1. Introduction

The economic recession caused by COVID-19 has become inevitable. Reducing investments and increasing efficiency will be the main focal points for the design, operation, and maintenance of natural gas (NG) pipelines for the managers and operators. Moreover, a reliable gas supply should be guaranteed. The compressor system (CS) is the power source of the long-distance NG pipeline, of which the operating state determines the pipeline flow and pressure, determining the reliability of the pipeline system. The reliability of the CS firstly refers to the operating reliability of a single compressor in a compressor station, and then refers to the reliability of the entire CS. Both depend on the compressor outage probability, including the failure probability and the scheduled outage probability. For the whole pipeline system, an important method to improve the reliability is to set up standby compressor units in the compressor stations, including unit standby and power standby. The unit standby needs the station to be equipped with standby units, resulting in increased investment and a large number of idle units [

1]. The power standby has a certain amount of surplus on the basis of the designed power demand. When a unit fails to work, the surplus power is applied to restore the flow and pressure of the entire pipeline, which means that, under normal conditions, the compressor unit with surplus power will work in a low load/efficiency state [

2]. In addition, for the actual design or operation of the CS, the way to set up the standby compressors is mainly based on expert experience. In order to increase the reliability of the pipeline, the conducted standby compressor plan is often conservative, which means the number or power of standby compressors is more than needed. The investment in compressor stations accounts for about 20% to 25% of the total investment in the gas pipeline system, and the investment in compressor accounts for more than half of the investments in compressor stations. Moreover, the annual operating costs of the compressor stations account for about 40% to 50% of the total operating costs of the gas pipeline, of which the power costs of the compressors account for more than 70% [

3]. Thereafter, reducing pipeline investments or operating costs without reducing reliability and safety has become the main focal point of pipeline managers and engineers. This is also the field of experience in the West–to–East Gas Transmission Project. Therefore, it is of great significance to design a standby compressor scheme for the CS based on reliability analyses.

The reliability of a pipeline system is treated as a complex task [

4]. The main focus at present is on the degradation mechanisms [

5,

6,

7,

8,

9,

10,

11] and structural integrity of the pipe [

12,

13,

14]. Structural integrity is influenced by loadings, such as corrosion or leakage, defined by thermal–hydraulic processes. The reliability of energy network systems also depends on the reliability of the installed equipment and the supply source. Praks et al. [

15] presented a probabilistic model to study the security of the supply source in a gas network. The model is based on Monte Carlo simulations with graph theory and is implemented in the software tool ProGasNet. Monforti and Szikszai [

16] presented a developed model, MC–GENERCIS, aimed to assess the robustness of the EU transnational gas transmission system during both normal and special operating conditions, including high-demand situations and/or supply shortages. Szikszai and Monforti [

17] developed a time-dependent model to assess responses to NG supply crises based on the Monte Carlo simulations, which were also discussed by Flouri et al. [

18]. Pambour et al. [

19] quantified the impact of disruption events in coupled gas and electricity transmission networks on the security of energy supply by a model named SAInt. The importance of the hydraulic characteristic was stressed. Fu estimated the failure probability of gas supply using the central moment method [

20] and data-driven model [

21], respectively. Fan et al. [

22] developed an evaluation method to calculate the gas supply reliability of the Shaanxi–Beijing NG pipeline systems. Yu et al. [

23] proposed a novel methodology to assess the gas supply reliability of NG transmission pipeline systems, considering both gas supply capacity and market demand uncertainties, which were integrated into a single Monte Carlo simulation. Shaikh et al. [

24] evaluated China’s NG supply security and employed a system-oriented modeling approach, namely, the ecological network analysis (ENA), to integrate all critical compartments of China’s NG supply system. Lu et al. [

25] applied an ecological network analysis to simulate the NG supply system in China and systematically measured its overall security level, in which the network information analysis, structural analysis, and utility analysis were conducted. These research studies focused on the reliability analyses of the gas supply source or the relation between the supply and the demand market, neglecting the installed equipment on the pipelines, which included underground gas storage, liquefied natural gas (LNG) terminals, and compressor stations. Li thought that the safe and efficient operation and management of large-scale NG pipeline network systems should be carried out with the objectives of analyzing the reliability indicators, system reliability, unit reliability, reliability data, and reliability management framework of the pipeline network system. Further, Su et al. [

