Modeling and Experimental Verification of the Required Power for Electrically Heated Clothing

Abstract

1. Introduction

2. State-of-Art

3. Materials and Methods

3.1. ISO 11079 Standard

- Air temperature;

- Mean radiant temperature;

- Air velocity;

- Metabolic rate;

- Thermal insulation of clothing.

3.2. Newton-Type Thermal Manikin

3.3. Mobile Freezing Chamber

3.4. Electrically Heated Clothing

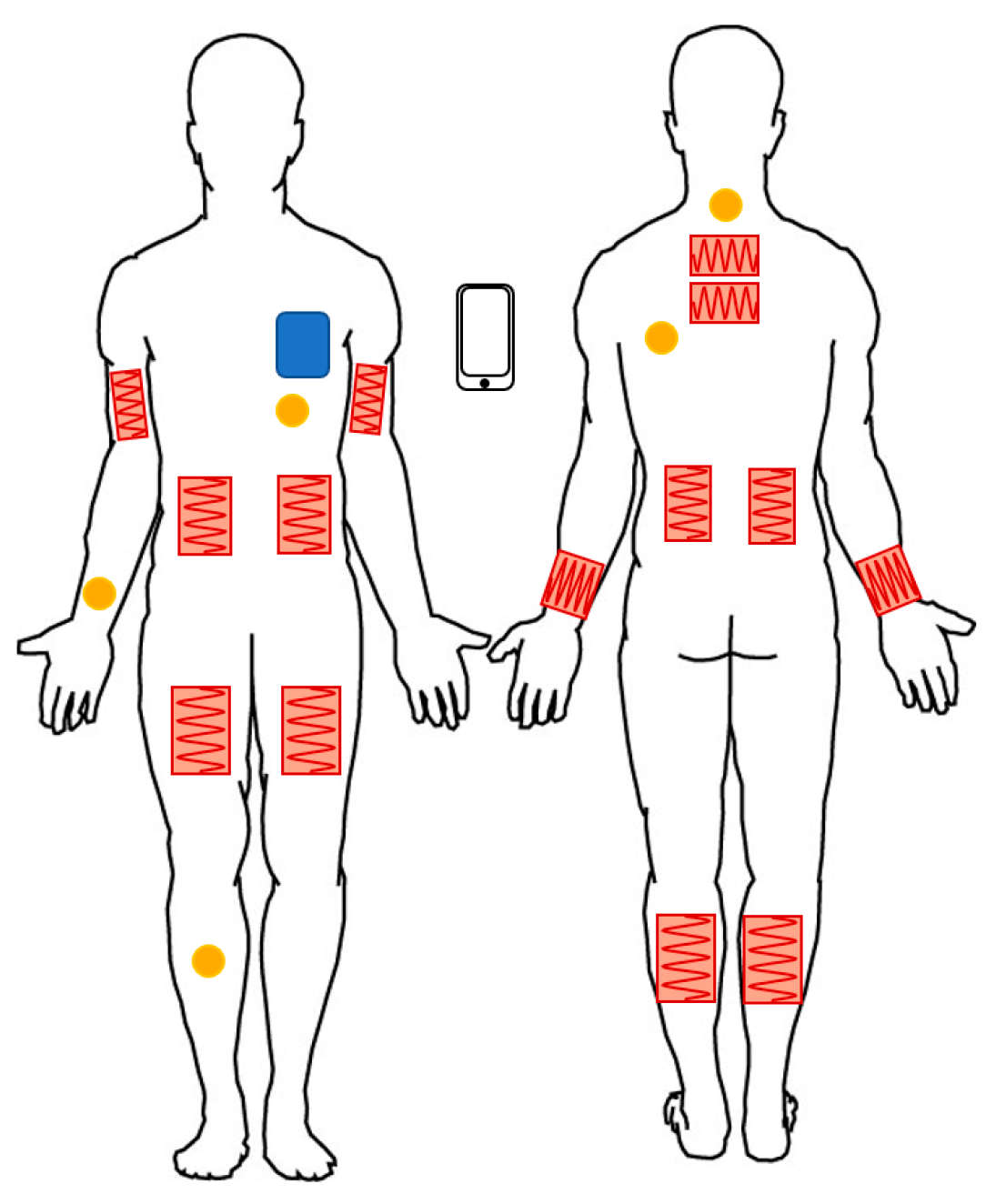

- the heated garment should be a single piece of clothing, so attaching heated gloves or socks was not possible,

- heaters could not be installed on chest and arms, as the rescuers install various electronic equipment in these places,

- the jumpsuit should fasten with zipper on the chest,

- the heaters could not hinder sitting down and squatting.

