1. Introduction

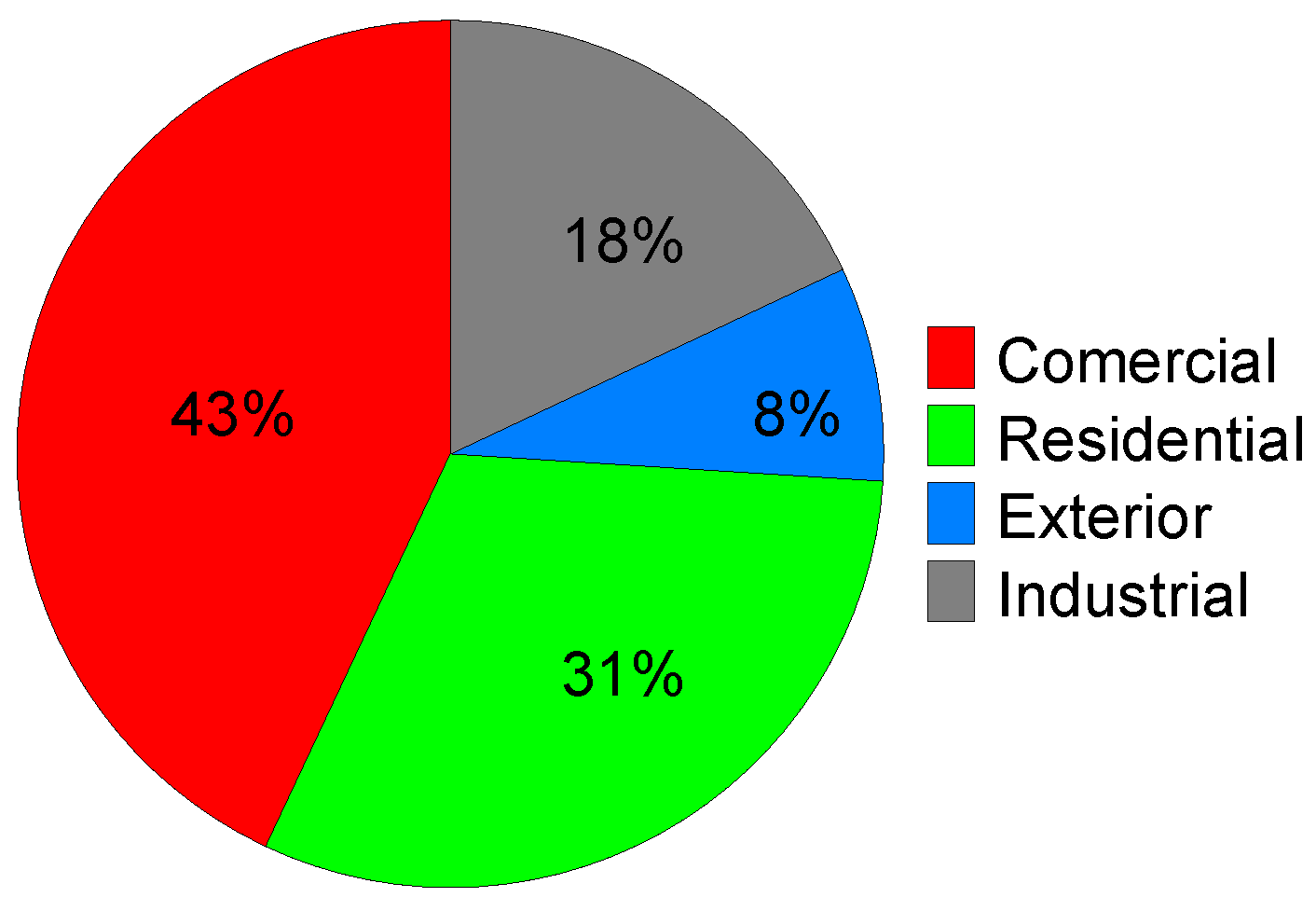

Artificial lighting represents an area of research that has a high consumption of electricity, as it is considered an essential application for quality of life [

1,

2,

3,

4,

5,

6,

7]. In the absence of natural light, it makes it possible to carry out commercial and leisure activities, among many others, in addition to promoting a feeling of security. This dependence on searches for energy efficiency in lighting sources is a challenge for researchers around the world [

2,

4,

5,

8]. Solid state light sources (SSL) have made progress in recent years, with light-emitting diodes (LEDs) being their biggest representative. These have progressed in terms of improving lamp efficiency and color quality to compete and even surpass traditional technologies in various applications [

3].

LED’s compact size allows optical designs to be more flexible. Additionally, LEDs incorporate other advantages when compared to traditional lighting sources, such as: (i) long lifespan, (ii) high brightness, (iii) low power consumption, (iv) fast response, (v) compact size, (vi) high reliability [

3,

9,

10] and (vi) mechanical shock and vibration resistance [

11]. However, there are still some difficulties in using luminaires with high-power LED (HP-LED). In addition to the high financial cost compared to other lighting technologies, there are other critical problems that constitute barriers to be overcome by this technology, such as (i) thermal dissipation that can degrade luminous efficiency, (ii) optical performance, and (iii) format of the region to be illuminated [

12]. These difficulties are challenges in interior and exterior lighting design when using HP-LED [

13].

To improve the design of outdoor lighting, Japanese researchers develop a luminaire with 700 white LEDs for street lighting. The white glow is obtained through a source that emits rays close to ultraviolet in a medium with multiphosphate materials. The project includes a prototype of a self-sustained light pole formed by the luminaire, solar energy plates, and batteries [

1]. White LED has superior characteristics of luminous efficiency (40 lm/W) and a color rendering index of about 0.93.

Wang et al. [

14] proposes an 80 W streetlamp composed of a combination of 5 W and 3 W LEDs, in which optical analysis is carried out through experimental tests and numerical simulation. A test region of 20 m × 10 m is defined at a height of 8 m from the ground. Numerical simulation results demonstrate that the average illumination is around

lx and the uniformity (uniformity is defined as the ratio of the minimum illuminance to the average illuminance in a specific plane) total is

. Luminaire achieved satisfactory performance, despite the multiple shadows, which need to be removed through optimization techniques.

Bender et al. [

15] develop a LED luminaire project for public lighting using mathematical modeling that calculates the total luminous flux considering losses such as light depreciation, dirt on the luminaire, efficiency, and utilization factor. A prototype with 30 LED is built and used in practical experiments seeking to validate the simulation methodology. Spatial diagrams obtained are in accordance with the standards of the Brazilian standard (NBR) 5101:2012 of the Brazilian Association of Technical Standards (ABNT). The method presents itself as a tool to calculate the amount of luminous flux needed for LED luminaires, optimizing the uniformity of lighting and luminance with the use of lenses, to guarantee current standards for public lighting.

Liu et al. [

16] seek to standardize the lighting of areas through the mixture of colored LEDs. The proposal for a colored LED luminaire aims to standardize the rectangular lighting pattern by optimizing the arrangement of the 36 LED matrix of the luminaire and the shape of the individual lenses of each LED unit. In the lens optimization process, the Downhill simplex algorithm is adopted and the difficulties are the selection of optimization variables and the reconstruction of the model. An array of

LED modules, in which each module consists of four lenses optimized for four color LEDs, gives the desired result with color uniformity. The color mixing method appears to be feasible and practical, requiring further studies. As technology advances, new LEDs of higher power and efficiency emerge. However, there is still the problem of heating the LEDs which reduces the luminous efficiency. There are several efforts that present analysis of thermal dissipation of HP-LED lamps and luminaires [

17,

18]. However, several studies are not concerned with thermal and photometrical analysis concomitantly [

19].

Chi et al. [

19] present a detailed thermal analysis of a luminaire consisting of three 1 W LEDs. The photometrical analysis is restricted to experimental tests in order to find the relationship between junction temperature and luminous flux. Based on the results of these experiments and using the finite element method, the authors propose a model of the lighting module, simulating, analyzing, and validating the thermal analysis. Simulation results are obtained with values close to the experimental data, with a 6.3% deviation. Once the model is validated, predictions are made in which it is possible to obtain a reduced junction temperature and a more efficient light output, when the number of fins and the opening radius of the lamp are increased.

Bender et al. [

20] present methodology for optimized design of LED lighting systems. The purpose of optimization is to provide designers with an ideal operating point, considering the characteristics of the thermal, electrical, and optical systems. The authors consider the output current of the driver circuit, the size of the heat sink, and the temperature of the LED junction in the system design. Mathematical analysis is presented, and the results of the thermal simulations and experimental tests validate the proposed methodology. Bender et al. [

21] propose a solution for a streetlight consisting of 30 LEDs and a forced air convection system in a closed cooling cycle. The methodology presented by the authors obtains satisfactory results and is indicated as a tool for the evaluation of thermal projects in LED luminaires.

Some studies present an evaluation of LED reliability and the influence of temperature on other parameters, such as Mean Time To Repair (MTTR) and Mean Time Between Failures (MTBF) [

22,

23]. Shailesh et al. [

24] carry out a review of methods for evaluating the reliability of LED luminaires using thermal measurements. The aim of the work is to develop a mathematical thermal model of the LED luminaire and validate it, reducing the need for experimental analysis. The study models the optical, electrical, and thermal properties of the LED luminaire to assess its performance reliability under various environmental and operational conditions. Thermal management of the LED module is one of the key points of the project, Huaiyu et al. [

25] present a review of passive thermal solutions used in LED modules, in which the authors present several thermal interface materials that have a high potential for improving the thermal performance of the module. For commercial LEDs with power consumption below 50 W, the authors report that passive heatsinks are theoretically sufficient for thermal management, with heatpipe technology being the future, due to the advantages of thermal performance, but still at a high monetary cost.

