Shades of Green: Life Cycle Assessment of a Novel Small-Scale Vertical Axis Wind Turbine Tree

Abstract

1. Introduction

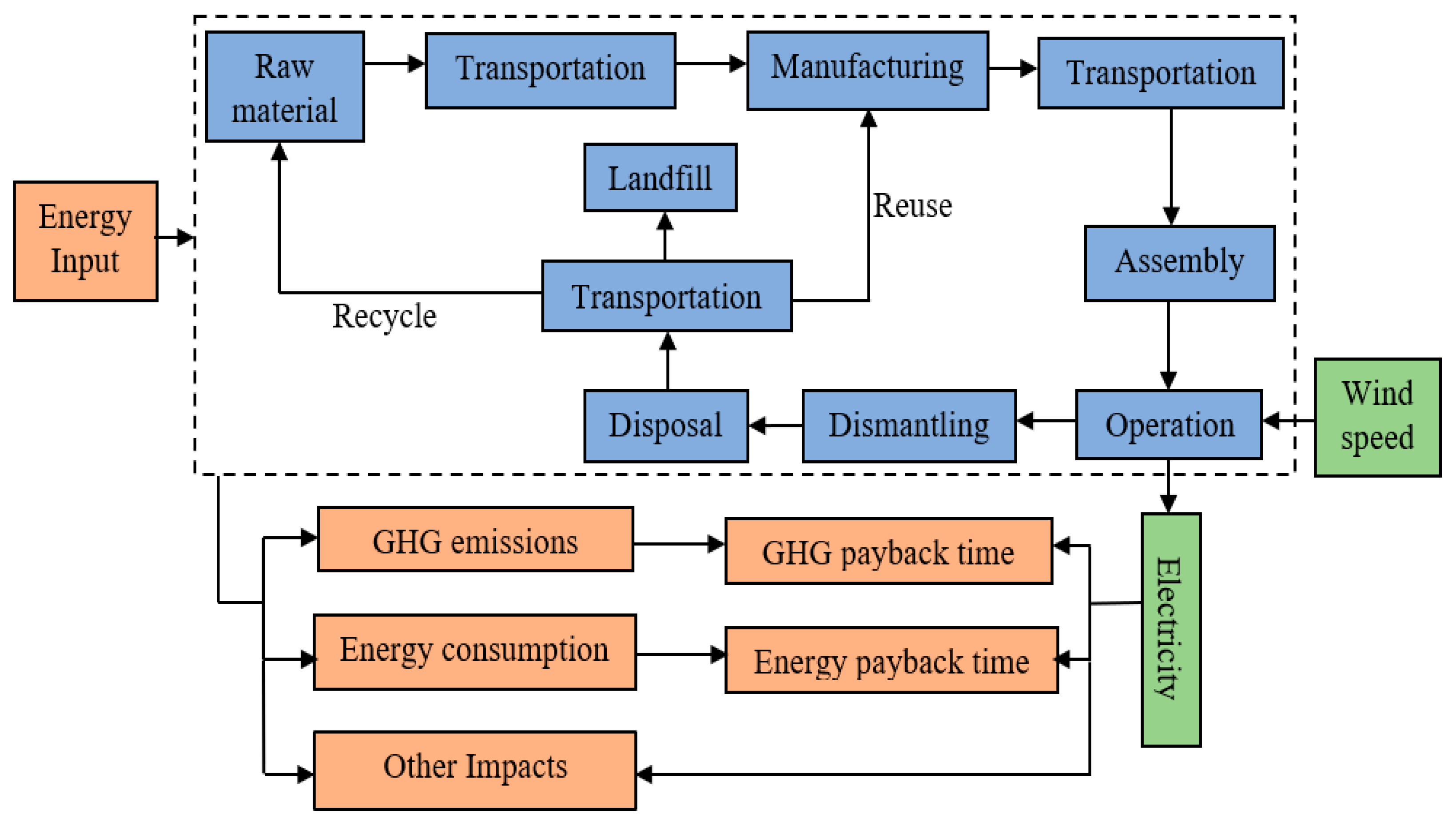

2. Materials and Methods

- Determination of goals and scope (see Section 2.1 below);

- Inventory analysis (see Section 2.2 below);

2.1. Goals and Scope

2.1.1. Goals

- How do environmental impacts of the VAWT tree at the lower-wind-speed location of Surat Thani and the higher-wind-speed location of Chiang Mai compare with impacts from the Thai grid mix when assessed with and without an end-of-life option?

- Which component materials of the VAWT tree contribute most to impacts?

- What are the energy and greenhouse gas (GHG) payback times at the lower-wind-speed location and the higher-wind-speed location?

- If the impacts of the VAWT tree are compared with each other using a common basis of comparison, which impacts are most significant?

- To mitigate important impacts, which change in life cycle aspect would reduce impacts most: transportation, design, or materials? How do these life cycle changes compare with alterations to impacts which result from location change?

