High-Precision Fault Detection for Electric Vehicle Battery System Based on Bayesian Optimization SVDD

Abstract

1. Introduction

1.1. Review of the Existing Data-Driven Fault Detention Methods for the Battery System

1.2. Contributions

- ●

- Low modeling cost and high modeling efficiency. Automated optimization search methods save training time and training costs. In addition, the Bayesian optimization algorithm is the most effective automated machine learning method in recent years, which greatly improves the efficiency of finding optimal parameters by simulating the original model with probabilistic proxy models.

- ●

- Strong applicability. Battery systems often generate complex distributed state data in actual operation, and the proposed method is highly applicable to building an effective fault detection model even under such circumstances.

- ●

- Excellent fault detection capability. Early and minor faults are often difficult to detect, especially when the data is high-dimensional. The most serious safety accidents of battery systems are due to small faults that cannot be detected. The proposed method can detect these faults in time, which greatly improves the safety of the battery system.

1.3. Organization of the Paper

2. Overview of the Battery System

2.1. Battery System Hardware Structure Analysis

2.2. State Data Analysis

3. SVDD Fault Detection Model Based on Bayesian Optimization

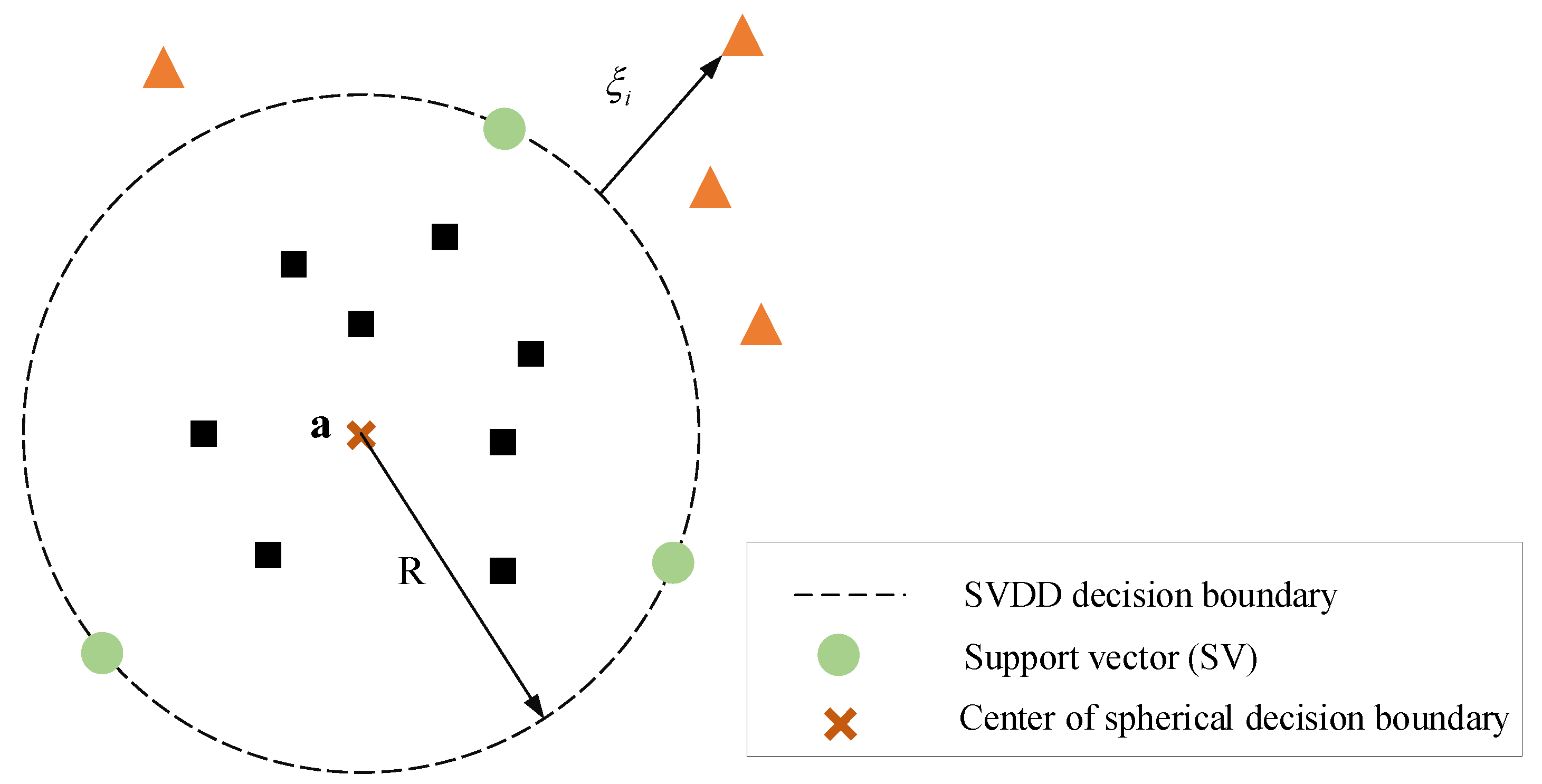

3.1. SVDD for Fault Detection

3.2. Bayesian Optimization for the SVDD Detection Model

4. Fault Detection Framework Based on BO-SVDD Model

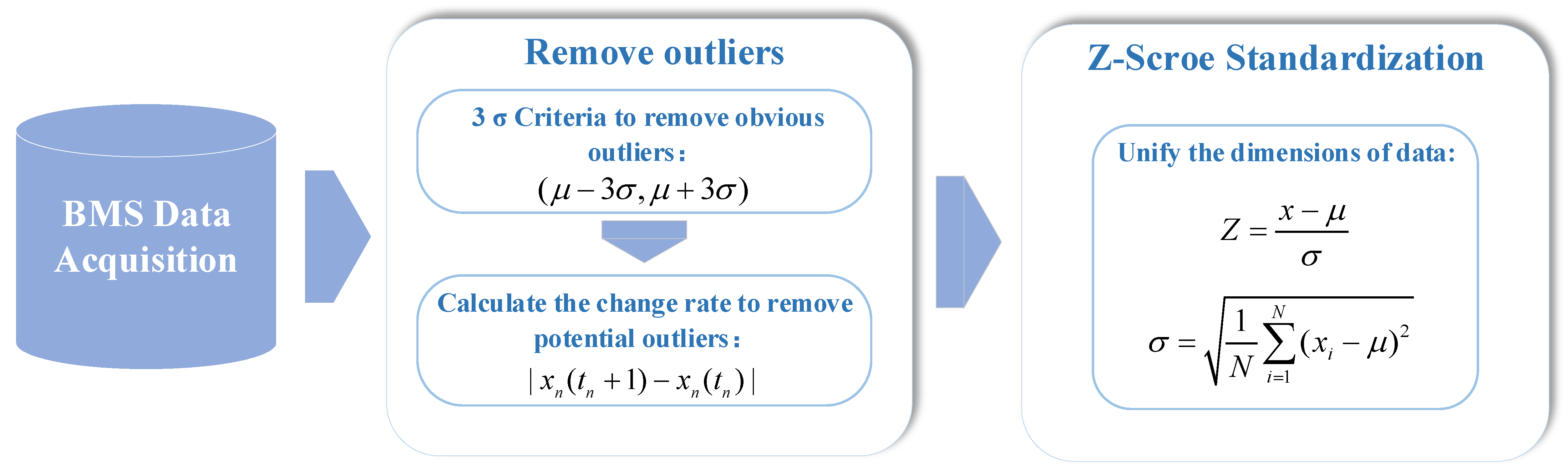

4.1. Data Acquisition and Data Pre-Processing

- The 3σ algorithm is used for each column in the data matrix to eliminate rows whose elements are not within three standard deviations of the column mean. This step can remove the more obvious outliers.

- First calculate the rate of change of the data, for example, the rate of change of at the moment is equal to . Then, calculate the mean and standard deviation of the rate of change. Finally, determine whether the rate of change of the data is within three standard deviations of the mean, if it is, determine it as normal data, otherwise remove the row. This step is to remove outliers whose values are within the normal range but have significant differences relative to neighboring points.

- Using Z-Score standardization unifies the voltage and temperature data on a uniform scale. Because the temperature data is much larger than the voltage data, if used directly for modeling, it would result in a model that is sensitive to temperature anomalies and insensitive to voltage anomalies.

