The Lean Blowout Prediction Techniques in Lean Premixed Gas Turbine: An Overview

Abstract

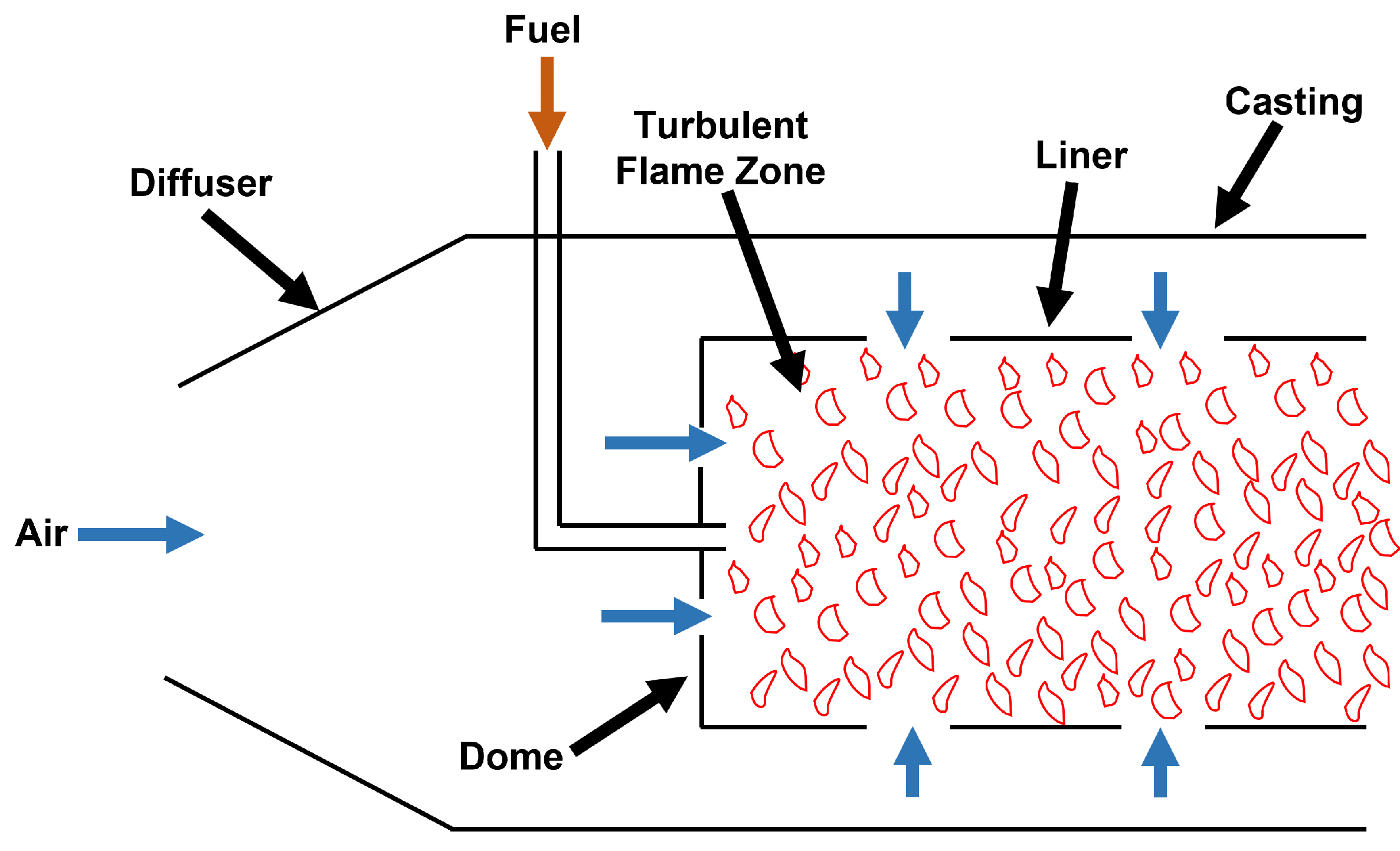

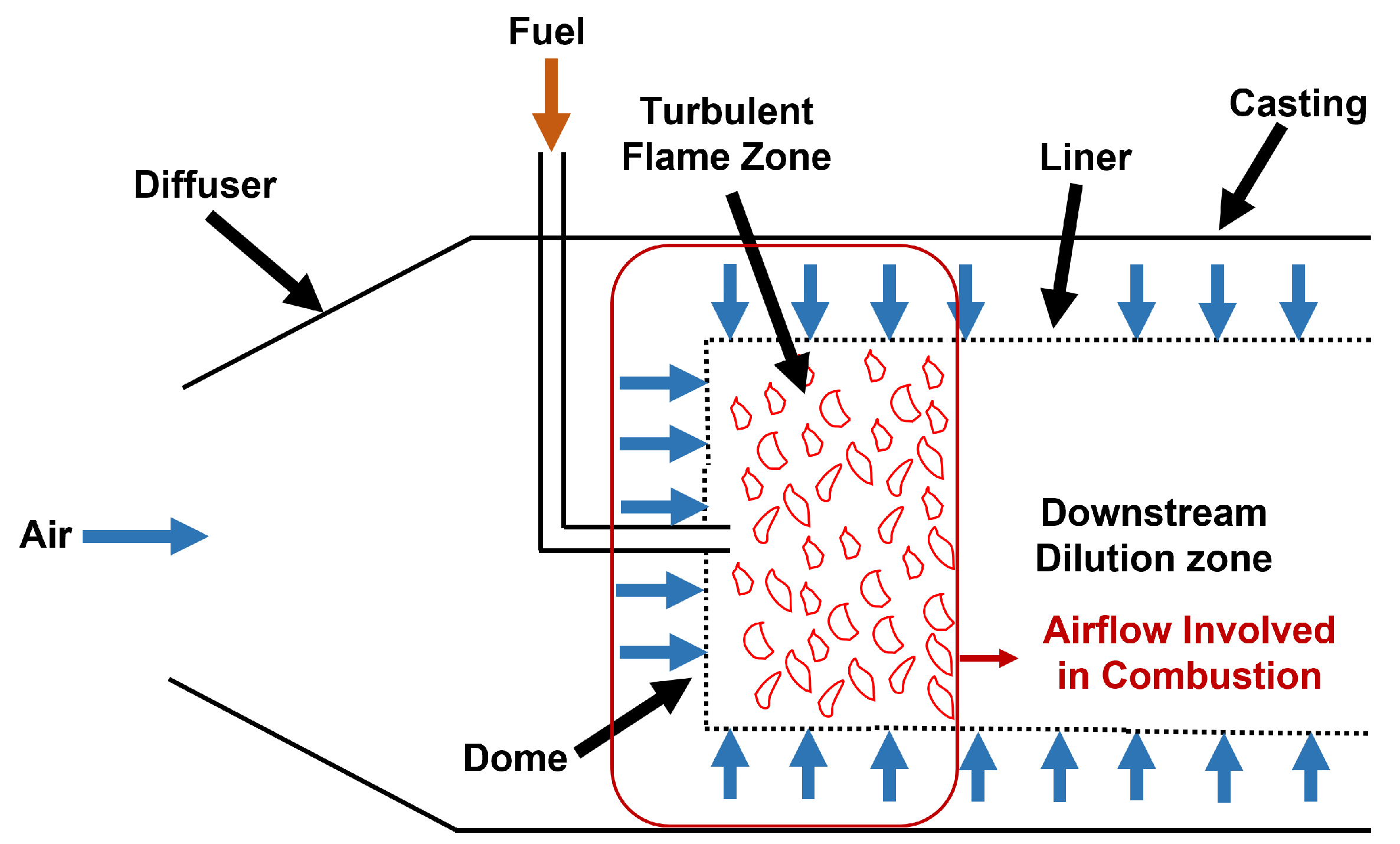

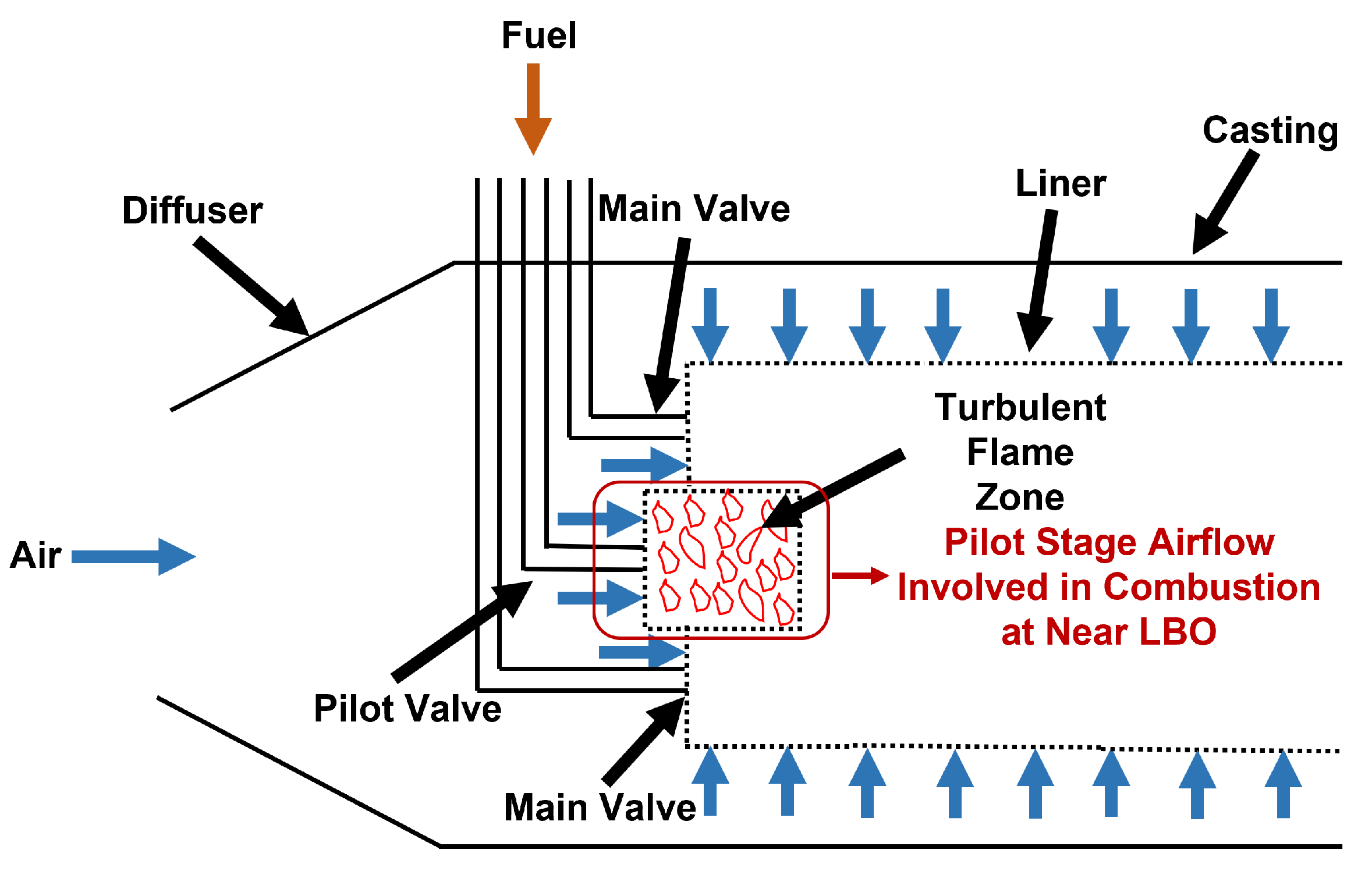

1. Introduction

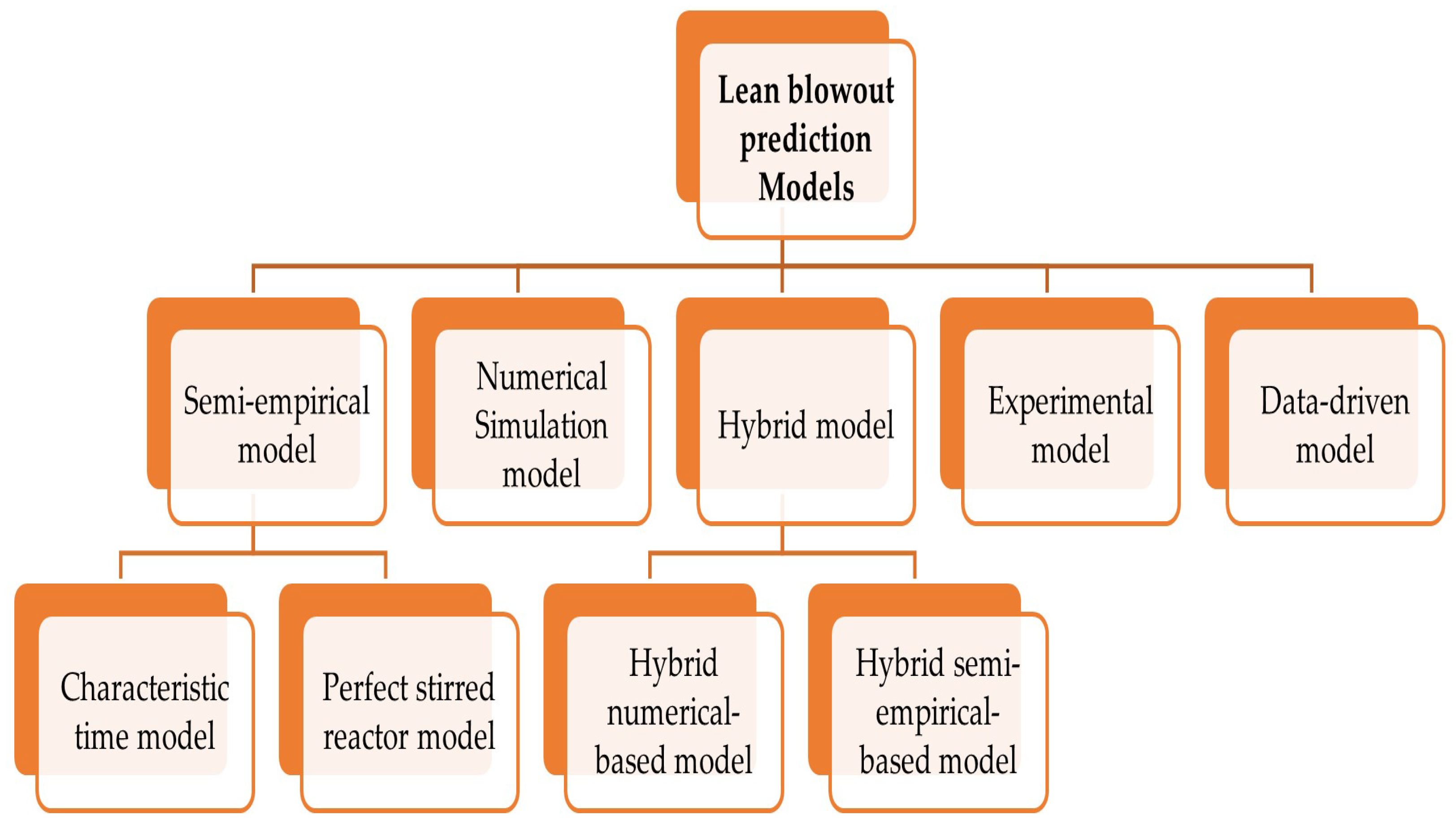

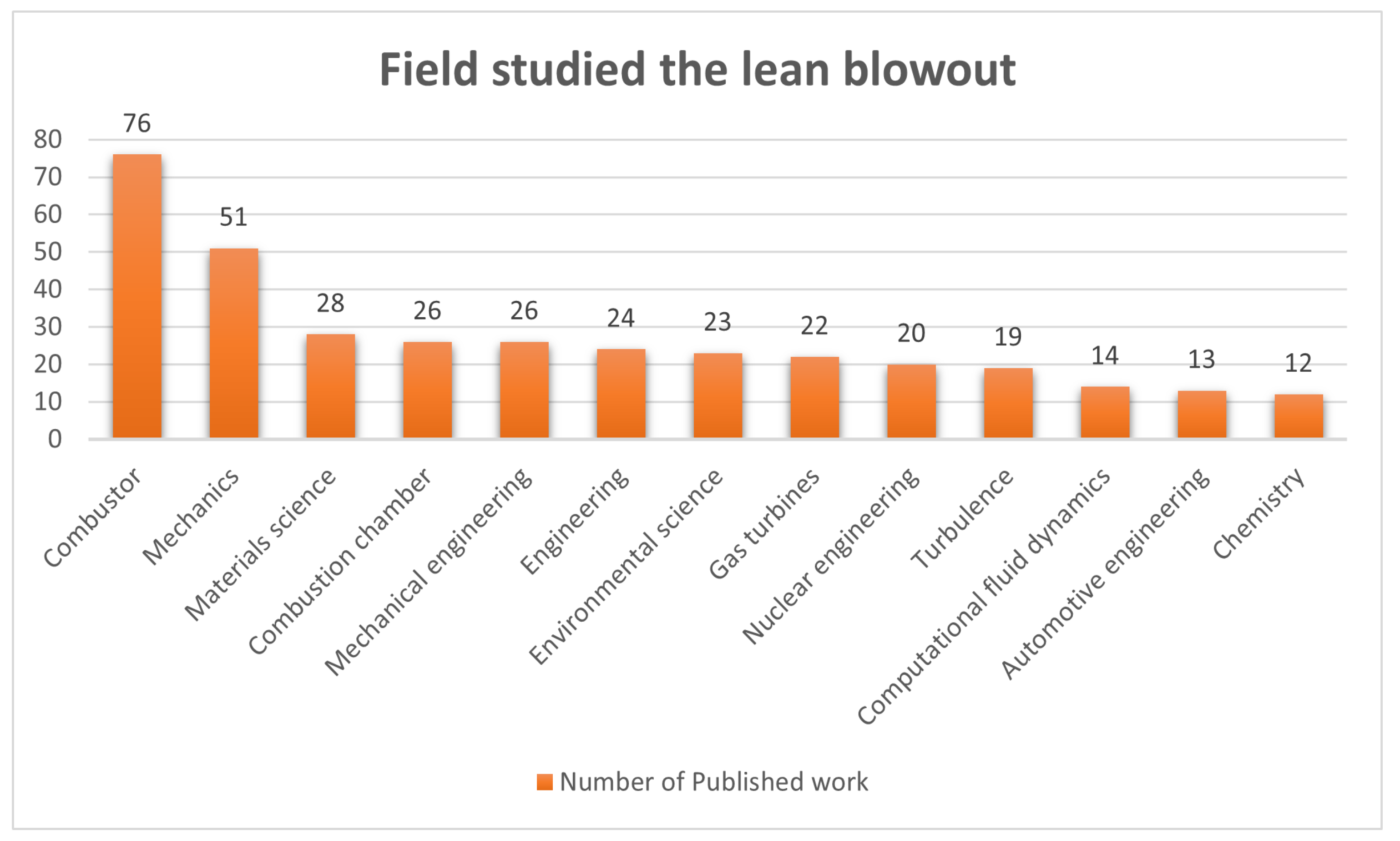

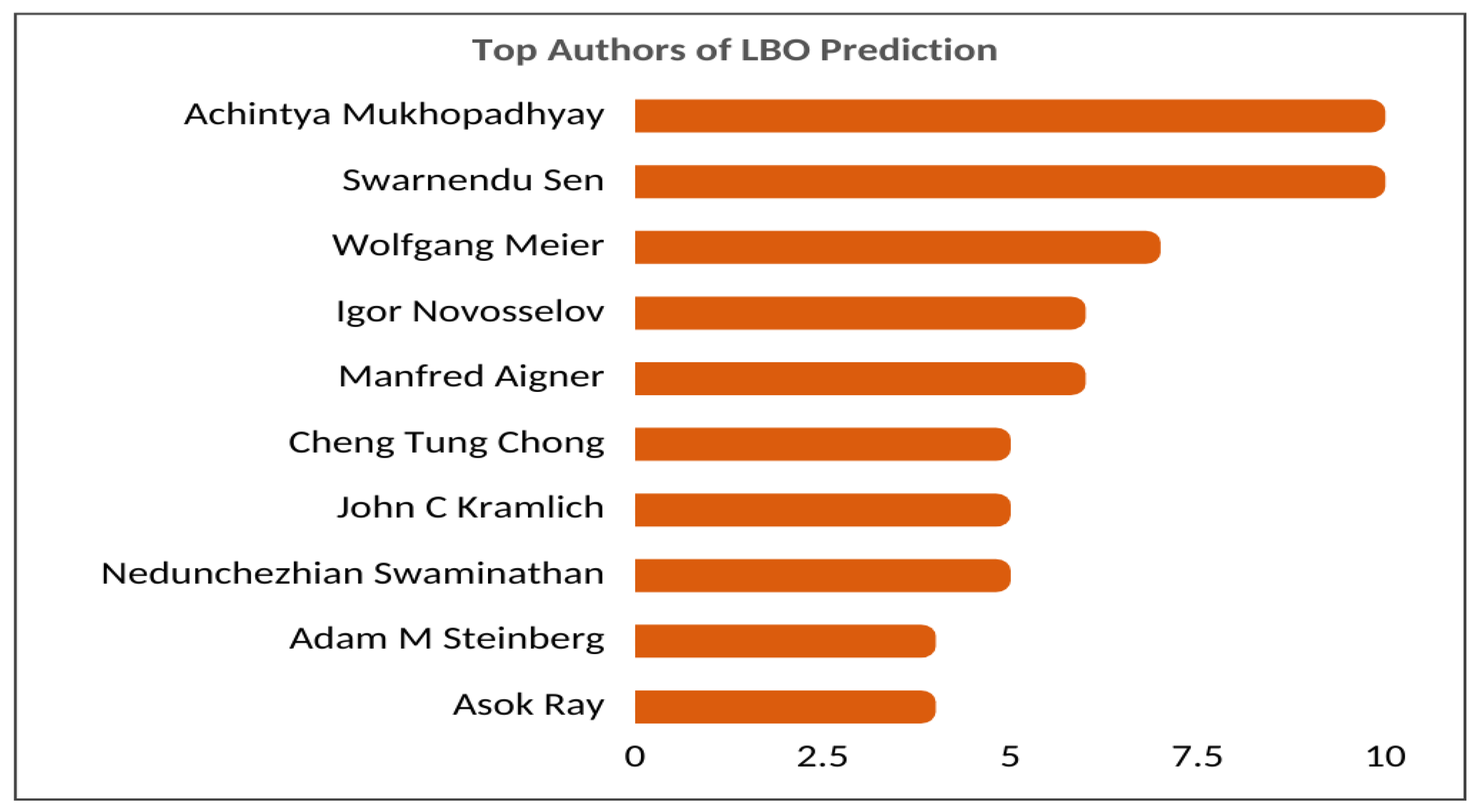

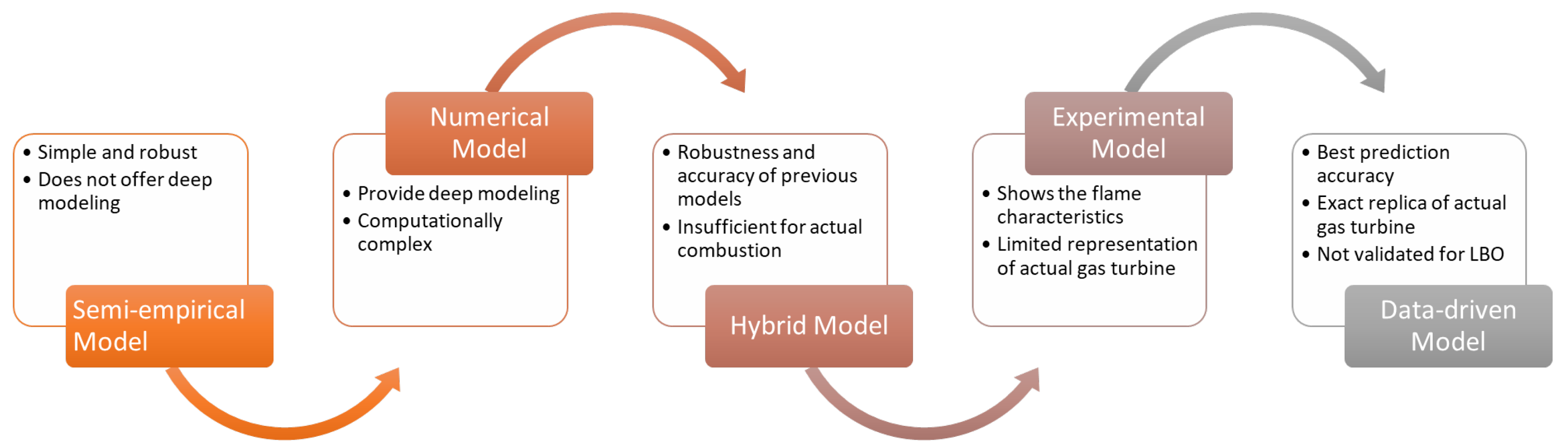