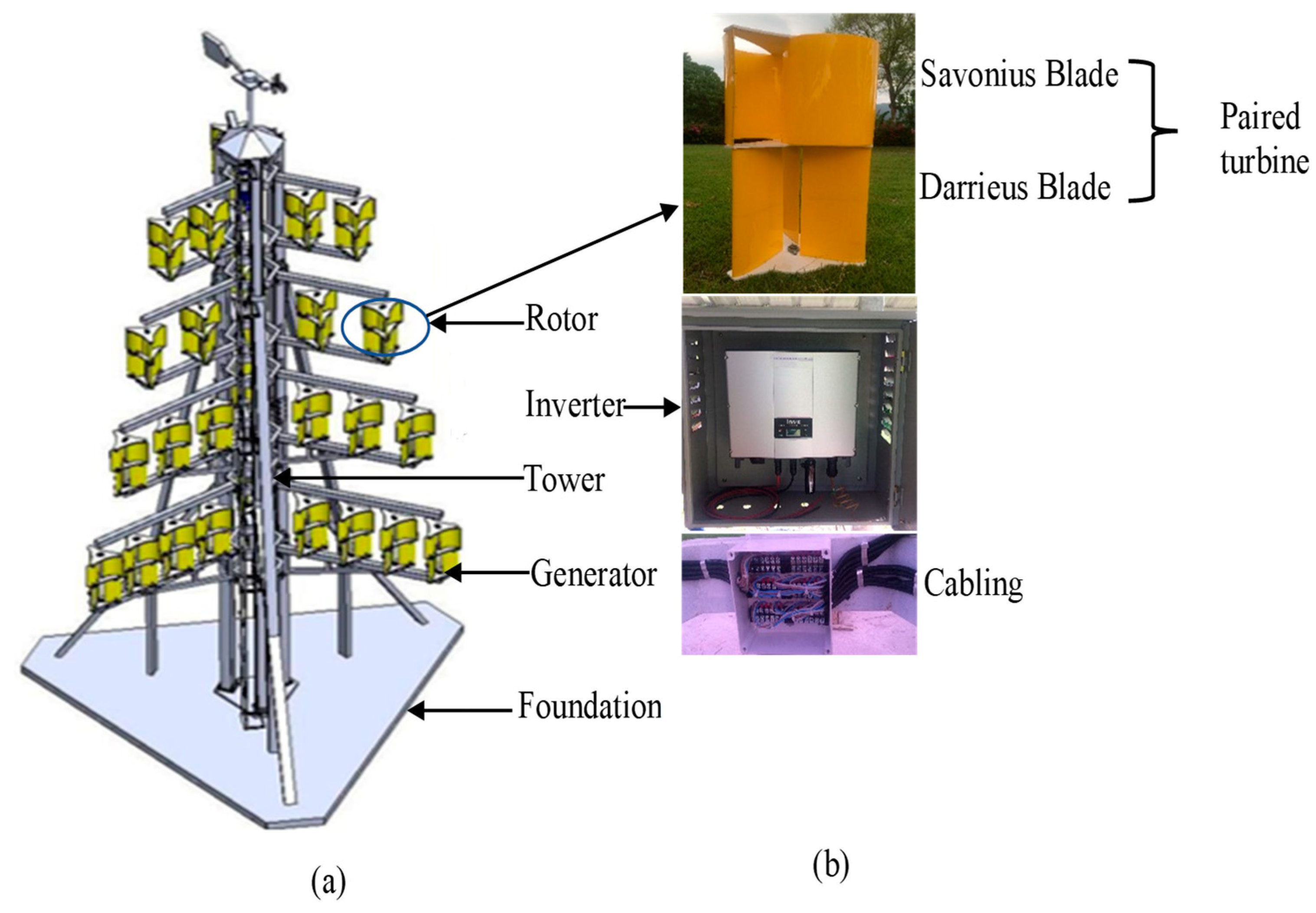

2.1.2. Scope

2.2. Life Cycle Inventory

2.2.1. Raw Material Acquisition and Manufacturing

2.2.2. Operation and Maintenance

2.2.3. Transport

2.2.4. Disposal and Recycling

2.2.5. Turbine Performance and Wind Speed

2.2.6. Thailand Electrical Grid Mix

2.3. Life Cycle Impact Assessment (LCIA) Methods

2.3.1. CML-IA Baseline 2000 V3.05 Method

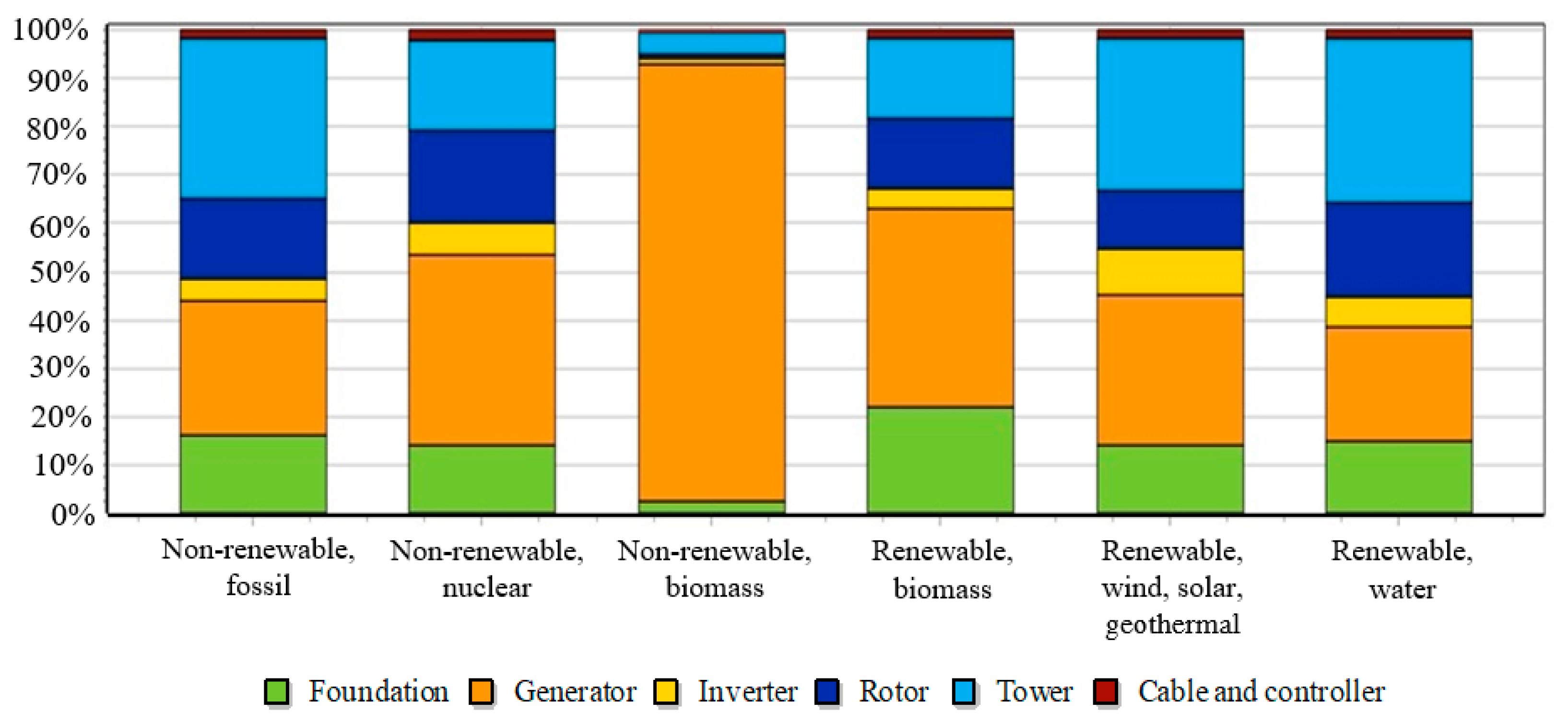

2.3.2. Cumulative Energy Demand (CED): Energy, GHG Payback Times and Component Contribution

2.3.3. Comparative Analyses

2.3.3.1. Environmental Prices of Impacts

2.3.3.2. Comparative Analysis of Three Scenarios on Four Impact Areas

3. Results

3.1. CML Base Case Analysis

3.1.1. CML Impacts per kWh for Scenarios A and B and Thailand Energy Mix

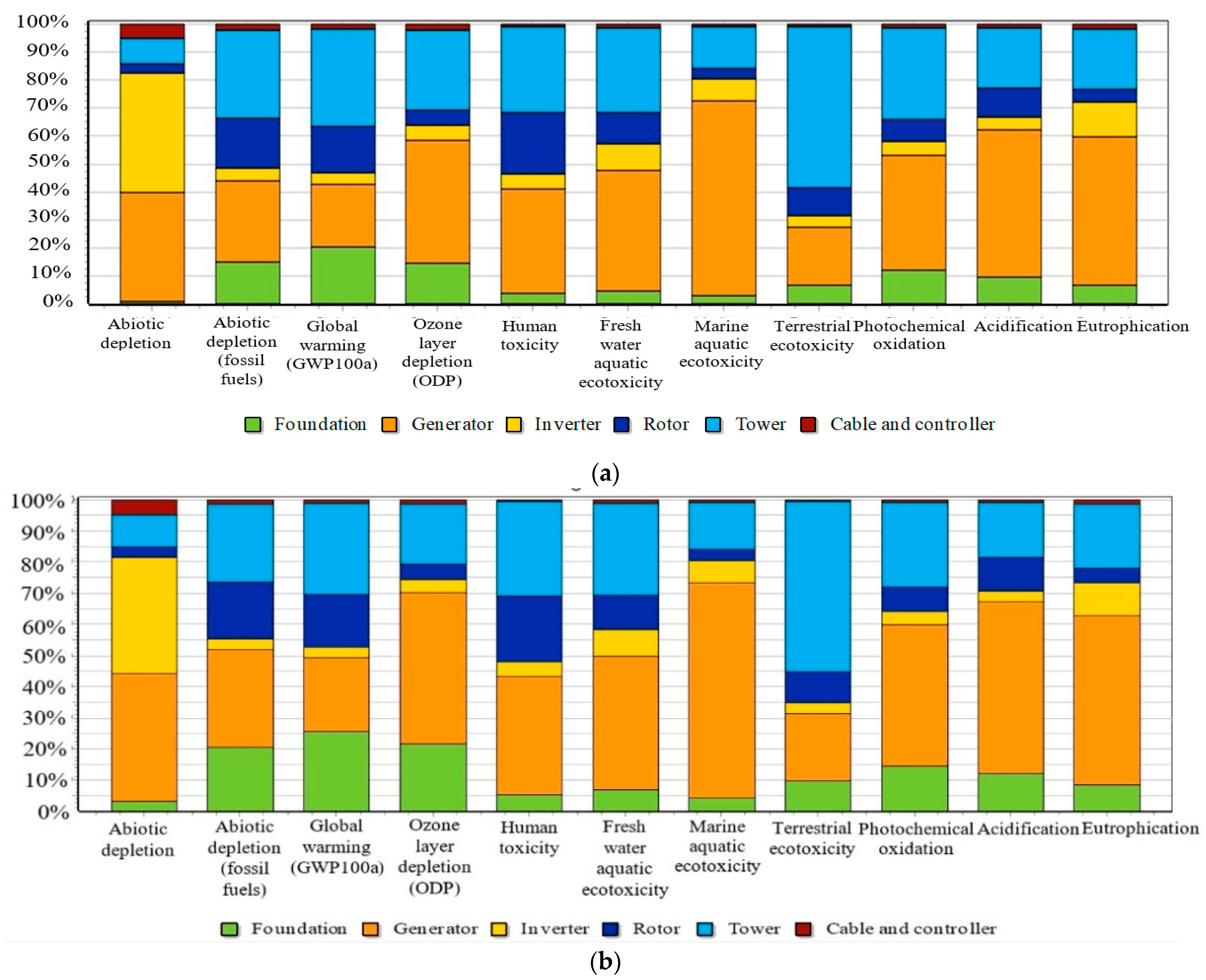

3.1.2. Analysis of Component Contribution

3.1.3. Cumulative Energy Demand (CED): Energy, GHG Payback Times and Component Contribution Results

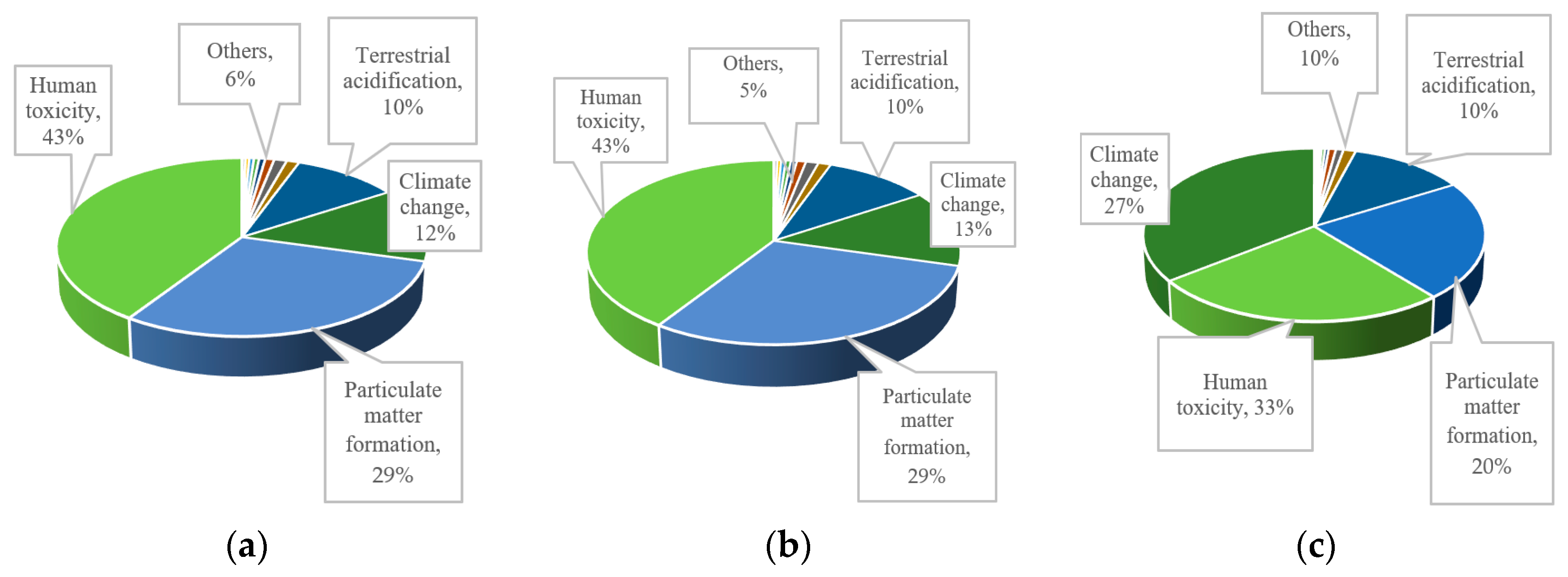

3.2. Environmental Prices Analysis Results

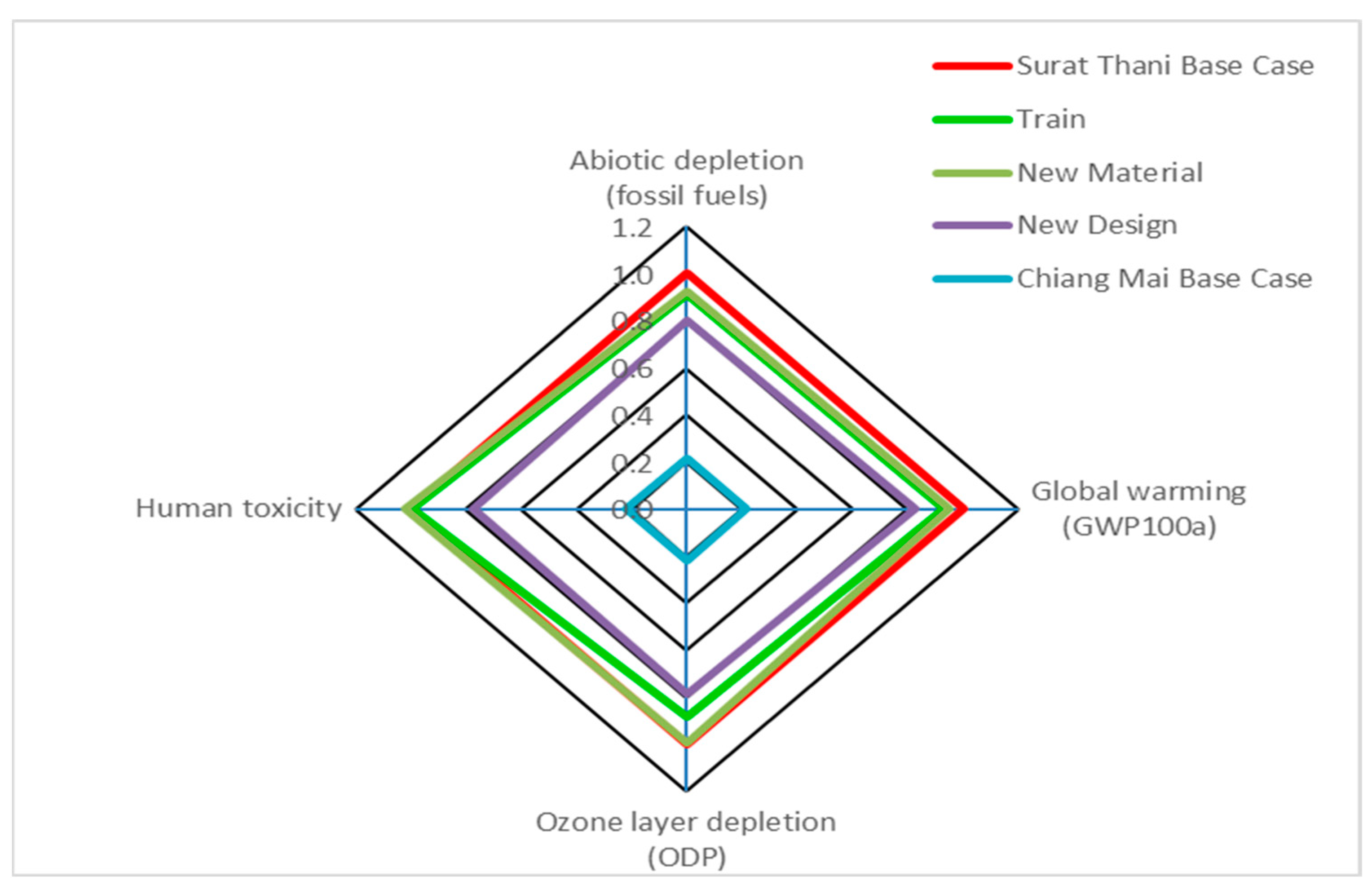

3.3. Results Comparing Three Mitigative Scenarios vs. Location Change

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Characteristic | Measure |

|---|---|

| Rated power (kW) | 10 |

| Rotor diameter (m) | 0.72 |

| Height of Darrieus blades (m) | 0.45 |

| Height of Savonius blades (m) | 0.6 |

| Cut-in speed (m/s) | 2.0 |

| Cut-out speed (m/s) | 15.0 |

| Rated power (kW) | 10 |

| Subcomponents | Raw Material/Ecoinvent Database | Quantity (kg) |

|---|---|---|

| Blades | Glass-fibre-reinforced plastic, polyamide, injection moulded {GLO}|market for|APOS, U | 172.8 |

| Hub | Glass-fibre-reinforced plastic, polyamide, injection moulded {GLO}|market for|APOS, U | 105.6 |

| Bearing | Steel, chromium steel 18/8 {GLO}|market for|APOS, U | 6.4 |

| Screw | Steel, chromium steel 18/8 {GLO}|market for|APOS, U | 0.26 |

| Shaft | Steel, chromium steel 18/8 {GLO}|market for|APOS, U | 160.32 |