Jakovenko et al. [

26] present thermal simulation of an 8 W commercial LED light bulb using finite element methods. Simulated thermal distribution is validated and a parametric study of materials is carried out to discover the problems that occurred in the heat transfer from the HP-LED to the environment. The intentions are to predict the thermal management by simulation and obtain the effect of the lamp shaping and of materials used, to design more efficient LED lamps. The results obtained agree with the desired objectives, however, improvements in the simulation model and parameters result in a better prediction of the measured temperature values. In luminaire projects, there is a tendency to use HP-LED grouping to obtain sufficient luminous flux for lighting a certain area [

8,

27]. The success of luminaire designs from HP-LED arrays is heavily dependent on thermal management performance, as high operating temperature directly affects light output, quality, reliability, and lifespan.

Luo et al. [

28] analyze the thermal distribution in an 80 W HP-LED luminaire, in which the authors use sixteen thermocouples to measure the temperature at different positions of the luminaire and then use numerical simulation to analyze the temperature distribution on the luminaire’s surface. A numerical model is validated and the results of the thermal resistance analysis show that at a temperature of ≈45

C on the surface of the luminaire, the maximum temperature of the LED crystal junction is equal to the critical temperature of 120

C, which leads to low reliability, shorter lifespan and lower optical efficiency of the luminaire. Christensen e Graham [

29] propose a thermal resistance network model combined with a 3D finite element submodel for the LED structure, in an attempt to predict the temperatures in the LED clusters and the unit chip. Active and passive cooling methods are tested and the impact of LED matrix density and LED power density is evaluated. The conducted analysis suggests the need to use active cooling in luminaires formed by compact HP-LED arrays for operation within the maximum temperature limit of 130

C.

Luo et al. [

30] propose modeling and optimization of the 112 W HP-LED street light heatsink geometry. Experimental results demonstrate that the maximum heatsink temperature remains stable at ≈45

C when the luminaire is at a temperature of 25

C. Comparing the results obtained in the modeling with the results obtained in the experiment, it is observed that the proposed methodology is viable and functional for the case of the horizontal heat sink of HP-LED lamps. Scheepers e Visser [

31] implements the detailed and computationally efficient HP-LED model. The authors use a gradient-based optimization algorithm, known as the DYNAMIC-Q method, which is applied to maximize the luminous flux output by optimizing power dissipation and thermal resistance. In addition to the geometric parameters of the heat sink, such as the amount, thickness, and height of the fins, the electrical operating current is also evaluated. Luminous flux of ≈42% greater than the initial luminous flux is achieved.

Tang et al. [

32] propose 30 W HP-LED luminaire heatsink geometry optimization. The model is simulated and validated through thermocouples and infrared images, showing an error

. Taguchi optimization method is implemented to find optimal values for the amount, width, and thickness of the heatsink fins. Optimized geometry provides weight reduction of ≈33.4% and LED junction temperature reduction from

C to

C. Jeong et al. [

33] develop a method of cooling the heat sink of HP-LED luminaires using fin optimization. The model proposed by the authors introduces openings in the base of the heatsink and the fins, improving air circulation. Response Surface Methodology (RSM) is used to optimize the heatsink geometry and the performance of the proposed model is compared with that of conventional heatsinks. The total thermal resistance of the model is reduced by 30.5% and the luminous efficiency increased by 23.7%. In addition, the financial costs of production are reduced, as the total volume of the model is 30.4% smaller.

Several efforts have carried out thermal studies of LED luminaires, each with its own peculiarity [

19,

21,

25,

26,

28,

29]. There are several methods for optimizing heatsink geometry parameters to reduce the LED junction temperature [

20,

30,

31,

32,

33]. Other studies focus on the photometrical analysis of the HP-LED luminaire, addressing the luminous uniformity on the target plane [

1,

13,

14,

15]. The application of the optimization process in lenses and coupled optical systems is presented in the studies of [

16,

34,

35].

There are several studies indicating prototypes of LED luminaires, in which some use analytical methodology (deterministic methods), others with numerical methodology (based on FEM), and others incipient using heuristic methods. Most methodologies use confined environments (internal environments) and methodologies that work with external environments are also incipient [

36]. There is a need to develop methods that include the new technologies of HP-LED lamps and luminaires applied to the lighting of large areas and outdoor areas. The proper design of an efficient lighting source represents high financial and environmental savings, as the best way to illuminate the intended region is the most economical and self-sustainable. The study that covers simulation by numerical methods, optimization by heuristic and deterministic methods together, and that is carried out for the system in an external environment, justifies this work.

The originality of the present study is the creation of a methodology for optimizing luminaire parameters, focusing on both the luminous and thermal aspects. The novelty of this work lies in the study of the sensitivity analysis of parameters to be applied in the optimization process, seeking to substantiate the importance of the selected parameters in the search for optimal/optimized results. Hence, the application of this new approach is relevant, which can generate cost savings for private and public entities with better specifications of lighting products, producing reasonableness. With the proper specification, HP-LED lighting products tend to have a longer lifespan with proper temperature management and an evenly lit environment prevents both excess and shortage of bright spots. The new technique presented has applicability in lighting areas with greater application in pedestrian and vehicle traffic lighting.

This work aims to develop an optimization methodology for designing HP-LED luminaires that present uniformity in the illuminated area according to references established by standards and adequate thermal management, ensuring luminous flux and valuable life in the nominal standards. The specific objectives are: (i) design a computational model of LED luminaire geometry, (ii) perform thermal and optical analysis through a simulator, and (iii) optimize luminaire geometry and LED matrix arrangement to standardize the lighting on the target plane, keeping the temperature of the LEDs below the maximum allowed values.

This work is structured as follows: in

Section 2 concepts related to theoretical foundations, the basis for understanding, the methodology, and results,

Section 3 describes the work methodology, with the procedures, materials, and methods used. In

Section 4 the results obtained from the application of the proposed methodology are displayed and the conclusions are exposed in

Section 5.

4. Results

In this section, the results obtained from the application of the proposed methodology are presented. First, the main parameters to be used are set out, the results obtained previously in other published works are presented and compared, the optimization process is applied using the new methodology and at the end, the work as a whole is discussed.

4.1. Parameter definition and evaluation function

Given the rectangular luminaire model composed of a matrix array of

HP-LED, optimization algorithms are proposed to find the parameters that define the geometry and power of the luminaire. HP-LED power range used in this work is 5 W. Luminaire is fixed at a height of

= 2 m above the target plane of dimensions 3 m × 3 m. Parameters manipulated in the optimization process are arranged in

Table 1 and restrictions on the search space of each parameter are defined as:

where the value of

in (

6) is dependent on

on (

7). Final evaluation function value in

(

4), was defined for

, chosen empirically in order to give weight between the two components of the final evaluation function. Thus, the final evaluation function

is the combination of

and

in the proportion given by:

To evaluate the optimization process considering the lighting effects, the expression (

2) as a metric to measure the quality of uniformity over the target plane. The new evaluation function is defined as the arithmetic mean of the expression

(

1), applied over six coordinate axes profiles:

,

,

,

,

and

, given by:

