Thermal Performance Analysis of Various Heat Sinks Based on Alumina NePCM for Passive Cooling of Electronic Components: An Experimental Study

Abstract

1. Introduction

2. Materials and Methods

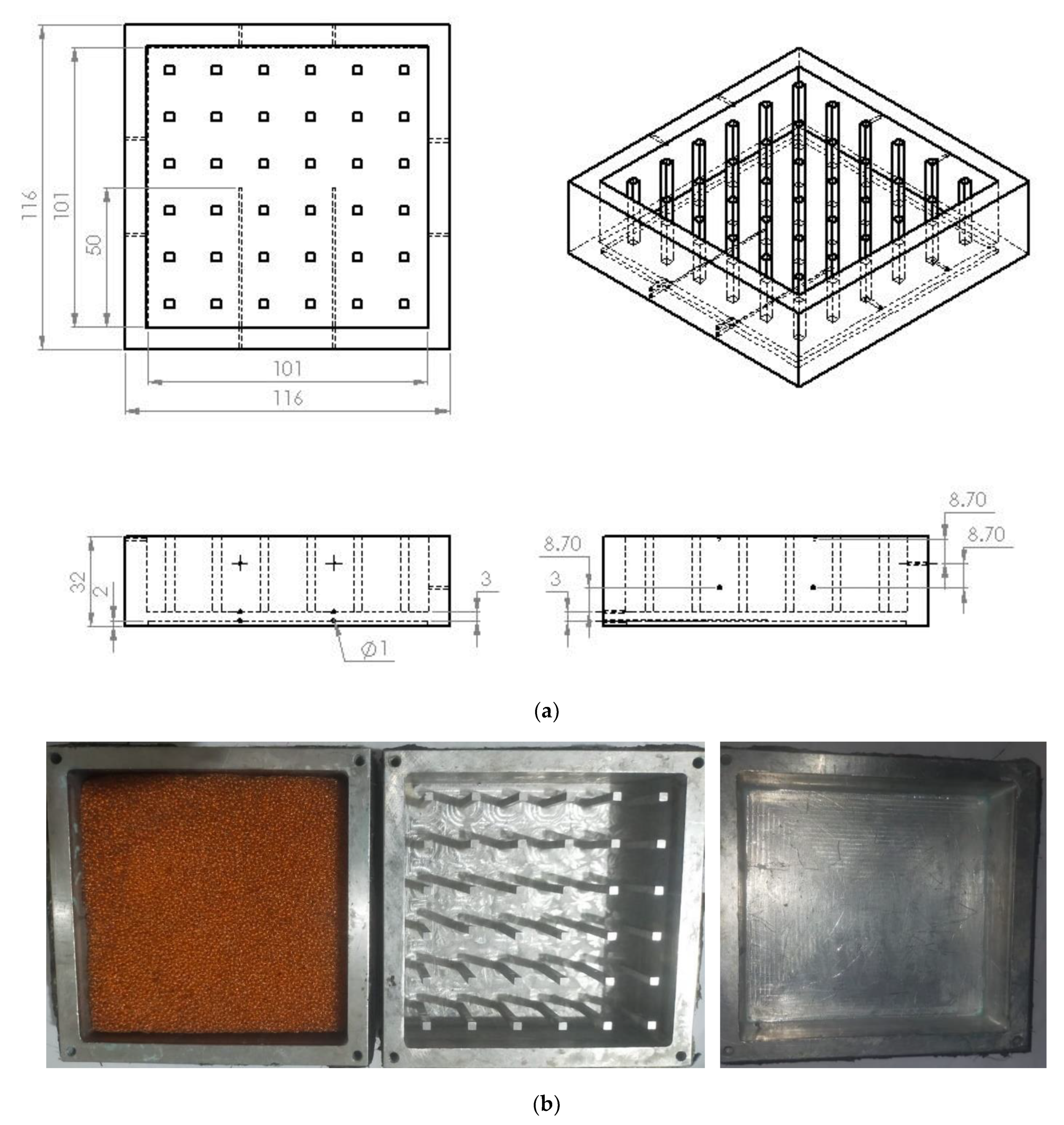

2.1. Experimental Setup

2.2. Heat Sink Assembly and Thermocouple Positioning

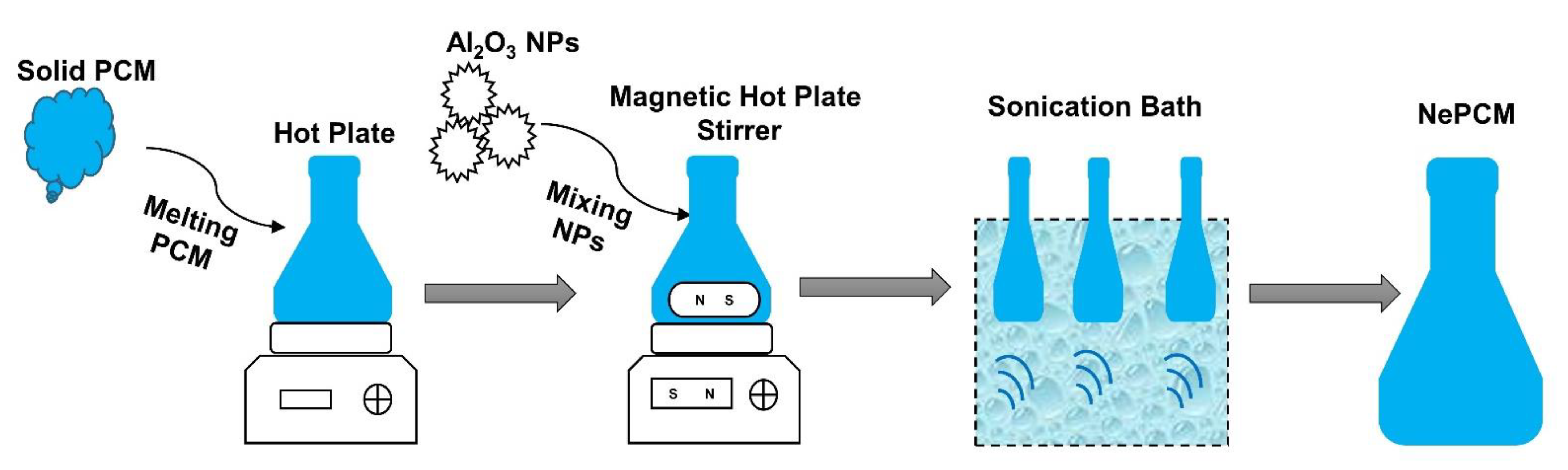

2.3. Preparation of NePCM

SEM and EDX Analysis of Alumina NPs