| Stick | Steel, chromium steel 18/8 {GLO}|market for|APOS, U | 19.2 |

| Subcomponents | Raw Material/Ecoinvent Database | Quantity (kg) |

|---|---|---|

| Generator | Permanent magnet, for electric motor {GLO}|production|APOS, U | 76.8 |

| Stator | Copper {GLO}|market for|APOS, U | 144 |

| Glass-fibre-reinforced plastic, polyester resin, hand lay-up {GLO}|market for|APOS, U | 96 |

| Subcomponents | Raw Material/Ecoinvent Database | Quantity (kg) |

|---|---|---|

| Tower | Steel, low-alloyed {GLO}|market for|APOS, U | 2849.43 |

| Welding | Welding, arc, steel {GLO}|market for|APOS, U | 20 |

| Paint | Acrylic varnish, without water, in 87.5% solution state {GLO}|market for|APOS, U | 25 |

| Subcomponents | Raw Material/Ecoinvent Database | Quantity (kg) |

|---|---|---|

| Reinforcement | Reinforcing steel {GLO}|market for|APOS, U | 629.83 |

| Concrete base | Concrete block {GLO}|market for|APOS, U | 27,600 |

| Subcomponents | Raw Material/Ecoinvent Database | Quantity (kg) |

|---|---|---|

| Cable | Copper wire, technology mix, consumption mix, at plant, cross Section 1 mm2 (duplicate) EU-15 S | 138.6 |

| Inverter | Simplified process | 15 |

| Aluminium alloy, AlLi {GLO}|market for|APOS, U | 7.64 | |

| Copper {GLO}|market for|APOS, U | 3.06 | |

| Steel, low-alloyed {GLO}|market for|APOS, U | 1.45 | |

| Electronics | 2.82 | |

| Controller | Electronics, for control units {GLO}| market for|APOS, U | 3 |

| Journey | Material/Ecoinvent Record | Distance (km) | |

|---|---|---|---|

| Surat Thani | Chiang Mai | ||

| Rotor | Transport, freight, lorry 3.5–7.5 metric ton, euro6 {RER}|market for transport, freight, lorry 3.5–7.5 metric ton, EURO6|APOS, U | 400 | 600 |

| Generator | 600 | 600 | |

| Tower | 600 | 600 | |

| Inverter | 360 | 686 | |

| Transport, freight, sea, transoceanic ship {GLO}|market for|APOS, U | 3015 | 3500 | |