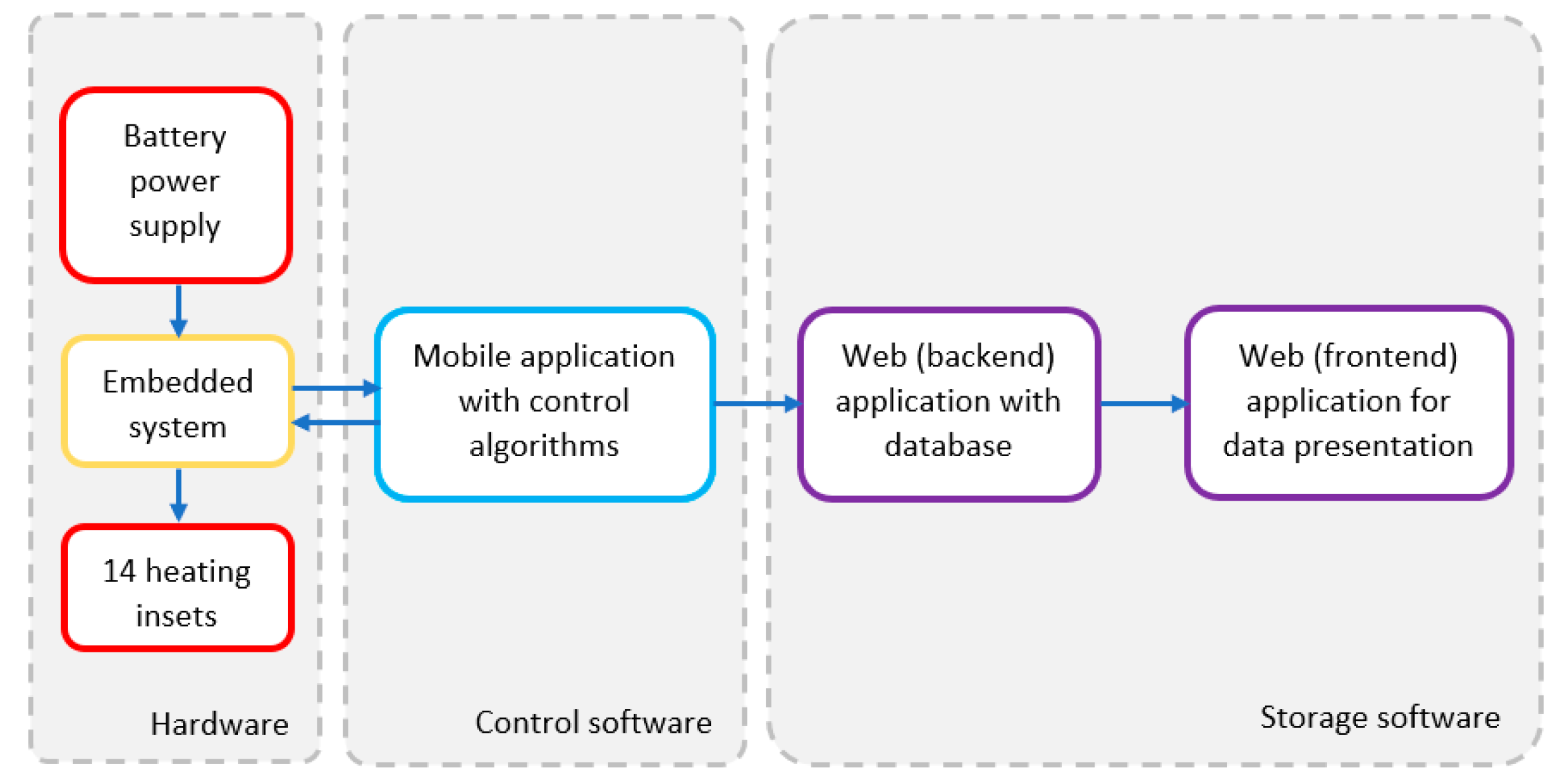

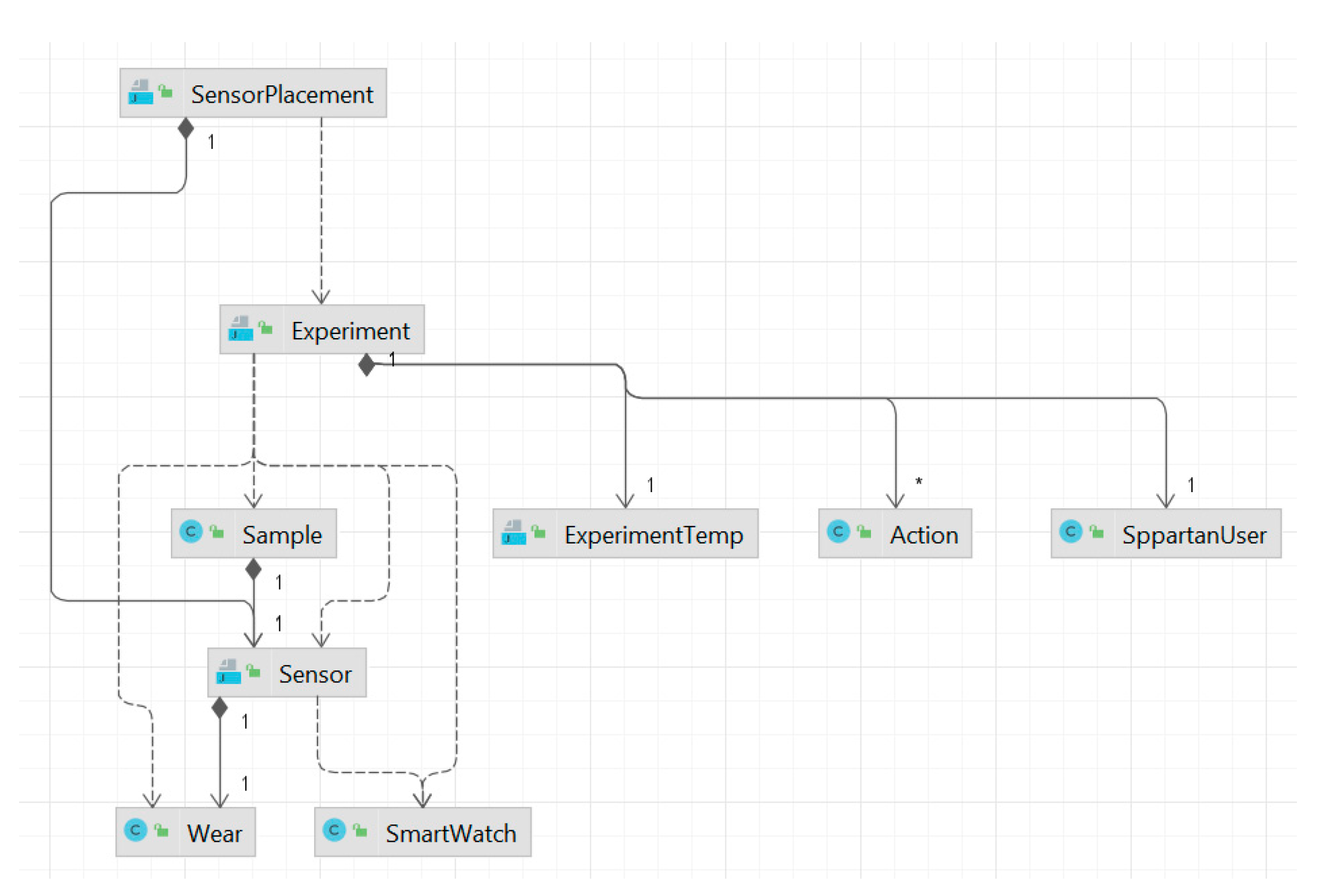

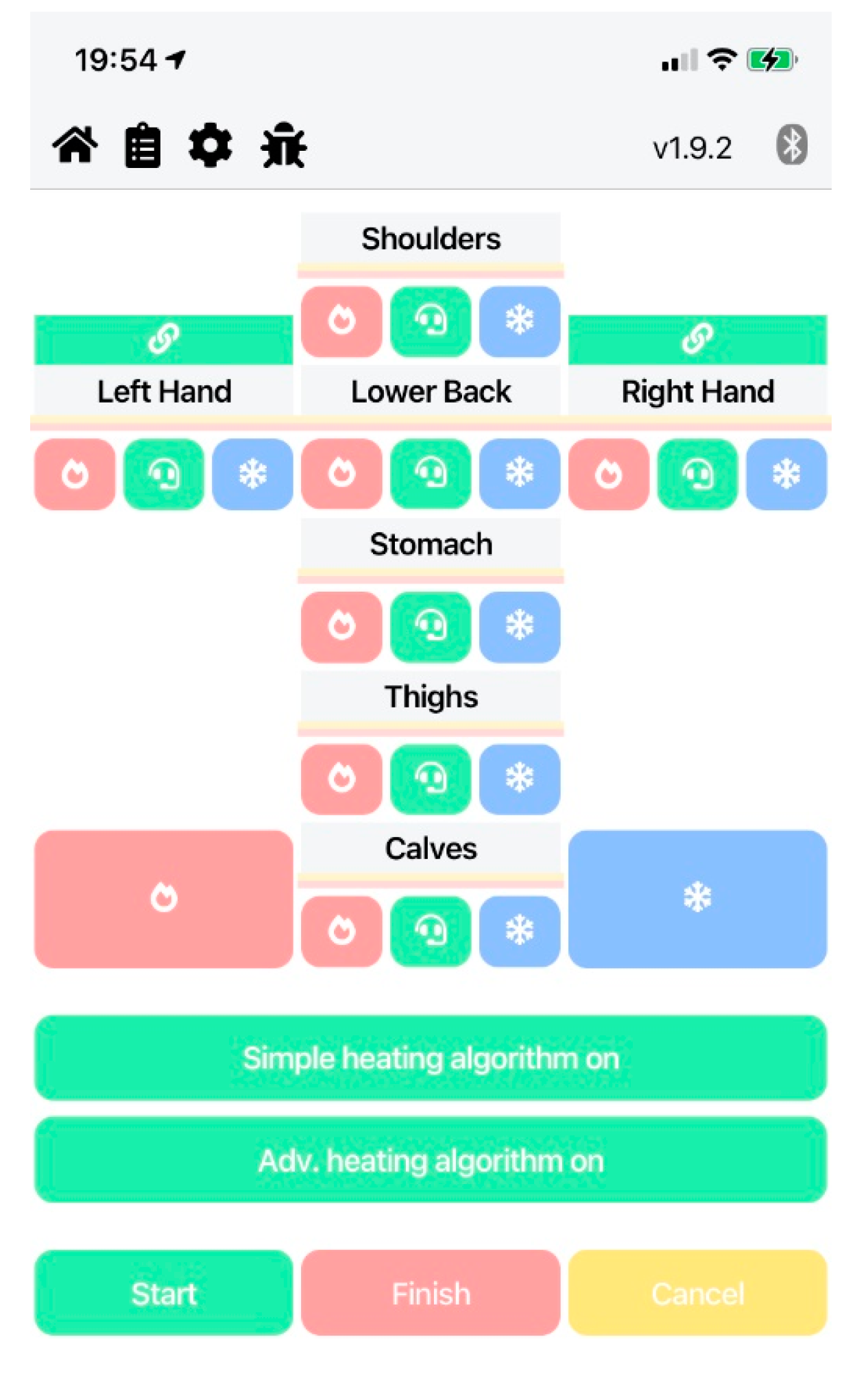

3.5. Power Supply and Control System

3.6. Ambient and Skin Temperature Measurements

3.7. Experiment

4. Results

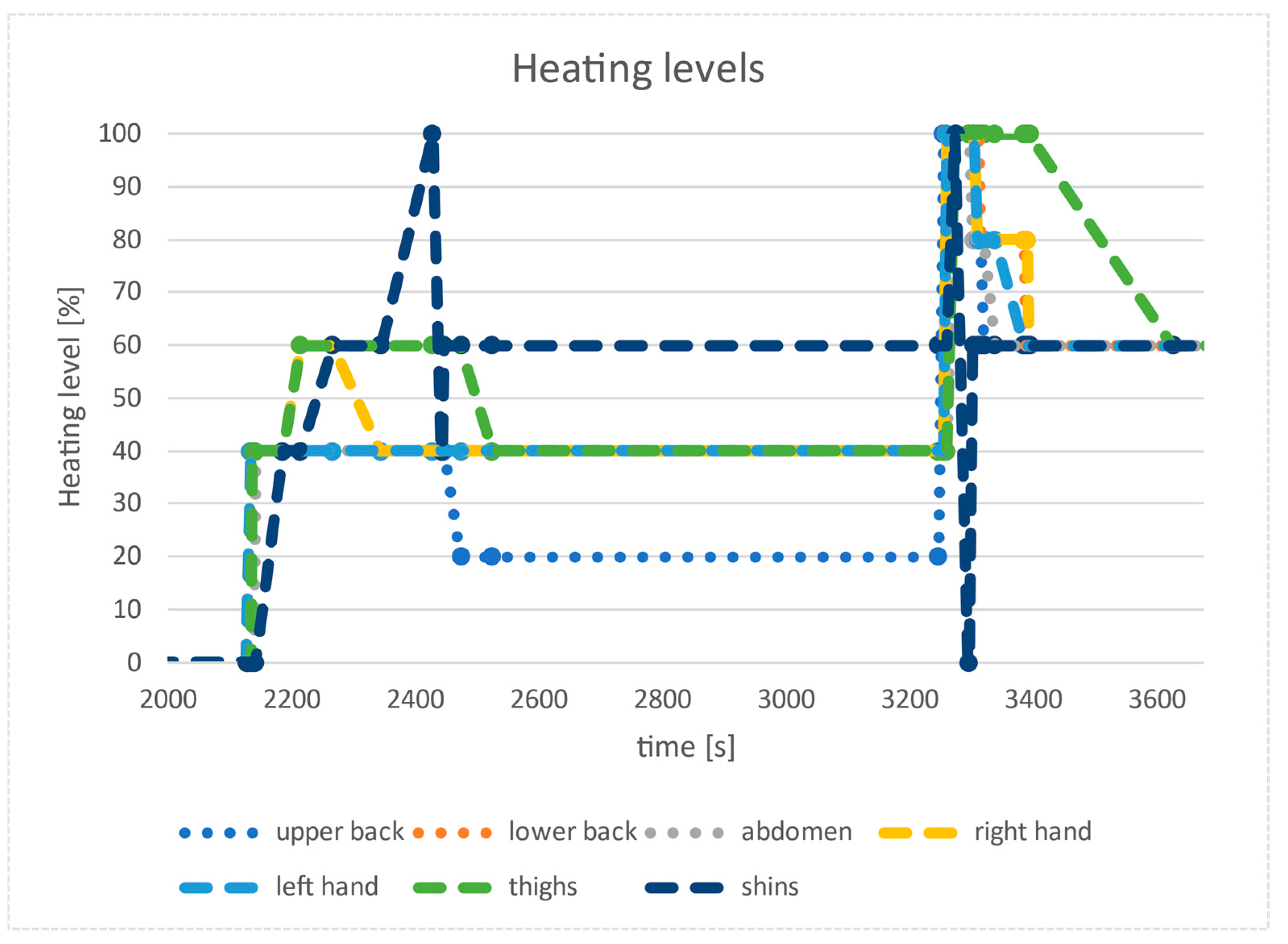

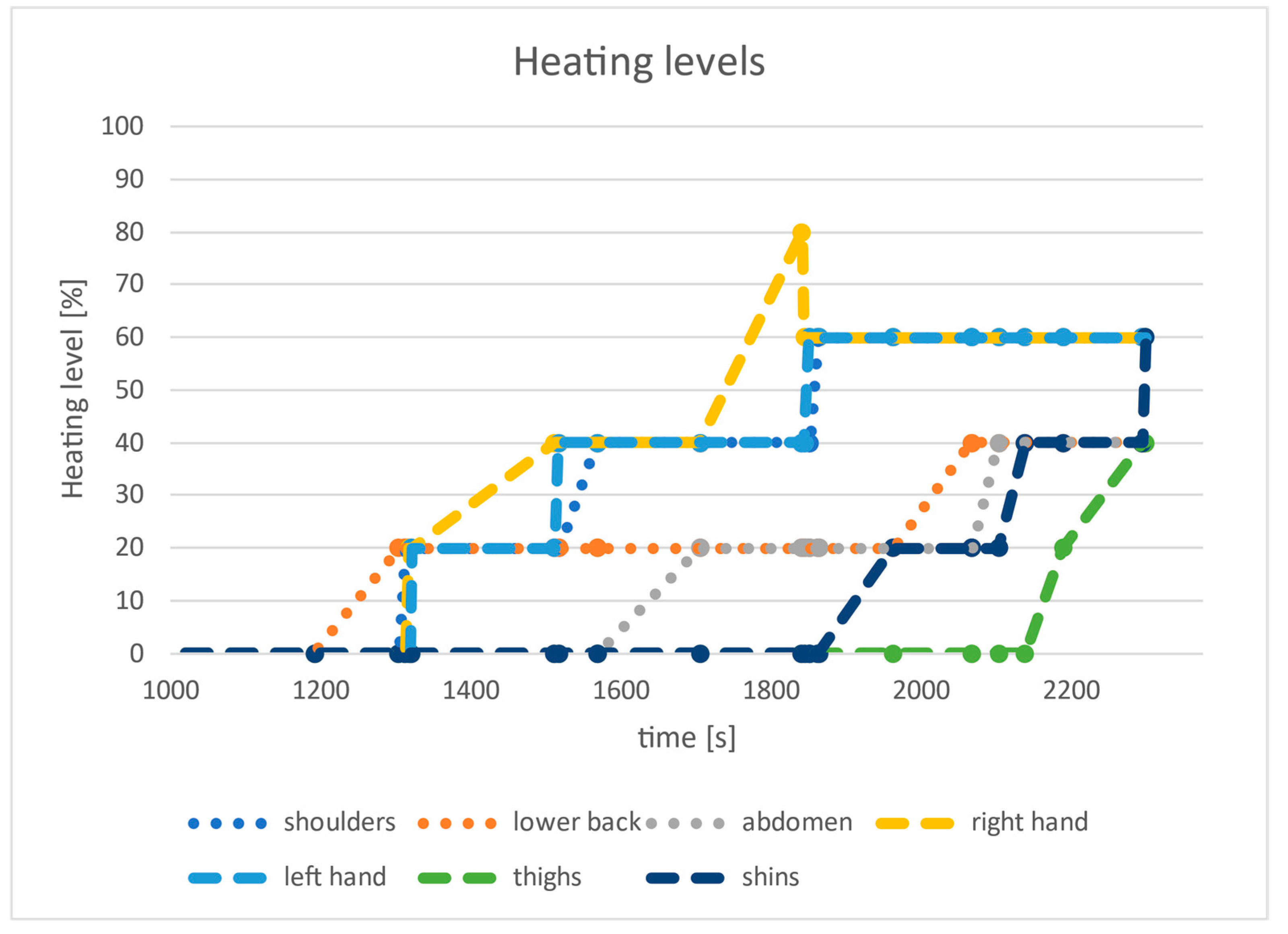

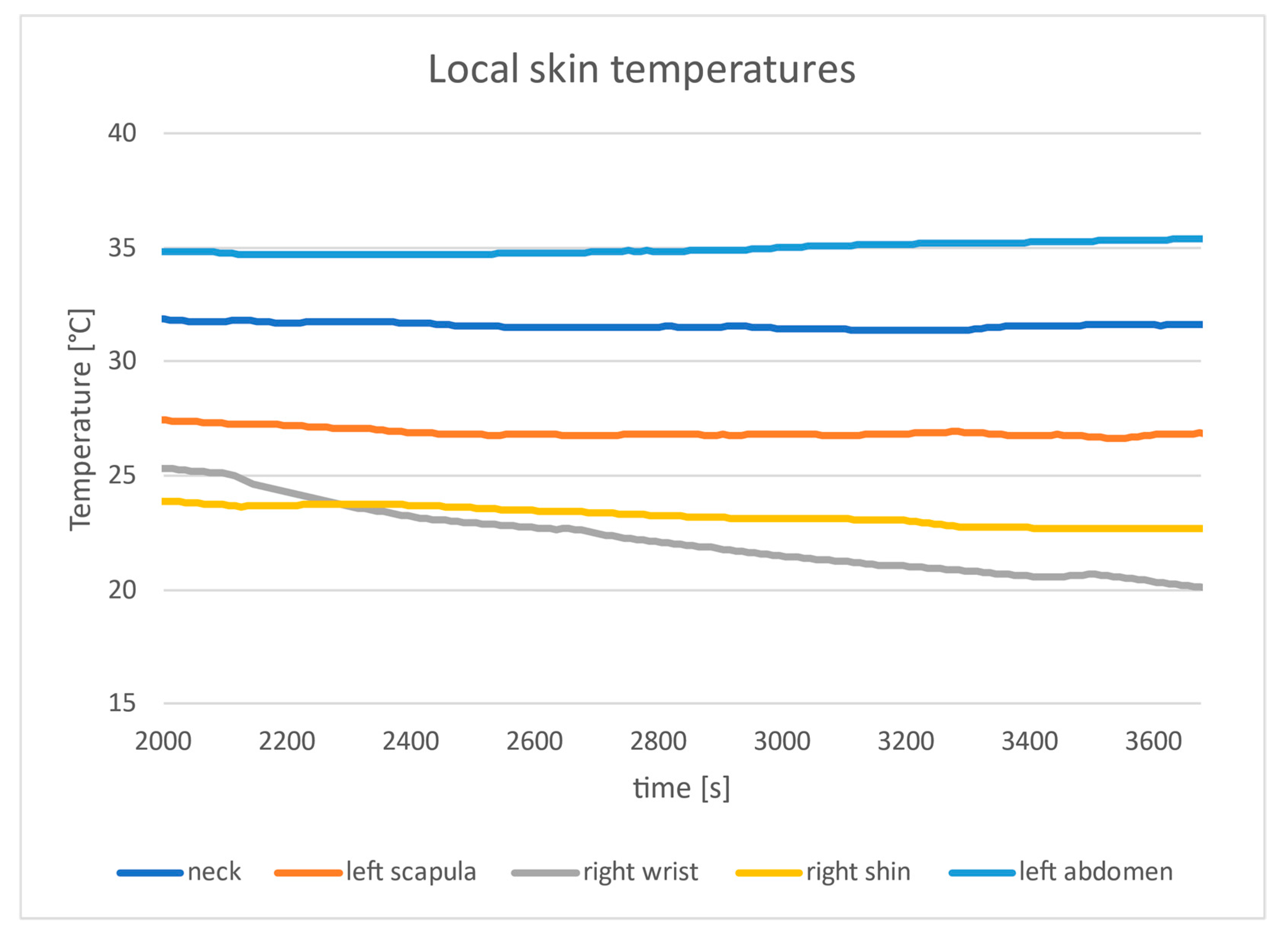

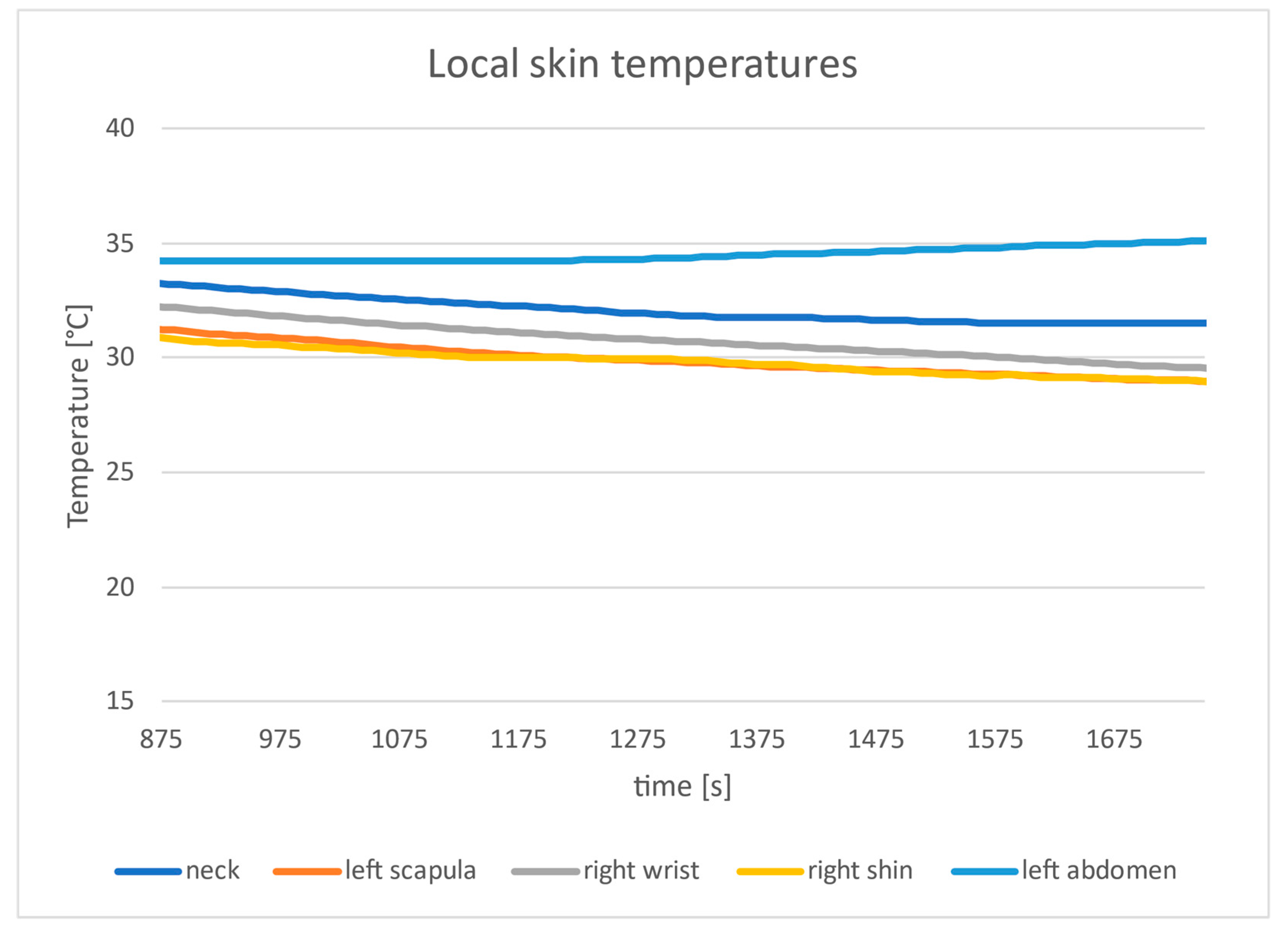

4.1. Computations Pursuant to ISO 11079

4.2. Experimental Results

5. Discussion

5.1. Theoretical vs. Experimental Values