2. LBO Prediction Techniques

2.1. The Semi-Empirical Model

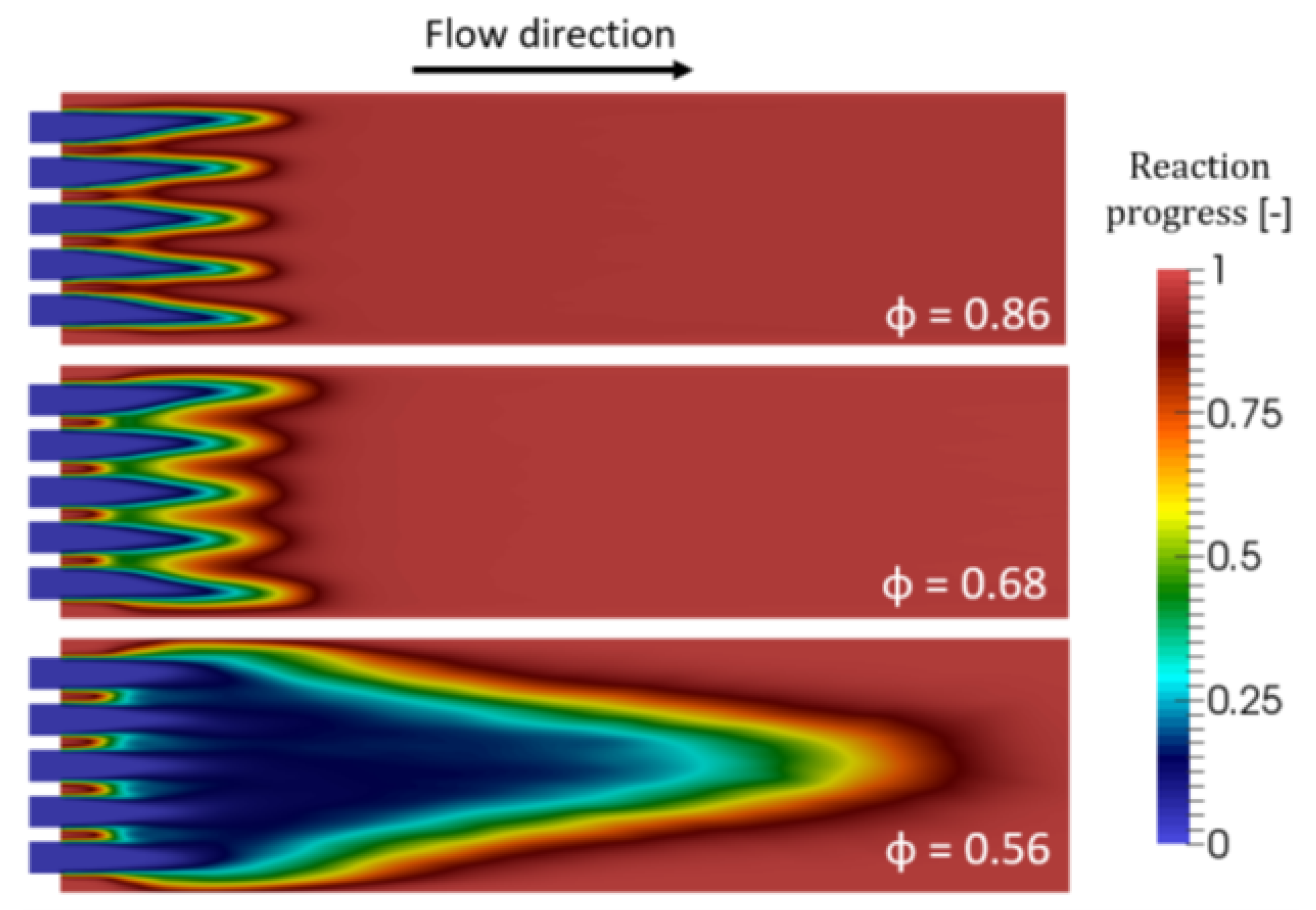

2.2. Numerical Simulation

| Author | Method | Tools | Strength | Weakness |

|---|---|---|---|---|

| Ahmed and Yong [35] | Using the flow structure in the primary zone as indicator of LBO | RANS | Provide better generalizability to be used in wider range of combustors | Not robust enough due to the long process |

