Real-Time Measurement of NOx Emissions from Modern Diesel Vehicles Using On-Board Sensors

Abstract

1. Introduction

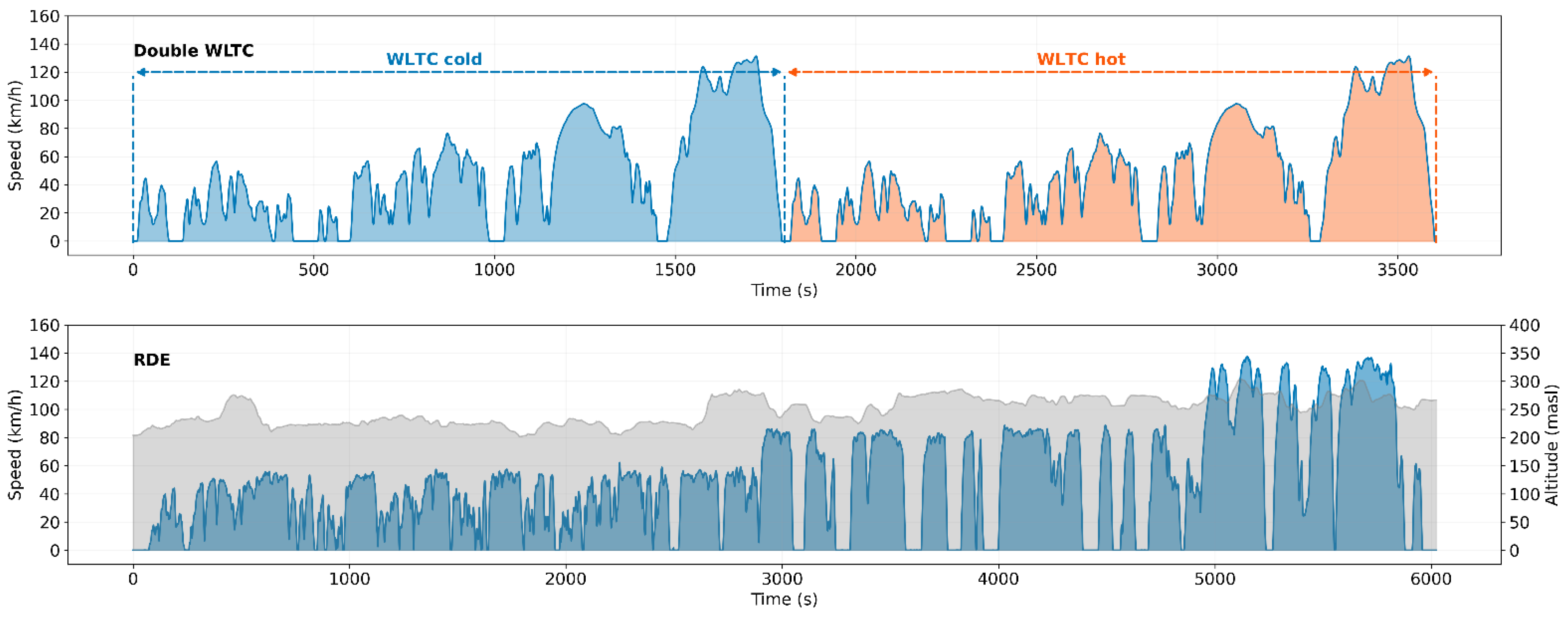

2. Materials and Methods

3. Results and Discussion

3.1. Flow Rate Validation

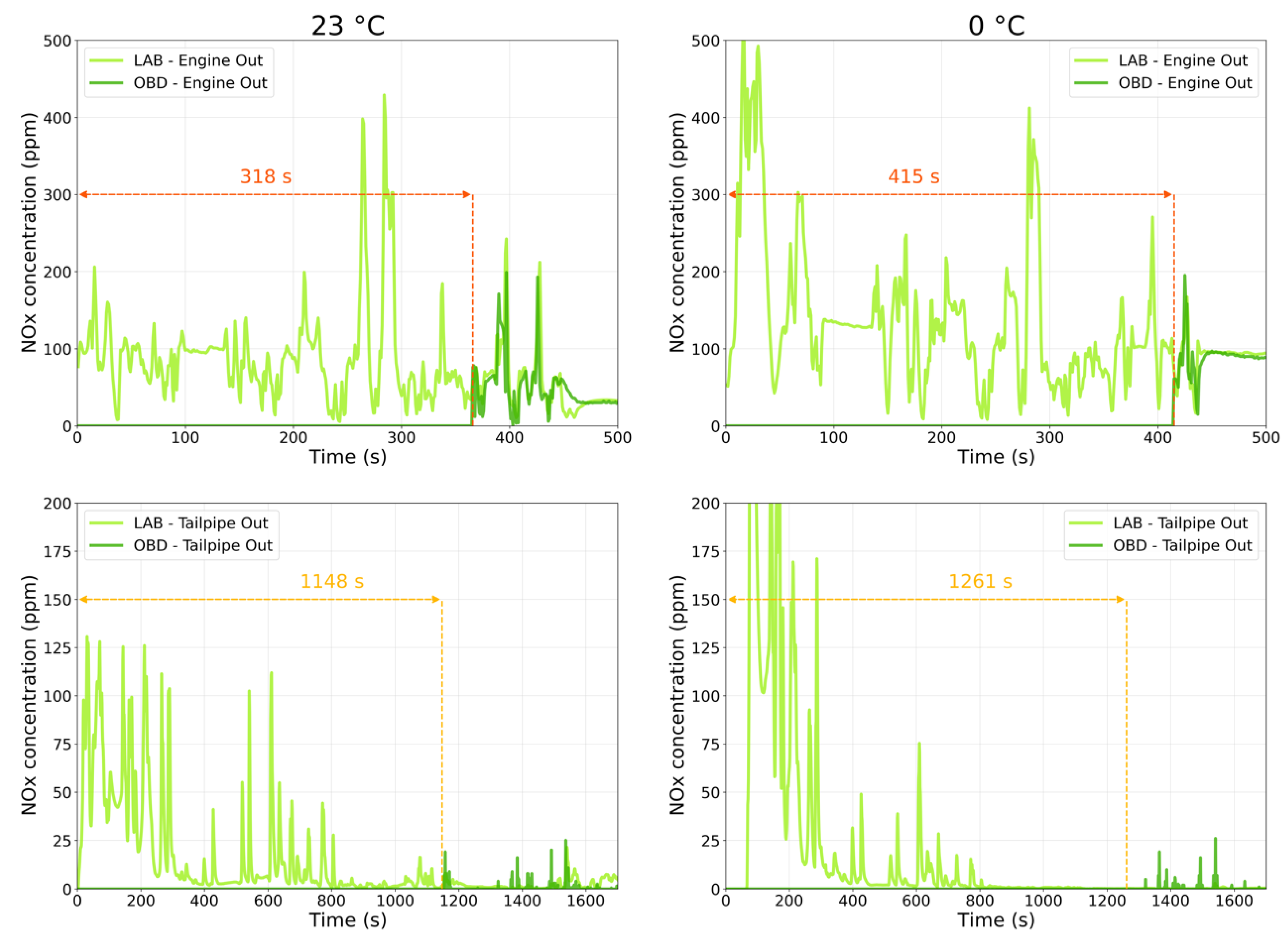

3.2. NOx Sensor Validation

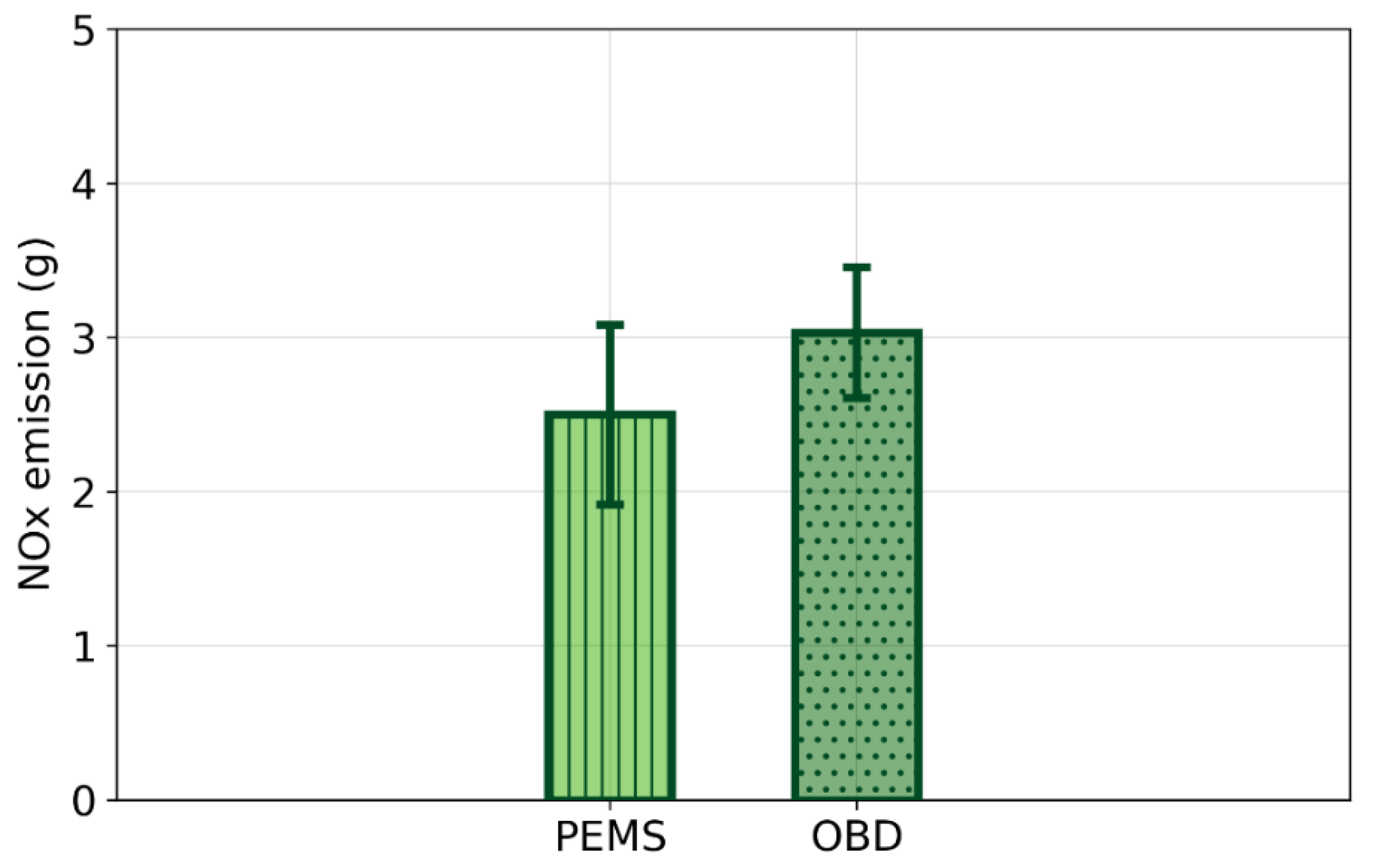

3.3. Mass Emissions Comparison

4. Conclusions

- Altogether, OBM signals were in fair agreement with emissions measured by PEMS and laboratory equipment.

- OBM signals were available only after the sensor warm-up time (in this study lasting from 318 s to 1261 s). The warm-up time needed depended on the sensor position and ambient temperature.

- OBM exhaust flow data correlated well with both laboratory-measured (CVS) and PEMS-measured flow rates.

- The correlation between 1 Hz recorded tailpipe OBM NOx concentration data and the laboratory measurements can be improved using moving average window statistics.

- Cumulative emissions calculated from the data measured by default on-board sensors are in fair agreement with both state-of-the-art laboratory and PEMS instruments, especially considering the relative simplicity of the measuring device.

- OBM results obtained during a DPF regeneration event were consistent with the laboratory reference, indicating that it would be possible to monitor malfunctioning ATSs by using properly functioning on-board sensors.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Selleri, T.; Melas, A.D.; Joshi, A.; Manara, D.; Perujo, A.; Suarez-Bertoa, R. An overview of lean exhaust denox aftertreatment technologies and nox emission regulations in the european union. Catalysts 2021, 11, 404. [Google Scholar] [CrossRef]

- COM(2019) 640 Final: Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: The European Green Deal. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2019%3A640%3AFIN (accessed on 23 October 2022).

