Numerical Study on Infrared Radiation Characteristics of Stealth Coating for Turbofan Engine Tail Nozzle

Abstract

:1. Introduction

2. Physical Models and Calculation Methods

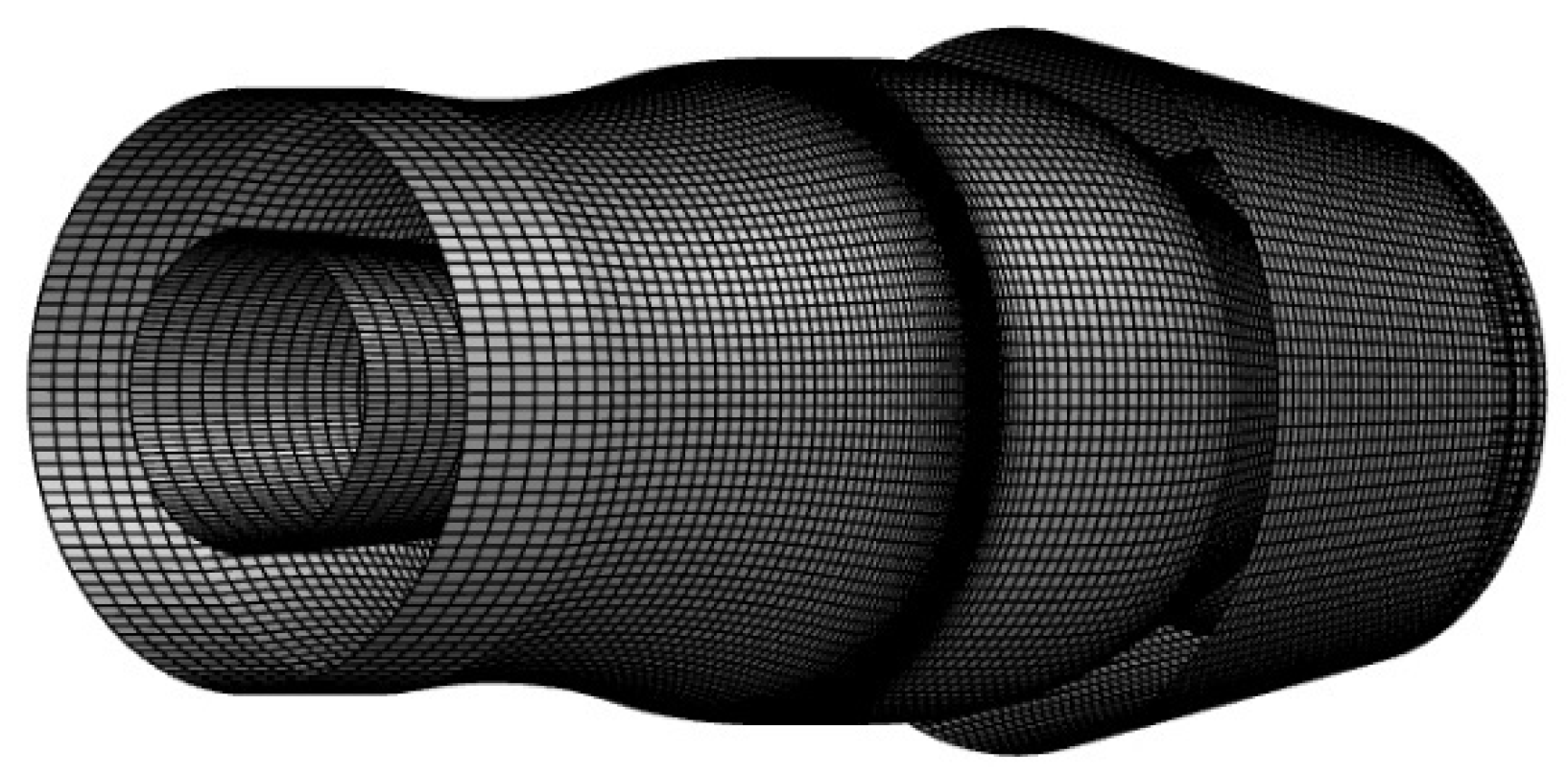

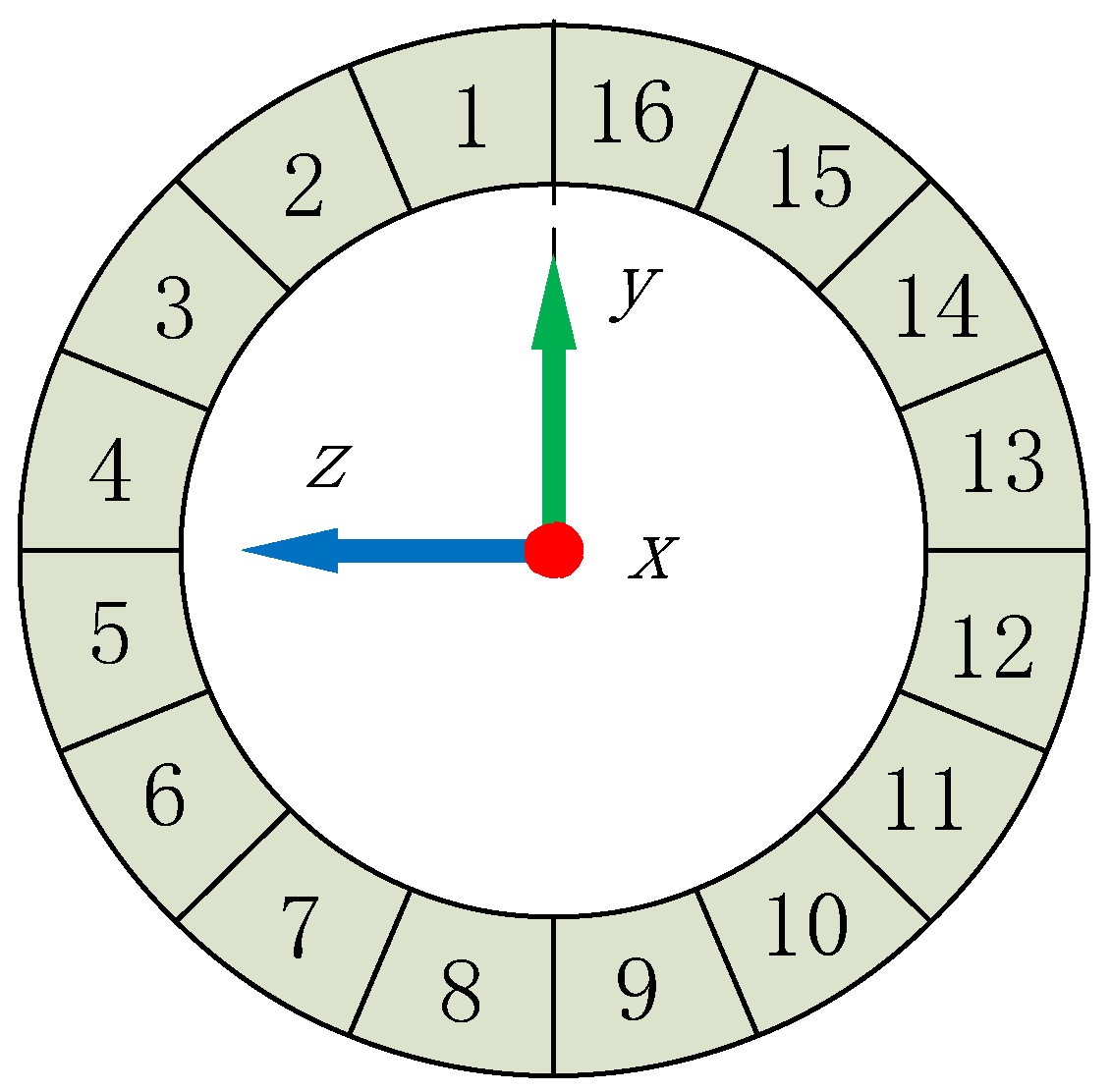

2.1. Physical Models

2.2. Flow Field Calculation Method and Boundary Condition Setting

2.3. Infrared Radiation Calculation Method

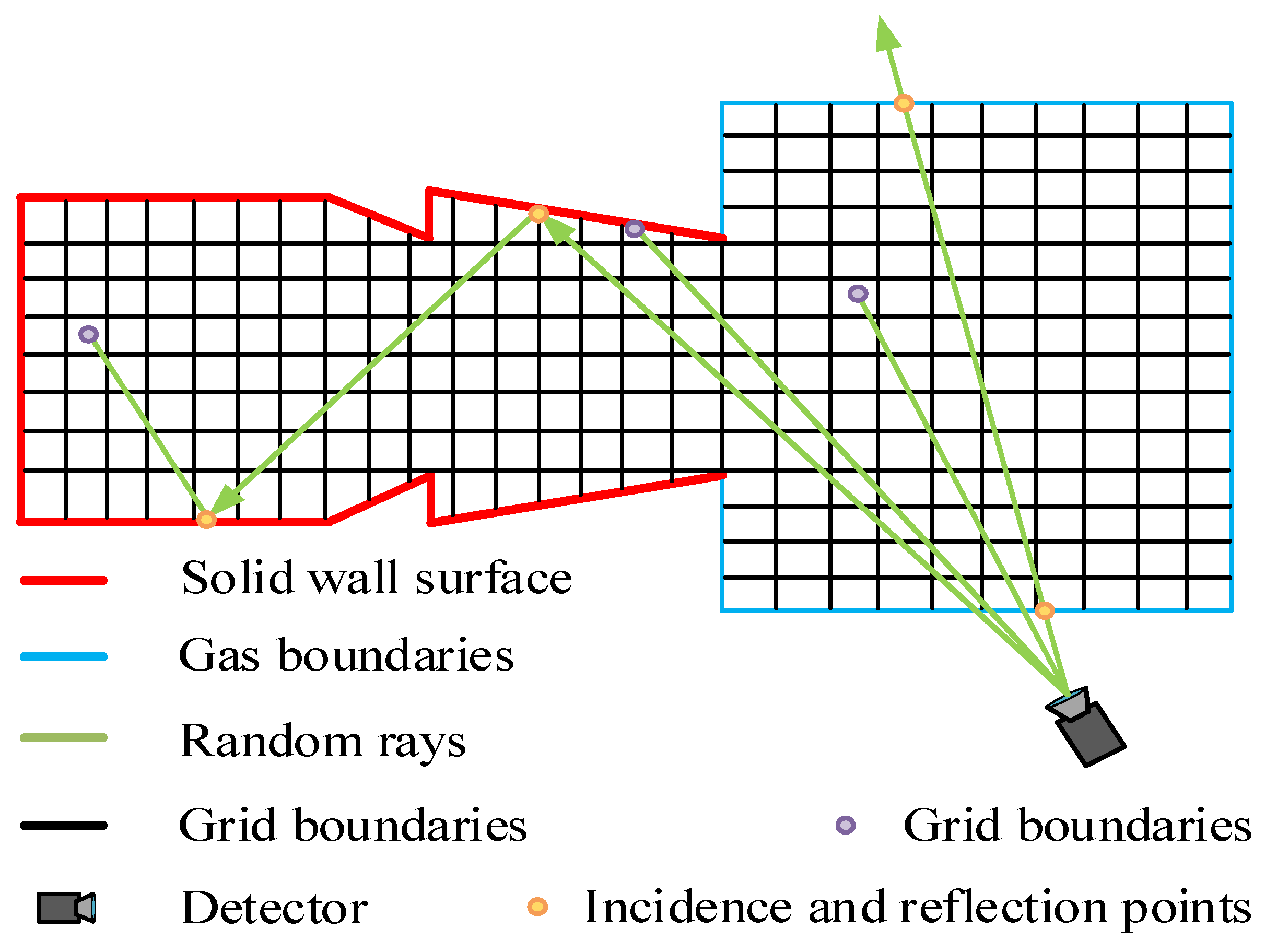

- Reverse Monte Carlo Method.

- (1)

- Calculation formula of target radiation intensity.

- (2)

- Backtracking of random rays.

- 2.

- Narrowband Model Parameter Library.