| Akhtar et al. [5] | Using the relationship of the flame location and the input velocity as LBO indicator | FGM and RANS | Provide better accuracy than the semi-empirical models to 16% | High uncertainty of 20% |

| Nassini et al. [53] | Studying the flame behavior as LBO indicator using the FGM based on the TFC technique | FGM and LES | Improved the uncertainty to 5% | Computationally expensive |

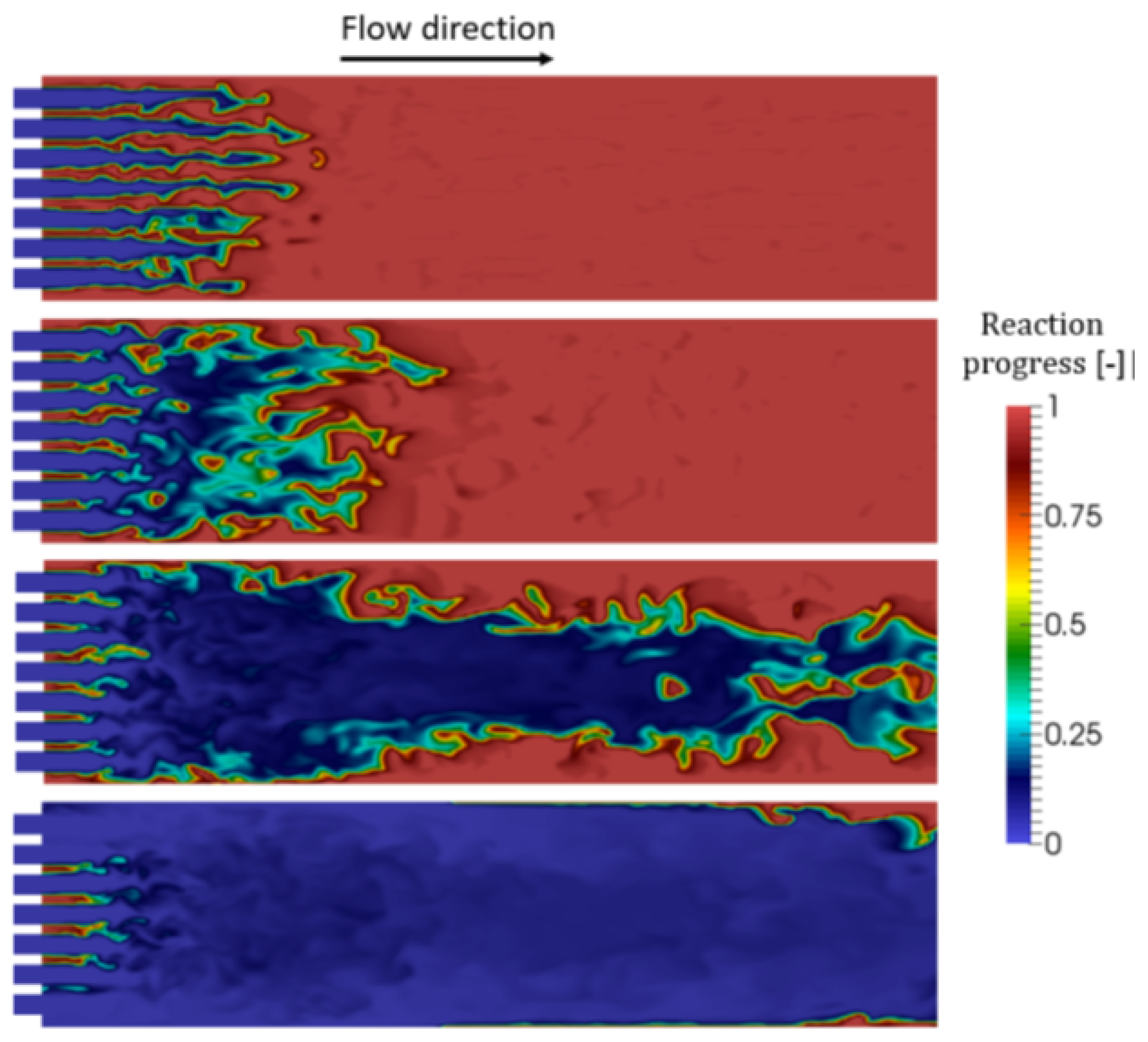

| Schwagerus et al. [54] | Using the FGM and LES to flame shape while changing the inlet velocity | FGM and LES | Strong observation of flame shape | Not validated in higher pressure conditions |

| Kaluri et al. [59] | Using the temperature measurement in real time by using the RT-CRN | CRN | Shows deep view of the chemical reaction near LBO | Long calculation time is required |