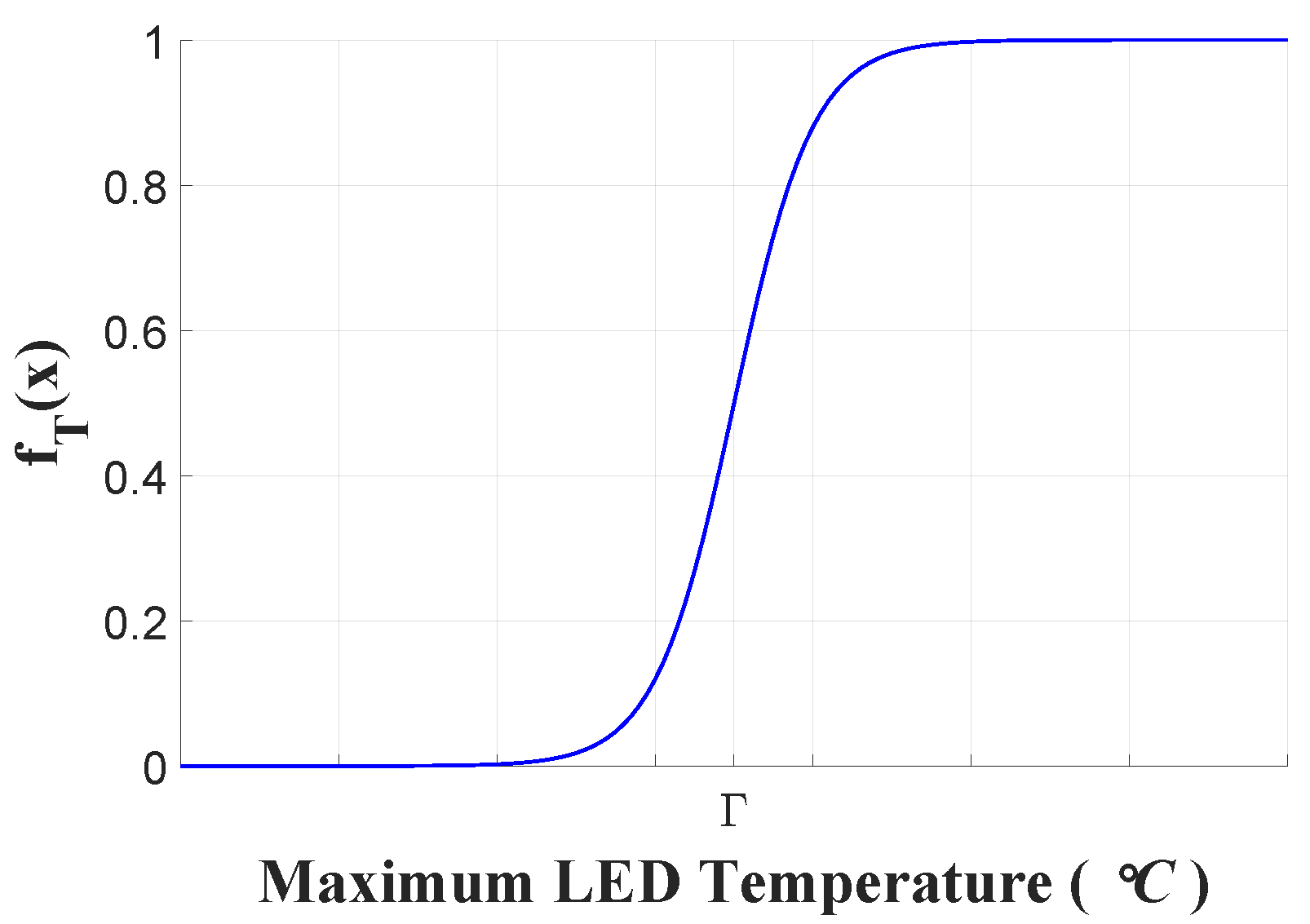

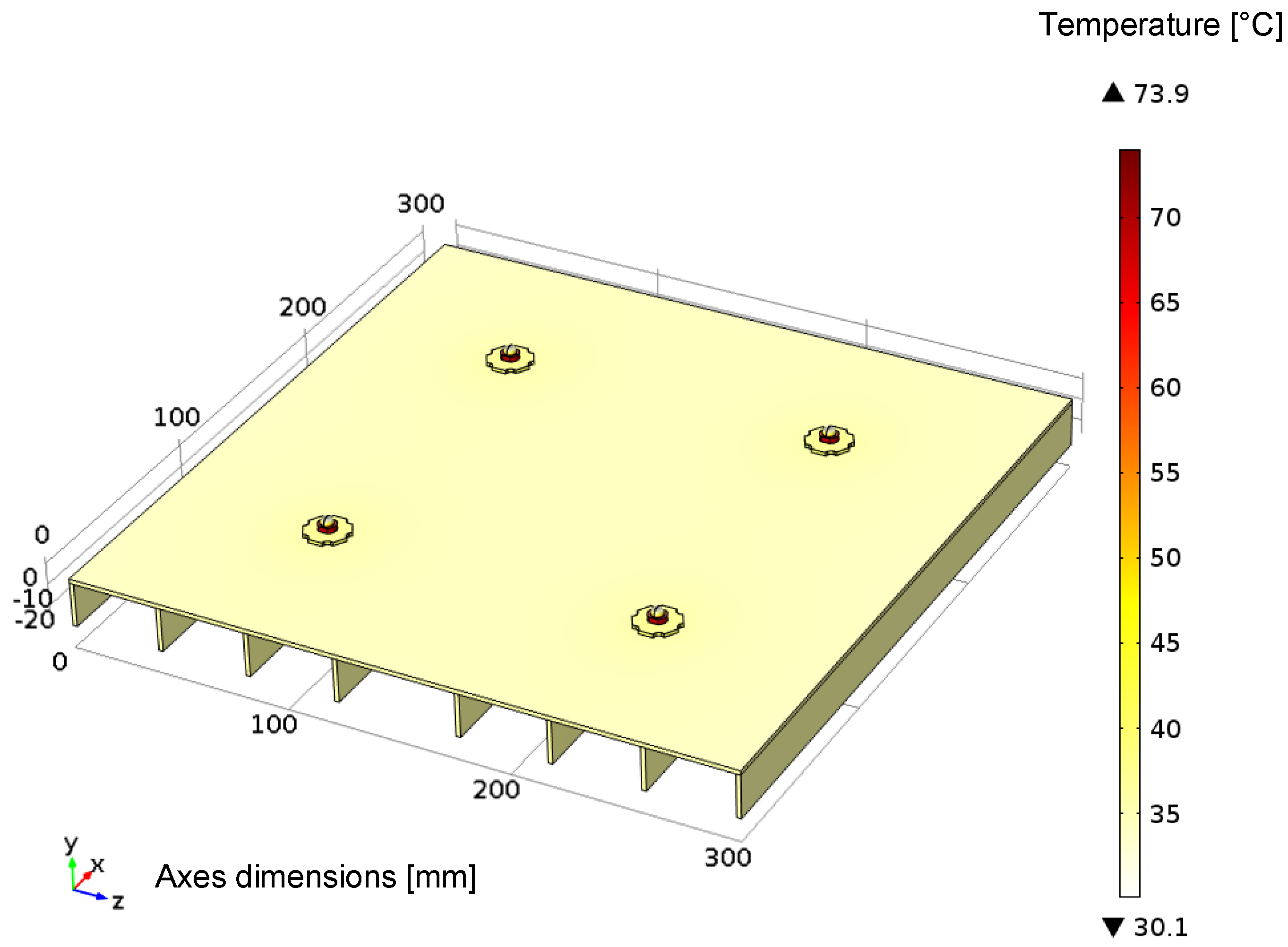

To evaluate the optimization process considering the thermal effects of heat dissipation, the new thermal dissipation evaluation function

is illustrated in

Figure 13 and in this way, the expression (

3) can be rewritten as:

Finite element method (FEM) software COMSOL Multiphysics is used to model the physical laws that describe the heat exchange [

69]. The thermal analysis is performed using the Heat Transfer Solid module from COMSOL.

Table 3 shows the thermal conductivities of the materials used in the model. The mesh element number is increased until it reaches grid independence during the thermal simulation. As the geometry of the luminaire is dynamic, i.e., the heat sink dimensions and the number of LEDs vary, the number of elements in the mesh depends on the geometry of the object being simulated. The boundary condition of the simulation model is defined as a room temperature of 27.2

C, and a heat coefficient value of 5 W/(m

K) is used for heat transfer from the heat sink to air (natural convection).

With regard to photometrical analysis, the HP-LED luminaire model is designed in the optical simulation software ZEMAX-EE Optical Design Program includes a stochastic simulation of about one million light rays emitted by each LED and the extraction of the luminous pattern from the target plane [

70]. The optimization algorithms aim to find the best geometric parameters for the HP-LED luminaire. For each candidate solution, the optimization algorithm runs the first simulator to perform a thermal simulation and then runs the second simulator to perform a ray tracing analysis. The results of the simulations are combined as in (

8).

4.2. Comparison with Previous Results

The methodology proposed in this work implements several improvements when compared to the methodology described in the previous study [

46]. One of them is the addition of a new parameter of the luminaire geometry called

. This newly proposed parameter allows a certain linear sequence of LED sources parallel to the dimension

to tilt at

. Inserting this parameter produces more uniform lighting results, as the sources (LED) are fixed on a flat base with a different slope in each row of LEDs.

Another improvement implemented is the changes defined in the values of geometric constraints for the parameter and that represent respectively the length and width of the heatsink. The value of is increased from 200 mm to 300 mm so that luminaires with a maximum arrangement of LED become thermally viable. Although the lower limiting value of the and parameter is 50 mm in theory, for a LED luminaire there is a geometric limitation so that to position yourself in this amount of LED, a minimum value of and of 150 mm is required. Thus, with the change, the real amplitude of the variation range of parameters and becomes .

A change was implemented in the positioning logic of the heatsink fins, which in the previous work [

46], the number of fins on the heatsink base, defined by the parameter

, has a fixed spacing being positioned from the lateral ends of the heatsink to the central part of it. With the change in logic, the spacing is no longer fixed and becomes dynamic, and symmetrically distributed according to the optimized value of

. In the optimization process of the previous work [

46], a target plane of 4 m × 4 m is used and in the optimization process proposed in this work a target plane of 3 m × 3 m is defined and the value of the font height is increased. The reduction in the dimension of the target plane from 16 m

to 9 m

was performed to better match the standards used in the distance of lighting points. The area of the target plan is empirically defined, as it seeks to develop a methodology to contemplate the analysis of any application of luminaire (for specific analysis, whether internal or external lighting—of pedestrians or motor vehicles—will exist in each case, specific standard to define maximum height and distance between two illuminated points).

The function of evaluating the illuminance uniformity over the target plane has been changed. Unlike the previous methodology that used only one evaluation profile along the

x coordinate axis (in

), it is proposed to use six evaluation profiles, with three evaluation profiles on the

x coordinate axis and three evaluation profiles on the

y coordinate axis. Regarding the thermal dissipation analysis, the empirical expression suggested in the initial methodology [

46] evaluates the maximum LED temperature values obtained in each simulation according to the distance from the value set as desirable. However, some results indicate the value of the evaluation function

is relatively high even for low values of simulated maximum temperature. Thus, even lower-than-desirable temperature values, which can produce optimal solutions, are penalized in the same way as higher-than-desirable temperature values. To solve this problem, the current proposal presents the modification of the thermal dissipation evaluation function

to assume the form of the sigmoid function.