26] thought that when the supply reliability assessment of NG pipeline networks was conducted, the failure probabilities of installed equipment should be considered. Compared with pipelines, compressor stations, LNG terminals, and NG storage [

27] are relatively stable in their operation conditions, which means the failure probabilities can be obtained from the historical data. In general, some research has been devoted to various perspectives on the gas transmission network under uncertainty or reliability analyses. However, the evaluation of the capability of a gas transmission network to withstand the impact of a compressor outage has not received much attention [

28], especially considering compressor operation styles in stations (i.e., serial, parallel, or both) [

29]. A complex and large-scale gas transmission network in China includes pipelines, compressor stations, regulators, valves, and other components. They experienced challenges in evaluating the network capability to withstand the impact of the compressor outage [

30].

Catchpole presented British Gas Corporation’s experience of gas compressor reliability growth to date and showed the methods that were used to evaluate operational trends, indicating the reliability growth of gas turbine-powered compressor units. Petrova et al. [

31] obtained a mathematical model for determining the reliability of the compressor unit based on the compressor failure mode combined with the control and measurement instruments, showing a calculation method for the compressor failure rate. Tran et al. [

32] put forward an effective maintenance policy for compressors at the national grid in the United Kingdom to mitigate the loss of network capability. Woo et al. [

33] suggested a reliability methodology to improve the lifetime of a mechanical system, such as a compressor, which could contribute to gas supply safety. Gentsch and King [

34] contributed to the modeling and supervision of multi-stage centrifugal compressors coping with real gas processes and steady-to-highly transient operating conditions. Li et al. [

35] proposed a novel ejector-based detection system for thermodynamic measurements of compressors to promote their reliability. In the present research studies on the reliability analyses of compressors, the reliability of the compressor itself is the main focus. To consider the impact of the compressor stations on the gas transmission network capability, a standby compressor unit is always applied. Sidney Pereira dos Santos et al. [

36] noted that a standby compressor unit was determined by the reliability of the compressor, and proposed a periodic/unscheduled maintenance strategy for the Bolivia–Brazil gas pipeline to calculate the reliability of the CS. Chen [

37] believed that in order to ensure the pipeline gas supply, each compressor station should be equipped with at least one standby unit. Tang discussed the compressor station plans for the West–East Gas Pipeline. The unit standby and power standby modes were compared, considering factors such as the operation, unit maintenance, and investment. Though the impacts of the compressor unit on the gas pipelines were discussed, the quantitative reliability analysis was little cared about, which led to the fact that the standby plan was always designed according to the experiences, causing great investments in the compressor numbers or power.

