Sugarcane Biomass as a Source of Biofuel for Internal Combustion Engines (Ethanol and Acetone-Butanol-Ethanol): A Review of Economic Challenges

Abstract

1. Introduction

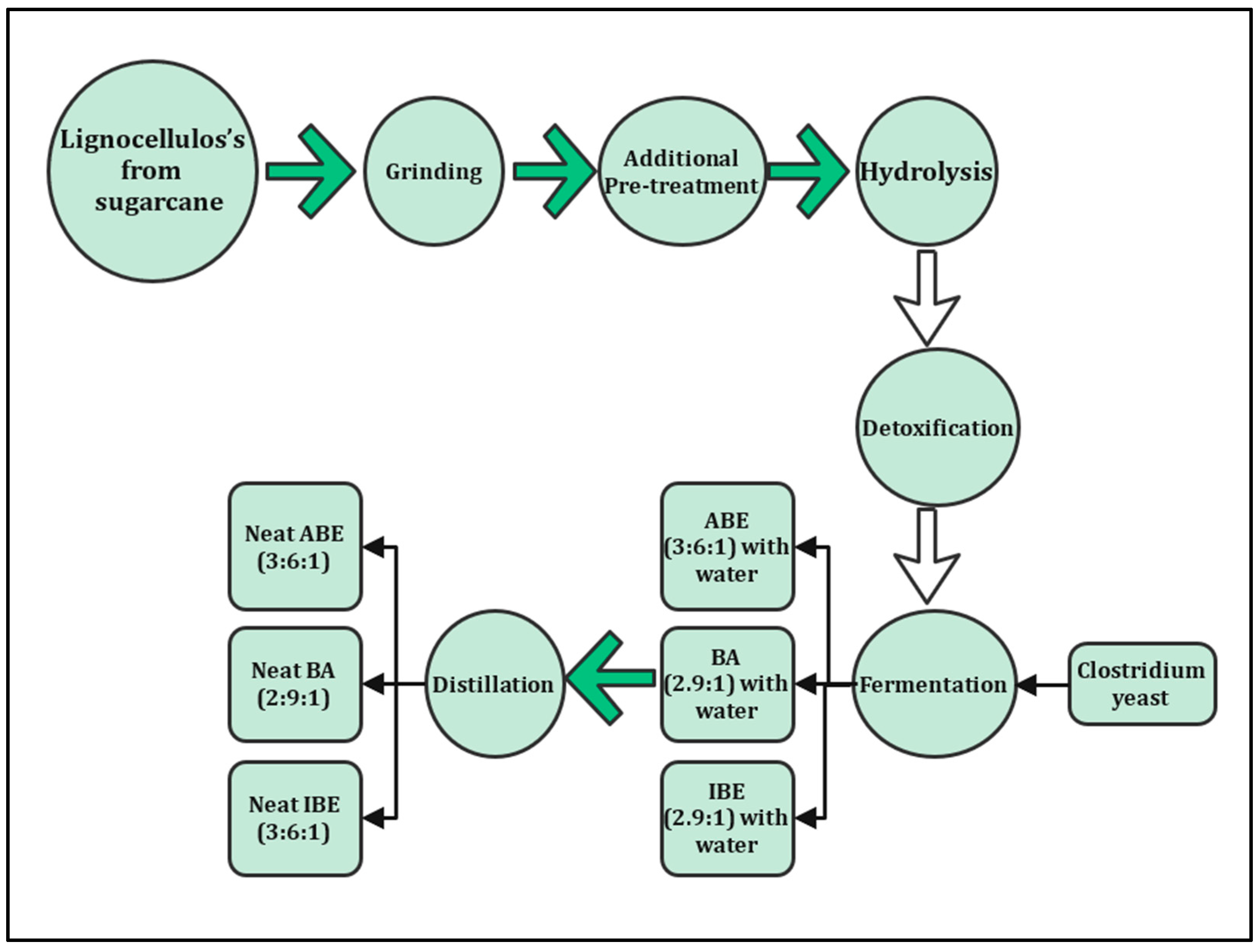

2. Sugarcane Biomass Extraction Pipeline

3. Properties and Chemistry of Sugarcane Bagasse

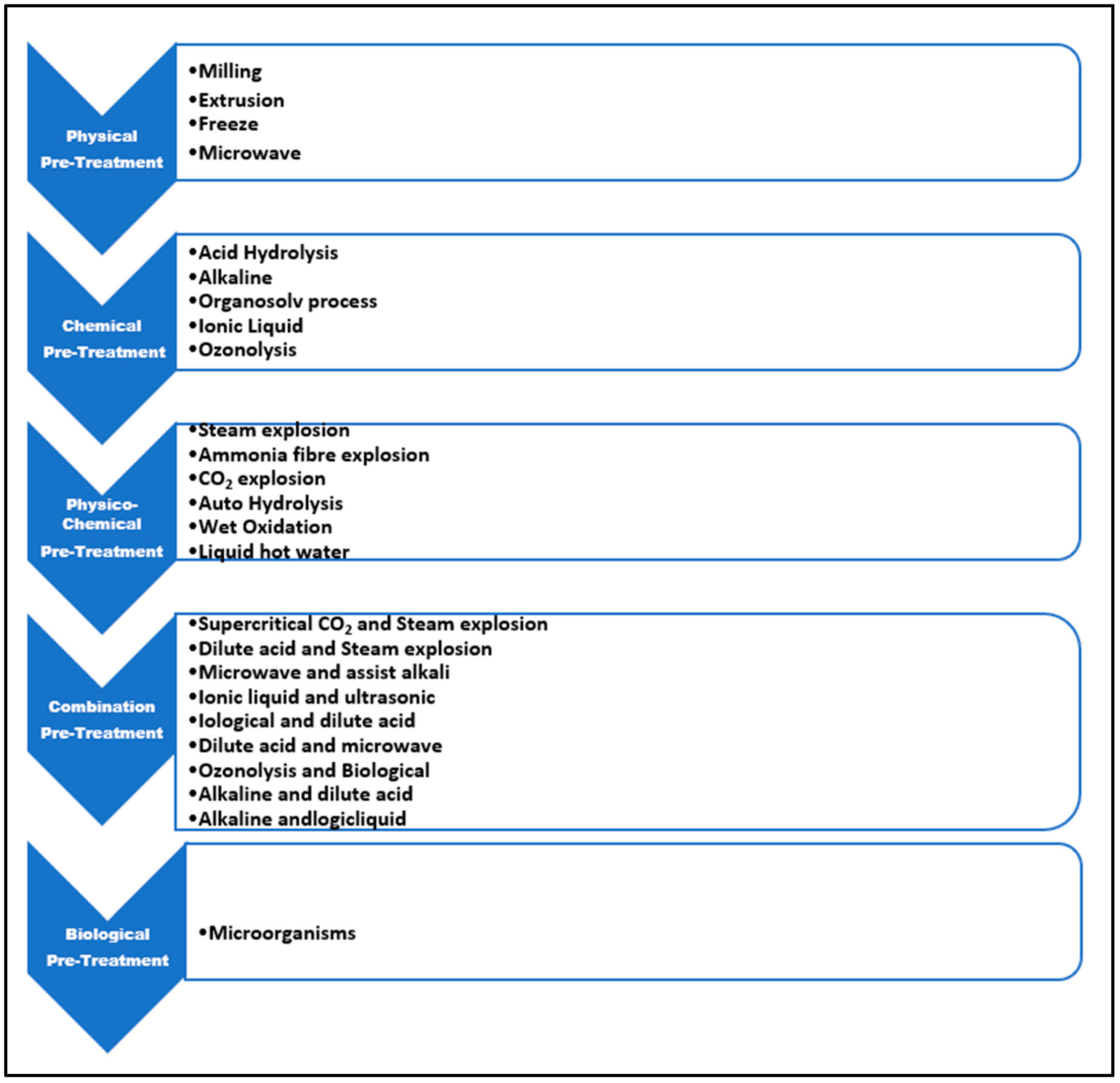

4. Pretreatment of Sugarcane Bagasse for Industrial Applications

5. Types of Anaerobic Bacteria Clostridia (Yeast)

6. Bioethanol Production from Sugarcane

7. Cost Analysis

8. Comparison between Bioethanol from Different Sources

9. Economic Challenges

10. ABE and Ethanol in Internal Combustion Engines

11. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ABE | Acetone-butanol-ethanol |

| ABEDI | ABE direct injection |

| BA | Butanol-acetone |

| BSFC | Brake specific fuel consumption |

| BTE | Brake thermal efficiency |

| 20ABE80 | 20% ABE80% diesel |

| CO | Carbon monoxide |

| EGR | Exhaust gas recirculation |

| ICE | Internal combustion engines |

| GPI | gasoline port injection |

| HC | Hydrocarbon emission |

| SL | Sugarcane lignin |

| LB | lignocellulosic biomass |

| NOx | Nitrogen oxides emission |

| SB | Sugarcane bagasse |

| SSF | simultaneous saccharification and fermentation |

| SI | Spark ignition |

References

- Mendiburu, A.Z.; Lauermann, C.H.; Hayashi, T.C.; Mariños, D.; da Costa, R.B.R.; Coronado, C.J.; Roberts, J.J.; de Carvalho, J.A., Jr. Ethanol as a renewable biofuel: Combustion characteristics and application in engines. Energy 2022, 257, 124688. [Google Scholar] [CrossRef]

- Masum, B.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Palash, S.M.; Abedin, M.J. Effect of ethanol–gasoline blend on NOx emission in SI engine. Renew. Sustain. Energy Rev. 2013, 24, 209–222. [Google Scholar] [CrossRef]

