A Proportional Digital Controller to Monitor Load Variation in Wind Turbine Systems

Abstract

:1. Introduction

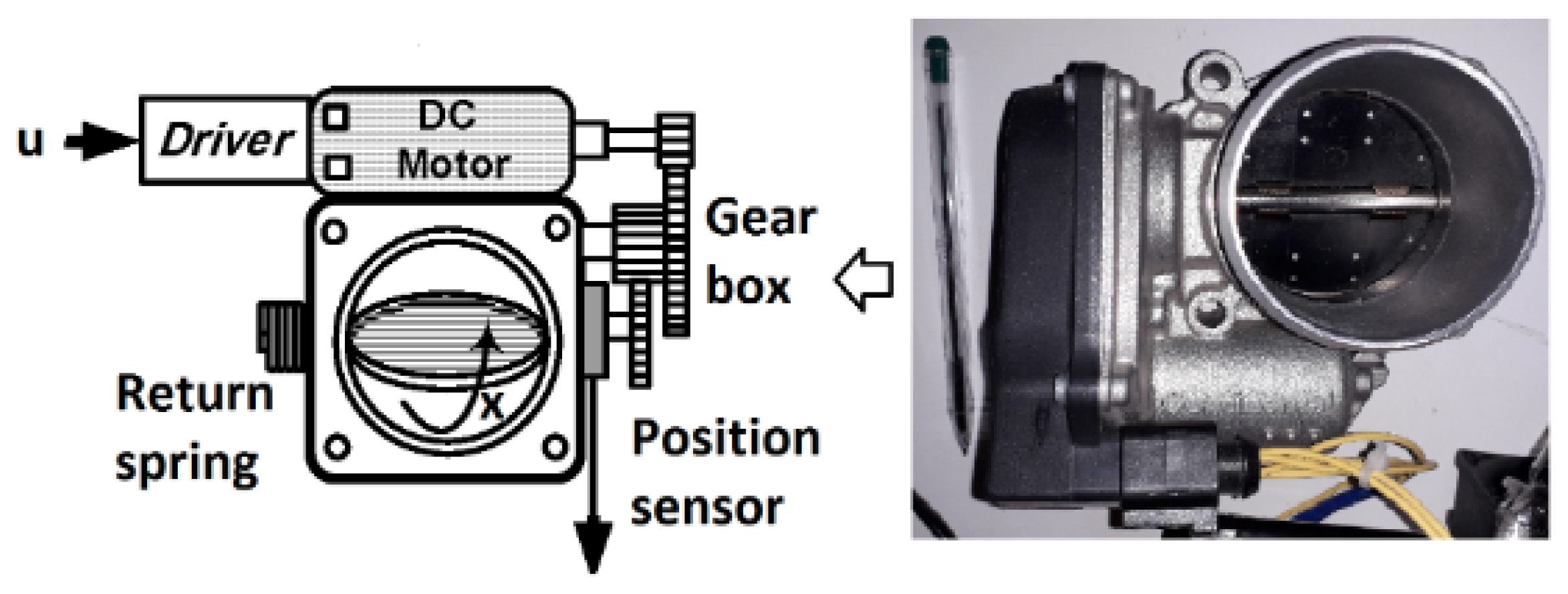

- Design of an experimental platform capable of reproducing the load variation in a wind turbine blade system. The electronics accompanying the throttle valve are modified to emulate the use of a real wind turbine with varying load on the blades.

- Implementation of a proportional digital micro-controller capable of detecting load variations.

- Define an algorithm that allows the detection of failures by studying only a specific statistical parameter, such as the statistical point change detection method.