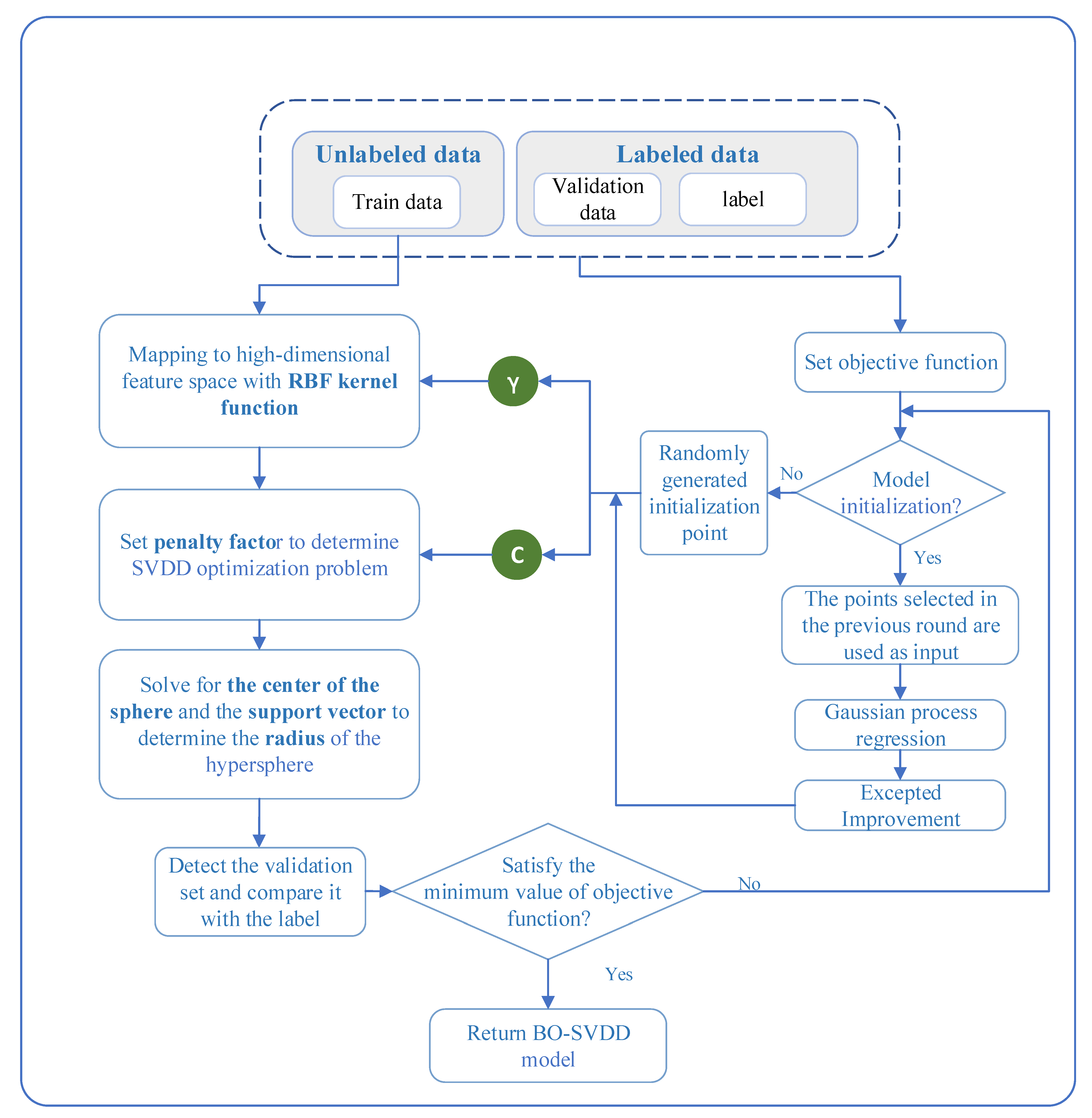

4.2. Fault Detection Framework

- A training set and a validation set are set up, where the training set consists of a large amount of unlabeled data, and the validation set consists of a small amount of labeled data.

- The penalty factor and Gaussian kernel width are set as the hyperparameters to be optimized.

- Random initialization of and is used to train the model, and the detection error rate of the validation set is used as the objective function.

- Perform Bayesian optimization by minimizing the objective function.

- The optimized parameters are loaded into the SVDD model and a new round of optimization is executed.