- Kandasamy, M.; Hamawand, I.; Bowtell, L.; Seneweera, S.; Chakrabarty, S.; Yusaf, T.; Shakoor, Z.; Algayyim, S.; Eberhard, F. Investigation of ethanol production potential from lignocellulosic material without enzymatic hydrolysis using the ultrasound technique. Energies 2017, 10, 62. [Google Scholar] [CrossRef]

- Zhang, W.L.; Liu, Z.Y.; Liu, Z.; Li, F.L. Butanol production from corncob residue using Clostridium beijerinckii NCIMB 8052. Lett. Appl. Microbiol. 2012, 55, 240–246. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, J.; Kuittinen, S.; Vepsäläinen, J.; Soininen, P.; Keinänen, M.; Pappinen, A. Enhanced sugar production from pretreated barley straw by additive xylanase and surfactants in enzymatic hydrolysis for acetone–butanol–ethanol fermentation. Bioresour. Technol. 2015, 189, 131–137. [Google Scholar] [CrossRef]

- Savaliya, M.L.; Dhorajiya, B.D.; Dholakiya, B.Z. Recent advancement in production of liquid biofuels from renewable resources: A review. Res. Chem. Intermed. 2013, 41, 475–509. [Google Scholar] [CrossRef]

- Algayyim, S.J.M. The Use of BA Mixture in Diesel Engines: Blend Preparation, Spray Visualisation and Engine Performance. Ph.D. Thesis, University of Southern Queensland, Toowoomba, Australia, 2019. [Google Scholar]

- Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Carlucci, F.V. Proposed best operating practices to improve technical efficiency in brazilian sugar and ethanol plants. In Proceedings of the 2018 Conference of the Australian Society of Sugar Cane Technologists, Mackay, QLD, Australia, 18–20 April 2018. [Google Scholar]