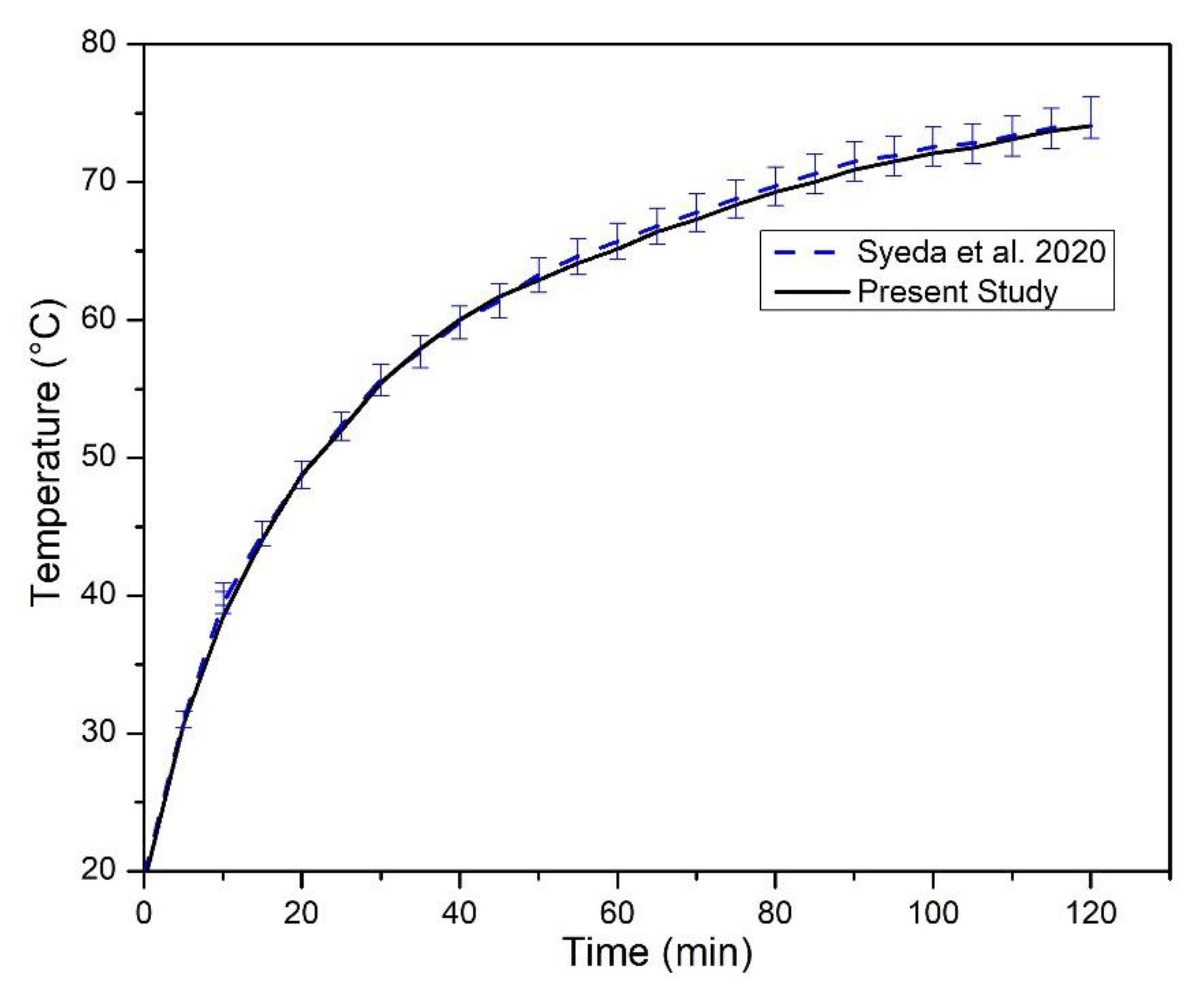

3. Validation and Uncertainty Estimation of the Test Setup

4. Results

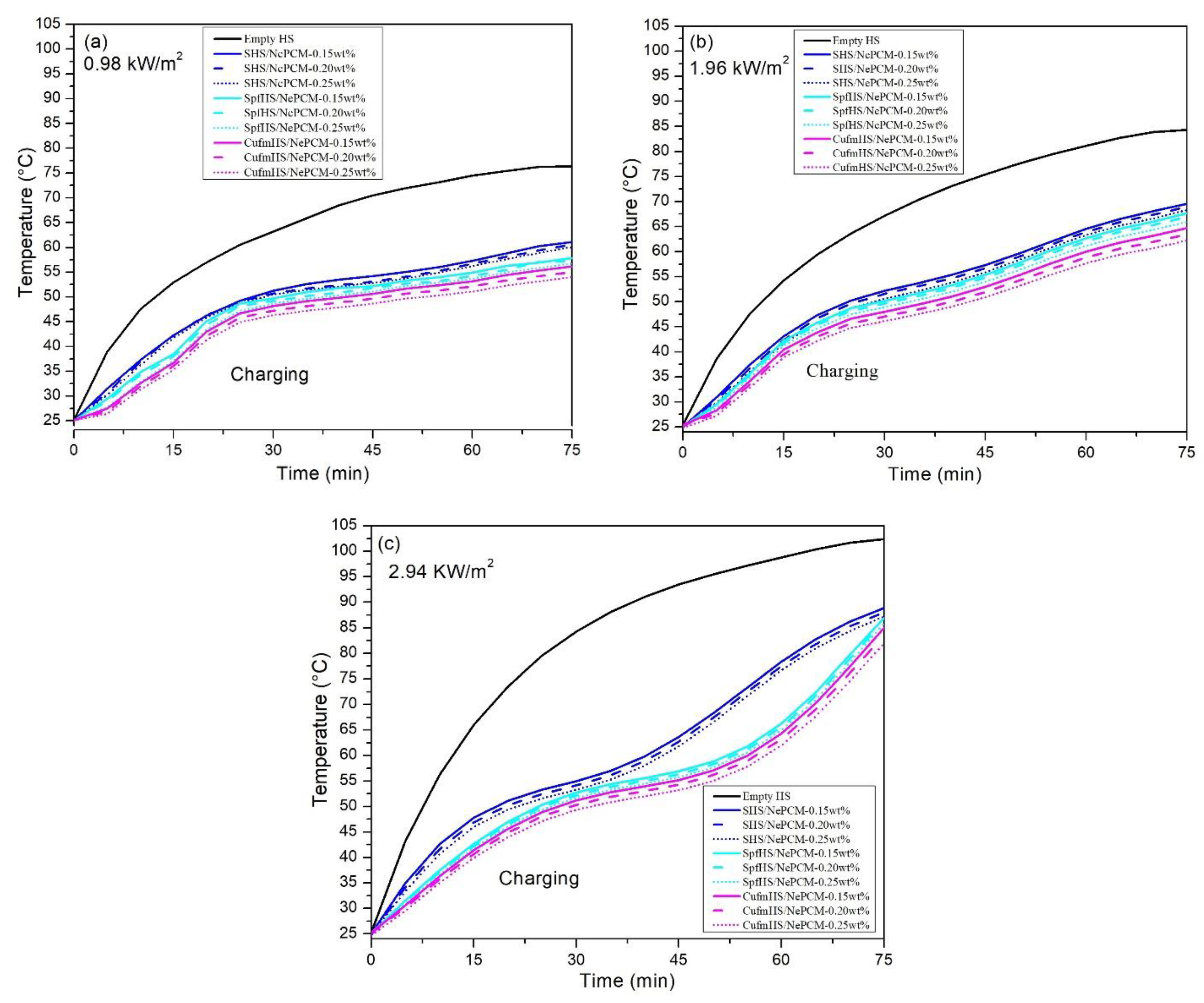

4.1. Effect of Mass Fractions Alumina NePCM for Various Heat Sink

4.2. Effect of Various Heat Fluxes

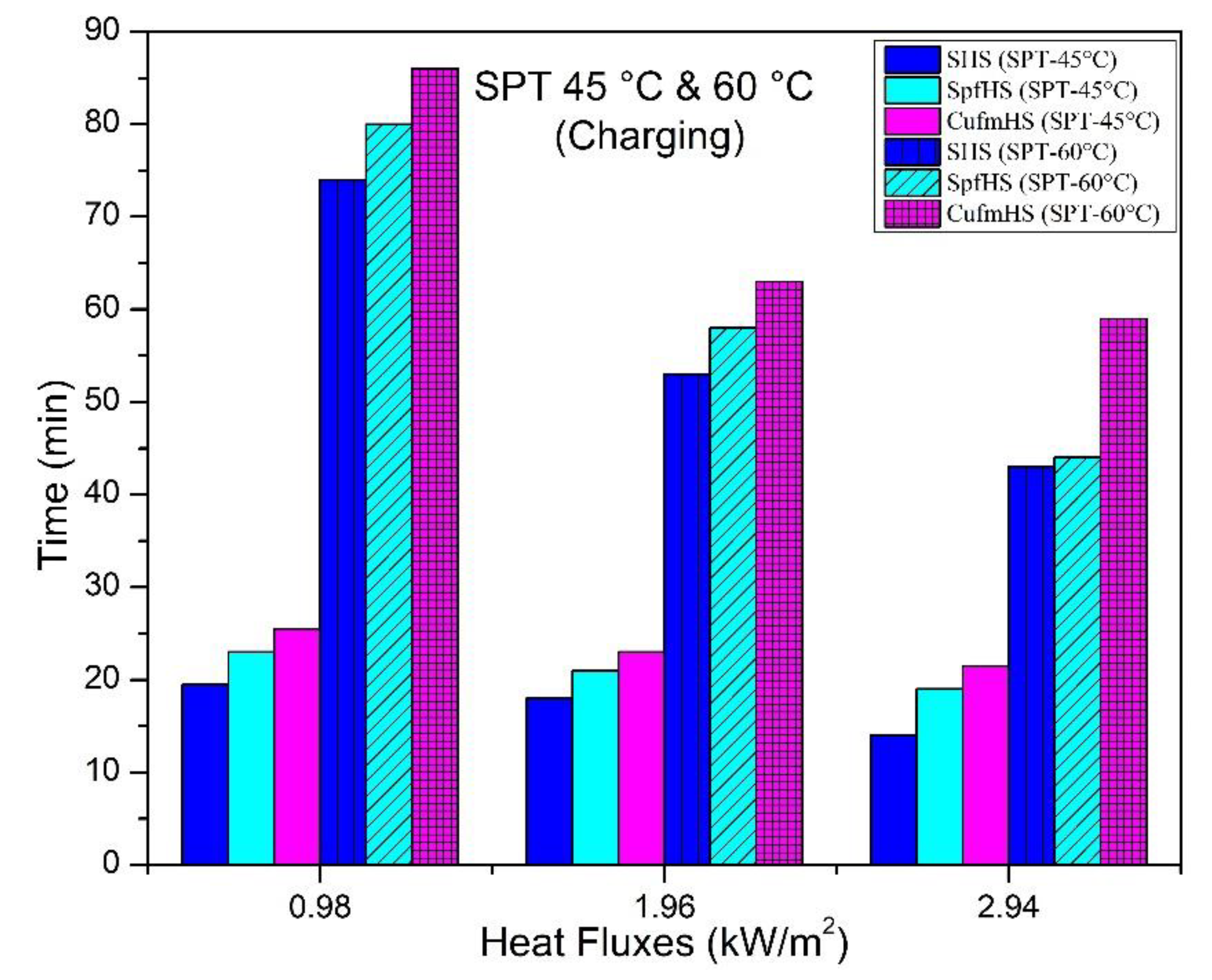

4.3. Setpoint Temperature Analysis in Operating Time of Heat Sink Performances

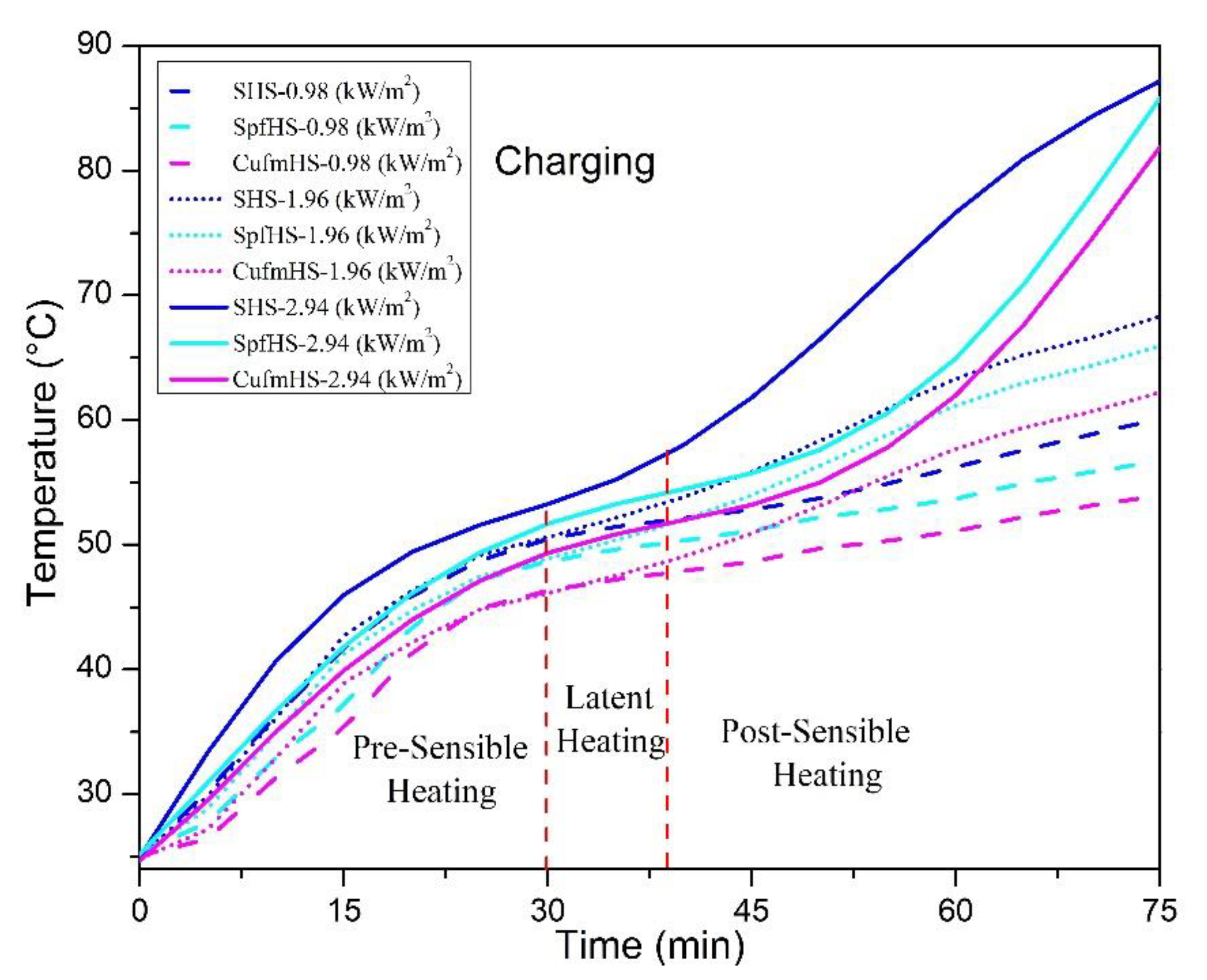

