1. Introduction

One of humanity’s main tasks in the 21st century is to significantly reduce global CO

2 emissions that cause climate change [

1]. Those harmful emissions have resulted from decades of using carbon-based fuels as the primary energy source, leading to significant global warming [

2]. Nowadays, energy use per capita is far more than the earlier generations [

3]. The reserve of fossil fuels on planet earth is found in various locations, and the predictions are that global energy demand will soon exceed supply. The need for alternative energy sources has become a priority during the last decades. This issue has acquired more attention by EU by focusing on alternative energy implemented through political compromise in Paris agreement 2016 [

4]. The Intergovernmental Panel on Climate Change emphasised that greenhouse gas (GHG) emissions, including CO

2, must be reduced by 45% before 2030 to limit severe environmental impacts [

5]. Worldwide, the transport sector produces approximately a quarter of GHG emissions (24% in 2018) [

6]. With increasing energy demand, global CO

2 emissions are set to increase significantly. The need for sustainable and more efficient transportation systems is growing worldwide.

New alternative vehicles have been developed in recent years to mitigate the impact of harmful emissions in the transport sector. One type of alternative vehicle powertrain is the “hybrid car”. Gasoline-powered hybrid electric vehicles (HEV) and plug-in hybrid electric vehicles (PHEV) propelled by rechargeable batteries combined with an internal combustion engine (ICE). PHEVs can be recharged from the electric grid in addition to partial recharging from the IC engine, whereas HEVs (sometimes referred to as ‘mild hybrids’) are charged from the ICE engine and any kinetic energy recovery systems built into the vehicle. Biofuel contributes to limitations in oil consumption, but appear to be a temporary solution due to biomass availability limitations and insufficient annual production [

7,

8].

One step in decarbonising the transport sector has been performed by introducing battery electric vehicles (BEVs) and fuel cell electric vehicles (FCEV), so familiar as “zero emissions” cars. Those alternative vehicles don’t produce any harmful gases from their tailpipes, but GHGs are emitted while producing their fuels (electricity and hydrogen) on a large scale.

Battery electric vehicles (BEV) are fully powered by the energy stored in a large onboard lithium-ion battery (LIB). LIB is a type of battery of complex chemistry, which include lithium as a primary element, used as electrode and electrolyte components. A BEV’s performance is based on its battery pack’s power and energy capacity. An automotive battery pack typically consists of many cells (a few hundred to thousands), to meet the required energy of a BEV. LIB provides the highest energy density of all commercially available batteries [

9,

10,

11]. It is about 0.876 MJ/kg, which results in a battery mass of at least 100 kg per 100 km driving range when fully charged [

12]. Although LIB-based packs allow up to about 400 km driving range on a single charge, the cost of such car is nearly twice the price of the standard economy car [

13].

Although BEVs appear to be less emitting than petrol-driven vehicles during operation, factors like mining/manufacturing to driving to disposal or recycling will significantly affect the total lifetime CO

2 emissions from BEVs. Analysis suggests that mid-size BEVs will bring a 50% reduction in CO

2 emission during operation compared to gasoline-driven vehicles of the same size [

13,

14]. The assumed CO

2 reduction depends on how the electricity is produced during manufacturing, battery charging and during operation. The total emissions will be higher if the electricity is generated from non-renewable carbon-based primary sources.

Fuel cell electric vehicles (FCEV) have gradually penetrated the market since their advent 20 years ago. Fuel cells are typically classified according to the type of their electrolyte [

15]. Most road transport fuel cells in use are proton exchange membrane fuel cells (PEMFC). PEMFCs are widely used due to their higher power-to-weight ratio and shorter start-up time. Phosphoric acid fuel cells (PAFC) have also seen some road transport applications and were first commercialised in buses in the early stage of their development [

15].

Hydrogen production, storage and transport are essential elements in the total CO2 emissions. Most of the global industrial hydrogen demand is met by steam methane reforming (SMR). The other hydrogen production methods, such as water electrolysis, are likely to dominate in the future. In the electrolysis process, an electrical potential difference splits water molecules into hydrogen and oxygen. Until the recent surge in global methane prices, renewably powered alkaline electrolysis was not economically competitive with SMR-hydrogen due to the high electrical power demand for electrolysis. However, the hydrogen gas produced by electrolysis is of very high purity and ideal for PEMFC applications, as contaminations in hydrogen can inhibit the durability of the FC due to Pt catalyst poisoning.

Storing and transporting hydrogen can be performed by compressing the gas to very high pressures, by liquification at a temperature of about 20 K using cryotechnical methods. The third method is storing in different chemicals, where hydrogen is chemically or physically bonded to the host material. The last technology is still under significant research. Today’s existing and preferred method for storing and utilizing hydrogen is high-pressure compression in specially designed high-pressure containers. Liquification is typically applied for large-scale transportation due to the shorter storage time for cryogenic fluids. Ognissanto et al. [

16] have investigated different scenarios for hydrogen generation, distribution and usage in FCEV and concluded that hydrogen produced by electrolysis using electricity from renewable (or nuclear) energy sources is the lowest CO

2 emitting. Indeed, it appears to be competitive with BEV in terms of CO

2 emissions. However, hydrogen refuelling requires significant investment in infrastructure. Investigating and evaluating alternative vehicles’ energy efficiency and CO

2 emissions as well as considering the use of primary energy and different hydrogen and electricity production pathways is essential in future de-carbonisation discussions.

