Data-Based Flow Rate Prediction Models for Independent Metering Hydraulic Valve

Abstract

1. Introduction

2. Data Collection

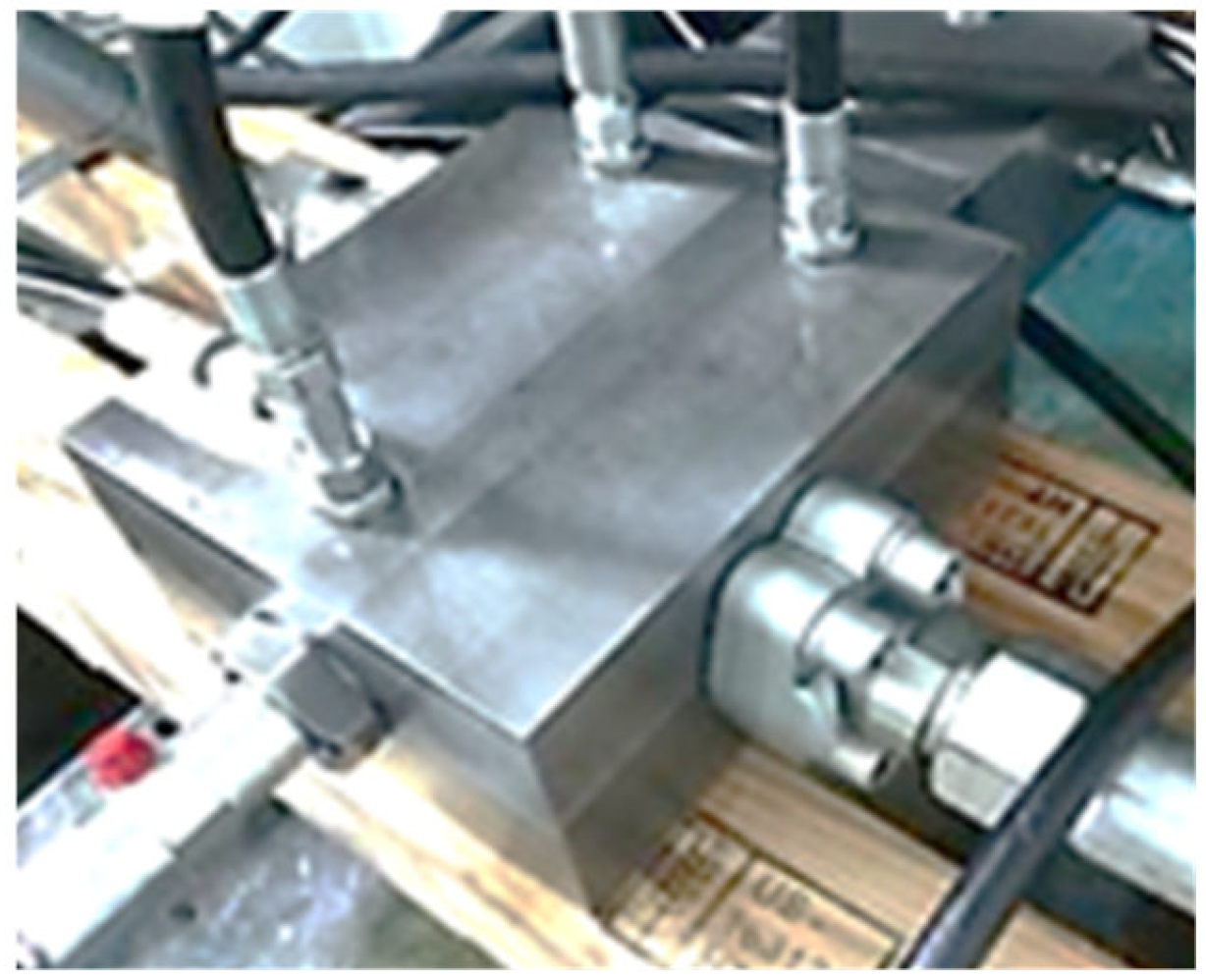

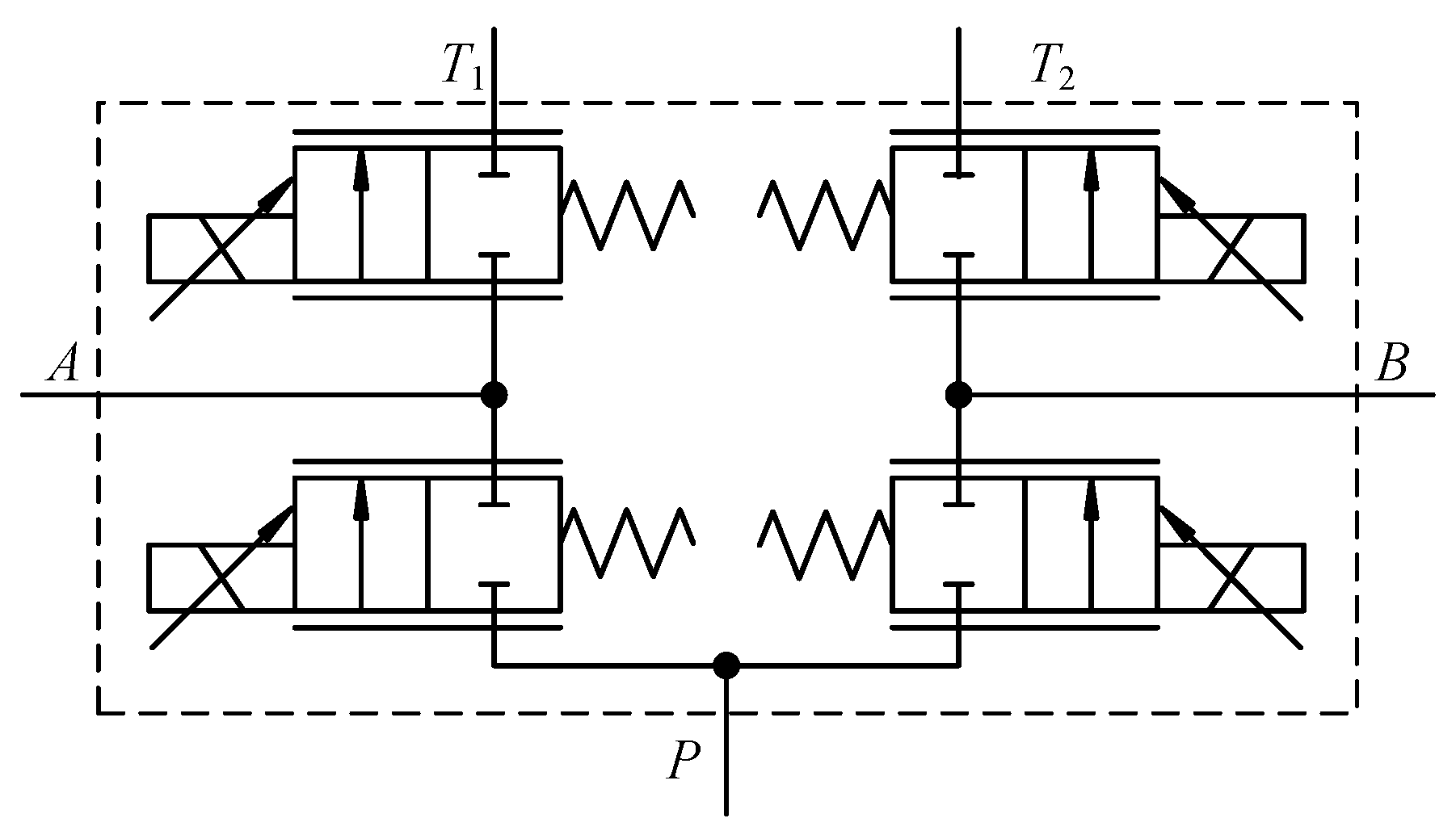

2.1. The Tested Valve

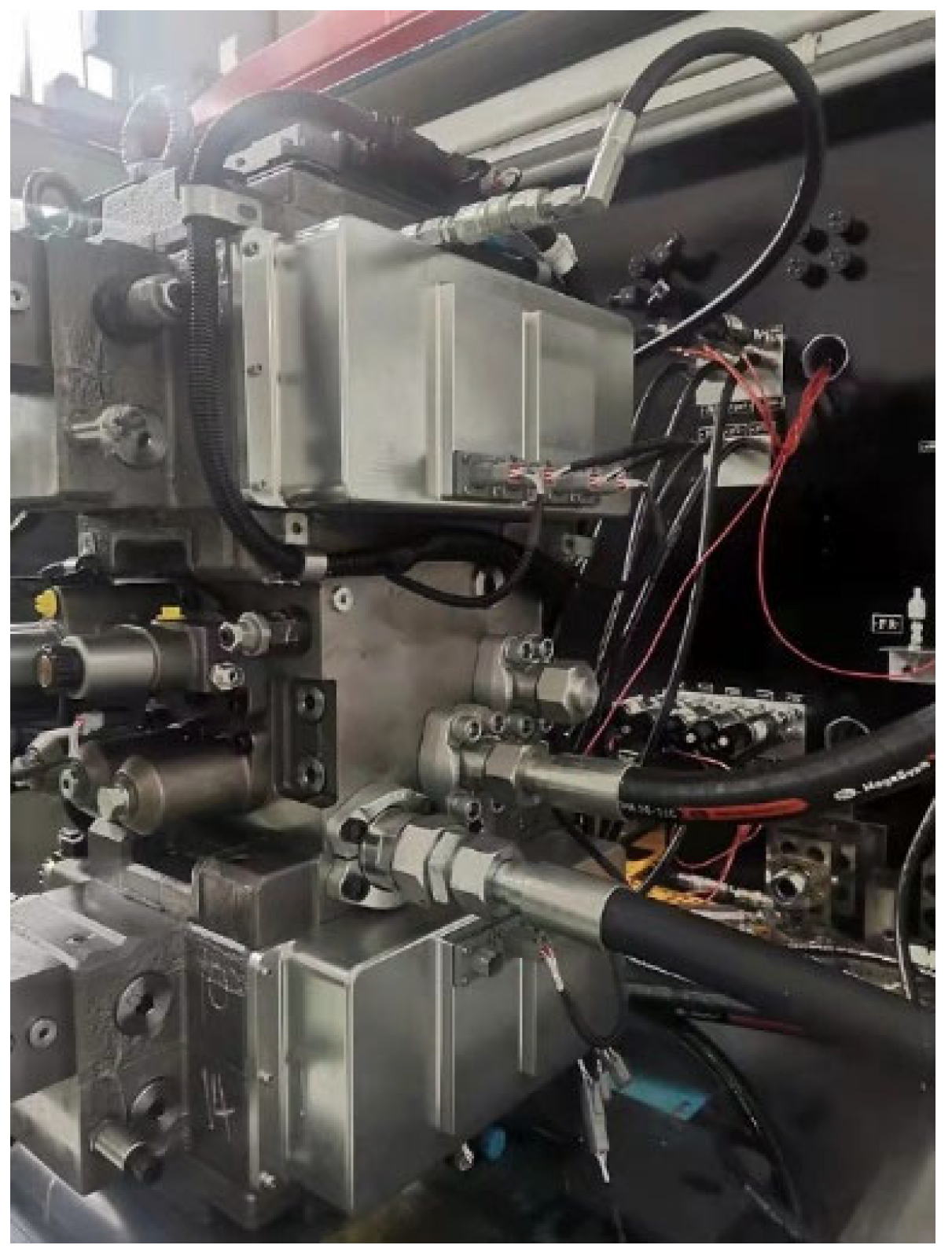