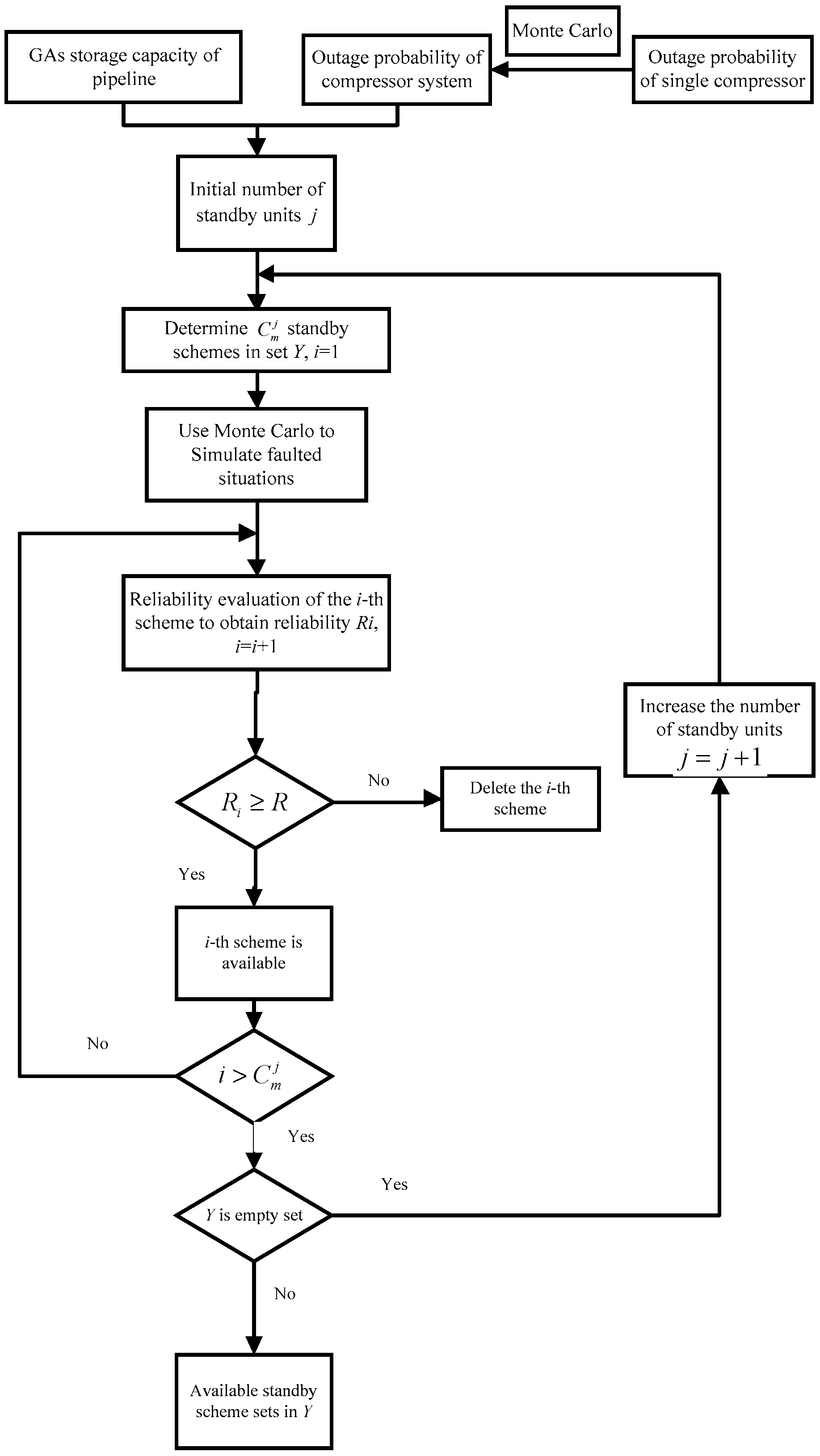

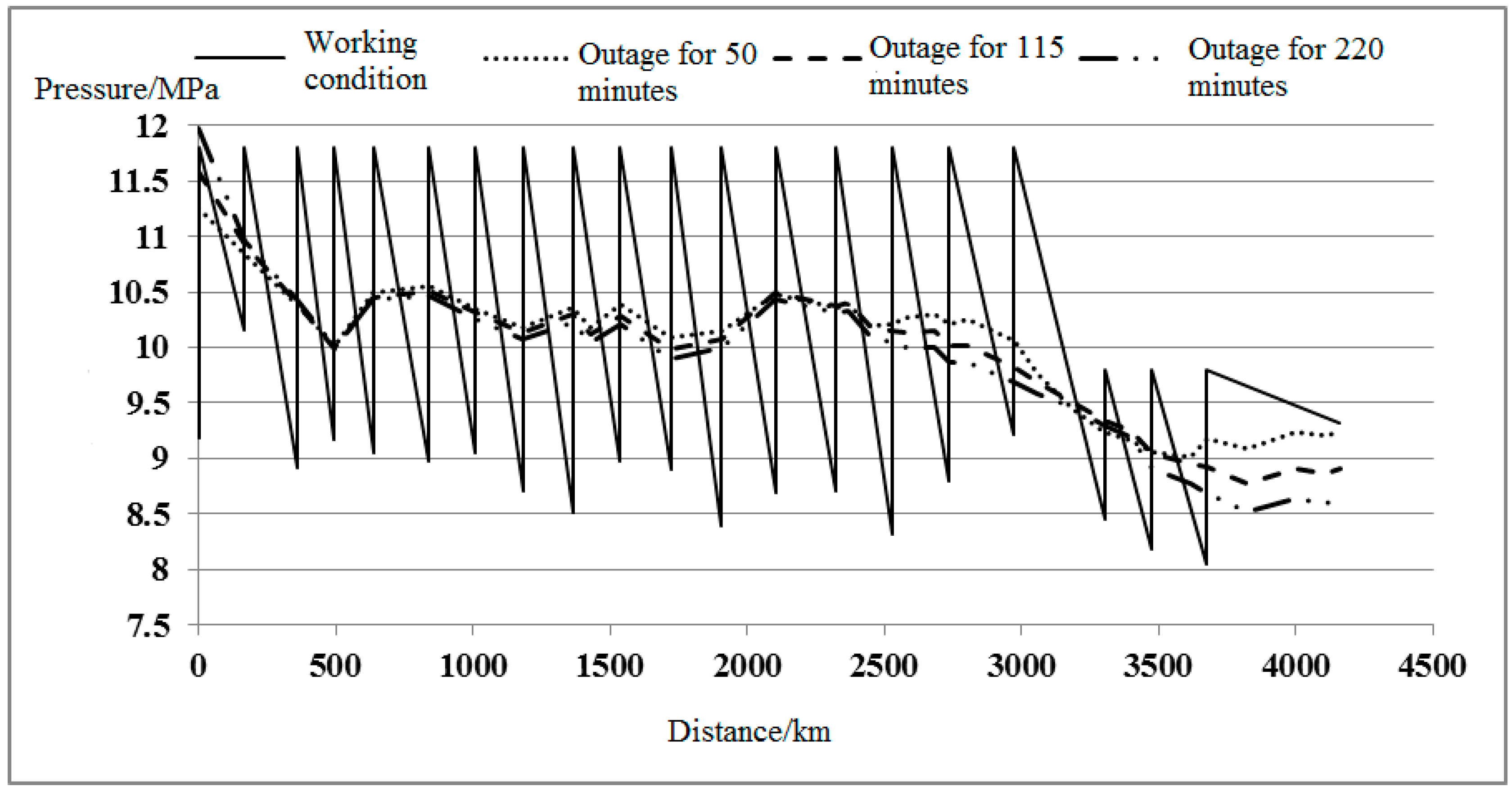

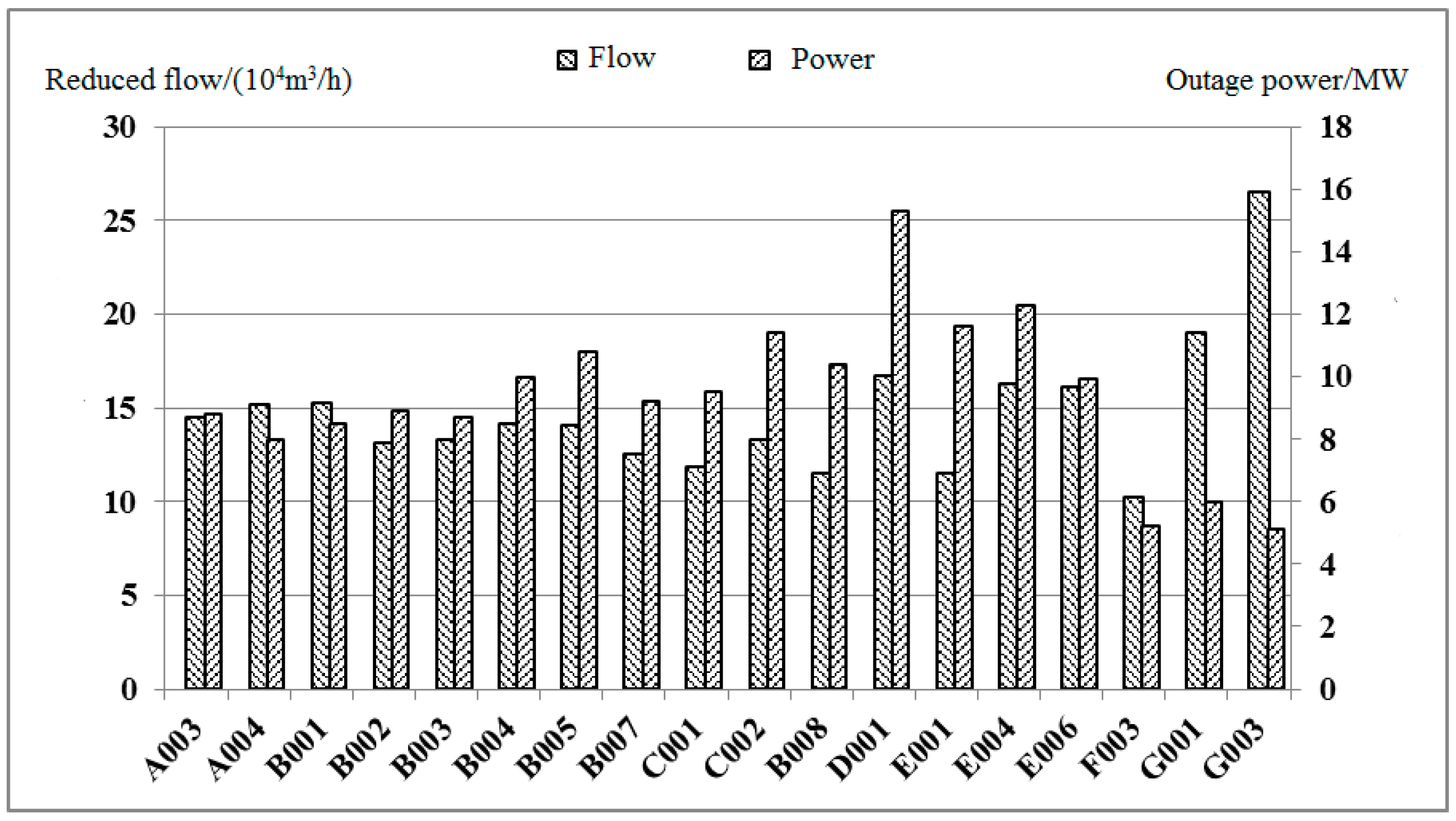

The main contribution of this study was to design a method to optimize the standby scheme for the CS based on the reliability analysis. Firstly, the ratio of the actual flow that withstands the compressor outage to the designed flow was defined as the index to evaluate the reliability, in which the flow can be calculated by the combined pipeline and compressor equations after the standby scheme is determined. Then, Monte Carlo method was used to calculate the compressor outage probability of the whole pipeline, respectively, through which the initial number of standby compressors was obtained, considering the gas storage capacity of the pipeline. Further, the standby schemes were designed with the help of the initial number, in which the positions of the failed compressors were obtained by the Monte Carlo simulation, to find out the effective standby scheme that could satisfy the flow and pressure boundary. Moreover, according to the influence of the compressor outage on the pipeline flow, the worst situation in which the compressors were shut down was used to test the standby scheme, calculating the flow reliability, pressure boundary, and total power. Finally, the standby scheme, which has the largest reliability with minimum power, was determined. The results of the case study indicate that for the Xin–Yue–Zhe (XYZ) pipeline, which had 20 standby compressors in the original scheme, the number of standby compressors in the improved schemes was reduced by seven and the pipeline reliability reached 96.86%.

This paper is organized as follows.

Section 2 presents the methods for the standby compressors based on the reliability analysis, feasibility analysis, and economic analysis, which are flow boundary, pressure boundary, and power, respectively.

Section 3 describes the details of the XYZ pipeline project, for which the standby scheme was designed and validated. Finally, the conclusions and future work are provided in

Section 4.