| Foundation | Transport, freight, lorry 16–32 metric ton, metric ton, euro6 {RoW}|market for transport, freight, lorry 16–32 metric ton, EURO6|APOS, U | 600 | 600 |

| End of life | Transport, freight, lorry 16–32 metric ton, metric ton, euro6 {RoW}|market for transport, freight, lorry 16–32 metric ton, EURO6|APOS, U | 80 | 80 |

| Material | Treatment |

|---|---|

| Aluminum | 90% recycled + 10% landfilled |

| Copper | 95% recycled + 5% landfilled |

| Steel | 90% recycled + 10% landfilled |

| Glass-fibre-reinforced plastic | 100% landfilled |

| Paint | 100% landfilled |

| Electronics | Treatment as hazardous waste mass |

References

- Glassbrook, K.A.; Carr, A.H.; Drosnes, M.L.; Oakley, T.R.; Kamens, R.M.; Gheewala, S.H. Life cycle assessment and feasibility study of small wind power in Thailand. Energy Sustain. Dev. 2014, 22, 66–73. [Google Scholar] [CrossRef]

- Martínez, E.; Sanz, F.; Pellegrini, S.; Jiménez, E.; Blanco, J. Life cycle assessment of a multi-megawatt wind turbine. Renew. Energy 2009, 34, 667–673. [Google Scholar] [CrossRef]

- Wang, W.C.; Teah, H.Y. Life cycle assessment of small-scale horizontal axis wind turbines in Taiwan. J. Clean. Prod. 2017, 141, 492–501. [Google Scholar] [CrossRef]

- Department of Alternative Energy Development and Efficiency. Annual Report; Ministry of Energy: Bangkok, Thailand, 2016.

- Lombardi, L.; Mendecka, B.; Carnevale, E.; Stanek, W. Environmental impacts of electricity production of micro wind turbines with vertical axis. Renew. Energy 2018, 128, 553–564. [Google Scholar] [CrossRef]

- Department of Alternative Energy Development and Efficiency. Thailand Alternative Energy Situation; Ministry of Energy: Bangkok, Thailand, 2016. Available online: http://webkc.dede.go.th/testmax/sites/default/files/thailandalternative2016.pdf (accessed on 14 November 2018).

- Energy Policy and Planning Office Thailand Power Development Plan 2015–2036 (PDP2015). Available online: https://www.egat.co.th/en/images/about-egat/PDP2015_Eng.pdf (accessed on 26 November 2018).

