appl. 2020, 56, 644–653. [Google Scholar] [CrossRef]

- Nordelöf, A.; Messagie, M.; Tillman, A.M.; Ljunggren Söderman, M.; van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—what can we learn from life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef]

- Buberger, J.; Kersten, A.; Kuder, M.; Eckerle, R.; Weyh, T.; Thiringer, T. Total CO2-equivalent life-cycle emissions from commercially available passenger cars. Renew. Sustain. Energy Rev. 2022, 159, 112158. [Google Scholar] [CrossRef]

- Lohse-Busch, H.; Stutenberg, K.; Duoba, M.; Liu, X.; Elgowainy, A.; Wang, M.; Wallner, T.; Richard, B.; Christenson, M. Automotive fuel cell stack and system efficiency and fuel consumption based on vehicle testing on a chassis dynamometer at min 18 °C to positive 35 °C temperatures. Int. J. Hydrogen Energy 2020, 45, 861–872. [Google Scholar] [CrossRef]

| Vehicle Properties | |

|---|---|

| Mass | 2571 kg |

| Vehicle wheelbase | 1900 mm |

| Track width | 1850 mm |

| Wheel radius | 680 mm |

| Nominal power | 73 kW @ 2600 rpm |

| Top speed | 42 km/h |

| Electric Motor Properties | |

|---|---|

| Rated power | 75 kW @ 2600 rpm |

| Rated torque | 258 Nm |

| Maximum efficiency | 94% |

| Parameters | Value | Unit |

|---|---|---|

| Number of cells | 360 | - |

| Cell active area | 220 | cm2 |

| Membrane thickness | 100 | m |

| Anode gas diffusion layer thickness | 200 | m |

| Cathode gas diffusion layer thickness | 200 | m |

| Exchange current density | A/cm2 | |

| Max current density | 1.4 | A/cm2 |

| Charge transfer coefficient | 0.5 | - |

| Density of dry membrane | 2000 | kg/m3 |

| Equivalent weight of dry membrane | 1.1 | kg/mol |

| Battery Pack Properties | |

|---|---|

| Nominal open circuit voltage | 240 V |

| Nominal capacity | 6 kWh |

| Ohmic resistance | 0.3 |

| 30 s | |

| 3000 s | |

| Emission Source | WtW Emission Factor | Unit |

|---|---|---|

| Diesel | 3.18 | kg -eq./L |

| 9.13 | kg -eq./kg |

| Sprayer Work Cycle | Weeder Work Cycle | |||

|---|---|---|---|---|

| Diesel | Hydrogen | Diesel | Hydrogen | |

| Fuel consumption | 5.35 L | 1.049 kg | 4.58 L | 0.714 kg |

| kg equivalent | 17.02 | 9.58 | 14.56 | 6.52 |

| Difference eq. | −44% | −55% | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martini, V.; Mocera, F.; Somà, A. Numerical Investigation of a Fuel Cell-Powered Agricultural Tractor. Energies 2022, 15, 8818. https://doi.org/10.3390/en15238818

Martini V, Mocera F, Somà A. Numerical Investigation of a Fuel Cell-Powered Agricultural Tractor. Energies. 2022; 15(23):8818. https://doi.org/10.3390/en15238818

Chicago/Turabian StyleMartini, Valerio, Francesco Mocera, and Aurelio Somà. 2022. "Numerical Investigation of a Fuel Cell-Powered Agricultural Tractor" Energies 15, no. 23: 8818. https://doi.org/10.3390/en15238818

APA StyleMartini, V., Mocera, F., & Somà, A. (2022). Numerical Investigation of a Fuel Cell-Powered Agricultural Tractor. Energies, 15(23), 8818. https://doi.org/10.3390/en15238818