Optimization of Operating Conditions of a Solid Oxide Fuel Cell System with Anode Off-Gas Recirculation Using the Model-Based Sensitivity Analysis

Abstract

:1. Introduction

2. Methodology

2.1. A System Configuration

2.2. Performance Factor

2.3. Sensitivity Analysis Parameters

2.4. Restrictions and Target Performance of the SOFC System

3. Results and Discussion

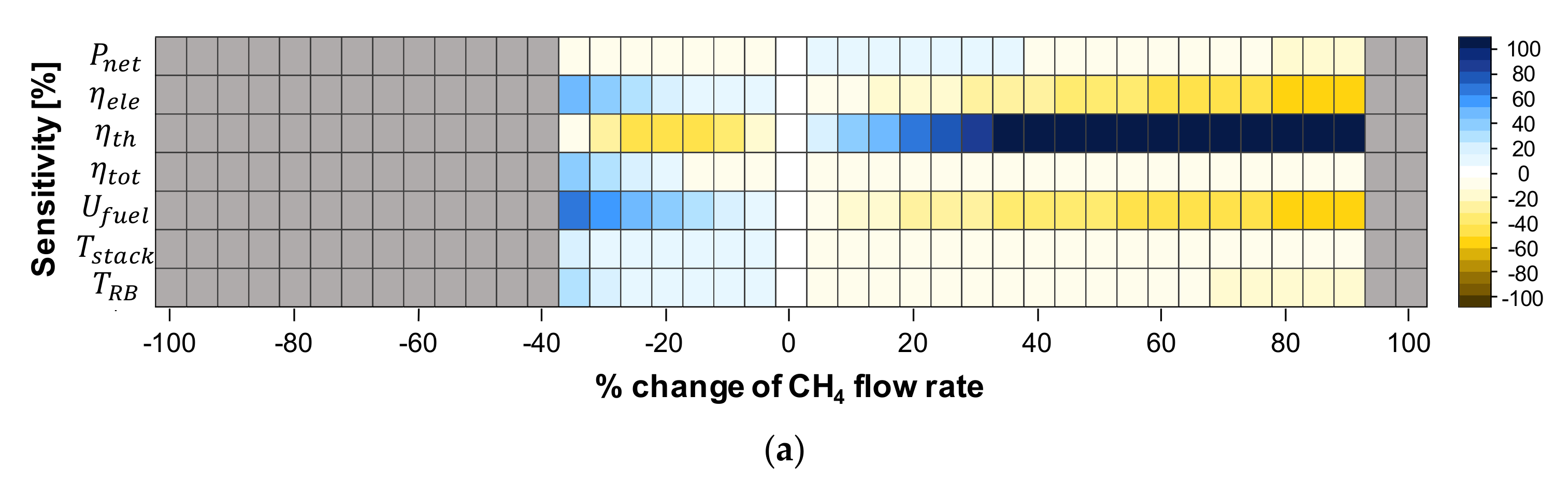

3.1. The Result of Sensitivity Analysis

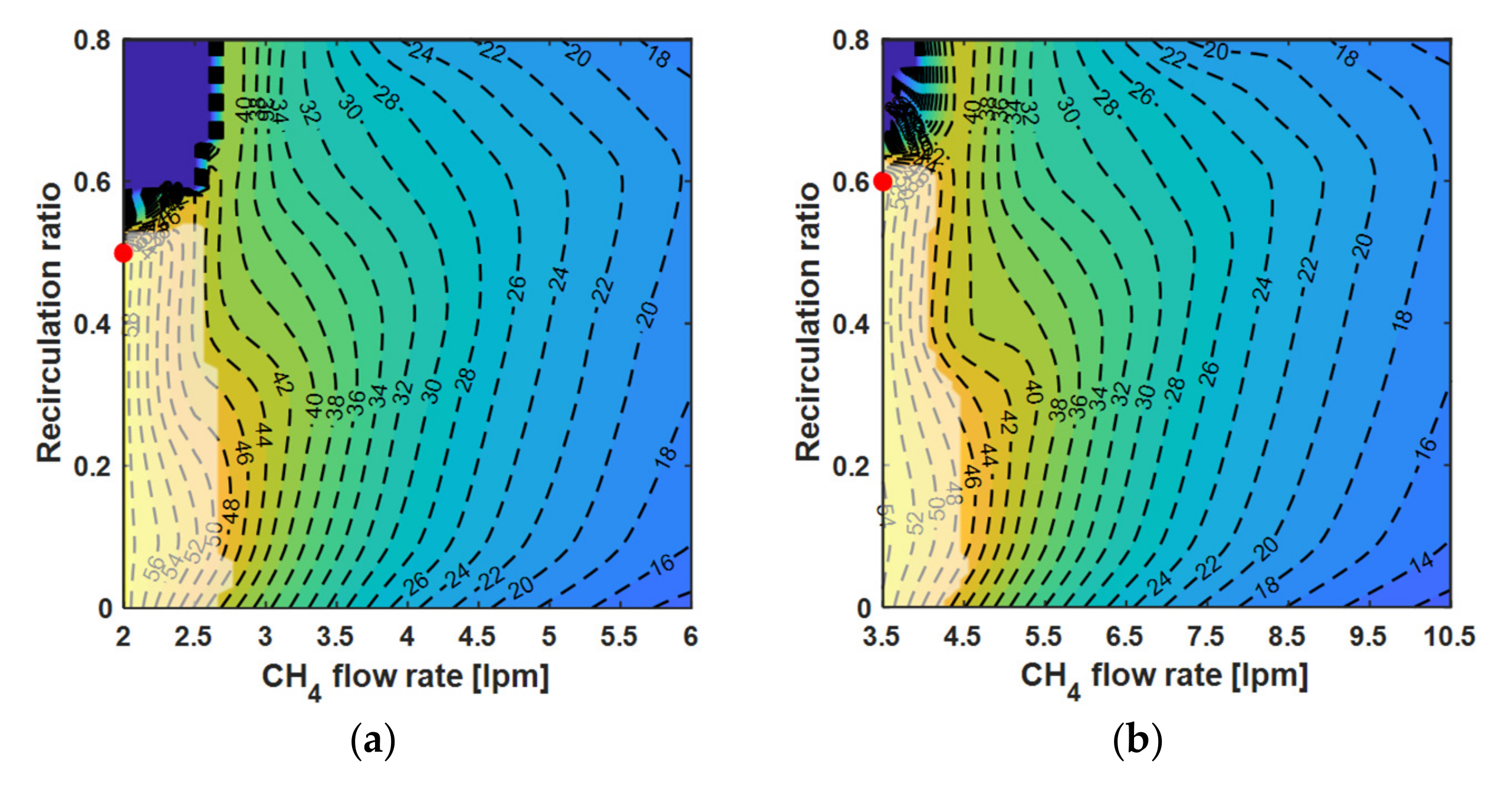

3.2. Optimization of Operating Condition

3.2.1. Desired Operating Conditions

3.2.2. Optimal Operating Point for Different Operating Scenario

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Nomenclature

| specific heat capacity (J kg−1 K−1) | |

| Faraday constant (C mole−1) | |

| current (A) | |

| current density (A cm−2) | |

| mass flow rate (kg s−1) | |

| molar flow rate (mole s−1) | |

| power (W) | |

| volume flow rate (lpm) | |

| temperature (K) | |

| utilization factor | |

| molar fraction | |

| efficiency | |

| Subscripts | |

| electrical | |

| thermal | |

| total | |

| outlet | |

| Abbreviations | |

| AOG | anode off-gas |

| AOGR | anode off-gas recirculation |

| BOP | balance of plant |

| CC | catalytic combustor |

| COG | cathode off-gas |

| CCOG | catalytic combustor off-gas |

| ESR | external steam reformer |

| HR-HE | heat recovery heat exchanger |

| LHV | lower heating value |

| RB | recirculation blower |

| RR | recirculation ratio |

| S/C | steam to carbon |

| SOFC | solid oxide fuel cell |

References

- Torii, R.; Tachikawa, Y.; Sasaki, K.; Ito, K. Anode Gas Recirculation for Improving the Performance and Cost of a 5-KW Solid Oxide Fuel Cell System. J. Power Sources 2016, 325, 229–237. [Google Scholar] [CrossRef]