- Siddiqui, O.; Dincer, I. Comparative assessment of the environmental impacts of nuclear, wind and hydro-electric power plants in Ontario: A life cycle assessment. J. Clean. Prod. 2017, 164, 848–860. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Du, H.; Zuo, J.; Yi, M.; Li, R.; Zhou, Z.; Bi, F.; Garvlehn, M.P. A comparative life-cycle assessment of hydro-, nuclear and wind power: A China study. Appl. Energy 2019, 249, 37–45. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldinelli, G.; D’Alessandro, F.; Scrucca, F. Life cycle assessment of electricity production from renewable energies: Review and results harmonization. Renew. Sustain. Energy Rev. 2015, 42, 1113–1122. [Google Scholar] [CrossRef]

- Shah, S.R.; Kumar, R.; Raahemifar, K.; Fung, A.S. Design, modeling and economic performance of a vertical axis wind turbine. Energy Rep. 2018, 4, 619–623. [Google Scholar] [CrossRef]

- Kouloumpis, V.; Sobolewski, R.A.; Yan, X. Performance and life cycle assessment of a small scale vertical axis wind turbine. J. Clean. Prod. 2020, 247, 119520. [Google Scholar] [CrossRef]

- Chingulpitak, S.; Wongwises, S. Critical review of the current status of wind energy in Thailand. Renew. Sustain. Energy Rev. 2014, 31, 312–318. [Google Scholar] [CrossRef]

- Uddin, M.S.; Kumar, S. Energy, emissions and environmental impact analysis of wind turbine using life cycle assessment technique. J. Clean. Prod. 2014, 69, 153–164. [Google Scholar] [CrossRef]

- Yildiz, N.; Hemida, H.; Baniotopoulos, C. Maintenance and End-of-Life Analysis in LCA for Barge-Type Floating Wind Turbine. Wind 2022, 2, 246–259. [Google Scholar] [CrossRef]

- Tasneem, Z.; Al Noman, A.; Das, S.K.; Saha, D.K.; Islam, M.R.; Ali, M.F.; R Badal, M.F.; Ahamed, M.H.; Moyeen, S.I.; Alam, F. An analytical review on the evaluation of wind resource and wind turbine for urban application: Prospect and challenges. Dev. Built Environ. 2020, 4, 100033. [Google Scholar] [CrossRef]

- Casini, M. Small Vertical Axis Wind Turbines for Energy Efficiency of Buildings. J. Clean Energy Technol. 2015, 4, 56–65. [Google Scholar] [CrossRef]

- Jamanun, M.J.; Misaran, M.S.; Rahman, M.; Muzammil, W.K. Performance Investigation of A Mix Wind Turbine Using A Clutch Mechanism at Low Wind Speed Condition. IOP Conf. Ser. Mater. Sci. Eng. 2017, 217, 012020. [Google Scholar] [CrossRef]

- Almotairi, A.M.M.; Mustapha, F.; Ariffin, M.K.A.M.; Zahari, R. Synergy of Savonius and Darrieus types for vertical axis wind turbine. Int. J. Adv. Appl. Sci. 2016, 3, 25–30. [Google Scholar] [CrossRef]

- Kumar, A.; Nikhade, A. Hybrid Kinetic Turbine Rotors: A Review. Int. J. Eng. Sci. Adv. Technol. 2014, 4, 453–463. [Google Scholar]

- Akwa, J.V.; Vielmo, H.A.; Petry, A.P. A review on the performance of Savonius wind turbines. Renew. Sustain. Energy Rev. 2012, 16, 3054–3064. [Google Scholar] [CrossRef]

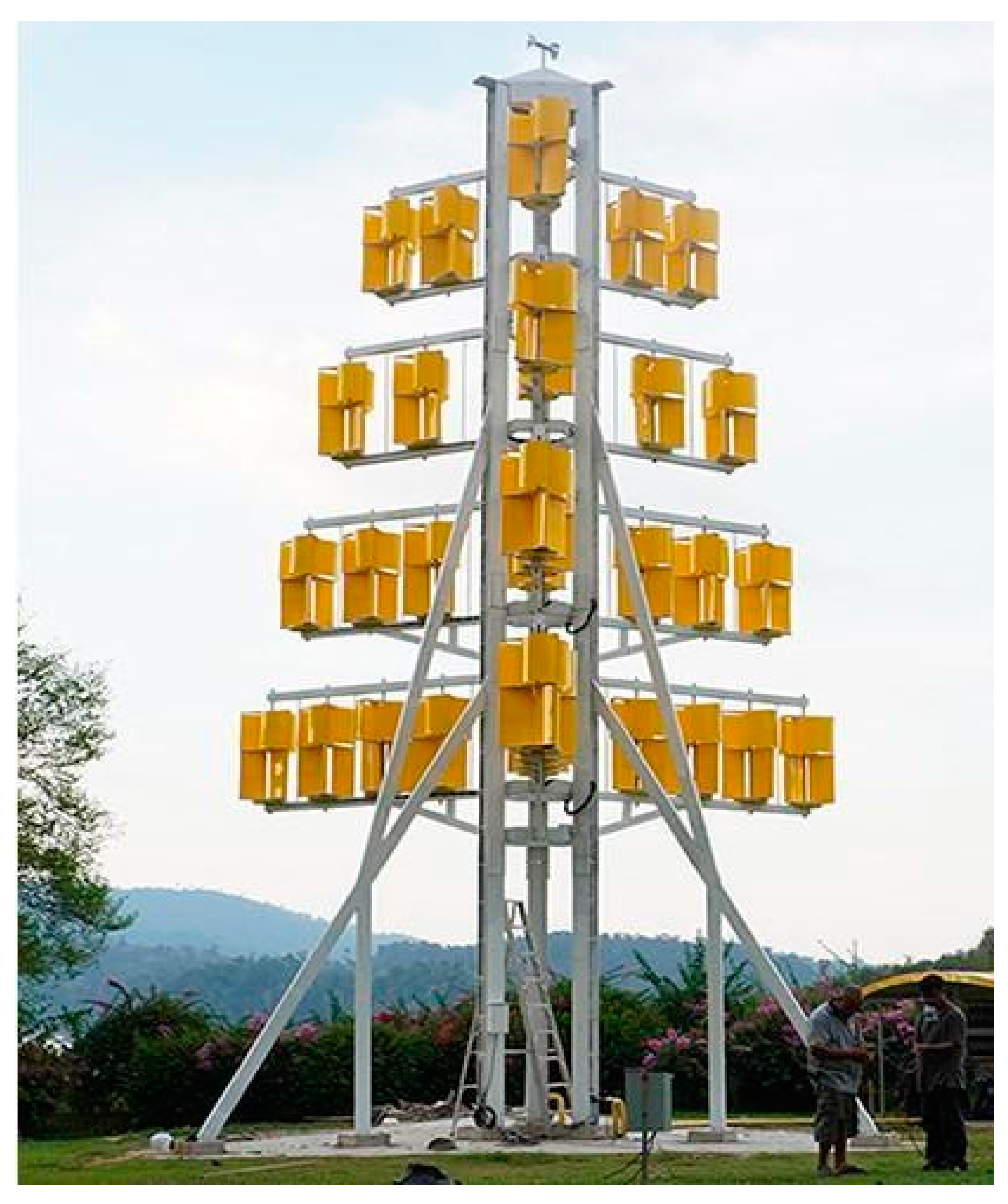

- Energy Systems Research Institute at Prince of Songkla University. Project Report; Development of 10 kW Low Speed Vertical Wind Turbine Using Tree Constructor; Energy Systems Research Institute at Prince of Songkla: Hat Yai, Thailand, 2019. [Google Scholar]

- Ngoc, D.M.; Techato, K.; Niem, L.D.; Thi, N.; Yen, H.; Van Dat, N. A Novel 10 kW Vertical Axis Wind Tree Design: Economic Feasibility Assessment. Sustainability 2021, 13, 12720. [Google Scholar] [CrossRef]

- de Bruyn, S.; Bijleveld, M.; de Graaff, L.; Schep, E.; Schrote, A.; Vergeer, R.; Ahdou, S. Environmental Prices Handbook; CE Delft: Delft, The Netherlands, 2018. [Google Scholar]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006; pp. 652–668. [CrossRef]

- PRé. Sustainability SimaPro 9.3.0.3, (Software); PRé: Amersfoort, The Netherlands, 2021.

