Abstract

The impact of single-slope solar still with and without flat-plate collector was evaluated experimentally and numerically. Experimental analysis was conducted for four different water depths (3, 6, 9, 12 cm) in on-sunshine hours between 11 AM to 5 PM in Bhopal (23.2599° N, 77.4126° E), India. The thermo efficiency was 51.31% for 3 cm water depth while 24.29% for 12 cm water depth in an active mode of operation. In the case of passive mode, the thermo efficiency was 17.02% for 3 cm water depth and 6.77% for 12 cm water depth. The average exergy efficiency of single-slope solar still is 66.60% for 3 cm depth which is higher than 12 cm depth, i.e., 23.14%. The hourly variation parameters of solar still were also calculated and analyzed. The overall results obtained in the analysis state that solar still performs effectively when coupled with a flat-plate solar collector. According to econometric evaluation, the fabrication expense of a single-slope solar-basin-still is 126.43$ whereas the cost of producing distilled water per day is 1.61$, and the payback period of a single-slope solar-basin-still with FPC is 17.53 months. In a nutshell, the single-slope solar-basin-still design is commercially viable, functional, and technically sustainable, minimizing manufacturing costs in comparison with a traditional solar still, and past findings. The proposed solar still produced remarkable results in all experimental trials.

1. Introduction

An adult human body comprises 60% water. This fact indicates the importance of water in our day-to-day life. History has also shown us that important civilizations that grew and flourished were on the banks of rivers where water was in abundance. Additionally, it is well known that water is a prerequisite for life. Nature has gifted water in abundance to us. As we know, out of the Earth’s total surface area, 71% is covered with water, out of which only 2.5% of this is fresh water that can be used by us.