- The participants remained in the chamber for a relatively short period of time, up to 60 min. It is possible that longer exposure would require increasing the heating power in order to maintain thermal comfort

- The computations using the ISO 11079 standard treat the power as generated through metabolic processes, which happens (to various extent) in all cells of the body. This means the heat is produced “inside” the body. On the other hand, when using the electrically heated garment, the heat is produced outside and close to the skin. Thermoreceptors are located in various parts of the body, but a significant number is located in the skin. Consequently, direct heating of the skin may result in false sensation of thermal comfort, while in fact the body is not in thermal balance and is losing heat.

- The standard assumes that the skin temperature at thermal comfort is given by (5)

5.2. Global vs. Local Comfort

5.3. Automatic Computation of Heating Power

- The difference between the measured and comfort skin temperature should be considered;

- The heating power should be linearly dependent on this difference;

- Body dimensions should be taken into account.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ISO 11079:2007; Ergonomics of the Thermal Environment—Determination and Interpretation of Cold Stress When Using Required Clothing Insulation (IREQ) and Local Cooling Effects. ISO: Geneva, Switzerland, 2007. Available online: https://www.iso.org/standard/38900.html (accessed on 25 July 2022).

- Tylman, W.; Kotas, R.; Kaminski, M.; Dabrowska, A.; Mlynarczyk, M. Experimental verification of the required power for electrically heated clothing. In Proceedings of the 2022 29th International Conference on Mixed Design of Integrated Circuits and System, Wroclaw, Poland, 23–24 June 2022; pp. 192–195. [Google Scholar] [CrossRef]

- Wang, F.; Gao, C.; Kuklane, K.; Holmér, I. A Review of Technology of Personal Heating Garments. Int. J. Occup. Saf. Ergon. JOSE 2010, 16, 387–404. [Google Scholar] [CrossRef] [PubMed]

- Heated Glove Liners, Gloves, Jackets + More. ActiVHeat. Available online: https://www.activheat.com/ (accessed on 25 March 2022).