- Xi, H.; Sun, J.; Tsourapas, V. A Control Oriented Low Order Dynamic Model for Planar SOFC Using Minimum Gibbs Free Energy Method. J. Power Sources 2007, 165, 253–266. [Google Scholar] [CrossRef]

- Haberman, B.A.; Young, J.B. Three-Dimensional Simulation of Chemically Reacting Gas Flows in the Porous Support Structure of an Integrated-Planar Solid Oxide Fuel Cell. Int. J. Heat Mass Transf. 2004, 47, 3617–3629. [Google Scholar] [CrossRef]

- Li, S.; Zhan, C.; Yang, Y. Control System Based on Anode Offgas Recycle for Solid Oxide Fuel Cell System. Math. Probl. Eng. 2018, 2018, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Fardadi, M.; Mueller, F.; Jabbari, F. Feedback Control of Solid Oxide Fuel Cell Spatial Temperature Variation. J. Power Sources 2010, 195, 4222–4233. [Google Scholar] [CrossRef]

- Peters, R.; Deja, R.; Engelbracht, M.; Frank, M.; Nguyen, V.N.; Blum, L.; Stolten, D. Efficiency Analysis of a Hydrogen-Fueled Solid Oxide Fuel Cell System with Anode Off-Gas Recirculation. J. Power Sources 2016, 328, 105–113. [Google Scholar] [CrossRef]

- Choi, E.-J.; Yu, S.; Kim, J.-M.; Lee, S.-M. Model-Based System Performance Analysis of a Solid Oxide Fuel Cell System with Anode Off-Gas Recirculation. Energies 2021, 14, 3607. [Google Scholar] [CrossRef]

- Wagner, P.H.; Van herle, J.; Schiffmann, J. Theoretical and Experimental Investigation of a Small-Scale, High-Speed, and Oil-Free Radial Anode Off-Gas Recirculation Fan for Solid Oxide Fuel Cell Systems. J. Eng. Gas Turbines Power 2020, 142, 041023. [Google Scholar] [CrossRef]

- Lee, T.S.; Chung, J.N.; Chen, Y.-C. Design and Optimization of a Combined Fuel Reforming and Solid Oxide Fuel Cell System with Anode Off-Gas Recycling. Energy Convers. Manag. 2011, 52, 3214–3226. [Google Scholar] [CrossRef]

- Testa, E.; Maggiore, P.; Pace, L. Sensitivity Analysis for a PEM Fuel Cell Model Aimed to Optimization. WSEAS Trans. Power Syst. 2015, 10, 10. [Google Scholar]

- Kalra, P.; Garg, R.K.; Kumar, A. Parametric Sensitivity Analysis for a Natural Gas Fueled High Temperature Tubular Solid Oxide Fuel Cell. Heliyon 2020, 6, e04450. [Google Scholar] [CrossRef] [PubMed]

- Kupecki, J. Sensitivity Analysis of Main Parameters of Pressurized SOFC Hybrid System. J. Power Technol. 2019, 99, 115. [Google Scholar]

- Dhingra, H.; Peppley, B.A. Sensitivity Analysis of a 1 KW Diesel-Fuelled SOFC Generator: A Single and Paired-Variable Study. J. Power Sources 2013, 239, 527–537. [Google Scholar] [CrossRef]

- Lee, K.; Kang, S.; Ahn, K.-Y. Development of a Highly Efficient Solid Oxide Fuel Cell System. Appl. Energy 2017, 205, 822–833. [Google Scholar] [CrossRef]