3. Calculation Results and Analysis

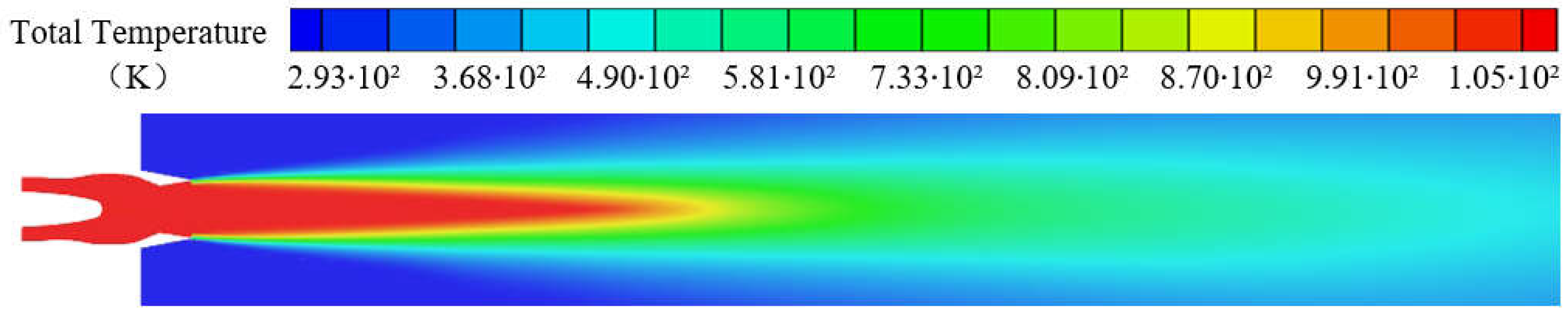

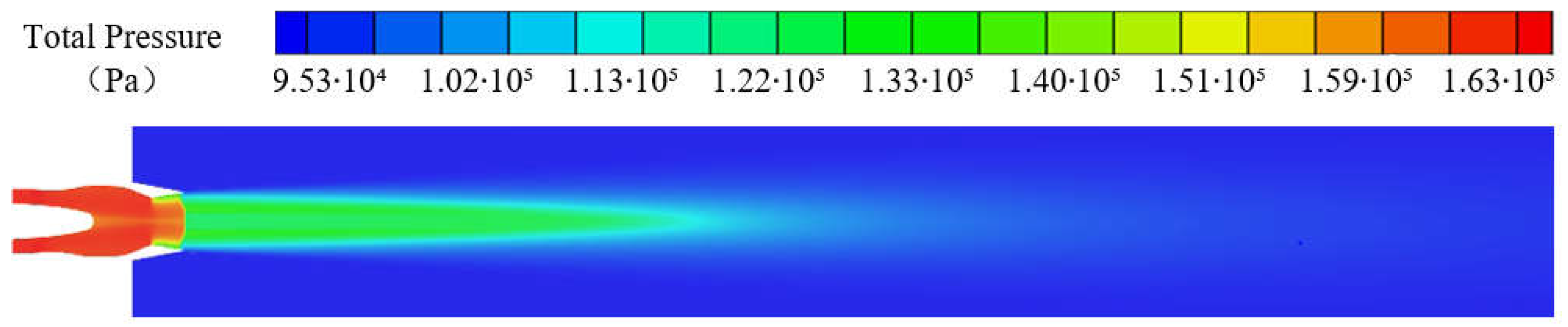

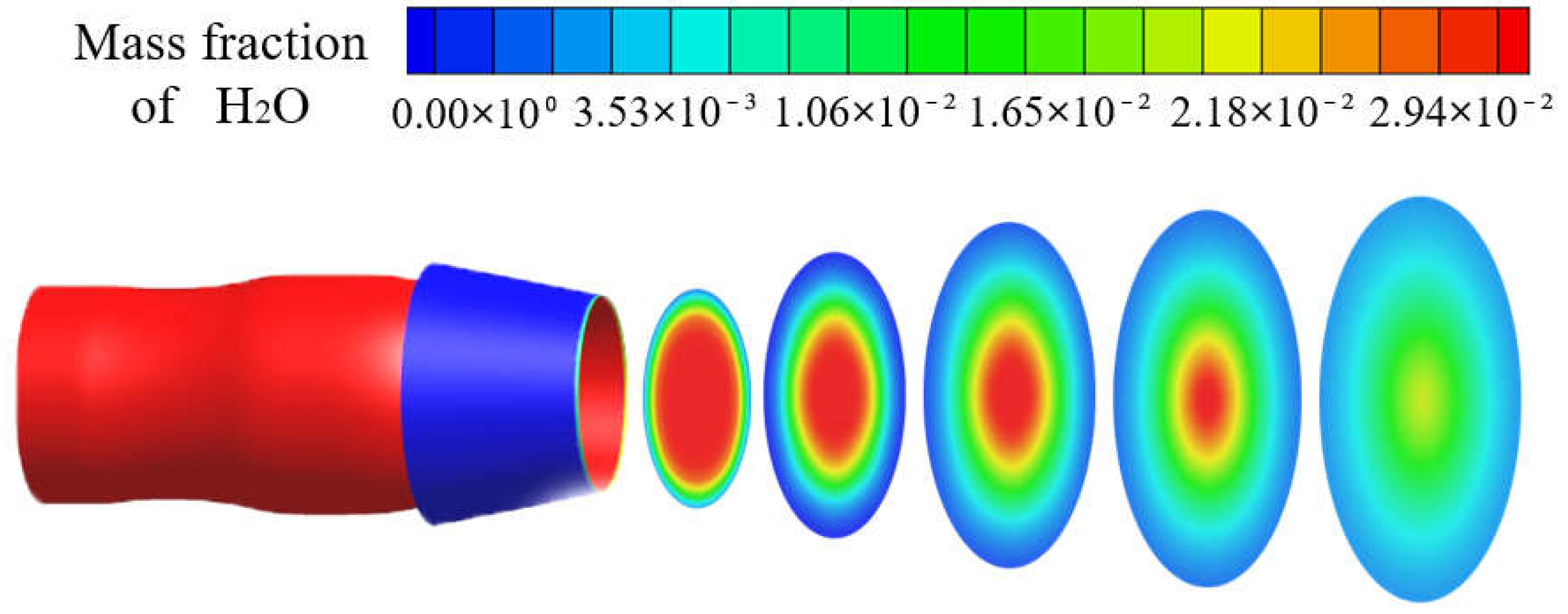

3.1. Flow Field Calculation Results

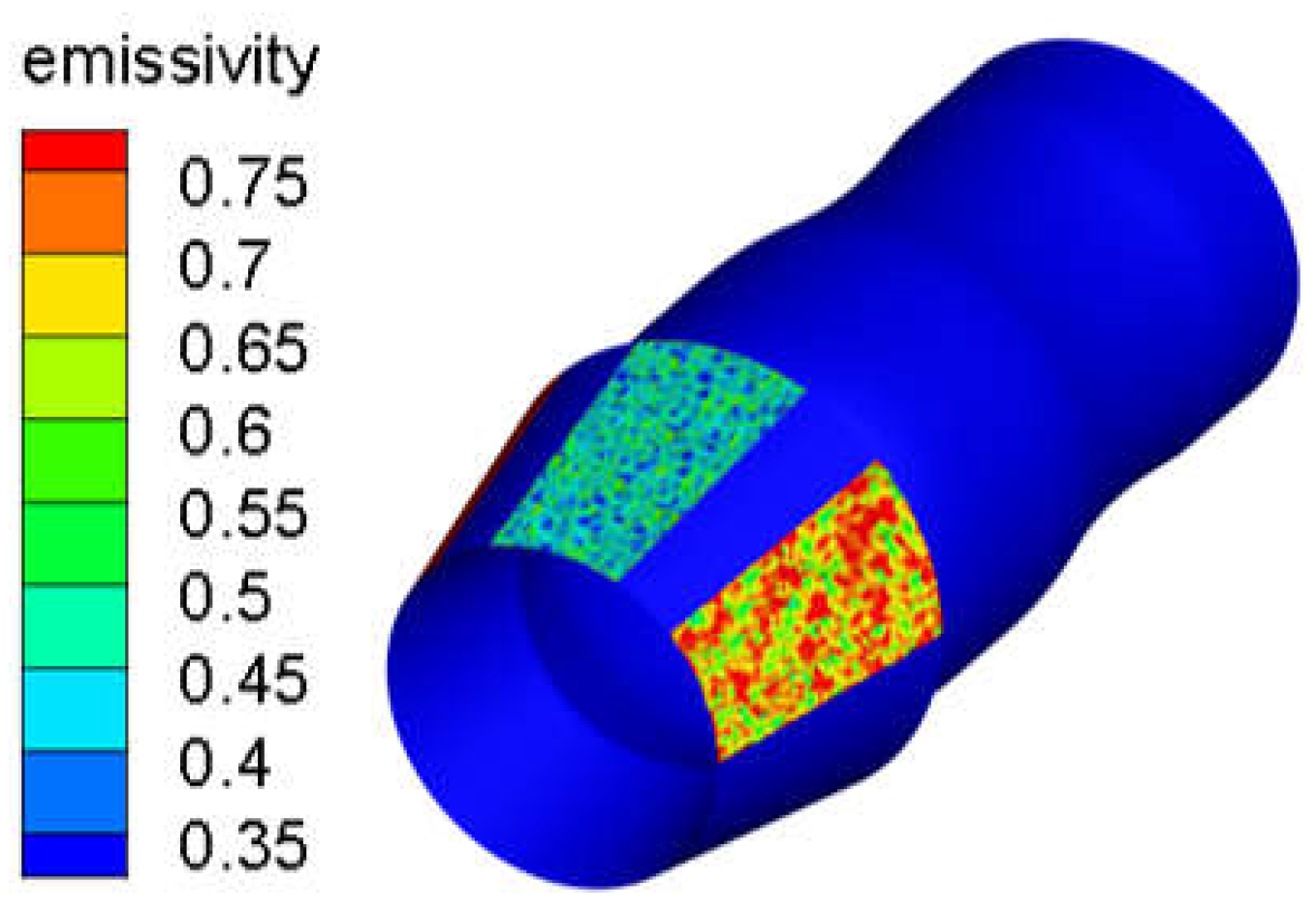

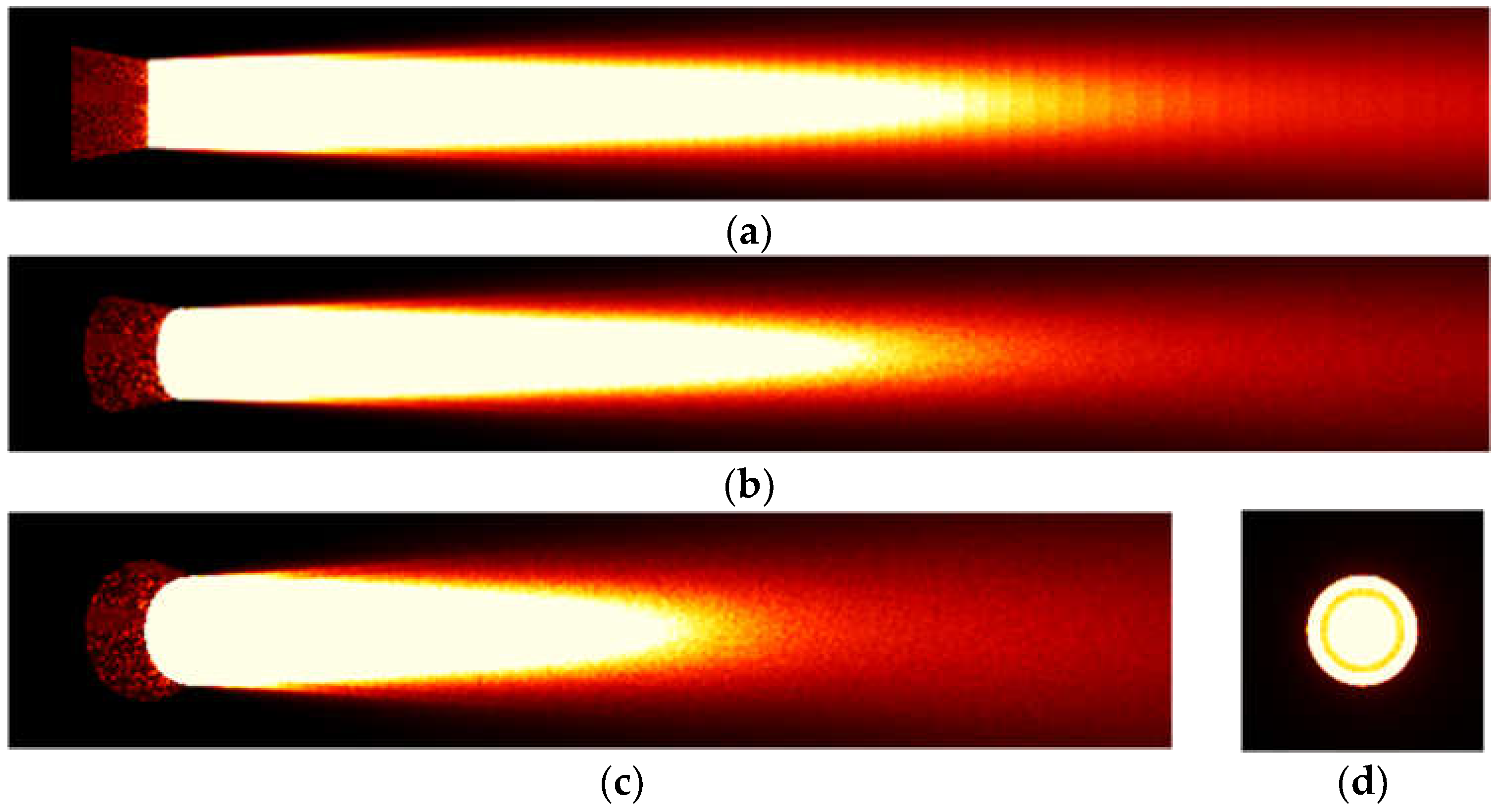