- Invt MG 4–5 kW Single Phase On-Grid Solar Inverter—INVT Solar Power. Available online: https://www.invt.com/products/mg-4-5kw-single-phase-on-grid-inverter-100 (accessed on 28 May 2019).

- Tremeac, B.; Meunier, F. Life cycle analysis of 4.5 MW and 250 W wind turbines. Renew. Sustain. Energy Rev. 2009, 13, 2104–2110. [Google Scholar] [CrossRef]

- Chaichana, T.; Chaitep, S. Wind power potential and characteristic analysis of Chiang Mai, Thailand. J. Mech. Sci. Technol. 2010, 24, 1475–1479. [Google Scholar] [CrossRef]

- Energy Policy and Planning Office. Electricity Statistic. Available online: http://www.eppo.go.th/index.php/en/en-energystatistics/electricity-statistic?orders[publishUp]=publishUp&issearch=1 (accessed on 6 November 2019).

- RIVM LCIA: The ReCiPe Model—RIVM. Available online: https://www.rivm.nl/en/life-cycle-assessment-lca/recipe%0Ahttps://www.rivm.nl/en/Topics/L/Life_Cycle_Assessment_LCA/ReCiPe (accessed on 3 October 2022).

- EGAT. Sustainability Report 2019; Electricity Generating Authority of Thailand: Bangkok, Thailand, 2019. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008: A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level, 1st ed.; Report I: Characterisation; Ministry of Housing, Spatial Planning and the Environment: The Hague, The Netherlands, 2009. [Google Scholar]

- Stocker, T.F.; Qin, D.; Plattner, G.K.; Tignor, M.M.; Allen, S.K.; Boschung, J.; Midgley, P.M. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Cambridge, NY, USA, 2013. [Google Scholar]

- Navrud, S. Possibilities and Challenges in Transfer and Generalisation of Monetary Estimates for Environmental and Health Benefits of Regulating Chemicals; OECD Environment Working Papers; OECD: Paris, France, 2017; Volume 6, p. 10. [Google Scholar] [CrossRef]

- Ghani, H.U.; Mahmood, A.; Ullah, A.; Gheewala, S.H. Life cycle environmental and economic performance analysis of bagasse-based electricity in Pakistan. Sustainability 2020, 12, 10594. [Google Scholar] [CrossRef]

- Macrotrends. Thailand GDP per Capita 1960–2021|MacroTrends. Available online: https://www.macrotrends.net/countries/THA/thailand/gdp-per-capita (accessed on 28 October 2021).

- Gkantou, M.; Rebelo, C.; Baniotopoulos, C. Life Cycle assessment of tall onshore hybrid steel wind turbine towers. Energies 2020, 13, 3950. [Google Scholar] [CrossRef]

- Caduff, M.; Huijbregts, M.A.J.; Althaus, H.J.; Koehler, A.; Hellweg, S. Wind power electricity: The bigger the turbine, the greener the electricity? Environ. Sci. Technol. 2012, 46, 4725–4733. [Google Scholar] [CrossRef]

- Doerffer, K.; Bałdowska-Witos, P.; Pysz, M.; Doerffer, P.; Tomporowski, A. Manufacturing and recycling impact on environmental life cycle assessment of innovative wind power plant part 1/2. Materials 2021, 14, 220. [Google Scholar] [CrossRef]

- Gough, M.; Lotfi, M.; Castro, R.; Madhlopa, A.; Khan, A.; Catalão, J.P.S. Urban wind resource assessment: A case study on Cape Town. Energies 2019, 12, 1479. [Google Scholar] [CrossRef]

| Design Attribute | Possible Impact on LCA |

|---|---|

| The design was small-scale (domestic) to fit into a space-limited niche. | With decreasing scale of wind turbines and correspondingly lower outputs, it is to be expected that when environmental impacts are expressed in proportion to kWhr, LCA outcomes become less favorable. This has been reported by Uddin and Kumar [14], who found impacts in inverse proportion to capacity factor. Yildiz [15], for example, also noted the inverse relationship between turbine size and energy payback time. |

| This design was a vertical axis wind turbine to utilize fluctuating wind speed and directions in space-limited settings (vertical axis designs typically require less space than horizontal designs) [16]. | VAWTs are less efficient than HAWTs due to additional drag created as blades rotate into the prevailing wind [17]. The lower energy output profile, as noted above, means environmental impacts per unit of energy produced may be relatively higher in an LCA analysis. |

| Since Savonius blades offer lower cut-in speeds but lower efficiency than Darrieus blades [18], our turbine tree was designed with combined Savonius-Darrieus turbines (see [19,20]), a design which allows the tree to be used in lower wind situations than Darrieus blades alone, but with higher efficiency than using Savonius blades alone. Additionally, since urban conditions often present complex vortex conditions with varying wind velocity, multiple or stacked turbines can act as out-of-phase generators that reduce moment fluctuations in power [21]. For this reason, a turbine tree of 33 paired turbines was implemented. | A turbine tree design, with its repeated use of materials for blades, rotors and generators, may have higher environmental impacts than single turbine designs. |

| Plastic was used in the design instead of rubber or steel for turbine blades as it was found to have higher performance efficiency [22]. | The choice of plastic, rather than a more ‘environmentally friendly’ material, may result in higher LCA impacts. |

| Location | Average Annual Wind Speed | Reference | Capacity Factor (CF) |

|---|---|---|---|

| Surat Thani | 2.58 m/s | Ngoc et al. [23] | 1.65% |

| Chiang Mai | 4.8 m/s | Chaichana and Chaitep [29] | 7.58% |

| Analysis | Goals | Section |

|---|---|---|

| Comparison of Scenarios A, B and grid mix (using CML-IA) | 1, 2 | Section 2.3.1 |

| Energy/GHG payback time (CML-IA) (using Equations (2) and (3) below) | 3 | Section 2.3.2 |

| Environmental price impacts (using IPCC and ReCIPe 2008, [26] | 4 | Section 2.3.3.1 |

| Mitigative strategies for impacts of concern (CML-IA) | 5 | Section 2.3.3.2 |

| Country | GDP (per Capita) | Source |

|---|---|---|

| Europe | 25,920 | Ghani et al. [36] |

| Thailand | 5840 | Macrotrends [37] |

| Input/Component Changed | Value in S.T. Base Case Scenario | Value in New Scenario; Scenario Number | |

|---|---|---|---|

| Transportation method | Light commercial vehicle | Train; Scenario 1 | |

| Material: Turbine blades | Glass fibre-reinforced plastic | Stainless sheet steel; Scenario 2 | |