- Powell, M.; Meinhardt, K.; Sprenkle, V.; Chick, L.; McVay, G. Demonstration of a Highly Efficient Solid Oxide Fuel Cell Power System Using Adiabatic Steam Reforming and Anode Gas Recirculation. J. Power Sources 2012, 205, 377–384. [Google Scholar] [CrossRef]

- Koo, T.; Kim, Y.S.; Lee, D.; Yu, S.; Lee, Y.D. System Simulation and Exergetic Analysis of Solid Oxide Fuel Cell Power Generation System with Cascade Configuration. Energy 2021, 214, 119087. [Google Scholar] [CrossRef]

- Wagner, P.H.; Wuillemin, Z.; Constantin, D.; Diethelm, S.; Van herle, J.; Schiffmann, J. Experimental Characterization of a Solid Oxide Fuel Cell Coupled to a Steam-Driven Micro Anode Off-Gas Recirculation Fan. Appl. Energy 2020, 262, 114219. [Google Scholar] [CrossRef]

- Baba, S.; Takahashi, S.; Kobayashi, N.; Hirano, S. Performance of Anodic Recirculation by a Variable Flow Ejector for a Solid Oxide Fuel Cell System under Partial Loads. Int. J. Hydrogen Energy 2020, 45, 10039–10049. [Google Scholar] [CrossRef]

- Tanaka, Y.; Sato, K.; Yamamoto, A.; Kato, T. Development of Anode Off-Gas Recycle Blowers for High Efficiency SOFC Systems. ECS Trans. 2013, 57, 443–450. [Google Scholar] [CrossRef]

- Dietrich, R.-U.; Lindermeir, A.; Immisch, C.; Spieker, C.; Spitta, C.; Stenger, S.; Leithner, R.; Kuster, T.; Oberland, A. SOFC System Using a Hot Gas Ejector for Offgas Recycling for High Efficient Power Generation from Propane. ECS Trans. 2013, 57, 171–184. [Google Scholar] [CrossRef]

- Kong, Q.; Yin, Y.; Xue, B.; Jin, Y.; Feng, W.; Chen, Z.-G.; Su, S.; Sun, C. Improved Catalytic Combustion of Methane Using CuO Nanobelts with Predominantly (001) Surfaces. Beilstein J. Nanotechnol. 2018, 9, 2526–2532. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Fang, R.; Khan, J.A.; Dougal, R.A. Parameter Setting and Analysis of a Dynamic Tubular SOFC Model. J. Power Sources 2006, 162, 316–326. [Google Scholar] [CrossRef]

| Authors | SOFC Power | AOGR Device | Comments | |

|---|---|---|---|---|

| Lee et al. [14] | 5 kW | 64.6% | Ejector | The turbocharger and ejector were used to blow cathode air and AOG. Sensitivity analysis was conducted to determine the optimal operating schemes. |

| Powell et al. [15] | 1.7–2.2 kW | 56.6% (LHV) | Blower | The system used an adiabatic external steam reformer and AOGR system. Heat and steam for steam methane reforming were provided by recirculated AOG. |

| Koo et al. [16] | 113.8 kW | 66% (LHV) | Blower | A cascade system with double SOFC system and single SOFC system with AOGR was analyzed using the exergy-based analysis method. |

| Wagner et al. [8,17] | 6 kW | 66% (LHV) | Fan | A novel micro AOGR fan was introduced and experimentally coupled to SOFC system. |

| Baba et al. [18] | 1 kW | - | Ejector | SOFC system with a variable flow ejector was examined under partial load and full load conditions. |

| Tanaka et al. [19] | 10 kW | 58.7% (LHV) | Blower | AOGR blowers were developed and coupled with SOFC system simulator. |

| Dietrich et al. [20] | 0.3 kW | 41% (LHV) | Injector | SOFC running on propane with AOGR was experimentally examined and compared to a partial oxidation system. |

| Choi et al. [7] | 1 kW | 53.44% (LHV) | Blower | System performances with different system configurations were numerically examined and compared to the SOFC system without AOGR. |