Well-to-wheel (WTW) GHG emissions comparison of alternative and currently used types of passenger cars, according to electricity and hydrogen production for South Korea for 2017 and future scenario 2030, was performed by Choi et al. [

17]. The CO

2 emissions generated by vehicle production and installation of the infrastructure were not included. South Korea imports about 94% of its total primary energy, and it still involves petroleum, natural gas, coal, uranium and about 5.7% (2017) of renewable energy. The lowest GHG emissions of 55 g CO

2 eq./km were observed for FCEV due to the low GHG emissions of hydrogen production by naphtha cracking, while BEVs were found to emit 109 g CO

2 eq./km.

Several other studies have concluded that BEVs are superior to FCEVs in terms of well-to-wheel efficiency and GHG emissions; if grid electricity, based on hydrocarbons or a mix of renewable and carbon-rich sources, is the energy source [

18]. Many other works discuss that electric passenger vehicles have a limited driving range with a one-time battery charge [

12,

19,

20].

It is generally assumed that using battery electric vehicles significantly reduces CO2 output compared to cars running on ICEs and that fuel cell electric vehicles do not (significantly) reduce CO2 output because of the energy conversion from electricity to hydrogen and back. While this will be true in many cases, it does not take into account that the production of the battery releases a lot of CO2 and that the CO2 released by electricity generation varies extremely depending on the energy source.

The present work aims to study the effect of varying the cruising range and thus the size of the power train and the battery and calculating the CO2 output during the lifetime of the car in four different European countries with different sources of energy ranging from nearly pure renewable energy (in Norway) to a coal-based generation (in Poland) to compare the effects of various sources of energies.

2. Materials and Methods

Calculations of total CO2 emissions in the lifetime of vehicles of the same size with different drive systems were performed, comparing battery electric vehicles (BEV) and fuel cell electric vehicle (FCEV) with cars using internal combustion engines (ICE) as well as two kinds of hybrids, the (BEV-ICE) hybrid car combining a battery motor with a combustion engine and the newer idea of combining a battery with a fuel cell car (BEV-FCEV).

The calculation includes CO2 emissions released due to the production of the car and its battery and running the vehicle throughout its life cycle. The latter strongly depends on the total mileage and (for electric vehicles) on the source of electricity production. The total mileage was arbitrarily set to 200,000 km. The influence of the source of electricity generation was studied by using mixtures of sources from different countries ranging from dominantly renewable sources in Norway to mainly coal in Poland.

One factor that has to be considered for a detailed calculation is the weight of the vehicle, as it has a significant influence on its energy consumption: The dependence of the consumption C(m) can be calculated as [

12]:

The consumption C(m

0) is assumed to be 0.557 kWh/km for an ICE-driven vehicle of m

0 = 1200 kg weight corresponding to 6 L petrol per 100 km. The primary energy consumptions of the different cars are calculated from this value using Equation (1). Values for the different efficiencies of the driving systems, energy conversions and energy transport are listed in

Appendix A.

As batteries have a significantly lower energy density than petrol, methane or hydrogen tanks, a heavy battery will be needed for a long cruising range, which increases the weight of the car compared to other driving systems. This increased weight requires more robust and thus heavier components (chassis, brakes, etc.), which makes it even heavier (

Figure 1). The increased vehicle weight also increases energy consumption and reduces performance in terms of range and acceleration.

For a fair comparison between power train types, the cars should have the same acceleration and speed. This can be achieved by keeping the power-to-weight ratio constant (set arbitrarily to 0.05 kW/kg). At the same time, the cruising range has to be kept constant by increasing the tank/battery according to the calculated consumption. A more powerful motor increases the vehicle’s weight again with the consequences described above. So, a second iteration of the same procedure is executed: updated consumption and engine power corresponding to the new weight, larger battery/tank giving a new weight, then the third iteration, a.s.o. until all values are stable within 4 or 5 digits. The calculation follows a procedure described earlier [

21]. The exact formulae and values for masses and efficiencies needed for the analysis are given in

Appendix A.

While batteries based on current Li-ion technology are heavier than a filled petrol or hydrogen tank, the electric motor is lighter than a combustion engine of the same power. Therefore, the additional battery weight is compensated by a lighter drive section for short cruising ranges. However, for long cruising ranges the BEV will be significantly heavier (see

Table 1).

For fuel cell electric vehicles (FCEV), high-pressure vessels for gaseous hydrogen and hydrogen stored in solid-state materials were considered. As the resulting values are comparable, the average of both is given in

Table 1.