- Proposal for a Regulation of the European Parliament and of the Council on Type-Approval of Motor Vehicles and Engines and of Systems, Components and Separate Technical Units Intended for Such Vehicles, with Respect to Their Emissions and Battery Durability (Euro 7) and Repealing Regulations (EC) No 715/2007 and (EC) No 595/2009, Brussels, 10.11.2022 COM(2022) 586 Final 2022/0365 (COD). Available online: https://single-market-economy.ec.europa.eu/publications/euro-7-standard-proposal_en (accessed on 23 October 2022).

- Regulation (EU) 2019/631 of the European Parliament and of the Council of 17 April 2019 Setting CO2 Emission Performance Standards for New Passenger Cars and for New Light Commercial Vehicles, and Repealing Regulations (EC) No 443/2009 and (EU) No 510/2011 (Recast) (Text with EEA Relevance.). Available online: http://data.europa.eu/eli/reg/2019/631/oj (accessed on 23 October 2022).

- Environmental Protection Agency (EPA). Control of Air Pollution From New Motor Vehicles: Heavy-Duty Engine and Vehicle Standards. Federal Register Vol. 87, No. 59, Monday, 28 March 2022. Proposed Rules. Available online: https://www.federalregister.gov/documents/2022/03/28/2022-04934/control-of-air-pollution-from-new-motor-vehicles-heavy-duty-engine-and-vehicle-standards (accessed on 23 October 2022).

- California Air Resources Board. CARB Gets ‘REAL’ to Further Cut Pollution from Diesel and Gas Vehicles. 2018. Available online: https://ww2.arb.ca.gov/news/carb-gets-real-further-cut-pollution-diesel-and-gas-vehicles (accessed on 23 October 2022).

- International Council on Clean Transportation (ICCT). China’s Stage VI Emission Standard for Heavy-Duty Vehicles (Final Rule). Available online: https://theicct.org/wp-content/uploads/2021/06/China_VI_Policy_Update_20180720.pdf (accessed on 23 October 2022).

- Beijing Municipal Bureau of Ecological Environment, Measures of the Installation and Management of Vehicle Remote Emission Terminals on Beijing Municipal Mobile Sources. Available online: http://lawinfochina.com/display.aspx?id=37236&lib=law&EncodingName=big5 (accessed on 23 October 2022).

- Tan, Y.; Henderick, P.; Yoon, S.; Herner, J.; Montes, T.; Boriboonsomsin, K.; Johnson, K.; Scora, G.; Sandez, D.; Durbin, T.D. On-Board Sensor-Based NOx Emissions from Heavy-Duty Diesel Vehicles. Environ. Sci. Technol. 2019, 53, 5504–5511. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; He, L.; He, W.; Zhao, P.; Wang, P.; Zhao, J.; Zhang, K.; Zhang, S. Evaluating on-board sensing-based nitrogen oxides (NOX) emissions from a heavy-duty diesel truck in China. Atmos. Environ. 2019, 216, 116908. [Google Scholar] [CrossRef]

- Mendoza-Villafuerte, P.; Suarez-Bertoa, R.; Giechaskiel, B.; Riccobono, F.; Bulgheroni, C.; Astorga, C.; Perujo, A. NOx, NH3, N2O and PN real driving emissions from a Euro VI heavy-duty vehicle. Impact of regulatory on-road test conditions on emissions. Sci. Total Environ. 2017, 609, 546–555. [Google Scholar] [CrossRef]

- Li, C.; Ma, T.; Karavalakis, G.; Johnson, K.C.; Durbin, T.D. Evaluation of On-Board Sensor-Based NOx emissions from the heavy-duty vehicles in an inspection and Maintenance program. Emiss. Control. Sci. Technol. 2022; In press. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, P.; He, L.; Yang, Y.; Liu, B.; He, W.; Cheng, Y.; Liu, Y.; Liu, S.; Hu, Q.; et al. On-board monitoring (OBM) for heavy-duty vehicle emissions in China: Regulations, early-stage evaluation and policy recommendations. Sci. Total Environ. 2020, 731, 139045. [Google Scholar] [CrossRef]

- Commission Regulation (EU) 2017/1151 of 1 June 2017 supplementing Regulation (EC) No 715/2007 of the European Parliament and of the Council on Type-Approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information, Amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No 1230/2012 and Repealing Commission Regulation (EC) No 692/2008. Available online: http://data.europa.eu/eli/reg/2017/1151/2020-01-25 (accessed on 23 October 2022).