Moreover, the majority of this freshwater is stored in glaciers, which means that the availability of clean water is scarce. There is a severe scarcity of potable drinking water in numerous regions/countries due to the rapid increase in the population. In rural areas, the infrastructure for drinking water is underdeveloped and hence, is unable to meet the requirements of the people [1]. For domestic use, drinking purposes, and industrial and agricultural needs, saline water is not suitable for consumption. Solar energy is feasible and economical for all solar-based appliances [2] Solar desalination is the process of utilizing solar energy and collecting water of low salt concentrate from seawater or saline water. Solar-still systems distill water and then evaporate it using solar energy. Durkaieswaran and Murugavel [3] The evaporated water is collected and purified in condensation traps, which can be utilized for drinking and other purposes. Solar distillation is both economical and pollution free as compared to the other existing desalination methods. Fathy et al. [4] In the case of the conventional methods of desalination, which are energy-intensive, higher productivity is obtained. Lower productivity was obtained for solar stills through the existing desalination methods, and extensive research was carried out to improve the system by installing condensers, basins, reflectors, etc. Single-slope single-basin solar stills are easy to construct and operate [2] The working principle of a solar still is based on evaporation and condensation. The evaporated water produces vapor in the basin, which is then allowed to condensate on a tilted glass cover. This method is environmentally friendly because the prime source of energy is from the Sun. The solar distillation process mainly consists of two modes, i.e., passive and active. In the passive solar still, the system works without a Flat-Plate Collector (FPC), while in active solar still, the system is coupled with FPC. Kumar et al. [5] examined the workings of an evacuated tube solar still and found that the thermo efficiency can be enhanced by minimizing heat losses. Eltawil et al. [6] investigated the productivity of a modified solar still coupled with FPC sprayers, tubes, etc., and found that the productivity was increased by 56% to 82% with the circulation of hot water in active and passive sprayers. Sheeba et al. [7] revealed that both the productivity and efficiency of a solar still increased when operated with saline water in a solar still equipped with FPC. Senthil et al. [8] used a modified solar still attached to a biomass water heater to enhance the evaporation rate and water temperature. The result shows that during sunlight and off-sunshine hours, the yield output increases using biomass heaters. Prakash et al. [9] functioned on a double-slope active solar still equipped with a parabolic-type trough collector and found an increment in the efficiency of about 28.1%. Deshmukh et al. [10] operated on a sensible heat-storage-based single-basin solar still and found an increase in water storage and mass. The result revealed that the productivity increased overnight and decreased with water storage and mass in daylight. Yousef et al. [11] worked on the exergy and energy performance of modified solar still with heat-storage materials, i.e., phase change materials (PCM), and explained that the average efficiency using pin fin PCM is 37.5% as compared to traditional solar stills. Panchal et al. [12]; Panchal and Sathyamurthy [13] studied a double-basin solar still with solid fin equipped with evacuated tubes and found that the distillate output is enhanced by about 25% when solid fins are attached. Rabhi et al. [14] showed a performance study in a single-slope single-basin solar still and found an increase of 32.18% in water production in solar still when coupled with airflow and an external condenser. Dashtban and Tabrizi [15] experimentally found that the total freshwater yield improved from 5.1 kg/m2 day for conventional stills to 6.7 kg/m2 day for modified still customized using PCM. Ansari et al. [16] in Errachidia city analytically found that the selection of PCM material depends on saline water’s highest value of temperature. Kumar et al. [17] conducted experiments on a hemispherical solar still with a solar concentrator with and without PCM and concluded an increase of 26% in yield for the still equipped with PCM compared to the still without PCM in his work. El-Sebaii et al. [18] analytically concluded using single-slope stills with and without PCM, that as a quantity of PCM is increased, not only nighttime productivity but daily productivity also increases. In contrast the productivity in the daytime decreases. Moreover, the authors also concluded that the freshwater yield increases when the basin is filled at shallow depths of brackish water. Kabeel et al. [19] used a customized solar still that incorporated a solar heater with a PCM storage unit and, through experiments, found a noticeable increase in the freshwater yield from 4.5 L/m2 day to 9.36 L/m2 day. Haddad et al. [20] employed vertical rotating-wick (VRW) to enhance the performance of the solar still basin. The result shows that the average thermo efficiency with VRW is 65%, and without VRW, it is 46%. García-Chávez et al. [21] performed computational fluid dynamics (CFD) analysis to conduct a thermal study on a solar distiller and observed that the solar still performance is affected by the climatic conditions, wind speed, and yield. The efficiency of the still is increased in accordance with solar radiation. Numerous studies have been conducted to improve solar still production throughout the day and at night. The literature survey made it evident that many researchers had made an attempt to raise the temperature of the water in the basin and enhance the efficiency of solar still. Table 1 provides the uniqueness of the current investigation as against the existing literature.

Table 1.

Uniqueness of the current investigation as against existing literature.

The main objective of the present experimentation is to perform a thermal analysis of the proposed setup. Secondly, economic analysis and exergy analysis were conducted to undertake the overall analysis of the system. Therefore, an attempt has been made to analyze the performance of both passive and active types of domestic solar stills. Four diverse water depths with intervals of 3 cm (3, 6, 9, and 12) were selected for the proposed study. The thermo efficiency of the proposed solar still is computed, and the solar still parameters are compared.