- O’Hara, I. Cellulosic Ethanol from Sugar Cane Bagasse in Australia: Exploring Industry Feasibility through Systems Analysis Techno-Economic Assessment and Pilot Plant Development. Ph.D. Thesis, Queensland University of Technology, Brisbane, QLD, Australia, 2011. [Google Scholar]

- Gonçalves, A.R.; Benar, P.; Costa, S.M.; Ruzene, D.S.; Moriya, R.Y.; Luz, S.M.; Ferretti, L.P. Integrated processes for use of pulps and lignins obtained from sugarcane bagasse and straw. Appl. Biochem. Biotechnol. 2005, 123, 821–826. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T.; Hamawand, I. Production and application of ABE as a biofuel. Renew. Sustain. Energy Rev. 2018, 82, 1195–1214. [Google Scholar] [CrossRef]

- Qureshi, N.; Bowman, M.; Saha, B.; Hector, R.; Berhow, M.; Cotta, M. Effect of cellulosic sugar degradation products (furfural and hydroxymethyl furfural) on acetone–butanol–ethanol (ABE) fermentation using Clostridium beijerinckii P260. Food Bioprod. Process. 2012, 90, 533–540. [Google Scholar] [CrossRef]

- Sun, J.-X.; Sun, X.-F.; Sun, R.-C.; Fowler, A.P.; Baird, M.S. Inhomogeneities in the Chemical Structure of Sugarcane Bagasse Lignin. J. Agric. Food Chem. 2003, 51, 6719–6725. [Google Scholar] [CrossRef] [PubMed]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T. Experimental and numerical investigation of spray characteristics of butanol-diesel blends. In Proceedings of the 11th Asia-Pacific Conference on Combustion, Sydney, Australia, 10–14 December 2017. [Google Scholar]

- Vandenberghe, L.P.S.; Valladares-Diestra, K.K.; Bittencourt, G.A.; Torres, L.Z.; Vieira, S.; Karp, S.G.; Sydney, E.B.; de Carvalho, J.C.; Soccol, V.T.; Soccol, C.R. Beyond sugar and ethanol: The future of sugarcane biorefineries in Brazil. Renew. Sustain. Energy Rev. 2022, 167, 112721. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P. Performance and emission levels of butanol, acetone-butanol-ethanol, butanol-acetone/diesel blends in a diesel engine. Biofuels 2022, 13, 449–459. [Google Scholar] [CrossRef]

- Veza, I.; Said, M.F.M.; Latiff, Z.A. Recent advances in butanol production by acetone-butanol-ethanol (ABE) fermentation. Biomass Bioenergy 2021, 144, 105919. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T.F.; Hamawand, I.; Al-lwayzy, S. Experimental study of spray characteristics, engine performance and emission levels of acetone-butanol-ethanol mixture-diesel blends in a diesel engine. In Proceedings of the 11th Asia-Pacific Conference on Combustion, Sydney, Australia, 10–14 December 2017. [Google Scholar]

- Laimon, M.; Yusaf, T.; Mai, T.; Goh, S.; Alrefae, W. A systems thinking approach to address sustainability challenges to the energy sector. Int. J. Fluids 2022, 15, 100161. [Google Scholar] [CrossRef]

- Laimon, M.; Mai, T.; Goh, S.; Yusaf, T. Energy sector development: System dynamics analysis. Appl. Sci. 2019, 10, 134. [Google Scholar] [CrossRef]

- ACCC. Inquiry into the National Electricity Market; ACCC: Canberra, ACT, Australia, 2022. [Google Scholar]

- Jesus Junior, M.M.; De Avila Rodrigues, F.; Moreira Da Costa, M.; Guirardello, R. Economic Evaluation for Bioproducts Production from Carbohydrates Obtained from Hydrolysis of Sugarcane Bagasse. Chem. Eng. Trans. 2022, 92, 703–708. [Google Scholar]

- Yadav, P.; Kumar Tiwari, S.; Kumar, V.; Singh, D.; Kumar, S.; Malik, V.; Singh, B. Sugarcane bagasse: An important lignocellulosic substrate for production of enzymes and biofuels. Biomass Conv. Bioref. 2022. [Google Scholar] [CrossRef]

- Haghdan, S.; Renneckar, S.; Smith, G.D. 1—Sources of lignin. In Lignin in Polymer Composites; Faruk, O., Sain, M., Eds.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 1–11. [Google Scholar]

- Zhao, X.; Peng, F.; Cheng, K.; Liu, D. Enhancement of the enzymatic digestibility of sugarcane bagasse by alkali–peracetic acid pretreatment. Enzym. Microb. Technol. 2009, 44, 17–23. [Google Scholar] [CrossRef]

- Doherty, W.; Halley, P.; Edye, L.; Rogers, D.; Cardona, F.; Park, Y.; Woo, T. Studies on polymers and composites from lignin and fiber derived from sugarcane. Polym. Adv. Technol. 2007, 18, 673–678. [Google Scholar] [CrossRef]

- Chandel, A.K.; da Silva, S.S.; Carvalho, W.; Singh, O.V. Sugarcane bagasse and leaves: Foreseeable biomass of biofuel and bio-products. J. Chem. Technol. Biotechnol. 2012, 87, 11–20. [Google Scholar] [CrossRef]

- Chandel, A.K.; Chan, E.; Rudravaram, R.; Narasu, M.L.; Rao, L.V.; Ravindra, P. Economics, and environmental impact of bioethanol production technologies: An appraisal. Biotechnol. Mol. Biol. Rev. 2007, 2, 14–32. [Google Scholar]