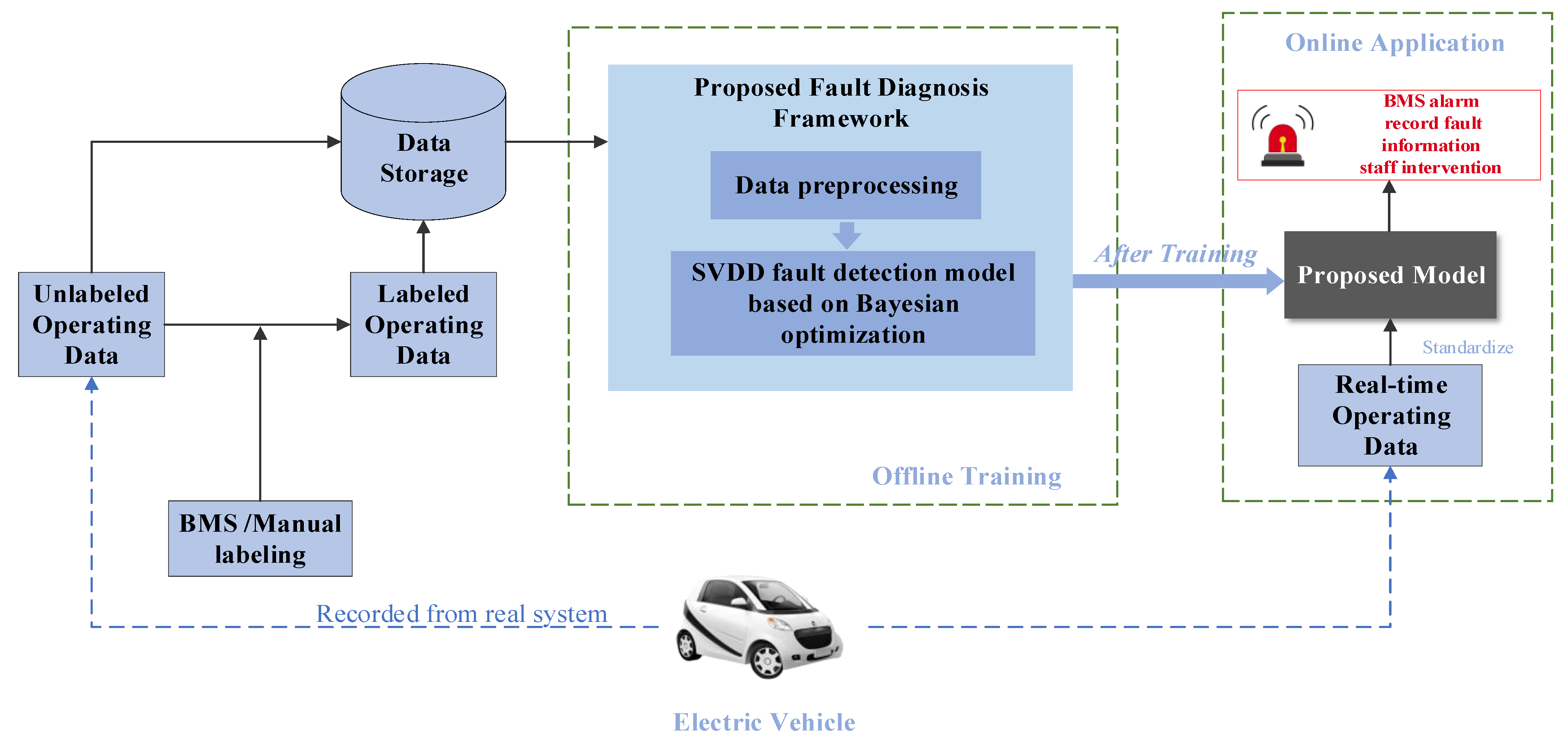

4.3. Application of the Proposed Method to Electric Vehicles

- A large amount of unlabeled data and a small amount of automatically labeled data from the BMS are collected in the actual operating vehicles. The labeled data can also be obtained from expert annotations so that more accurate detection models can be constructed.

- The base SVDD model is constructed using unlabeled data, and then the B0-SVDD model is trained using a small amount of labeled data for Bayesian optimization iterations.

- Based on the above steps, the proposed model is deployed to the BMS for online application. The method can be used in the real-world operation of the vehicle to provide real-time alerts for minor and early faults in the battery system.

5. Experiment

5.1. Building BO-SVDD Fault Detection Model

- Training set: Containing 3000 unlabeled data that have been preprocessed.

- Validation set: Consisting of 100 normal data with labels and 100 fault data with labels.

- Testing set: Consisting of a momentary short circuit fault (msf), cumulative short circuit fault (csf), overcharge fault (ocf), and over-discharge fault (odf) data sets, where the first 50 items of each data set are normal data and the last 150 items are fault data, as shown in Table 1.