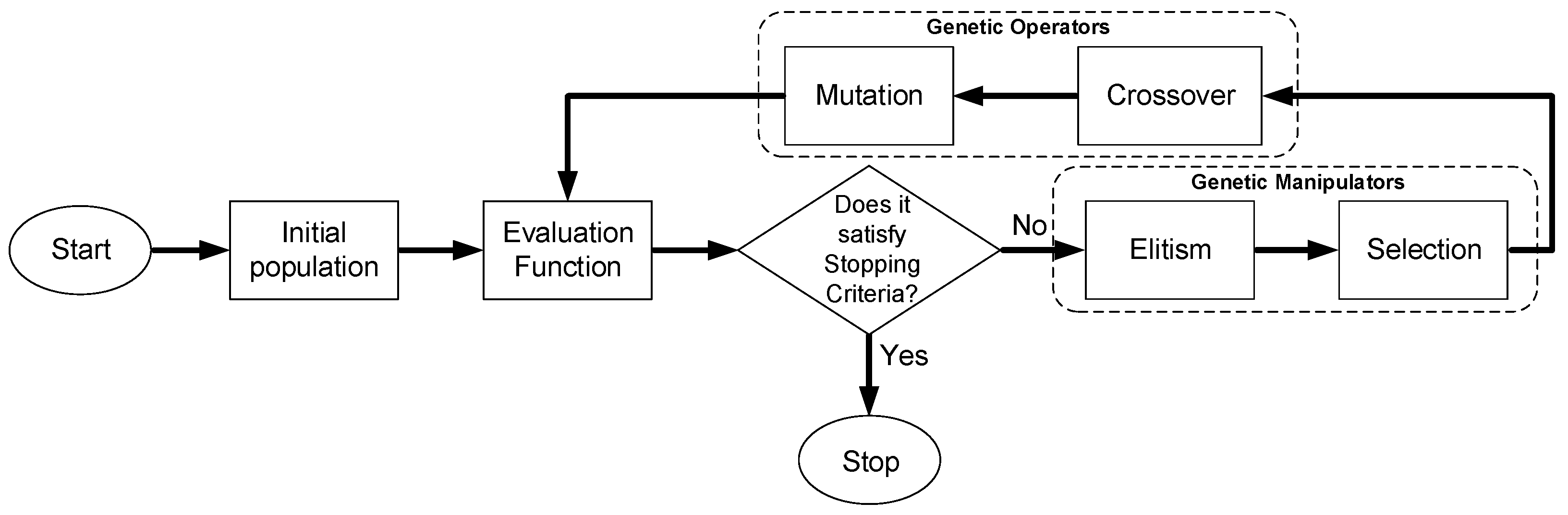

Finally, in this proposal, another heuristic optimization technique is used to expand the analysis and compare other optimization techniques. A genetic algorithm with real coding (GARC) is used, consisting of the characteristics: (i) tournament selection with

, (ii) simple crossover operator, and (iii) evolutionary mutation operator with 1/5 rule success. In possession of both results, the methodology proposed in this work and previous studies [

46], the respective solutions are compared, reassessing/simulating them with all the proposed modifications. The illuminance distribution curves of the three profiles on the

x and

y coordinate axes are shown in

Figure 14,

Figure 15,

Figure 16 and

Figure 17.