Two types of hybrid cars were studied: (BEV-ICE) hybrid car combining a battery motor with a combustion engine and a (BEV-FCEV) car combining a battery with a fuel cell drive system. In both cases, the idea is to have a low-carbon option and a long-range backup. In this study, they are designed to run 100 km on battery but to enable 500 km using the backup mode of driving. As typical car journeys are significantly shorter than 100 km, it is assumed that 50% of the total distance is run on batteries. (This should be easily feasible, though it is currently not reached by most users). The BEV-petrol hybrid car has the drawback that it needs two motors and associated driving systems making it heavier and more expensive, while the BEV-FCEV can use the same motor and driving system.

The calculation of the CO

2 release for the different sources of electricity production follows values taken from database electricity maps [

22] and are present in

Table 2. Data on the energy sources for power generation in Europe and some particular countries (Romania, Germany, Poland) for the year 2021 are taken mostly from the database Statista [

23]. The data were compared with official statistical data for different countries: Norway [

24], Europe [

25], Romania [

26] and Poland [

27].

Mean values of CO

2 release for the production of cars and batteries have been calculated using data taken from different sources, cited in a review article [

28]. They are shown in

Table 1. The CO

2 release due to operation of the vehicle depends on the energy source for electricity production and varies from country to country. The calculated values are shown in

Figure 2,

Figure 3,

Figure 4,

Figure 5 and

Figure 6, presented in the

Section 3. Combined with the values for the production of car and battery, they give the total CO

2 output. However, the following contributions have not been considered in the calculation:

- -

The CO2 release for dismantling/recycling the car and the battery.

- -

Additional power consumption for heating or cooling

Cooling increases fuel consumption for all cars, while heating can be done using excess heat from the ICE of the petrol car or the fuel cell of the FCEV, while it causes additional consumption for the BEV.

3. Results and Discussion

A comparison of the total CO2 emission of medium-sized cars with different drive trains was performed for different countries. The analysis includes CO2 emissions during the production of the car including its drive system, and the CO2 released over its lifetime with an assumed 200,000 km of use. A petrol car serves as the reference, for which 33 t of total CO2 emissions were calculated.