- Canilha, L.; Kumar Chandel, A.; dos Santos Milessi, T.S.; Fernandes Antunes, F.A.; da Costa Freitas, W.L.; das Gracas Almeida Felipe, M.; da Silva, S.S. Bioconversion of Sugarcane Biomass into Ethanol: An Overview about Composition, Pretreatment Methods, Detoxification of Hydrolysates, Enzymatic Saccharification, and Ethanol Fermentation. J. Biomed. Biotechnol. 2012, 2012, 989572. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, N.; Ezeji, T.C.; Ebener, J.; Dien, B.S.; Cotta, M.A.; Blaschek, H.P. Butanol production by Clostridium beijerinckii. Part I: Use of acid and enzyme hydrolyzed corn fiber. Bioresour. Technol. 2008, 99, 5915–5922. [Google Scholar] [CrossRef]

- Qureshi, N.; Saha, B.C.; Hector, R.E.; Hughes, S.R.; Cotta, M.A. Butanol production from wheat straw by simultaneous saccharification and fermentation using Clostridium beijerinckii: Part I—Batch fermentation. Biomass Bioenergy 2008, 32, 168–175. [Google Scholar] [CrossRef]

- Efremenko, E.; Nikolskaya, A.B.; Lyagin, I.V.; Sen’Ko, O.V.; Makhlis, T.A.; Stepanov, N.A.; Maslova, O.V.; Mamedova, F.; Varfolomeev, S.D. Production of biofuels from pretreated microalgae biomass by anaerobic fermentation with immobilized Clostridium acetobutylicum cells. Bioresour. Technol. 2012, 114, 342–348. [Google Scholar] [CrossRef]

- Bankar, S.B.; Survase, S.A.; Singhal, R.S.; Granström, T. Continuous two stage acetone–butanol–ethanol fermentation with integrated solvent removal using Clostridium acetobutylicum B 5313. Bioresour. Technol. 2012, 106, 110–116. [Google Scholar] [CrossRef]

- Yen, H.-W.; Li, R.-J.; Ma, T.-W. The development process for a continuous acetone–butanol–ethanol (ABE) fermentation by immobilized Clostridium acetobutylicum. J. Taiwan Inst. Chem. Eng. 2011, 42, 902–907. [Google Scholar] [CrossRef]

- Jonglertjunya, W.; Chinwatpaiboon, P.; Thambaramee, H.; Prayoonyong, P. Butanol, Ethanol and Acetone Production from Sugarcane Bagasses by Acid Hydrolysis and Fermentation Using Clostridium sp. Adv. Mater. Res. 2014, 931–932, 1602–1607. [Google Scholar] [CrossRef]

- Lu, C.; Zhao, J.; Yang, S.-T.; Wei, D. Fed-batch fermentation for n-butanol production from cassava bagasse hydrolysate in a fibrous bed bioreactor with continuous gas stripping. Bioresour. Technol. 2012, 104, 380–387. [Google Scholar] [CrossRef]

- Wang, L.; Chen, H. Increased fermentability of enzymatically hydrolyzed steam-exploded corn stover for butanol production by removal of fermentation inhibitors. Process Biochem. 2011, 46, 604–607. [Google Scholar] [CrossRef]

- Qureshi, N.; Saha, B.C.; Dien, B.; Hector, R.E.; Cotta, M.A. Production of butanol (a biofuel) from agricultural residues: Part I—Use of barley straw hydrolysate. Biomass Bioenergy 2010, 34, 559–565. [Google Scholar] [CrossRef]

- Rodríguez-Chong, A.; Ramírez, J.A.; Garrote, G.; Vázquez, M. Hydrolysis of sugarcane bagasse using nitric acid: A kinetic assessment. J. Food Eng. 2004, 61, 143–152. [Google Scholar] [CrossRef]

- Dalena, F.; Senatore, A.; Iulianelli, A.; Di Paola, L.; Basile, M.; Basile, A. Ethanol from Biomass: Future and Perspectives. In Ethanol; Basile, A., Iulianelli, A., Dalena, F., Veziroğlu, T.N., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 2; pp. 25–59. [Google Scholar]

- Pattra, S.; Sangyoka, S.; Boonmee, M.; Reungsang, A. Bio-hydrogen production from the fermentation of sugarcane bagasse hydrolysate by Clostridium butyricum. Int. J. Hydrogen Energy 2008, 33, 5256–5265. [Google Scholar] [CrossRef]

- Mohapatra, S.; Ray, R.C.; Ramachandran, S. Bioethanol from Biorenewable Feedstocks: Technology, Economics, and Challenges. In Bioethanol Production from Food Crops; Ray, R.C., Ramachandran, S., Eds.; Academic Press: Cambridge, MA, USA, 2019; Chapter 1; pp. 3–27. [Google Scholar]

- Dias, M.O.S.; Junqueira, T.L.; Jesus, C.D.F.; Rossell, C.E.V.; Maciel Filho, R.; Bonomi, A. Improving second generation ethanol production through optimization of first-generation production process from sugarcane. Energy 2012, 43, 246–252. [Google Scholar] [CrossRef]

- Balat, M.; Balat, H.; Öz, C. Progress in bioethanol processing. Prog. Energy Combust. Sci. 2008, 34, 551–573. [Google Scholar] [CrossRef]

- Vasić, K.; Knez, Ž.; Leitgeb, M. Bioethanol Production by Enzymatic Hydrolysis from Different Lignocellulosic Sources. Molecules 2021, 26, 753. [Google Scholar] [CrossRef]

- Leite, G.B.; Abdelaziz, A.E.M.; Hallenbeck, P.C. Algal biofuels: Challenges and opportunities. Bioresour. Technol. 2013, 145, 134-41. [Google Scholar] [CrossRef]

- Bertrand, E.; Vandenberghe, L.P.S.; Soccol, C.R.; Sigoillot, J.-C.; Faulds, C. First generation bioethanol. In Green Fuels Technology: Biofuels; Soccol, C.R., Brar, S.K., Faulds, C., Ramos, L.P., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 175–212. [Google Scholar]