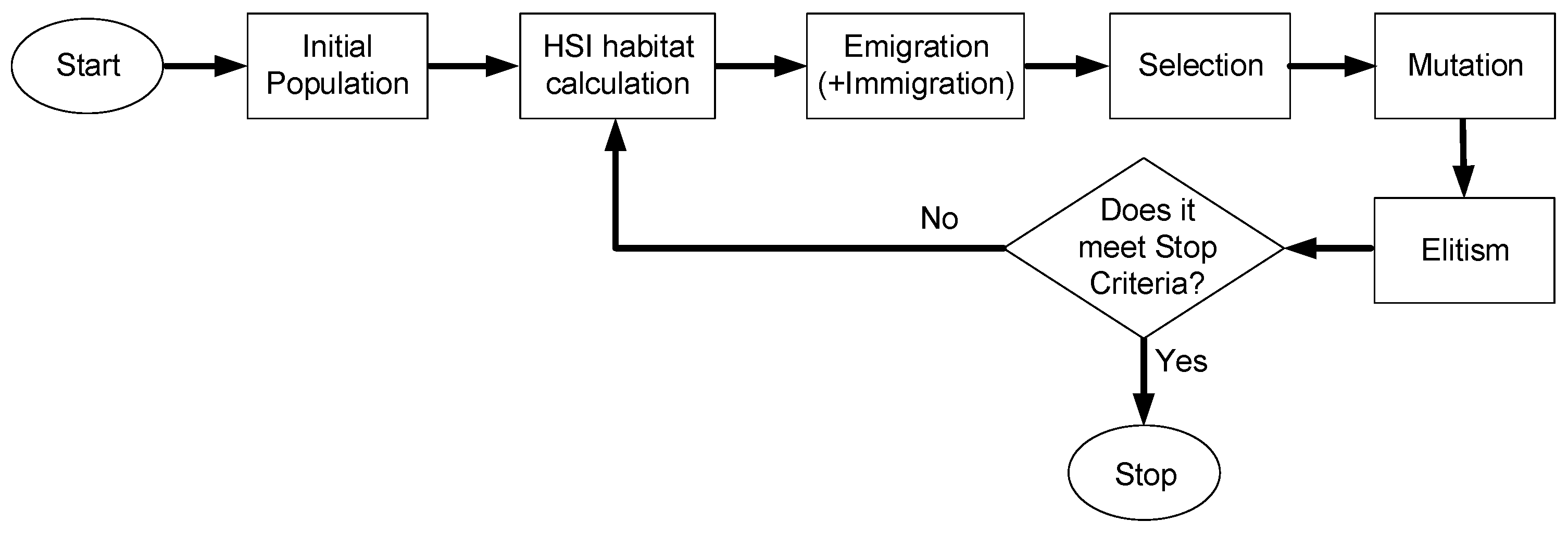

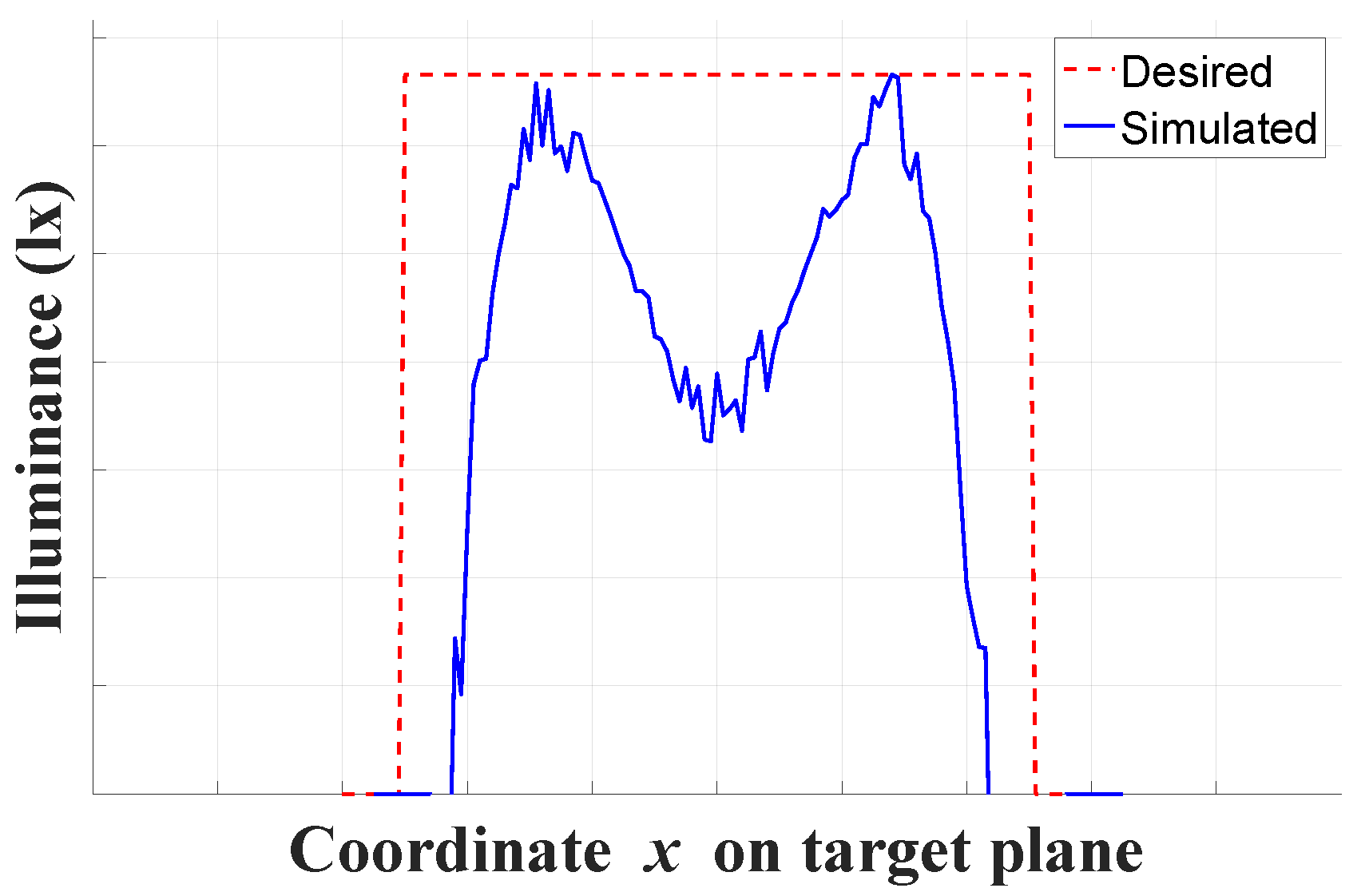

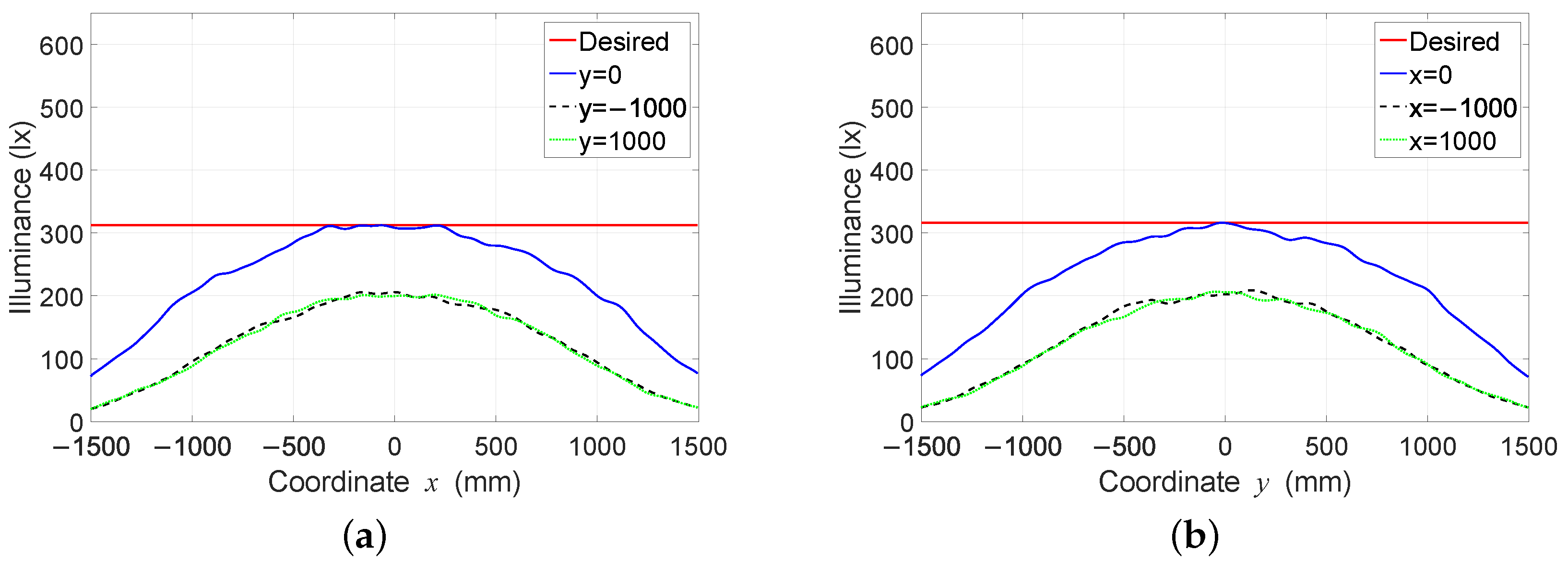

Figure 14a,b represent the illuminance on the target plane using the six verification profiles. This result is obtained by the solution found through the Quasi-Newton optimization technique in [

46]. In this case, the optimized luminaire is composed of an array of

HP-LED.

Figure 15a,b are obtained by the optimized solution using the Nelder-Mead optimization technique, with an array of

HP-LED. Comparing

Figure 14 with

Figure 15 there is an increase

lx in the peak of illuminance obtained by the Nelder-Mead method, which possibly occurred due to the greater amount of LED.

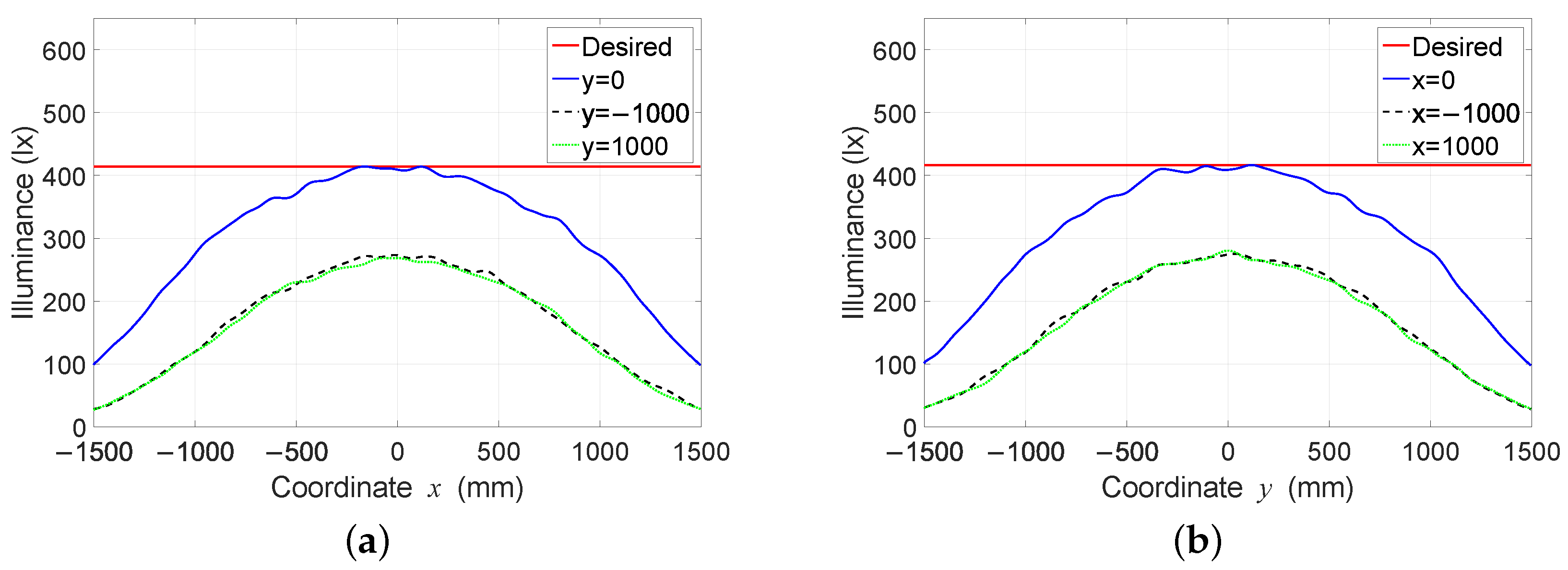

Figure 16a,b are results of the illuminance on the target plane obtained by the optimized luminaire using the BBO optimization technique with an array of

HP-LED. Comparing the

Figure 16 with

Figure 15 it is possible to observe that there was a reduction in the illuminance peak in

lx which is justified by the reduction in the number of HP-LEDs in the optimized arrangement. Thus, each pair of LEDs removed produces a

lx reduction in the maximum illuminance value.

Figure 17a,b represent the illuminance on the target plane of luminaire optimized through the genetic algorithm technique and reflects the result for the optimized arrangement of

HP-LED. It is observed that there are no differences in the peak values of illuminance between the results in

Figure 16 with

Figure 17 obtained through the two heuristic techniques.

Each optimization method was simulated twice, once for the old evaluation function, published in [

46] and another for the new evaluation function given by (

8). To perform the comparison between the evaluation functions, the parameter

was considered in the evaluation function in (

8). The values of

obtained through the new evaluation function in (

8) and those obtained from the old evaluation function [

46] are arranged in the

Table 4. It is observed that in relation to the heuristic algorithms (genetic algorithm and BBO) the values found are the same and present a reduction of 50% in relation to the results of the deterministic algorithms. While in the old evaluation function [

46] the genetic algorithm presents an approximate value to that of the BBO algorithm, due to the new evaluation function in (

8), both reach the same value. On the other hand, the deterministic algorithms, in both evaluation functions, produce worse results than the heuristic algorithms, however, the solution obtained by the Nelder-Mead algorithm produces a better solution than the Quasi-Newton algorithm, when applying the new evaluation function.

The uniformity index

U is calculated between two adjacent luminaires with the best case of

. Standards require specific values depending on each environment, purpose, and pedestrian and vehicle traffic. For external lighting cases, it is required

. To measure the uniformity in the same luminaire, which is in addition to what is required by the standards, the uniformity index is computed for each case. Minimum and average illuminance are extracted to calculate the uniformity. They are obtained through the illuminance distribution curves of the three profiles on the coordinate axes

x and

y, generated in the simulation of a model parameterized by the proposed solution of the four optimization algorithms. The summary of these results, together with the values of minimum illuminance and average illuminance found, are displayed in

Table 5.

In

Table 5 it is observed that the average of the minimum illuminance found in the best results of the four algorithms was

lx. In the case of the Nelder-Mead algorithm, the minimum illuminance is ≈50% greater than the mean illuminance, however, an increase in the mean illuminance value is also observed. Thus, the result of the ratio between the minimum value and the average value does not change. Therefore, the value of the uniformity index found for the four algorithms is approximately

and the uniformity calculation method is unable to differentiate how uniform the illuminance is in the target plane for different lighting solutions. The initially proposed method of the evaluation function on a profile in [

46], produces different results for each geometry obtained, as shown in

Table 4.