Hybrid Method

2.3. Experimental Method

| Author | Method | Tools | Strength | Weakness |

|---|---|---|---|---|

| Rieker et al. [82] | Using the exhaust temperature as an indicator of LBO | Diode laser-based absorption sensor | It can detect the fluctuation and instability in temperature | Such sensor has a critical heat problem |

| Li et al. [84], Wollgarten et al. [85], Chang et al. [86] | Detecting the frequency fluctuation to prediction the LBO | Ion current sensor | Does not require significant modification | The frequency signal can be easily interfered |

| De et al. [87], Mondal et al. [15] | Using the collected data of the CH* in a statistical analysis to predict LBO | AI (RQA) (HMM) | Non-intrusive and provide strong performance | Requires significant processing time |

| De et al. [88] | Using the heat release rate as LBO indicator | Frequency analysis | Non-intrusive statistical method with high accuracy | Cant be used with changes in fuel flow |

| Chaudhari et al. [90] De et al. [93] | By using a CCD camera to collect images and use RGB colors intensity as the LBO indication | CCD camera | Low-cost tools | The CCD camera provides low-precision images |

| Bhattacharya et al. [94] | Using the frequency fluctuation in the combustion as LBO indicator | FFT | Provide high accuracy prediction | Requires deep knowledge of acoustic mode |

2.4. Date-Driven Method

3. Recent Trends and Possible Future Work

- The LES simulation is a powerful tool and has been extensively used to study the chemistry and dynamics of the combustion near LBO. With the increase of computational power, a 3D simulation could give deeper information on the combustion system.

- As of today, the existence of strong mathematical/simulation software such as MATLAB and Scilab allowed the improvement of a complex mathematical and physical representation of a gas turbine which integrates multiple parameters that can be adjusted for the testing of gas turbine performance and LBO limit. Such software could be used in a hybrid approach such as by using the Rowen’s model in simulation to be used for LBO limits.

- The data-driven approach could make a significant improvement in the LPM combustors. LBO limits prediction at the design stages and in the early detection of a variety of faults, including the LBO during the operation. However, the data-driven model is a promising technique in all fields, especially in engineering, machinery, automotive, and power generation fields for faults and performance prediction. In fact, the model has been successfully used in gas turbines to predict faults in sensors, blades, and combustion health and performance.

- The hybrid of multiple models, such as using historical data from an actual gas turbine to develop a powerful numerical simulation, could significantly impact the combustion field by forecasting and predicting the faults beforehand, preventing sudden accidents.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tahan, M.; Tsoutsanis, E.; Muhammad, M.; Abdul Karim, Z.A. Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: A review. Appl. Energy 2017, 198, 122–144. [Google Scholar] [CrossRef]

- Tsoutsanis, E.; Meskin, N.; Benammar, M.; Khorasani, K. A dynamic prognosis scheme for flexible operation of gas turbines. Appl. Energy 2016, 164, 686–701. [Google Scholar] [CrossRef]

- Chen, W.; Jin, D.; Cui, W.; Huang, S. Characteristics of Gliding Arc Plasma and Its Application in Swirl Flame Static Instability Control. Processes 2020, 8, 684. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Campilongo, S.; Ficarella, A.; De Falco, G.; Commodo, M.; D’Anna, A. Pollutant Formation during the Occurrence of Flame Instabilities under Very-Lean Combustion Conditions in a Liquid-Fuel Burner. Energies 2017, 10, 352. [Google Scholar] [CrossRef]

- Akhtar, S.; Piffaretti, S.; Shamim, T. Numerical investigation of flame structure and blowout limit for lean premixed turbulent methane-air flames under high pressure conditions. Appl. Energy 2018, 228, 21–32. [Google Scholar] [CrossRef]

- Pavri, R.E.; Moore, G.D. GE Power Systems Gas Turbine Emissions and Control; GE Energy Services: Atlanta, GA, USA, 2001. [Google Scholar]

- Faqih, M.; Omar, M.B.; Ibrahim, R.; Omar, B.A.A. Dry-Low Emission Gas Turbine Technology: Recent Trends and Challenges. Appl. Sci. 2022, 12, 10922. [Google Scholar] [CrossRef]

- Feng, R.; Sun, Z.; Hu, X.; Li, G.; Deng, B. Role of particle oxidation catalyst on emission reduction of a non-road diesel engine: A multi case study. Chem. Eng. Sci. 2022, 260, 117914. [Google Scholar] [CrossRef]

- Deng, B.; Li, Q.; Chen, Y.; Li, M.; Liu, A.; Ran, J.; Xu, Y.; Liu, X.; Fu, J.; Feng, R. The effect of air/fuel ratio on the CO and NOx emissions for a twin-spark motorcycle gasoline engine under wide range of operating conditions. Energy 2019, 169, 1202–1213. [Google Scholar] [CrossRef]

- Nemitallah, M.A.; Rashwan, S.S.; Mansir, I.B.; Abdelhafez, A.A.; Habib, M.A. Review of novel combustion techniques for clean power production in gas turbines. Energy Fuels 2018, 32, 979–1004. [Google Scholar] [CrossRef]

- Kirubakaran, V.; Bhatt, D. Experimental and numerical prediction of lean blowout limits for micro gas turbine combustor. Aircr. Eng. Aerosp. Technol. 2021, 93, 607–614. [Google Scholar] [CrossRef]

- Yoshida, S.; Hassa, C.; Yamamoto, T.; Heinze, J.; Schroll, M. Influence of Fluidic Control in a Staged Lean Jet Engine Burner on Combustor Performance. Fluids 2019, 4, 188. [Google Scholar] [CrossRef]

- Dubey, A.; Nema, P.; Kushari, A. Investigation of Reverse Flow Slinger Combustor with Jet A-1 and Methanol. J. Eng. Gas Turbines Power 2021, 143, 916. [Google Scholar] [CrossRef]

- Mongia, H.C. N+3 and N+4 Generation Aeropropulsion Engine Combustors: Part 6: Operating Conditions, Target Goals and Lifted Jets. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, San Jose, CA, USA, 14–17 July 2013. [Google Scholar] [CrossRef]

- Mondal, S.; De, S.; Mukhopadhyay, A.; Sen, S.; Ray, A. Early Prediction of Lean Blowout from Chemiluminescence Time Series Data. Combust. Sci. Technol. 2020, 194, 1108–1135. [Google Scholar] [CrossRef]

- Vignat, G.; Minesi, N.; Soundararajan, P.R.; Durox, D.; Renaud, A.; Blanchard, V.; Laux, C.O.; Candel, S. Improvement of lean blow out performance of spray and premixed swirled flames using nanosecond repetitively pulsed discharges. Proc. Combust. Inst. 2021, 38, 6559–6566. [Google Scholar] [CrossRef]

- Li, M.; Tong, Y.; Thern, M.; Klingmann, J. Influence of the Steam Addition on Premixed Methane Air Combustion at Atmospheric Pressure. Energies 2017, 10, 1070. [Google Scholar] [CrossRef]

- Iannitelli, M.; Allegorico, C.; Garau, F.; Capanni, M. A Hybrid Model for on-line Detection of Gas Turbine Lean Blowout Events. PHM Soc. Eur. Conf. 2018, 4. [Google Scholar] [CrossRef]

- Musa, G.; Alrashed, M.; Muhammad, N.M. Development of big data lean optimisation using different control mode for Gas Turbine engine health monitoring. Energy Rep. 2021, 7, 4872–4881. [Google Scholar] [CrossRef]

- Lei, S.; Yong, H. An overview of methodologies to predict lean blowout limits for gas turbine combustors. In Proceedings of the 2019 16th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 8–12 January 2019; pp. 709–718. [Google Scholar]

- Zukoski, E.E.; Marble, F.E. Experiments concerning the mechanism of flame blowoff from bluff bodies. Caltech 1983. Available online: https://resolver.caltech.edu/CaltechAUTHORS:20110203-125953778 (accessed on 6 October 2022).

