Analyzing Optimal Battery Sizing in Microgrids Based on the Feature Selection and Machine Learning Approaches

Abstract

1. Introduction

1.1. Background

1.2. Research Problem Statement

1.3. Related Works

1.4. Contribution

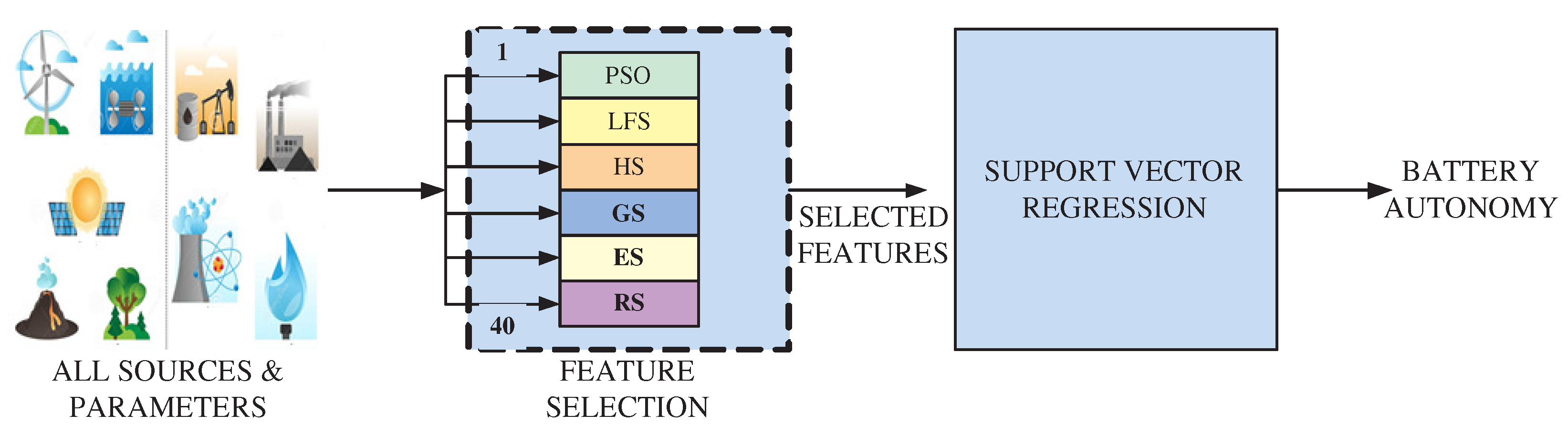

- A dataset for the residential load of a microgrid with 24,000 instances and 40 attributes per instance is generated using the mixed integer linear programming (MILP) technique. It permits to assess the optimal battery size in microgrids.

- The robust feature selection algorithms are utilized to identify the attributes that are more relevant and have a higher impact on assessing the optimal battery sizing in microgrids.

- A machine learning-based approach is used to process the selected features sets for an automated decision of the optimal battery sizing in microgrids.

2. Dataset Generation Using Mixed Integer Linear Programming (MILP)

3. Proposed Methodology

3.1. Feature Selection

3.1.1. Harmony Search (HS)

3.1.2. Evolutionary Search (ES)

3.1.3. Genetic Search (GS)

3.1.4. Linear Forward Search

3.1.5. Particle Swarm Optimization (PSO)

3.1.6. Ranker Search

4. Experimental Results and Discussion

4.1. Data Set and Evaluations’ Parameters

4.1.1. Spearman Ranked Correlation Coefficient (SROCC)

4.1.2. Kendal Correlation Constant

4.1.3. LCC: Linear Correlation Constant

4.1.4. RMSE: Root Mean Square Error

4.2. Performance Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MILP | Mixed Integer Linear Programming |

| RE | Renewable Energy |

| DGENs | Distributed Generation market demand models |

| DERs | Distributed Energy Resources |

| BESS | Battery Energy Storage System |

| GAMS | Generic Algebraic Modelling System |

| ELM | Extreme Learning Machine |

| NPC | Net Present Cost |

| L-SVR | Linear Support Vector Regression |

| PV | Photovoltaic |

| HS | Harmony Search |

| ES | Evolutionary Search |

| GS | Genetic Search |

| PSO | Particle Swarm Optimization |

| SVR | Support Vector Regression |

| SROCC | Spearman Ranked Correlation Coefficient |

| KCC | Kendal Correlation Constant |

| LCC | Linear Correlation Constant |

Appendix A. Generation Techniques’ Factors and External Factors

| Sr. No. | Parameter | Description |

| 1. | Photovoltaic (PV) | It is the power made available by Photovoltaic cells |