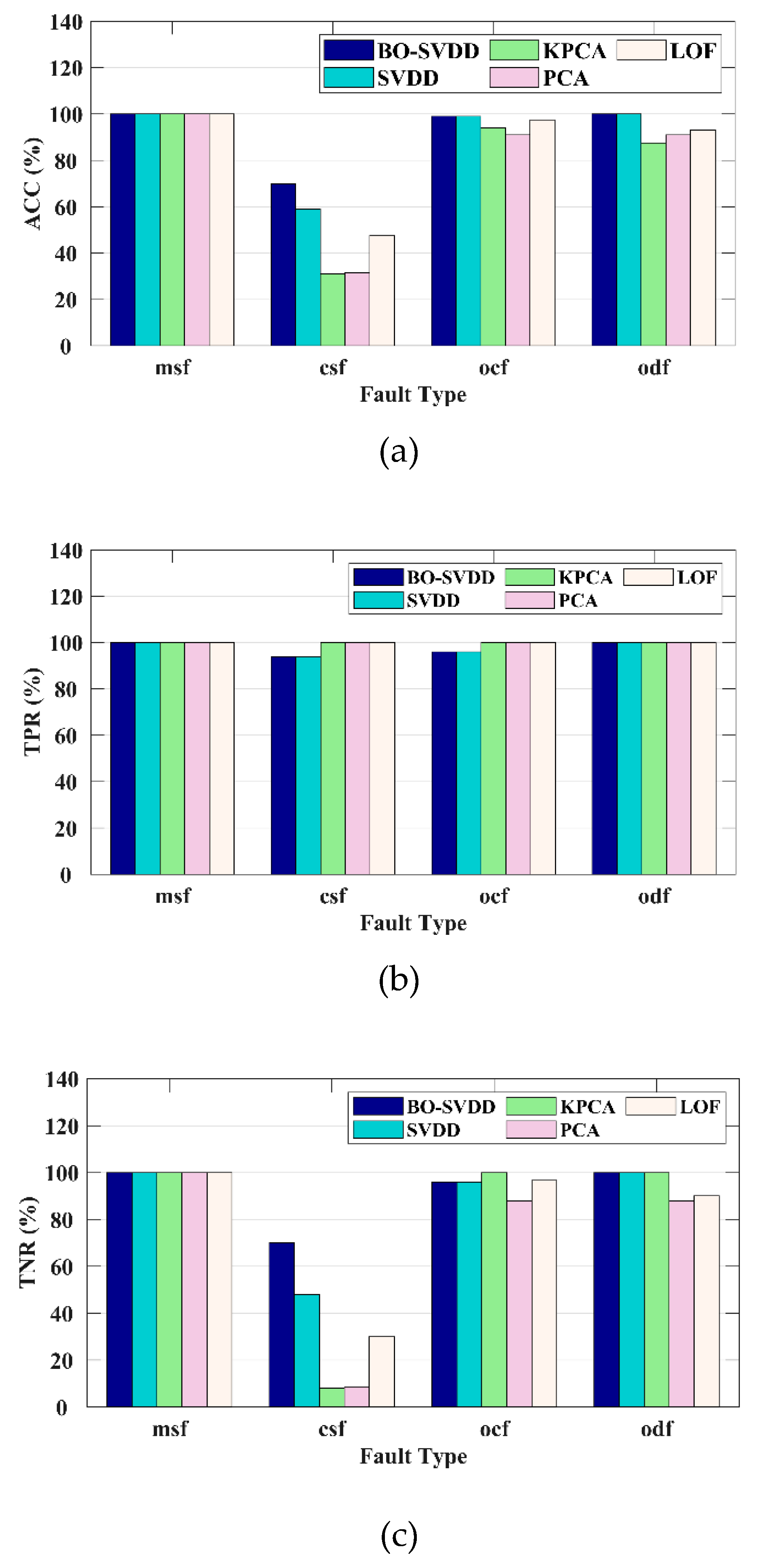

5.2. Fault Detection Experiment

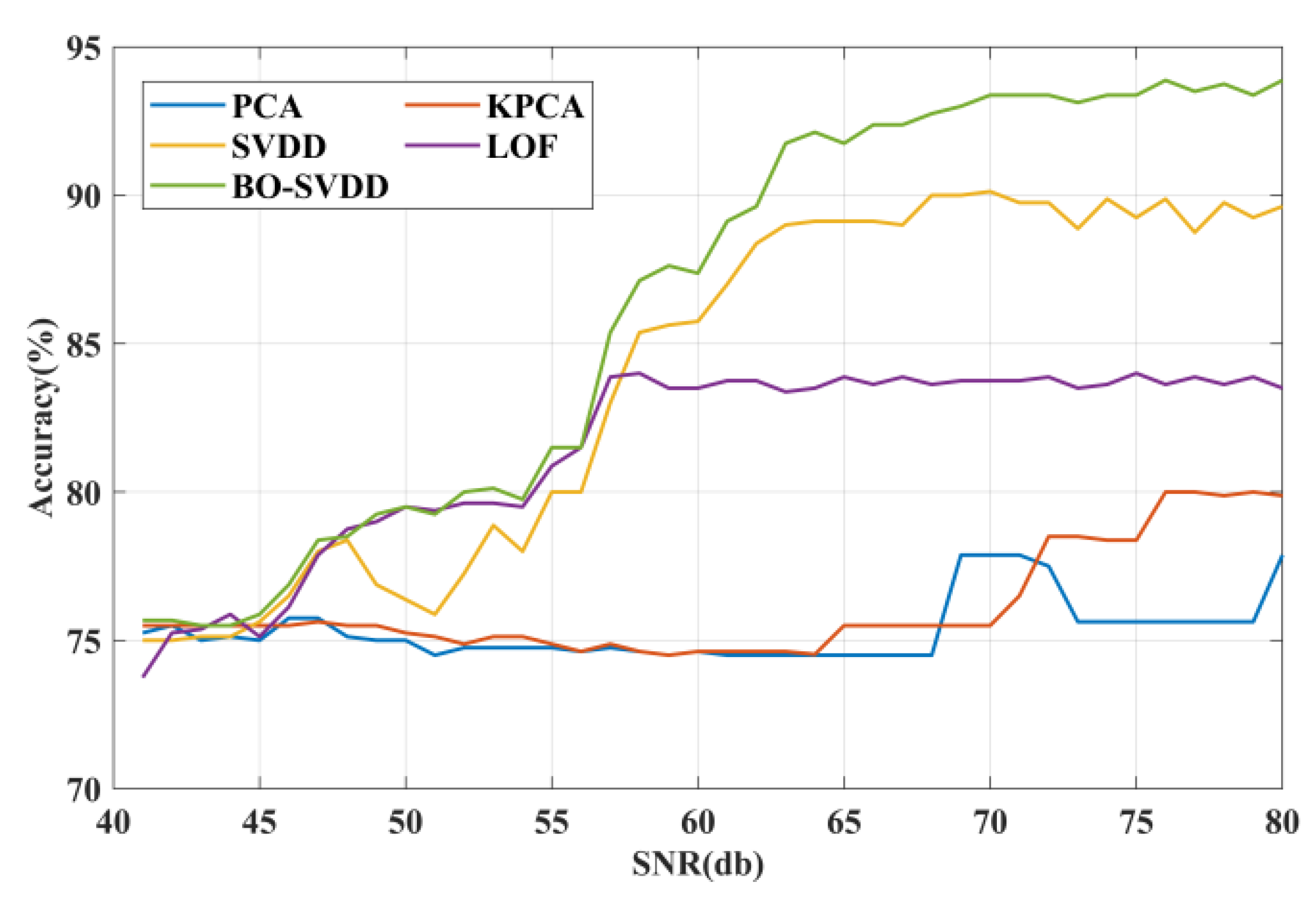

5.3. Robustness Experiments

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, P.; Sun, Z.; Wang, Z.; Zhang, J. Entropy-based voltage fault diagnosis of battery systems for electric vehicles. Energies 2018, 11, 136. [Google Scholar] [CrossRef]

- Rallo, H.; Casals, L.C.; De La Torre, D.; Reinhardt, R.; Marchante, C.; Amante, B. Lithium-ion battery 2nd life used as a stationary energy storage system: Ageing and economic analysis in two real cases. J. Clean. Prod. 2020, 272, 122584. [Google Scholar] [CrossRef]

- Guo, J.; Jiang, F. A novel electric vehicle thermal management system based on cooling and heating of batteries by refrigerant. Energy Convers. Manag. 2021, 237, 114145. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, H.; Wang, X.; Gao, Y.; Allu, S.; Cakmak, E.; Wang, Z. Internal short circuit and failure mechanisms of lithium-ion pouch cells under mechanical indentation abuse conditions: An experimental study. J. Power Sources 2020, 455, 227939. [Google Scholar] [CrossRef]

- Liu, Z.; He, H. Sensor fault detection and isolation for a lithium-ion battery pack in electric vehicles using adaptive extended Kalman filter. Appl. Energy 2017, 185, 2033–2044. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, Y.; Jiang, J.; Cheng, G.; Diao, W.; Zhang, W. Study on battery pack consistency evolutions and equilibrium diagnosis for serial-connected lithium-ion batteries. Appl. Energy 2017, 207, 510–519. [Google Scholar] [CrossRef]