- Plee, S.; Mellor, A. Review of flashback reported in prevaporizing/premixing combustors. Combust. Flame 1978, 32, 193–203. [Google Scholar] [CrossRef]

- Plee, S.L.; Mellor, A.M. Characteristic time correlation for lean blowoff of bluff-body-stabilized flames. Combust. Flame 1979, 35, 61–80. [Google Scholar] [CrossRef]

- Derr, W.S.; Mellor, A.M. Characteristic times for lean blowoff in turbine combustors. J. Propuls. Power 1987, 3, 377–380. [Google Scholar] [CrossRef]

- Jarymowycz, T.A.; Mellor, A.M. Correlation of lean blowoff in an annular combustor. J. Propuls. Power 1986, 2, 190–192. [Google Scholar] [CrossRef]

- Leonard, P.; Mellor, A. Correlation of lean blowoff of gas turbine combustors using alternative fuels. J. Energy 1983, 7, 729–732. [Google Scholar] [CrossRef]

- Longwell, J.P.; Frost, E.E.; Weiss, M.A. Flame Stability in Bluff Body Recirculation Zones. Ind. Eng. Chem. 1953, 45, 1629–1633. [Google Scholar] [CrossRef]

- Lefebvre, A. Fuel effects on gas turbine combustion—ignition, stability, and combustion efficiency. J. Eng. Gas Turbines Power. 1985, 107, 24–37. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; Ballal, D.R. Gas Turbine Combustion: Alternative Fuels and Emissions; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Ballal, D.R.; Lefebvre, A.H. Weak Extinction Limits of Turbulent Flowing Mixtures. J. Eng. Power 1979, 101, 343–348. [Google Scholar] [CrossRef]

- Xie, F.; Huang, Y.; Hu, B.; Wang, F. Improved Semiempirical Correlation to Predict Lean Blowout Limits for Gas Turbine Combustors. J. Propuls. Power 2012, 28, 197–203. [Google Scholar] [CrossRef]

- Ateshkadi, A.; McDonell, V.G.; Samuelsen, G.S. Lean blowout model for a spray-fired swirl-stabilized combustor. Proc. Combust. Inst. 2000, 28, 1281–1288. [Google Scholar] [CrossRef]

- Mongia, H.; Vermeersch, M.; Held, T. A simple reactor-based approach for correlating lean blowout of turbopropulsion engine combustors. In Proceedings of the 37th Joint Propulsion Conference and Exhibit, Salt Lake City, UT, USA, 8–11 July 2001; p. 3420. [Google Scholar]

- Mongia, H.; Vermeersch, M.; Held, T. Data Reduction and Analysis (DRA) for Emissions and Lean Blowout. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 2003. [Google Scholar] [CrossRef]

- Ahmed, E.; Yong, H. Prediction of lean blowout performance of gas turbine combustor based on flow structures. Aeronaut. J. 2017, 122, 238–259. [Google Scholar] [CrossRef]

- Sun, L.; Huang, Y.; Wang, R.; Feng, X.; Liu, Z.; Wu, J. FV-MP model to predict lean blowout limits for multi-point lean direct injection combustors. Aerosp. Sci. Technol. 2019, 88, 185–192. [Google Scholar] [CrossRef]

- Rowen, W.I. Simplified Mathematical Representations of Heavy-Duty Gas Turbines. J. Eng. Power 1983, 105, 865–869. [Google Scholar] [CrossRef]

- Omar, M.; Ibrahim, R.; Abdullah, M.F.; Tarik, M.H.M. Modelling and System Identification of Gas Fuel Valves in Rowen’s Model for Dry Low Emission Gas Turbine. In Proceedings of the 2018 IEEE Conference on Big Data and Analytics (ICBDA), Langkawi, Kedah, Malaysia, 21–22 November 2018; pp. 33–37. [Google Scholar] [CrossRef]

- Omar, M.; Tarik, M.H.M.; Ibrahim, R.; Abdullah, M.F. Suitability study on using rowen’s model for dry-low emission gas turbine operational performance. In Proceedings of the TENCON 2017—2017 IEEE Region 10 Conference, Penang, Malaysia, 5–8 November 2017; pp. 1925–1930. [Google Scholar] [CrossRef]

- Omar, M.B.; Ibrahim, R.B.; Abdullah, M.F.; Tarik, M.H.M. Modelling of Dry-Low Emission Gas Turbine Fuel System using First Principle Data-Driven Method. J. Power Technol. 2020, 100, 1–13. [Google Scholar]

- Faqih, M.; Omar, M.B.; Ibrahim, R.B. Development of Rowen’s Model for Dry-Low Emission Gas Turbine Dynamic Simulation using Scilab. In Proceedings of the 2022 IEEE 5th International Symposium in Robotics and Manufacturing Automation (ROMA), Malacca, Malaysia, 6–8 August 2022; pp. 1–5. [Google Scholar]

- Hu, B.; Huang, Y.; Wang, F. FIA method for LBO limit predictions of aero-engine combustors based on FV model. Aerosp. Sci. Technol. 2013, 28, 435–446. [Google Scholar] [CrossRef]

- Huang, Y.; Sun, L. On the Quick Prediction of Lean Blowout Limits for Gas Turbine Combustors. Destech Trans. Environ. Energy Earth Sci. 2018. [Google Scholar] [CrossRef]

- Sun, L.; Huang, Y.; Wang, X.; Zheng, Z.; Wang, R.; Feng, X. Hybrid method based on flame volume concept for lean blowout limits prediction of aero engine combustors. Chin. J. Aeronaut. 2021, 34, 425–437. [Google Scholar] [CrossRef]

- Ladeinde, F. Advanced computational-fluid-dynamics techniques for scramjet combustion simulation. AIAA J. 2010, 48, 513–514. [Google Scholar] [CrossRef]

- Chen, J.H. Petascale direct numerical simulation of turbulent combustion—Fundamental insights towards predictive models. Proc. Combust. Inst. 2011, 33, 99–123. [Google Scholar] [CrossRef]

- Mercier, R.; Auzillon, P.; Moureau, V.; Darabiha, N.; Gicquel, O.; Veynante, D.; Fiorina, B. Les modeling of the impact of heat losses and differential diffusion on turbulent stratified flame propagation: Application to the tu darmstadt stratified flame. Flow Turbul. Combust. 2014, 93, 349–381. [Google Scholar] [CrossRef]

- Gonzalez-Juez, E.; Kerstein, A.; Ranjan, R.; Menon, S. Advances and challenges in modeling high-speed turbulent combustion in propulsion systems. Prog. Energy Combust. Sci. 2017, 60, 26–67. [Google Scholar] [CrossRef]

- Ihme, M.; Pitsch, H. Prediction of extinction and reignition in nonpremixed turbulent flames using a flamelet/progress variable model: 2. Application in LES of Sandia flames D and E. Combust. Flame 2008, 155, 90–107. [Google Scholar] [CrossRef]

- Garmory, A.; Mastorakos, E. Capturing localised extinction in Sandia Flame F with LES–CMC. Proc. Combust. Inst. 2011, 33, 1673–1680. [Google Scholar] [CrossRef]

- Ayache, S.; Mastorakos, E. Conditional Moment Closure/Large Eddy Simulation of the Delft-III Natural Gas Non-premixed Jet Flame. Flow Turbul. Combust. 2012, 88, 207–231. [Google Scholar] [CrossRef]

- Hasti, V.R.; Kundu, P.; Kumar, G.; Drennan, S.A.; Som, S.; Won, S.H.; Dryer, F.L.; Gore, J.P. Lean blow-out (LBO) computations in a gas turbine combustor. In Proceedings of the 2018 Joint Propulsion Conference, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar] [CrossRef]

- Nassini, P.C.; Pampaloni, D.; Meloni, R.; Andreini, A. Lean blow-out prediction in an industrial gas turbine combustor through a LES-based CFD analysis. Combust. Flame 2021, 229, 111391. [Google Scholar] [CrossRef]

- Schwagerus, A.; Habisreuther, P.; Zarzalis, N. Lean-Blow-Out Simulation of Natural Gas Fueled, Premixed Turbulent Jet Flame Arrays with LES and FGM-Modeling. In Proceedings of the ASME Turbo Expo 2021: Turbomachinery Technical Conference and Exposition, Combustion, Fuels, and Emissions, Online, 7–11 June 2021; Volume 3A. [Google Scholar] [CrossRef]

- Ren, Z.; Lu, Z.; Hou, L.; Lu, L. Numerical simulation of turbulent combustion: Scientific challenges. Sci. China Phys. Mech. Astron. 2014, 57, 1495–1503. [Google Scholar] [CrossRef]

- Li, R.; Konnov, A.A.; He, G.; Qin, F.; Zhang, D. Chemical mechanism development and reduction for combustion of NH3/H2/CH4 mixtures. Fuel 2019, 257, 116059. [Google Scholar] [CrossRef]

- Bongers, H.; Van Oijen, J.; Somers, L.; De Goey, L. The flamelet generated manifold method applied to steady planar partially premixed counterflow flames. Combust. Sci. Technol. 2005, 177, 2373–2393. [Google Scholar] [CrossRef]