3.2. Infrared Simulation Calculation Results

4. Conclusions

- (1)

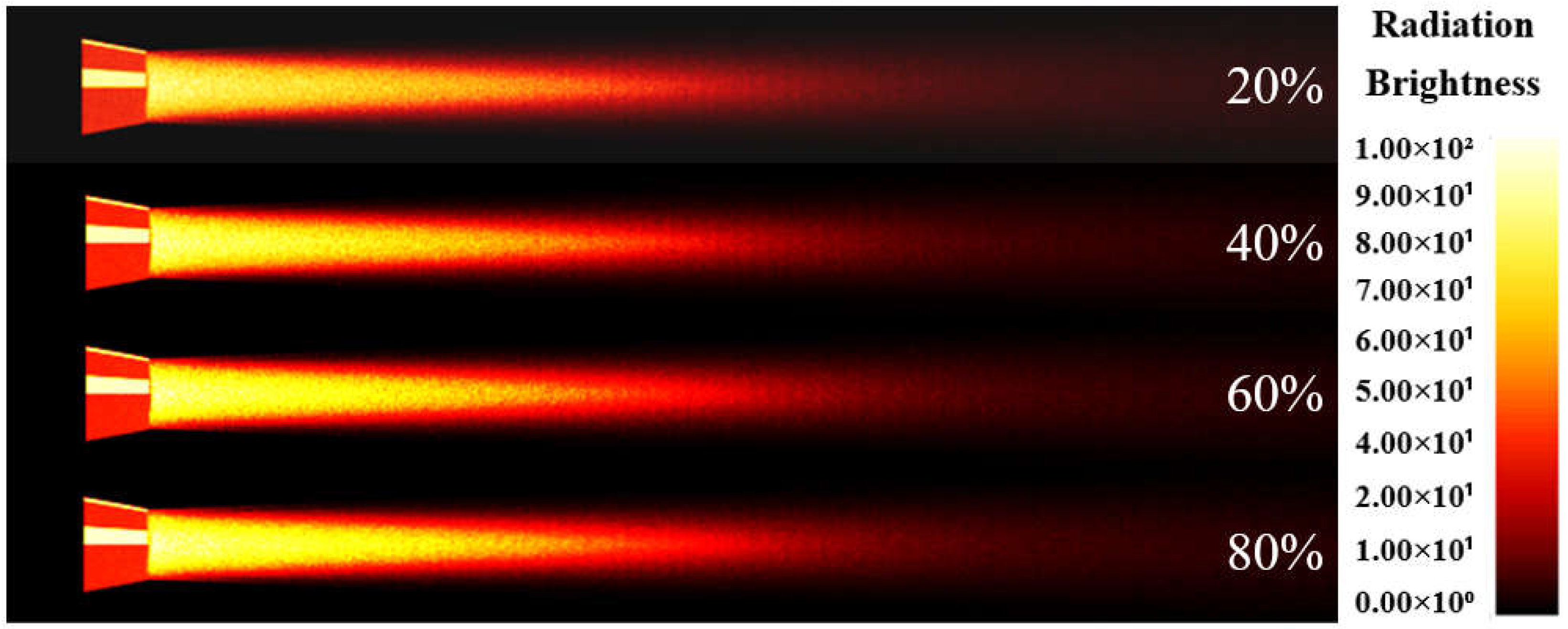

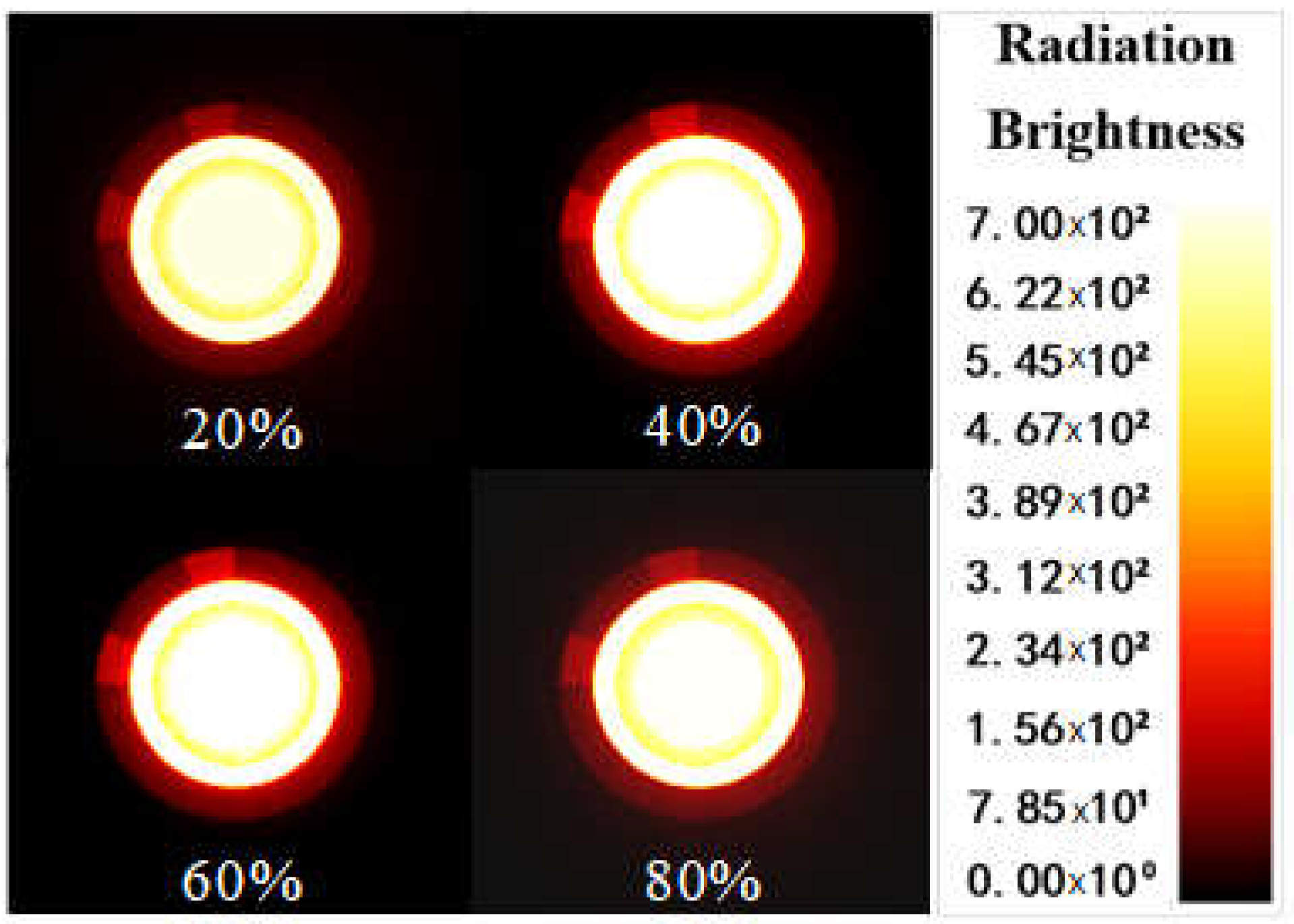

- As the radiation of the aircraft exhaust system primarily stems from the impact of the tail jet, the radiation of the tail jet is mainly distributed in the 3–5-µm wave band. However, in the 8–14-µm band, the radiation from the solid walls, such as that from the adjusting plates outside the tail nozzle, has a certain impact on the overall radiation intensity.