2. Materials and Methods

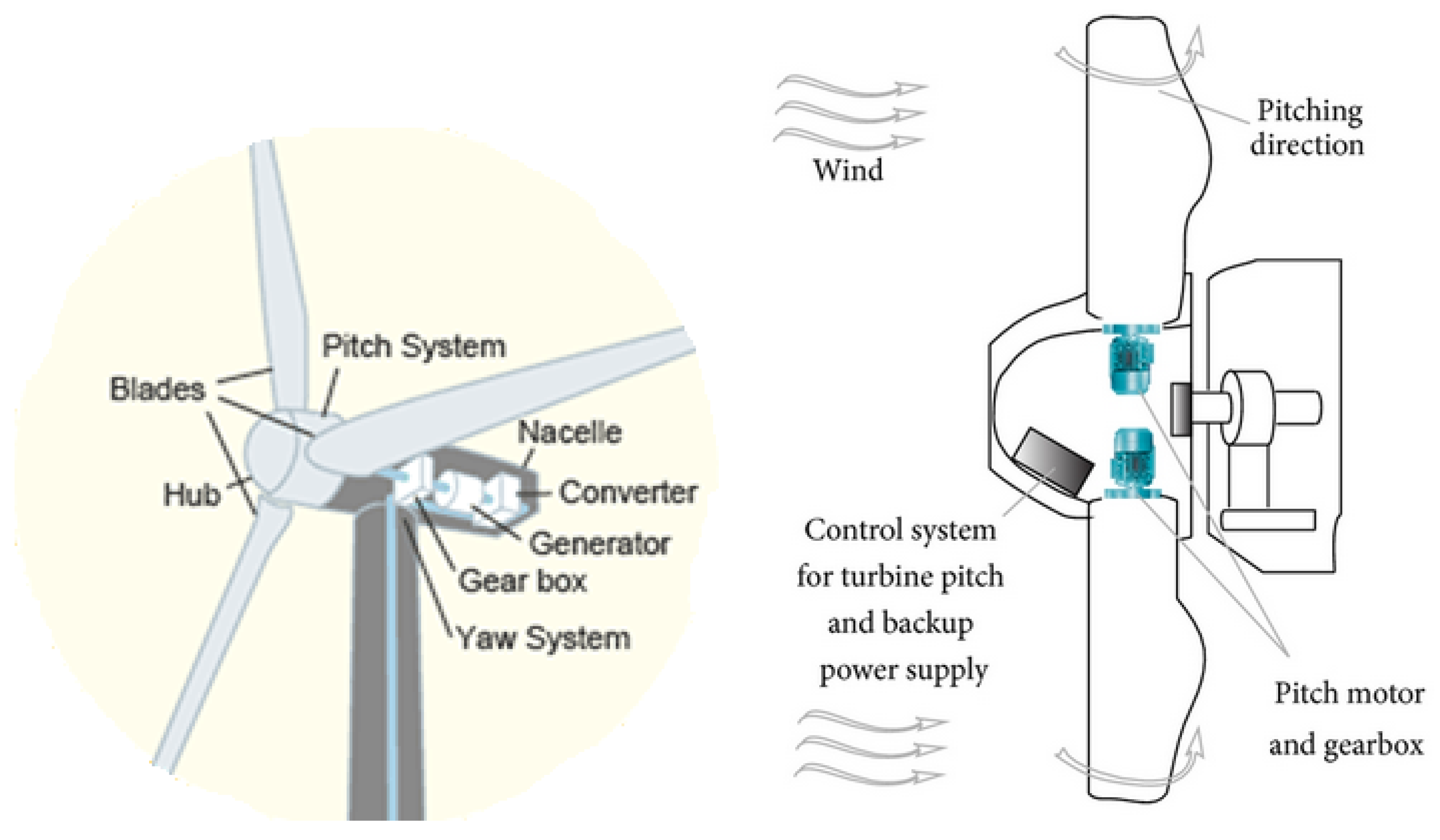

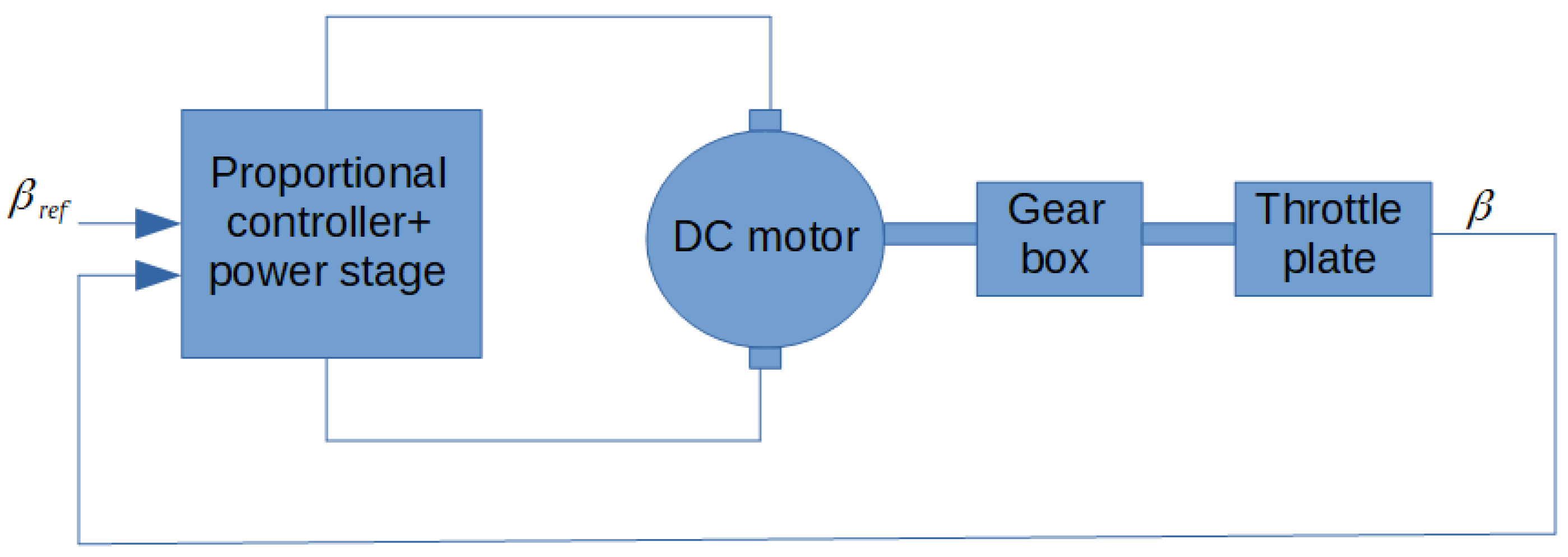

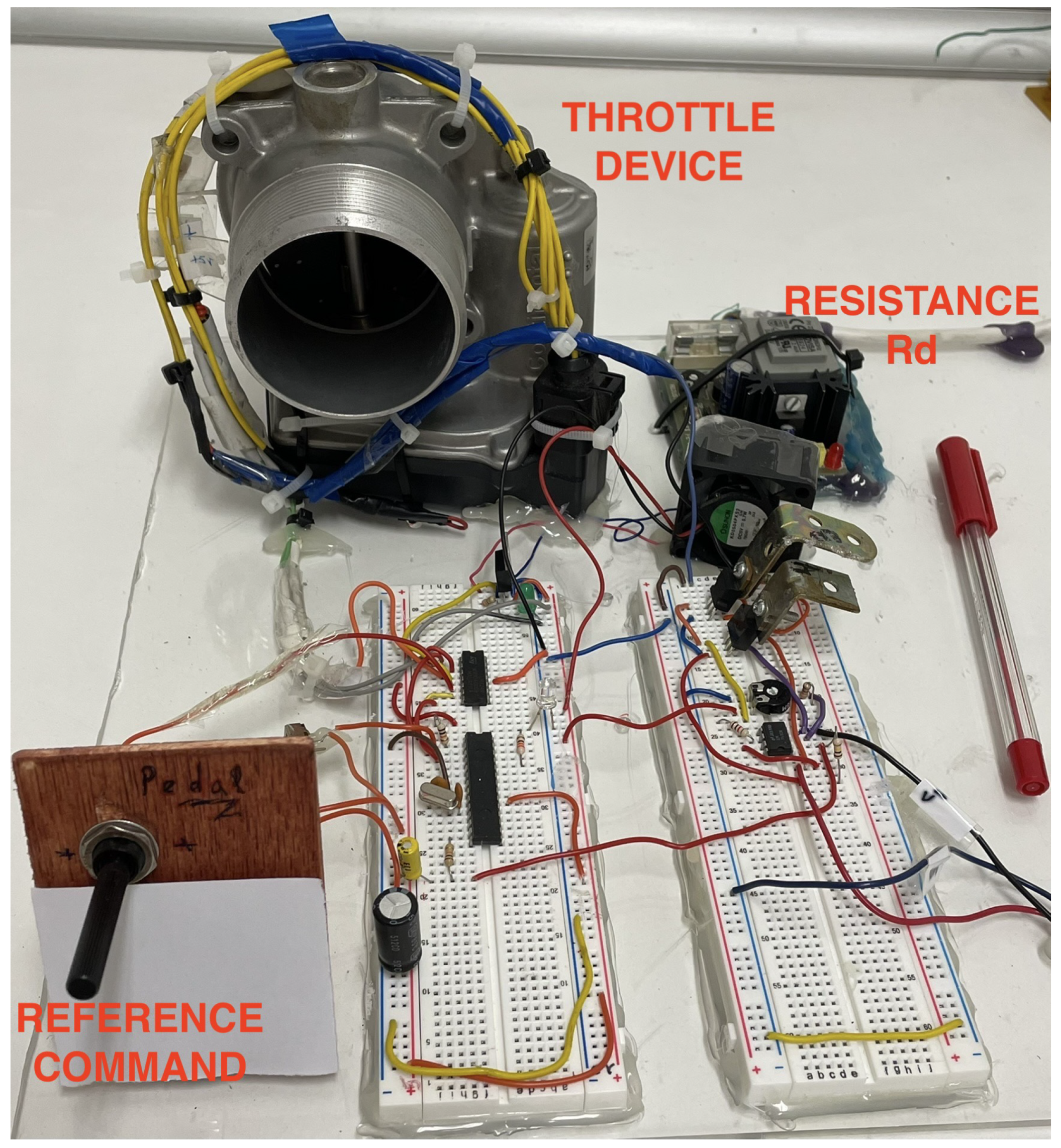

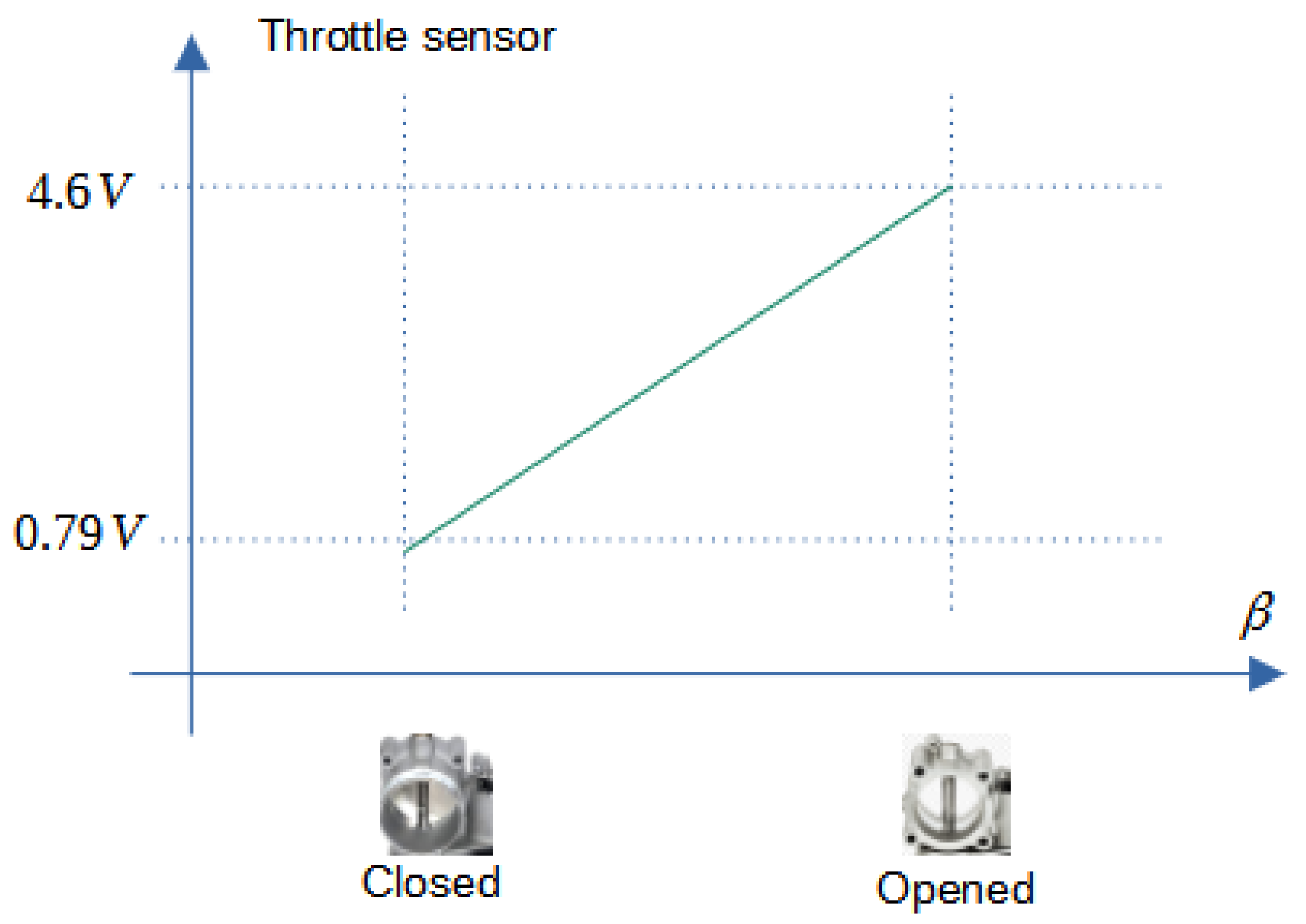

2.1. Load Blade Emulator

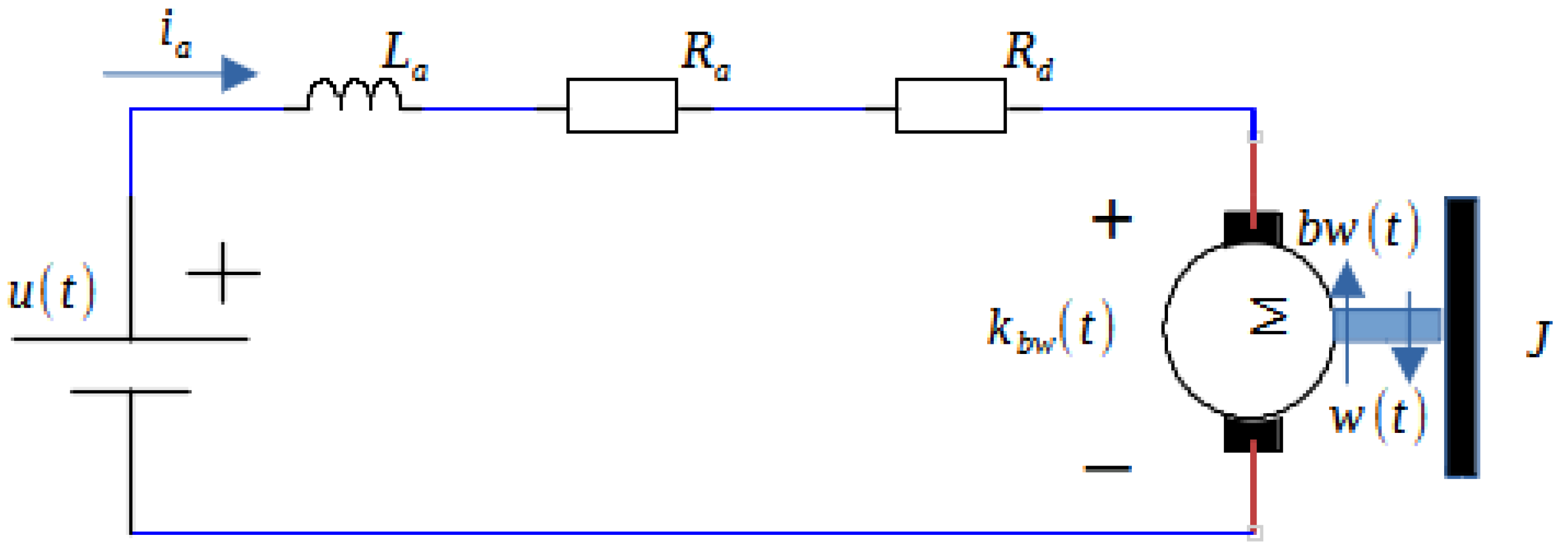

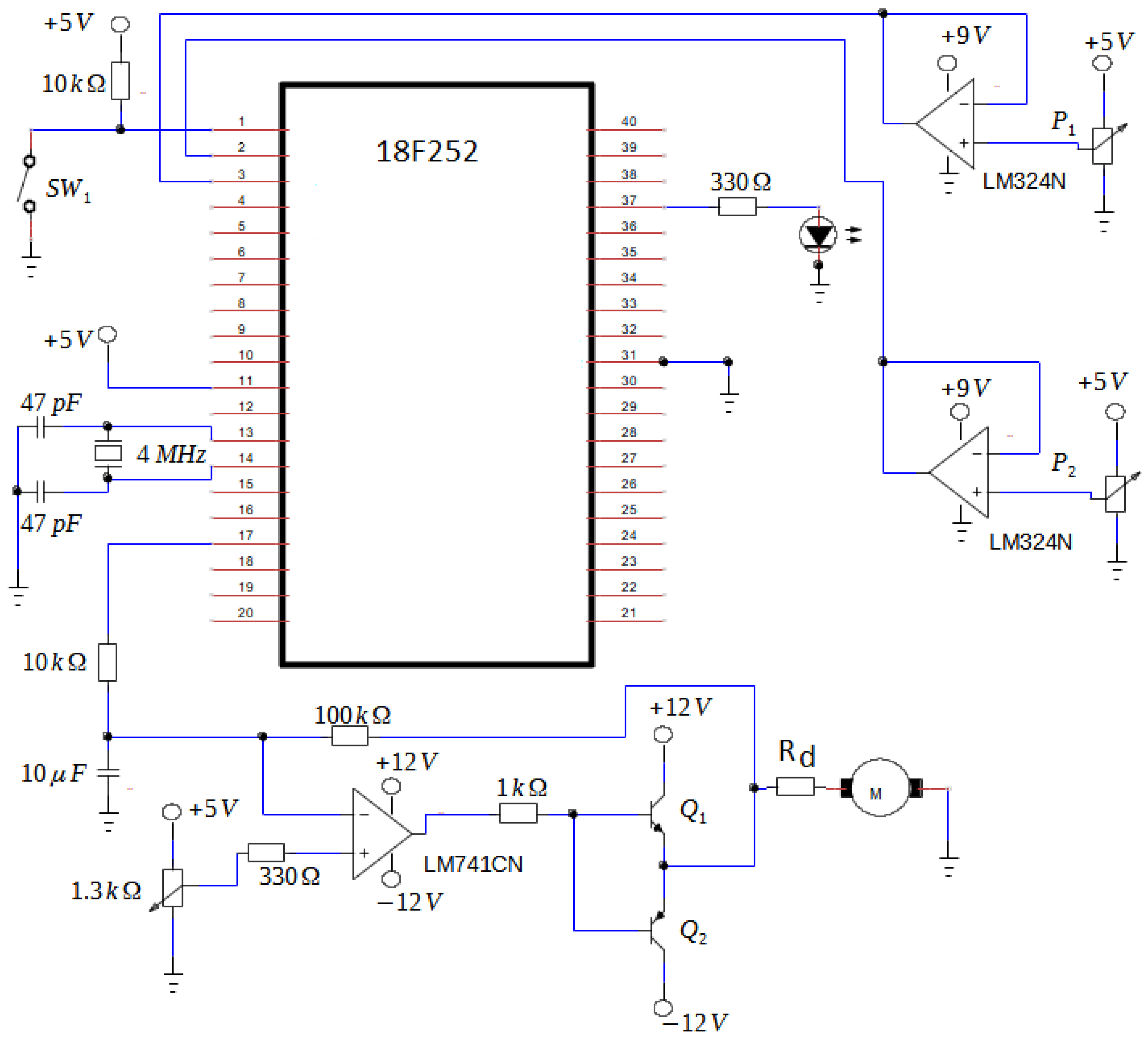

2.2. Electronic Circuit Design

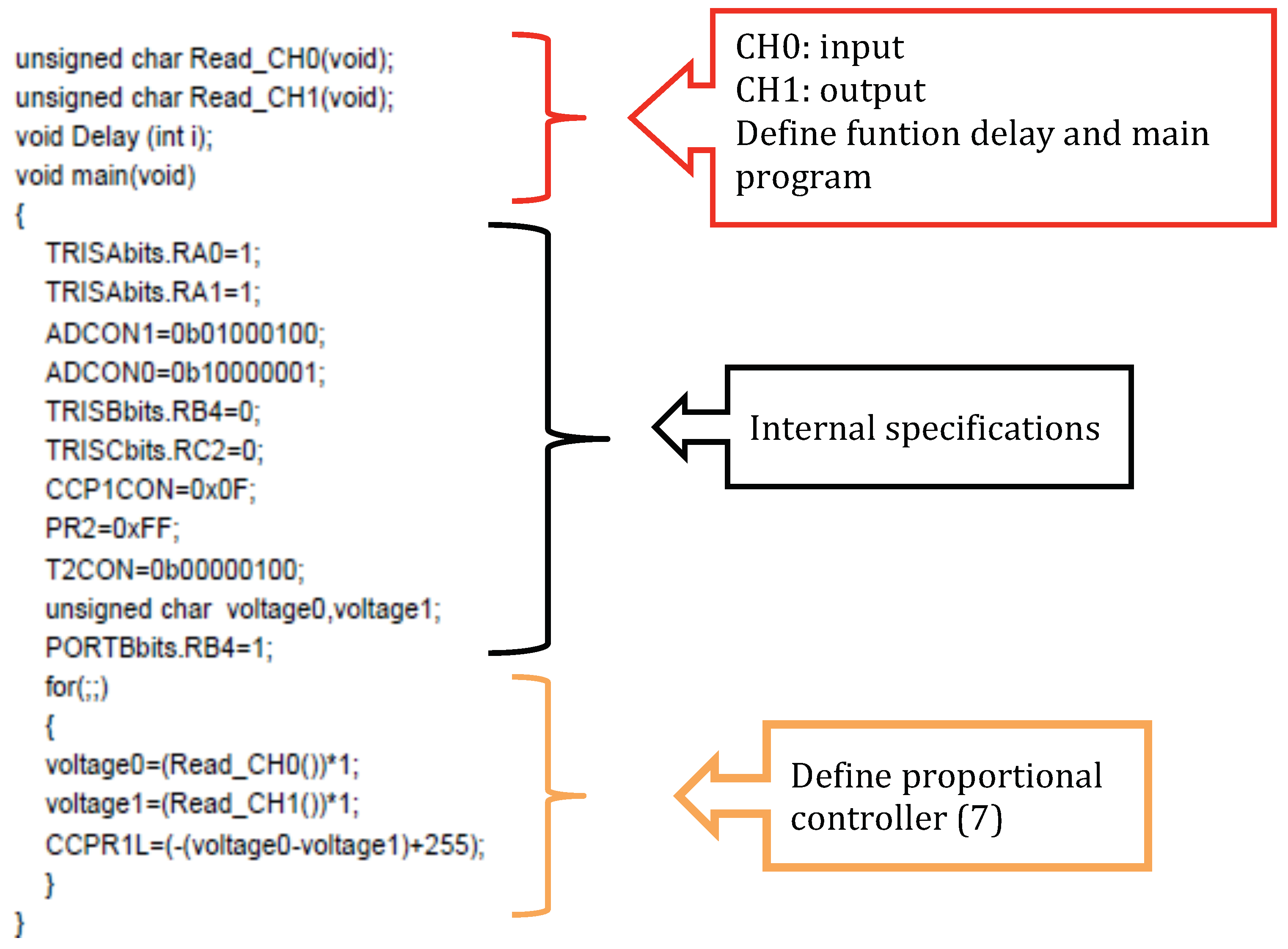

