Quality Assessment of Biofuel Briquettes Obtained from Greenhouse Waste Using a Mobile Prototype Briquetting Machine with PTO Drive

Abstract

1. Introduction

2. Materials and Methods

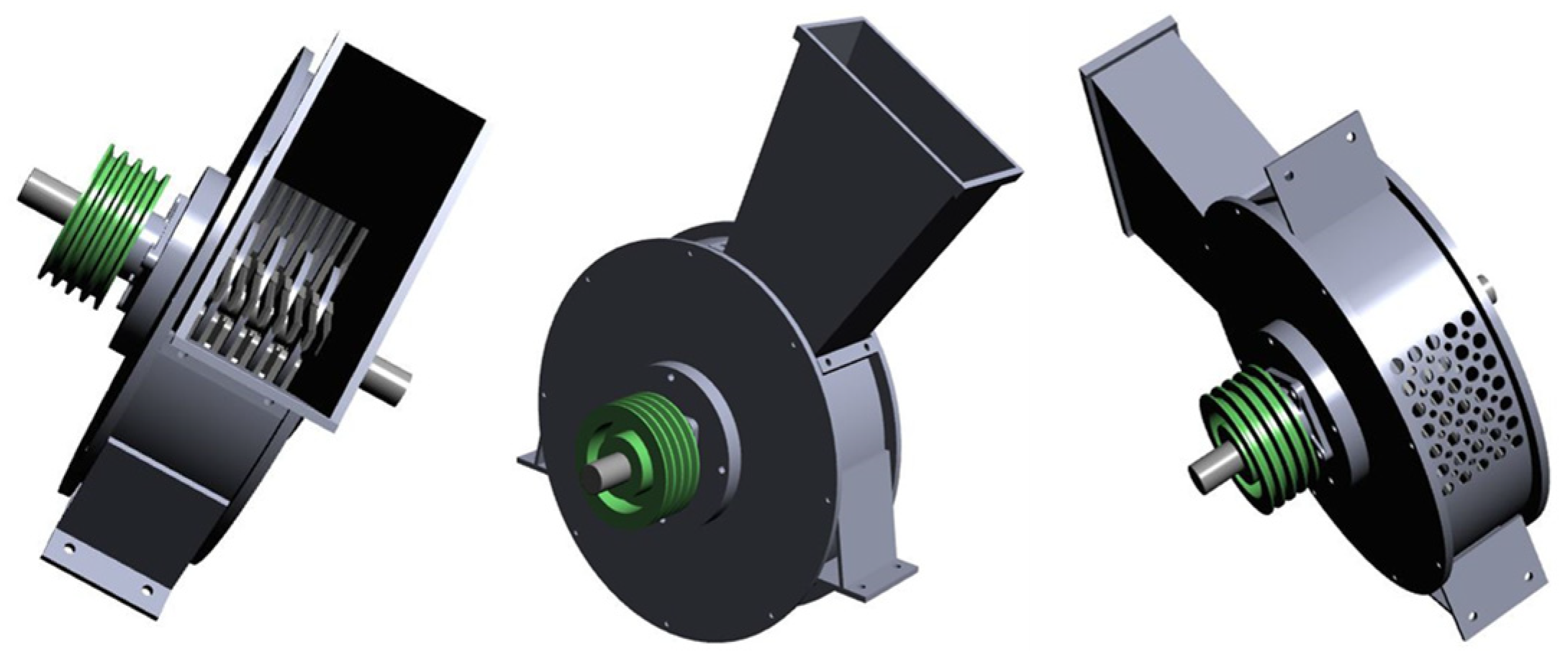

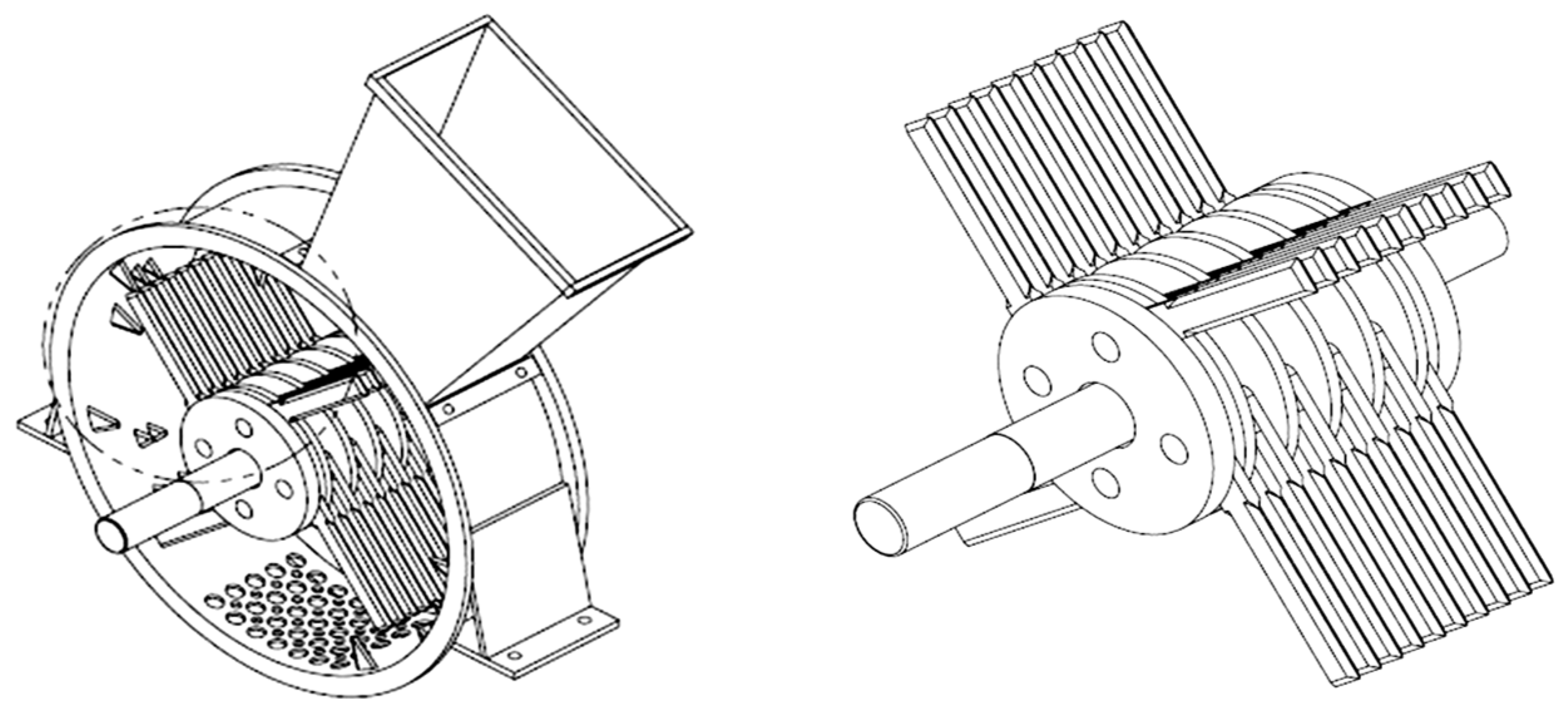

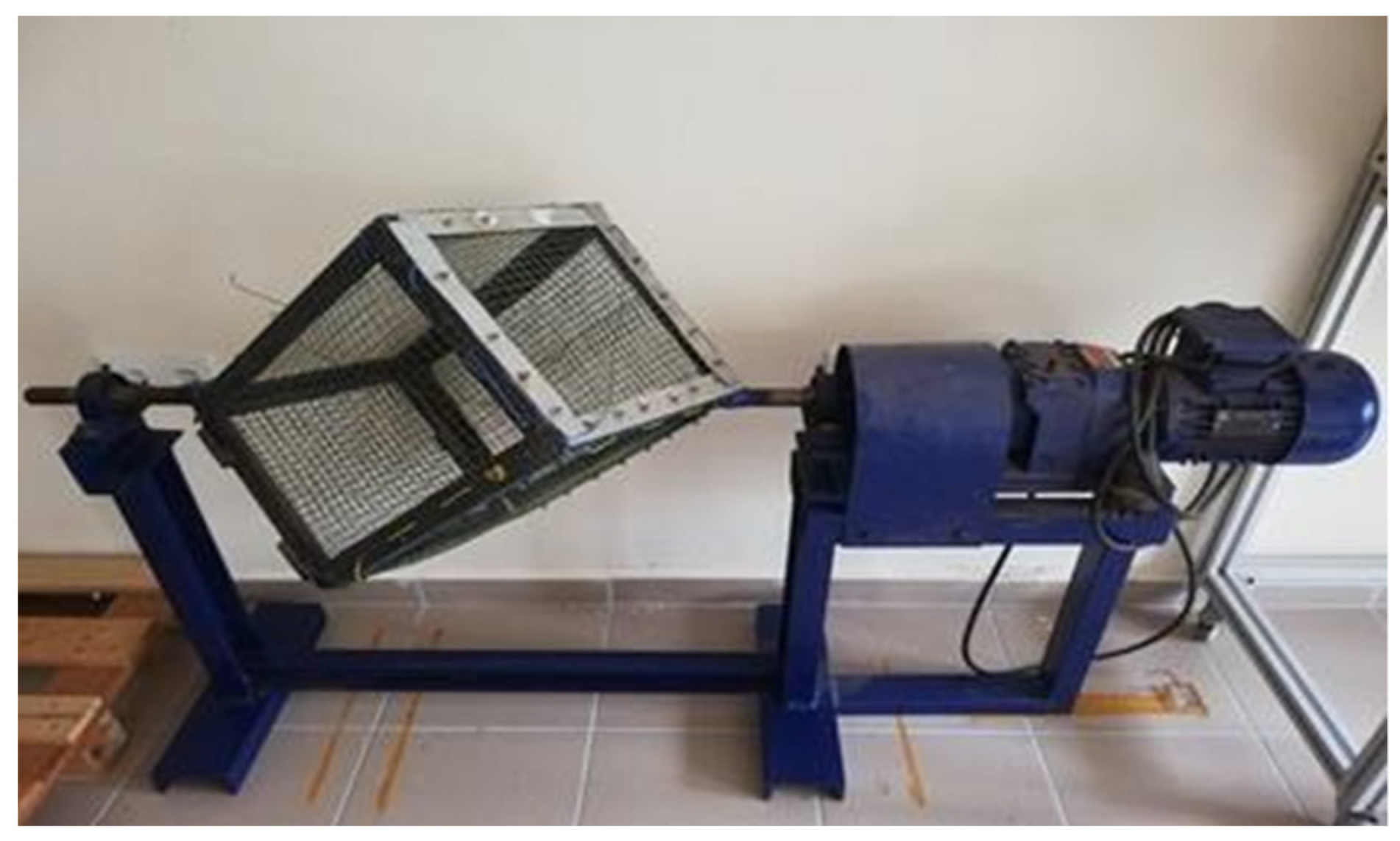

2.1. Bio-Briquetting Procedures

2.2. Experimental Measurements of Bio-Briquettes Quality

3. Results

3.1. Moisture Content of Bio-Briquette Samples

3.2. Density of Bio-Briquette Samples

3.3. Tumbler and Shatter Resistance Index

3.4. Compression Resistance Analysis of Bio-Briquettes

3.5. Compression Resistance Analysis of Bio-Briquettes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krajnc, N. Wood Fuel Handbook; Food and Agriculture Organisation of the United Nations: Pristina, Republic of Kosovo, 2015. [Google Scholar]

- Niño, A.; Arzola, N.; Araque, O. Experimental study on the mechanical properties of biomass briquettes from a mixture of rice husk and pine sawdust. Energies 2020, 13, 1060. [Google Scholar] [CrossRef]