- Macedo, I.C.; Seabra, J.E.A.; Silva, J.E.A.R. Greenhouse gases emissions in the production and use of ethanol from sugarcane in Brazil: The 2005/2006 averages and a prediction for 2020. Biomass Bioenergy 2008, 32, 582–595. [Google Scholar] [CrossRef]

- Humbert, R.P. The Growing of Sugarcane; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Bell, M.J.; Garside, A.L. Shoot and stalk dynamics and the yield of sugarcane crops in tropical and subtropical Queensland, Australia. Field Crops Res. 2005, 92, 231–248. [Google Scholar] [CrossRef]

- Hemwong, S.; Cadisch, G.; Toomsan, B.; Limpinuntana, V.; Vityakon, P.; Patanothai, A. Dynamics of residue decomposition and N2 fixation of grain legumes upon sugarcane residue retention as an alternative to burning. Soil Tillage Res. 2008, 99, 84–97. [Google Scholar] [CrossRef]

- Peng, F.; Ren, J.-L.; Xu, F.; Bian, J.; Peng, P.; Sun, R.-C. Comparative Study of Hemicelluloses Obtained by Graded Ethanol Precipitation from Sugarcane Bagasse. J. Agric. Food Chem. 2009, 57, 6305–6317. [Google Scholar] [CrossRef]

- Li, X.; Kondo, R.; Sakai, K. Biodegradation of sugarcane bagasse with marine fungus Phlebia sp. MG-60. J. Wood Sci. 2002, 48, 159–162. [Google Scholar] [CrossRef]

- Guo, G.-L.; Hsu, D.-C.; Chen, W.-H.; Chen, W.-H.; Hwang, W.-S. Characterization of enzymatic saccharification for acid-pretreated lignocellulosic materials with different lignin composition. Enzym. Microb. Technol. 2009, 45, 80–87. [Google Scholar] [CrossRef]

- Zhao, X.Q.; Bai, F.W. Mechanisms of yeast stress tolerance and its manipulation for efficient fuel ethanol production. J. Biotechnol. 2009, 144, 23–30. [Google Scholar] [CrossRef] [PubMed]

- Khare, S.K.; Pandey, A.; Larroche, C. Current perspectives in enzymatic saccharification of lignocellulosic biomass. Biochem. Eng. J. 2015, 102, 38–44. [Google Scholar] [CrossRef]

- Hoang, A.T.; Ong, H.C.; Fattah, I.M.R.; Chong, C.T.; Cheng, C.K.; Sakthivel, R.; Ok, Y.S. Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process. Technol. 2021, 223, 106997. [Google Scholar] [CrossRef]

- Methrath Liyakathali, N.A.; Muley, P.D.; Aita, G.; Boldor, D. Effect of frequency and reaction time in focused ultrasonic pretreatment of energy cane bagasse for bioethanol production. Bioresour. Technol. 2016, 200, 262–271. [Google Scholar] [CrossRef]

- Jugwanth, Y.; Sewsynker-Sukai, Y.; Gueguim Kana, E.B. Valorization of sugarcane bagasse for bioethanol production through simultaneous saccharification and fermentation: Optimization and kinetic studies. Fuel 2020, 262, 116552. [Google Scholar] [CrossRef]

- Valladares-Diestra, K.K.; Porto de Souza Vandenberghe, L.; Zevallos Torres, L.A.; Nishida, V.S.; Zandoná Filho, A.; Woiciechowski, A.L.; Soccol, C.R. Imidazole green solvent pre-treatment as a strategy for second-generation bioethanol production from sugarcane bagasse. Chem. Eng. J. 2021, 420, 127708. [Google Scholar] [CrossRef]

- Ramadoss, G.; Muthukumar, K. Influence of dual salt on the pretreatment of sugarcane bagasse with hydrogen peroxide for bioethanol production. Chem. Eng. J. 2015, 260, 178–187. [Google Scholar] [CrossRef]

- Asada, C.; Sasaki, C.; Oka, C.; Nakamura, Y. Ethanol Production from Sugarcane Bagasse Using Pressurized Microwave Treatment with Inorganic Salts and Salt-Tolerant Yeast. Waste Biomass Valoriz. 2020, 11, 2001–2007. [Google Scholar] [CrossRef]

- Tura, A.; Fontana, R.C.; Camassola, M. Schizosaccharomyces pombe as an Efficient Yeast to Convert Sugarcane Bagasse Pretreated with Ionic Liquids in Ethanol. Appl. Biochem. Biotechnol. 2018, 186, 960–971. [Google Scholar] [CrossRef] [PubMed]

- Raj, K.; Krishnan, C. Improved high solid loading enzymatic hydrolysis of low-temperature aqueous ammonia-soaked sugarcane bagasse using laccase-mediator system and high concentration ethanol production. Ind. Crops Prod. 2019, 131, 32–40. [Google Scholar] [CrossRef]

- Bu, J.; Yan, X.; Wang, Y.-T.; Zhu, S.-M.; Zhu, M.-J. Co-production of high-gravity bioethanol and succinic acid from potassium peroxymonosulfate and deacetylation sequentially pretreated sugarcane bagasse by simultaneous saccharification and co-fermentation. Energy Convers. Manag. 2019, 186, 131–139. [Google Scholar] [CrossRef]

- Neves, P.V.; Pitarelo, A.P.; Ramos, L.P. Production of cellulosic ethanol from sugarcane bagasse by steam explosion: Effect of extractives content, acid catalysis and different fermentation technologies. Bioresour. Technol. 2016, 208, 184–194. [Google Scholar] [CrossRef]