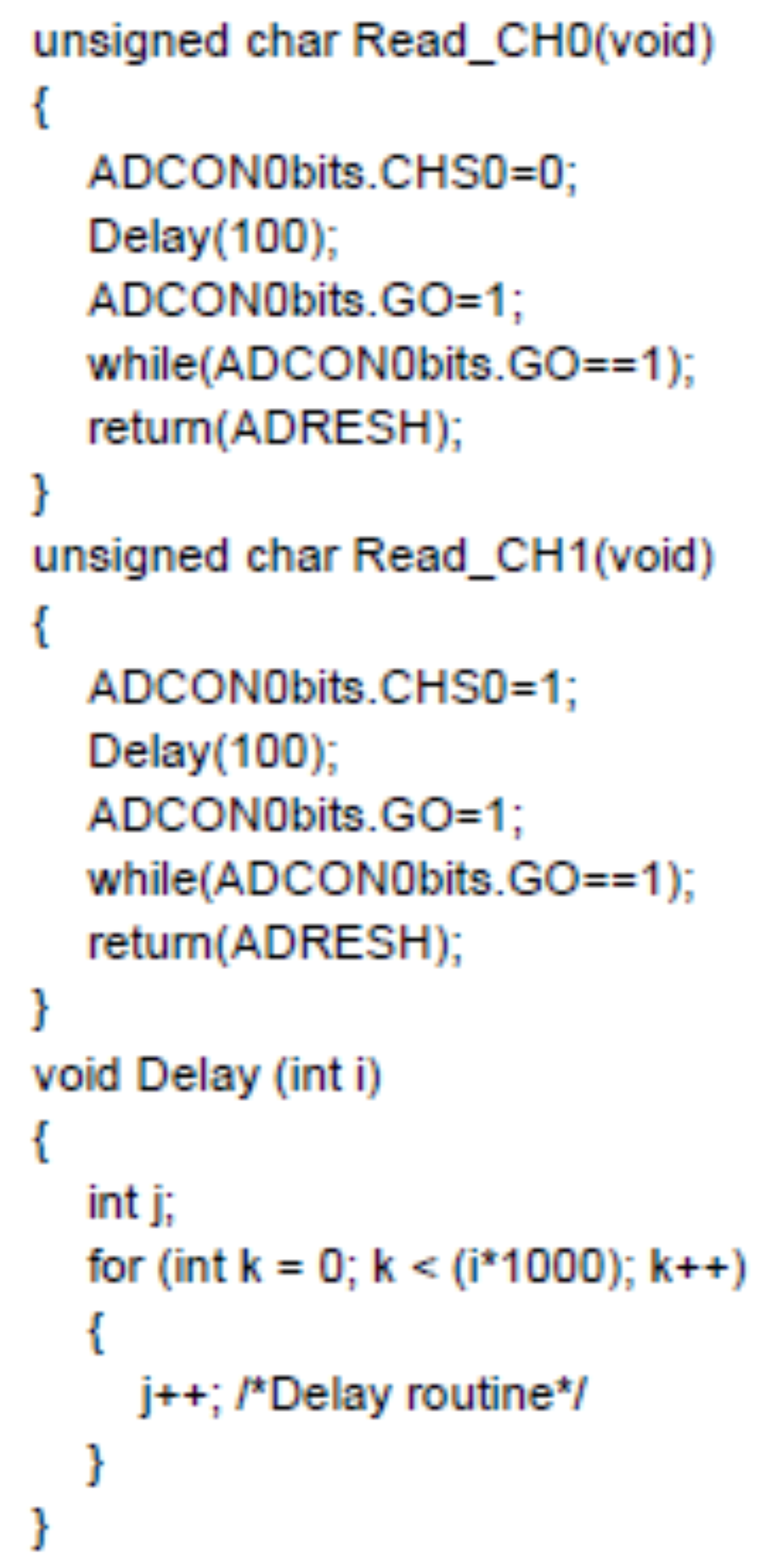

2.3. Micro-Controller Programming

3. Results

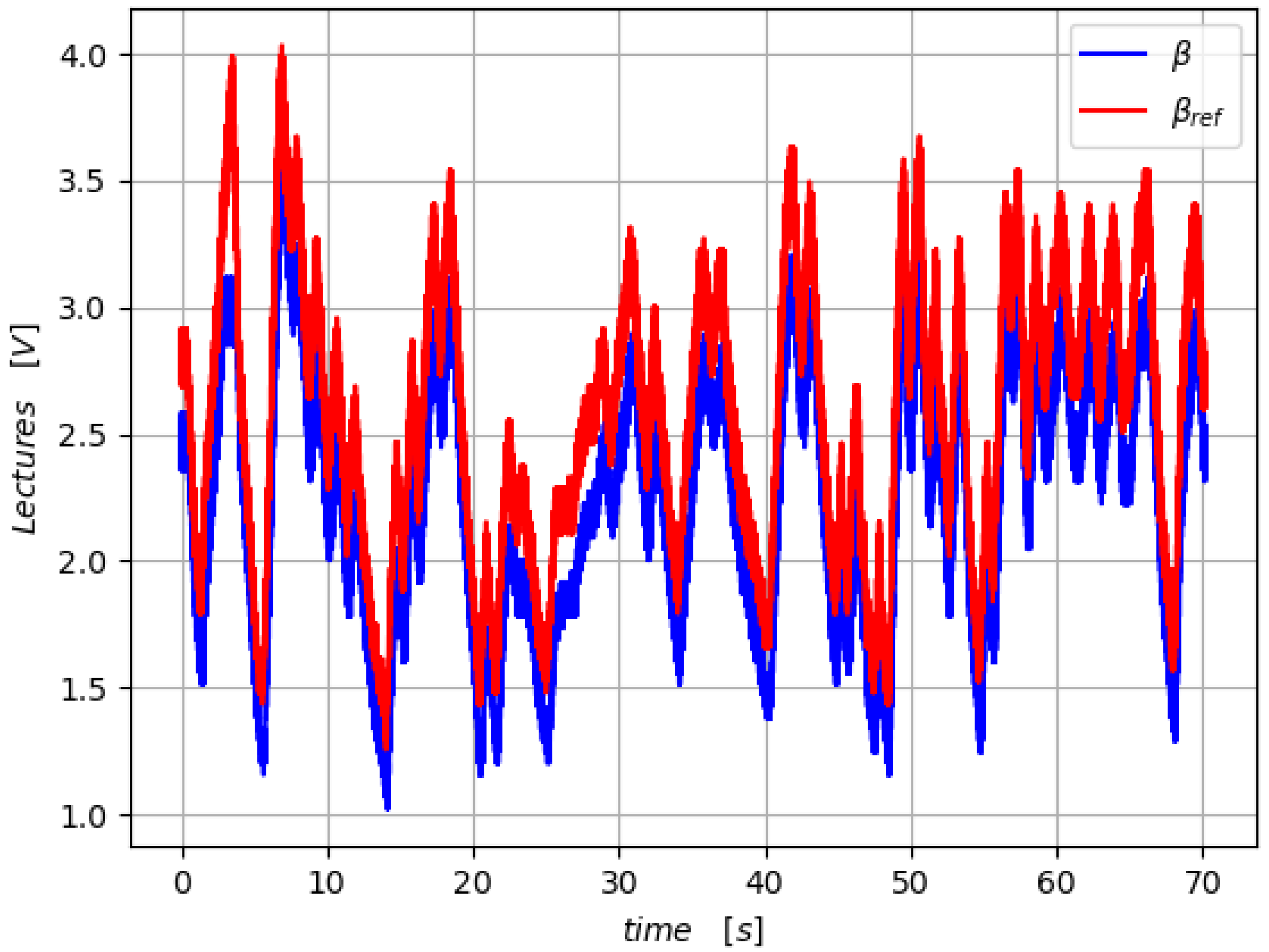

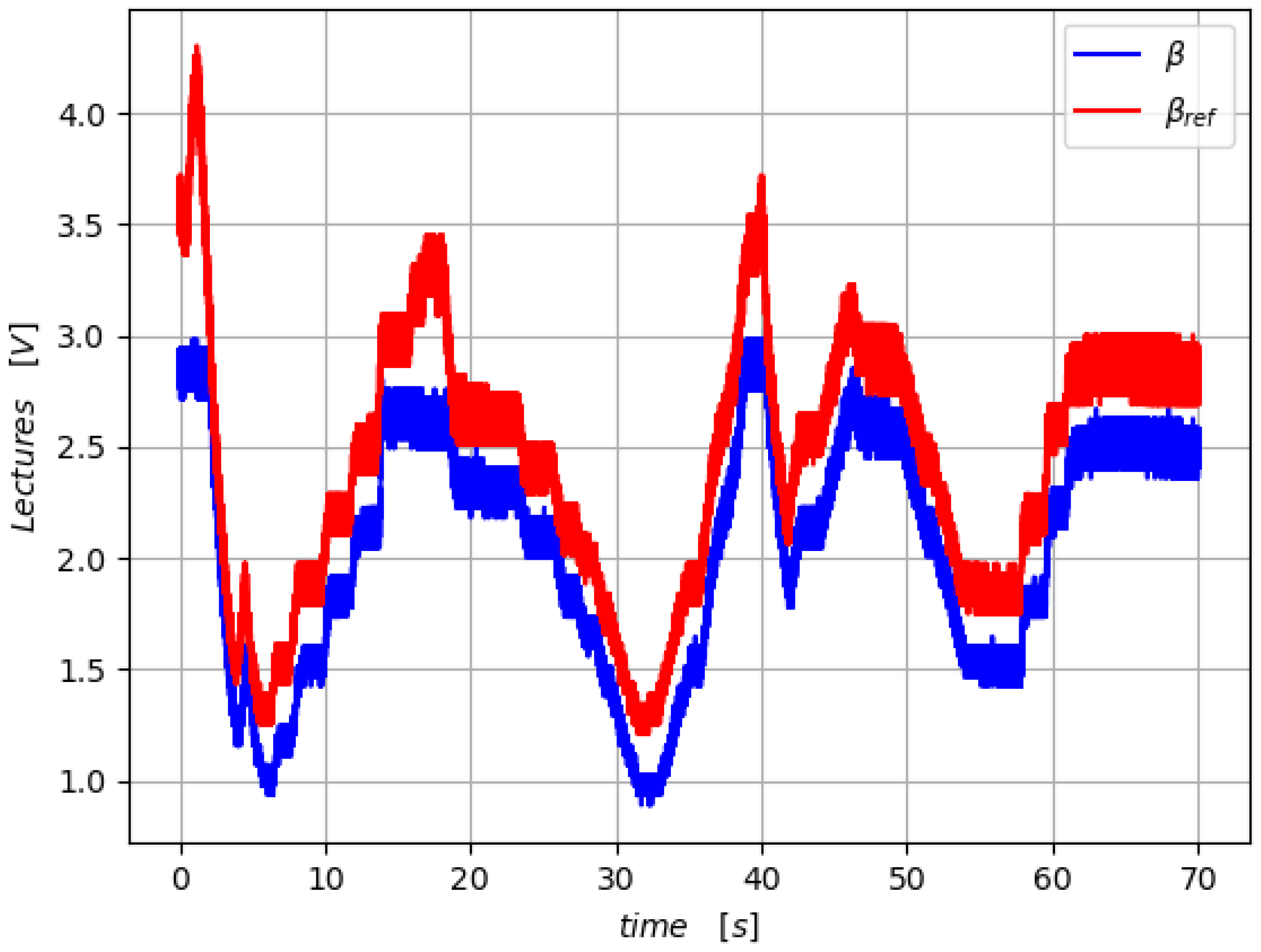

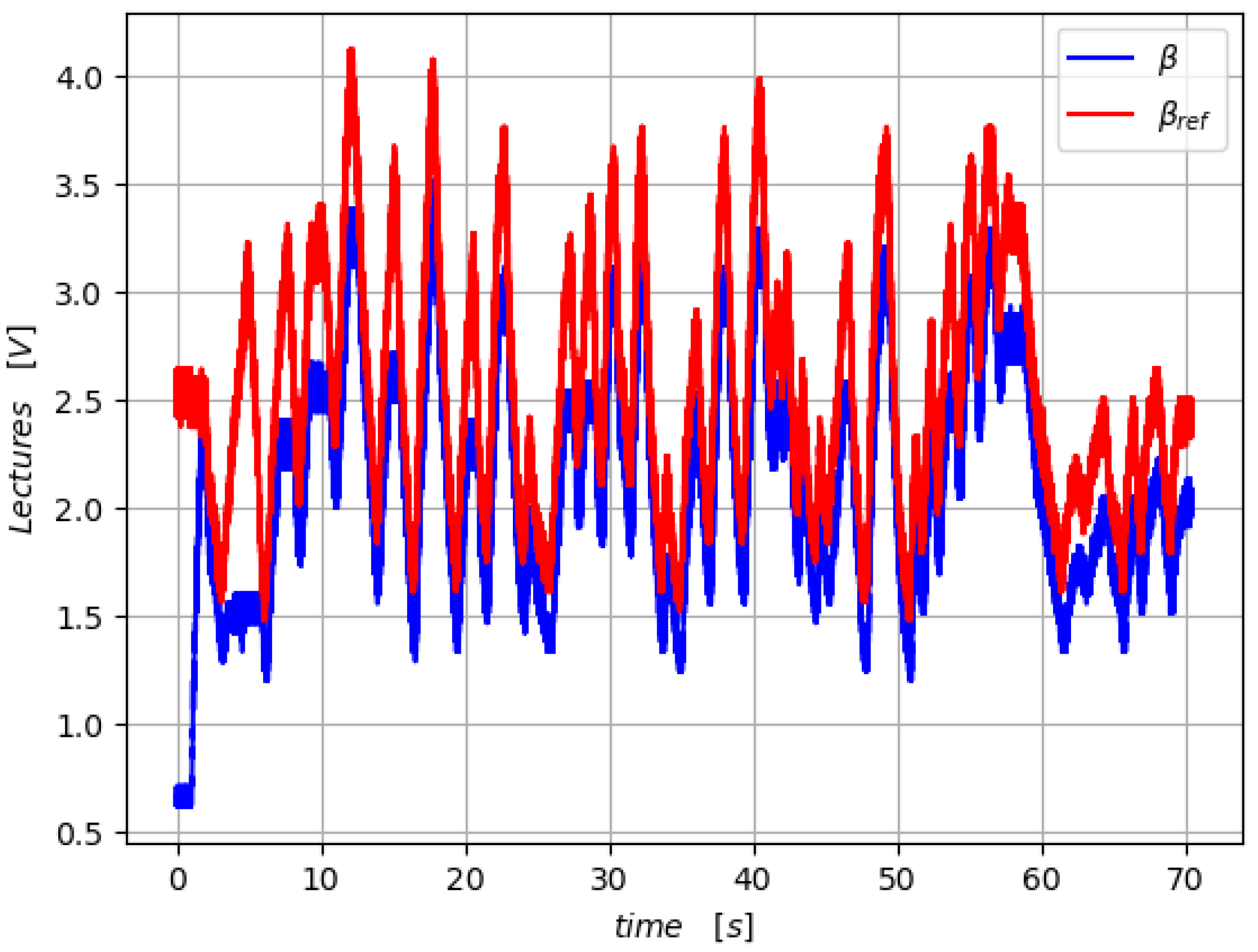

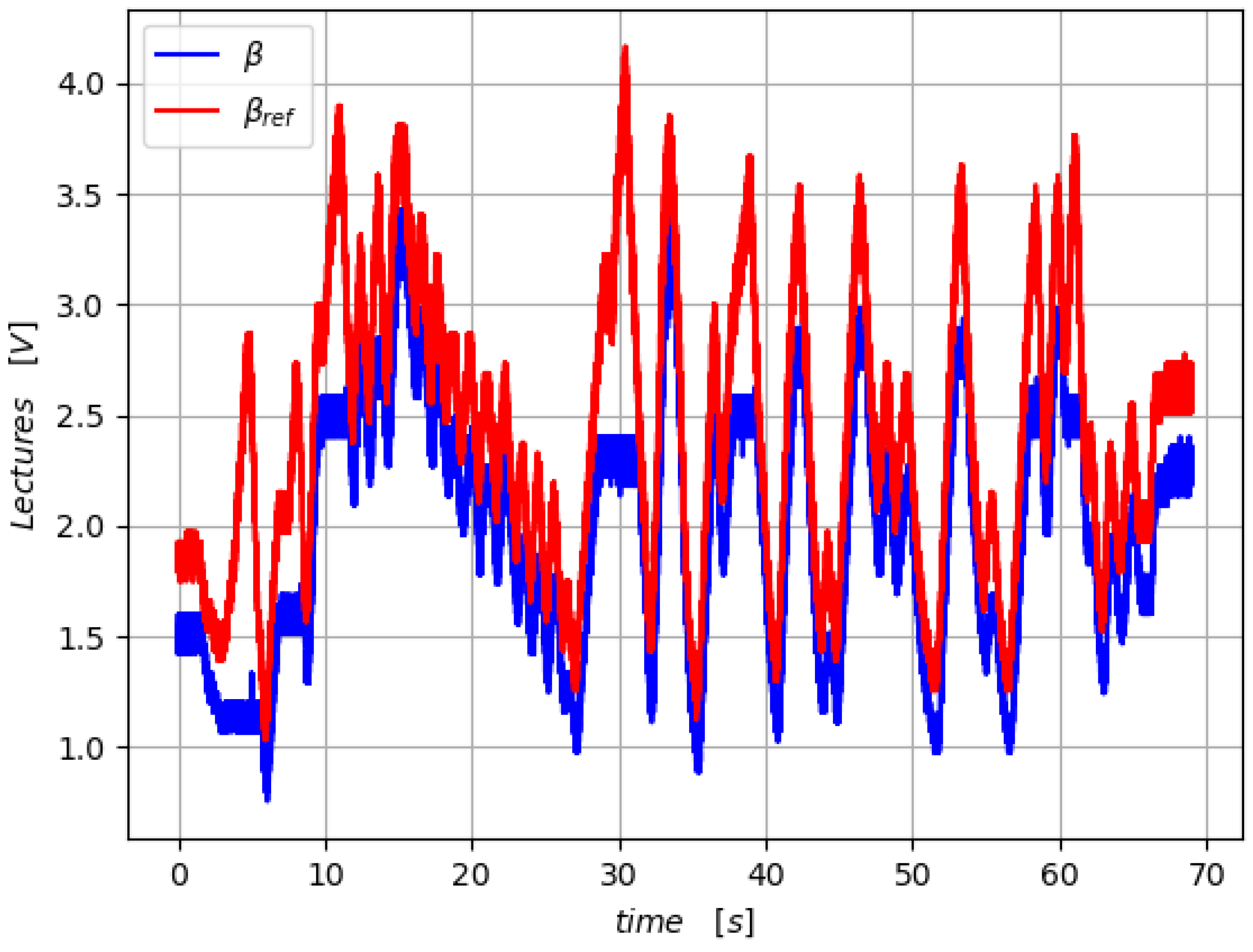

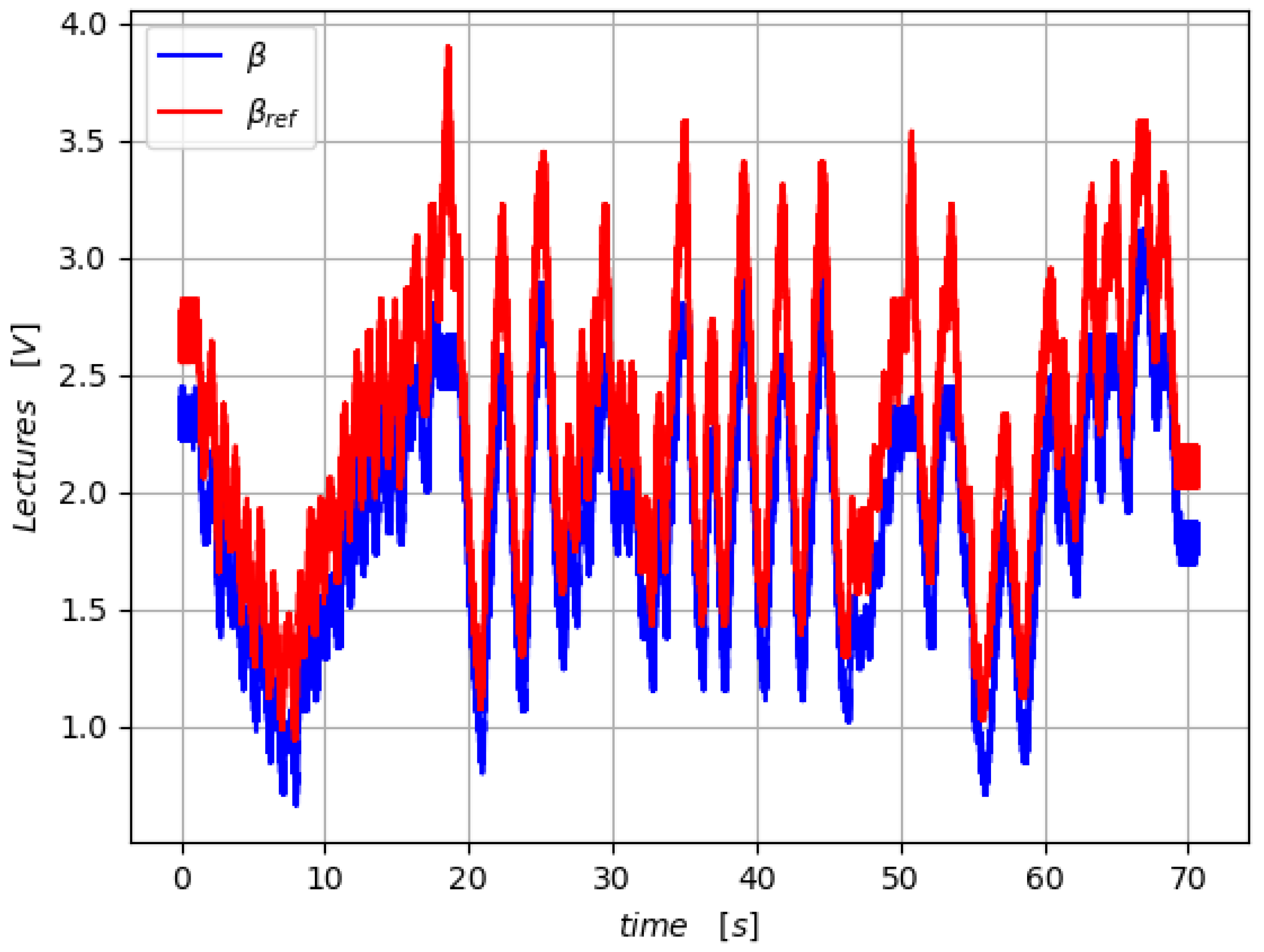

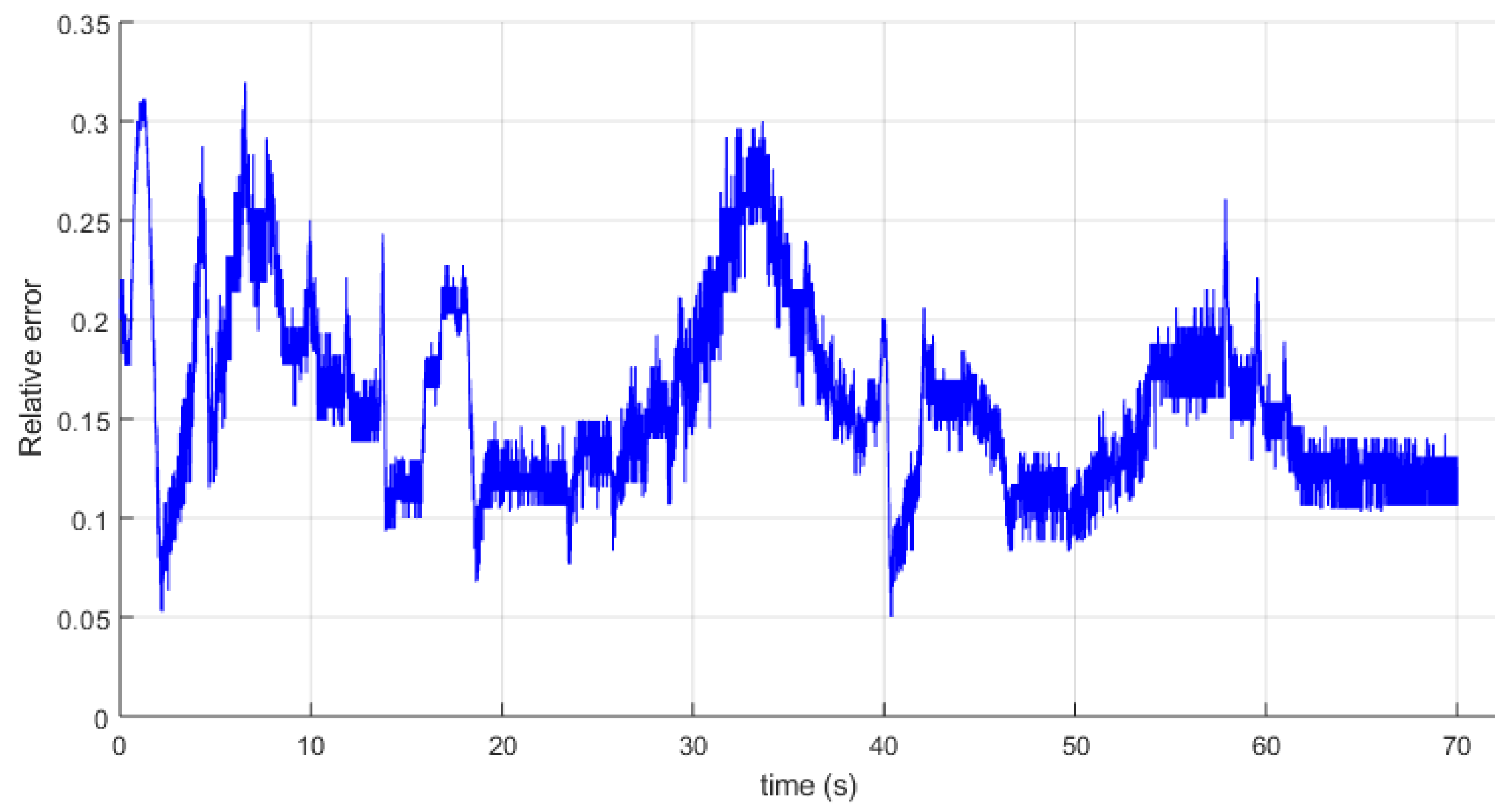

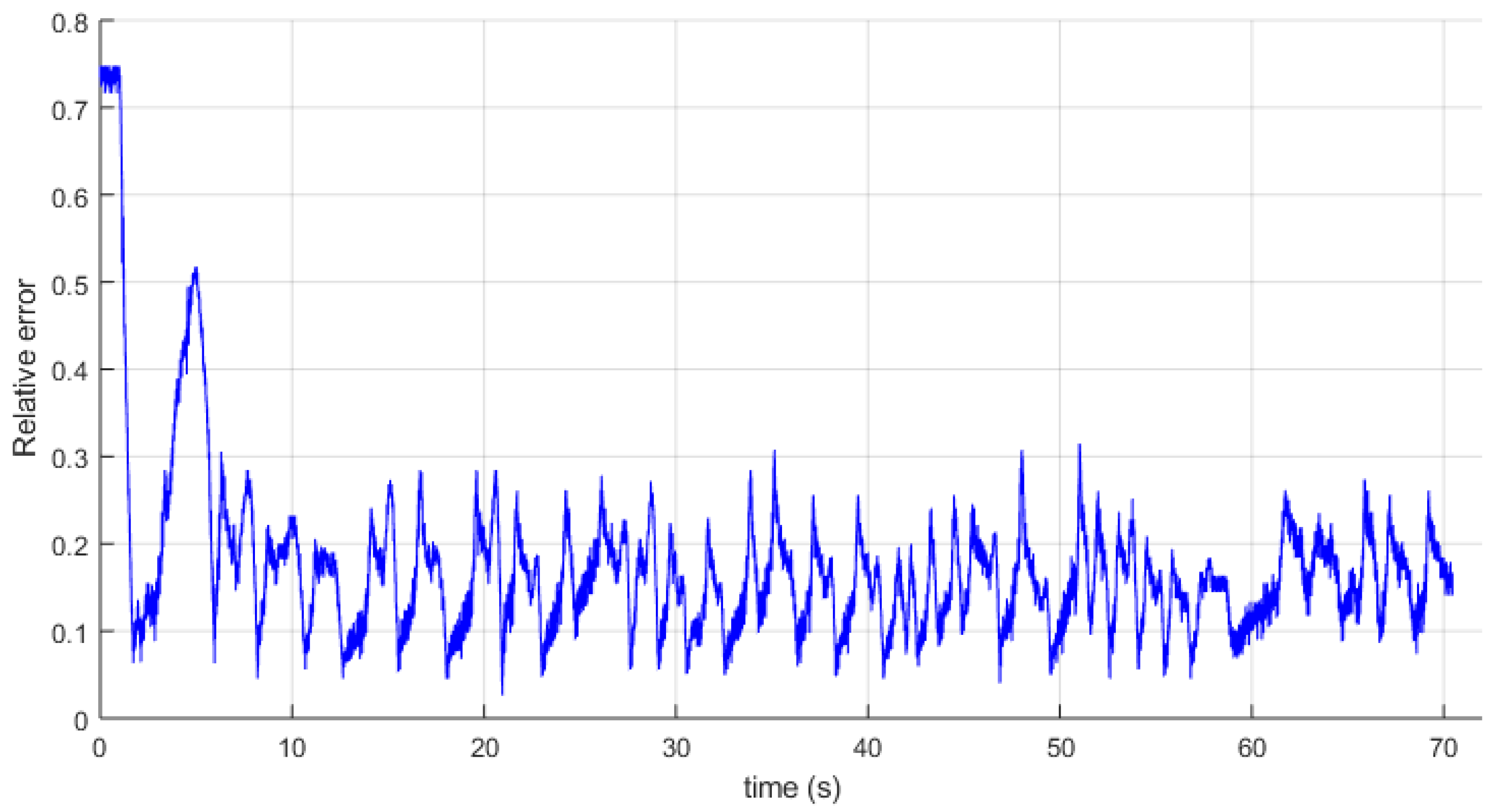