- Battery Heated Clothing Delivers Active Heat When You Need It. With Rechargeable Battery Technology It Is Easy to Choose between Different Heating Levels. Available online: https://heatexperience.eu/ (accessed on 25 March 2022).

- Heated Clothing, Heated Jackets, Heated Gloves, Heated Socks, Heated Vests. The Warming Store. Available online: https://www.thewarmingstore.com/ (accessed on 25 March 2022).

- Givoni, B.; Goldman, R.F. Predicting rectal temperature response to work, environment and clothing. J. Appl. Physiol. 1972, 2, 812–822. [Google Scholar] [CrossRef] [PubMed]

- Stolwijk, J.A.J.; Hardy, J.D. Control of Body Temperature. In Handbook of Physiology, Section 9: Reaction to Environmental Agents; American Physiological Society: Bethesda, MD, USA, 1977; pp. 45–68. [Google Scholar]

- Wissler, E.H. Mathematical simulation of human thermal behavior using whole body models. In Heat Transfer in Medicine and Biology; Shitzer, A., Eberhart, R.C., Eds.; Plenum: New York, NY, USA, 1985; Volume 1, pp. 325–373. [Google Scholar]

- Werner, L. Properties of the human thermostat: Results from mathematical and experimental analyses. In Proceedings of the International Conference on Environmental Ergonomics—IV, University of Texas, Austin, TX, USA, 1–5 October 1990. [Google Scholar]

- Fiala, D.; Lomas, K.J.; Stohrer, M. Dynamic simulation of human heat transfer and thermal comfort. In Proceedings of the 12th International Conference on Environmental Ergonomics, Portoroz, Slovenia, 19–24 August 2007. [Google Scholar]

- Parsons, K. Human Thermal Environments: The Effects of Hot, Moderate, and Cold Environments on Human Health, Comfort, and Performance, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2014; ISBN 978-1-4665-9600-9. [Google Scholar]

- Haslam, R.A.; Parsons, K.C. Computerbased models of human responses to the thermal environments: Are their predictions accurate enough for practical use? In Thermal Physiology; Mercer, J.B., Ed.; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Li, X.; Kuai, B.; Tu, X.; Tan, J.; Zhou, X. Three-dimensional analysis model of electric heating fabrics considering the skin metabolism. J. Eng. Fibers Fabr. 2021, 16, 15589250211047980. [Google Scholar] [CrossRef]

- Wang, F.; Lee, H. Evaluation of an Electrically Heated Vest (EHV) Using a Thermal Manikin in Cold Environments. Ann. Occup. Hyg. 2010, 54, 117–124. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Irzmańska, E.; Jurczyk-Kowalska, M. Assessment of the thermal effectiveness of mineral warmers for protective gloves used in cold environments. Int. J. Heat Technol. 2020, 38, 28–36. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Y.; Kim, J.; Yin, H. The key local segments of human body for personalized heating and cooling. J. Therm. Biol. 2019, 81, 118–127. [Google Scholar] [CrossRef] [PubMed]

- Neves, S.F.; Couto, S.; Campos, J.B.L.M.; Mayor, T.S. Advances in the optimisation of apparel heating products: A numerical approach to study heat transport through a blanket with an embedded smart heating system. Appl. Therm. Eng. 2015, 87, 491–498. [Google Scholar] [CrossRef]

- Wu, J.-X.; Liao, Y.-C. Self-regulated thermal comfort control for wearable heating device. J. Taiwan Inst. Chem. Eng. 2021, 121, 74–80. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort. In Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- JAVA Applet for ISO 11079. 2008. Available online: https://www.eat.lth.se/fileadmin/eat/Termisk_miljoe/IREQ2009ver4_2.html (accessed on 25 March 2022).

- ISO 15831:2004; Clothing—Physiological Effects—Measurement of Thermal Insulation by Means of a Thermal Manikin. ISO: Geneva, Switzerland, 2004. Available online: https://www.iso.org/standard/28720.html (accessed on 25 July 2022).

- PN-EN 342:2018; Protective Clothing—Ensembles and Garments for Protection against Cold. European Committee for Standardization: Brussels, Belgium, 2018. Available online: https://sklep.pkn.pl/pn-en-342-2018-01e.html (accessed on 25 July 2022).

- Młynarczyk, M. Characteristics of Specialised Firefighter Clothing Used in Poland—The Thermal Parameters. Fibres Text. East. Eur. 2020, 139, 65–70. [Google Scholar] [CrossRef]

- Tylman, W.; Kotas, R.; Kamiński, M.; Woźniak, S.; Dąbrowska, A. Thermal Model for Processing Data from Undergarment Sensors in Automatic Control of Actively Heated Clothing. Energies 2022, 15, 169. [Google Scholar] [CrossRef]

- PostgreSQL: The World’s Most Advanced Open Source Relational Database. Available online: https://www.postgresql.org/ (accessed on 25 July 2022).

- Hibernate. Available online: https://hibernate.org/ (accessed on 25 July 2022).

- Spring Framework. Available online: https://spring.io/ (accessed on 25 July 2022).

- The Progressive JavaScript Framework. Available online: https://vuejs.org/ (accessed on 25 July 2022).