| Design | (a) rotor number | 33 | 22; Scenario 3 |

| (b) tower weight (kg) | 2894.43 | 2664.012; Scenario 3 | |

| Impact Category | Unit | Surat Thani | Chiang Mai | Thailand Low-Voltage Grid | |||

|---|---|---|---|---|---|---|---|

| Scenarios A | Scenarios B | Scenarios A | Scenarios B | ||||

| 1 | Abiotic depletion | kg Sb eq | 2.44 × 10−5 | 2.43 × 10−5 | 5.31 × 10−6 | 5.30 × 10−6 | 5.54 × 10−7 |

| 2 | Abiotic depletion (fossil fuels) | MJ | 7.71 | 6.37 | 1.68 | 1.39 | 8.64 |

| 3 | Global warming (GWP100a) | kg CO2 eq | 6.90 × 10−1 | 4.90 × 10−1 | 1.50 × 10−1 | 1.09 × 10−1 | 7.03 × 10−1 |

| 4 | Ozone layer depletion (ODP) | kg CFC-11 eq | 7.03 × 10−8 | 6.41 × 10−8 | 1.54 × 10−8 | 1.40 × 10−8 | 2.98 × 10−8 |

| 5 | Human toxicity | kg 1,4-DB eq | 2.36 | 2.29 | 5.10 × 10−1 | 4.99 × 10−1 | 2.50 × 10−1 |

| 6 | Fresh water aquatic ecotoxicity | kg 1,4-DB eq | 8.90 × 10−1 | 8.70 × 10−1 | 1.90 × 10−1 | 1.90 × 10−1 | 4.30 × 10−1 |

| 7 | Marine aquatic ecotoxicity | kg 1,4-DB eq | 3.28 × 103 | 3.16 × 103 | 7.14 × 102 | 6.87 × 102 | 9.37 × 102 |

| 8 | Terrestrial ecotoxicity | kg 1,4-DB eq | 6.37 × 10−3 | 6.08 × 10−3 | 1.38 × 10−3 | 1.32 × 10−3 | 3.50 × 10−3 |

| 9 | Photochemical oxidation | kg C2H4 eq | 3.21 × 10−4 | 2.12 × 10−4 | 7.00 × 10−5 | 4.62 × 10−5 | 8.79 × 10−5 |

| 10 | Acidification | kg SO2 eq | 4.57 × 10−3 | 3.90 × 10−3 | 9.98 × 10−3 | 8.50 × 10−3 | 2.03 × 10−3 |

| 11 | Eutrophication | kg PO4 eq | 2.85 × 10−3 | 2.63 × 10−3 | 6.21 × 10−4 | 5.73 × 10−4 | 1.54 × 10−3 |

| Impact Category | Foundation | Generator | Inverter | Rotor | Tower | Cable and Controller | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S. T. | C. M. | S. T. | C. M. | S. T. | C. M. | S. T. | C. M. | S. T. | C. M. | S. T. | C. M. | |

| Abiotic depletion | 2.54 | 3.31 | 41.30 | 41.01 | 37.40 | 37.12 | 3.57 | 3.54 | 10.20 | 10.14 | 4.92 | 4.88 |

| Abiotic depletion (fossil fuels) | 16.20 | 20.64 | 33.1 | 31.37 | 3.62 | 3.43 | 19.20 | 18.23 | 26.4 | 25.01 | 1.40 | 1.32 |

| Global warming (GWP100a) | 22.10 | 25.40 | 24.90 | 23.84 | 3.59 | 3.44 | 17.50 | 16.79 | 30.60 | 29.30 | 1.28 | 1.23 |

| Ozone layer depletion (ODP) | 15.90 | 21.55 | 52.10 | 48.58 | 4.45 | 4.15 | 5.62 | 5.24 | 20.4 | 18.99 | 1.59 | 1.49 |

| Human toxicity | 4.91 | 5.24 | 38.00 | 37.87 | 4.81 | 4.79 | 21.10 | 21.03 | 30.60 | 30.47 | 0.60 | 0.60 |

| Fresh water aquatic ecotoxicity | 6.31 | 6.71 | 43.30 | 43.11 | 8.55 | 8.52 | 11.00 | 10.92 | 29.80 | 29.71 | 1.04 | 1.04 |

| Marine aquatic ecotoxicity | 3.88 | 4.18 | 69.50 | 69.24 | 6.88 | 6.86 | 3.92 | 3.91 | 15.00 | 14.93 | 0.89 | 0.89 |

| Terrestrial ecotoxicity | 8.81 | 9.49 | 21.90 | 21.72 | 3.74 | 3.71 | 9.85 | 9.78 | 55.20 | 54.75 | 0.55 | 0.55 |

| Photochemical oxidation | 13.20 | 14.46 | 45.90 | 45.26 | 4.32 | 4.26 | 8.10 | 7.99 | 27.60 | 27.25 | 0.81 | 0.79 |

| Acidification | 11.00 | 12.23 | 55.70 | 54.95 | 3.71 | 3.65 | 10.70 | 10.51 | 18.00 | 17.72 | 0.96 | 0.94 |

| Eutrophication | 9.76 | 8.47 | 54.40 | 54.07 | 10.8 | 10.77 | 4.69 | 4.66 | 20.80 | 20.65 | 1.39 | 1.39 |

| Location | Capacity Factor | Energy Payback Time (EP) (Years) | GHG Payback Time (GHGP) (Years) |

|---|---|---|---|

| Surat Thani | 1.65% | 54.77 | 28.61 |

| Chiang Mai | 7.58% | 12.50 | 6.50 |

| Impact Category | Surat Thani Location | Chiang Mai Location | Thailand Low-Voltage Grid |

|---|---|---|---|

| Climate change | 2.30 × 10−2 | 5.00 × 10−3 | 1.7 × 10−2 |

| Ozone depletion | 5.62 × 10−6 | 1.30 × 10−6 | 1.96 × 10−6 |

| Terrestrial acidification | 1.8 × 10−2 | 4.0 × 10−3 | 6.0 × 10−3 |

| Freshwater eutrophication | 8.89 × 10−4 | 1.94 × 10−4 | 2.87 × 10−4 |

| Marine eutrophication | 5.43 × 10−4 | 1.19 × 10−4 | 2.55 × 10−4 |

| Human toxicity | 8.1 × 10−2 | 1.7 × 10−2 | 2.0 × 10−2 |

| Photochemical oxidant formation | 1.87 × 10−3 | 4.16 × 10−4 | 7.08 × 10−4 |

| Particulate matter formation | 5.4 × 10−2 | 1.1 × 10−2 | 1.3 × 10−2 |

| Terrestrial ecotoxicity | 9.71 × 10−4 | 2.19 × 10−4 | 1.19 × 10−4 |

| Freshwater ecotoxicity | 6.99 × 10−4 | 1.53 × 10−4 | 5.44 × 10−4 |

| Marine ecotoxicity | 1.44 × 10−4 | 3.15 × 10−5 | 9.73 × 10−5 |

| Ionising radiation | 1.47 × 10−3 | 3.32 × 10−4 | 1.57 × 10−3 |

| Agricultural land occupation | 2.42 × 10−3 | 5.27 × 10−4 | 2.00 × 10−3 |

| Urban land occupation | 9.13 × 10−4 | 2.11 × 10−4 | 5.87 × 10−5 |

| Total | 1.87 × 10−1 | 4.10 × 10−2 | 6.40 × 10−2 |

| Scenario | Impact Category | |||

|---|---|---|---|---|

| Abiotic Depletion (Fossil Fuels) | Global Warming | Ozone Layer Depletion | Human Toxicity | |