| power generation | ||

| 2. | Distributed generation | It is for the analysis of the factors that affect the future market |

| market demand (DGEN) | demands for energy resources | |

| 3. | Hoppecke 6 OPzS 300 | It is a 300 Ah battery, with dimensions of about 147 × 208 × 420 |

| mm, and weighs about 24.9 kg | ||

| 4. | Converter | It is the typical rating of the power inversion of an operation |

| inverter. | ||

| 5. | Total Capital Cost (TCC) | The project overhead costs and the running costs would sum up |

| the TCC | ||

| 6. | Unmet Load Fraction | It is the proportion of the total annual electrical load that went |

| unserved because of insufficient generation for the system | ||

| 7. | Total net present cost | It is an economic parameter used for decision-making when |

| (TNPC) | doing a feasibility study on the power model | |

| 8. | Total Emissions | It is the volume of effluents that are released by a project into the |

| environment | ||

| 9. | Total annual capital cost | it is the project lifetime cost of operations. |

| (TACC) | ||

| 10. | Total annual replacement cost | It is the annual cost of the replacement for the various components |

| (TARC) | that will be used for the grid system | |

| 11. | Total operations & maintenance | It is the annual cost of the operation and maintenance |

| cost (TOMC) | ||

| 12. | Total fuel cost (TFC) | It is the cost of fuel, which can be fossil-based or gases |

| 13. | Total annual cost (TAC) | It is the total annual cost of operations |

| 14. | Operating cost | It is the cost of factors for production that are used for the |

| generation of the power for 1 year | ||

| 15. | Cost of energy (COE) | It is the average cost per kWh of useful electrical energy |

| 16. | Photovoltaic (PV) Production | It is the average projection of the photovoltaic cell power |

| production | ||

| 17. | Distributed generation production | It is a tool is developed for the analysis of the factors that affect |

| (dGENP) | the future market production of energy resources | |

| 18. | Grid purchases (GP) | It is the cost incurred for the acquisition of power into the grid this |

| is payable to the production companies | ||

| 19. | Grid net purchases (GNP) | It is the cost minus the working expenses for the grid production |

| of power | ||

| 20. | Total electrical production | It is the peak value of the power produced for the grid system |

| (TEP) | that can be converted to useful power | |

| 21. | AC primary Load Served | It is the total amount of energy that can be used towards serving |

| (AC-PLS) | the AC primary load(s) for a year | |

| 22. | Deferrable load served (DLS) | It is the electrical load that requires a certain amount of |

| energy for a given time | ||

| 23. | Renewable fraction (RF) | It is the renewable fraction i.e., the ratio of the nonrenewable to |

| the total electrical energy served to a specified load | ||

| 24. | Capacity shortage (CS) | It is the total amount of capacity energy shortage that occurs |

| throughout the year | ||

| 25. | Unmet load (UL) | It is termed as the fraction for the proportion of the total |

| annual electrical load that arises from the insufficient generation | ||

| 26. | Unmet load fraction (ULF) | It is the ratio of the working power load to the unmet load |

| 27. | Excess electricity (EE) | It is the surplus power that is produced by a system based |

| on the estimated base loads for a given duration | ||

| 28. | Diesel | It evaluates the volumetric consumption of diesel for a given |

| duration | ||

| 29. | Carbon dioxide | It is the deposition of CO2 as effluent into the air in terms of |

| (CO2) Emissions | weight per given duration | |

| 30. | Carbon mono oxide | It is the deposition of CO (carbon monoxide gas) as effluent |