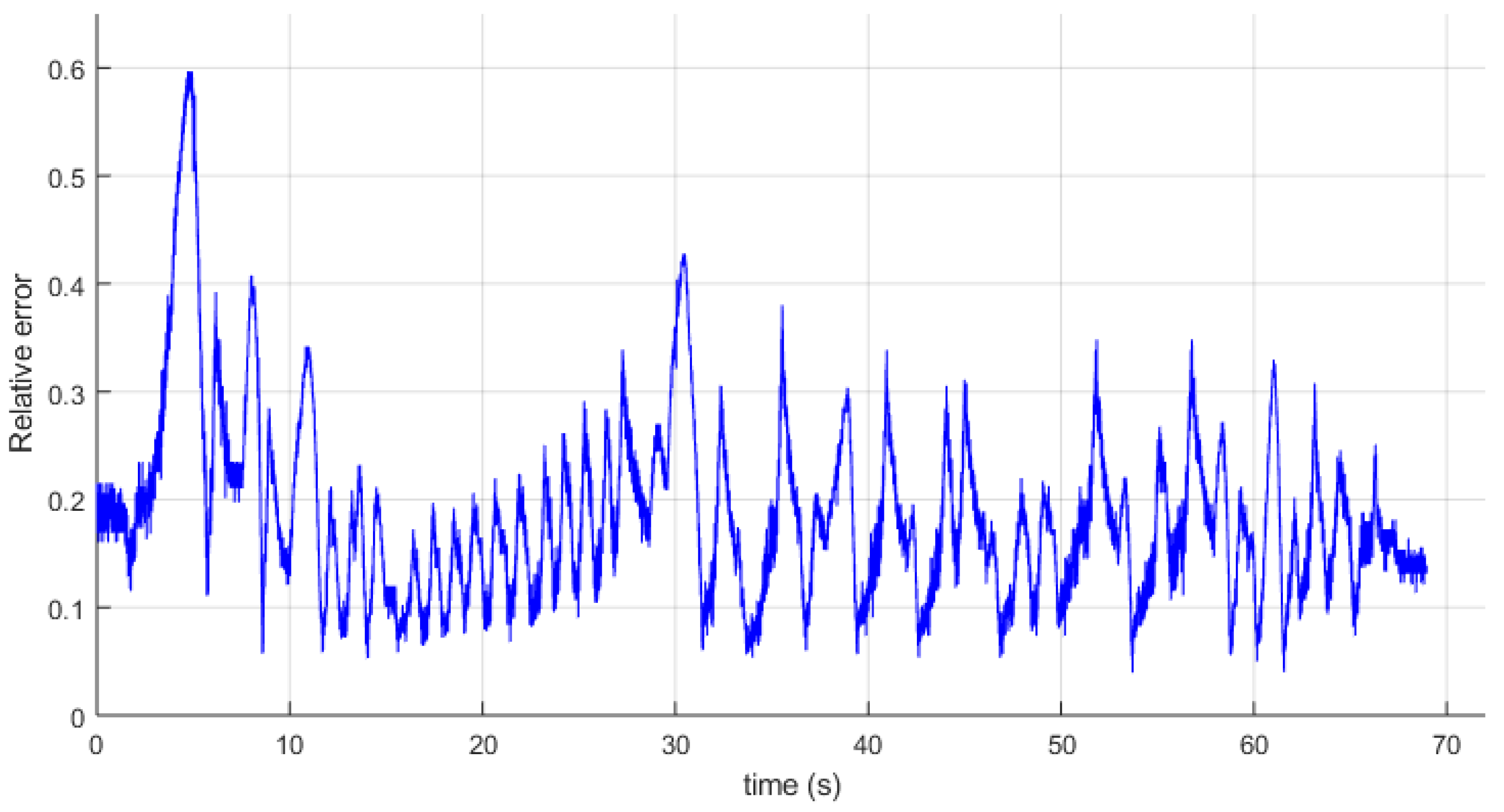

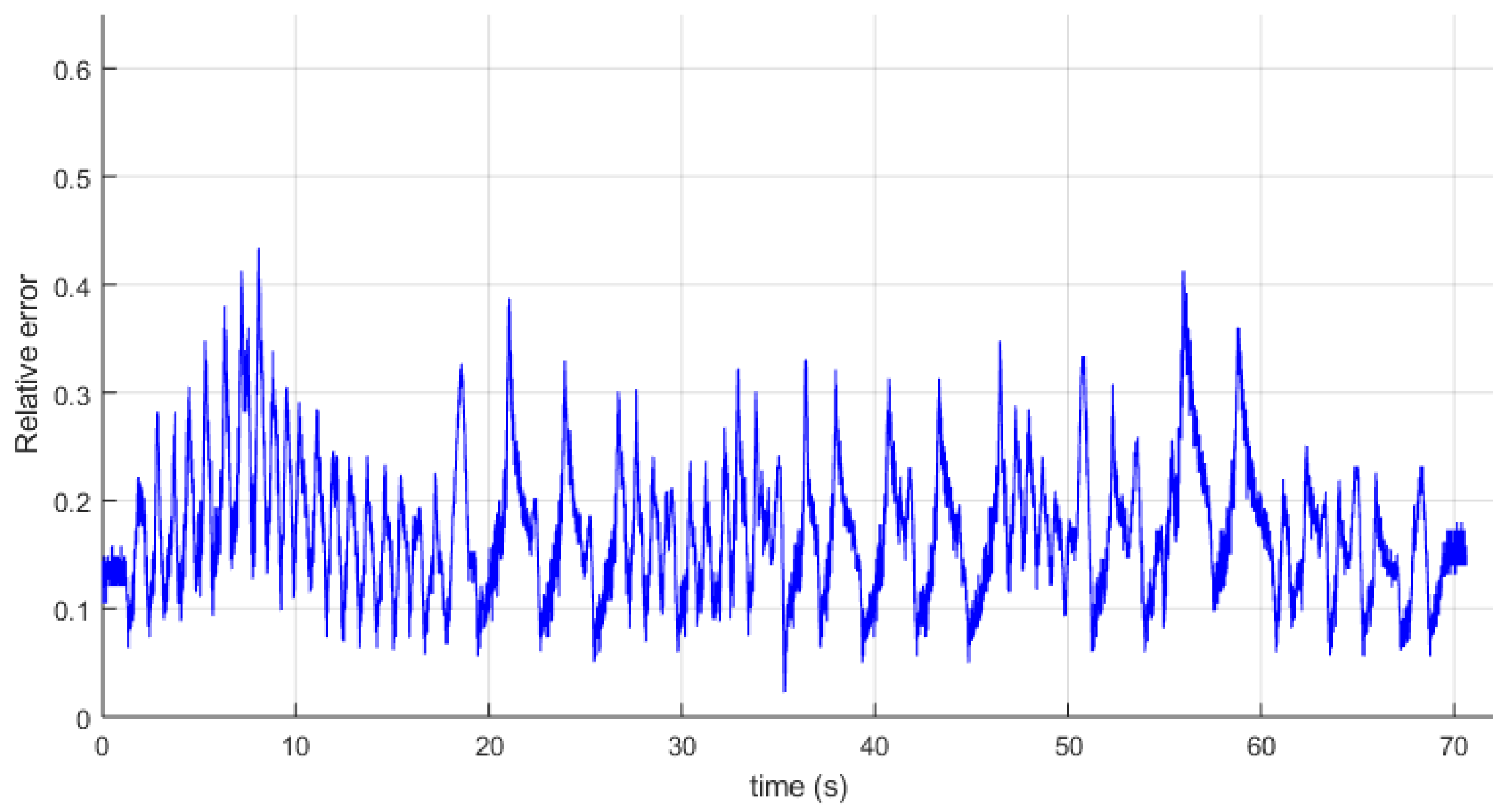

3.1. Experimental Data

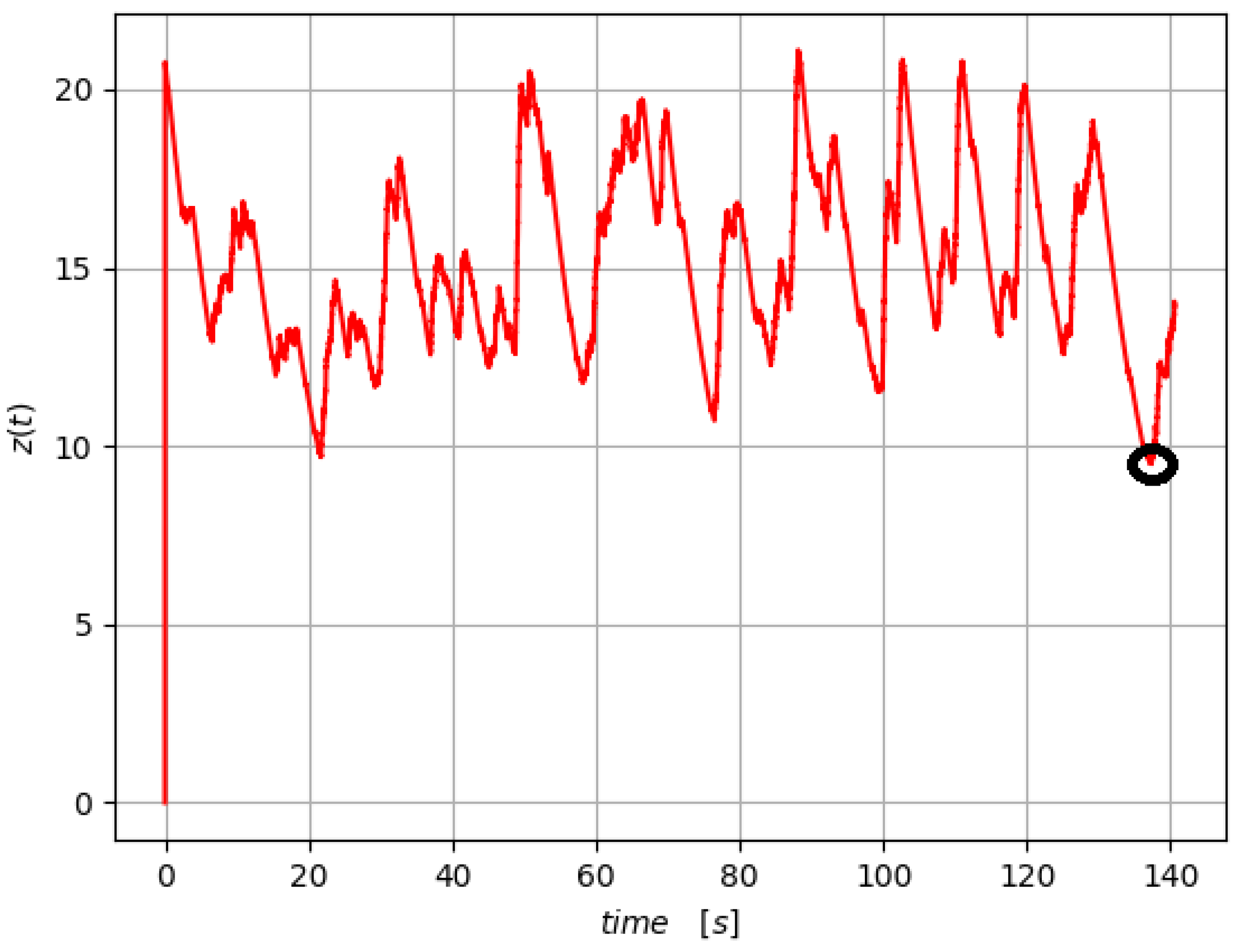

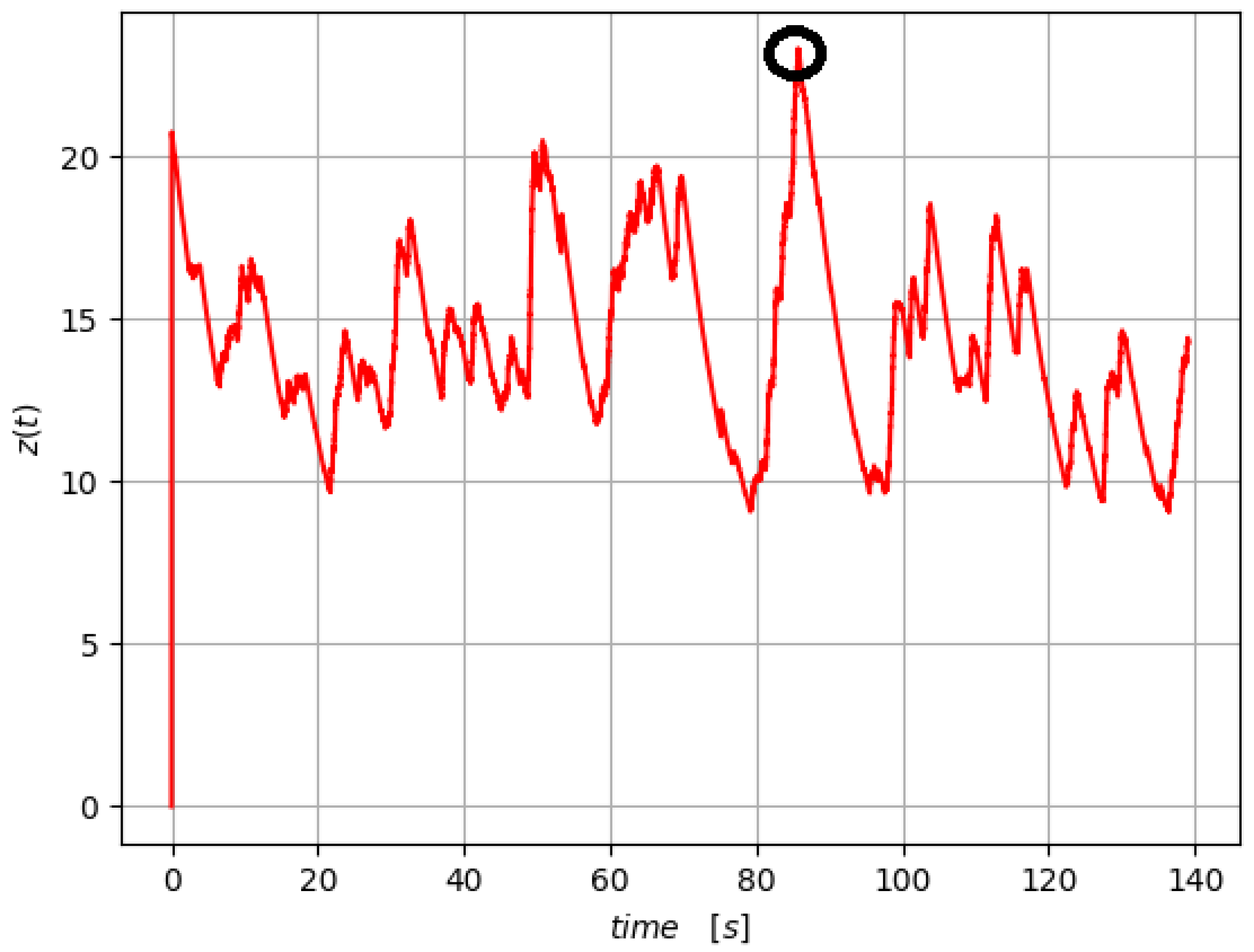

3.2. Experimental Correlation with a Real Wind Turbine

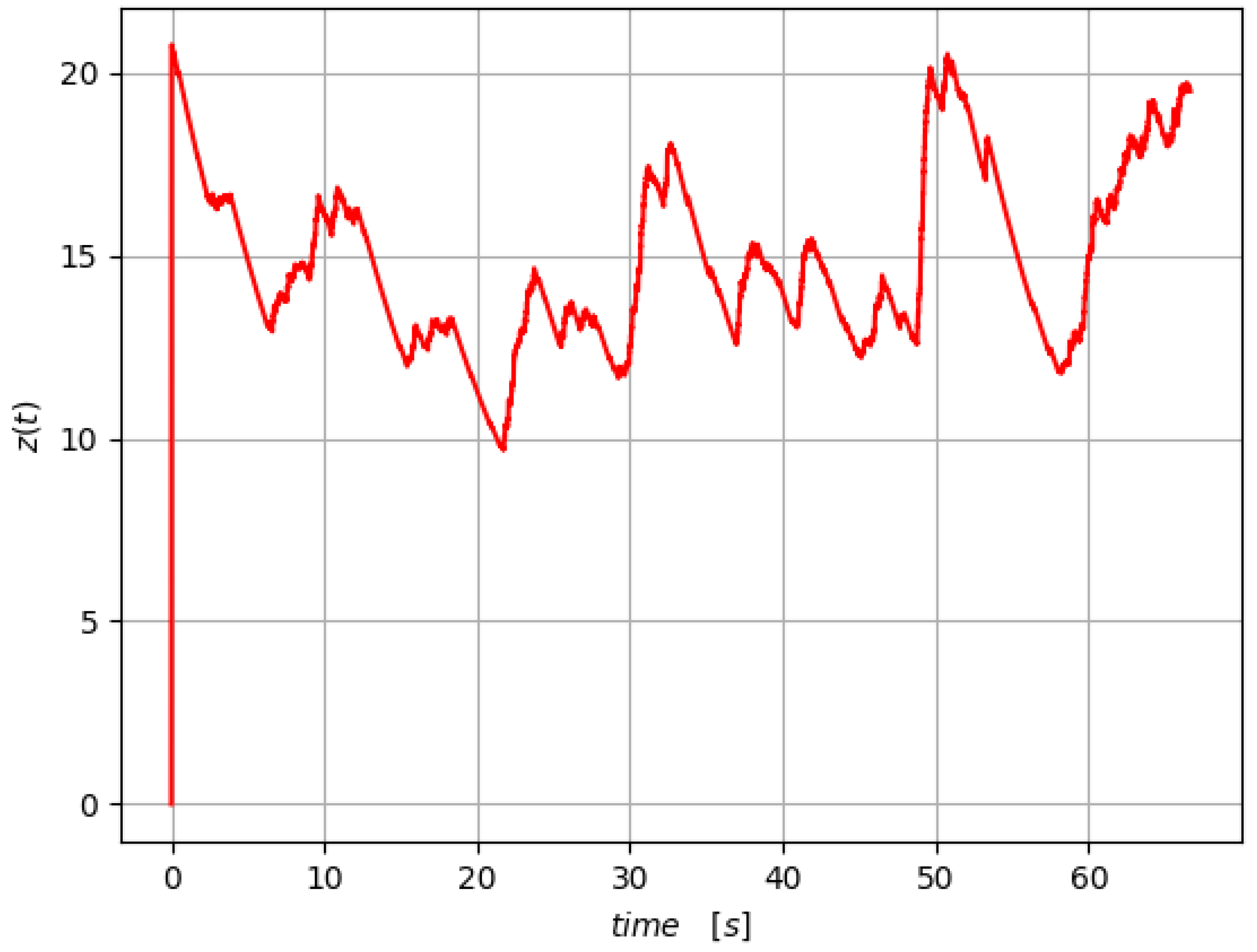

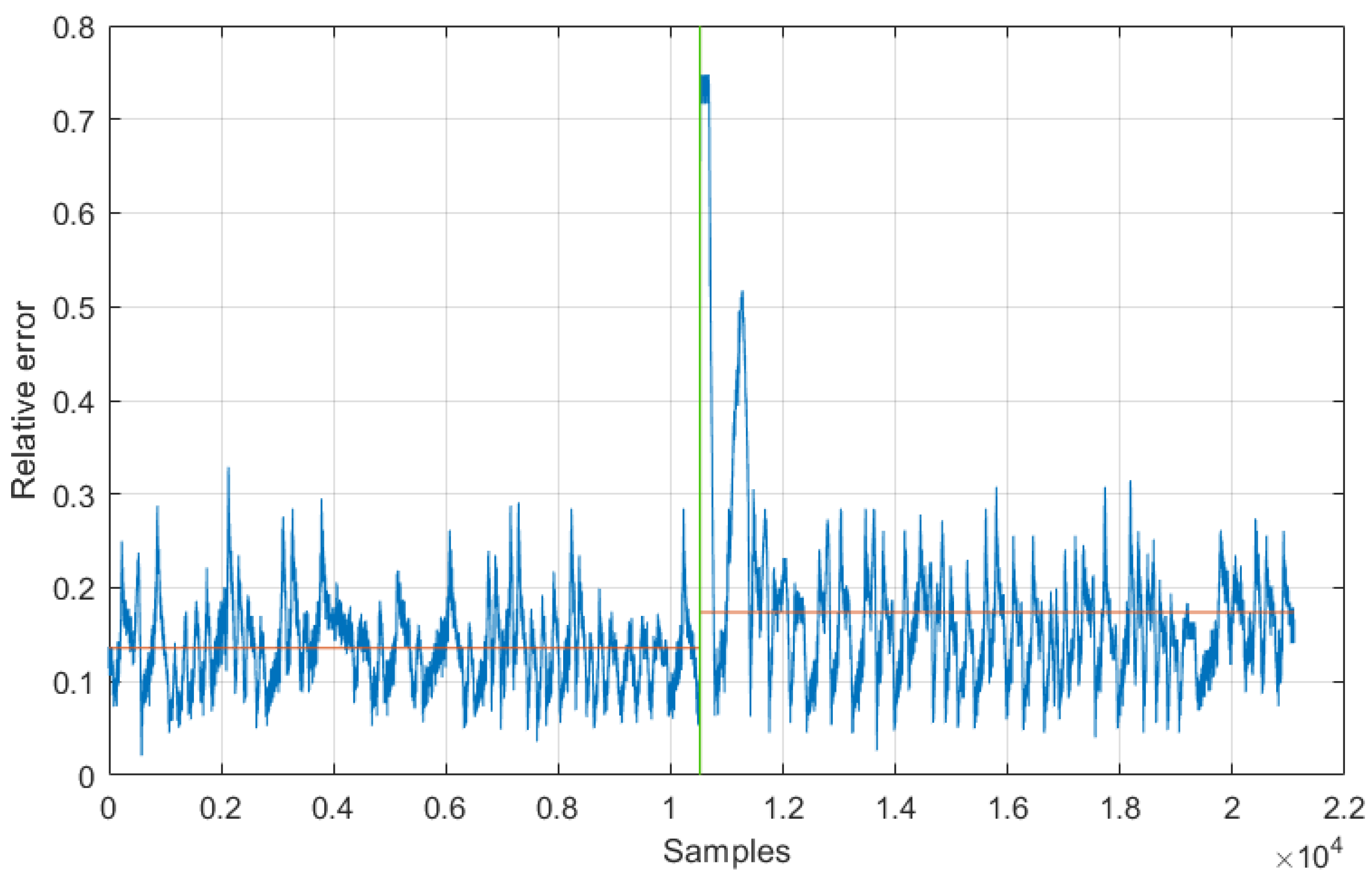

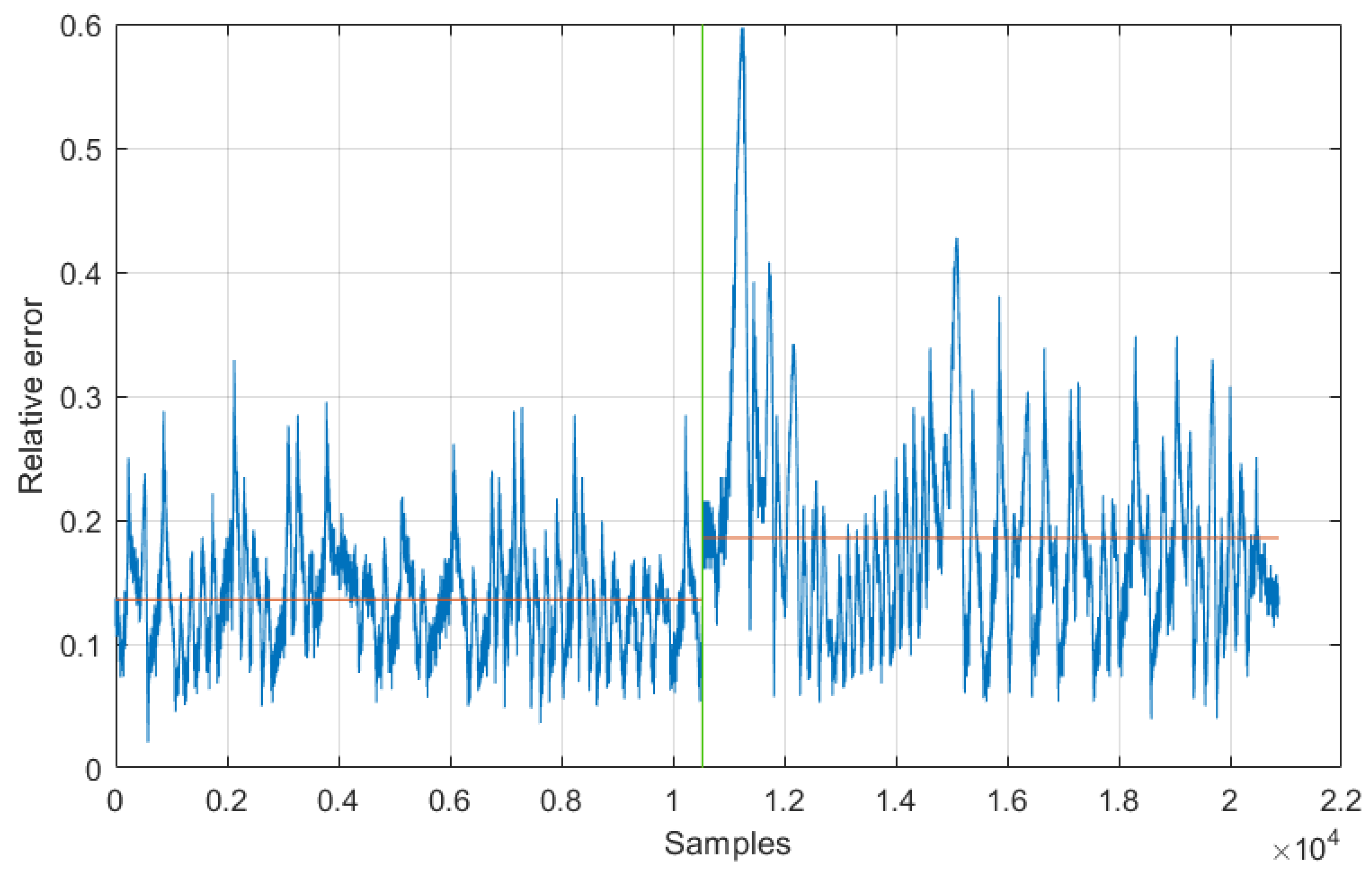