- Kim, W.W.; Lienau, J.J.; Van Slooten, P.R.; Colket, M.B., III; Malecki, R.E.; Syed, S. Towards modeling lean blow out in gas turbine flameholder applications. J. Eng. Gas Turbines Power. 2006, 128, 40–48. [Google Scholar] [CrossRef]

- Kaluri, A.; Malte, P.; Novosselov, I. Real-time prediction of lean blowout using chemical reactor network. Fuel 2018, 234, 797–808. [Google Scholar] [CrossRef]

- Maran, P.; Boopathi, S.; Gowtham, P.; Chidambaram, S. Prediction of Lean Blowout Limits for Methane-Air Bluff Body Stabilized Combustion using a Temperature Gradient Method in a Model Gas-Turbine Afterburner. Int. J. Turbo Jet-Engines 2020, 37, 343–352. [Google Scholar] [CrossRef]

- Kirubakaran, V.; Naren Shankar, R. Prediction of lean blowout performance on variation of combustor inlet area ratio for micro gas turbine combustor. Aircr. Eng. Aerosp. Technol. 2021, 93, 915–924. [Google Scholar] [CrossRef]

- Gupta, S.; Malte, P.; Brunton, S.L.; Novosselov, I. Prevention of lean flame blowout using a predictive chemical reactor network control. Fuel 2019, 236, 583–588. [Google Scholar] [CrossRef]

- Tian, D.; Xin, H.; Zhang, X.-C. Numerical Simulation Research on the Lean Blowout Boundary of the Multi-Point LDI Combustor. J. Aeronaut. Astronaut. Aviat. 2020, 52, 293–310. [Google Scholar]

- Li, S.; Li, S.; Mira, D.; Zhu, M.; Jiang, X. Investigation of dilution effects on partially premixed swirling syngas flames using a LES-LEM approach. J. Energy Inst. 2018, 91, 902–915. [Google Scholar] [CrossRef]

- Li, S.; Zheng, Y.; Zhu, M.; Martinez, D.M.; Jiang, X. Large-eddy simulation of flow and combustion dynamics in a lean partially premixed swirling combustor. J. Energy Inst. 2017, 90, 120–131. [Google Scholar] [CrossRef]

- Hasti, V.R.; Kundu, P.; Kumar, G.; Drennan, S.A.; Som, S.; Gore, J.P. Numerical simulation of flow distribution in a realistic gas turbine combustor. In Proceedings of the 2018 Joint Propulsion Conference, Cincinnati, OH, USA, 9–11 July 2018; p. 4956. [Google Scholar]

- Basso, F.O.; Franco, A.T.; Pitz, D.B. Large-eddy simulation of turbulent pipe flow of Herschel-Bulkley fluids-Assessing subgrid-scale models. Comput. Fluids 2022, 244, 105522. [Google Scholar] [CrossRef]

- Hassanaly, M.; Raman, V. Classification and computation of extreme events in turbulent combustion. Prog. Energy Combust. Sci. 2021, 87, 100955. [Google Scholar] [CrossRef]

- Oberkampf, W.L.; Trucano, T.G. Verification and validation in computational fluid dynamics. Prog. Aerosp. Sci. 2002, 38, 209–272. [Google Scholar] [CrossRef]

- Menon, S. Multi-scale modeling for LES of engineering designs of large-scale combustors. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 5–8 January 2004; p. 157. [Google Scholar]

- Eggenspieler, G.; Menon, S. Structure of locally quenched swirl stabilized turbulent premixed flames. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 5–8 January 2004; p. 979. [Google Scholar]

- Porumbel, I.; Menon, S. Large eddy simulation of bluff body stabilized premixed flame. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; p. 152. [Google Scholar]

- Massey, J.C.; Chen, Z.X.; Swaminathan, N. Lean flame root dynamics in a gas turbine model combustor. Combust. Sci. Technol. 2019, 191, 1019–1042. [Google Scholar] [CrossRef]

- Poinsot, T. Prediction and control of combustion instabilities in real engines. Proc. Combust. Inst. 2017, 36, 1–28. [Google Scholar] [CrossRef]

- Han, M.; Xu, Q.; Han, X.; Lin, Y. Dynamics of stratified swirl flame near lean blow out. Propuls. Power Res. 2021, 10, 235–246. [Google Scholar] [CrossRef]

- Rizk, N.; Mongia, H. Gas turbine combustor design methodology. In Proceedings of the 22nd Joint Propulsion Conference, Huntsville, AL, USA, 16–18 June 1986; p. 1531. [Google Scholar]

- Rizk, N.K.; Mongia, H.C. Three-dimensional combustor performance validation with high-densityfuels. J. Propuls. Power 1990, 6, 660–667. [Google Scholar] [CrossRef]

- Hu, B.; Huang, Y.; Xu, J. A hybrid semi-empirical model for lean blow-out limit predictions of aero-engine combustors. J. Eng. Gas Turbines Power 2015, 137, 031502. [Google Scholar] [CrossRef]

- Hu, B.; Huang, Y.; Wang, F.; Xie, F. Lean blow-out prediction of aero-engine combustor based on cold flow field numerical simulation. Tuijin Jishu J. Propuls. Technol. 2012, 33, 232–238. [Google Scholar]

- Hu, B.; Zhao, Q.; Xu, J. Predicting lean blowout limit of combustors based on semi-empirical correlation and simulation. J. Propuls. Power 2016, 32, 108–120. [Google Scholar] [CrossRef]

- Sturgess, G.; Shouse, D. A hybrid model for calculating lean blowouts in practical combustors. In Proceedings of the 32nd Joint Propulsion Conference and Exhibit, Buena Vista, FL, USA, 1–3 July 1996. [Google Scholar] [CrossRef]

- Rieker, G.B.; Jeffries, J.B.; Hanson, R.K.; Mathur, T.; Gruber, M.R.; Carter, C.D. Diode laser-based detection of combustor instabilities with application to a scramjet engine. Proc. Combust. Inst. 2009, 32, 831–838. [Google Scholar] [CrossRef]

- Xu, H.; Fan, W.; Feng, J.; Yan, P.; Qi, S.; Zhang, R. Parameter Determination and Ion Current Improvement of the Ion Current Sensor Used for Flame Monitoring. Sensors 2021, 21, 697. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Xu, L.; Du, M.; Yang, L.; Cao, Z. Ion current sensing-based lean blowout detection for a pulse combustor. Combust. Flame 2017, 176, 263–271. [Google Scholar] [CrossRef]

- Wollgarten, J.C.; Zarzalis, N.; Turrini, F.; Peschiulli, A. Experimental investigations of ion current in liquid-fuelled gas turbine combustors. Int. J. Spray Combust. Dyn. 2017, 9, 172–185. [Google Scholar] [CrossRef]

- Chang, L.; Cao, Z.; Fu, B.; Lin, Y.; Xu, L. Lean blowout detection for bluff-body stabilized flame. Fuel 2020, 266, 117008. [Google Scholar] [CrossRef]

- De, S.; Bhattacharya, A.; Mondal, S.; Mukhopadhyay, A.; Sen, S. Application of recurrence quantification analysis for early detection of lean blowout in a swirl-stabilized dump combustor. Chaos 2020, 30, 043115. [Google Scholar] [CrossRef]

- De, S.; Bhattacharya, A.; Mondal, S.; Mukhopadhyay, A.; Sen, S. Identification and early prediction of lean blowout in premixed flames. Sādhanā 2020, 45, 222. [Google Scholar] [CrossRef]

- De, S.; Bhattacharya, A.; Mukhopadhyay, A.; Sen, S. Early detection of lean blowout in a combustor using symbolic analysis of colour images. Measurement 2021, 186, 110113. [Google Scholar] [CrossRef]

- Chaudhari, R.R.; Sahu, R.P.; Ghosh, S.; Mukhopadhyay, A.; Sen, S. Flame color as a lean blowout predictor. Int. J. Spray Combust. Dyn. 2013, 5, 49–66. [Google Scholar] [CrossRef]

- Sen, U.; Sharma, A.; Panja, S.; Mukherjee, S.; Sen, S.; Mukhopadhyay, A. Correlation of equivalence ratio with spectrometric analysis for premixed combustion. Fluid Mech. Fluid Power Contemp. Res. 2017, 1475–1483. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Gupta, B.; Hansda, S.; Haque, Z.; Kumar, A.; Mishra, M.K.; De, S.; Mukhopadhyay, A.; Sen, S. Lean Blowout Phenomena and Prior Detection of Lean Blowout in a Premixed Model Annular Combustor. In Proceedings of the Gas Turbine India Conference. American Society of Mechanical Engineers, Online, 29 November 2021; Volume 83532, p. V002T04A009. [Google Scholar]