| (CO) Emissions | into the air in terms of weight per given duration | |

| 31. | UHC Emissions | It is the emission of the Unburned Hydrocarbons as effluent |

| into the air in terms of weight per given duration | ||

| 32. | Particulate matter | It is a feature that investigates the emissions of the PM as effluent into |

| (PM) Emissions | the air in terms of weight per given duration | |

| 33. | Sulfur dioxide | It is the deposition of SO2 gas as effluent into the air in terms |

| (SO2) Emissions | of weight per given duration | |

| 34. | Nitrogen oxide | It is a feature that investigates the emissions of the Nitrogen Oxides |

| (NOx) Emissions | (NOx) as effluent into the air in terms of weight per given duration | |

| 35. | Distributed generation market | It is a feature that evaluates the distributed generation of the fuel, and |

| demand (DGEN) model Fuel | it is expressed as liters per year | |

| 36. | Distributed generation market | It evaluates the Distributed Generation in terms of active hours |

| demand (DGEN) model Hours | to produce electricity for a given duration | |

| 37. | Distributed generation market | It analyzes the working statistics for the Distributed Generation |

| demand (DGEN) model starts/yr | of the power system for a given year | |

| 38. | Distributed generation market | It analyzes the working life for the Distributed Generation of the |

| demand (DGEN) model Life | power system for a given year | |

| 39. | Battery Throughput | It is the lifetime of the battery in years that is worked out by |

| dividing the energy level by the duration | ||

| 40. | Battery Life | It is the estimated working life of the battery under which it can |

| operate. |

References

- Houran, M.A.; Yang, X.; Chen, W. Energy management of microgrid in smart building considering air temperature impact. In Proceedings of the 2018 IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018; pp. 2398–2404. [Google Scholar]

- Klansupar, C.; Chaitusaney, S. Optimal Sizing of Utility-scaled Battery with Consideration of Battery Installation Cost and System Power Generation Cost. In Proceedings of the 2020 17th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications, and Information Technology (ECTI-CON), Phuket, Thailand, 24–27 June 2020; pp. 498–501. [Google Scholar]

- Sobon, J.; Stephen, B. Model-Free Non-Invasive Health Assessment for Battery Energy Storage Assets. IEEE Access 2021, 9, 54579–54590. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, N.-C.; Liu, J.-H. Optimal Sizing of PV/Wind/Battery Hybrid Microgrids Considering Lifetime of Battery Banks. Energies 2021, 14, 6655. [Google Scholar] [CrossRef]

- Takano, H.; Hayashi, R.; Asano, H.; Goda, T. Optimal Sizing of Battery Energy Storage Systems Considering Cooperative Operation with Microgrid Components. Energies 2021, 14, 7442. [Google Scholar] [CrossRef]

- Hoyos-Velandia, C.; Ramirez-Hurtado, L.; Quintero-Restrepo, J.; Moreno-Chuquen, R.; Gonzalez-Longatt, F. Cost Functions for Generation Dispatching in Microgrids for Non-Interconnected Zones in Colombia. Energies 2022, 15, 2418. [Google Scholar] [CrossRef]

- Belboul, Z.; Toual, B.; Kouzou, A.; Mokrani, L.; Bensalem, A.; Kennel, R.; Abdelrahem, M. Multiobjective Optimization of a Hybrid PV/Wind/Battery/Diesel Generator System Integrated in Microgrid: A Case Study in Djelfa, Algeria. Energies 2022, 15, 3579. [Google Scholar] [CrossRef]

- Cano, A.; Arévalo, P.; Jurado, F. A comparison of sizing methods for a long-term renewable hybrid system. Case study: Galapagos Islands 2031. Sustain. Energy Fuels 2021, 5, 1548–1566. [Google Scholar] [CrossRef]

- Kumar, J.; Parthasarathy, C.; Västi, M.; Laaksonen, H.; Shafie-Khah, M.; Kauhaniemi, K. Sizing and Allocation of Battery Energy Storage Systems in Åland Islands for Large-Scale Integration of Renewables and Electric Ferry Charging Stations. Energies 2020, 13, 317. [Google Scholar] [CrossRef]