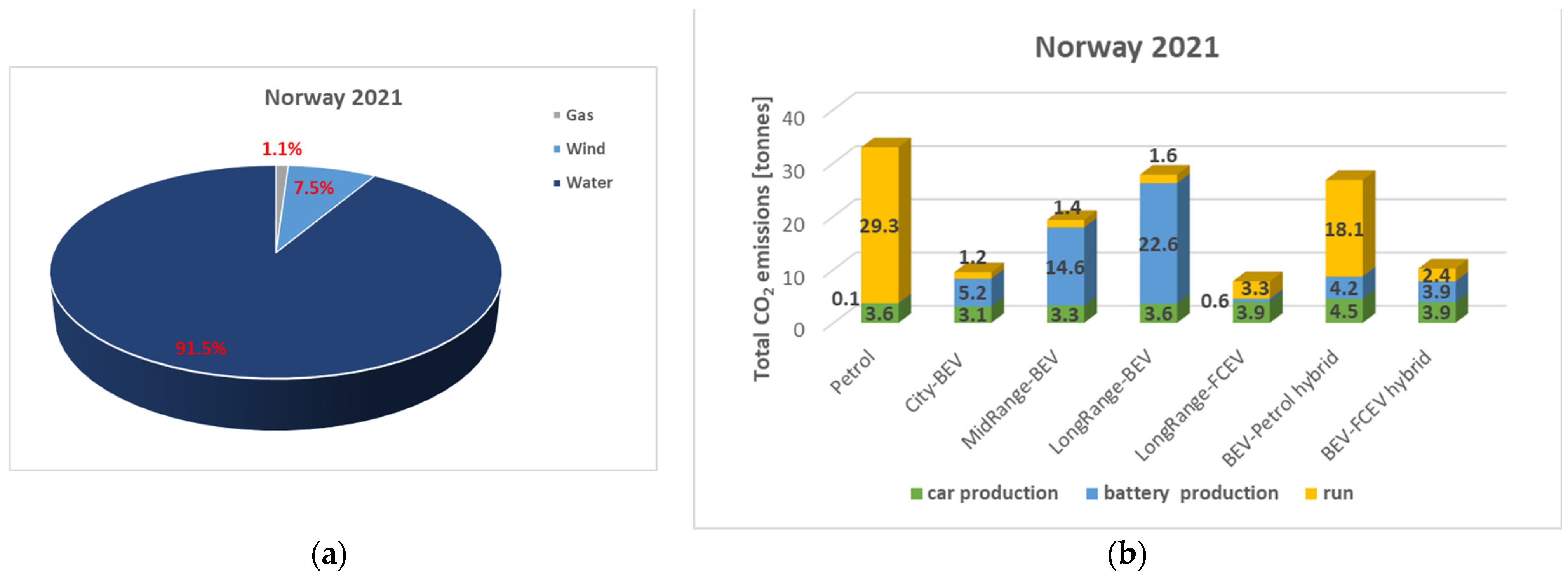

Figure 2a,

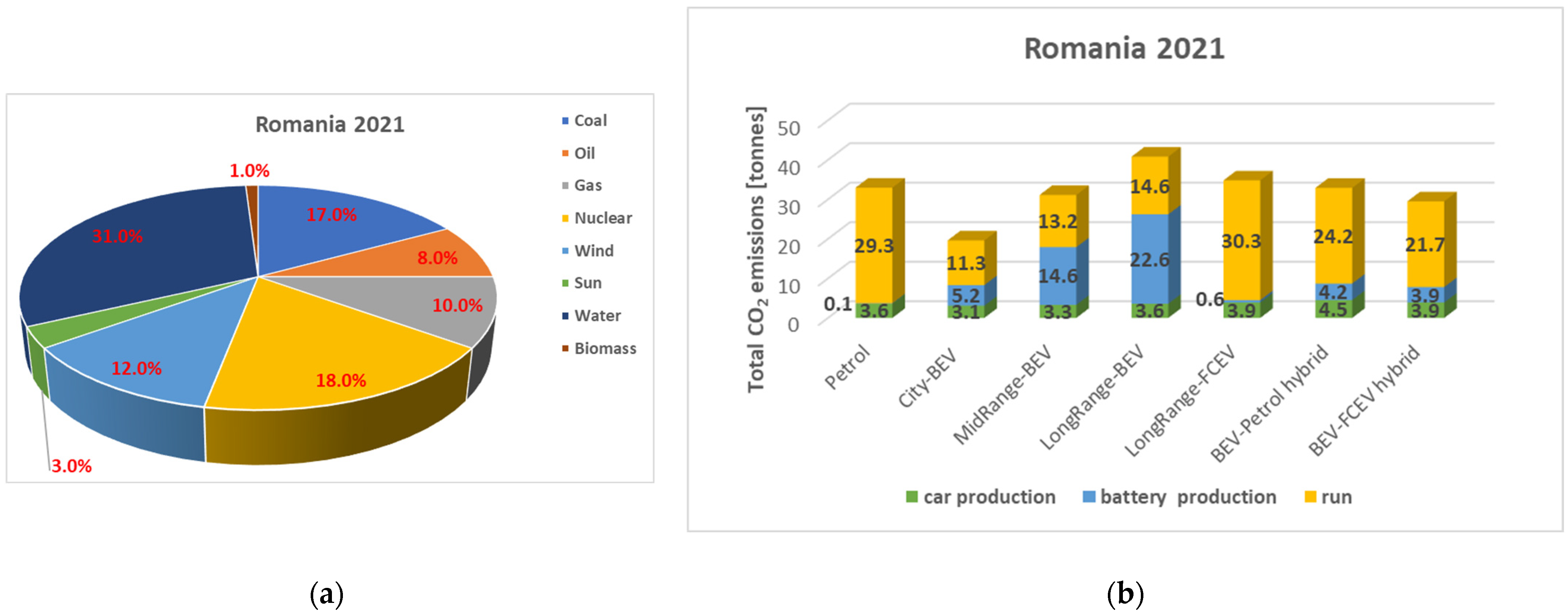

Figure 3a,

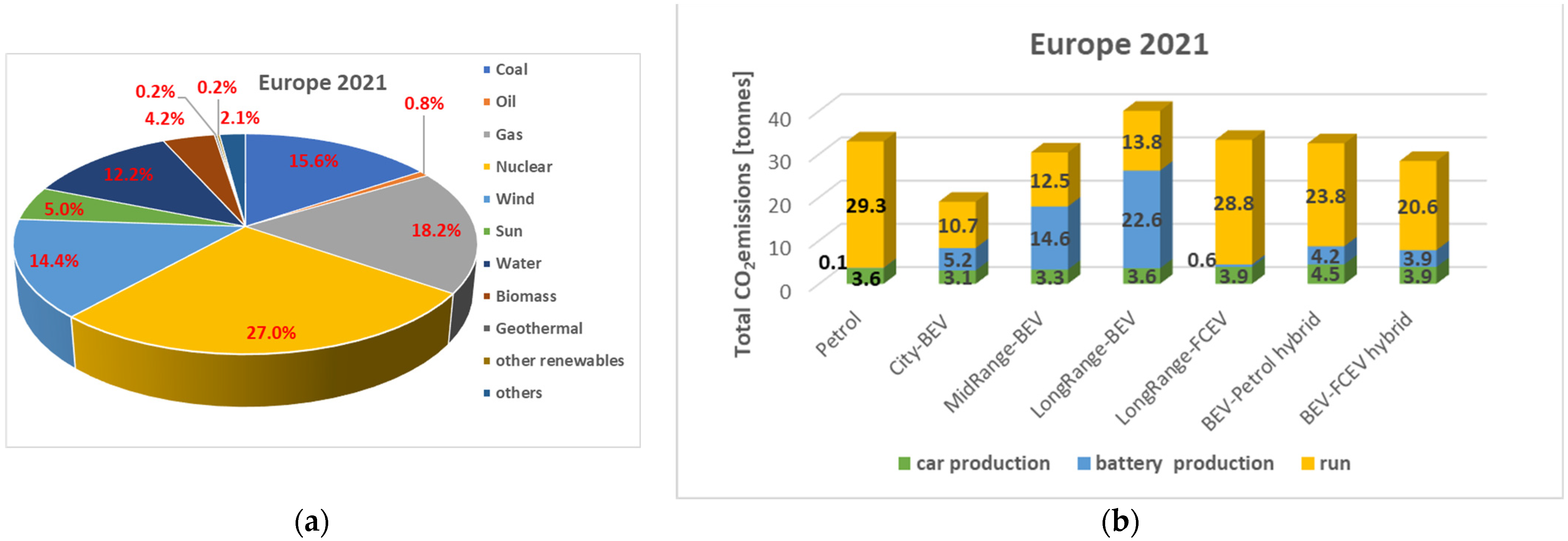

Figure 4a,

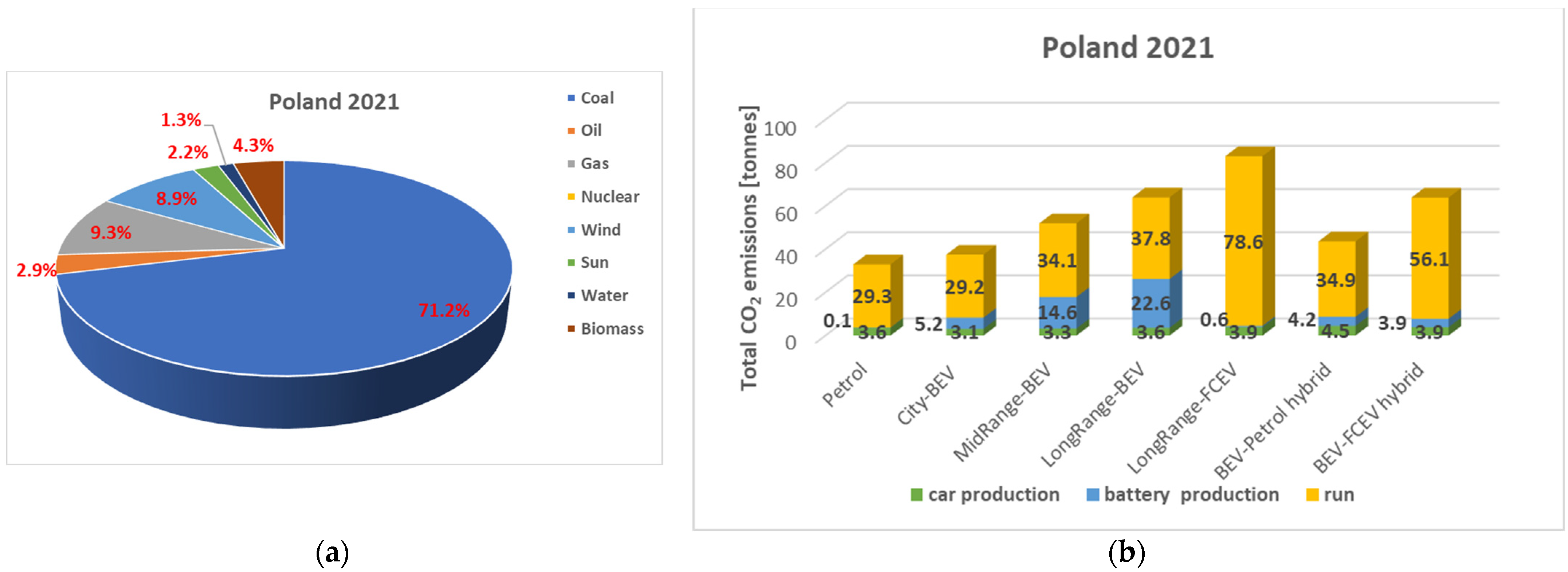

Figure 5a and

Figure 6a present the different mixtures of electricity production and, accordingly, different CO

2 releases per kWh for Norway (

Figure 2a), Romania (

Figure 3a), Europe (

Figure 4a), Germany (

Figure 5a) and Poland (

Figure 6a). The values for CO

2 emissions for different primary energy source production were used in

Table 2. The percentage mix for each source from

Figure 2a,

Figure 3a,

Figure 4a,

Figure 5a and

Figure 6a was taken into consideration in calculating the total amount of CO

2 emissions for the corresponding country.