- Archer, S.A.; Steinberger-Wilckens, R. Systematic analysis of biomass derived fuels for fuel cells. Int. J. Hydrogen Energy 2018, 43, 23178–23192. [Google Scholar] [CrossRef]

- Catuti, M.; Milan, E.; Alessi, M.; Egenhofer, C. Biomass and Climate Neutrality. CEPS Policy Insights 2020, No 2020-19. Available online: https://www.ceps.eu/wp-content/uploads/2020/08/PI2020-19_Biomass-and-climate-neutrality.pdf (accessed on 2 November 2022).

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A review of densified solid biomass for energy production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Sohni, S.; Norulaini, N.A.N.; Hashim, R.; Khan, S.B.; Fadhullah, W.; Omar, A.K.M. Physicochemical characterization of Malaysian crop and agro-industrial biomass residues as renewable energy resources. Ind. Crop. Prod. 2018, 111, 642–650. [Google Scholar] [CrossRef]

- Voicea, I.; Vlăduţ, V.; Cârdei, P.; Matache, M.; Găgeanu, I.; Voicu, G.; Popescu, C.; Paraschiv, G.; Kabas, O. Compacting process and mathematical analysis of miscanthus briquettes expansion. In Proceeding of the 43rd International Symposium “Actual Tasks on Agricultural Engineering”, Opatija, Croaţia, 24–27 February 2015; Volume 43, pp. 667–676. [Google Scholar]

- Angın, D.; Şensöz, S. Effect of drifting gas (N2) flow on pyrolysis of safflower seed pulps and characterization of liquid product. Sci. Eng. J. Fırat Univ. 2006, 18, 535–542. [Google Scholar]

- Tüzel, Y.; Gül, A.; Öztekin, B.G.; Engindeniz, S.; Boyacı, F.; Duyar, H.; Cebeci, E.; Durdu, T. Türkiye’de örtüaltı yetiştiriciliği ve yeni gelişmeler. In Proceedings of the Türkiye Ziraat Mühendisliği IX.Teknik Kongresi, Ankara, Turkey, 13–17 October 2020. (In Turkish). [Google Scholar]

- Çerçioğlu, M. Sürdürülebilir atık yönetiminde sera atıklarının kompost olarak değerlendirilmesi. Bursa Uludağ Üniversitesi Ziraat Fakültesi Derg. 2019, 33, 167–178. (In Turkish) [Google Scholar]

- Bilgin, S.; Yılmaz, H.; Koçer, A. Briquetting of greenhouse pepper crop residues. Agric. Eng. Int. CIGR J. 2015, 185–192. Available online: https://www.researchgate.net/publication/282220438_Briquetting_of_greenhouse_pepper_crop_residues (accessed on 13 September 2022).

- Rosa, L.; Mazzotti, M. Potential for hydrogen production from sustainable biomass with carbon capture and storage. Renew. Sustain. Energy Rev. 2022, 157, 112123. [Google Scholar] [CrossRef]

- Găgeanu, I.; Cujbescu, D.; Persu, C.; Tudor, P.; Cârdei, P.; Matache, M.; Vlăduț, V.; Biriș, S.; Voicea, I.; Ungureanu, N. Influence of input and control parameters on the process of pelleting powdered biomass. Energies 2021, 14, 4104. [Google Scholar] [CrossRef]

- Ungureanu, N.; Vlăduț, V.; Voicu, G.; Dincă, M.; Zăbavă, B.Ș. Influence of biomass moisture content on pellet properties—A review. In Proceedings of the 17th International Conference Engineering for Rural Development, Jelgava, Latvia, 23−25 May 2018; Volume 17, pp. 1876–1883. [Google Scholar] [CrossRef]

- Vaish, S.; Kaur, G.; Sharma, N.K.; Gakkhar, N. Estimation for Potential of Agricultural Biomass Sources as Projections of Bio-Briquettes in Indian Context. Sustainability 2022, 14, 5077. [Google Scholar] [CrossRef]