| S.T. base case | 1.00 | 1.00 | 1.00 | 1.00 |

| Scenario 1: Transport—(train replaces light commercial vehicle) | 0.91 | 0.93 | 0.88 | 0.99 |

| Scenario 2: new material (stainless steel sheet replaces glass-fibre-reinforced plastic) | 0.93 | 0.95 | 1.00 | 1.02 |

| Scenario 3: new design (tree, less one ‘arm’) | 0.80 | 0.83 | 0.79 | 0.77 |

| Chiang Mai location (CF = 7.58%) | 0.22 | 0.22 | 0.22 | 0.22 |

| Base Case Surat Thani | Base Case Chiang Mai | Scenario 1: Train | Scenario 2: New Material | Scenario 3: New Design | Thai Low-Voltage Grid | |

|---|---|---|---|---|---|---|

| Abiotic depletion | 2.44 × 10−3 | 5.31 × 10−6 | 2.42 × 10−5 | 2.45 × 10−5 | 1.88 × 10−5 | 5.54 × 10−7 |

| Abiotic depletion (fossil fuels) | 7.71 | 1.683 | 7.013 | 7.137 | 6.162 | 8.638 |

| Global warming | 6.89 × 10−1 | 1.5 × 10−1 | 6.43 × 10−1 | 6.57 × 10−1 | 5.71 × 10−1 | 7.03 × 10−1 |

| Ozone layer depletion | 7.03 × 10−8 | 1.54 × 10−8 | 6.18 × 10−8 | 7.00 × 10−8 | 5.52 × 10−8 | 2.98 × 10−8 |

| Human toxicity | 2.36 | 5.14 × 10−1 | 2.35 | 2.42 | 1.83 | 2.45 × 10−1 |

| Fresh water aquatic ecotoxicity | 8.99 × 10−1 | 1.95 × 10−1 | 8.95 × 10−1 | 9. 06 × 10−1 | 7.05 × 10−1 | 4.27 × 10−1 |

| Marine aquatic ecotoxicity | 3.28 × 103 | 7.14 × 102 | 3.27 × 103 | 3.28 × 103 | 2.40 × 103 | 9.37 × 102 |

| Terrestrial ecotoxicity | 6.40 × 10−3 | 1.40 × 10−3 | 6.30 × 10−3 | 6.40 × 10−3 | 5.40 × 10−3 | 3.50 × 10−3 |

| Photochemical oxidation | 3.21 × 10−4 | 7.00 × 10−5 | 3.15 × 10−4 | 3.28 × 10−4 | 2.56 × 10−4 | 8.79 × 10−5 |

| Acidification | 5.00 × 10−3 | 9.98 × 10−4 | 4.00 × 10−3 | 4.00 × 10−3 | 3.00 × 10−3 | 2.00 × 10−3 |

| Eutrophication | 3.00 × 10−3 | 6.21 × 10−4 | 2.00 × 10−3 | 3.00 × 10−3 | 2.00 × 10−3 | 1.00 × 10−3 |

| Impact Category | S.T. (CF) | C.M. (CF) |

|---|---|---|

| Abiotic depletion | 72.62 | 72.49 |

| Abiotic depletion (fossil fuels) | 1.47 | 1.22 |

| Global warming | 1.62 | 1.17 |

| Ozone layer depletion | 3.89 | 3.57 |

| Human toxicity | 15.92 | 15.42 |

| Fresh water aquatic ecotoxicity | 3.48 | 3.36 |

| Marine aquatic ecotoxicity | 5.78 | 5.56 |

| Terrestrial ecotoxicity | 3.01 | 2.87 |

| Photochemical oxidation | 6.03 | 3.99 |

| Acidification | 3.73 | 3.18 |

| Eutrophication | 3.06 | 2.82 |

| Analysis | Results | Conclusions/Recommendations |

|---|---|---|

| CML-IA base case analysis, Scenarios A, B (no end-of-life, end-of-life treatment) | In Surat Thani, (CF = 1.65%), Scenario A and B impacts usually higher than Thai grid, only lower for global warming and abiotic depletion (fossil fuels); in Chiang Mai, (CF = 7.58%), Scenario A and B impacts usually lower than Thai grid, only higher for human toxicity and abiotic depletion; recycling and reuse is effective (Scenario B impacts always lower than Scenario A); end-of-life treatment lowers impacts (both locations) by an average of 11% | This VAWT has environmental benefits. Site selection is important. Regarding impacts, the VAWT outperformed the Thai grid at CF = 7.58% but underperformed the grid at CF = 1.65%. CF > 4% recommended to halve impacts. Recycling and reuse strategies should be incorporated into planning. Materials with higher recycling potential should be used. |

| Component Contribution to Impacts | Tower and generator dominate impacts in 10 of 11 categories. | Research into material alternatives or structural redesign, especially with respect to tower and generator. |

| Energy and GHG Payback Times | At CF = 7.58%, energy and GHG payback times are within estimated VAWT lifespan, but exceed lifespan for CF = 1.65%. CED indicates tower and generator deplete renewables and non-renewables the most. | Installation at locations of higher windspeed (CF > 4%) is desirable. Research alternate materials for tower and generator. |

| Environmental Prices | Monetizing impacts with environmental prices indicate four impact categories (human toxicity, particulate matter formation, climate change and terrestrial acidification) account for the majority (94% or 95%) of costs. These percent contributions are independent of CF. | Research into design, materials and transportation alternatives to mitigate costs from climate change, particulate matter, human toxicity and terrestrial acidification impacts. |

| Mitigative Alterations to Life Cycle (Scenarios 1 to 3)—effects on GHG, Human Toxicity, Ozone Depletion, Abiotic Resource Depletion; Grid impact CF equivalents. | The ranking of the potential of mitigative alterations to make the VAWT more environmentally friendly (than grid impact values) is: 1. CF, 2. design changes, 3. transportation changes, 4. material changes (in that order). CF = 4% means at least 60% of impact categories are less than grid impact values. | During planning, consider CF at site with respect to cut-in, rated wind speed, and calculate the CF necessary to achieve impacts equivalent to or less than grid impacts. Consider prevailing wind direction at site with respect to redesigns. Optimize transportation to reduce fossil fuel consumption. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ngoc, D.M.; Luengchavanon, M.; Anh, P.T.; Humphreys, K.; Techato, K. Shades of Green: Life Cycle Assessment of a Novel Small-Scale Vertical Axis Wind Turbine Tree. Energies 2022, 15, 7530. https://doi.org/10.3390/en15207530

Ngoc DM, Luengchavanon M, Anh PT, Humphreys K, Techato K. Shades of Green: Life Cycle Assessment of a Novel Small-Scale Vertical Axis Wind Turbine Tree. Energies. 2022; 15(20):7530. https://doi.org/10.3390/en15207530

Chicago/Turabian StyleNgoc, Duong Minh, Montri Luengchavanon, Pham Thi Anh, Kim Humphreys, and Kuaanan Techato. 2022. "Shades of Green: Life Cycle Assessment of a Novel Small-Scale Vertical Axis Wind Turbine Tree" Energies 15, no. 20: 7530. https://doi.org/10.3390/en15207530

APA StyleNgoc, D. M., Luengchavanon, M., Anh, P. T., Humphreys, K., & Techato, K. (2022). Shades of Green: Life Cycle Assessment of a Novel Small-Scale Vertical Axis Wind Turbine Tree. Energies, 15(20), 7530. https://doi.org/10.3390/en15207530