- Sherman, M.T.; Chase, R.; Mauti, A.; Rauker, Z.; Silvis, W. Evaluation of Horiba MEXA 7000 Bag Bench Analyzers for Single Range Operation; SAE Technical Paper 1999-01-0147; SAE International: Warrendale, PN, USA, 1999. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Astorga, C. Impact of cold temperature on Euro 6 passenger car emissions. Environ. Pollut. 2018, 234, 318–329. [Google Scholar] [CrossRef] [PubMed]

- Suarez-Bertoa, R.; Selleri, T.; Gioria, R.; Melas, A.D.; Ferrarese, C.; Franzetti, J.; Arlitt, B.; Nagura, N.; Hanada, T.; Giechaskiel, B. Real-Time Measurements of Formaldehyde Emissions from Modern Vehicles. Energies 2022, 15, 7680. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Gioria, R.; Selleri, T.; Lilova, V.; Melas, A.; Onishi, Y.; Franzetti, J.; Forloni, F.; Perujo, A. NH3 and N2O Real World Emissions Measurement from a CNG Heavy Duty Vehicle Using On-Board Measurement Systems. Appl. Sci. 2021, 11, 10055. [Google Scholar] [CrossRef]

- Kato, N.; Kurachi, H.; Hamada, Y. Thick film ZrO2 NOx sensor for the measurement of low NOx concentration. SAE Trans. 1998, 107, 312–320. [Google Scholar] [CrossRef]

- Selleri, T.; Gioria, R.; Melas, A.D.; Giechaskiel, B.; Forloni, F.; Mendoza Villafuerte, P.; Demuynck, J.; Bosteels, D.; Wilkes, T.; Simons, O.; et al. Measuring Emissions from a Demonstrator Heavy-Duty Diesel Vehicle under Real-World Conditions—Moving Forward to Euro VII. Catalysts 2022, 12, 184. [Google Scholar] [CrossRef]

| Vehicle ID | Vehicle 1 | Vehicle 2 |

|---|---|---|

| Fuel | Diesel | Diesel |

| Injection | DI | DI |

| ICE displacement (cm3) | 1968 | 1995 |

| Emission control system | EGR, DOC, DPF, SCR, ASC | EGR, DOC, DPF, SCR * |

| Registration | 2019 | 2021 |

| Mileage (km) | ~52,000 | ~22,000 |

| Vehicle category | N1 Class III | N1 Class III |

| Euro standard | Euro 6d-TEMP-EVAP-ISC | Euro 6d-ISC-FCM |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selleri, T.; Ferrarese, C.; Franzetti, J.; Suarez-Bertoa, R.; Manara, D. Real-Time Measurement of NOx Emissions from Modern Diesel Vehicles Using On-Board Sensors. Energies 2022, 15, 8766. https://doi.org/10.3390/en15228766

Selleri T, Ferrarese C, Franzetti J, Suarez-Bertoa R, Manara D. Real-Time Measurement of NOx Emissions from Modern Diesel Vehicles Using On-Board Sensors. Energies. 2022; 15(22):8766. https://doi.org/10.3390/en15228766

Chicago/Turabian StyleSelleri, Tommaso, Christian Ferrarese, Jacopo Franzetti, Ricardo Suarez-Bertoa, and Dario Manara. 2022. "Real-Time Measurement of NOx Emissions from Modern Diesel Vehicles Using On-Board Sensors" Energies 15, no. 22: 8766. https://doi.org/10.3390/en15228766

APA StyleSelleri, T., Ferrarese, C., Franzetti, J., Suarez-Bertoa, R., & Manara, D. (2022). Real-Time Measurement of NOx Emissions from Modern Diesel Vehicles Using On-Board Sensors. Energies, 15(22), 8766. https://doi.org/10.3390/en15228766