- Gao, W.; Li, X.; Ma, M.; Fu, Y.; Jiang, J.; Mi, C. Case study of an electric vehicle battery thermal runaway and online internal short-circuit detection. IEEE Trans. Power Electron. 2020, 36, 2452–2455. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, W.; Yu, Q.; Sun, F. Research progress, challenges and prospects of fault diagnosis on battery system of electric vehicles. Appl. Energy 2020, 279, 115855. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, K.; Liu, K.; Lin, X.; Dey, S.; Onori, S. Advanced fault diagnosis for lithium-ion battery systems: A review of fault mechanisms, fault features, and diagnosis procedures. IEEE Ind. Electron. Mag. 2020, 14, 65–91. [Google Scholar] [CrossRef]

- She, C.; Zhang, Z.; Liu, P.; Sun, F. Overview of the application of big data analysis technology in new energy vehicle industry: Based on operating big data of new energy vehicle. J. Mech. Eng. 2019, 55, 3–16. [Google Scholar]

- Liu, Z.; Yin, X.; Zhang, Z.; Chen, D.; Chen, W. Online rotor mixed fault diagnosis way based on spectrum analysis of instantaneous power in squirrel cage induction motors. IEEE Trans. Energy Convers. 2004, 19, 485–490. [Google Scholar] [CrossRef]

- Wang, Z.; Hong, J.; Liu, P.; Zhang, L. Voltage fault diagnosis and prognosis of battery systems based on entropy and Z-score for electric vehicles. Appl. Energy 2017, 196, 289–302. [Google Scholar] [CrossRef]

- Xia, B.; Shang, Y.; Nguyen, T.; Mi, C. A correlation based fault detection method for short circuits in battery packs. J. Power Sources 2017, 337, 1–10. [Google Scholar] [CrossRef]

- Cheng, F.; Cai, W.; Zhang, X.; Liao, H.; Cui, C. Fault detection and diagnosis for Air Handling Unit based on multiscale convolutional neural networks. Energy Build. 2021, 236, 110795. [Google Scholar] [CrossRef]

- Li, B.; Cheng, F.; Zhang, X.; Cui, C.; Cai, W. A novel semi-supervised data-driven method for chiller fault diagnosis with unlabeled data. Appl. Energy 2021, 285, 116459. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Z.; Liu, P.; Zhang, Z.; Chen, Y.; Qu, C. Overview of fault diagnosis in new energy vehicle power battery system. J. Mech. Eng. 2021, 57, 87–104. [Google Scholar]

- Yang, R.; Xiong, R.; Ma, S.; Lin, X. Characterization of external short circuit faults in electric vehicle Li-ion battery packs and prediction using artificial neural networks. Appl. Energy 2020, 260, 114253. [Google Scholar] [CrossRef]

- Huo, W.; Li, W.; Zhang, Z.; Sun, C.; Zhou, F.; Gong, G. Performance prediction of proton-exchange membrane fuel cell based on convolutional neural network and random forest feature selection. Energy Convers. Manag. 2021, 243, 114367. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, R.; Lu, J.; Li, X. Temperature rise prediction of lithium-ion battery suffering external short circuit for all-climate electric vehicles application. Appl. Energy 2018, 213, 375–383. [Google Scholar] [CrossRef]

- Yang, R.; Xiong, R.; He, H.; Chen, Z. A fractional-order model-based battery external short circuit fault diagnosis approach for all-climate electric vehicles application. J. Clean. Prod. 2018, 187, 950–959. [Google Scholar] [CrossRef]

- Liu, P.; Wang, J.; Wang, Z.; Zhang, Z.; Wang, S.; Dorrell, D.G. High-dimensional data abnormity detection based on improved Variance-of-Angle (VOA) algorithm for electric vehicles battery. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 5072–5077. [Google Scholar]

- Kim, T.; Makwana, D.; Adhikaree, A.; Vagdoda, J.S.; Lee, Y. Cloud-based battery condition monitoring and fault diagnosis platform for large-scale lithium-ion battery energy storage systems. Energies 2018, 11, 125. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, P.; Wang, Z.; Zhang, L.; Hong, J. Fault and defect diagnosis of battery for electric vehicles based on big data analysis methods. Appl. Energy 2017, 207, 354–362. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, R.; Sun, F. Research status and analysis for battery safety accidents in electric vehicles. J. Mech. Eng. 2019, 55, 93–104. [Google Scholar]

- Ren, D.; Feng, X.; Lu, L.; He, X.; Ouyang, M. Overcharge behaviors and failure mechanism of lithium-ion batteries under different test conditions. Appl. Energy 2019, 250, 323–332. [Google Scholar] [CrossRef]