Figure 2b,

Figure 3b,

Figure 4b,

Figure 5b and

Figure 6b illustrate the total CO

2 emissions for different drivetrains for each country, calculated by taking into consideration the CO

2 equivalents for car and battery production from

Table 1. Those values are kept constant for each type of powertrain, expressed in

Figure 2b,

Figure 3b,

Figure 4b,

Figure 5b and

Figure 6b. For each case, the values for vehicle operation, calculated for each primary energy mix were added to car and battery production in order to show the car run contribution to the total CO

2 release. Battery production significantly contributes to the total CO

2 release, especially for long driving ranges and green electricity production (

Table 1). As a result, the total CO

2 emission and even the choice of the best (least emitting) option depend on the national grid electricity production in each country (

Figure 7).

Figure 2.

(a) Energy production from primary sources for Norway for 2021. (b) total CO2 emissions for 2021 for Norway for different types of cars, including car and battery production, as well as running of the vehicle considering different sources for energy production.

Figure 2.

(a) Energy production from primary sources for Norway for 2021. (b) total CO2 emissions for 2021 for Norway for different types of cars, including car and battery production, as well as running of the vehicle considering different sources for energy production.

Figure 3.

(a) Energy production from primary sources for Romania for 2021. (b) total CO2 emissions for 2021 for Romania for different types of cars, including car and battery production, as well as running of the vehicle considering different sources for energy production.

Figure 3.

(a) Energy production from primary sources for Romania for 2021. (b) total CO2 emissions for 2021 for Romania for different types of cars, including car and battery production, as well as running of the vehicle considering different sources for energy production.

Figure 4.

(a) Energy production from primary sources for Europe for 2021. (b) total CO2 emissions for 2021 for Europe for different types of cars, including car and battery production, as well as running of the vehicle considering different sources for energy production.

Figure 4.

(a) Energy production from primary sources for Europe for 2021. (b) total CO2 emissions for 2021 for Europe for different types of cars, including car and battery production, as well as running of the vehicle considering different sources for energy production.

Figure 5.

(a) Energy production from primary sources for Germany for 2021. (b) total CO2 emissions for 2021 for Germany for different types of cars, including car and battery production, as well as running of the vehicle considering different sources for energy production.

Figure 5.

(a) Energy production from primary sources for Germany for 2021. (b) total CO2 emissions for 2021 for Germany for different types of cars, including car and battery production, as well as running of the vehicle considering different sources for energy production.

Figure 6.

(a) Energy production from primary sources for Poland for 2021. (b) total CO2 emissions for 2021 for Poland for different types of cars, including car and battery production as well as running of the vehicle considering different sources for energy production.

Figure 6.

(a) Energy production from primary sources for Poland for 2021. (b) total CO2 emissions for 2021 for Poland for different types of cars, including car and battery production as well as running of the vehicle considering different sources for energy production.

Figure 7.

Comparative CO2 equivalent emissions for Norway, Germany, Romania, Poland and Europe for 150 and 500 km cruising range for BEVs and 500 for all other vehicle types.

Figure 7.

Comparative CO2 equivalent emissions for Norway, Germany, Romania, Poland and Europe for 150 and 500 km cruising range for BEVs and 500 for all other vehicle types.

3.1. Dependency of CO2 Output on Electricity Production

3.1.1. Scenario 1: Green Electricity Production (Example: Norway)

According to Statistic Norway [

24], the country has produced only 1.1% of its electricity by burning fossil fuels (gas), 7.5% from wind and the rest 91.5% from hydropower for year 2021 (

Figure 2a). The calculated amount of CO

2 output is 28 g/kWh. This results in only 1.2 to 1.6 tons of CO

2 for running a battery electric vehicle over the chosen 200,000 km distance (

Figure 2b). On the other hand, the production of the battery releases between 5 and 22.6 tons of CO

2 in addition to the 3 to 4 tons for the car production (

Table 1). The total CO

2 emissions in tonnes are 33 t for petrol car, 9.5 t for city BEV, 19.3 for mid-range-BEV, 27.8 t for long-range-BEV, 7.8 t for long-range FCEV, 26.8 t for BEV-petrol hybrid and 10.2 t for BEV-FCEV hybrid (

Figure 1b). As a result, all electric vehicles have a lower CO

2 footprint than petrol car (see

Figure 2b). However, while the difference is significant for a battery car with a small battery, the difference is reduced to 15% for the BEV with the longest cruising range of 500 km because of the high CO

2 output for battery production. This also has the consequence that the fuel cell electric vehicle (FCEV) has a lower CO

2 release than any BEV, though its efficiency for running the vehicle (in comparison to a BEV power train) is by far lower [

12]. FCEVs release 1.7–2.1 t more CO

2 for the 200,000 km but have no significant contribution from the battery production.