- Senila, L.; Tenu, I.; Carlescu, P.; Scurtu, D.A.; Kovacs, E.; Senila, M.; Cadar, O.; Roman, M.; Dumitras, D.E.; Roman, C. Characterization of biobriquettes produced from vineyard wastes as a solid biofuel resource. Agriculture 2022, 12, 341. [Google Scholar] [CrossRef]

- Kpalo, S.; Zainuddin, M. Briquettes from agricultural residues; an alternative clean and sustainable fuel for domestic cooking in Nasarawa State, Nigeria. Energy Power 2020, 10, 40–47. [Google Scholar] [CrossRef]

- Saeed, A.; Harun, N.Y.; Bilad, M.; Afzal, M.; Parvez, A.; Roslan, F.; Rahim, S.A.; Vinayagam, V.; Afolabi, H. Moisture content impact on properties of briquette produced from rice husk waste. Sustainability 2021, 13, 3069. [Google Scholar] [CrossRef]

- Yang, W.; Lv, L.; Han, Y.; Li, Y.; Liu, H.; Zhu, Y.; Zhang, W.; Yang, H. Effect of densification on biomass combustion and particulate matter emission characteristics. Atmosphere 2022, 13, 1582. [Google Scholar] [CrossRef]

- Manyuchi, M.M.; Mbohwa, C.; Muzenda, E. Potential to produce biomass briquettes from tea waste. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Washington, DC, USA, 27–29 September 2018. [Google Scholar]

- Thekedar, K.; Karale, S.; Awari, G. A systematic review on the future potential of tea waste and other admixtures in bio briquetting from rice husk. AIP Conf. Proc. 2021, 2417, 020008. [Google Scholar] [CrossRef]

- Obi, O.F.; Pecenka, R.; Clufford, M.J. A review of biomass briquette binders and quality parameters. Energies 2022, 15, 2426. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Fillerup, E. Briquetting characteristics of woody and herbaceous biomass blends: Impact on physical properties, chemical composition, and calorific value. Biofuels Bioprod. Biorefin. 2020, 14, 1105–1124. [Google Scholar] [CrossRef]

- Ajiboye, T.K.; Abdulkareem, S.; Anibijuwon, A.O.Y. Investigation of mechanical properties of briquette product of sawdust-charcoal as a potential domestic energy source. J. Appl. Sci. Environ. Manag. 2016, 20, 1179–1188. [Google Scholar] [CrossRef]

- Stahl, M.; Berghel, J. Energy efficient pilot-scale production of wood fuel pellets made from a raw material mix including sawdust and rapeseed cake. Biomass Bioenerg. 2011, 35, 4849–4854. [Google Scholar] [CrossRef]

- Aigbefo, V.; Jeje, A. Production of palm fibre briquettes and the determination of elemental composition and calorific value. SAU Sci.-Tech. J. 2019, 4, 107–116. [Google Scholar]

- Kurklu, A.; Bilgin, S. Pamuk ve susam saplarının briketlenmesi üzerine bir çalışma. Tarım Makinaları Bilim. Derg. 2007, 3, 151–159. (In Turkish) [Google Scholar]

- Callejón-Ferre, A.J.; López-Martínez, J.A. Briquettes of plant remains from the greenhouses of Almeria (Spain). Span. J. Agric. Res. 2009, 7, 525–534. [Google Scholar] [CrossRef]

- Kaķītis, A.; Nulle, I.; Ancāns, D. Mechanical properties of composite biomass briquettes. Environment, technology and resources. In Proceedings of the 8th International Scientific and Practical Conference, Rēzeknes Augstskola, Rēzekne, Latvia, 20–22 June 2011; RA Izdevniecība: Rēzekne, Latvia, 2011; Volume 1, pp. 175–183. [Google Scholar] [CrossRef]

- Akman, H.E.; Bilgin, S. A research on the briquetting of cotton stalks with hydraulic type machine. J. Agric. Mach. Sci. 2012, 8, 99–106. [Google Scholar]