- Tagade, P.; Hariharan, K.S.; Ramachandran, S.; Khandelwal, A.; Naha, A.; Kolake, S.M.; Han, S.H. Deep Gaussian process regression for lithium-ion battery health prognosis and degradation mode diagnosis. J. Power Sources 2020, 445, 227281. [Google Scholar] [CrossRef]

- Tax, D.M.; Duin, R.P. Support vector domain description. Pattern Recognit. Lett. 1999, 20, 1191–1199. [Google Scholar] [CrossRef]

- Seo, J.; Ko, H. Face detection using support vector domain description in color images. In Proceedings of the 2004 IEEE International Conference on Acoustics, Speech, and Signal Processing, Montreal, QC, Canada, 17–21 May 2004; IEEE: Piscataway, NJ, USA, 2004; p. V-729. [Google Scholar]

- Lai, C.; Tax, D.M.; Duin, R.P.; Pękalska, E.; Paclík, P. A study on combining image representations for image classification and retrieval. Int. J. Pattern Recognit. Artif. Intell. 2004, 18, 867–890. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, S.; Xiao, F. Pattern recognition-based chillers fault detection method using support vector data description (SVDD). Appl. Energy 2013, 112, 1041–1048. [Google Scholar] [CrossRef]

- Bergstra, J.; Bardenet, R.; Bengio, Y.; Kégl, B. Algorithms for hyper-parameter optimization. Adv. Neural Inf. Process. Syst. 2011, 24, 2546–2554. [Google Scholar]

- Snoek, J.; Larochelle, H.; Adams, R.P. Practical bayesian optimization of machine learning algorithms. Adv. Neural Inf. Process. Syst. 2012, 25, 2960–2968. [Google Scholar]

- Seeger, M. Gaussian processes for machine learning. Int. J. Neural Syst. 2004, 14, 69–106. [Google Scholar] [CrossRef] [PubMed]

- Robert, C. Machine Learning, a Probabilistic Perspective; Taylor & Francis: Oxfordshire, UK, 2014. [Google Scholar]

- Schmid, M.; Kneidinger, H.-G.; Endisch, C. Data-driven fault diagnosis in battery systems through cross-cell monitoring. IEEE Sens. J. 2020, 21, 1829–1837. [Google Scholar] [CrossRef]

- Qiu, Y.; Dong, T.; Lin, D.; Zhao, B.; Cao, W.; Jiang, F. Fault diagnosis for lithium-ion battery energy storage systems based on local outlier factor. J. Energy Storage 2022, 55, 105470. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, F.; Huang, Y.; Lu, C.; Peng, W.; Fan, J.; Zhang, Y.; Ma, F.; Duan, Y.; Bao, W.; et al. Technical Conditions for Battery Management Systems for Electric Vehicles; China National Standardization Administration Committee: Beijing, China, 2020; Volume GB/T 38661-2020, p. 44. [Google Scholar]

| Expert Labeled Data | Normal Process Data | msf | csf | ocf | odf |

|---|---|---|---|---|---|

| 800 | 50 + 50 + 50 + 50 | 150 | 150 | 150 | 150 |

| Real Classification | Output Result | |

|---|---|---|

| Normal Classification | Abnormal Classification | |

| Normal | True Positive (TP) | False Negative (FN) |

| Abnormal | False Positive (FP) | True Negative (TN) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Cheng, F.; Duodu, M.; Li, M.; Han, C. High-Precision Fault Detection for Electric Vehicle Battery System Based on Bayesian Optimization SVDD. Energies 2022, 15, 8331. https://doi.org/10.3390/en15228331

Yang J, Cheng F, Duodu M, Li M, Han C. High-Precision Fault Detection for Electric Vehicle Battery System Based on Bayesian Optimization SVDD. Energies. 2022; 15(22):8331. https://doi.org/10.3390/en15228331

Chicago/Turabian StyleYang, Jiong, Fanyong Cheng, Maxwell Duodu, Miao Li, and Chao Han. 2022. "High-Precision Fault Detection for Electric Vehicle Battery System Based on Bayesian Optimization SVDD" Energies 15, no. 22: 8331. https://doi.org/10.3390/en15228331

APA StyleYang, J., Cheng, F., Duodu, M., Li, M., & Han, C. (2022). High-Precision Fault Detection for Electric Vehicle Battery System Based on Bayesian Optimization SVDD. Energies, 15(22), 8331. https://doi.org/10.3390/en15228331