| Torii et al. [1] | 5 kW | 69.2% | Blower | Effects of AOGR on system performance were investigated considering carbon deposition on a stack. The possibility of reducing operation cost with a AOGR system was also revealed. |

| Lee et al. [9] | 30 W | - | - | Sensitivity analysis of diverse parameters on a SOFC system’s performance with AOGR was conducted to predict key operating parameters and an optimal operating point was suggested. |

| Authors | System Variables | System Performance | Method | Results |

|---|---|---|---|---|

| Lee et al. [9] | S/C ratio, stack temperature, AOGR ratio, CO2 adsorbent | Power density, peak power, efficiency | Numerical individual parametric analysis | Suggested the optimal operating point for maximum efficiency (@ fuel cell temperature = 900 °C with S/C ratio > 3, maximum CO2 capture, and minimum AOG recirculation) |

| Kalra et al. [11] | S/C ratio, fuel temperature, pressure, geometry of the SOFC | Power density | Numerical individual parametric analysis | Compared the effects of each parameter |

| Kupecki [12] | Mass flow rate, pressure ratio and polytrophic efficiency of air compressor, fuel flow rate of combustion chamber, pre-heater heat exchanger UA factor | Electrical efficiency, outlet temperature of SOFC, gas turbine, and combustion chamber | Numerical individual parametric analysis | Compared the effects of each parameter |

| Dhingra et al. [13] | Air and fuel utilization, oxygen to carbon ratio, S/C ratio, temperature of inlet cathode and pre-heater | System efficiency, stack efficiency, system exhaust temperature | Numerical individual and paired parametric analysis | Suggested the optimal operating point, the maximum system and stack efficiency (@ air utilization = 0.5, fuel utilization = 0.9, S/C ratio = 3) |

| Lee et al. [14] | Fuel utilization, S/C ratio, external reforming ratio | Electrical and thermal efficiency | Numerical individual parametric analysis | Compared the effects of each parameter |

| Components | Descriptions | Ref. of Detailed Specifications |

|---|---|---|

| Stack | 1 kW class planar SOFC A direct internal reforming stack Anode-supported cell type | Table 2 in the paper [7] |

| ESR | An adiabatic reformer A shell and tube type catalytic reformer | Table 4 in the paper [7] |

| CC | A Pt-catalyzed monolithic combustor | Table 6 in the paper [7] |

| Parameter | Values | Variation | |

|---|---|---|---|

| Inlet fuel | CH4 | - | |

| Operating pressure of the system (bar) | 1.2 | - | |

| Operating current density (A/cm2) | 0.3, 0.5 | - | |

| Exhaust gas temperature (K) | 393.15 | - | |

| S/C ratio at ESR | 2.5 | - | |

| Ambient temperature (K) | 298.15 | - | |

| Fuel flow rate (lpm) | j = 0.3 A/cm2 | 3.20 | 2.00–6.00 |

| j = 0.5 A/cm2 | 5.35 | 3.50–10.50 | |

| Air flow rate (lpm) | j = 0.3 A/cm2 | 30.56 | 20.00–60.00 |

| j = 0.5 A/cm2 | 50.94 | 30.00–100.00 | |

| Recirculation ratio | 0.4 | 0–0.8 | |

| Parameter | Values |

|---|---|

| Desired operating temperature of an SOFC stack (K) | 973.15–1123.15 |

| Maximum temperature of a recirculation blower (K) | 1073.15 |

| Maximum temperature of a catalytic combustor (K) | 1123.15 |

| Target fuel utilization factor | 0.7 |

| Target electrical efficiency of the system (%) | 45 |

| 1. Sensitivity of CH4 Flow Rate to System Performance (%) | ||||||||||||||||||||||

| Load | ||||||||||||||||||||||

| % Change | −100 | −80 | −60 | −40 | −20 | 0 | 20 | 40 | 60 | 80 | 100 | −100 | −80 | −60 | −40 | −20 | 0 | 20 | 40 | 60 | 80 | 100 |

| - | - | - | - | −8.5 | 0 | 2.9 | −1.0 | −6.1 | −10.3 | - | - | - | - | - | −12.1 | 0 | 2.8 | −2.5 | −7.6 | −12.2 | - | |