- Hannan, M.; Faisal, M.; Jern Ker, P.; Begum, R.; Dong, Z.; Zhang, C. Review of optimal methods and algorithms for sizing energy storage systems to achieve decarbonization in microgrid applications. Renew. Sustain. Energy Rev. 2020, 131, 110022. [Google Scholar] [CrossRef]

- El-Bidairi, K.; Nguyen, H.; Mahmoud, T.; Jayasinghe, S.; Guerrero, J. Optimal sizing of Battery Energy Storage Systems for dynamic frequency control in an islanded microgrid: A case study of Flinders Island, Australia. Energy 2020, 195, 117059. [Google Scholar] [CrossRef]

- Yang, Z.; Xia, L.; Guan, X. Fluctuation Reduction of Wind Power and Sizing of Battery Energy Storage Systems in Microgrids. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1195–1207. [Google Scholar] [CrossRef]

- Gao, T.; Lu, W. Machine learning toward advanced energy storage devices and systems. iScience 2021, 24, 101936. [Google Scholar] [CrossRef] [PubMed]

- Boonluk, P.; Siritaratiwat, A.; Fuangfoo, P.; Khunkitti, S. Optimal Siting and Sizing of Battery Energy Storage Systems for Distribution Network of Distribution System Operators. Batteries 2020, 6, 56. [Google Scholar] [CrossRef]

- Talent, O.; Du, H. Optimal sizing and energy scheduling of photovoltaic-battery systems under different tariff structures. Renew. Energy 2018, 129, 513–526. [Google Scholar] [CrossRef]

- Prabpal, P.; Kongjeen, Y.; Bhumkittipich, K. Optimal Battery Energy Storage System Based on VAR Control Strategies Using Particle Swarm Optimization for Power Distribution System. Symmetry 2021, 13, 1692. [Google Scholar] [CrossRef]

- Gupta, Y.; Vaidya, R.; Kumar Nunna, H.; Kamalasadan, S.; Doolla, S. Optimal PV—Battery Sizing for Residential and Commercial Loads Considering Grid Outages. In Proceedings of the IEEE International Conference on Power Electronics, Smart Grid and Renewable Energy (PESGRE2020), Cochin, India, 2–4 January 2020. [Google Scholar] [CrossRef]

- Lazaar, N.; Fakhri, E.; Barakat, M.; Sabor, J.; Gualous, H. A Genetic Algorithm Based Optimal Sizing Strategy for PV/Battery/Hydrogen Hybrid System. In Proceedings of the International Conference onArtificial Intelligence and Industrial Applications, Meknes, Morocco, 19–20 March 2020; pp. 247–259. [Google Scholar]

- Xie, S.; Zhang, Q.; Hu, X.; Liu, Y.; Lin, X. Battery sizing for plug-in hybrid electric buses considering variable route lengths. Energy 2021, 226, 120368. [Google Scholar]

- Mirhoseini, P.; Ghaffarzadeh, N. Economic battery sizing and power dispatch in a grid-connected charging station using convex method. J. Energy Storage 2020, 31, 101651. [Google Scholar] [CrossRef]

- Sampietro, J.L.; Puig, V.; Costa-Castelló, R. Optimal sizing of storage elements for a vehicle based on fuel cells, supercapacitors, and batteries. Energies 2019, 12, 925. [Google Scholar] [CrossRef]

- Nuhic, A.; Terzimehic, T.; Soczka-Guth, T.; Buchholz, M.; Dietmayer, K. Health diagnosis and remaining useful life prognostics of lithium-ion batteries using data-driven methods. J. Power Sources 2013, 239, 680–688. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, C.; Chen, Z. An online method for lithium-ion battery remaining useful life estimation using importance sampling and neural networks. Appl. Energy 2016, 173, 134–140. [Google Scholar] [CrossRef]

- Kanwal, S.; Khan, B.; Ali, S.M. Machine learning based weighted scheduling scheme for active power control of hybrid microgrid. Int. J. Electr. Power Energy Syst. 2021, 125, 106461. [Google Scholar] [CrossRef]