- Wang, Z.; Dien, B.S.; Rausch, K.D.; Tumbleson, M.E.; Singh, V. Improving ethanol yields with deacetylated and two-stage pretreated corn stover and sugarcane bagasse by blending commercial xylose-fermenting and wild type Saccharomyces yeast. Bioresour. Technol. 2019, 282, 103–109. [Google Scholar] [CrossRef]

- Ninomiya, K.; Utami, A.R.I.; Tsuge, Y.; Kuroda, K.; Ogino, C.; Taima, T.; Saito, J.; Kimizu, M.; Takahashi, K. Pretreatment of bagasse with a minimum amount of cholinium ionic liquid for subsequent saccharification at high loading and co-fermentation for ethanol production. Chem. Eng. J. 2018, 334, 657–663. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, W.; Tan, X.; Zahoor; Chen, X.; Guo, Y.; Yu, Q.; Yuan, Z.; Zhuang, X. Low-temperature sodium hydroxide pretreatment for ethanol production from sugarcane bagasse without washing process. Bioresour. Technol. 2019, 291, 121844. [Google Scholar] [CrossRef]

- biofuel.org.uk. Major Biofuel Producers by Region. Available online: http://biofuel.org.uk/major-producers-by-region.html (accessed on 15 July 2022).

- Alternative Fuels Data Center. Maps and Data—Global Ethanol Production by Country or Region. 2021. Available online: https://afdc.energy.gov/data/10331 (accessed on 15 July 2022).

- Ong, H.C.; Tiong, Y.W.; Goh, B.H.H.; Gan, Y.Y.; Mofijur, M.; Fattah, I.M.R.; Chong, C.T.; Alam, M.A.; Lee, H.V.; Silitonga, A.S.; et al. Recent advances in biodiesel production from agricultural products and microalgae using ionic liquids: Opportunities and challenges. Energy Convers. Manag. 2021, 228, 113647. [Google Scholar] [CrossRef]

- Imtenan, S.; Varman, M.; Masjuki, H.H.; Kalam, M.A.; Sajjad, H.; Arbab, M.I.; Rizwanul Fattah, I.M. Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels: A review. Energy Convers. Manag. 2014, 80, 329–356. [Google Scholar] [CrossRef]

- Shahir, S.A.; Masjuki, H.H.; Kalam, M.A.; Imran, A.; Rizwanul Fattah, I.M.; Sanjid, A. Feasibility of diesel–biodiesel–ethanol/bioethanol blend as existing CI engine fuel: An assessment of properties, material compatibility, safety and combustion. Renew. Sustain. Energy Rev. 2014, 32, 379–395. [Google Scholar] [CrossRef]

- Gupta, A.; Verma, J.P. Sustainable bio-ethanol production from agro-residues: A review. Renew. Sustain. Energy Rev. 2015, 41, 550–567. [Google Scholar] [CrossRef]

- Haankuku, C.; Epplin, F.M.; Kakani, V.G. Industrial sugar beets to biofuel: Field to fuel production system and cost estimates. Biomass Bioenergy 2015, 80, 267–277. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, J.J. Dilute acid pretreatment of rye straw and bermudagrass for ethanol production. Bioresour. Technol. 2005, 96, 1599–1606. [Google Scholar] [CrossRef]

- Aiyejagbara, M.; Aderemi, B.; Ameh, A.; Ishidi, E.; Ibeneme, E.F.; Olakunle, M. Production of Bioethanol from Elephant Grass (Pennisetum purpureum) Stem. Int. J. Innov. Math. Stat. Energy Policies 2016, 4, 1–9. [Google Scholar]

- Semhaoui, I.; Zarguili, I.; Rezzoug, S.A.; Maugard, T.; Zhao, J.M.Q.; Toyir, J.; Nawdali, M.; Maache-Rezzoug, Z. Bioconversion of Moroccan Alfa (Stipa Tenacissima) by Thermomechanical Pretreatment Combined to Acid or Alkali Spraying for Ethanol Production. J. Mater. Environ. Sci. 2017, 8, 2619–2631. [Google Scholar]

- Cardona, E.; Rios, J.; Peña, J.; Peñuela, M.; Rios, L. King Grass: A very promising material for the production of second-generation ethanol in tropical countries. Biomass Bioenergy 2016, 95, 206–213. [Google Scholar] [CrossRef]

- Keshwani, D.R.; Cheng, J.J. Switchgrass for bioethanol and other value-added applications: A review. Bioresour. Technol. 2009, 100, 1515–1523. [Google Scholar] [CrossRef]

- Carpio, L.G.T.; de Souza, F.S. Optimal allocation of sugarcane bagasse for producing bioelectricity and second-generation ethanol in Brazil: Scenarios of cost reductions. Renew. Energy 2017, 111, 771–780. [Google Scholar] [CrossRef]

- Adsul, M.; Sandhu, S.K.; Sinhania, R.R.; Gupta, R.; Puri, S.K.; Mathur, A. Designing a cellulolytic enzyme cocktail for the efficient and economical conversion of lignocellulosic biomass to biofuels. Enzym. Microb. Technol. 2020, 133, 109442. [Google Scholar] [CrossRef]

- Prajapati, B.P.; Jana, U.K.; Suryawanshi, R.K.; Kango, N. Sugarcane bagasse saccharification using Aspergillus tubingensis enzymatic cocktail for 2G bio ethanol production. Renew. Energy 2020, 152, 653–663. [Google Scholar] [CrossRef]

- Raj, K.; Krishnan, C. Improved co-production of ethanol and xylitol from low temperature aqueous ammonia pretreated sugarcane bagasse using two-stage high solids enzymatic hydrolysis and Candida tropicalis. Renew. Energy 2020, 153, 392–403. [Google Scholar] [CrossRef]