- De, S.; Biswas, A.; Bhattacharya, A.; Mukhopadhyay, A.; Sen, S. Use of Flame Color and Chemiluminescence for Early Detection of Lean Blowout in Gas Turbine Combustors at Different Levels of Fuel–Air Premixing. Combust. Sci. Technol. 2019, 192, 933–957. [Google Scholar] [CrossRef]

- Bhattacharya, C.; De, S.; Mukhopadhyay, A.; Sen, S.; Ray, A. Detection and classification of lean blow-out and thermoacoustic instability in turbulent combustors. Appl. Therm. Eng. 2020, 180, 115808. [Google Scholar] [CrossRef]

- Klusmeyer, A.; Cross, C.; Lubarsky, E.; Bibik, O.; Shcherbik, D.; Zinn, B. Prediction of blow-offs of bluff body stabilized flames utilizing close-coupled injection of liquid fuels. J. Eng. Gas Turbines Power 2013, 135, 011504. [Google Scholar] [CrossRef]

- Chen, Y.; Fan, Y.; Han, Q.; Shan, X.; Bi, Y.; Deng, Y. The influence of cooling air jets on the premixed flame structure and stability of air-cooled bluff-body flameholder. Fuel 2022, 310, 122239. [Google Scholar] [CrossRef]

- Docquier, N.; Candel, S. Combustion control and sensors: A review. Prog. Energy Combust. Sci. 2002, 28, 107–150. [Google Scholar] [CrossRef]

- Kirubakaran, V.; Bhatt, D. Experimental Prediction of Lean Blowout Limits for 3kW Micro Gas Turbine Combustor fuelled with LPG. Incas Bull. 2021, 13, 89–95. [Google Scholar] [CrossRef]

- Yan, W.; Yu, L. On accurate and reliable anomaly detection for gas turbine combustors: A deep learning approach. arXiv 2019, arXiv:1908.09238. [Google Scholar]

- Roman, R.C.; Precup, R.E.; Petriu, E.M.; Dragan, F. Combination of data-driven active disturbance rejection and Takagi-Sugeno fuzzy control with experimental validation on tower crane systems. Energies 2019, 12, 1548. [Google Scholar] [CrossRef]

- Hashemi, S.M.; Botez, R.M.; Grigorie, T.L. New reliability studies of data-driven aircraft trajectory prediction. Aerospace 2020, 7, 145. [Google Scholar] [CrossRef]

- Naderi, E.; Khorasani, K. Data-driven fault detection, isolation and estimation of aircraft gas turbine engine actuator and sensors. Mech. Syst. Signal Process. 2018, 100, 415–438. [Google Scholar] [CrossRef]

- Pourbabaee, B.; Meskin, N.; Khorasani, K. Robust sensor fault detection and isolation of gas turbine engines subjected to time-varying parameter uncertainties. Mech. Syst. Signal Process. 2016, 76, 136–156. [Google Scholar] [CrossRef]

- Navi, M.; Davoodi, M.R.; Meskin, N. Sensor fault detection and isolation of an industrial gas turbine using partial kernel PCA. IFAC-PapersOnLine 2015, 48, 1389–1396. [Google Scholar] [CrossRef]

- Cartocci, N.; Napolitano, M.R.; Costante, G.; Valigi, P.; Fravolini, M.L. Aircraft robust data-driven multiple sensor fault diagnosis based on optimality criteria. Mech. Syst. Signal Process. 2022, 170, 108668. [Google Scholar] [CrossRef]

- Tayarani-Bathaie, S.S.; Khorasani, K. Fault detection and isolation of gas turbine engines using a bank of neural networks. J. Process. Control 2015, 36, 22–41. [Google Scholar] [CrossRef]

- Liu, J. Gas path fault diagnosis of aircraft engine using HELM and transfer learning. Eng. Appl. Artif. Intell. 2022, 114, 105149. [Google Scholar] [CrossRef]

- Liu, S.; Wang, H.; Tang, J.; Zhang, X. Research on fault diagnosis of gas turbine rotor based on adversarial discriminative domain adaption transfer learning. Measurement 2022, 196, 111174. [Google Scholar] [CrossRef]

- Olsson, T.; Ramentol, E.; Rahman, M.; Oostveen, M.; Kyprianidis, K. A data-driven approach for predicting long-term degradation of a fleet of micro gas turbines. Energy AI 2021, 4, 100064. [Google Scholar] [CrossRef]

- Sanaye, S.; Hosseini, S. Prediction of blade life cycle for an industrial gas turbine at off-design conditions by applying thermodynamics, turbo-machinery and artificial neural network models. Energy Rep. 2020, 6, 1268–1285. [Google Scholar] [CrossRef]

| Semi-Empirical Models | Authors | Concept | Drawback |

|---|---|---|---|

| CT | Zukoski and Marble [21] | LBO is occurring when the ignition delay time is longer than the particle time spent in the shear layer; therefore, when both times are equal, it is the LBO indicator | High uncertainty for LBO limits prediction |

| Plee and Mellor [22,23] | Adding the particle evaporation rate to Zukoski and Marble concept instead of the particle time spent in the shear layer | Limited to three types of combustors | |

| PSR | Longwell et al. [27] | LBO occurs when the heat loss in the recirculation zone is equal to the heat release and the pressure of the recirculation zone is proportional to the stability of blowout velocity | Not capable of predicting LBO limit in swirl-stabilized combustors |

| Lefebvre et al. [28,29] | Developed Longwell concept to be used in the swirl-stabilized combustors for LBO prediction | High uncertainty of 30% | |

| Mongia et al. [34] | Improved Lefebvre mode to be used in 5 different combustors by improving the parameters of the model | Limited to specific combustors configuration | |

| Ateshkadi et al. [31] | Improved the Lefebvre equation by introducing temperature-dependent parameters instead of the constant A | Not generalized for new combustors | |

| Xie et al. [32] | By using the flame volume to improve the accuracy and generalizability of the Lefebvre model by two parameters of mass fraction of the airflow in the combustor’s dome and the non-dimensional flame volume | Cannot be used for the new ultra low NOx combustors | |

| Sun et al. [36] | Improving the Lefebvre and flame to be applicable in ultra-low NOx combustors | Does not satisfy the industrial acceptable level of accuracy |

| Author | Method | Tools | Strength | Weakness |

|---|---|---|---|---|

| Rizk and Mongia [77] | By combining the flow field of the simulation with the semi-empirical model of fuel data | 3D combustor code | It can predict LBO, emission and performance | Limited to one combustor configuration |

| Hu et al. [78] | Estimating the parameters of FV from the simulation of non-reacting flow | CPU | Provide better accuracy than the semi-empirical model at 16% uncertainty | Computationally and timely expensive |

| Sun et al. [44] | Using the threshold of flame in the simulation as the parameter of the FV | CFD and Fluent | Improved the uncertainty to 10% | Computationally expensive |

| Prediction Method | Usages | Advantages | Disadvantages | Accuracy |

|---|---|---|---|---|

| Semi-empirical |

|

|

| 30% to 50% uncertainties |

| Numerical Simulation |

|

|

| 10% to 15% uncertainty |

| Hybrid |

|

|

| 5% to 15% uncertainty |

| Prediction Method | Usages | Advantages | Disadvantages | Accuracy |

|---|---|---|---|---|

| Experimental |

|

|

| Accuracy of 91% in predicting the lean blowout |

| Data-driven |

|

|

| Prediction accuracy above 99% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahashwan, A.A.; Ibrahim, R.B.; Omar, M.B.; Faqih, M. The Lean Blowout Prediction Techniques in Lean Premixed Gas Turbine: An Overview. Energies 2022, 15, 8343. https://doi.org/10.3390/en15228343

Bahashwan AA, Ibrahim RB, Omar MB, Faqih M. The Lean Blowout Prediction Techniques in Lean Premixed Gas Turbine: An Overview. Energies. 2022; 15(22):8343. https://doi.org/10.3390/en15228343

Chicago/Turabian StyleBahashwan, Abdulrahman Abdullah, Rosdiazli Bin Ibrahim, Madiah Binti Omar, and Mochammad Faqih. 2022. "The Lean Blowout Prediction Techniques in Lean Premixed Gas Turbine: An Overview" Energies 15, no. 22: 8343. https://doi.org/10.3390/en15228343

APA StyleBahashwan, A. A., Ibrahim, R. B., Omar, M. B., & Faqih, M. (2022). The Lean Blowout Prediction Techniques in Lean Premixed Gas Turbine: An Overview. Energies, 15(22), 8343. https://doi.org/10.3390/en15228343