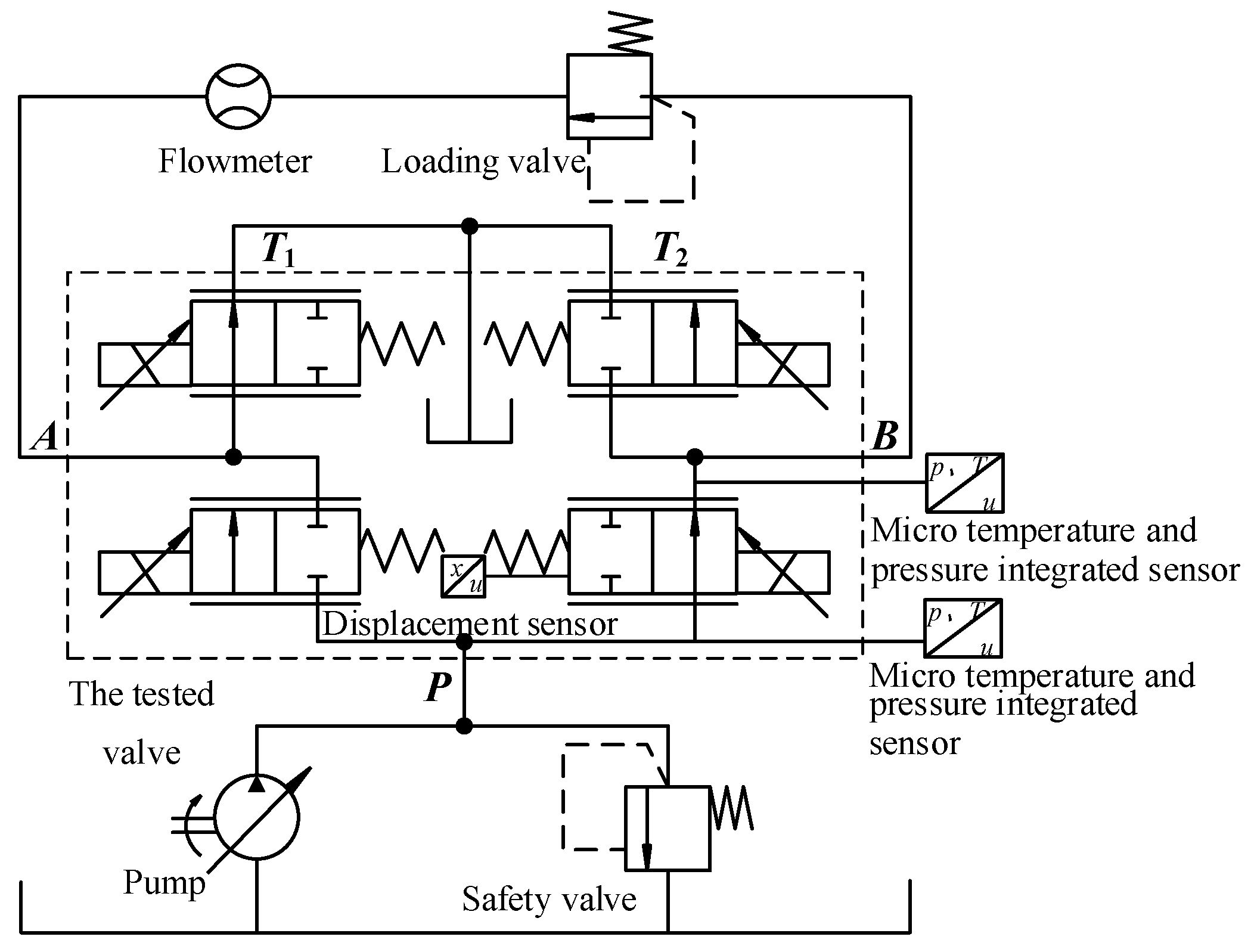

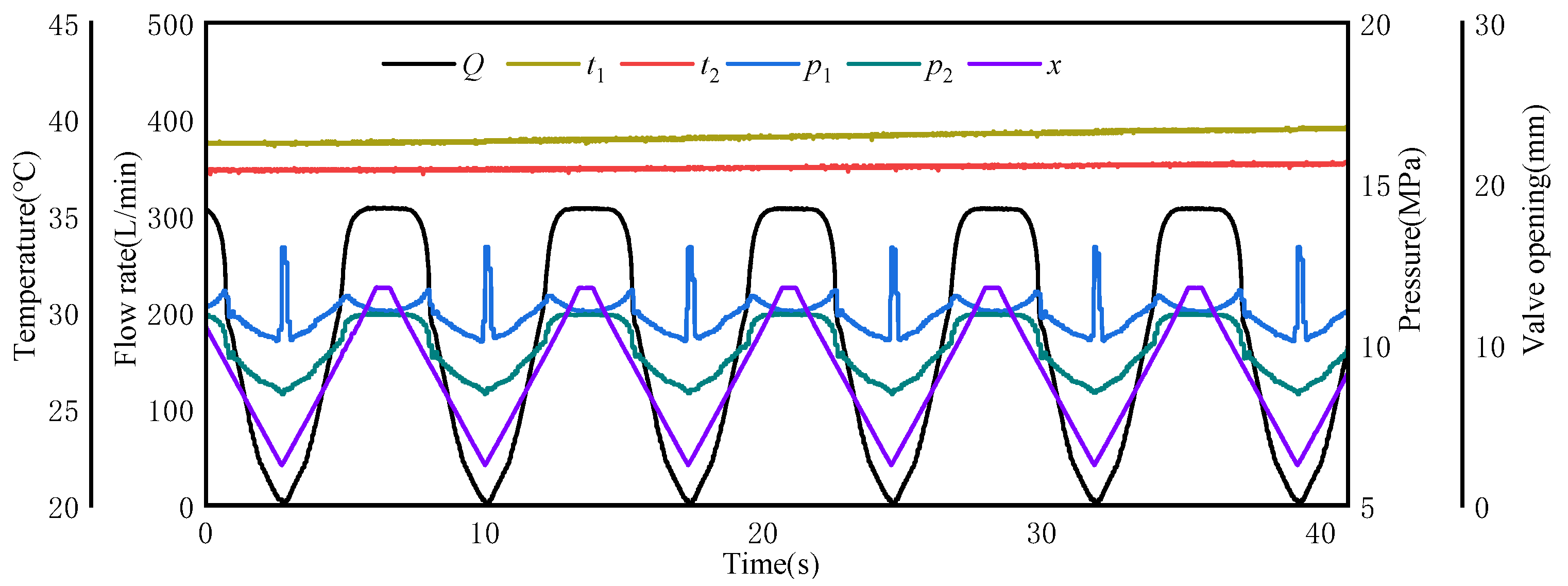

2.2. Data Generation by Experiments

3. Dataset Analysis and Input Selection

3.1. Dataset Analysis

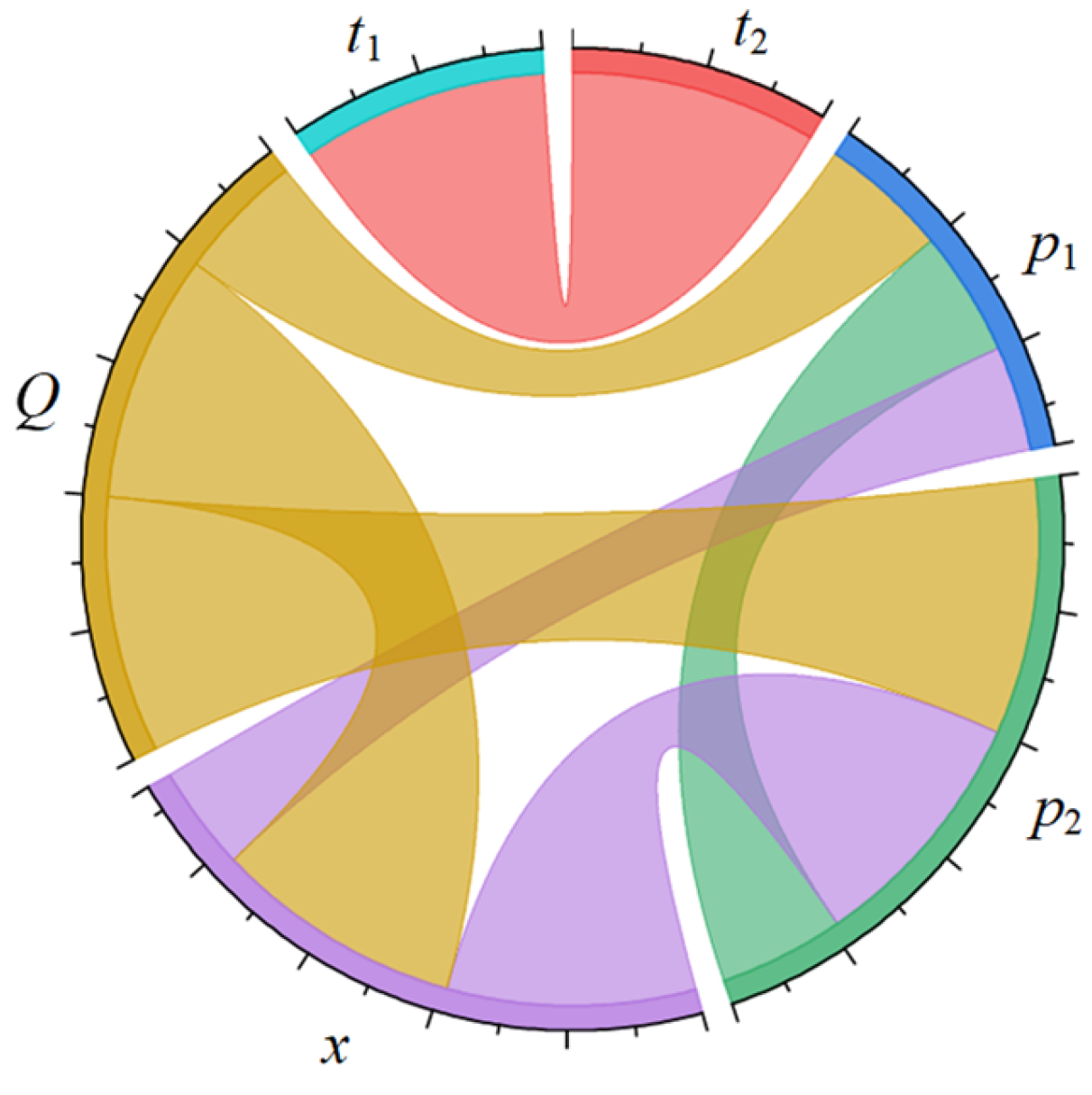

3.2. Input Selection

4. Regression Models and Hyperparameters Optimization