- Unrean, P.; Ketsub, N. Integrated lignocellulosic bioprocess for co-production of ethanol and xylitol from sugarcane bagasse. Ind. Crop Prod. 2018, 123, 238–246. [Google Scholar] [CrossRef]

- Valladares-Diestra, K.K.; de Souza Vandenberghe, L.P.; Soccol, C.R. Integrated xylooligosaccharides production from imidazole-treated sugarcane bagasse with application of in house produced enzymes. Bioresour. Technol. 2022, 362, 127800. [Google Scholar] [CrossRef]

- Duan, X.; Xu, Z.; Sun, X.; Deng, B.; Liu, J. Effects of injection timing and EGR on combustion and emissions characteristics of the diesel engine fuelled with acetone–butanol–ethanol/diesel blend fuels. Energy 2021, 231, 121069. [Google Scholar] [CrossRef]

- Aguado-Deblas, L.; López-Tenllado, F.J.; Luna, D.; Bautista, F.M.; Romero, A.A.; Estevez, R. Advanced Biofuels from ABE(Acetone/Butanol/Ethanol) and Vegetable Oils (Castor or Sunflower Oil) for Using in Triple Blends with Diesel: Evaluation on a Diesel Engine. Materials 2022, 15, 6493. [Google Scholar] [CrossRef]

- Nilaphai, O.; Komanee, K.; Chuepeng, S. Expansion heat release and thermal efficiency of acetone-butanol-ethanol- diesel blended fuel (ABE20) combustion in piston engine. Fuel 2022, 309, 122214. [Google Scholar] [CrossRef]

- Dinesha, P.; Mohan, S.; Kumar, S. Experimental investigation of SI engine characteristics using Acetone-Butanol-Ethanol (ABE)—Gasoline blends and optimization using Particle Swarm Optimization. Int. J. Hydrogen Energy 2022, 47, 5692–5708. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, X.; Guo, Z.; Li, Y.; Zhang, J.; Liu, D. Study on Combustion and Emissions of a Spark Ignition Engine with Gasoline Port Injection Plus Acetone–Butanol–Ethanol (ABE) Direct Injection under Different Speeds and Loads. Energies 2022, 15, 7028. [Google Scholar] [CrossRef]

- Kunwer, R.; Pasupuleti, S.R.; Bhurat, S.S.; Gugulothu, S.K.; Rathore, N. Blending of ethanol with gasoline and diesel fuel—A review. Mater. Today Proc. 2022, in press. [CrossRef]

| Material | Conditions of Hydrolysis | Main Components of Hydrolysates | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Solvent | Temp. | Reaction Time (mm) | Enzyme | Glucose (g/L) | Xylose (g/L) | Arabinose (g/L) | Reducing Sugar (g/L) | Refs. | |

| Cassave Bagasse | H2O | 121 | 30 | Glucoamylase Accellerase 1500 | 44.8 | 1.6 | 0.06 | [36] | |

| Corn Stover | 4% H2O 1% NAOH | 25 | 1440 | Cellulase Xylanase | 32.8 | 13.4 | 53.5 | [37] | |

| Barley Straw | 1% H2SO4 (v/v) | 121 | 60 | Cellulase β-Glucosidase Xylanase | 20.2 | 15.9 | 6.1 | 44.9 | [38] |

| Corn Fiber | 1% H2SO4 (v/v) | 121 | 60 | 4.3 | 29.8 | [39] | |||

| Wheat Straw | 1% H2SO4 (v/v) | 121 | 60 | 2.8 | 17.8 | 3.1 | [40] | ||

| Sugarcane Bagasse | 6% HNO3 (v/v) | 121 | 9.3 | 2.9 | 18.6 | 2 | [41] | ||

| Sugarcane Bagasse | 5% H2SO4 (v/v) | 121 | 60 | 18.7 | 19.8 | 2.4 | [42] | ||

| Test Condition | Theoretical Yield (%) | Productivity (g/L h−1) | Production of Bioethanol (L/ton) | Refs. |

|---|---|---|---|---|

| MnSO4 H2O and ZnO system Temp: 100 °C Time: 30 min Ratio 0.05/10 (w/v) biomass/solvent Pretreatment: Dilute acid (hydrolysis) | 84.3 | 0.182 | 233.2 a | [58] |

| MgCl2 Temp: 200 °C Time: 5 min Freq: 2.45 GHz Ratio: 1/15 (w/v) biomass/solution Pretreatment: Pressurized microwave (hydrothermal) | 90 | Nr | 228.1 a | [59] |

| A. tubingensis enzymatic cocktail with 1 FPU pH: 5.0 Temp: 45 °C Time: 6 h Ratio: 0.7/10 (w/v) biomass/solution Pretreatment: enzymatic | 77.9 | 0.161 | 84.9 a | [60] |

| NH4OH (20%) Temp: 50 °C Time: 48 h Ratio: 1/10 (w/v) biomass/solution Pretreatment: Aqueous ammonia soaking | 90.9 | 1.21 | 169.5 a | [61] |

| Potassium peroxymonosulfate combined with NaOH Temp: 65 °C/65 °C Time: 10 h/1 h Amount: 175 mmol/L/12.5 mmol/L Ratio: 1/20 (w/v) biomass/solution Pretreatment: Sequential | 79.01 | 0.56 | 135 a | [62] |

| H3PO4 (9.5 mg/g of biomass) Temp: 195 °C (18 atm) Time: 7.5 min Pretreatment: Steam explosion | 88.9 | 0.29 | 174.7 a | [63] |

| [C4mim] [OAc] Temp: 120 °C Time: 24 h Ratio: 1/4 (w/w) biomass/Ils Pretreatment: Ionic liquid | 78 | Nr | 152.5 a | [64] |