4.3.1. Charging Process

4.3.2. Discharging Process

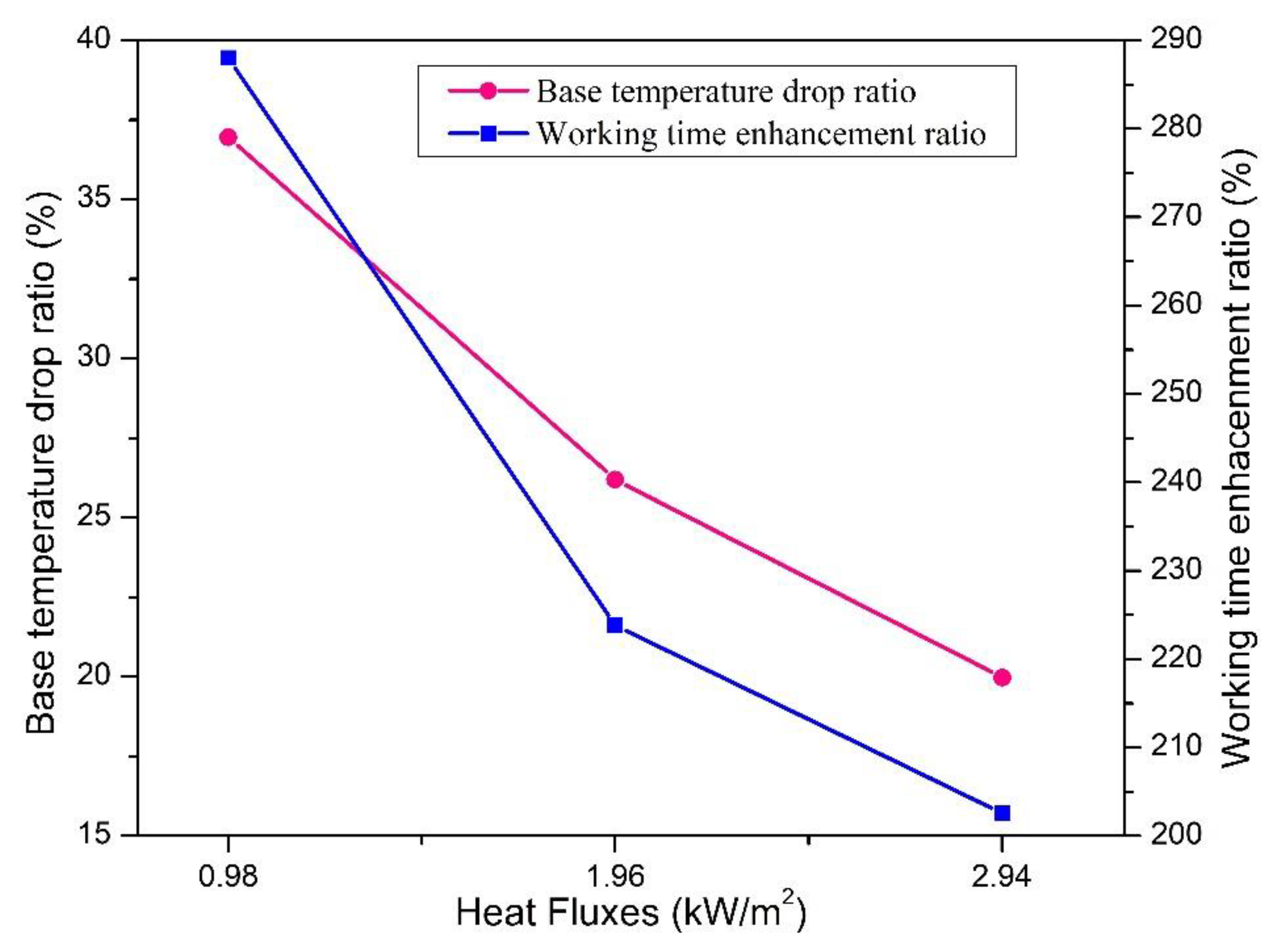

4.4. Effect of the Mass Concentration of Alumina NPs and Heat Flux on Tb Drop and Working Time Improvement

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siddiqi, H.-R.; Qamar, A.; Shaukat, R.; Anwar, Z.; Amjad, M.; Farooq, M.; Abbas, M.M.; Imran, S.; Ali, H.; Khan, T.Y.; et al. Heat transfer and pressure drop characteristics of ZnO/DIW based nanofluids in small diameter compact channels: An experimental study. Case Stud. Therm. Eng. 2022, 39, 102441. [Google Scholar] [CrossRef]

- Qian, X.; Lee, S.W.; Yang, Y. Heat Transfer Coefficient Estimation and Performance Evaluation of Shell and Tube Heat Exchanger Using Flue Gas. Processes 2021, 9, 939. [Google Scholar] [CrossRef]

- Sohel Murshed, S.M.; Nieto de Castro, C.A. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew. Sustain. Energy Rev. 2017, 78, 821–833. [Google Scholar] [CrossRef]

- Viswanath, R.; Viswanath, R.; Wakharkar, V.; Watwe, A.; Lebonheur, V.; Group, M.; Corp, I. Thermal Performance Challenges from Silicon to Systems. 2000. Available online: http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.14.8322 (accessed on 6 May 2022).