- Jayashree, S.; Malarvizhi, K. Methodologies for Optimal Sizing of Battery Energy Storage in Microgrids: A Comprehensive Review. In Proceedings of the International Conference on Computer Communication and Informatics (ICCCI), Coimbatore, India, 22–24 January 2020. [Google Scholar] [CrossRef]

- Tang, R.; Yildiz, B.; Leong, P.H.; Vassallo, A.; Dore, J. Residential battery sizing model using net meter energy data clustering. Appl. Energy 2019, 251, 113324. [Google Scholar] [CrossRef]

- Abba, S.I.; Rotimi, A.; Musa, B.; Yimen, N.; Kawu, S.J.; Lawan, S.M.; Dagbasi, M. Emerging Harris Hawks Optimization based load demand forecasting and optimal sizing of stand-alone hybrid renewable energy systems—A case study of Kano and Abuja, Nigeria. Results Eng. 2021, 12, 100260. [Google Scholar] [CrossRef]

- Hassan, Q.; Pawela, B.; Hasan, A.; Jaszczur, M. Optimization of Large-Scale Battery Storage Capacity in Conjunction with Photovoltaic Systems for Maximum Self-Sustainability. Energies 2022, 15, 3845. [Google Scholar] [CrossRef]

- Chiang, M.-Y.; Huang, S.-C.; Hsiao, T.-C.; Zhan, T.-S.; Hou, J.-C. Optimal Sizing and Location of Photovoltaic Generation and Energy Storage Systems in an Unbalanced Distribution System. Energies 2022, 15, 6682. [Google Scholar] [CrossRef]

- Driebeek, N.J. An algorithm for the solution of mixed integer programming problems. Manag. Sci. 1966, 12, 485–625. [Google Scholar] [CrossRef]

- Fareeha, A.; Waqar, A.; Elavarasan, R.M.; Md Rabiul, I.; Md Moktadir, R.; Muhammad, Z. New Method for Battery Sizing in Microgrids by Seeing Battery Autonomy as a Chance Constraint. In Proceedings of the 2021 31st Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia, 26–30 September 2021; pp. 1–6. [Google Scholar]

- Pilati, F.; Lelli, G.; Regattieri, A.; Gamberi, M. Intelligent management of hybrid energy systems for techno-economic performances maximisation. Energy Convers. Manag. 2020, 224, 113329. [Google Scholar] [CrossRef]

- Mehrtash, M.; Capitanescu, F.; Heiselberg, P. An Efficient Mixed-Integer Linear Programming Model for Optimal Sizing of Battery Energy Storage in Smart Sustainable Buildings. In Proceedings of the 2020 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 6–7 February 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Bagheri-Sanjareh, M.; Nazari, M.; Gharehpetian, G. A Novel and Optimal Battery Sizing Procedure Based on MG Frequency Security Criterion Using Coordinated Application of BESS, LED Lighting Loads, and Photovoltaic Systems. IEEE Access 2020, 8, 95345–95359. [Google Scholar] [CrossRef]

- Elnozahy, A.; Ramadan, H.S.; Abo-Elyousr, F.K. Efficient metaheuristic Utopia-based multi-objective solutions of optimal battery-mix storage for microgrids. J. Clean. Prod. 2021, 303, 127038. [Google Scholar] [CrossRef]

- Ye, L.; Wu, X.; Du, J.; Song, Z.; Wu, G. Optimal sizing of a wind-energy storage system considering battery life. Renew. Energy 2020, 147, 2470–2483. [Google Scholar]

- Liu, W.; Yan, L.; Zhang, X.; Gao, D.; Chen, B.; Yang, Y.; Jiang, F.; Huang, Z.; Peng, J. A Denoising SVR-MLP Method for Remaining Useful Life Prediction of Lithium-ion Battery. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 545–550. [Google Scholar]

- Qaisar, S.M. EEfficient mobile systems based on adaptive rate signal processing. Comput. Electr. Eng. 2019, 79, 1062–1070. [Google Scholar] [CrossRef]

- Mian Qaisar, S. Signal-piloted processing and machine learning based efficient power quality disturbances recognition. PLoS ONE 2021, 16, e0252104. [Google Scholar] [CrossRef] [PubMed]