4.3. Optimization Results Applying the New Methodology

To finalize the proposed methodology, the optimization process is performed considering all the changes proposed in this work, including the

parameter. The question to be answered is whether it is possible to obtain different and better results than the methodology adopted in Barbosa [

46]. A summary of these results is displayed in

Table 6, in which for each optimization algorithm technique applied, the value of the evaluation function

is presented, the uniformity index

U and the values of the six optimized luminaire geometry parameters.

In

Table 6, it is observed that the solution found by the deterministic algorithms Quasi-Newton and Nelder-Mead obtained values of the

better with the addition of the parameter

, with a reduction of

and

, respectively. Comparing the heuristic algorithms, a reduction of ≈50% in the value of

. In relation to the uniformity index, an increase was observed for all cases, which represents better results than those previously published in Barbosa [

46]. It is verified that the genetic algorithm presented the best result among all the methods used for the optimization of the rectangular luminaire with

HP-LED.

Figure 18 shows the evolution of the value of

across generations. The optimization was limited to ten generations with a population of 42 individuals. The computational time required to obtain the optimized solution was ≈54 h using a machine with an Intel Xeon 3.5Ghz board with twelve physical processors and 32 GB of RAM.

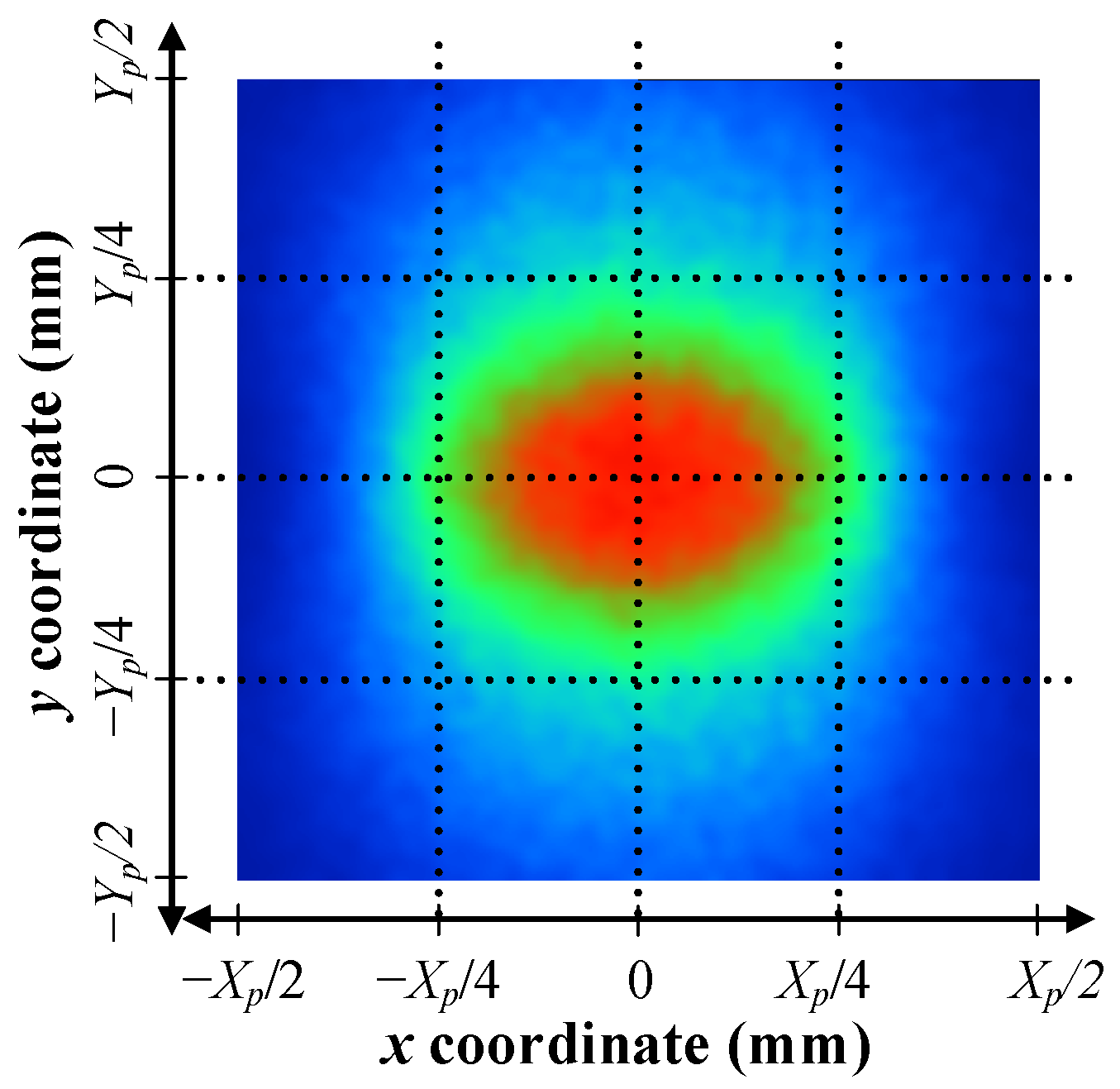

The optimized solution obtained proposes the design of a rectangular luminaire with an arrangement of

HP-LED.

Figure 19 presents the result of the optimized design of the HP-LED luminaire, as well as the heat distribution in a steady state. It is possible to see that the LED body is more reddish (warmer), representing higher temperatures. LED temperature in the simulation reaches a maximum value of

C in a steady state, which is desired since temperatures above 120

C may damage the HP-LEDs.