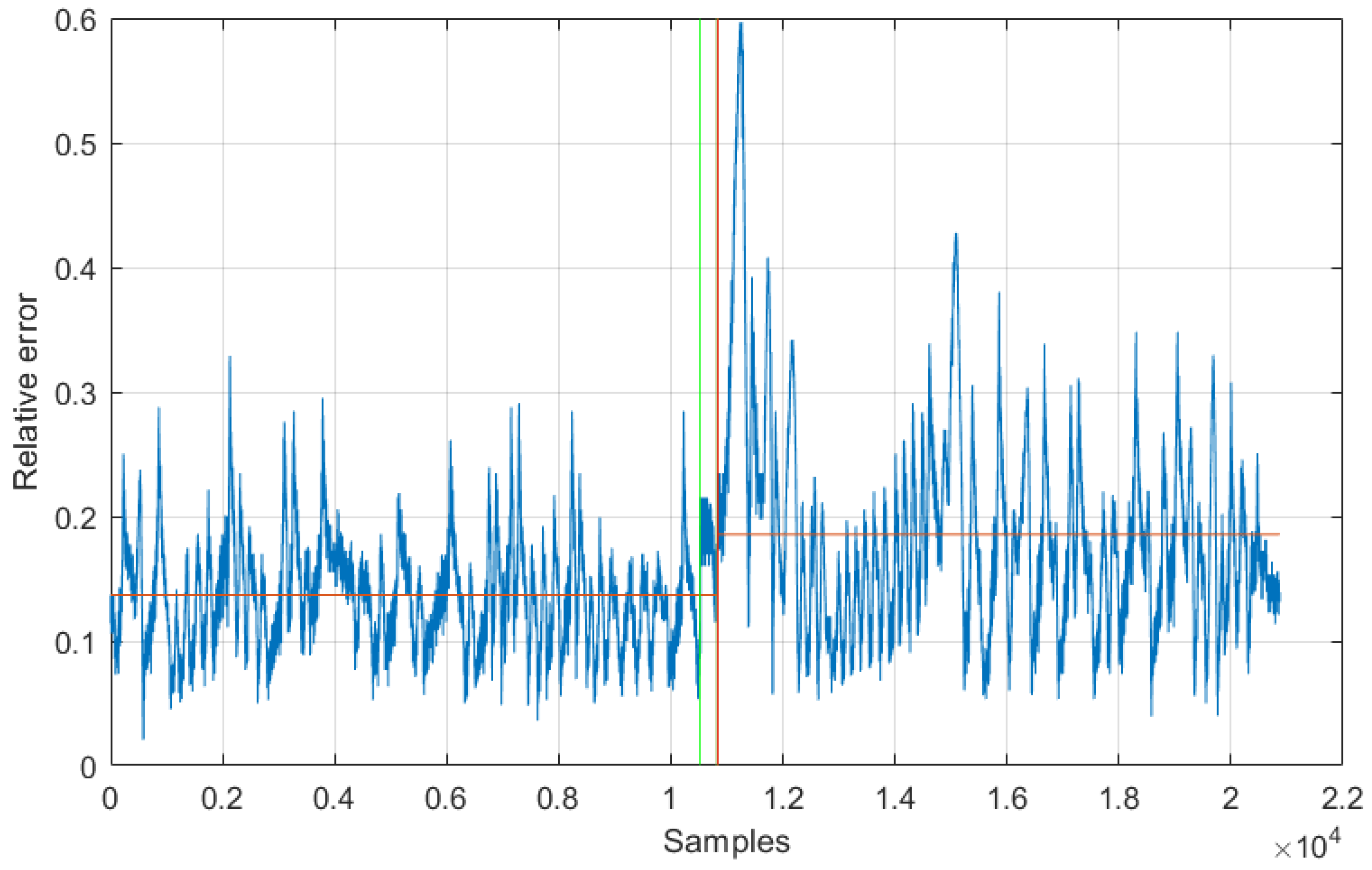

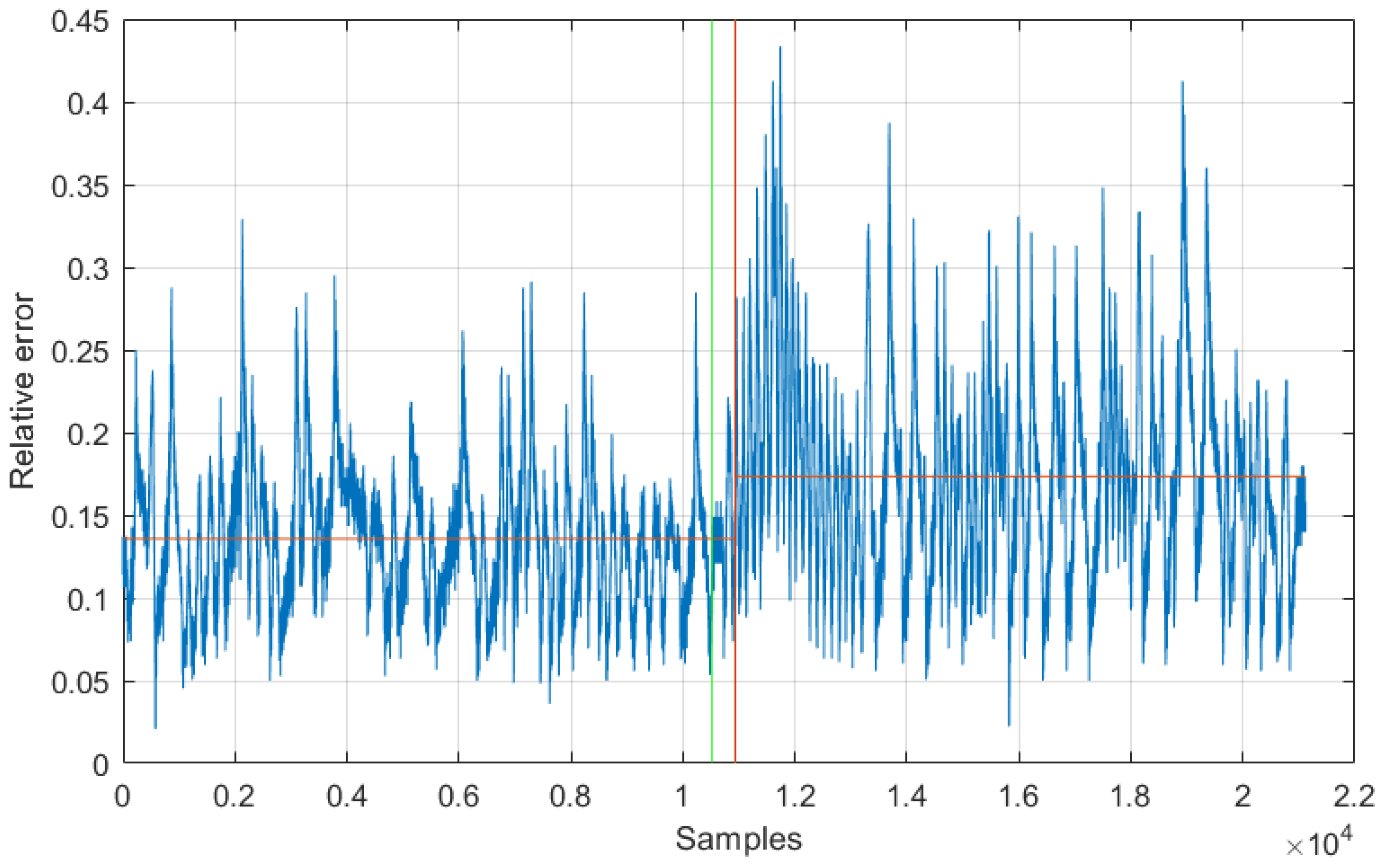

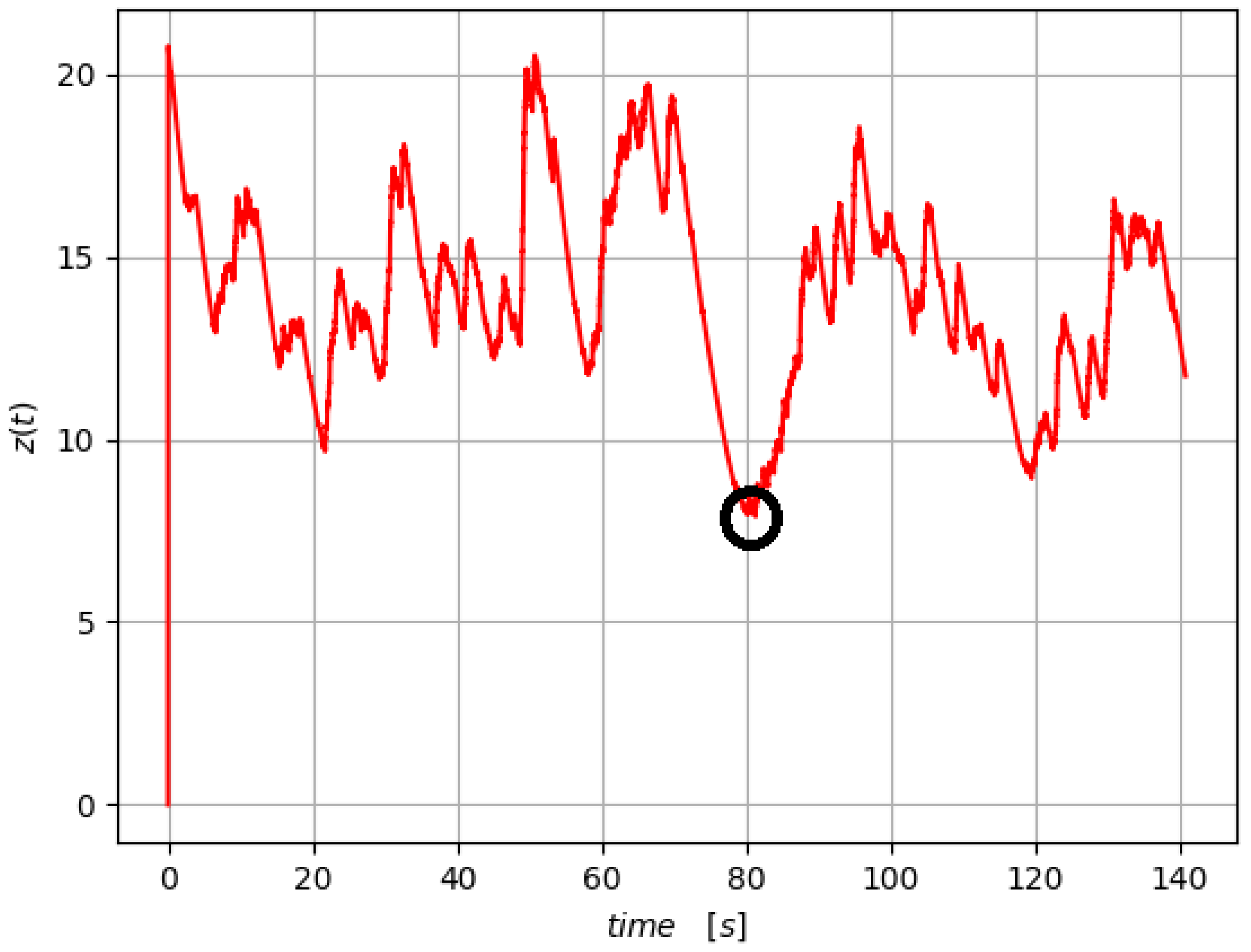

3.3. Statistical Diagnosis of Fault Detection

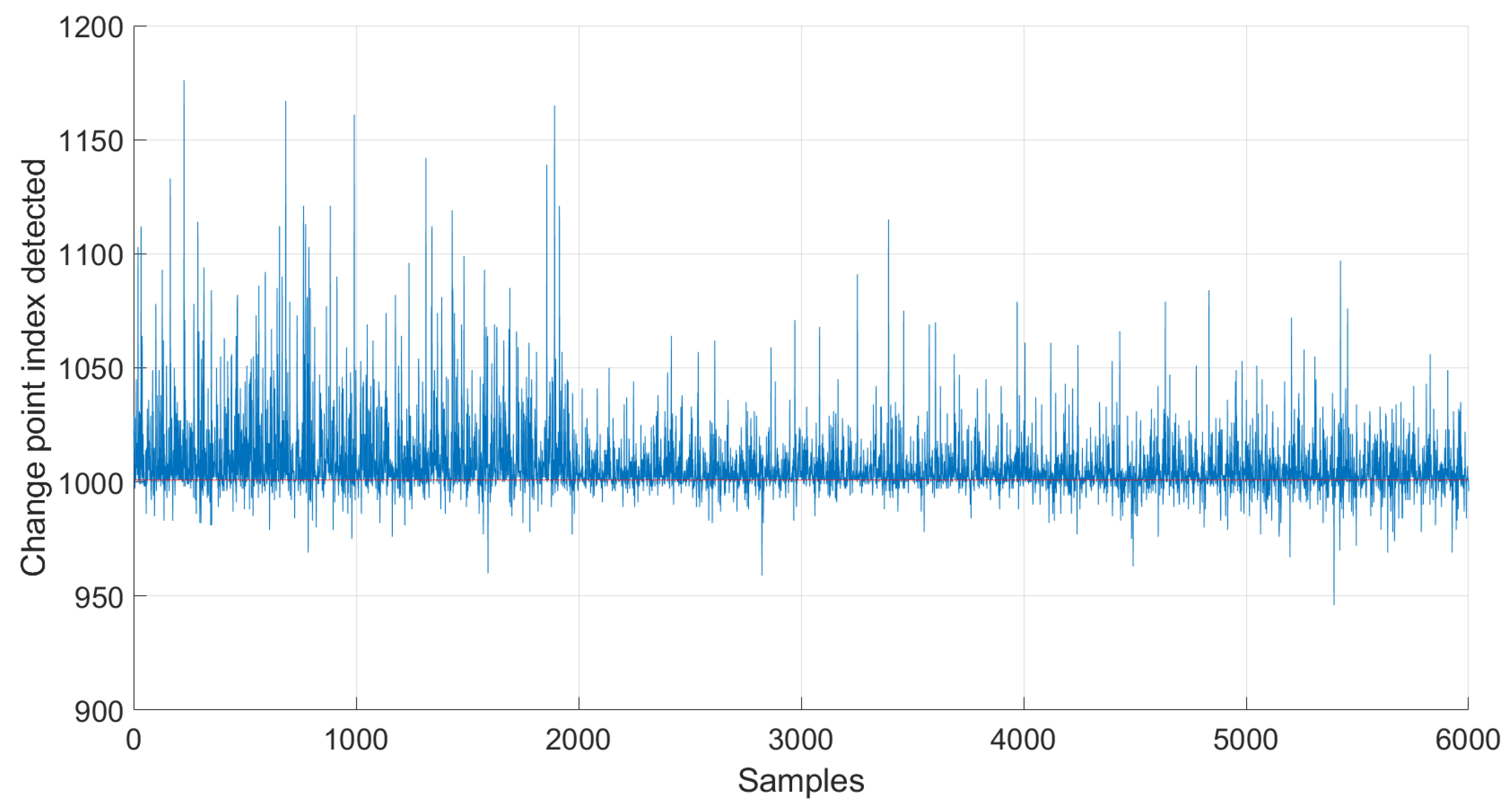

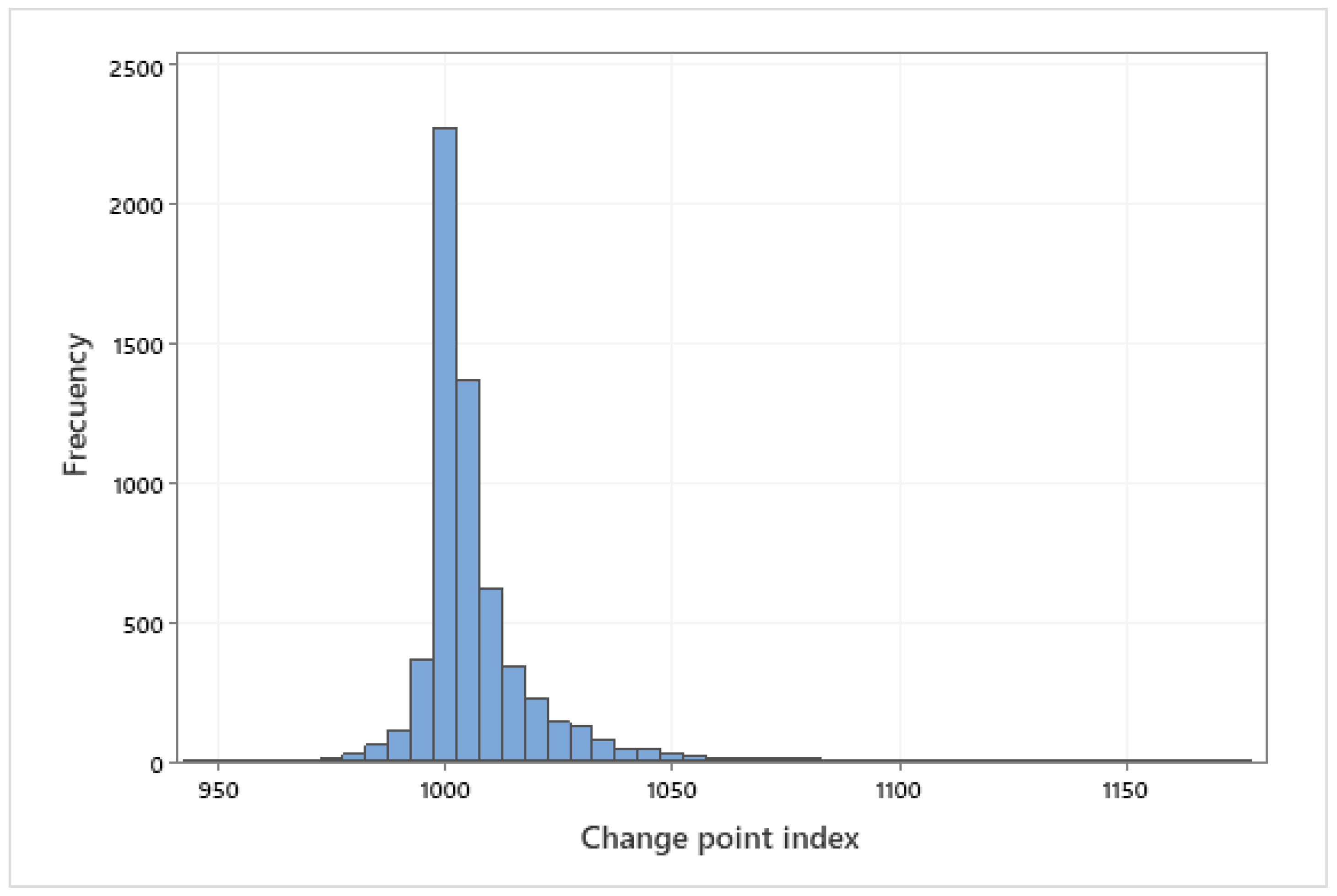

3.4. A Fault Detection Algorithm

- Obtain the experimental data series (within the series, the system can change status, as previously described).

- Minimize the index (15), using the arithmetic mean and the standard deviation, to detect the point of change:

- (a)

- Choose a point and divide the signal into two sections.

- (b)

- Compute an empirical estimate of the desired statistical property () for each section.

- (c)

- At each point within a section, measure how much the property deviates from the empirical estimate. Add the deviations for all points.

- (d)

- Add the deviations section to section to find the total residual error.

- (e)

- Vary the location of the division point until the total residual error attains a minimum.

- The presence of a point of change detects a system fault and when it has happened.