4.1. Machine Learning Techniques

4.1.1. Linear Regression

4.1.2. K-Nearest Neighbor

4.1.3. Decision Tree

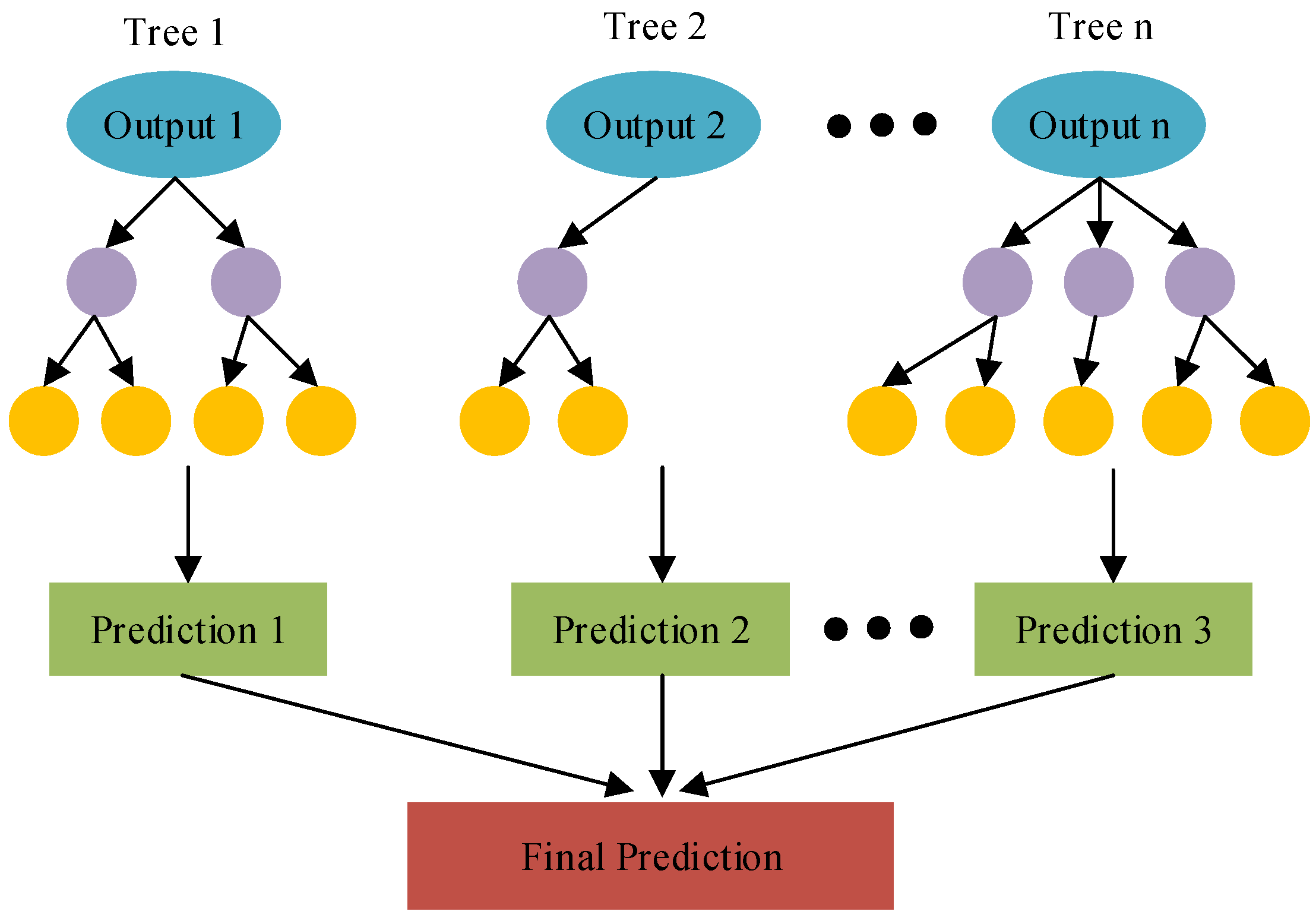

4.1.4. Random Forest

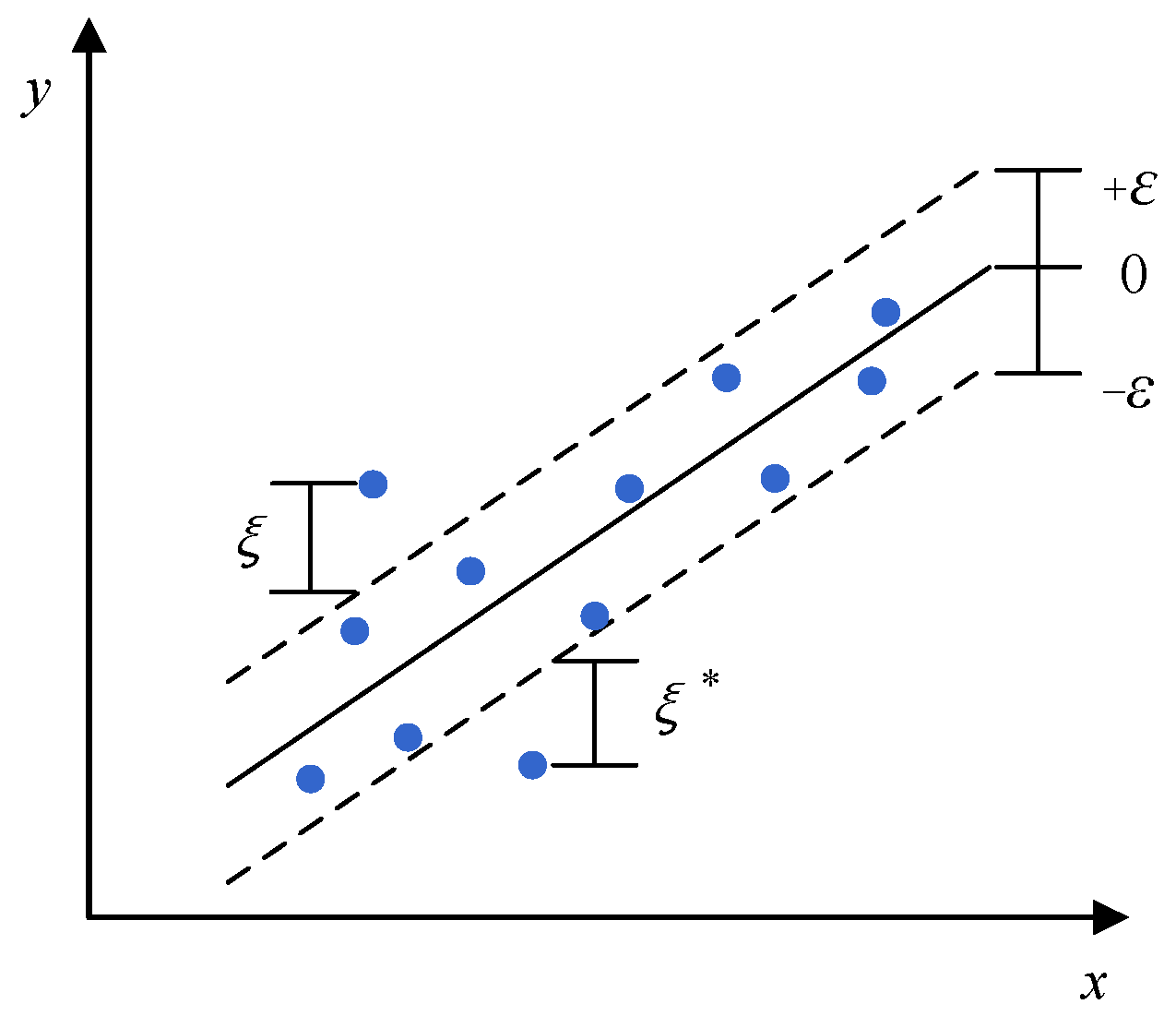

4.1.5. Support Vector Regression

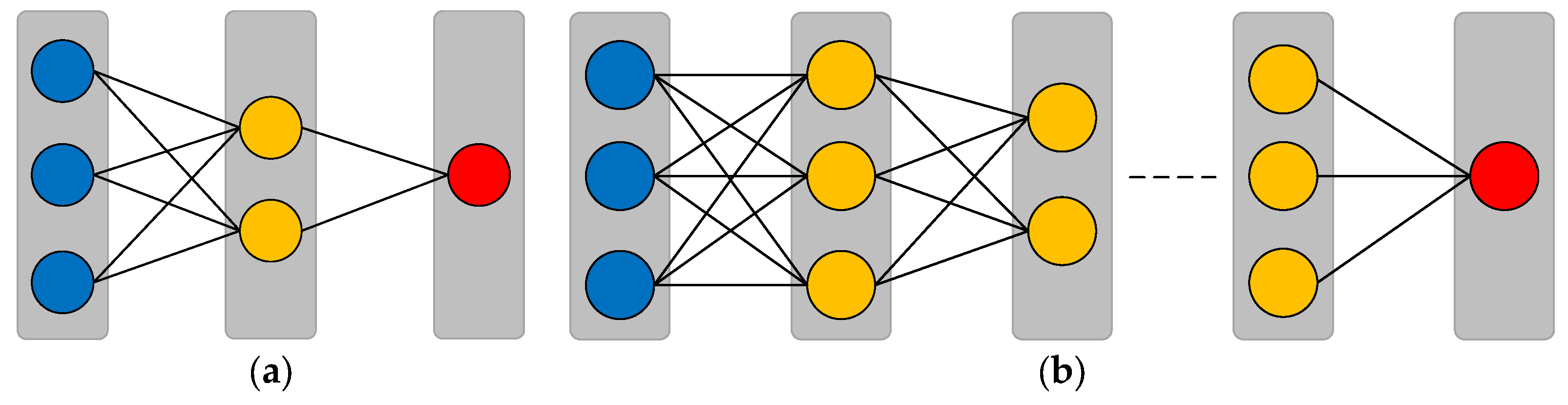