- Bilgin, S.; Ertekin, C.; Kürklü, A. Enerji bitkisi olarak farklı kamış türlerinin briketlenmesi üzerine bir araştırma. Akdeniz Üniversitesi Ziraat Fakültesi Derg. 2014, 27, 43–50. (In Turkish) [Google Scholar]

- Bilgin, S.; Yılmaz, H.; Koçer, A.; Acar, M.; Dok, M. Ayçiçeği saplarının konik helezon tip briket makinesinde briketlenmesi. Akdeniz Üniversitesi Ziraat Fakültesi Derg. 2014, 27, 91–97. (In Turkish) [Google Scholar]

- Urbanovičová, O.; Krištof, K.; Findura, P.; Jobbágy, J.; Angelovič, M. Physical and mechanical properties of briquettes produced from energy plants. Acta Univ. Agric. Et Silvic. Mendel. Brun. 2017, 65, 219–224. [Google Scholar] [CrossRef]

- Dok, M.; Acar, M.; Çelik, A.E.; Atagün, G.; Akbaş, U. Farklı parçacık boyutlarındaki kivi budama artıklarından elde edilen briketlerin yakıt özelliklerinin karşılaştırılması. Tarım Makinaları Bilim. Derg. 2018, 14, 73–78. (In Turkish) [Google Scholar]

- Dok, M.; Acar, M.; Çelik, A.E.; Atagün, G.; Akbaş, U. Briquetting of corn stalk as a renewable energy source and determination of physical properties of briquettes. MKU. Tar. Bil. Derg. 2019, 24, 61–70. [Google Scholar]

- Masullo, L.S.; Alesi, L.S.; Quadros, T.M.C.; Silva, D.; De Pádua, F.A.; Yamaji, F.M. Use of blends containing different proportions of straw and sugarcane bagasse for the production of briquettes. Rev. Virtual Quím. 2018, 10, 641–654. [Google Scholar] [CrossRef]

- EN 14774-1; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 1: Total Moisture. Reference European Committee for Standardization: Brussels, Belgium, 2009.

- EN 13183-1; Moisture Content of a Piece of Sawn Timber—Part 1: Determination by oven dry method. Reference European Committee for Standardization: Brussels, Belgium, 2002.

- Gendek, A.; Aniszewska, M.; Malaťák, J.; Velebil, J. Evaluation of selected physical and mechanical properties of briquettes produced from cones of three coniferous tree species. Biomass Bioenergy 2018, 117, 173–179. [Google Scholar] [CrossRef]

- ASTM D 440-86; International Standard Test Method of Drop Shatter Test for Coal. Annual Book of ASTM Standards. ASTM: West Conshohocken, PA, USA, 1998.

- ASAE S269.4; Cubes, Pellets, and Crumbles Definitions and Methods for Determining Density, Durability, and Moisture Content. American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2000.

- CRA. Le Densification de la Biomass. In Commission des Communuates Europeennes; Centre de Recherches Agronomiques: Gembloux, Belgium, 1987. [Google Scholar]

- Kabas, O.; Vlăduț, V. Determination of some engineering properties of pecan (Carya illinoinensis) for new design of cracking system. Erwerbs-Obstbau 2016, 58, 31–39. [Google Scholar] [CrossRef]

- ASTM E9-89; International Standard Test Methods of Compression Testing. Annual Book of ASTM Standards. ASTM: West Conshohocken, PA, USA, 2018.

- EN 12504-1; Testing concrete in structures—Part 1: Cored specimens—Taking, examining and testing in compression. Reference European Committee for Standardization: Brussels, Belgium, 2019.