A well-to-wheel study comparison between different types of passenger cars for Norway has been reported in a previous study and came to similar conclusions [

19]. They considered that about 99% of electricity production is based on renewable energy (hydropower). The results suggest that under those regional circumstances, medium-sized BEVs appear to be the best choice regarding GHG emissions and efficiency. The use is limited due to the shorter driving range with one-time charging. In this study, the authors showed that in the case of the energy production average mix taken for Europe, electric vehicles’ efficiency and harmful emissions are similar to fossil-fuel cars. The same study concludes that hydrogen must be produced from renewable energy sources or natural gas with carbon capture and storage (CCS) to achieve higher well-to-wheel energy efficiency and lower GHG emissions than hybridized diesel and gasoline vehicles. Similar results were reported for Sweden by Larsson [

29]. The authors concluded that for the country delivering most of the electricity by renewable sources, BEV appears to be the better choice due to their high energy efficiency, but they have to be complemented by FCEV in order to fulfil all the needs in the light-duty transport sector.

3.1.2. Scenario 2: Intermediate CO2 Output by Electricity Generation (Example: Romania, Europe)

The average use of fossil fuels for electricity generation for Europa for 2021 is about 35% (from coal, oil and gas expressed in

Figure 4a), 27% from nuclear, and the rest from renewable sources (

Figure 4a). This results in about 250 g/kWh of CO

2 release. Romania, with its mixture of electricity production from different sources for 2021, is very close to this value. The country produces 35% of its energy from fossil fuels (

Figure 3a), the rest from renewable and nuclear sources and current data yield in 255 g/kWh (

Figure 3a).

Figure 3b shows the results for running different cars, added to the car and battery production for Romania. The total CO

2 emissions release for different car drive systems for Romania are as follows: 33 t for petrol, 19.6 t for city-BEV, 31.1 t for mid-range-BEV, 40.8 t for long-range-BEV, 34.8 t for long-range-FCEV, 32.9 t for BEV-petrol hybrid and 29.5 t for BEV-FCEV hybrid (

Figure 3b). The results calculated in this study indicate that all cars produce about the same amount of CO

2 during their lifetime, except for the battery car with only a 150 km cruising range (city-BEV), which releases significantly less CO

2, and the long-range BEV of 500 km cruising range, which has the highest CO

2 output (in the total lifetime of the car). Hybrid cars perform slightly better than cars with only one driving system, with the lowest CO

2 release of all vehicles of 500 km driving range found for the BEV-FCEV hybrid car, this can be attributed to less dependence on battery, which reduces emissions due to battery production (see

Figure 3b).

3.1.3. Scenario 3: Elevated CO2 Output by Electricity Generation (Example: Germany)

Germany generates about 44% of its electricity from fossil fuels (27.8% coal, 0.8% oil and 15.2% gas,

Figure 5a) yielding a CO

2 release of 336 g/kWh. The total CO

2 emissions for different types of powertrains are: 33 t for petrol, 23.1 t for city-BEV, 35.2 t for midrange-BEV, 45.4 t for long-range-BEV, 44.5 t for long-range-FCEV, 35 t for BEV-petrol hybrid and 36.3 t for BEV-FCEV hybrid. As for scenario 2, the city-BEV clearly has the lowest CO

2 release. The long-range BEV and FCEV have the highest CO

2 release, while the mid-range BEV and the hybrid solutions have about the same CO

2 output as the petrol car (

Figure 5b). This shows that with an elevated CO

2 output for electricity generation, the hybrid solutions are better options for long-range cars-provided the battery is used 50% of the mileage (or even more). Compared to the BEV, the hybrid cars profit from the much smaller battery which causes less CO

2 output in its production. Compared to the FCEV, they profit from low emission while running on battery. The calculations also show that, under these conditions, electric cars do not have a significant advantage over ICE cars, unless the cruising range of the battery car is less than 360 km (on the highway).

Comparing Romania (Scenario 3) and Germany (Scenario 3) in terms of dependence on fossil fuels in electricity production, it is observed that Romania is using 35% and Germany 44% of carbon-based fuels for electricity production. This leads to differences in the total CO2 emissions for different powertrains for both countries. The results are clearly visible for long-range vehicles, where a difference of 10 tonnes of CO2 emissions is calculated for the operation of the vehicle in its lifetime.

Similar results are obtained by Bossel [

18] and Haugen [

30]. In the case where the electricity grid is a mixture of different sources including both renewable and carbon-based, BEV turns out to be the best solution. On the other hand, using FCEVs appears to be unfavourable [

18]. In the case the electric grid is mostly dominated by natural gas; light-duty BEV appears to be a better solution in terms of less GHG emissions. The optimisation of renewable sources in energy production appears to be mandatory in reducing harmful emissions in the transport sector [

30].