2. Methodology

2.1. Experimental Setup

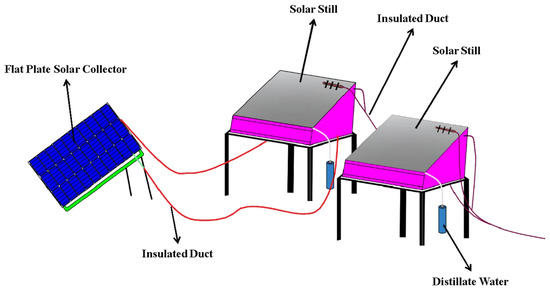

The experimentations were conducted in hot and dry climatic conditions during the sunny period from 11 a.m.–5 p.m. (IST) from 28 April 2022 to 1 May 2022. The proposed setup was titled at the latitude angle of Bhopal, India, i.e., 23.2599° N, 77.4126° E. The inner walls of the solar still basin were 4 mm thick and were of fiber-reinforced plastic (FRP). The still basin bottom surface area has a dimension of (50.80)2 cm2, and muddy black paint was applied to enhance the absorptivity, i.e., ‘ε’ = 0.88. The refractive index determines the differences between the angle of incidence and the transmission of light, with a higher index implying greater differences. The glasses used in solar stills have a refractive index of 1.5, which means that reflection losses at the surface result in approximately a 4% decrease in light intensity. In a solar still basin, hot water flows naturally to improve the temperature difference among the water surface, and glass has an absorptivity of 0.04. The area of the FPC is 5,960,000 cm2 and is tilted at a latitude angle (23.2599° N, 77.4126° E). The FPC and solar still are coupled together to circulate water in a passive mode. Figure 1 shows the schematic view, and Figure 2 depicts the experimental setup of the solar still (single slope) connected with FPC.

Figure 1.

Schematic view of experimental setup.

Figure 2.

Solar still experimental setup.

Table 2a depicts the specifications of the proposed solar still design. Table 2b shows the specifications of FPC. The rubber gasket is used to fix the condensing cover to the top of the vertical walls.

Table 2.

(a). Specifications of proposed solar-still design. (b). Specs of proposed flat-plate solar collector.

2.2. Equipment

The solar still performance was evaluated on the basis of hourly output, hourly variations in solar intensity, water temperature, glass temperature, and ambient temperature for different water depths. To measure the water vapor and glass temperatures, digital temperature and thermocouples (calibrated) were used. A solar power meter with a least count of 1 W/m2 was used to measure the solar intensity. A digital anemometer equipped with a humidity test meter and temperature sensor detects the temperature outside and within the proposed solar still, as well as the mass flow rate of air and relative humidity. Table 3 provides details on the full measuring instrument’s specifications.

Table 3.

Uses, accuracies, and ranges of the measuring devices used for experimentation.

2.3. Experimental Procedure and Observations

The experiment was conducted in sunny hours between 11:00 am to 05:00 pm in Bhopal. The latitude location of the experimental testing was 23°, and the experiment was performed in hourly variation. For mathematical calculations, the total and diffuse radiation on the collector and glass, inner and outer glass temperature, vapor, and water temperature, ambient temperature, distillate output, wind velocity, and relative humidity are the hourly variation parameters at different water depths. These parameters were observed, considering one water depth each day. The parametric values measured are used in the thermal analysis of active and passive solar stills.

2.4. Experimental Uncertainty

Many variables influenced error and uncertainty analysis, including environmental conditions, experiment instruments, test preparation, observation, reading, and calibration. In the current experiment, various parameters have been examined, necessitating the calculation of parameters including temperature, wind velocity at the dryer’s outlet and inlet, and sun intensity. The most effective instrument for planning and carrying out an experiment is uncertainty. The uncertainty analysis can be evaluated as per Equation (1): [26,27]

where, and are independent parameter while, R and are the result of the given function.

The total uncertainty for the measurement of the temperature will be calculated as Equation (2):

The total uncertainty for the measurement of wind speed will be calculated as Equation (3):

The total uncertainty for the evaluation of solar radiation will be calculated as Equation (4):

The total uncertainty of the experiment will be calculated as Equation (5):

It has been observed that all uncertainties were in the acceptable range. Table 3 shows the uses and accuracy of the measuring devices used for experimentation.

3. Performance Analysis

In this analysis, the efficiency of FPC and active solar still needs to be calculated. The inlet water temperature was heated by the collector, and the temperature of the water was increased after achieving a useful amount of energy [28]. The useful energy gained by FPC can be calculated by using Equation (6).

The thermo efficiency of FPC is described as the proportion of usable energy to the energy incident on the glazing area (aperture) and was calculated with Equations (7) and (8), [29].

3.1. The Efficiency of Proposed Solar-Still System Coupled with Flat-Plate Collector

The efficiency of the proposed solar still coupled with FPC is expressed as the proportion between the total amount of energy utilized to acquire distilled water within a specific duration and the amount of energy supplied to the solar still during the same time duration. The efficiency equation is given in Equations (9) and (10).