- Kumar, A.; Kothari, R.; Sahu, S.K.; Kundalwal, S.I. Thermal performance of heat sink using nano-enhanced phase change material (NePCM) for cooling of electronic components. Microelectron. Reliab. 2021, 121, 114144. [Google Scholar] [CrossRef]

- Qian, X.; Lee, S.; Chandrasekaran, R.; Yang, Y.; Caballes, M.; Alamu, O.; Chen, G. Electricity Evaluation and Emission Characteristics of Poultry Litter Co-Combustion Process. Appl. Sci. 2019, 9, 4116. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Vishwakarma, D.K.; Srinivasan, A.; Soni, M.K.; Goel, V.; Sharifpur, M.; Ahmadi, M.H.; Issakhov, A.; Meyer, J. Thermal performance enhancement in heat exchangers using active and passive techniques: A detailed review. J. Therm. Anal. Calorim. 2022, 147, 9229–9281. [Google Scholar] [CrossRef]

- Watson, J.; Castro, G. A review of high-temperature electronics technology and applications. J. Mater. Sci. Mater. Electron. 2015, 26, 9226–9235. [Google Scholar] [CrossRef]

- Elias, C.N.; Stathopoulos, V.N. A comprehensive review of recent advances in materials aspects of phase change materials in thermal energy storage. Energy Procedia 2019, 161, 385–394. [Google Scholar] [CrossRef]

- Tofani, K.; Tiari, S. Nano-Enhanced phase change materials in latent heat thermal energy storage systems: A review. Energies 2021, 14, 3821. [Google Scholar] [CrossRef]

- Eanest Jebasingh, B.; Valan Arasu, A. A comprehensive review on latent heat and thermal conductivity of nanoparticle dispersed phase change material for low-temperature applications. Energy Storage Mater. 2020, 24, 52–74. [Google Scholar] [CrossRef]

- Leong, K.Y.; Chew, S.P.; Gurunathan, B.A.; Ku Ahmad, K.Z.; Ong, H.C. An experimental approach to investigate thermal performance of paraffin wax and 1-hexadecanol based heat sinks for cooling of electronic system. Int. Commun. Heat Mass Transf. 2019, 109, 104365. [Google Scholar] [CrossRef]

- Li, W.Q.; Guo, S.J.; Tan, L.; Liu, L.L.; Ao, W. Heat transfer enhancement of nano-encapsulated phase change material (NEPCM) using metal foam for thermal energy storage. Int. J. Heat Mass Transf. 2021, 166, 120737. [Google Scholar] [CrossRef]

- Ijaz, M.; Farhan, M.; Farooq, M.; Moeenuddin, G.; Nawaz, S.; Soudagar, M.E.M.; Saqib, H.M.; Ali, Q. Numerical investigation of particles characteristics on cyclone performance for sustainable environment. Part. Sci. Technol. 2021, 39, 495–503. [Google Scholar] [CrossRef]

- Ur Rehman, S.; Farooq, M.; Qamar, A.; Usman, M.; Ahmad, G.; Sultan, M.; Wajid Saleem, M.; Hussain, I.; Imran, M.; Ali, Q.; et al. Experimental investigation to thermal performance of different photo voltaic modules for efficient system design. Alexandria Eng. J. 2022, 61, 12623–12634. [Google Scholar] [CrossRef]

- Sattar, A.; Farooq, M.; Amjad, M.; Saeed, M.A.; Nawaz, S.; Mujtaba, M.A.; Anwar, S.; El-Sherbeeny, A.M.; Soudagar, M.E.M.; Bandarra Filho, E.P.; et al. Performance evaluation of a direct absorption collector for solar thermal energy conversion. Energies 2020, 13, 4956. [Google Scholar] [CrossRef]

- Alam, M.W.; Bhattacharyya, S.; Souayeh, B.; Dey, K.; Hammami, F.; Rahimi-Gorji, M.; Biswas, R. CPU heat sink cooling by triangular shape micro-pin-fin: Numerical study. Int. Commun. Heat Mass Transf. 2020, 112, 104455. [Google Scholar] [CrossRef]

- Kazemi, M.; Hosseini, M.J.; Ranjbar, A.A.; Bahrampoury, R. Improvement of longitudinal fins configuration in latent heat storage systems. Renew. Energy 2018, 116, 447–457. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Huang, Y.K.; Hu, N.; Zeng, Y.; Fan, L.W. Transient performance of a PCM-based heat sink with a partially filled metal foam: Effects of the filling height ratio. Appl. Therm. Eng. 2018, 128, 966–972. [Google Scholar] [CrossRef]

- Dammak, K.; El Hami, A. Thermal reliability-based design optimization using Kriging model of PCM based pin fin heat sink. Int. J. Heat Mass Transf. 2021, 166, 120745. [Google Scholar] [CrossRef]

- Arshad, A.; Ali, H.M.; Khushnood, S.; Jabbal, M. Experimental investigation of PCM based round pin-fin heat sinks for thermal management of electronics: Effect of pin-fin diameter. Int. J. Heat Mass Transf. 2018, 117, 861–872. [Google Scholar] [CrossRef]

- Jilte, R.; Ahmadi, M.H.; Kumar, R.; Kalamkar, V.; Mosavi, A. Cooling Performance of a Novel Circulatory Flow Concentric Multi-Channel Heat Sink with Nanofluids. Nanomaterials 2020, 10, 647. [Google Scholar] [CrossRef] [PubMed]

- Manoj Kumar, P.; Saminathan, R.; Sumayli, A.; Mittal, M.; Abishek, A.S.; Atharsh Kumaar, A.S.; Reddy, T.D.K.; Rinawa, M.L. Experimental analysis of a heat sink for electronic chipset cooling using a nano improved PCM (NIPCM). Mater. Today Proc. 2022, 56, 1527–1531. [Google Scholar] [CrossRef]

- Arshad, A.; Jabbal, M.; Faraji, H.; Talebizadehsardari, P.; Bashir, M.A.; Yan, Y. Numerical study of nanocomposite phase change material-based heat sink for the passive cooling of electronic components. Heat Mass Transf. Stoffuebertragung 2021, 15, 1–15. [Google Scholar] [CrossRef]