4. Discussion

4.1. Validation: Experimental Study

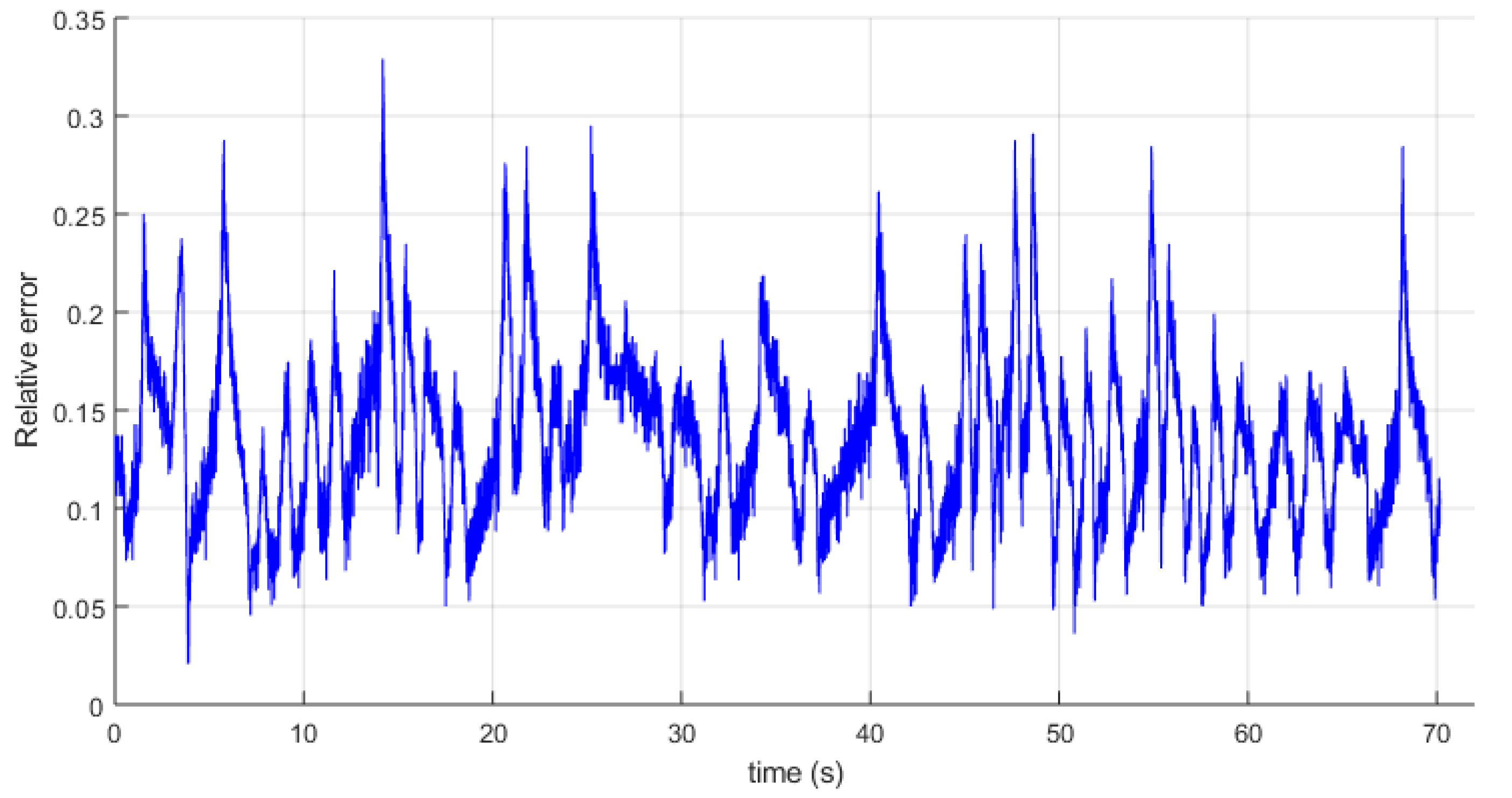

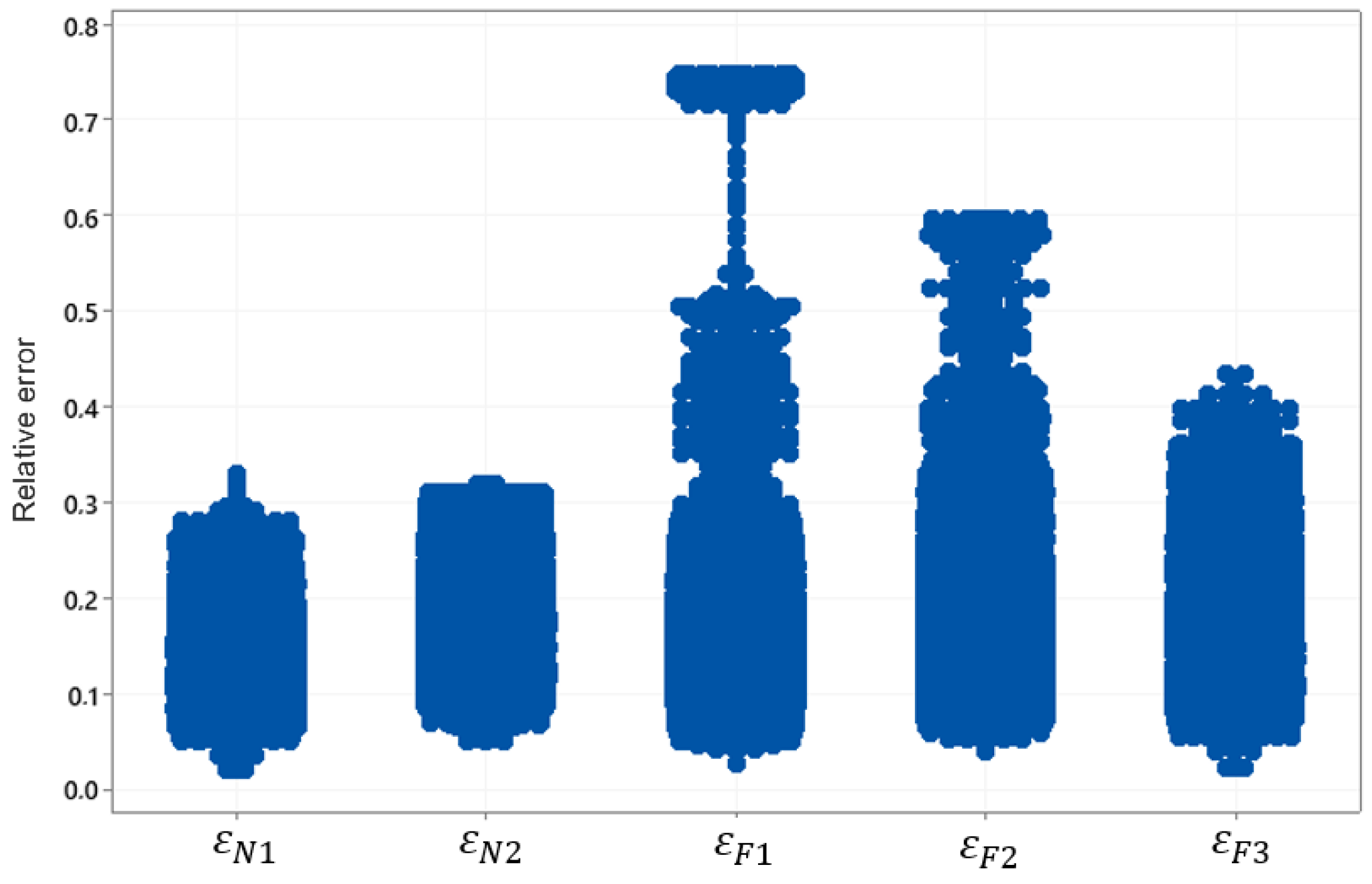

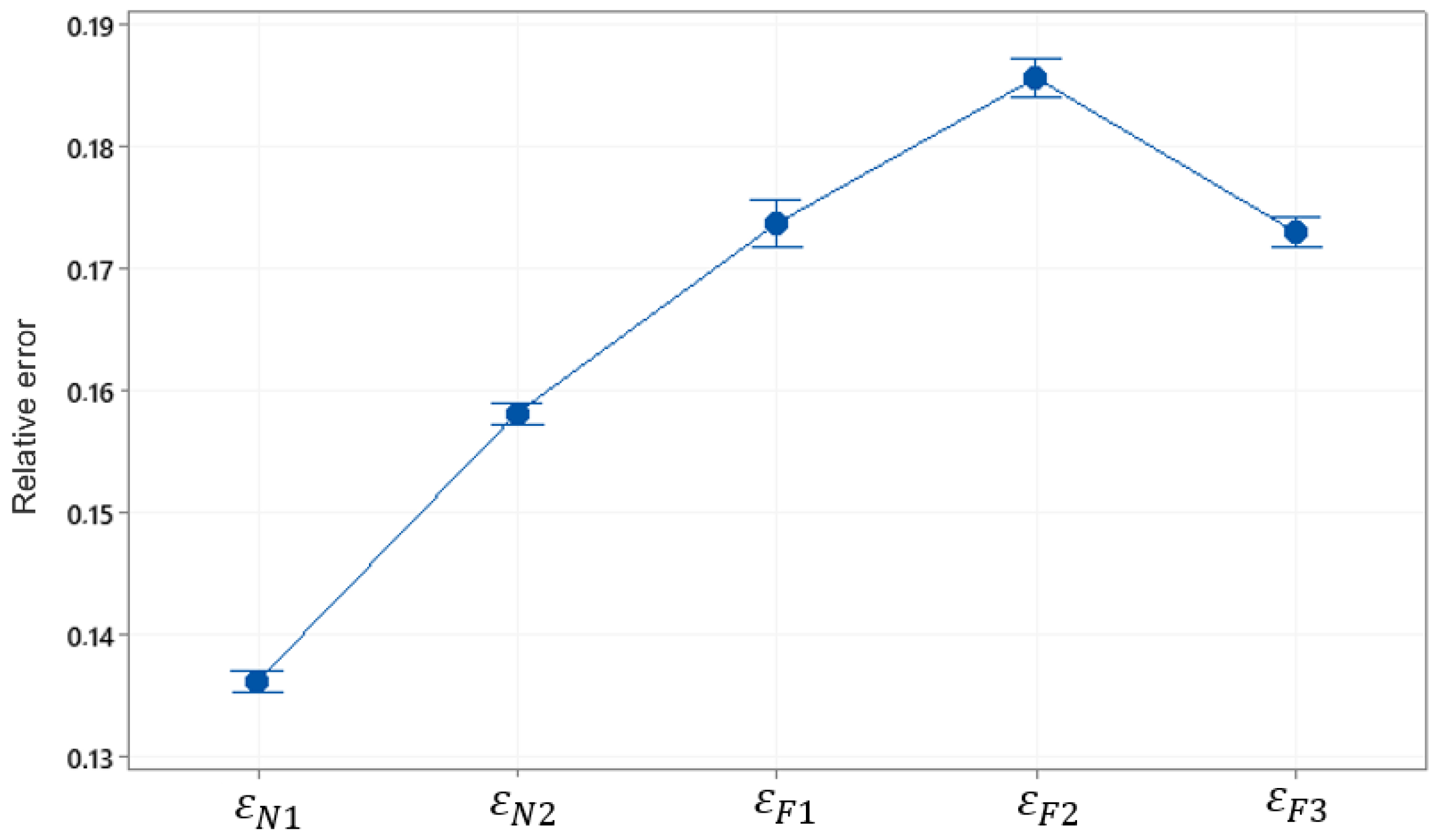

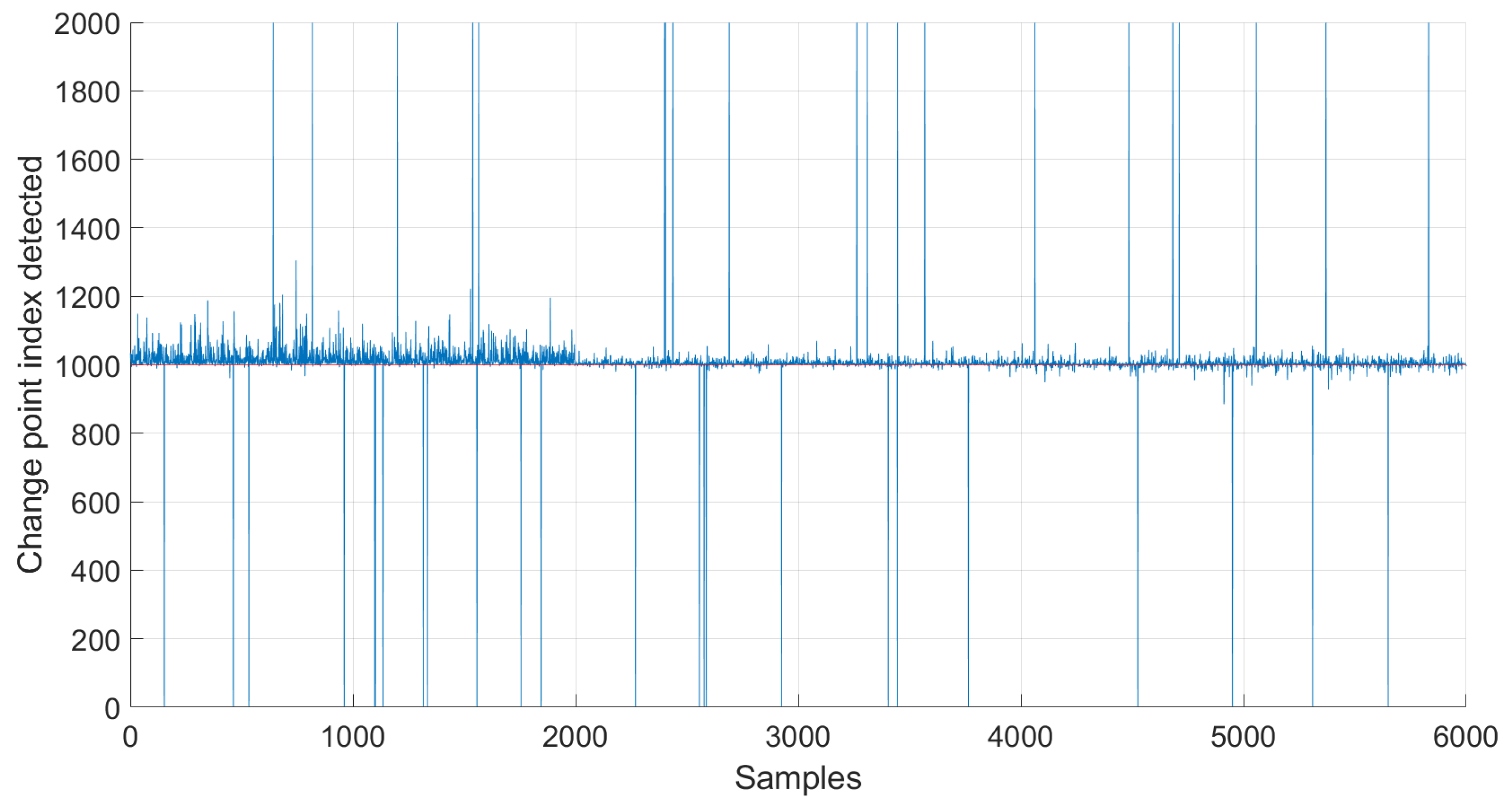

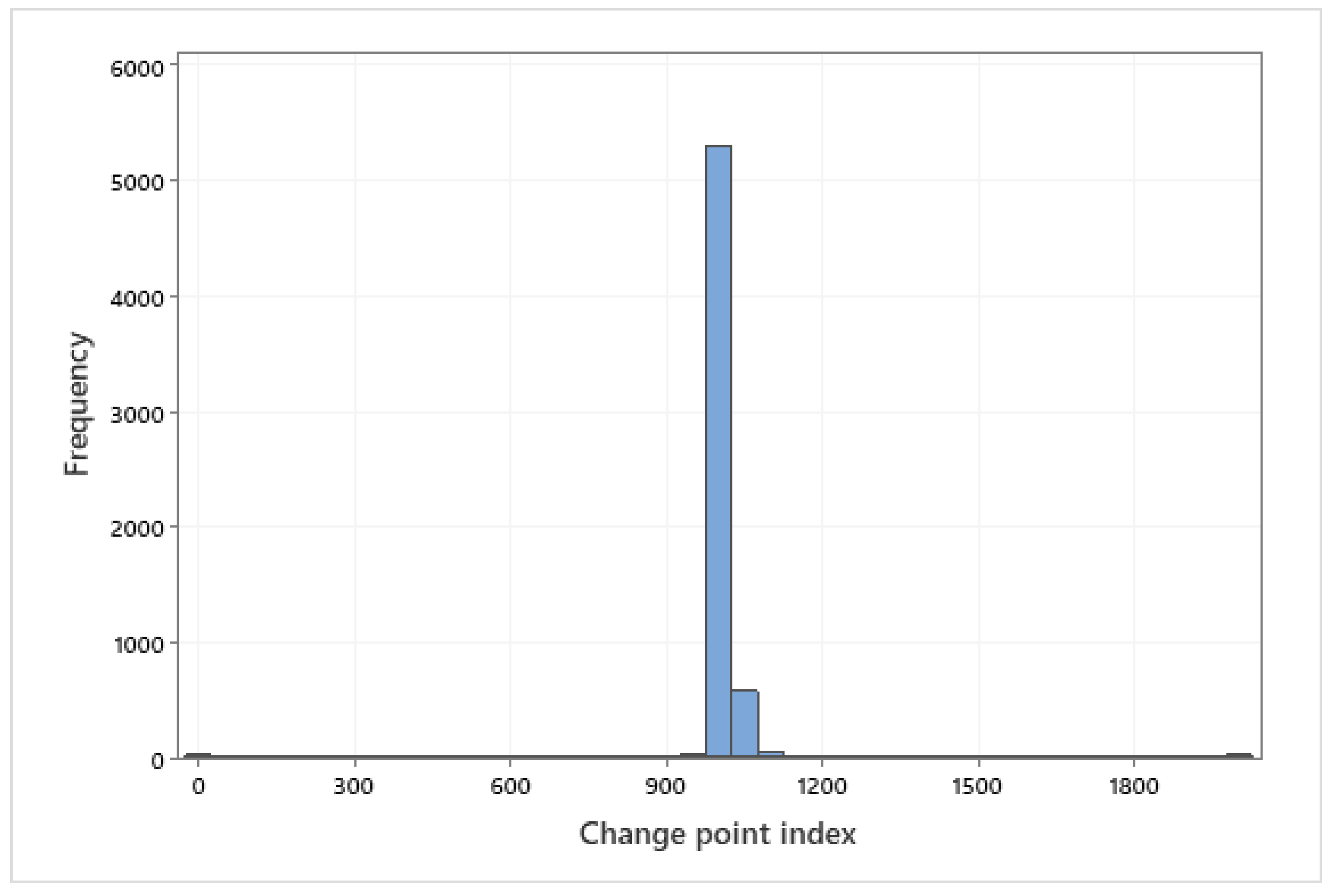

4.2. Accuracy Study of Fault Detection Algorithm

- True positive (TP): there is a change point, and the algorithm detects it.

- True negative (TN): there is no change point, and the algorithm does not detect anything.

- False negative (FN): there is a change point, and the algorithm does not detect it.

- False positive (FP): there is no change point, but the algorithm detects change.

- Accuracy, calculated as the ratio of correctly classified data points to total data points. This measure provides a high-level idea about the algorithm’s performance:

- Sensitivity, also referred to as recall or the true positive rate (TP Rate). This refers to the portion of a class of interest (change points) that was recognized correctly:

- Precision. This is calculated as the ratio of true positive data points (change points) to total points classified as change points:

4.3. Deterministic Diagnosis of Fault Detection

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CPD | Change Point Detection |

| PIC | Programmable Integrated Circuit |

| TP | True Positive |

| TN | True Negative |

| FP | False Positive |

| FN | False Negative |

| WT | Wind Turbine |

Appendix A. C-Program and Micro-Controller Settings

References

- Njiri, J.G.; Beganovic, N.; Do, M.H.; Söffker, D. Consideration of lifetime and fatigue load in wind turbine control. Renew. Energy 2019, 131, 818–828. [Google Scholar] [CrossRef]

- Habibi, H.; Howard, I.; Simani, S. Reliability improvement of wind turbine power generation using model-based fault detection and fault tolerant control: A review. Renew. Energy 2019, 135, 877–896. [Google Scholar] [CrossRef]

- Du, Y.; Zhou, S.; Jing, X.; Peng, Y.; Wu, H.; Kwok, N. Damage detection techniques for wind turbine blades: A review. Mech. Syst. Signal Process. 2020, 141, 1–23. [Google Scholar] [CrossRef]

- Yang, B.; Sun, D. Testing, inspecting and monitoring technologies for wind turbine blades: A survey. Renew. Sustain. Energy Rev. 2013, 22, 515–526. [Google Scholar] [CrossRef]

- Dong, X.; Gao, D.; Li, J.; Jincao, Z.; Zheng, K. Blades icing identification model of wind turbines based on SCADA data. Renew. Energy 2020, 162, 575–586. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Tong, R.; Lia, P.; Lang, X.; Liang, J.; Cao, M. A novel adaptive weighted kernel extreme learning machine algorithm and its application in wind turbine blade icing fault detection. Measurements 2021, 185, 110009. [Google Scholar] [CrossRef]

- Pujol-Vazquez, G.; Acho, L.; Gibergans-Báguena, J. Fault Detection Algorithm for Wind Turbines Pitch Actuator Systems. Energies 2020, 13, 2861. [Google Scholar] [CrossRef]

- Vidal, Y.; Tutivén, C.; Rodellar, J.; Acho, L. Fault diagnosis and fault-tolerant control of wind turbines via a discrete time controller with a disturbance compensator. Energies 2015, 8, 4300–4316. [Google Scholar] [CrossRef] [Green Version]

- Ruiz, M.; Mujica, L.E.; Alferez, S.; Acho, L.; Tutiven, C.; Vidal, Y.; Pozo, F. Wind turbine fault detection and classification by means of image texture analysis. Mech. Syst. Signal Process. 2018, 107, 149–167. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Fan, Z.; Jia, W.; Jiang, C. Fault detection of wind turbines via multivariate process monitoring based on vine copulas. Renew. Energy 2020, 161, 939–955. [Google Scholar] [CrossRef]

- Ohishi, K.; Nakao, M.; Ohnishi, K.; Miyachi, K. Microprocessor-controlled DC motor for load-insensitive position servo system. IEEE Trans. Ind. Electron. 1987, 1, 44–49. [Google Scholar] [CrossRef]

- Acho, L. A proportional plus a hysteretic term control design: A throttle experimental emulation to wind turbines pitch control. Energies 2019, 12, 1961. [Google Scholar] [CrossRef] [Green Version]

- Shajiee, S.; Pao, L.Y.; McLeod, R.R. Monitoring ice accumulation and active de-icing control of wind turbine blades. In Wind Turbine Control and Monitoring; Springer: Cham, Switzerland, 2014; pp. 193–230. [Google Scholar]

- Yun, H.; Zhang, C.; Hou, C.; Liu, Z. An Adaptive Approach for Ice Detection in Wind Turbine With Inductive Transfer Learning. IEEE Access 2019, 7, 122205–122213. [Google Scholar] [CrossRef]

- Aminikhanghahi, S.; Cook, D.J. A Survey of Methods for Time Series Change Point Detection. Knowl. Inf. Syst. 2017, 51, 339–367. [Google Scholar] [CrossRef] [Green Version]

- Page, E.S. Continuous Inspection Schemes. Biometrika 1954, 41, 100–115. [Google Scholar] [CrossRef]

- Gallagher, C.; Lund, R.; Robbins, M. Changepoint Detection in Climate Time Series with Long-Term Trends. J. Clim. 2013, 26, 4994–5006. [Google Scholar] [CrossRef]

- Mudelsee, M. Trend analysis of climate time series: A review of methods. Earth-Sci. Rev. 2019, 190, 310–322. [Google Scholar] [CrossRef]

- You, S.H.; Jang, E.J.; Kim, M.S.; Lee, M.T.; Kang, Y.J.; Lee, J.E.; Eom, J.H.; Jung, S.Y. Change Point Analysis for Detecting Vaccine Safety Signals. Vaccines 2021, 9, 206. [Google Scholar] [CrossRef] [PubMed]

- Militino, A.F.; Moradi, M.; Ugarte, M.D. On the Performances of Trend and Change-Point Detection Methods for Remote Sensing Data. Remote Sens. 2020, 12, 1008. [Google Scholar] [CrossRef] [Green Version]

- Borsoi, R.; Richard, C.; Ferrari, A.; Chen, J.; Bermudez, J.M. Online graph-based change point detection in multiband image sequences. In Proceedings of the 28th European Signal Processing Conference (EUSIPCO), Amsterdam, The Netherlands, 18–21 January 2021; pp. 850–854. [Google Scholar]

- Taylor, S.J.; Letham, B. Forecasting at Scale. Am. Stat. 2018, 72, 37–45. [Google Scholar] [CrossRef]

- Killick, R.; Fearnhead, P.; Eckley, I.A. Optimal Detection of Changepoints with a Linear Computational Cost. J. Am. Stat. Assoc. 2012, 197, 1590–1598. [Google Scholar] [CrossRef]

- Truong, C.; Oudre, L.; Vayatis, N. Selective review of offline change point detection methods. Signal Process. 2019, 197, 107299. [Google Scholar] [CrossRef] [Green Version]

- Usman, H.M.; Mukhopadhyay, S.; Rehman, H. Permanent magnet DC motor parameters estimation via universal adaptive stabilization. Control Eng. Pract. 2019, 90, 50–62. [Google Scholar] [CrossRef]

- Bates, M. PIC Microcontrollers: An Introduction to Microelectronics, 2nd ed.; Newnes: Burlington, WA, USA, 2004; p. 215. [Google Scholar]

- Inthamoussou, F.A.; Bianchi, F.D.; De Battista, H.; Mantz, R.J. Gain Scheduled H-∞ Control of Wind Turbines for the Entire Operating Range. In Wind Turbine Control and Monitoring; Springer: Cham, Switzerland, 2014; pp. 71–95. [Google Scholar] [CrossRef]

- Acho, L.; Pujol, G. A boundary control technique to the string-tip-mass system based on a non-symmetric peak-detector model. In Proceedings of the 2017 21st International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 19–21 October 2017; pp. 759–762. [Google Scholar] [CrossRef]

- Caulcutt, R. Statistics in Research and Development; Chapman and Hall/CRC: Boca Raton, FL, USA, 2019; ISBN 9780367450472. [Google Scholar]

- Matlab, Signal Processing Toolbox Reference, 1988–2021 The MathWorks, Inc. Available online: https://www.mathworks.com/ (accessed on 20 December 2021).

- Cai, C.; Maeda, T.; Kamada, Y.; Wang, X.; Zhou, S.; Zhang, F. Wind tunnel and numerical study of a floating offshore wind turbine based on the cyclic pitch control. Renew. Energy 2021, 172, 453–464. [Google Scholar] [CrossRef]

| Variable | N | Mean | Std | Min | Max | |||

|---|---|---|---|---|---|---|---|---|

| 10,526 | 0.13622 | 0.04262 | 0.02076 | 0.10456 | 0.13308 | 0.16068 | 0.32907 | |

| 10,505 | 0.15813 | 0.04636 | 0.04998 | 0.12179 | 0.14896 | 0.18132 | 0.31979 | |

| 10,568 | 0.17363 | 0.09997 | 0.02631 | 0.11780 | 0.15973 | 0.19675 | 0.74766 | |

| 10,344 | 0.18553 | 0.08385 | 0.03956 | 0.13128 | 0.17252 | 0.21989 | 0.59667 | |

| 10,596 | 0.17294 | 0.06197 | 0.02245 | 0.12830 | 0.16826 | 0.20616 | 0.43353 |

| Change Point Detected | Non-Change Point Detected | |

|---|---|---|

| True change point | ||

| True non-change point |

| Change Point Detected | Non-Change Point Detected | |

|---|---|---|

| True change point | ||

| True non-change point |

| Arithmetic Mean | Standard Deviation | |

|---|---|---|

| Accuracy | ||

| Sensitivity | ||

| Precision |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gibergans-Báguena, J.; Buenestado, P.; Pujol-Vázquez, G.; Acho, L. A Proportional Digital Controller to Monitor Load Variation in Wind Turbine Systems. Energies 2022, 15, 568. https://doi.org/10.3390/en15020568

Gibergans-Báguena J, Buenestado P, Pujol-Vázquez G, Acho L. A Proportional Digital Controller to Monitor Load Variation in Wind Turbine Systems. Energies. 2022; 15(2):568. https://doi.org/10.3390/en15020568

Chicago/Turabian StyleGibergans-Báguena, José, Pablo Buenestado, Gisela Pujol-Vázquez, and Leonardo Acho. 2022. "A Proportional Digital Controller to Monitor Load Variation in Wind Turbine Systems" Energies 15, no. 2: 568. https://doi.org/10.3390/en15020568

APA StyleGibergans-Báguena, J., Buenestado, P., Pujol-Vázquez, G., & Acho, L. (2022). A Proportional Digital Controller to Monitor Load Variation in Wind Turbine Systems. Energies, 15(2), 568. https://doi.org/10.3390/en15020568