- Mian Qaisar, S.; Alsharif, F. Signal piloted processing of the smart meter data for effective appliances recognition. J. Electr. Eng. Technol. 2020, 15, 2279–2285. [Google Scholar] [CrossRef]

- Mian Qaisar, S. Event-driven coulomb counting for effective online approximation of Li-ion battery state of charge. Energies 2020, 13, 5600. [Google Scholar] [CrossRef]

- Peng, X.; Zhang, C.; Yu, Y.; Zhou, Y. Battery remaining useful life prediction algorithm based on support vector regression and unscented particle filter. In Proceedings of the 2016 IEEE International Conference on Prognostics and Health Management (ICPHM), Ottawa, ON, Canada, 20–22 June 2016; pp. 1–6. [Google Scholar]

- Ali, A.Y.; Basit, A.; Ahmad, T.; Qamar, A.; Iqbal, J. Optimizing coordinated control of distributed energy storage system in microgrid to improve battery life. Comput. Electr. Eng. 2020, 86, 106741. [Google Scholar] [CrossRef]

- Seyed, A.F.; Ardalan, V. Mixed-Integer Linear Programming for Optimal Scheduling of Autonomous Vehicle Intersection Crossing. IEEE Trans. Intell. Veh. 2018, 3, 287. [Google Scholar]

- Adriana, C.L.; Nelson, L.D.; Moises, G.; Juan, C.V.; Josep, M.G. Mixed-integer- linear-programming-based energy management system for hybrid PV-wind-battery microgrids: Modeling, design, and experimental verification. IEEE Trans. Power Electron. 2017, 32, 2769–2783. [Google Scholar]

- Hossein, S.; Majid, M.; SHamid, F.; Gevork, B.G. Optimal sizing and energy management of a grid connected microgrid using homer software. In Proceedings of the Smart Grids Conference 2016, Kerman, Iran, 20–21 December 2016; pp. 20–21. [Google Scholar]

- Sung, M.; Ko, Y. Machine-learning-integrated load scheduling for reduced peak power demand. IEEE Trans. Consum. Electron. 2015, 6, 167–174. [Google Scholar] [CrossRef]

- Lu, B.; Shahidehpour, M. Short-term scheduling of battery in a grid-connected PV/battery system. IEEE Trans. Power Syst. 2005, 20, 1053–1061. [Google Scholar] [CrossRef]

- Elavarasan, R.M.; Shafiullah, G.M.; Padmanaban, S.; Kumar, N.M.; Annam, A.; Vetrichelvan, A.M.; Holm-Nielsen, J.B. A Comprehensive Review on Renewable Energy Development, Challenges, and Policies of Leading Indian States with an International Perspective. IEEE Access 2020, 8, 74432–74457. [Google Scholar] [CrossRef]

- Momete, D.C. Analysis of the Potential of Clean Energy Deployment in the European Union. IEEE Access 2018, 6, 54811–54822. [Google Scholar] [CrossRef]

- Papadaskalopoulos, D.; Pudjianto, D.; Strbac, G. Decentralized Coordination of Microgrids with Flexible Demand and Energy Storage. IEEE Trans. Sustain. Energy 2014, 5, 1406–1414. [Google Scholar] [CrossRef]

- Ganesan, S.; Subramaniam, U.; Ghodke, A.A.; Elavarasan, R.M.; Raju, K.; Bhaskar, M.S. Investigation on Sizing of Voltage Source for a Battery Energy Storage System in Microgrid with Renewable Energy Sources. IEEE Access 2020, 8, 188861–188874. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Jiang, L.; Huang, Y.; Cao, Y. PSO-based optimization for constant- current charging pattern for li-ion battery. Chin. J. Electr. Eng. 2019, 5, 72–78. [Google Scholar] [CrossRef]

- Kolluri, R.; de Hoog, J. Adaptive Control Using Machine Learning for Distributed Storage in Microgrids. In Proceedings of the Eleventh ACM International Conference on Future Energy Systems, Virtual, 22–26 June 2020. [Google Scholar]