- Yang, X.; Yu, J.; Guo, Z.; Jin, L.; He, Y.L. Role of porous metal foam on the heat transfer enhancement for a thermal energy storage tube. Appl. Energy 2019, 239, 142–156. [Google Scholar] [CrossRef]

- Wang, S.; Xing, Y.; Hao, Z.; Yin, J.; Hou, X.; Wang, Z. Experimental study on the thermal performance of PCMs based heat sink using higher alcohol/graphite foam. Appl. Therm. Eng. 2021, 198, 117452. [Google Scholar] [CrossRef]

- Farzanehnia, A.; Khatibi, M.; Sardarabadi, M.; Passandideh-Fard, M. Experimental investigation of multiwall carbon nanotube/paraffin based heat sink for electronic device thermal management. Energy Convers. Manag. 2019, 179, 314–325. [Google Scholar] [CrossRef]

- Fan, L.W.; Zhu, Z.Q.; Zeng, Y.; Xiao, Y.Q.; Liu, X.L.; Wu, Y.Y.; Ding, Q.; Yu, Z.T.; Cen, K.F. Transient performance of a PCM-based heat sink with high aspect-ratio carbon nanofillers. Appl. Therm. Eng. 2015, 75, 532–540. [Google Scholar] [CrossRef]

- Alimohammadi, M.; Aghli, Y.; Alavi, E.S.; Sardarabadi, M.; Passandideh-Fard, M. Experimental investigation of the effects of using nano/phase change materials (NPCM) as coolant of electronic chipsets, under free and forced convection. Appl. Therm. Eng. 2017, 111, 271–279. [Google Scholar] [CrossRef]

- Bayat, M.; Faridzadeh, M.R.; Toghraie, D. Investigation of finned heat sink performance with nano enhanced phase change material (NePCM). Therm. Sci. Eng. Prog. 2018, 5, 50–59. [Google Scholar] [CrossRef]

- Zhang, P.; Meng, Z.N.; Zhu, H.; Wang, Y.L.; Peng, S.P. Melting heat transfer characteristics of a composite phase change material fabricated by paraffin and metal foam. Appl. Energy 2017, 185, 1971–1983. [Google Scholar] [CrossRef]

- Zhao, L.; Xing, Y.; Liu, X. Experimental investigation on the thermal management performance of heat sink using low melting point alloy as phase change material. Renew. Energy 2020, 146, 1578–1587. [Google Scholar] [CrossRef]

- Joseph, M.; Sajith, V. Graphene enhanced paraffin nanocomposite based hybrid cooling system for thermal management of electronics. Appl. Therm. Eng. 2019, 163, 114342. [Google Scholar] [CrossRef]

- Farooq, M.; Farhan, M.; Ahmad, G.; Tahir, Z.U.R.; Usman, M.; Sultan, M.; Saad Hanif, M.; Imran, M.; Anwar, S.; El-Sherbeeny, A.M.; et al. Thermal performance enhancement of nanofluids based parabolic trough solar collector (NPTSC) for sustainable environment. Alex. Eng. J. 2022, 61, 8943–8953. [Google Scholar] [CrossRef]

- Jurčević, M.; Nižetić, S.; Arıcı, M.; Ocłoń, P. Comprehensive analysis of preparation strategies for phase change nanocomposites and nanofluids with brief overview of safety equipment. J. Clean. Prod. 2020, 274, 122963. [Google Scholar] [CrossRef]

- Ali, H.M.; Babar, H.; Shah, T.R.; Sajid, M.U.; Qasim, M.A.; Javed, S. Preparation Techniques of TiO2 Nanofluids and Challenges: A Review. Appl. Sci. 2018, 8, 587. [Google Scholar] [CrossRef]

- Arshad, A.; Jabbal, M.; Yan, Y. Preparation and characteristics evaluation of mono and hybrid nano-enhanced phase change materials (NePCMs) for thermal management of microelectronics. Energy Convers. Manag. 2020, 205, 112444. [Google Scholar] [CrossRef]

- Aurangzeb, M.; Noor, F.; Qamar, A.; Shah, A.N.; Kumam, P.; Shah, Z.; Shutaywi, M. Investigation of enhancement in the thermal response of phase change materials through nano powders. Case Stud. Therm. Eng. 2022, 29, 101654. [Google Scholar] [CrossRef]

- Qamar, A.; Anwar, Z.; Ali, H.; Imran, S.; Shaukat, R.; Abbas, M.M. Experimental investigation of dispersion stability and thermophysical properties of ZnO/DIW nanofluids for heat transfer applications. Alex. Eng. J. 2022, 61, 4011–4026. [Google Scholar] [CrossRef]

- Tariq, S.L.; Ali, H.M.; Akram, M.A.; Janjua, M.M. Experimental investigation on graphene based nanoparticles enhanced phase change materials (GbNePCMs) for thermal management of electronic equipment. J. Energy Storage 2020, 30, 101497. [Google Scholar] [CrossRef]

| Sr. No | PCM, NPs/(wt%) | Method/Melting Point (°C) | HS Size (mm3) | HS Type | Metallic Foams | Heat Input (kW/m2)/W | Sonication Time (Hr) | Ref. |

|---|---|---|---|---|---|---|---|---|

| 1 | Paraffin wax, MWCNT/ (0.2, 2) | Experimental (46–48) | 73 × 68 × 44.5 | Plate fins | - | 2–6 | 5 | [27] |

| 2 | PCM. CNT, GNP/ (0.3, 1, 3) | Experimental (50) | 80 × 80 × 30 | Simple | - | 40, 80 and 120 | 0.83 | [28] |