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Lindley, J.; Vossoughi, M. Physical properties of biomass briquettes. Trans. ASAE 1989, 3, 361–366. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, Y. Physical properties of solid fuel briquettes made from caragana korshinskii kom. Powder Technol. 2014, 256, 293–299. [Google Scholar] [CrossRef]

- Križan, P.; Šooš, L.; Matúš, M.; Beniak, J.; Svátek, M. Research of significant densifcation parameters influence on final briquettes quality. Wood Res. 2015, 60, 301–316. [Google Scholar]

- Karaca, C. Çukurova Bölgesindeki tarıma dayalı sanayi atıklarının enerjiye dönüşüm olanaklarının incelenmesi. Ph.D. Thesis, Çukurova Üniversitesi, Fen Bilimleri Enstitüsü, Tarım Makinaları Anabilim Dalı, Adana, Turkey, 2008. (In Turkish). [Google Scholar]

- Grover, P.D.; Mishra, S.K. Biomass briquetting: Technology and practices. In Regional Wood Energy Development program in Asia, Field Document No. 46; Food and Agriculture Organization of the United Nations: Bangkok, Thailand, 1996. [Google Scholar]

- Tumuluru, J.S. Effect of process variables on the density and durability of the pellets made from high moisture corn stover. Biosyst. Eng. 2014, 119, 44–57. [Google Scholar] [CrossRef]

- Karaca, C.; Başçetinçelik, A. Yerfıstığı kabuğunun briketleme özelliklerinin ve yanma emisyonlarının belirlenmesi. Vı. Yeni Ve Yenilenebilir Enerji Kaynakları Sempozyumu Bildiriler Kitabı, Ekim. 2011. Available online: https://dergipark.org.tr/tr/pub/mkutbd/issue/51091/653985 (accessed on 13 September 2022).

- Brunerová, A.; Roubík, H.; Brožek, M.; Van Dung, D.; Phung, L.D.; Hasanudin, U.; Herak, D. Briquetting of sugarcane bagasse as a proper waste management technology in Vietnam. Waste Manag. Res. 2020, 38, 1239–1250. [Google Scholar] [CrossRef]

- EN 14961-3; Solid Biofuel—Fuel Specification and Classes. Part 3: Wood Briquettes for Non-İndustrial Use. Reference European Committee for Standardization: Brussels, Belgium, 2011.

- Eriksson, S.; Prior, M. The Briquetting of Agricultural Wastes for Fuel (No. 11); Food and Agriculture Organization of the United Nations: Bangkok, Thailand, 1990. [Google Scholar]

- Bazargan, A.; Rough, S.L.; McKay, G. Compaction of palm kernel husk biochars for application as solid fuel. Biomass Bioenergy 2014, 70, 489–497. [Google Scholar] [CrossRef]

- Fengmin, L.; Mingquan, Z. Technological parameters of biomass briquetting of macrophytes in Nansi Lake. Energy Procedia 2011, 5, 2449–2454. [Google Scholar] [CrossRef][Green Version]

- Supatata, N.; Buates, J.; Hariyanont, P. Characterization of fuel briquettes made from sewage sludge mixed with water hyacinth and sewage sludge mixed with sedge. Int. J. Environ. Sci. Dev. 2013, 4, 179–181. [Google Scholar] [CrossRef]

- Davies, R.M.; Davies, O.A. Physical and combustion characteristics of briquettes made from water hyacinth and phytoplankton scum as binder. J. Combust. 2013, 2013, 549894. [Google Scholar] [CrossRef]

- Brožek, M. The effect of moisture of the raw material on the properties briquettes for energy use. Acta Univ. Agric. Silvic. Mendel. Brun. 2016, 64, 1453–1458. [Google Scholar] [CrossRef]