4.1.6. Artificial and Deep Neural Network

4.2. Hyperparameters Optimization

5. Results and Discussion

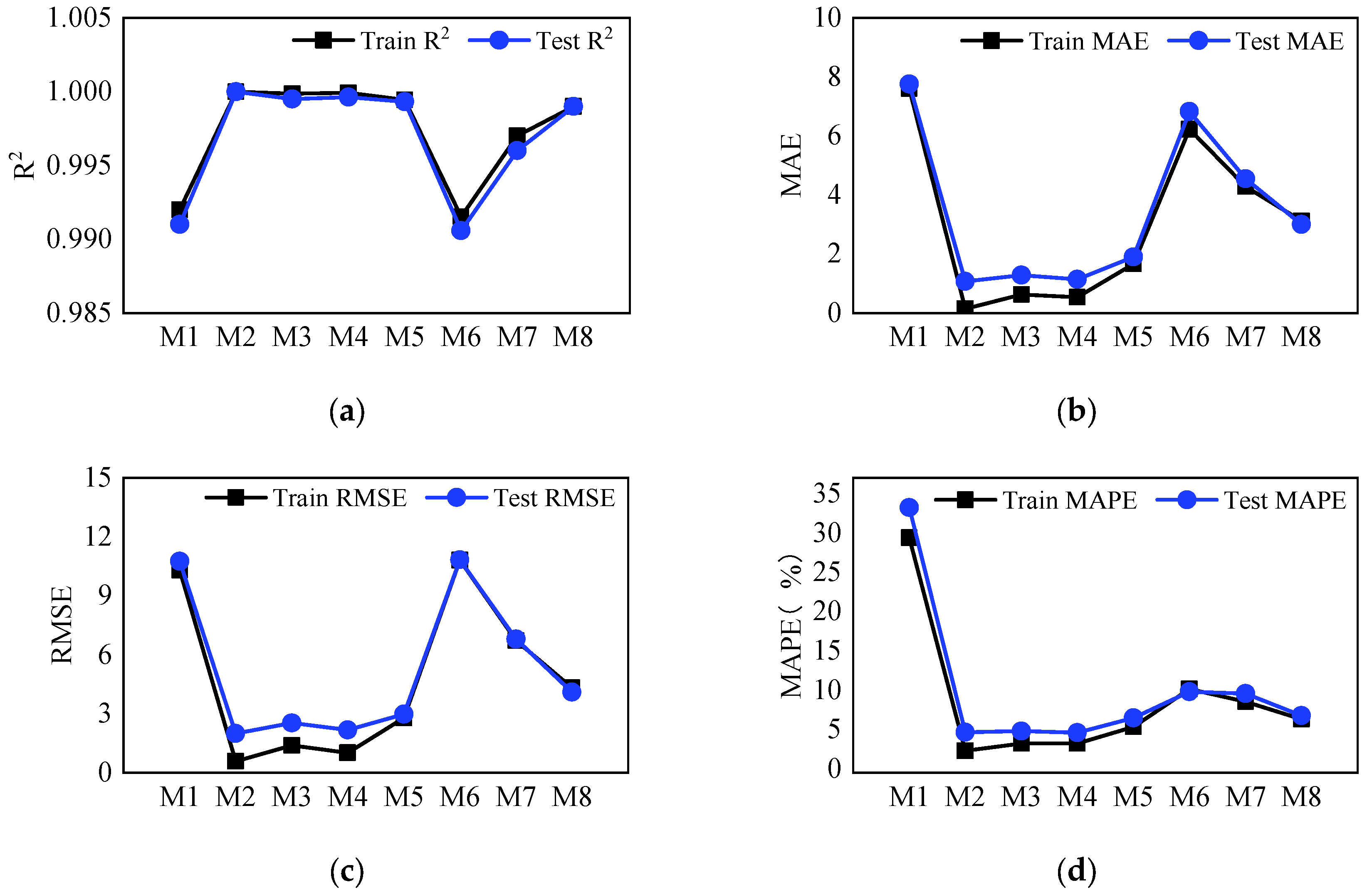

5.1. Performance Evaluation Criteria of Models

- (i)

- Coefficient of determination, R2. High R2 value indicates a good performance of the model.

- (ii)

- Mean absolute error, MAE. The mean absolute error is used to measure the accuracy of continuous variables.

- (iii)

- Root mean square error, RMSE. The root mean square error is determined by the square root of the sum of the differences between observation and prediction values. The situation that the root mean square error on the training set is lower the error on the test set indicates overfitting possibly.

- (iv)

- Mean absolute percentage error, MAPE. The mean absolute percentage error can avoid positive and negative errors canceling each other out.