3.1.4. Scenario 4: High CO2 Output by Electricity Generation (Example: Poland)

In Poland, 83% of the electricity is generated from fossil fuels (71.2% coal, 2.9% oil and 9.3% gas,

Figure 6a. That corresponds to 660 g CO

2/kWh. The total CO

2 emissions for different powertrains are as follows: 33 t for petrol, 37.5 t for city-BEV, 52 t for mid-range BEV, 64 t for long-range BEV, 83.1 t for long-range-FCEV, 43.6 t for BEV-petrol hybrid and 63.9 t for BEV-FCEV hybrid (

Figure 6b). In this situation, the petrol car has the lowest CO

2 release. Even the city BEV has a higher total CO

2 output because running the battery car releases about as much CO

2 as a petrol vehicle (because of the CO

2-rich electricity generation), and the CO

2 contribution from battery production adds to the emission. The fuel cell car has the highest CO

2 output since the energy conversions require high primary energy consumption, which is realised by a CO

2-rich national grid electricity generation. Hybrid solutions give advantages, especially the BEV-petrol hybrid car performs quite well (

Figure 6b). This confirms the result of Varga that electric cars are only environmentally beneficial if the production of electricity is based on low-carbon techniques [

31]. The authors also point out that if nuclear and green energy (like wind and hydropower) do not dominate electricity generation in the future, the application of electric cars will not benefit the environment. Another study on life cycle analysis for BEV and FCEV from China’s perspective suggests that fuel cell cars, using hydrogen produced by electrolysis from the electricity grid, dominated by coal-based sources, cannot achieve energy saving and CO

2 emission reduction. It can lead to more severe energy and environmental issues than petrol-driven cars. The concern about the origins of national grid-based electricity also applies to BEVs, because they are more dependent on the electricity mix [

32]. The same study found that when nuclear energy occupies more than 90% of the Chinese electricity mix, BEV and FCEV using hydrogen from electrolysis can achieve less particulate matter (PM) emissions than petrol vehicles. Similar results and conclusions are also obtained for India [

33].

3.1.5. Summary

A comparison between different drivetrains in terms of the total CO

2 emissions in tonnes, calculated for 2021, based on different electricity mixes for each country is presented in (

Figure 7). Petrol cars give the same performance in all countries, but the operation of “zero emission” vehicles gives diverse results of the calculated total CO

2 emissions for different regions. For Norway, where electricity is mostly generated from green sources, it is found that the city-BEV and long-range FCEV are more favourable than using a petrol car. In the case of Germany, where electricity is generated using a decent percentage of carbon-based fuels, it is found that the utilization of short-range city-BEV rather than petrol-driven cars is more environmentally friendly. In the case of Romania, with less fossil fuel utilisation in electricity generation than Germany, short-range and long-range BEVs appear to be a better choice in terms of less pollution. For Poland, where the generation of electricity is mostly by carbon-based fuels, it is found that huge CO

2 emissions are released by using “zero emissions” cars, like short-, mid- and long-range BEV and FCEV, as well as hybrids.

3.2. Influence of Mileage

Interestingly, it is found that when the mileage of the vehicle is reduced, the amount of CO2 released during a car operation is better in the case of petrol cars compared to BEVs. This decrease in CO2 release varies linearly with mileage reduction. The (relative) reduction is much smaller for the BEV as the contribution from battery manufacturing remains dominant. The CO2 release of FCEVs depends on the energy mix for electricity generation used for hydrogen production. If this causes a high CO2 release, the reduction is comparable to the petrol engine. Otherwise, it is lower.

If we assume a mileage of 100,000 km instead of 200,000 km, the CO2 release of a petrol car in Norway is comparable to that of a mid-range BEV. In Europe, it is between the mid-range BEV and the City-BEV, and in Germany, it is even close to the city-BEV. Hybrid cars become preferable, as they profit from the reduced CO2 output of the small battery.

A mileage of 300,000, favours the use of BEV even for longer driving ranges, except for the case of high CO2 output like in Poland. Interestingly, for this mileage, all solutions for a 500 km driving range have about the same total CO2 output for electricity production as in Europe (250 g CO2/kWh), except for the FCEV-BEV hybrid, which has a significantly lower output (39 tons compared to about 47 tons).

3.3. Frequency of Battery Use

While hybrid cars often perform better than either of the driving systems alone, this advantage disappears or even becomes a disadvantage if the use of BEV is significantly lower than the assumed 50%, e.g., only 25%.

4. Conclusions

Total CO2 release of a battery car depends strongly on its battery size. While the city BEV (150 km range) is usually the best, the long-range BEV (500 km range) is often the worst. So, the cruising range is of high importance. The performance of the fuel cell car (FCEV) with respect to CO2 emissions depends strongly on the energy mix used for electricity generation, which is used to produce hydrogen. Using renewable energy, the FCEV has the lowest CO2 output, and using coal—the highest. So, the choice of the best car in terms of CO2 release depends strongly on electricity generation: for generation from renewable sources, it is a fuel cell car. For generation from fossil fuels, it is the petrol car. For a mixture of both, a battery car is the best if a short cruising range is sufficient. Otherwise, a battery-fuel cell hybrid car is the car of choice.

To summarise, low-carbon electricity production is a prerequisite for electric cars to be ecological. If this is achieved, switching from petrol cars to battery or fuel cell cars brings additional reduction of CO2 release.