- Shivam, K.; Tzou, J.; Wu, S. A multi-objective predictive energy management strategy for residential grid-connected PV-battery hybrid systems based on machine learning technique. Energy Convers. Manag. 2021, 237, 114103. [Google Scholar] [CrossRef]

- Khorramdel, H.; Aghaei, J.; Khorramdel, B.; Siano, P. Optimal battery sizing in microgrids using probabilistic unit commitment. IEEE Trans. Ind. Inform. 2015, 12, 834–843. [Google Scholar] [CrossRef]

- Waqar, A.; Wang, S.; Khalid, M.S.; Shi, X. Multi-objective chance constrained programming model for operational-planning of V2G integrated microgrid. In Proceedings of the 2015 5th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Changsha, China, 26–29 November 2015; pp. 443–448. [Google Scholar]

- Waqar, A.; Shaorong, W.; Samir, M.D.; Tao, T.; Yida, W. Optimal capacity expansion-planning of distributed generation in microgrids considering uncertainties. In Proceedings of the 2015 5th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Changsha, China, 26–29 November 2015; pp. 437–442. [Google Scholar]

- Waqar, A.; Muhammad, S.N.; Muhammad, A.; Imtiaz, A.; Syed, U.A.; Jehanzeb, A. Multi-objective analysis of DER sizing in microgrids using probabilistic modeling. In Proceedings of the 2019 International Conference on Electrical, Communication, and Computer Engineering (ICECCE), Swat, Pakistan, 24–25 July 2019; pp. 1–6. [Google Scholar]