In the case of the passive solar still, the incident energy on the collector was not considered because of the absence of FPC. Only the effect of the glass-cover solar still will be the incidence of the solar energy input [30].

3.2. Economic & Exergy Analysis

The primary goal of any solar-still system is to reduce the cost of distillate water production per liter (CPL). The researched examples are economically examined, and the economic analysis techniques can be reduced as follows:

According to Equation (11), a solar distillation unit’s first annual cost (FAC) is as follows:

where P and CRF stand for the solar still’s capital cost and capital recovery factor, respectively.

The CRF is calculated as follows:

where n represents the lifetime years of the solar still, which are assumed to be ten years, and i is the annual rate of interest.

According to Equation (13), the solar distillation unit’s annual salvage value (ASV) is as follows:

where SSF and S stand for a system sinking fund factor (SFF) and the solar still salvage value, respectively.

S is revealed in Equation (14):

SSF can be evaluated as:

The AMC is supposedly 15% of the initial annual cost:

Equation (17) provides the solar distillation unit’s total annual cost as follows:

Lastly, the freshwater yield’s cost per liter (CPL) is calculated using Equation (18)

where Pn is the average annual production of distilled water.

The exergy analysis function represents an indicator of the energy’s ability to conduct work and is derived from the second law of thermodynamics. Exergy is defined as the maximum amount of work that a system is capable of producing when it approaches thermodynamic equilibrium in a particular environment. The general equation for the exergy balance is given below:

The exergy input of the proposed system is evaluated as per Equation (20):

While the exergy output of the proposed system is evaluated as per Equation (21):

The exergy efficiency is calculated as the difference between the input and output exergy, and it is written as follows:

4. Result and Discussion

4.1. Experimentation Data Analysis

The vapor temperature, quasi-steady static condition, and vapor leakage were analyzed in the present experimentation. The observations are listed between Table 4, Table 5, Table 6 and Table 7 at four different water depths (3, 6, 9, and 12 cm) of active and passive types of single-slope solar still from 11:00 to 17:00 h (6 h per day).

Table 4.

(a). Experimental observations of single-slope solar still without FPC at 3 cm water depth. (b). Experimental observations of single-slope solar still with FPC at 3 cm water depth.

Table 5.

(a). Experimental observations of single-slope solar still without FPC at 6 cm water depth. (b). Experimental observations of single-slope solar still with FPC at 6 cm water depth.

Table 6.

(a). Experimental observations of single-slope solar still without FPC at 9 cm water depth. (b). Experimental observations of single-slope solar still with FPC at 9 cm water depth.

Table 7.

(a). Experimental observations of single-slope solar still without FPC at 12 cm water depth. (b). Experimental observations of single-slope solar still with FPC at 12 cm water depth.

Parameters such as the ambient temperature and sun radiation can be used to perform the heat transfer analysis. The temperature within the solar still varies as a result of these factors. For the desalination process, relative humidity is crucial. The variance in the temperature is determined by the variation in the relative humidity. The moisture content of the air increases as relative humidity increases, resulting in a drop in air temperature.

It is very well known that the volume of yield output depends on the evaporative surface and the condensing surface. As the temperature difference between them enhances, the yield output of the solar still also increases. All the parametric effects on yield, convective heat-transfer coefficients, evaporative heat-transfer coefficients, and thermo efficiency are discussed in this section.

In Table 4, Table 5, Table 6 and Table 7, the ambient temperature and relative humidity variations are shown with respect to the global and the diffused radiations at 3, 6, 9, and 12 cm water depths. There is an effect on the ambient temperature due to a decrease in global and diffuse radiations since the observations are made between 11:00 and 17:00 h. It was observed that the relative humidity is inversely proportional to ambient temperature.

The variation in the temperature of the water, both, inside the glass as well as outside, with respect to diffuse global radiations with time were also shown in Table 4, Table 5, Table 6 and Table 7. The inner glass temperature is higher at a lower depth of water at 15:00 h. The temperature of the water is maximum when the Ig is at the peak.