- (2)

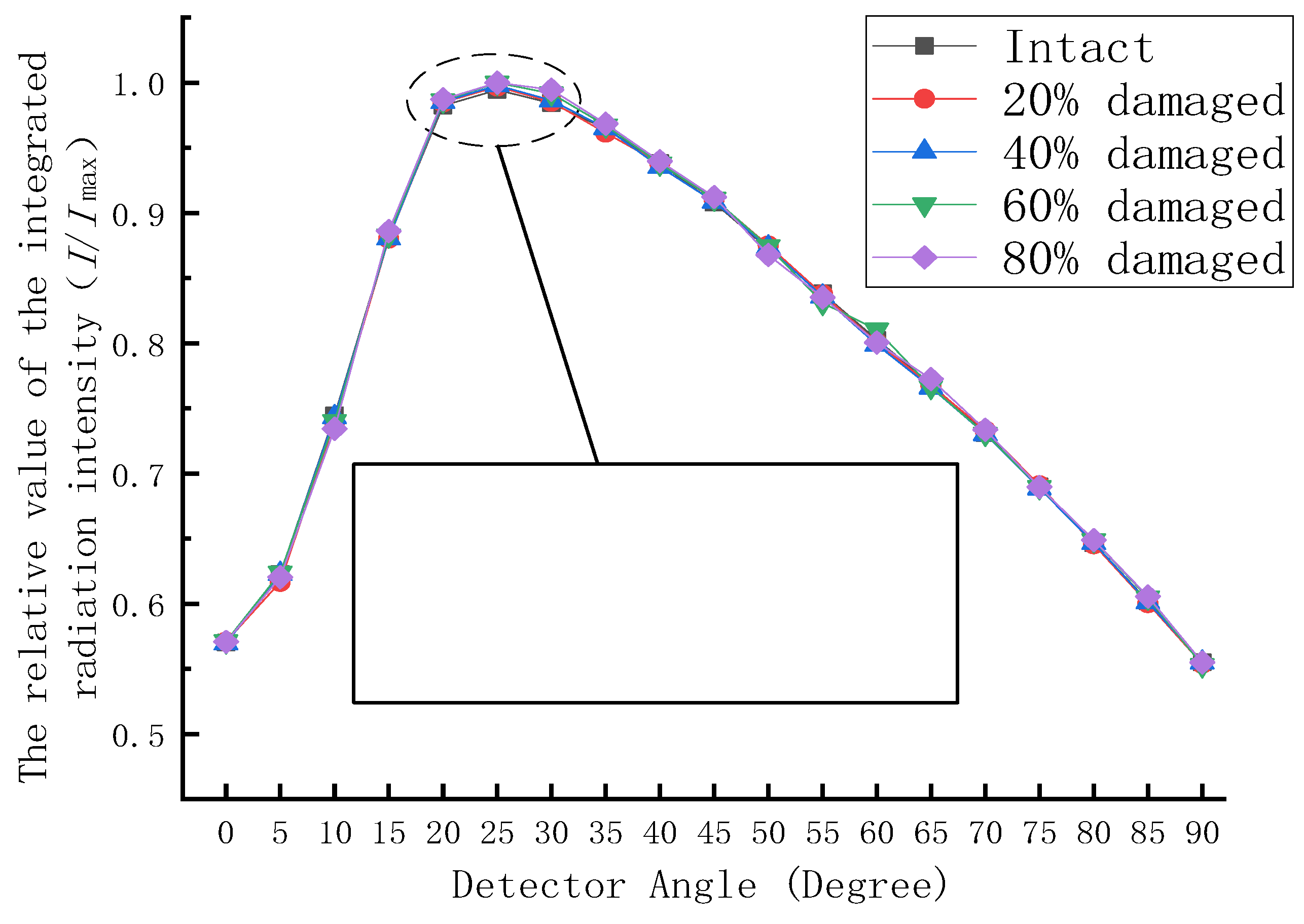

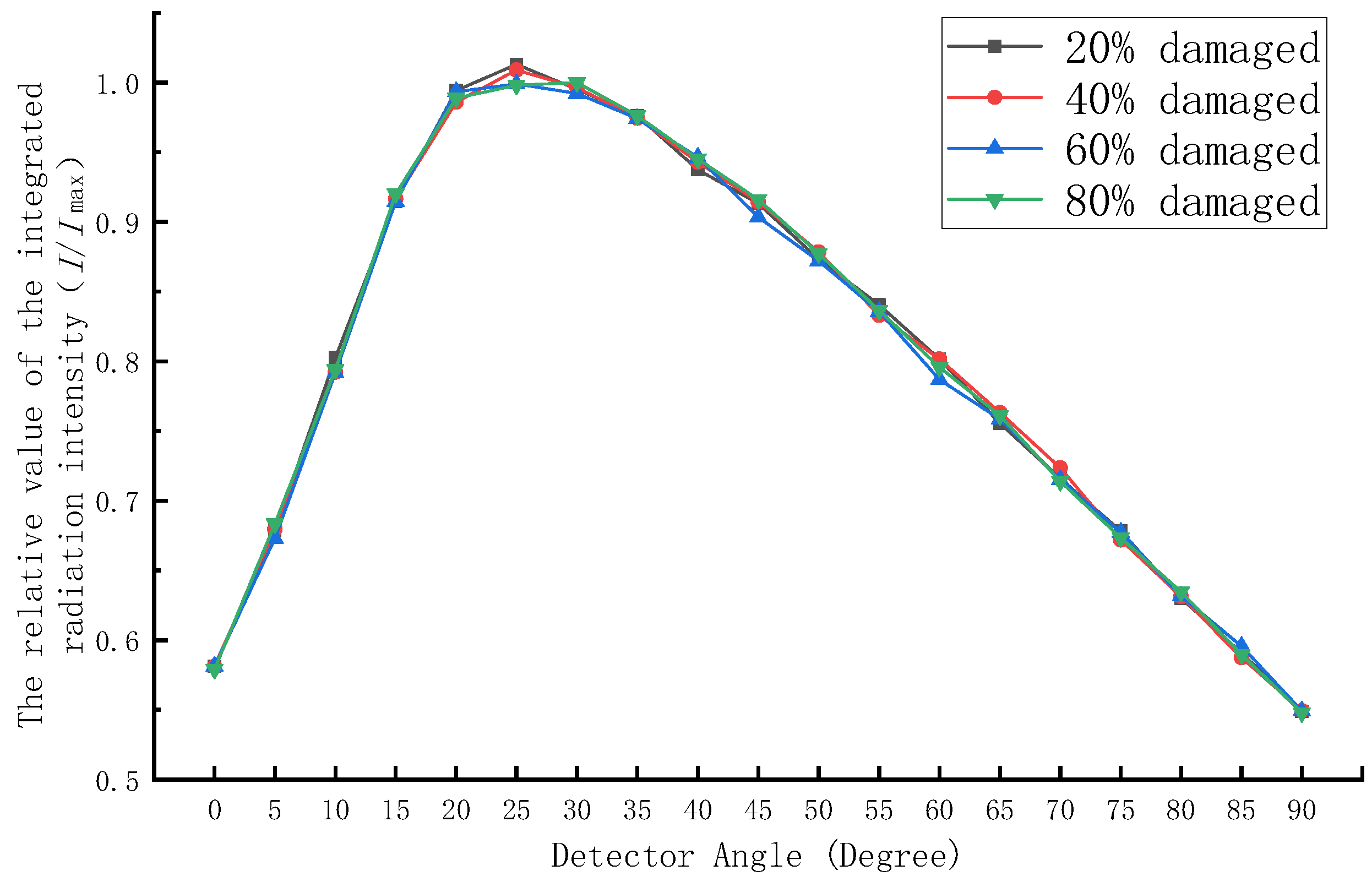

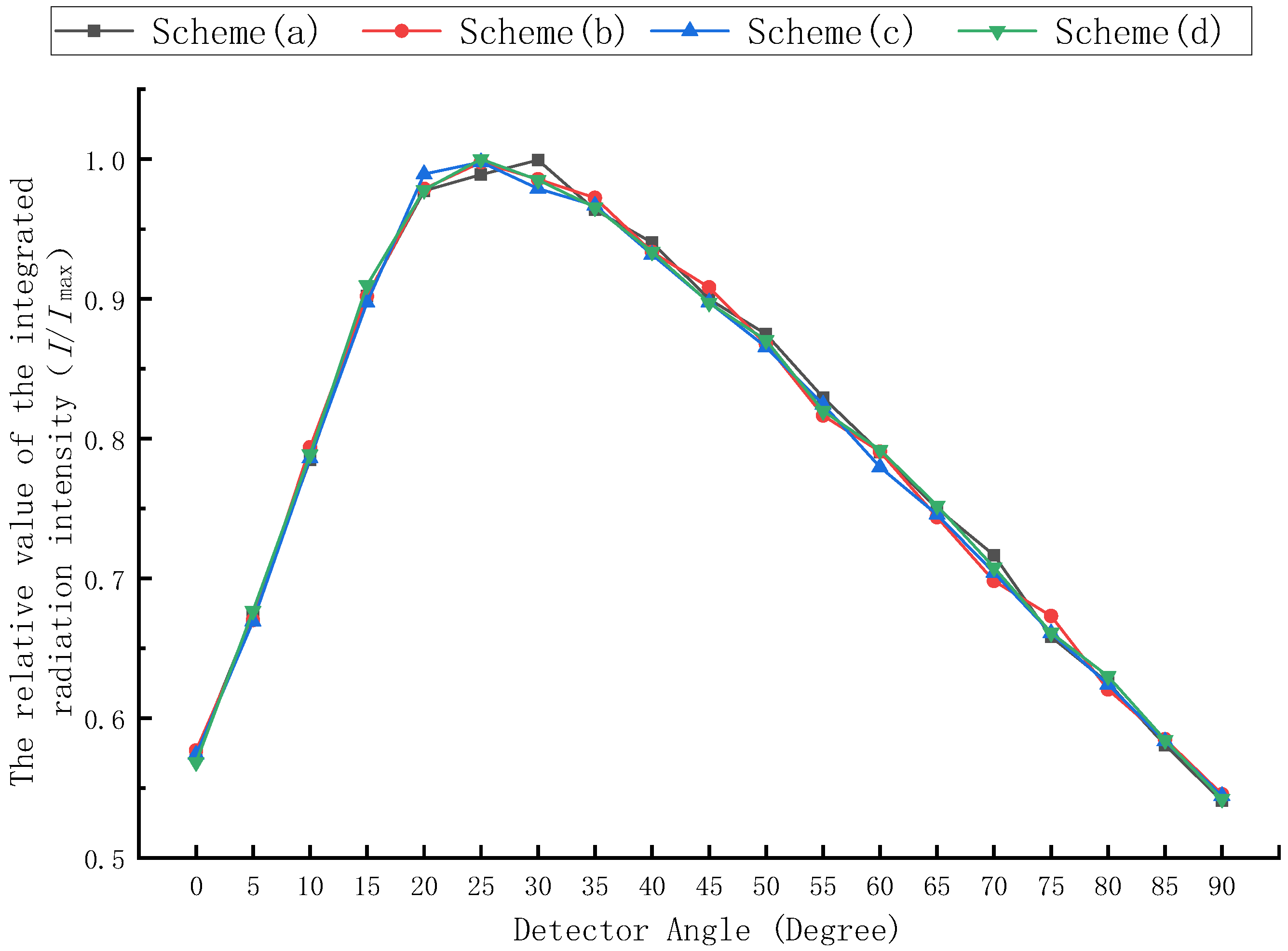

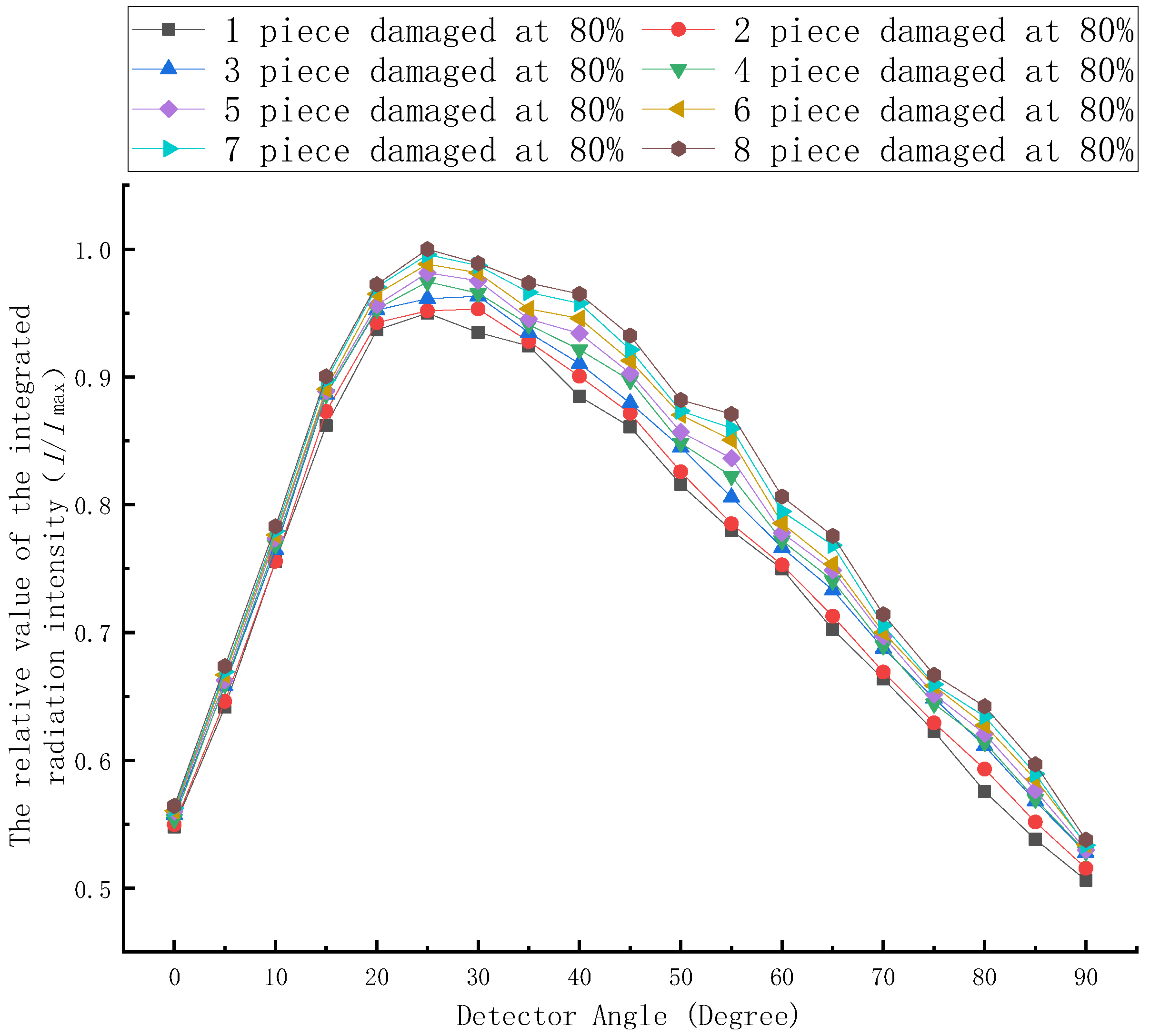

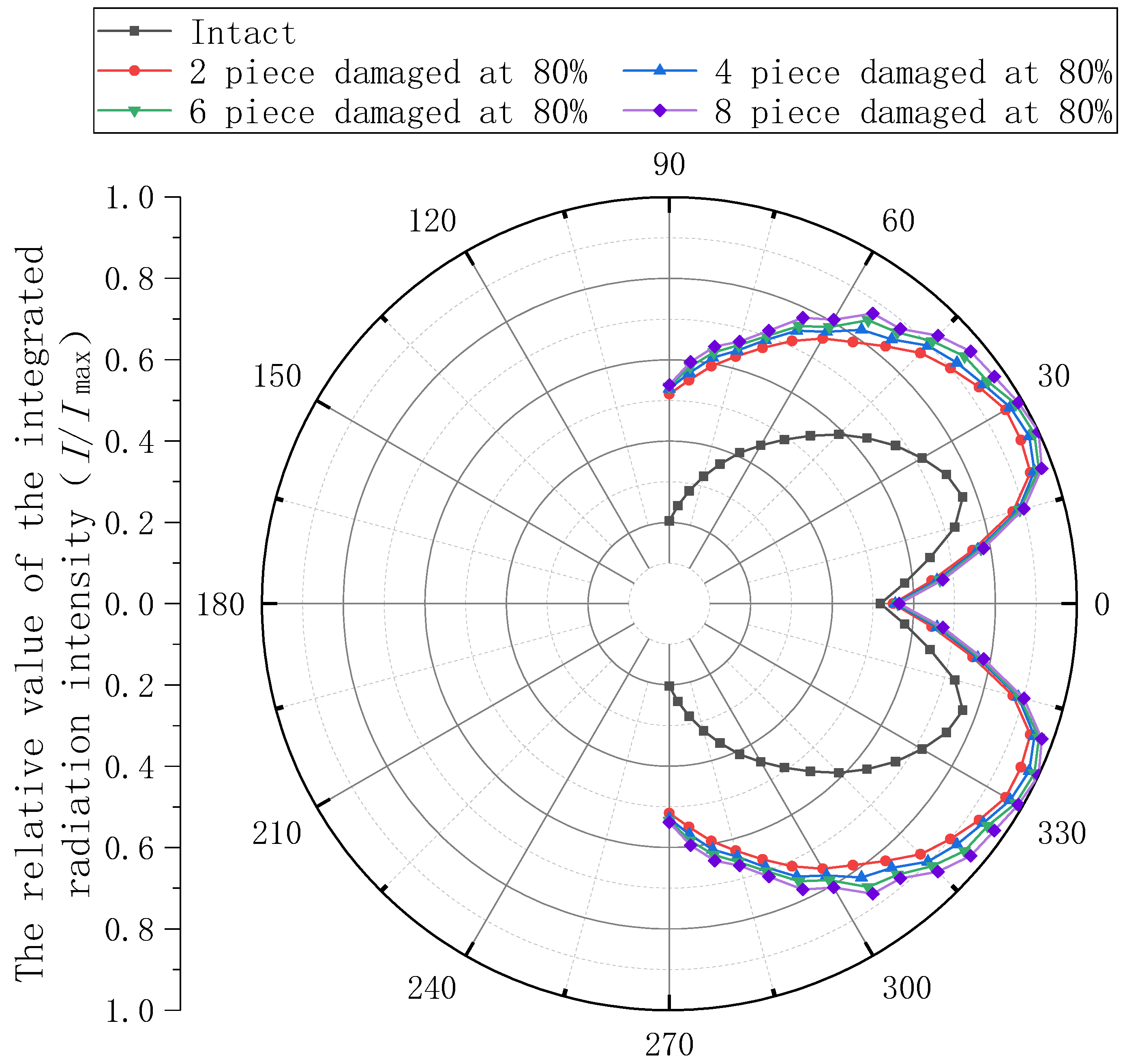

- Within the 8–14-µm wavelength band, the radiation intensity of the exhaust system increases first and then decreases from 0° to 90°, with the peak appearing near the azimuth angle of 25°. The angular distribution of the infrared radiation of the nozzle presents a “pear shape”, which conforms to the general pattern, proving that the calculation of the results is reasonable and reliable.

- (3)