- Brunerová, A.; Brožek, M.; Müller, M. Utilization of waste biomass from post–harvest lines in the form of briquettes for energy production. Agron. Res. 2017, 15, 344–358. [Google Scholar]

| Biomass Waste | Waste Properties | |||

|---|---|---|---|---|

| Aubergine plant | Density (kg·m−3) | Moisture content (%) | ||

| 200.47 | 8.23 | |||

| Sieve analysis and size distribution of material | ||||

| 0–1 (mm) | 1–2 (mm) | 2–3 (mm) | >3 (mm) | |

| 56.32 | 36.73 | 4.27 | 2.68 | |

| Tomato plant | Density (kg·m−3) | Moisture content (%) | ||

| 198.53 | 8.65 | |||

| Sieve analysis and size distribution of material | ||||

| 0–1 (mm) | 1–2 (mm) | 2–3 (mm) | >3 (mm) | |

| 50.48 | 38.71 | 5.71 | 5.10 | |

| Pepper plant | Density (kg·m−3) | Moisture content (%) | ||

| 203.25 | 7.82 | |||

| Sieve analysis and size distribution of material | ||||

| 0–1 (mm) | 1–2 (mm) | 2–3 (mm) | >3 (mm) | |

| 58.41 | 36.64 | 2.52 | 2.43 | |

| Biomass Waste | Moisture Content of Ground Waste (%) | Moisture Content of Briquette (%) |

|---|---|---|

| Aubergine plant | 8.23 ± 0.03 | 5.66 ± 0.05 |

| Tomato plant | 8.65 ± 0.06 | 5.98 ± 0.04 |

| Pepper plant | 7.82 ± 0.04 | 5.14 ± 0.07 |

| Biomass Waste | Density of Ground Waste (kg·m−3) | Density of Briquette (kg·m−3) |

|---|---|---|

| Aubergine plant | 200.47 | 1045.74 ± 16.36 |

| Tomato plant | 198.53 | 1150.18 ± 25.53 |

| Pepper plant | 203.25 | 1143.52 ± 21.42 |

| Level of significance | n.s |

| Biomass Waste | Tumbler Index (%) | Shatter Index (%) |

|---|---|---|

| Aubergine plant | 98.52 a | 90.73 b |

| Tomato plant | 97.26 a | 98.67 a |

| Pepper plant | 93.61 b | 99.24 a |

| Level of significance | ** | ** |

| Biomass Waste | Compression Force (N) | Compression Stress (N·mm−2) | Specific Compression Force (N·mm−1) |

|---|---|---|---|

| Aubergine plant | 3090 b | 62.85 c | 35.68 b |

| Tomato plant | 3315 a | 69.43 a | 40.09 a |

| Pepper plant | 3117 b | 64.38 b | 36.42 b |

| Level of significance | * | ** | * |

| Biomass Waste | Water Intake Capacity (%) | Resistance to Moisture-Humidity (%) |

|---|---|---|

| Aubergine plant | 84.45 a | 94.92 |

| Tomato plant | 84.14 a | 94.71 |

| Pepper plant | 80.63 b | 95.05 |

| Level of significance | * | ns |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabaş, Ö.; Ünal, İ.; Sözer, S.; Selvi, K.C.; Ungureanu, N. Quality Assessment of Biofuel Briquettes Obtained from Greenhouse Waste Using a Mobile Prototype Briquetting Machine with PTO Drive. Energies 2022, 15, 8371. https://doi.org/10.3390/en15228371

Kabaş Ö, Ünal İ, Sözer S, Selvi KC, Ungureanu N. Quality Assessment of Biofuel Briquettes Obtained from Greenhouse Waste Using a Mobile Prototype Briquetting Machine with PTO Drive. Energies. 2022; 15(22):8371. https://doi.org/10.3390/en15228371

Chicago/Turabian StyleKabaş, Önder, İlker Ünal, Salih Sözer, Kemal Cagatay Selvi, and Nicoleta Ungureanu. 2022. "Quality Assessment of Biofuel Briquettes Obtained from Greenhouse Waste Using a Mobile Prototype Briquetting Machine with PTO Drive" Energies 15, no. 22: 8371. https://doi.org/10.3390/en15228371

APA StyleKabaş, Ö., Ünal, İ., Sözer, S., Selvi, K. C., & Ungureanu, N. (2022). Quality Assessment of Biofuel Briquettes Obtained from Greenhouse Waste Using a Mobile Prototype Briquetting Machine with PTO Drive. Energies, 15(22), 8371. https://doi.org/10.3390/en15228371