It is inferred from the table that the yield of the solar still is maximum at the peak point of solar radiation. However, in the case of 12 cm depth, the yield is maximum, and it is concluded that the storage effect of heat results in an increment of yield output.

The variations in yield and wind velocity with respect to time are indicated at four different water depths (3, 6, 9, and 12 cm). From the table, it can be inferred that with the increase in wind velocity, the convective heat transfer coefficient also increases. If the temperature difference increases, then the yield also increases. Whenever there is an increase in the wind velocity, the yield will be reduced due to heat loss on the surface of glass and this can be clearly observed in the case of 9 cm water depth. Table 3, Table 4, Table 5 and Table 6 also show the variation in the yield per hour of a single-slope solar still with respect to water temperatures, inner glass, and time. It is concluded from the chart that yield is maximum in case of 12 cm water depth because of the difference in water temperatures. When the water-temp. is maximum, the distillate output rate enhances. As the difference in temperature increases, evaporation increases, and hence, the yield output also increases.

4.2. Exergy Analysis

Exergy is found to be higher due to solar irradiation. However, the same is not true for the exergy efficiency of a solar collector. Moreover, the exergy efficiency improved with increases in the temperature of the solar collector. The highest increase in exergy efficiency was achieved at the highest temperature. Therefore, considering the economic aspect and increased costs, heat storage-based materials were considered for the system to provide a constant temperature. Table 8 depicts the daily exergy output and exergy efficiency. Equation (15) provides the daily exergies according to varying depths, as shown in Table 7. It has been observed that the highest ᶯ is obtained for the proposed system at the 3 cm basin depth and lowest at 12 water depth as the heat obtained in the depth of 3 cm is higher due to the presence of a lower amount of water in comparison to the depth of 12 cm.

Table 8.

Exergy analysis of proposed solar still at different depth.

4.3. Cost Analysis

The cost of the solar desalination unit is affected by inlet water properties, water quantity, unit, and location site. Its cost is mainly influenced by capital cost, annual interest rate, depreciation value, annual average production in liters, maintenance cost, and expectancy of the system. The fabrication cost and GST for the solar still are not considered [31,32]. Table 9 depicts the component price in Indian currency. It has been observed that the maximum cost was acquired by the GI sheet while the minimum cost was acquired by the Supply tank. The ratio of the total annual cost and annual average production in liters were considered in calculating the unit cost of saline water. Table 10 depicts the various economic factors of all parameters.

Table 9.

Cost of solar still.

Table 10.

Economic parameters for the proposed system.

The payback period is the minimum time needed to recoup/recuperate the initial outlay or capital investment. The factors considered for calculating the payback period includes fabrication, operating, and maintenance cost. The payback period of the proposed setup is calculated as 1.46 years, while the cost of water produced per liter is analyzed as 1.61 INR. Table 11 indicates the payback duration of single-slope solar basin still with FPC.

Table 11.

Payback duration of single-slope solar basin still with FPC.

4.4. Validation

The efficiency of the solar still is 51.31% for the water depth of 3 cm with FPC and is lower at 8.87% at 9 cm depth without FPC. As the experimental setup is situated at the latitude angle of 23° N, nocturnal distillation tendency is the factor of the higher water depth [33,34]. However, at the morning time of observation at 11:00 h, the initial temperature is higher at the initial stage at 3 cm and then decreases at 6 cm, 9 cm, and 12 cm depth, respectively. The efficiency has been compared with Farid and Hamad [35] and it was found that the proposed solar still is more efficient in comparison to other investigators, as shown in Table 12.

Table 12.

Comparative Table.

5. Conclusions

In this paper, an investigational study of a modified solar still with FPC and its effects was carried out. From the different parameters, it is observed that the highest yield of the experiment is 0.238 kg/h. The hourly variations in the distillate output is dependent upon the radiation throughout the day. The experimental location latitude angle of 23° (Bhopal) yields more when the solar still is coupled with FPC. The following conclusions are drawn from the paper:

- (i).

- Thermal efficiency of solar still coupled with FPC at a water depth of 3 cm is 51.31%, which is the highest.

- (ii).