- When the numbers of damages and damaged positions of the external adjusting plates are the same, the change in the overall infrared radiation intensity is limited when the damage percentage increases from 20% to 80%. Furthermore, the change of the positions of the damaged adjusting plates on one side has little effect on the overall radiation intensity.

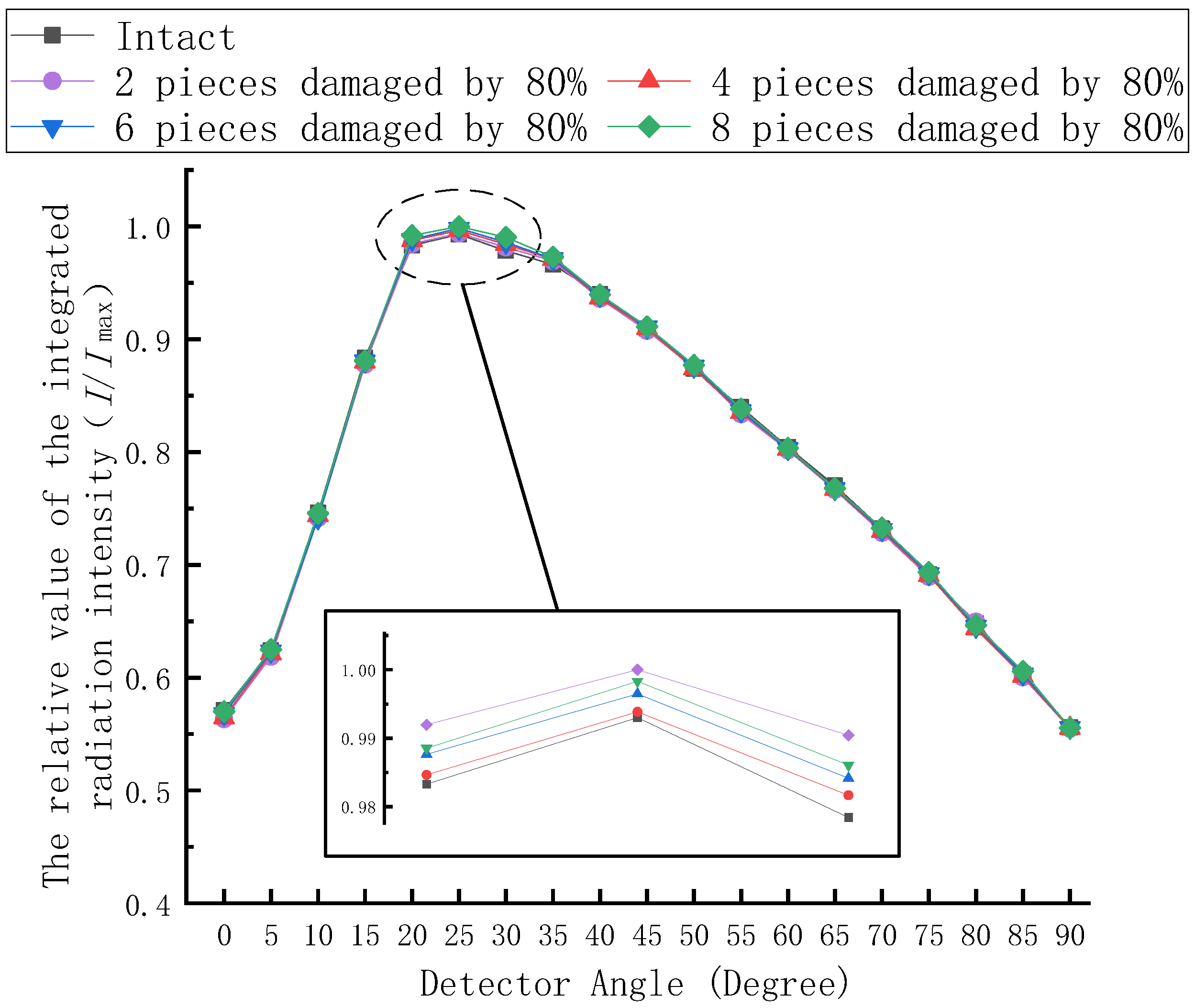

- (4)

- When the damage percentage of the external adjusting plates is constant, the overall infrared radiation intensity shows a trend of steady growth with the increase in the number of damaged adjusting plates. With a detection angle of 45°, the maximum change in the overall infrared radiation intensity contrast value I/Imac of one and eight damaged adjusting plates is 8.31%, and that under a detection angle of 55° is 11.67%. Thus, the stealth coating of the external adjusting plate of the tail nozzle of the outer aero-engine must be inspected and maintained regularly to ensure the integrity of the stealth performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, W.J. Aircraft Overall Design; Northwestern Polytechnical University Press: Xi’an, China, 2005. [Google Scholar]

- Bin, Y. Investigation on aerodynamic design and infrared radiation characteristics of s-shaped nozzle with complicated variable cross-section. Trainer 2014, 3, 29–37. [Google Scholar]