- Kotas, R.; Kamiński, M.; Tylman, W.; Woźniak, S.; Wojtera, M.; Dąbrowska, A. Comprehensive Information System for Management of Personalized Protective Thermally Active Clothing. In Proceeding of the 2021 28th International Conference on Mixed Design of Integrated Circuits and System, Lodz, Poland, 24–26 June 2021; pp. 274–279. [Google Scholar] [CrossRef]

- ISO 9920:2007; Ergonomics of the Thermal Environment—Estimation of Thermal Insulation and Water Vapour Resistance of a Clothing Ensemble. ISO: Geneva, Switzerland, 2007. Available online: https://www.iso.org/standard/39257.html (accessed on 25 July 2022).

- MDawe, M.; Raftery, P.; Woolley, J.; Schiavon, S.; Bauman, F. Comparison of mean radiant and air temperatures in mechanically-conditioned commercial buildings from over 200,000 field and laboratory measurements. Energy Build. 2020, 206, 109582. [Google Scholar] [CrossRef]

- Du Bois, D.; Du Bois, E.F. A formula to estimate surface area if height and weight are known. Arch. Intern. Med. 1916, 17, 86. [Google Scholar]

- ISO 9886:2004; Ergonomics—Evaluation of Thermal Strain by Physiological Measurements. ISO: Geneva, Switzerland, 2004. Available online: https://www.iso.org/standard/34110.html (accessed on 25 July 2022).

| Parameter | Participant | ||

|---|---|---|---|

| A | B | C | |

| age | 36 | 40 | 46 |

| height | 1.88 m | 1.72 m | 1.79 m |

| weight | 85 kg | 65 kg | 76 kg |

| underwear | none | thin | Medium |

| Garment | Participant | ||

|---|---|---|---|

| A | B | C | |

| tested clothing 1 | 1.27 clo | 1.27 clo | 1.27 clo |

| underwear 2 | 0.05 clo | 0.14 clo | 0.17 clo |

| boots 2 | 0.1 clo | 0.1 clo | 0.1 clo |

| gloves 2 | 0.05 clo | 0.05 clo | 0.05 clo |

| cap 2 | 0.1 clo | 0.1 clo | 0.1 clo |

| total 3 | 1.57 clo | 1.66 clo | 1.69 clo |

| Parameter | Participant | ||

|---|---|---|---|

| A | B | C | |

| air temperature | −3 °C | 0 °C | −3 °C |

| radiant temperature | −3 °C | 0 °C | −3 °C |

| air velocity | 0.4 m/s | 0.4 m/s | 0.4 m/s |

| clothing insulation | 1.57 clo | 1.66 clo | 1.69 clo |

| body surface area | 2.11 m2 | 1.76 m2 | 1.94 m2 |

| required power, scaled | 126 W/m2 | 111 W/m2 | 119 W/m2 |

| electrical power, scaled | 61 W/m2 | 46 W/m2 | 54 W/m2 |

| electrical power | 128.66 W | 81.22 W | 104.81 W |

| Heating Inset | Participant | ||

|---|---|---|---|

| A | B | C | |

| upper back | 8.57 W | 8.57 W | 8.57 W |

| lower back | 8.57 W | 5.71 W | 8.57 W |

| abdomen | 8.57 W | 5.71 W | 8.57 W |

| right upper limb | 8.57 W | 8.57 W | 8.57 W |

| left upper limb | 8.57 W | 8.57 W | 8.57 W |

| thighs | 8.57 W | 5.71 W | 0 W |

| shins | 8.57 W | 5.71 W | 0 W |

| Total | 59.99 W | 48.55 W | 42.85 W |

| Sensor Placement | Participant | ||

|---|---|---|---|

| A | B | C | |

| neck | 31.63 °C | 28.20 °C | 31.52 °C |

| left scapula | 26.83 °C | 25.75 °C | 29.73 °C |

| left abdomen | 35.35 °C | 31.69 °C | 34.98 °C |

| right wrist | 20.26 °C | 16.77 °C | 29.73 °C |

| right shin | 22.69 °C | 26.32 °C | 29.09 °C |

| Computation Method | Participant | ||

|---|---|---|---|

| A | B | C | |

| ISO 4-point | 25.96 °C | 25.16 °C | 30.05 °C |

| ISO 4-point w/o wrist sensor | 27.05 °C | 26.75 °C | 30.11 °C |

| Approach | Participant | |||

|---|---|---|---|---|

| Skin Temperature | Body Dimension | A | B | C |

| ISO-4 point | Area | 3.61 | 3.18 | 5.82 |

| ISO-4 point | Mass | 0.089 | 0.086 | 0.148 |

| ISO 4-point w/o hand sensor | Area | 4.18 | 3.89 | 5.91 |

| ISO 4-point w/o hand sensor | Mass | 0.104 | 0.105 | 0.151 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tylman, W.; Kotas, R.; Kamiński, M.; Dąbrowska, A.; Młynarczyk, M. Modeling and Experimental Verification of the Required Power for Electrically Heated Clothing. Energies 2022, 15, 7713. https://doi.org/10.3390/en15207713

Tylman W, Kotas R, Kamiński M, Dąbrowska A, Młynarczyk M. Modeling and Experimental Verification of the Required Power for Electrically Heated Clothing. Energies. 2022; 15(20):7713. https://doi.org/10.3390/en15207713

Chicago/Turabian StyleTylman, Wojciech, Rafał Kotas, Marek Kamiński, Anna Dąbrowska, and Magdalena Młynarczyk. 2022. "Modeling and Experimental Verification of the Required Power for Electrically Heated Clothing" Energies 15, no. 20: 7713. https://doi.org/10.3390/en15207713

APA StyleTylman, W., Kotas, R., Kamiński, M., Dąbrowska, A., & Młynarczyk, M. (2022). Modeling and Experimental Verification of the Required Power for Electrically Heated Clothing. Energies, 15(20), 7713. https://doi.org/10.3390/en15207713