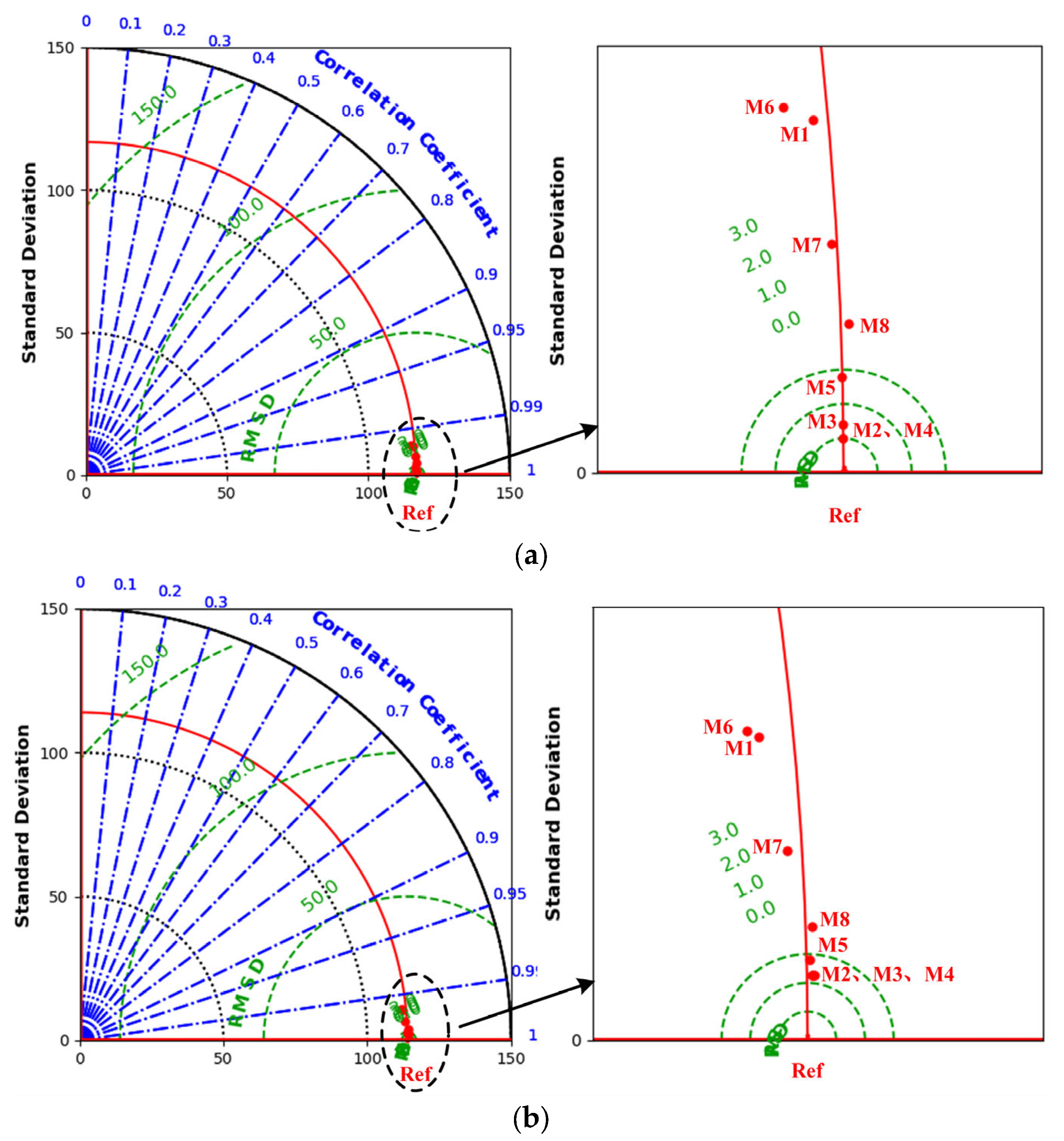

5.2. Comparison of Regression Models

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lin, T.L.; Chen, Q.; Ren, H.L.; Huang, W.P.; Chen, Q.H.; Fu, S.J. Review of boom potential energy regeneration technology for hydraulic construction machinery. Renew. Sust. Energ. Rev. 2017, 79, 358–371. [Google Scholar] [CrossRef]

- Do, T.C.; Dang, T.D.; Dinh, T.Q.; Ahn, K.K. Developments in energy regeneration technologies for hydraulic excavators: A review. Renew. Sust. Energ. Rev. 2021, 145, 111076. [Google Scholar] [CrossRef]

- Xu, B.; Cheng, M. Motion control of multi-actuator hydraulic systems for mobile machineries: Recent advancements and future trends. Front. Mech. Eng. 2018, 13, 151–166. [Google Scholar] [CrossRef]

- Quan, L.; Xia, L.; Zhao, B.; Ge, L. Innovation Progress in Research on Gravitational Potential Energy Recovery and Utilization of Hydraulic Driven Mechanical Arm. J. Mech. Eng. 2018, 54, 4–13. [Google Scholar] [CrossRef]

- Kailei, L.; Shaopeng, K.; Rongsheng, L. Optimal Metering Mode for Improving Transform Efficiency of Independent Metering System. In Proceedings of the 2019 IEEE 8th International Conference on Fluid Power and Mechatronics (FPM), Wuhan, China, 10–13 April 2019; pp. 1035–1041. [Google Scholar]

- Zhang, X.G.; Qiao, S.F.; Quan, L.; Ge, L. Velocity and Position Hybrid Control for Excavator Boom Based on Independent Metering System. IEEE Access 2019, 7, 71999–72011. [Google Scholar] [CrossRef]

- Zatopa, A.; Walker, S.; Menguc, Y. Fully Soft 3D-Printed Electroactive Fluidic Valve for Soft Hydraulic Robots. Soft Robot. 2018, 5, 258–271. [Google Scholar] [CrossRef]

- Pan, M.; Plummer, A.; El Agha, A. Theoretical and Experimental Studies of a Switched Inertance Hydraulic System in a Four-Port High-Speed Switching Valve Configuration. Energies 2017, 10, 780. [Google Scholar] [CrossRef]

- Kong, L.X.; Wei, W.; Yan, Q.D. Application of flow field decomposition and reconstruction in studying and modeling the characteristics of a cartridge valve. Eng. Appl. Comp. Fluid Mech. 2018, 12, 385–396. [Google Scholar] [CrossRef]

- Dempster, W.; Elmayyah, W. Two phase discharge flow prediction in safety valves. Int. J. Pressure Vessels Pip. 2013, 110, 61–65. [Google Scholar] [CrossRef][Green Version]

- Sekar, V.; Jiang, Q.H.; Shu, C.; Khoo, B.C. Fast flow field prediction over airfoils using deep learning approach. Phys. Fluids 2019, 31, 057103. [Google Scholar] [CrossRef]

- Choi, D.; An, Y.; Lee, N.; Park, J.; Lee, J. Comparative Study of Physics-Based Modeling and Neural Network Approach to Predict Cooling in Vehicle Integrated Thermal Management System. Energies 2020, 13, 5301. [Google Scholar] [CrossRef]

- Sun, Y.B.; Sun, Q.K.; Qin, K. Physics-Based Deep Learning for Flow Problems. Energies 2021, 14, 7760. [Google Scholar] [CrossRef]