- Li, X.; Yang, Q.Z.; Chen, L.H.; Gao, X.; Huan, X. Numerical simulation of infrared characteristics of aero-engine exhaust nozzle. Adv. Aeronaut. Sci. Eng. 2013, 4, 126–133. [Google Scholar] [CrossRef]

- Sun, Z.Q.; Yang, Q.Z.; Chen, L.H.; Liu, Y. Numerical simulation on the infrared radiation characteristics of turbofan engine’s ejector nozzle. Adv. Aeronaut. Sci. Eng. 2012, 3, 92–97. [Google Scholar] [CrossRef]

- Li, R.T.; Tong, Z.X.; Huang, H.S.; Wang, C.Z.; Li, S.B. Study on infrared radiation characteristics of aircraft. Laser Infrared 2017, 47, 189–194. [Google Scholar] [CrossRef]

- Jin, J.; Zhu, G.J.; Xu, N.R.; Zhang, X.Y. Numerical simulation of infrared radiation characteristics for aeroengine high-speed exhaust system. J. Aerosp. Power 2002, 17, 582–585. [Google Scholar] [CrossRef]

- Decher, R. Infrared Emissions from Turbofans with High Aspect Ratio Nozzles. J. Aircr. 1981, 18, 1025–1031. [Google Scholar] [CrossRef]

- Nelson, E.L.; Mahan, J.R.; Birckelbaw, L.D.; Turk, J.A.; Wardwell, D.A.; Hange, C.E. Temperature, Pressure and Infrared Image Survey of an Axisymmetric Heated Exhaust Plume; NASA-TM-110382; US Government: Washington, DC, USA, 1996.

- Liu, Y.H.; Shao, W.R.; Zhang, J.X. Numerical simulation of flowfield and infrared characteristics of an aeroengine exhaust system and its plume. J. Aerosp. Power 2008, 23, 591–597. [Google Scholar] [CrossRef]

- Zhai, Q.H.; Wang, Q.; E Ri, Q.T. Numerical simulation of ir image of high-speed aircraft. Laser Infrared 2002, 32, 146–148. [Google Scholar] [CrossRef]

- Reardon, J.E.; Lee, Y.C. A Computer Program for Thermal Radiation from Gaseous Rocket Exhuast Plumes; GASRAD. RTR014-9; US Government: Washington, DC, USA, 1979.

- Luo, M.D.; Ji, H.H.; Huang, W. Numerical evaluation on infrared radiant intensity of exhaust system of turbine engine without afterburning. J. Aerosp. Power 2007, 22, 1609–1616. [Google Scholar] [CrossRef]

- Li, J.L.; Wang, W.H. Review of Infrared Radiation Characteristics Numerical Simulation Study on Unmanned Aerial Vehicle. Ship Electron. Eng. 2010, 30, 22–26. [Google Scholar] [CrossRef]

- Irwin, S.; Semerjian, H. Turbine Engine Infrared Signature Program. In Turbine Engine Infrared Signat. Program; Defense Technical Information Center: Alexandria, VA, USA, 1976. [Google Scholar] [CrossRef]

- Noah, M.A.; Kristl, J.; Schroeder, J.W.; Sandford, B.P. NIRATAM-NATO infrared air target model. Surveill. Technol. Int. Soc. Opt. Photonics 1991, 1479, 275–282. [Google Scholar]

- Cline, J.; Behm, D.; Kidd, K.; Young, K. F-22 IR Signature Flight Test Model Validation. Int. Aviat. Fall. 2003, 3, 9–11. [Google Scholar]

- Jin, J.; Zhu, G.J.; Xu, N.R.; Zhang, X.Y. Numerical calculation and analysis of infrared radiation characteristics of engine high-speed exhaust systems. J. Aerodyn. 2002, 17, 5. [Google Scholar]

- Zhang, S.Y.; Wang, S.W. Numerical computational study of infrared characteristics of axisymmetric vector nozzle. J. Aerodyn. 2004, 19, 3. [Google Scholar]

- Liu, Y.; Shao, W.; Zhang, J. Numerical simulation of flow field and infrared characteristics of engine exhaust system and wake jet. J. Aerodyn. 2008, 23, 4. [Google Scholar]

- Luo, M.D.; Ji, H.H.; Huang, W. Numerical computation of infrared radiation intensity of non-boosted turbine engine exhaust system. J. Aerodyn. 2007, 22, 10. [Google Scholar]

- Xu, D.; Sang, J.; Luo, M. Research on the application of infrared stealth technology to unmanned aircraft. Infrared Laser Eng. 2012, 41, 12. [Google Scholar]

- Huang, W. Research on Infrared Feature Calculation and Suppression Techniques for Turbofan Engine Exhaust System. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2010. [Google Scholar] [CrossRef]

- Huang, W. Research on Infrared Characteristic Calculation and Suppression Technology of Vorfan Engine Exhaust System. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2010. [Google Scholar]

- Yang, D.H. Apparent Radiative Properties Studies of High-Temperature Semitransparent Coatings. Master’s Thesis, University of Science and Technology of China, Hefei, China, 2011. [Google Scholar]

- Yu, B.; Deng, X.J.; Yang, Q.Z.; Xie, X.H.; Sun, Y.W. Investigation on Aerodynamics and Infrared Radiation Characteristics of Duplex-throat Aerodynamic Vector Nozzle. Trainer 2015, 1, 16–23. [Google Scholar]

- Ji, X.J.; Chen, S.G.; Jiang, B.K. Numerical simulation of infrared radiation for cruise missile exhaust system. Laser Infrared 2017, 47, 828–832. [Google Scholar]

- Wang, B.; Tong, Z.X.; Wang, C.Z.; Ma, B. Infrared image simulation of aircraft. Laser Infrared 2015, 8, 911–917. [Google Scholar] [CrossRef]

- Chen, S.G.; Chen, L.H.; Mo, D.L.; Shi, J.C.; Mei, F. Construction of Malkmus statistical narrow spectral band model parameters database based on HITEMP2010. Infrared Laser Eng. 2015, 44, 2327–2333. [Google Scholar] [CrossRef]

- Shi, J.W. Investigation on Flow Mechanism and Performance Estimation of Fixed-Geometric Thrust Vectoring Nozzle. Ph.D. Thesis, Northwestern Polytechnical University, Xi’an, China, 2011. [Google Scholar]

- Xu, N. Infrared Radiation and Guidance; National Defense Industry Press: Beijing, China, 1997. [Google Scholar]

- Xu, N.; Qu, R. Infrared properties of flying vehicles. Infrared Laser Eng. 1999, 28, 8–14. [Google Scholar]

- Zhang, J.; Fang, X. Infrared Physics; Xi’an University of Electronic Science and Technology Press: Xi’an, China, 2004. [Google Scholar]

- Rao, G.A.; Mahulikar, S.P. Aircraft Powerplant and Plume Infrared Signature Modelling and Analysis. AIAA 2005, 6, 221. [Google Scholar] [CrossRef]

- Mahulikar, S.P.; Sonawane, H.R.; Rao, G.A. Infrared Signature Studies of Aerospace Vehicles. Prog. Aerosp. Sci. 2007, 43, 218–245. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Zeng, H.; Li, Y.; He, L.; Chen, L. Numerical Study on Infrared Radiation Characteristics of Stealth Coating for Turbofan Engine Tail Nozzle. Energies 2022, 15, 7486. https://doi.org/10.3390/en15207486

Yuan Y, Zeng H, Li Y, He L, Chen L. Numerical Study on Infrared Radiation Characteristics of Stealth Coating for Turbofan Engine Tail Nozzle. Energies. 2022; 15(20):7486. https://doi.org/10.3390/en15207486

Chicago/Turabian StyleYuan, Yuwei, Hao Zeng, Yiwen Li, Liming He, and Lihai Chen. 2022. "Numerical Study on Infrared Radiation Characteristics of Stealth Coating for Turbofan Engine Tail Nozzle" Energies 15, no. 20: 7486. https://doi.org/10.3390/en15207486

APA StyleYuan, Y., Zeng, H., Li, Y., He, L., & Chen, L. (2022). Numerical Study on Infrared Radiation Characteristics of Stealth Coating for Turbofan Engine Tail Nozzle. Energies, 15(20), 7486. https://doi.org/10.3390/en15207486