| - | - | - | - | 14.6 | 0 | −14.5 | −28.9 | −41.4 | −50.6 | - | - | - | - | - | 9.7 | 0 | −14.4 | −30.3 | −42.3 | −51.2 | - | |

| - | - | - | - | −47.6 | 0 | 61.8 | 116 | 161.8 | 199 | - | - | - | - | - | −47.6 | 0 | 57.2 | 107.5 | 149.7 | 182.4 | - | |

| - | - | - | - | 4.1 | 0 | −1.8 | −4.8 | −7.5 | −8.9 | - | - | - | - | - | -1.4 | 0 | −1.4 | −5.4 | −7.5 | −8.9 | - | |

| - | - | - | - | 33.1 | 0 | −20.4 | −33.4 | −43.0 | −50.5 | - | - | - | - | - | 33.6 | 0 | −20.3 | −33.6 | −43.0 | −50.1 | - | |

| - | - | - | - | 3.2 | 0 | −0.8 | −2.7 | −4.8 | −6.0 | - | - | - | - | - | 4.4 | 0 | −0.9 | −3.8 | −5.6 | −6.9 | - | |

| - | - | - | - | 6.4 | 0 | −3.9 | −7.3 | −9.6 | −10.6 | - | - | - | - | - | 7.8 | 0 | −4.0 | −8.8 | −10.4 | −11.4 | - | |

| 2. Sensitivity of Air Flow Rate to System Performance (%) | ||||||||||||||||||||||

| Load | ||||||||||||||||||||||

| % Change | −100 | −80 | −60 | −40 | −20 | 0 | 20 | 40 | 60 | 80 | 100 | −100 | −80 | −60 | −40 | −20 | 0 | 20 | 40 | 60 | 80 | 100 |

| - | - | - | - | 1.7 | 0 | −2.9 | −5.9 | −8.7 | −11.4 | - | - | - | - | 4.7 | 3.3 | 0 | −3.2 | −6.2 | −9.2 | −12.0 | - | |

| - | - | - | - | 1.7 | 0 | −2.9 | −5.9 | −8.7 | −11.4 | - | - | - | - | 4.7 | 3.3 | 0 | −3.2 | −6.2 | −9.2 | −12.0 | - | |

| - | - | - | - | −19.7 | 0 | 9.4 | 18.3 | 27.5 | 36.6 | - | - | - | - | −33.6 | −9.2 | 0 | 9.3 | 18.6 | 27.9 | 37.1 | - | |

| - | - | - | - | −1.9 | 0 | −0.9 | −1.8 | −2.6 | −3.4 | - | - | - | - | −2.3 | 1 | 0 | −0.9 | −1.7 | −2.5 | −3.1 | - | |

| - | - | - | - | 0 | 0 | 0 | 0 | 0 | 0 | - | - | - | - | 0 | 0 | 0 | 0 | 0 | 0 | 0 | - | |

| - | - | - | - | 0.7 | 0 | −1.2 | −2.3 | −3.2 | −4.1 | - | - | - | - | 2.4 | 1.7 | 0 | −1.4 | −2.6 | −3.6 | −4.5 | - | |

| - | - | - | - | −1.5 | 0 | 0.8 | 1 | 1 | 0.9 | - | - | - | - | −1.7 | −2.0 | 0 | 0.7 | 0.8 | 0.8 | 0.6 | - | |

| 3. Sensitivity of Recirculation Ratio to System Performance (%) | ||||||||||||||||||||||

| Load | ||||||||||||||||||||||

| % Change | −100 | −80 | −60 | −40 | −20 | 0 | 20 | 40 | 60 | 80 | 100 | −100 | −80 | −60 | −40 | −20 | 0 | 20 | 40 | 60 | 80 | 100 |