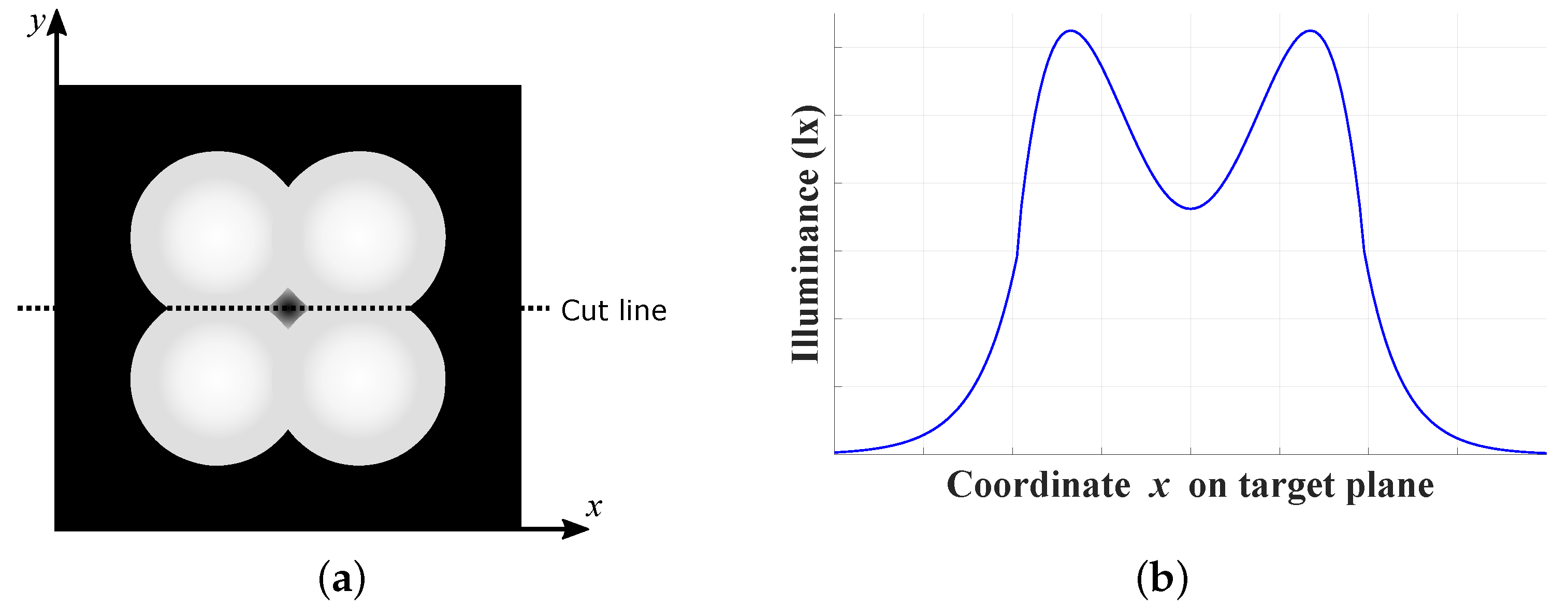

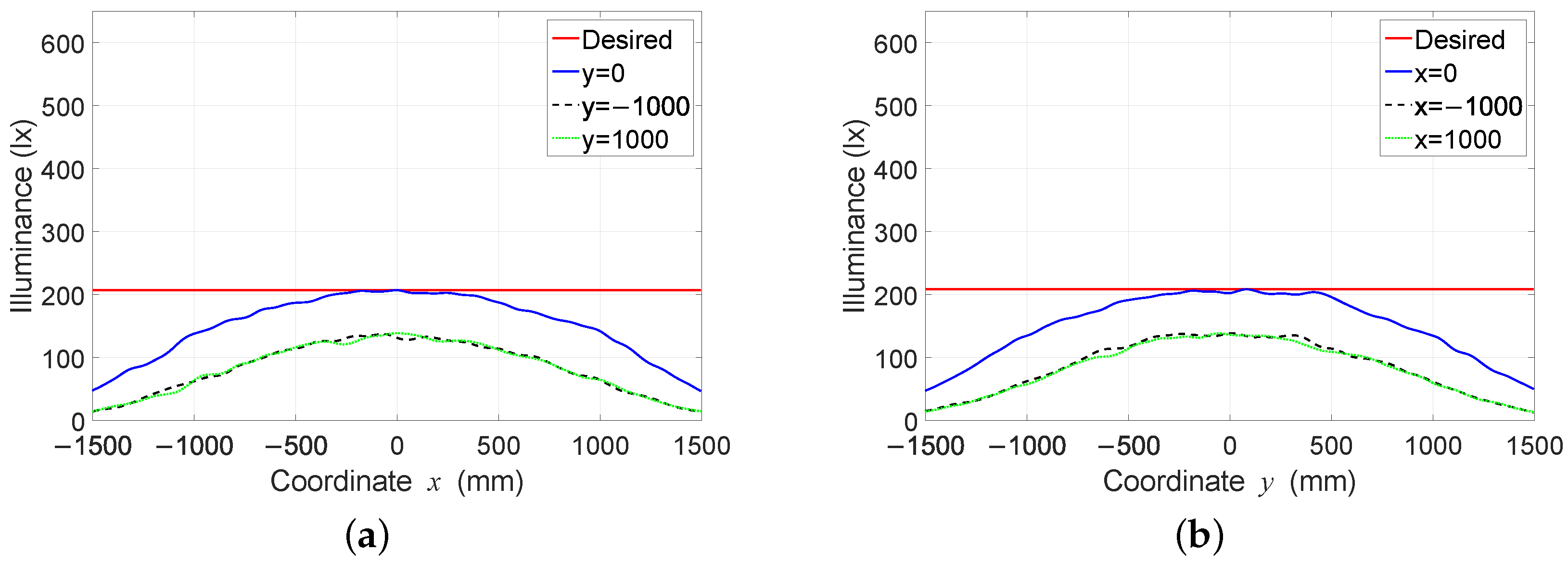

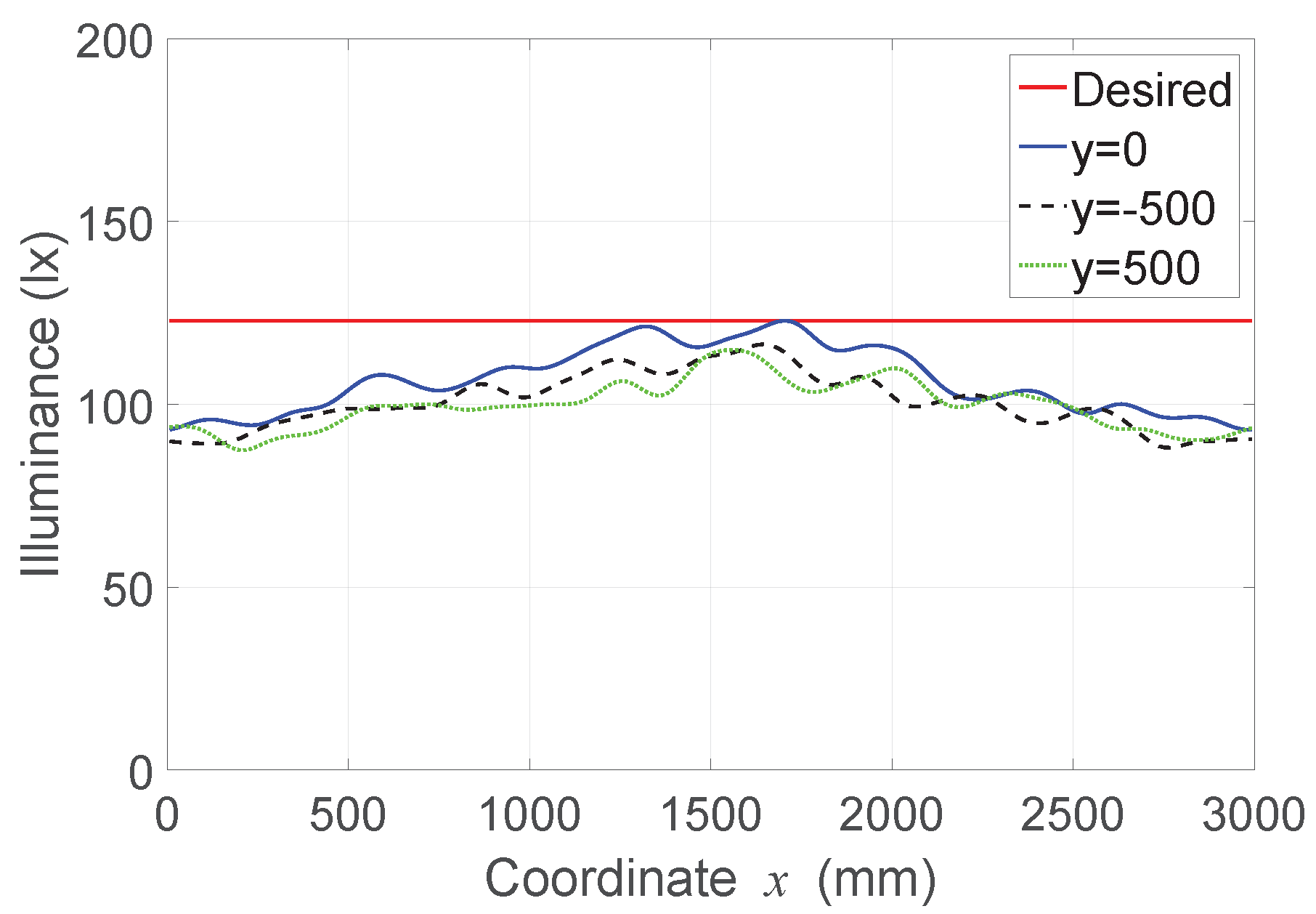

Figure 20a presents the illuminance distribution curves for the GA-optimized solution on the coordinate axis

x and

Figure 20b on the coordinate axis

y. To calculate the uniformity index, the lowest illuminance value in the six axes is found and the average illuminance value among all the values of the set is calculated.

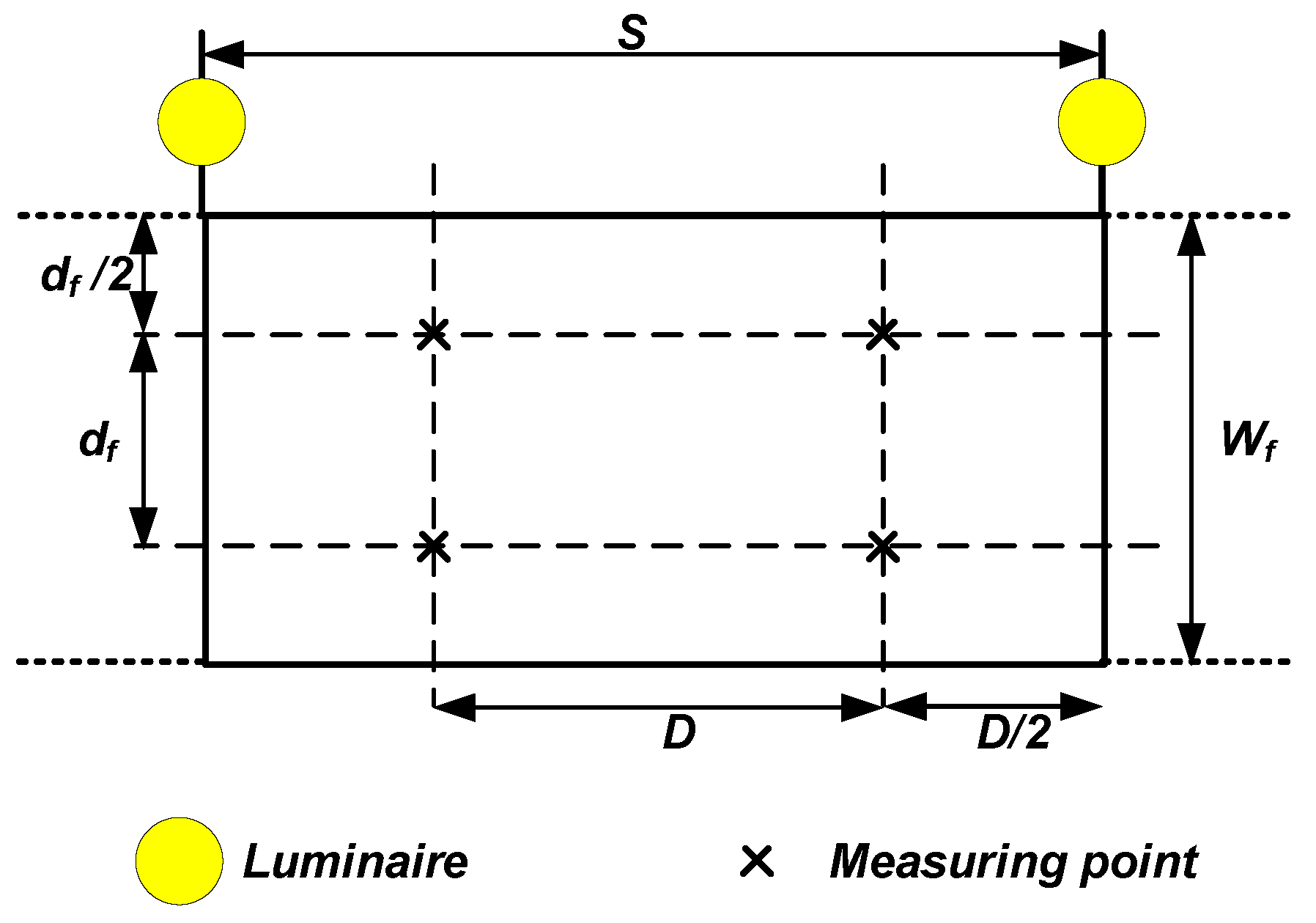

International standards establish a mesh of points on the target plane to measure uniformity in the lighting of external and internal environments. For work environments, it is recommended to measure the illuminance between nine and 36 points on the mesh. For public pedestrian or vehicular traffic lighting, a mesh is established consisting of fifteen measuring points arranged between two axes of luminaires. Another point that must be obeyed is the minimum horizontal illuminance value for each case and application. For the purpose of testing the validation of the results of the proposed methodology, the application of the luminaire for external area lighting is chosen, but precisely for the pedestrian way, with a sidewalk of

m wide, distant sources of

m, with axes located at the ends of the target plane. The lighting sources are suspended by 3 m high poles and a 1 m extension arm, so that they are centered under the road. With this perspective, the target plane illuminance distribution by two adjacent HP-LED optimized luminaires is analyzed.