| Feature Selection Algorithm | Number of Features Selected |

|---|---|

| All | 40 |

| Ranker search | 29 |

| Particle swarm optimization | 14 |

| Linear forward search | 6 |

| Harmony search | 8 |

| Evolutionary search | 12 |

| Genetic search | 11 |

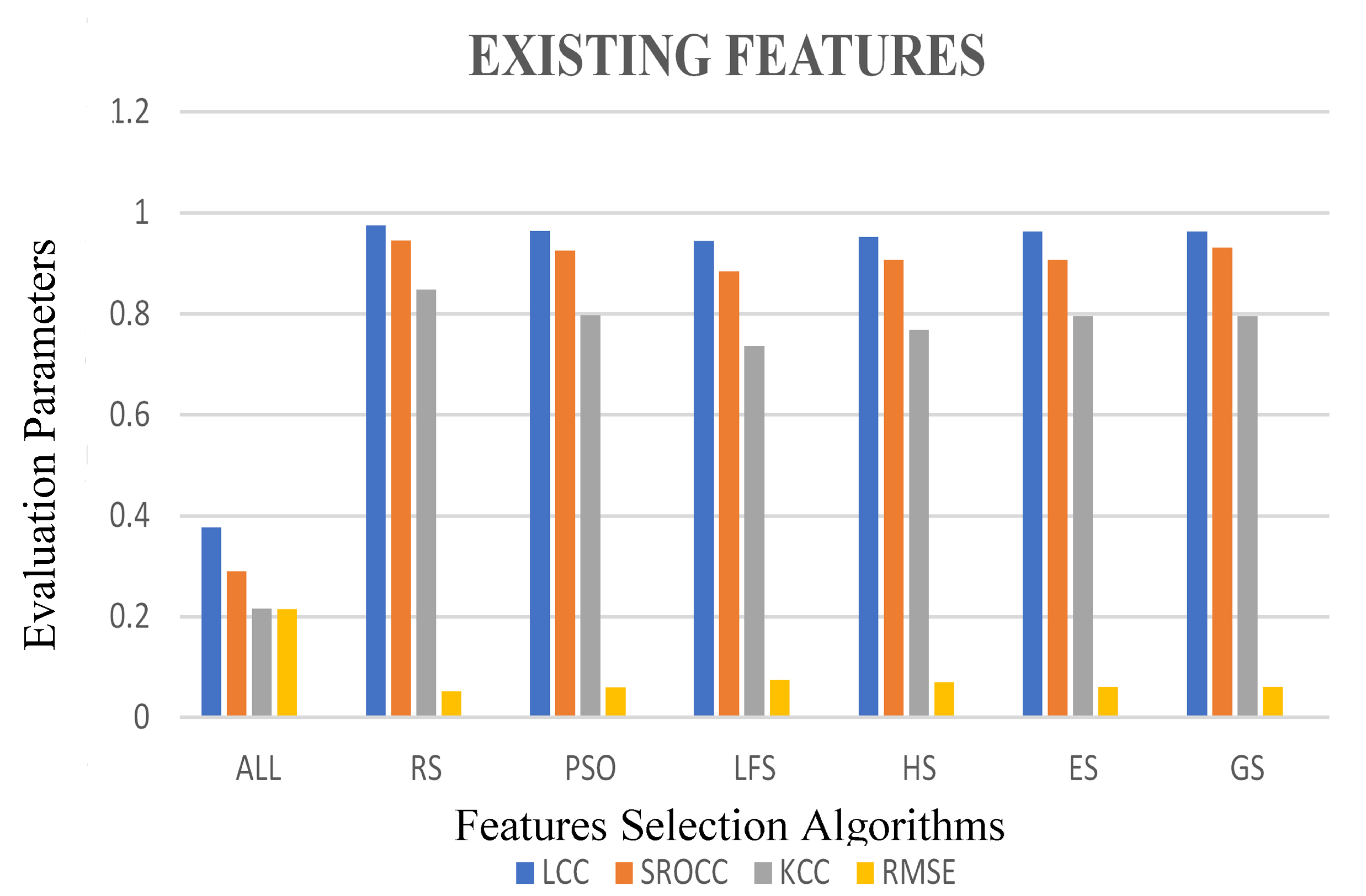

| Feature Selection Algorithm | LCC | SROCC | KCC | RMSE |

|---|---|---|---|---|

| All | 0.3760 | 0.2893 | 0.2165 | 0.2152 |

| Ranker | 0.9756 | 0.9452 | 0.8488 | 0.0525 |

| PSO | 0.9645 | 0.9252 | 0.7983 | 0.0608 |

| Linear forward | 0.9443 | 0.8846 | 0.7369 | 0.07518 |

| Harmony search | 0.9528 | 0.9076 | 0.7685 | 0.0701 |

| Evolutionary search | 0.9639 | 0.9229 | 0.7954 | 0.0613 |

| Genetic search | 0.9640 | 0.9237 | 0.7959 | 0.0613 |

| Technique | RMSE Score |

|---|---|

| Multi-Layer Perception [36] | 6.3000 |

| Linear Support Vector Regression [37] | 2.4090 |

| K-means clustering [24] | 0.7170 |

| Support Vector Regression integrated with Harris Hawks Optimization [27] | 0.1961 |

| Neural Network [26] | 0.4240 |

| Proposed method () | 0.0525 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, H.; Nizami, I.F.; Qaisar, S.M.; Waqar, A.; Krichen, M.; Almaktoom, A.T. Analyzing Optimal Battery Sizing in Microgrids Based on the Feature Selection and Machine Learning Approaches. Energies 2022, 15, 7865. https://doi.org/10.3390/en15217865

Khan H, Nizami IF, Qaisar SM, Waqar A, Krichen M, Almaktoom AT. Analyzing Optimal Battery Sizing in Microgrids Based on the Feature Selection and Machine Learning Approaches. Energies. 2022; 15(21):7865. https://doi.org/10.3390/en15217865

Chicago/Turabian StyleKhan, Hajra, Imran Fareed Nizami, Saeed Mian Qaisar, Asad Waqar, Moez Krichen, and Abdulaziz Turki Almaktoom. 2022. "Analyzing Optimal Battery Sizing in Microgrids Based on the Feature Selection and Machine Learning Approaches" Energies 15, no. 21: 7865. https://doi.org/10.3390/en15217865

APA StyleKhan, H., Nizami, I. F., Qaisar, S. M., Waqar, A., Krichen, M., & Almaktoom, A. T. (2022). Analyzing Optimal Battery Sizing in Microgrids Based on the Feature Selection and Machine Learning Approaches. Energies, 15(21), 7865. https://doi.org/10.3390/en15217865