| 3 | Mn(NO3)2, Fe3O4/(1) | Experimental (37) | 75 × 75 × 40 | Plate fins | - | 5.5–22.5 | 4 | [29] |

| 4 | RT-44, CuO, Al2O3/ (2) | Numerical (41–45) | 50 × 50 × 40 | Plate fins | - | 10, 20 and 30 | - | [30] |

| 5 | Paraffin wax, | Numerical and Experimental (52–54) | 100 × 100 × 10 | Simple | Cu foam | - | - | [31] |

| 6 | Bi-Pb-Sn-Cd, | Experimental (69.59) | 104 × 104 × 25 | Simple | Cu foam | 2, 3 and 4 | - | [32] |

| 7 | PCM, GNP | Experimental (58–60) | 42 × 42 × 32 | Plate fins | - | 5–20 | 15 | [33] |

| Material | Pores per Inch (PPI) | Purity (%) | Porosity (%) | Specific Heat (kJ/kg·K) | Density (kg/m3) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|---|

| Cu Foam | 32 | >99 | 94 | 0.38 | 421 | 387 |

| Thermocouples | B1–B2 | P1–P2 | P3–P4 | P5–P6 | P7–P8 | T9 |

|---|---|---|---|---|---|---|

| Positions (mm) | Heat sink Base | 0 | 8.7 | 17.4 | 26.1 | Room |

| Material | Melting Point (°C) | Latent Heat (kJ/kg) | Density (kg/m3) | Specific Heat (kJ/kg·K) | Purity (%) | Thermal Conductivity (W/m·K) | References |

|---|---|---|---|---|---|---|---|

| RT-54HC | 54 | 200 | 0.85 (s), 0.8 (l) | 2 | - | 0.2 | Authors Work |

| Al2O3 NPs | 2977 | - | - | 2.40 | 100 | 35 | Auregzaib et al. [38] |

| Heat Sink Type | Charging | Charging | Discharging | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Time to Access SPT-45 °C (s) | Time to Access SPT-60 °C (s) | Time to Access SPT-40 °C (s) | |||||||

| kW/m2 | 0.98 | 1.96 | 2.94 | 0.98 | 1.96 | 2.94 | 0.98 | 1.96 | 2.94 |

| SHS | 1170 | 1080 | 840 | 4440 | 3180 | 2580 | 2400 | 3030 | 4020 |

| SpfHS | 1380 | 1260 | 1140 | 4800 | 4380 | 3240 | 1680 | 2580 | 3840 |

| CufmHS | 1530 | 1380 | 1290 | 5180 | 3780 | 3540 | 1500 | 2220 | 3780 |

| 0.98 kW/m2 | 1.96 kW/m2 | 2.94 kW/m2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NPs (wt%) | Ratio (%) | SHS | SpfHS | CufmHS | SHS | SpfHS | CufmHS | SHS | SpfHS | CufmHS |

| 0.15 | Tb drop | 20 | 24.22 | 31.57 | 17.49 | 19.77 | 23.22 | 13.15 | 15.06 | 16.99 |

| Working time enhancement | 180 | 228 | 252 | 142 | 161.90 | 185.71 | 110.26 | 157.95 | 182.05 | |

| 0.20 | Tb drop | 20.61 | 25.11 | 34.94 | 18.21 | 20.59 | 24.73 | 14 | 15.63 | 18.38 |

| Working time enhancement | 192 | 236 | 276 | 150 | 171.43 | 204.76 | 121.54 | 167.69 | 192.31 | |

| 0.25 | Tb drop | 21.32 | 25.75 | 36.95 | 18.96 | 21.76 | 26.20 | 14.83 | 16.16 | 19.98 |

| Working time enhancement | 198 | 244 | 288 | 158.57 | 180.95 | 223.81 | 128.21 | 175.38 | 202.56 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahid, I.; Farooq, M.; Farhan, M.; Usman, M.; Qamar, A.; Imran, M.; Alqahtani, M.A.; Anwar, S.; Sultan, M.; Javaid, M.Y. Thermal Performance Analysis of Various Heat Sinks Based on Alumina NePCM for Passive Cooling of Electronic Components: An Experimental Study. Energies 2022, 15, 8416. https://doi.org/10.3390/en15228416

Zahid I, Farooq M, Farhan M, Usman M, Qamar A, Imran M, Alqahtani MA, Anwar S, Sultan M, Javaid MY. Thermal Performance Analysis of Various Heat Sinks Based on Alumina NePCM for Passive Cooling of Electronic Components: An Experimental Study. Energies. 2022; 15(22):8416. https://doi.org/10.3390/en15228416

Chicago/Turabian StyleZahid, Imran, Muhammad Farooq, Muhammad Farhan, Muhammad Usman, Adnan Qamar, Muhammad Imran, Mejdal A. Alqahtani, Saqib Anwar, Muhammad Sultan, and Muhammad Yasar Javaid. 2022. "Thermal Performance Analysis of Various Heat Sinks Based on Alumina NePCM for Passive Cooling of Electronic Components: An Experimental Study" Energies 15, no. 22: 8416. https://doi.org/10.3390/en15228416

APA StyleZahid, I., Farooq, M., Farhan, M., Usman, M., Qamar, A., Imran, M., Alqahtani, M. A., Anwar, S., Sultan, M., & Javaid, M. Y. (2022). Thermal Performance Analysis of Various Heat Sinks Based on Alumina NePCM for Passive Cooling of Electronic Components: An Experimental Study. Energies, 15(22), 8416. https://doi.org/10.3390/en15228416