- Rao, M.M.; Wang, L.; Chen, C.T.; Xiong, K.; Li, M.F.; Chen, Z.P.; Dong, J.B.; Xu, J.L.; Li, X. Data-Driven State Prediction and Analysis of SOFC System Based on Deep Learning Method. Energies 2022, 15, 3099. [Google Scholar] [CrossRef]

- Croitoru, I.; Bogolin, S.V.; Leordeanu, M. Unsupervised Learning of Foreground Object Segmentation. Int. J. Comput. Vis. 2019, 127, 1279–1302. [Google Scholar] [CrossRef]

- Zhang, Y.; He, X.F.; Chen, Z.Q.; Bai, Q.; Nolan, A.M.; Roberts, C.A.; Banerjee, D.; Matsunaga, T.; Mo, Y.F.; Ling, C. Unsupervised discovery of solid-state lithium ion conductors. Nat. Commun. 2019, 10, 5260. [Google Scholar] [CrossRef]

- Li, Y.F.; Guo, L.Z.; Zhou, Z.H. Towards Safe Weakly Supervised Learning. IEEE Trans. Pattern Anal. Mach. Intell. 2021, 43, 334–346. [Google Scholar] [CrossRef] [PubMed]

- Ohri, K.; Kumar, M. Review on self-supervised image recognition using deep neural networks. Knowl. Based Syst. 2021, 224, 107090. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Ma, J.W.; Wang, F.J.; Liu, W. Hybrid of simulated annealing and SVM for hydraulic valve characteristics prediction. Expert Syst. Appl. 2011, 38, 8030–8036. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, S.; Shang, Y. Fault diagnosis for piston head looseness of aero hydraulic pump. J. Beijing Univ. Aeronaut. Astronaut. 2010, 36, 261–264. [Google Scholar]

- Guo, Y.; Zeng, Y.C.; Fu, L.D.; Chen, X.Y. Modeling and Experimental Study for Online Measurement of Hydraulic Cylinder Micro Leakage Based on Convolutional Neural Network. Sensors 2019, 19, 2159. [Google Scholar] [CrossRef]

- Jumin, E.; Zaini, N.; Ahmed, A.N.; Abdullah, S.; Ismail, M.; Sherif, M.; Sefelnasr, A.; Ei-Shafie, A. Machine learning versus linear regression modelling approach for accurate ozone concentrations prediction. Eng. Appl. Comp. Fluid Mech. 2020, 14, 713–725. [Google Scholar] [CrossRef]

- Korkmaz, M. A study over the general formula of regression sum of squares in multiple linear regression. Numer. Meth. Part Differ. Equ. 2021, 37, 406–421. [Google Scholar] [CrossRef]

- Speybroeck, N. Classification and regression trees. Int. J. Public Health 2012, 57, 243–246. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Guo, J.Z.; Jin, J.W. An improved improved Id3 algorithm for medical data classification. Comput. Electr. Eng. 2018, 65, 474–487. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Ozbas, E.E.; Aksu, D.; Ongen, A.; Aydin, M.A.; Ozcan, H.K. Hydrogen production via biomass gasification, and modeling by supervised machine learning algorithms. Int. J. Hydrogen Energy 2019, 44, 17260–17268. [Google Scholar] [CrossRef]

- Valencia, F.; Arcos, H.; Quilumba, F. Prediction of Stress in Power Transformer Winding Conductors Using Artificial Neural Networks: Hyperparameter Analysis. Energies 2021, 14, 4242. [Google Scholar] [CrossRef]

- Li, B.; Yao, Q.-Z.; Luo, Z.-M.; Tian, Y.; Wang, W. Gird-pattern method for model selection of support vector machines. Comput. Eng. Applic. 2008, 44, 136–138. [Google Scholar]

- Taylor, K.E. Summarizing multiple aspects of model performance in a single diagram. J. Geophys. Res. Atmos. 2001, 106, 7183–7192. [Google Scholar] [CrossRef]

| Descriptive Statistics | MIN | MAX | AVG | CV |

|---|---|---|---|---|

| t1 (°C) | 38.591 | 39.602 | 39.081 | 0.010 |

| t2 (°C) | 37.142 | 38.841 | 37.490 | 0 |

| p1 (MPa) | 10.090 | 13.042 | 10.922 | 0.050 |

| p2 (MPa) | 8.462 | 10.964 | 9.821 | 0.091 |

| X (mm) | 2.503 | 13.543 | 8.040 | 0.410 |

| Q (L/min) | 1.453 | 307.942 | 167.794 | 0.692 |

| Ridge | KNN | DT | RF | SVR | ANN | DNN (H = 2) | DNN (H = 3) | |

|---|---|---|---|---|---|---|---|---|

| Hyper-parameters | A = 10−4 | K = 8 | max_depth = 20 min_leaf_nodes = 4 | max_depth = 10 min_leaf_nodes = 1 trees = 40 | C = 32 Γ = 2 | h1 = 5 activation = tanh batch_size = 400 learning_rate = 0.01 | h1 = 4 h2 = 7 activation = tanh batch_size = 100 learning_rate = 0.01 | h1 = 6 h2 = 11 h3 = 1 activation = tanh batch_size = 200 learning_rate = 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, W.; Ren, W.; Sun, H.; Liu, C.; Lu, X.; Hua, Y.; Wei, H.; Jia, H. Data-Based Flow Rate Prediction Models for Independent Metering Hydraulic Valve. Energies 2022, 15, 7699. https://doi.org/10.3390/en15207699

Su W, Ren W, Sun H, Liu C, Lu X, Hua Y, Wei H, Jia H. Data-Based Flow Rate Prediction Models for Independent Metering Hydraulic Valve. Energies. 2022; 15(20):7699. https://doi.org/10.3390/en15207699

Chicago/Turabian StyleSu, Wenbin, Wei Ren, Hui Sun, Canjie Liu, Xuhao Lu, Yingli Hua, Hongbo Wei, and Han Jia. 2022. "Data-Based Flow Rate Prediction Models for Independent Metering Hydraulic Valve" Energies 15, no. 20: 7699. https://doi.org/10.3390/en15207699

APA StyleSu, W., Ren, W., Sun, H., Liu, C., Lu, X., Hua, Y., Wei, H., & Jia, H. (2022). Data-Based Flow Rate Prediction Models for Independent Metering Hydraulic Valve. Energies, 15(20), 7699. https://doi.org/10.3390/en15207699