- Thermal efficiency of solar still without FPC at a water depth of 9 cm is 17.02%, which is 66.82% lower than 3 cm.

- (iii).

- The overall thermal efficiency of a solar still coupled with FPC is 42.065%, while for a solar still without FPC, it is 13.955%.

- (iv).

- The cost of the proposed solar still is 8847INR; hence the payback period of the proposed system is found as 1.46 years, which is comparatively lower than the traditional solar still.

- (v).

- Relative humidity varies inversely with ambient temperature.

- (vi).

- The solar still yield is maximum at the peak point of solar radiation.

- (vii).

- Whenever there is an increase in the wind velocity, the yield will be reduced due to heat loss on the surface of glass and this can be clearly observed in the case of 9 cm water depth.

- (viii).

- Highest ᶯ is obtained for the proposed system at the 3 cm basin depth and lowest at 12 water depth.

- (ix).

- The proposed modified solar still can be used anywhere in the world with a small modification.

Author Contributions

Conceptualization, O.P., A.A., A.K., R.C., S.C. and S.S.; formal analysis, O.P., A.A., A.K., R.C., S.C., S.S. and A.S.; investigation, O.P., A.A., A.K., R.C., S.C. and S.S.; writing—original draft preparation, O.P., A.A., A.K., R.C., S.C. and S.S.; writing—review and editing, S.S., A.S., C.L. and E.M.T.E.; supervision, S.S., C.L. and E.M.T.E.; project administration, S.S., C.L. and E.M.T.E.; funding acquisition, S.S. and E.M.T.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Annualized salvage value | |

| Aglass | Glass cover area in ‘m2′ |

| PCM | Phase Change Materials |

| VRW | Vertical Rotating Wick |

| FRP | Fibre Reinforced Plastic |

| Ig(Inc) | Global Radiation on inclined surface (W/m2) |

| Id(Inc) | Diffuse Radiation on inclined surface (W/m2) |

| m | Mass flow rate of fluid flow, (Kg/s) |

| mew | Distillate Output (Yield), mL/h. |

| hew | Evaporative coefficient |

| Tv | Temperature of vapor in ‘°C’ |

| Tgi | Temperature of glass (inside) in ‘°C’ |

| Tgo | Temperature of glass in ‘°C’ |

| SSF | Sinking Fund Factor |

| Ti | Solar collector inlet fluid temperature in ‘°C’ |

| To | Solar collector outlet fluid temperature in ‘°C’ |

| Tw | Water Temperature in ‘°C’ |

| Ta | Ambient Temperature ‘°C’ |

| Lv | Latent heat of vaporization (J/kg) |

| vg | Wind Velocity, m/s |

| γa | Relative Humidity, % |

| ε | Absorptivity |

| ατ | Absorptance–transmittance product |

References

- Elashmawy, M. Experimental study on water extraction from atmospheric air using tubular solar still. J. Clean. Prod. 2020, 249, 119322. [Google Scholar] [CrossRef]

- Prakash, O.; Ahmad, A.; Kumar, A.; Hasnain, S.M.; Kumar, G. Comprehensive analysis of design software application in solar distillation units. Mater. Sci. Energy Technol. 2022, 5, 171–180. [Google Scholar] [CrossRef]

- Durkaieswaran, P.; Murugavel, K.K. Various special designs of single basin passive solar still—A review. Renew. Sustain. Energy Rev. 2015, 49, 1048–1060. [Google Scholar] [CrossRef]

- Fathy, M.; Hassan, H.; Ahmed, M.S. Experimental study on the effect of coupling parabolic trough collector with double slope solar still on its performance. Sol. Energy 2018, 163, 54–61. [Google Scholar] [CrossRef]

- Kumar, S.; Dubey, A.; Tiwari, G. A solar still augmented with an evacuated tube collector in forced mode. Desalination 2014, 347, 15–24. [Google Scholar] [CrossRef]

- Eltawil, M.A.; Omara, Z. Enhancing the solar still performance using solar photovoltaic, flat plate collector and hot air. Desalination 2014, 349, 1–9. [Google Scholar] [CrossRef]