| NaOH (0.1 M) Temp: 80 °C Tie: 3 h Ratio: 1/9 (w/v) biomass/solution, Water/biomass ratio of 1/4 at 70 rpm, 180 °C and 10 min Pretreatment: Deacetylation, Liquid hot water | Nr | 1.42 | 343.5 a | [65] |

| Choline acetate Temp: 110 °C Time: 21 h Ratio: 2/3 (w/w) biomass/Ils Pretreatment: Ionic liquid | 85 | 0.625 | 152.1 a | [66] |

| ZnCl2 and NaOH (Time: 30 min Temp: 121 °C/121 °C Ratio: n.a./0.97/10 (w/v) biomass/solvent) Pretreatment: Steam-assisted sequential salt-alkali | 95.9 | 0.290 | 62.1 b | [67] |

| NaOH Temp: 50 °C Time: 4 h Ratio: 1/9 (w/v) biomass/solvent Pretreatment: Low-temperature sodium hydroxide | 67.5 | 0.932 | 212.9 a | [68] |

| Imidazole Temp: 180°C Time: 1 h Ratio: 1/9 (w/w) biomass/solvent Pretreatment: Imidazole green solvent | 83.7 | 1.11 | 217.9 a | [69] |

| Region | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|---|

| United States | 15,413 | 15,936 | 16,091 | 15,778 | 13,941 | 15,015 |

| Brazil | 6840 | 6730 | 8060 | 8860 | 8100 | 7430 |

| European Union | 1190 | 1250 | 1300 | 1350 | 1280 | 1350 |

| China | 730 | 850 | 810 | 1010 | 930 | 860 |

| India | 260 | 230 | 430 | 460 | 540 | 860 |

| Canada | 460 | 460 | 460 | 497 | 429 | 434 |

| Thailand | 330 | 380 | 390 | 430 | 390 | 350 |

| Argentina | 240 | 290 | 290 | 290 | 210 | 260 |

| Rest of World | 587 | 644 | 709 | 655 | 650 | 711 |

| Total | 26,050 | 26,770 | 28,540 | 29,330 | 26,470 | 27,270 |

| Country | Bioethanol Production per Year (Billion Litres) | Costs (US$/L) |

|---|---|---|

| China | 3.33 (2020) | 0.32, 0.29 |

| Thailand | 1.0 | 0.18 |

| Belgium | 0.4 | - |

| EU | 4.73 (2020) | - |

| France | 1.0 | 0.60–0.68 |

| Spain | 0.4 | - |

| Sweden | – | 0.40–0.45 |

| Poland | 0.2 | 0.55–0.65 |

| US | 52.72 (2020) | 0.25–0.40 |

| Canada | 1.8 | - |

| Brazil | 30.02 (2020) | 0.16–0.22 |

| Argentina | 0.5 | - |

| Australia | 0.3 | - |

| Energy Crops | Composition (%) | Biomass Yield (tons/ha) | Bioethanol Yield | Rate of Bioethanol Production (L/ha/Year) | Refs. | |||

|---|---|---|---|---|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | Practical (g/L) | Theoretical (g/L) | ||||

| Coastal Bermuda grass | 25 | 37.5 | 6.4 | 600,000 | - | - | 10,786 | [76] |

| Elephant grass | 22 | 24 | 24 | 18,000 | 23.4 | 36.4 | 23,700 | [77] |

| Moroccan grass | 33–38 | 27–32 | 17–19 | 10,805 | 17.62 | 23.11 | 6762 | [78] |

| Orchard grass | 32 | 40 | 4.7 | 74,131.61 | 7672 | [79] | ||

| King grass | 50 | 23 | 21 | 8013 | 30.8 | 32.7 | 12,616 | [80] |

| Switch grass | 45 | 31 | 12 | 60,000 | 46.5 | 54.06 | 32,915 | [81] |

| Sugarcane bagasse | 40–45 | 30–35 | 20–30 | 30–34 tons/100 tons of sugarcane | - | 0.350–1.42 (g L−1 hr−1) | 62.1–290.2 (L/ton) | [82] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Algayyim, S.J.M.; Yusaf, T.; Hamza, N.H.; Wandel, A.P.; Fattah, I.M.R.; Laimon, M.; Rahman, S.M.A. Sugarcane Biomass as a Source of Biofuel for Internal Combustion Engines (Ethanol and Acetone-Butanol-Ethanol): A Review of Economic Challenges. Energies 2022, 15, 8644. https://doi.org/10.3390/en15228644

Algayyim SJM, Yusaf T, Hamza NH, Wandel AP, Fattah IMR, Laimon M, Rahman SMA. Sugarcane Biomass as a Source of Biofuel for Internal Combustion Engines (Ethanol and Acetone-Butanol-Ethanol): A Review of Economic Challenges. Energies. 2022; 15(22):8644. https://doi.org/10.3390/en15228644

Chicago/Turabian StyleAlgayyim, Sattar Jabbar Murad, Talal Yusaf, Naseer H. Hamza, Andrew P. Wandel, I. M. Rizwanul Fattah, Mohamd Laimon, and S. M. Ashrafur Rahman. 2022. "Sugarcane Biomass as a Source of Biofuel for Internal Combustion Engines (Ethanol and Acetone-Butanol-Ethanol): A Review of Economic Challenges" Energies 15, no. 22: 8644. https://doi.org/10.3390/en15228644

APA StyleAlgayyim, S. J. M., Yusaf, T., Hamza, N. H., Wandel, A. P., Fattah, I. M. R., Laimon, M., & Rahman, S. M. A. (2022). Sugarcane Biomass as a Source of Biofuel for Internal Combustion Engines (Ethanol and Acetone-Butanol-Ethanol): A Review of Economic Challenges. Energies, 15(22), 8644. https://doi.org/10.3390/en15228644