Figure 21 presents the illuminance distribution curves of the three profiles across the path (coordinate axis

x) for the solution by genetic algorithm.

The overall uniformity index found is , with a minimum illuminance of lx, a maximum illuminance of lx and an average illuminance of lx. Standard EN 13201-2:2015, recommends average horizontal illuminance of 15 lx and minimum of 3 lx for the P1 (most critical) pedestrian street class. In this case, the minimum horizontal uniformity should be . Therefore, the values obtained by the optimized luminaire meet the standard EN 13201-2:2015, and consequently other standards that were derived from it.

4.4. Discussion

Electricity demand is growing at a faster rate than the electricity production capacity. Energy efficiency in lighting not only reduces the gap between demand and production, but also includes other benefits such as the reduction of CO emitted in the process of energy consumption and thus helps to preserve the environment. HP-LEDs have emerged as an efficient and energy-efficient lighting alternative. Some of the technical challenges associated with using HP-LEDs are addressed in this document.

This work proposes to develop an optimization methodology for high-power LED luminaire projects that consider both thermal safety and luminous efficiency aspects. The evaluation function was developed in two parts, one considering the thermal study and the other considering the light study. In the light study, six uniformity evaluation profiles were proposed, three on the horizontal axis and three on the vertical axis that makes up the metric developed to position the solutions obtained. The optimized solution obtained by the genetic algorithm managed to obtain uniformity and illuminance index values higher than the minimum values recommended by the standards used.

In the proposed work, HP-LED lifespan is considered as indicated by the manufacturer, as long as the nominal specifications are maintained. This lifetime refers to the individual light source only and not to the entire luminaire. In the optimization process, the HP-LED lifespan was not taken into account, but rather the maintenance of the nominal specifications described by the manufacturer. If the nominal specifications are guaranteed, then the estimated lifespan is guaranteed.

As the market demands that LEDs have high brightness and small size, there is a contradiction between power density and operating temperature [

30]. Thus, the P-N junction temperature of the HP-LED is directly related to the operating temperature of the lighting device. HP-LED lifespan is associated with their operating temperature and can be drastically reduced under high temperatures, which can even lead to permanent partial degradation or even total degradation. The thermal management challenge is to conduct heat from the LED chip to the environment at a sufficient heat transfer rate. The LED junction temperature is estimated through some techniques such as (i) from the LED module temperature and the LED junction thermal resistance, obtained from the manufacturer’s datasheet, (ii) through the derivation of the changes from the direct voltage on the component, and (iii) through direct measurements of the LED temperature via thermocouple sensor or infrared images [

71,

72]. Thus, the proposed methodology does not calculate the thermal uniformity of the LED junction temperature but limits the HP-LED temperature to a maximum value in the evaluation function. In the thermal simulation, it is possible to obtain the temperature value at the center of the LED and the thermal simulator was validated by a thermal camera.

Outdoor lighting is an extremely broad topic, covering roads, highways, tunnel lighting, traffic signs, parking, squares, sidewalks, paths dedicated to pedestrians, and others. Tomczuk’s et al. [

73] work proposed unique lighting indexes for crosswalks as a reference. Five lighting classes are created, in which the recommended average horizontal illuminance ranges from 15 lx to 75 lx and the uniformity index is equal to

for all classes. The need for new classes arises to fill the deficiency of the metrics normally used as references for a wide range of applications. The present work can be adapted for crosswalk applications, being a potential tool for comparing commercially existing solutions with projects obtained through optimized solutions.

Studies conducted by Boyce et al. [

74] take into account the lighting of car parking lots in the USA and present a method for classifying safety and identifying the ideal illuminance. The results given suggest that the approximate average horizontal illuminance of 30 lx in a parking lot or sidewalk provides sufficient light to ensure safety perceptions. The initial results obtained in the present work indicate that the optimized luminaire design, in addition to meeting the minimum references presented in the standards, also meets specific studies such as the Boyce study et al. [

74].

Wang et al. [

14] presented numerical simulation results for average illuminance of

lx and total uniformity of

. The proposed 80 W streetlight is comprised of a 5 W and 3 W LED combination in a target plan of 20 m × 10 m and a height of 8 m. The application of the luminaire is for secondary roads and no thermal analysis is performed on it. The analyzes presented in the present work are broader, contemplating both the light analysis and the thermal analysis. In this proposal, application-specific parameters can be adjusted for motorized roads.

Lo et al. [

13] presented numerical simulation results for average illuminance of 14 lx and total uniformity of

. The proposed street light is 120 W composed of two LEDs clustered in a target plane of 30 m × 10 m and a height of 10 m. A similar study presented by Bender et al. [

15] simulated in an 80 W luminaire with 30 LEDs achieved average illuminance results of 7 lx and total uniformity of

. Both studies are about applications on motorized roads and in both cases, lenses are used as an additional resource to the luminaire. In the first case, the values reached by the solution are too high due to the type of LED solution presented. In the present work, it appears that it is possible to achieve satisfactory results with lower financial and energy costs.

In the literature, most works focusing on illuminance and luminance indices talk about highways and crosswalks or cycle paths. There are few works that report studies and improvements in illuminance and luminance levels in pedestrian-only streets and promote the construction of a new metric to measure these indices. The present work innovates in creating a tool that allows the verification of uniformity for individual luminaires on the target plane. The widely used metrics only take into account the ratio between the minimum and average illuminance. The metric developed in this proposal is capable of evaluating lighting criteria and nominal thermal limitation criteria. In previous works published by the authors, both thermal and lighting simulations were validated by practical experiments. The present work presents an improvement in the optimization methodology and adds a new optimization technique for comparative effects.

5. Conclusions

The objective of this work was to develop an optimization methodology for the design of HP-LED luminaires that presented uniformity on the target plane according to references established by standards and adequate thermal management, ensuring luminous flux and useful life in the nominal standards of LEDs. A computational model of the geometry of the LED luminaire was also designed, thermal and optical analyzes were carried out through a simulator, and the luminaire geometry and the arrangement of the LED matrix were optimized, keeping the LED temperature below the maximum allowed values. In the proposal, the design of the luminaire can be used for internal or external lighting and can be applied in both cases with the necessary adaptations.

The process of optimizing HP-LED luminaire parameters is proposed and the tests are restricted to some heatsink designs and the LED array design. Optical accessories and cooling systems are not used in the optimization process, in an attempt to obtain a low-cost project. The results obtained are satisfactory when the values are compared with the standards. The proposed optimization process presented different luminaire geometries capable of improving the uniformity of the illuminance distribution on the target plane, without ceasing to be a thermally viable solution. In the results obtained, despite the deterministic methods reaching viable solutions, it was observed that they are strongly dependent on the seed. The heuristic methods achieved better performance with a lower amount of HP-LED, implying a lower initial and long-term financial cost, due to lower energy consumption.

The solution presented in this work was the best obtained, being able to compete with commercial models already existing in the market, however, adjustments are necessary for the domain restrictions initially defined. The luminaires currently sold do not have a lifetime study, maximum working temperature, or about luminous uniformity on the target plane. The methodology can be reproduced for the design of luminaires with a specific application, whether for internal or external environments, such as pedestrian circulation or vehicle traffic. To do so, the design domain constraints must be expanded and the simulation parameters defined according to the application, such as the height of the required lighting point.

Therefore, it is concluded that the metric currently used, which only considers the ratio between the minimum and average illuminance, is not efficient and cannot distinguish between different patterns of luminaire geometry which one has better uniformity in the distribution of the luminous flux. The metric developed in this proposal is capable of evaluating lighting criteria and nominal criteria for thermal limitation, even managing to classify different types of luminaires. For applications on roads with vehicular traffic, it should be considered that the recommendations on lighting quality defined in international standards also take into account luminance uniformity. The illuminance uniformity evaluates the brightness of the luminaire over a given region, while the luminance uniformity evaluates the brightness seen by the driver in the same region. Therefore, the evaluation of luminance uniformity is also necessary on roads with vehicular traffic.

Future research may include the construction of a prototype of the optimized solution found in this work with practical tests to validate the results obtained. It is also suggested the inclusion of new parameters for the luminaire design, such as those related to auxiliary optics to produce other desired lighting patterns in the target plane. Another suggestion would be to include in the evaluation function the verification of other requirements such as energy consumption of the luminaire, and total illuminance, among others.