- Sheeba, K.N.; Prakash, P.; Jaisankar, S. Performance Evaluation of a Flat Plate Collector Coupled Solar Still System. Energy Sources Part A Recover. Util. Environ. Eff. 2015, 37, 291–298. [Google Scholar] [CrossRef]

- Sampathkumar, K.; Arjunan, T.V.; Senthilkumar, P. The Experimental Investigation of a Solar Still Coupled with an Evacuated Tube Collector. Energy Sources Part A Recover. Util. Environ. Eff. 2013, 35, 261–270. [Google Scholar] [CrossRef]

- Prakash, O.; Bhushan, B.; Kumar, A.; Ahmed, A. Thermal analysis of domestic type single Slope–Basin solar still under two different water depths. Mater. Today Proc. 2021, 46, 5482–5489. [Google Scholar] [CrossRef]

- Deshmukh, H.S.; Thombre, S.B. Solar distillation with single basin solar still using sensible heat storage materials. Desalination 2017, 410, 91–98. [Google Scholar] [CrossRef]

- Yousef, M.S.; Hassan, H. Energetic and exergetic performance assessment of the inclusion of phase change materials (PCM) in a solar distillation system. Energy Convers. Manag. 2019, 179, 349–361. [Google Scholar] [CrossRef]

- Panchal, H.; Sathyamurthy, R. Experimental analysis of single-basin solar still with porous fins. Int. J. Ambient Energy 2020, 41, 563–569. [Google Scholar] [CrossRef]

- Panchal, H.; Sathyamurthy, R.; Pandey, A.K.; Kumar, M.; Arunkumar, T.; Patel, D.K. Annual performance analysis of a single-basin passive solar still coupled with evacuated tubes: Comprehensive study in climate conditions of Mahesana, Gujarat. Int. J. Ambient Energy 2019, 40, 229–242. [Google Scholar] [CrossRef]

- Rabhi, K.; Nciri, R.; Nasri, F.; Ali, C.; Ben Bacha, H. Experimental performance analysis of a modified single-basin single-slope solar still with pin fins absorber and condenser. Desalination 2017, 416, 86–93. [Google Scholar] [CrossRef]

- Dashtban, M.; Tabrizi, F.F. Thermal analysis of a weir-type cascade solar still integrated with PCM storage. Desalination 2011, 279, 415–422. [Google Scholar] [CrossRef]

- Ansari, O.; Asbik, M.; Bah, A.; Arbaoui, A.; Khmou, A. Desalination of the brackish water using a passive solar still with a heat energy storage system. Desalination 2013, 324, 10–20. [Google Scholar] [CrossRef]

- Kumar, A.; Denkenberger, D.; Ahsan, A.; Jayaprakash, R. The augmentation of distillate yield by using concen-trator coupled solar still with phase change material. Desalination 2013, 314, 189–192. [Google Scholar]

- El-Sebaii, A.A.; Al-Ghamdi, A.A.; Al-Hazmi, F.S.; Faidah, A.S. Thermal performance of a single basin solar still with PCM as a storage medium. Appl. Energy 2009, 86, 1187–1195. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Abdelgaied, M. Improving the performance of solar still by using PCM as a thermal storage medium under Egyptian conditions. Desalination 2016, 383, 22–28. [Google Scholar] [CrossRef]

- Haddad, Z.; Chaker, A.; Rahmani, A. Improving the basin type solar still performances using a vertical rotating wick. Desalination 2017, 418, 71–78. [Google Scholar] [CrossRef]

- García-Chávez, R.; De México, U.N.A.; Chávez-Ramirez, A.; Villafán-Vidales, H.; Velázquez-Fernández, J.B.; Rosales, I.H. Thermal study of a solar distiller using computational fluid dynamics (CFD). Rev. Mex. De Ing. 2019, 19, 677–689. [Google Scholar] [CrossRef]