| −9.9 | −1.9 | 2.4 | 4.8 | 4.7 | 0 | −4.7 | −10.5 | −15.2 | −17.3 | −16.8 | −13.3 | −2.9 | 1.6 | 4.3 | 4.8 | 0 | −4.8 | −11.3 | −15.6 | −16.9 | −16.8 | |

| −10.2 | −1.9 | 2.4 | 4.8 | 4.7 | 0 | −4.7 | −10.5 | −15.2 | −17.3 | −16.8 | −13.3 | −2.9 | 1.6 | 4.3 | 4.8 | 0 | −4.8 | −11.3 | −15.6 | −16.9 | −16.8 | |

| 45.3 | 257.5 | 200.8 | 116.8 | 49.7 | 0 | −40.7 | −72.4 | −90.1 | −97.7 | −100.0 | 368.6 | 269.2 | 185.2 | 110.2 | 46.8 | 0 | −38.5 | −68.8 | −84.2 | −91.4 | −96.3 | |

| −0.9 | 41.7 | 35.2 | 23.5 | 12.1 | 0 | −10.7 | −20.8 | −27.7 | −30.7 | −30.7 | 55.9 | 46.2 | 35 | 23.6 | 12.3 | 0 | −10.9 | −21.7 | −28.1 | −30.4 | −31.2 | |

| 8.2 | 5.4 | 3.1 | 1.4 | 0.4 | 0 | 0.5 | 2.3 | 4.1 | 4.9 | 4.7 | 8.6 | 5.5 | 3.1 | 1.4 | 0.4 | 0 | 0.5 | 2.4 | 3.7 | 4 | 3.8 | |

| −5.4 | 0.3 | 1.5 | 2.2 | 2.3 | 0 | −1.5 | −2.2 | −1.9 | −1.2 | −0.8 | 1.8 | 0.5 | 1 | 1.9 | 2.4 | 0 | −1.5 | −2.0 | −1.6 | −1.0 | −0.6 | |

| - | −11.5 | −3.6 | −1.6 | −0.1 | 0 | 0.9 | 2.7 | 5.3 | 8.2 | 11 | −12.1 | −4.1 | −1.8 | −0.1 | 0 | 0.9 | 2.9 | 5.7 | 8.6 | 11.5 | ||

| Operating Conditions and the System Performances | ||||

|---|---|---|---|---|

| Load | ||||

| 851.2 (●) | 863.7 (●) | 1374.8 (●) | 1398.5 (●) | |

| (lpm) | 2.6 | 3.2 | 4.4 | 5.3 |

| 0.11 | 0.28 | 0.15 | 0.29 | |

| (%) | 50.4 | 41.7 | 48.1 | 40.7 |

| (%) | 17.3 | 14.3 | 16.1 | 13.9 |

| (%) | 67.9 | 56.0 | 64.3 | 54.7 |

| 0.72 | 0.56 | 0.71 | 0.56 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, E.-J.; Yu, S.; Lee, S.-M. Optimization of Operating Conditions of a Solid Oxide Fuel Cell System with Anode Off-Gas Recirculation Using the Model-Based Sensitivity Analysis. Energies 2022, 15, 644. https://doi.org/10.3390/en15020644

Choi E-J, Yu S, Lee S-M. Optimization of Operating Conditions of a Solid Oxide Fuel Cell System with Anode Off-Gas Recirculation Using the Model-Based Sensitivity Analysis. Energies. 2022; 15(2):644. https://doi.org/10.3390/en15020644

Chicago/Turabian StyleChoi, Eun-Jung, Sangseok Yu, and Sang-Min Lee. 2022. "Optimization of Operating Conditions of a Solid Oxide Fuel Cell System with Anode Off-Gas Recirculation Using the Model-Based Sensitivity Analysis" Energies 15, no. 2: 644. https://doi.org/10.3390/en15020644

APA StyleChoi, E.-J., Yu, S., & Lee, S.-M. (2022). Optimization of Operating Conditions of a Solid Oxide Fuel Cell System with Anode Off-Gas Recirculation Using the Model-Based Sensitivity Analysis. Energies, 15(2), 644. https://doi.org/10.3390/en15020644