- Boopalan, N.; Kalidasan, B.; Ranjith, K.; Dhanush, B.; Anbarasu, S.; Selvam, S.P. Experimental Study and Performance Analysis of Phase Change Material Integrated Stepped Slope Solar Still. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1059, 012002. [Google Scholar] [CrossRef]

- Pathak, A.K.; Tyagi, V.V.; Anand, S.; Pandey, A.K.; Kothari, R. Advancement in solar still integration with phase change materials-based TES systems and nanofluid for water and wastewater treatment applications. J. Therm. Anal. 2022, 147, 9181–9227. [Google Scholar] [CrossRef]

- Thakur, A.K.; Sathyamurthy, R.; Sharshir, S.W.; Kabeel, A.E.; Elkadeem, M.R.; Ma, Z.; Manokar, A.M.; Arıcı, M.; Pandey, A.K.; Saidur, R. Performance analysis of a modified solar still using reduced graphene oxide coated absorber plate with activated carbon pellet. Sustain. Energy Technol. Assess. 2021, 45, 101046. [Google Scholar] [CrossRef]

- Panchal, H.; Sadasivuni, K.K.; Suresh, M.; Yadav, S.; Brahmbhatt, S. Performance analysis of evacuated tubes coupled solar still with double basin solar still and solid fins. Int. J. Ambient Energy 2020, 41, 1031–1037. [Google Scholar] [CrossRef]

- Ahmad, A.; Prakash, O. Thermal analysis of north wall insulated greenhouse dryer at different bed conditions operating under natural convection mode. Environ. Prog. Sustain. Energy 2019, 38, e13257. [Google Scholar] [CrossRef]

- Ahmad, A.; Prakash, O. Performance Evaluation of a Solar Greenhouse Dryer at Different Bed Conditions Under Passive Mode. J. Sol. Energy Eng. 2020, 142, 011006. [Google Scholar] [CrossRef]

- Subramanian, R.S.; Kumaresan, G.; Ajith, R.; Sabarivasan, U.; Gowthamaan, K.; Anudeep, S. Performance analysis of modified solar still integrated with flat plate collector. Mater. Today Proc. 2020, 45, 1382–1387. [Google Scholar] [CrossRef]

- Gómez-Paredes, M.D.; Hernández-Rodríguez, L.; López-Ortega, J.; González-Blanco, G.; Beristain-Cardoso, R.; México, U.A.D.E.D. Industrial wastewater treatment by anaerobic digestion using a solar heater as renewable energy for temperature-control. Rev. Mex. De Ing. 2020, 19, 9–16. [Google Scholar] [CrossRef]

- Ahmad, A.; Prakash, O.; Kumar, A. Drying kinetics and economic analysis of bitter gourd flakes drying inside hybrid greenhouse dryer. Environ. Sci. Pollut. Res. 2021, 1–15. [Google Scholar] [CrossRef]

- Quan, Q.; Gao, S.; Shang, Y.; Wang, B. Assessment of the sustainability of Gymnocypris eckloni habitat under river damming in the source region of the Yellow River. Sci. Total Environ. 2021, 778, 146312. [Google Scholar] [CrossRef]

- Fang, X.; Wang, Q.; Wang, J.; Xiang, Y.; Wu, Y.; Zhang, Y. Employing extreme value theory to establish nutrient criteria in bay waters: A case study of Xiangshan Bay. J. Hydrol. 2021, 603, 127146. [Google Scholar] [CrossRef]

- Quan, Q.; Liang, W.; Yan, D.; Lei, J. Influences of joint action of natural and social factors on atmospheric process of hydrological cycle in Inner Mongolia, China. Urban Clim. 2022, 41, 101043. [Google Scholar] [CrossRef]

- Ren, L.; Kong, F.; Wang, X.; Song, Y.; Li, X.; Zhang, F.; Sun, N.; An, H.; Jiang, Z.; Wang, J. Triggering ambient polymer-based Li-O2 battery via photo-electro-thermal synergy. Nano Energy 2022, 98, 107248. [Google Scholar] [CrossRef]

- Farid, M.; Hamad, F. Performance of a single-basin solar still. Renew. Energy 1993, 3, 75–83. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).