Abstract

This study aimed to evaluate the effects of mechanical disintegration of waste activated sludge (WAS) on full scale anaerobic digestion, considering the possibility of obtaining a positive energy balance. The results showed that an increase in energy density (εL) used in disintegration was accompanied by an increase in the release of organic compounds from sludge (SCOD increased from 211 ± 125 mg O2/L for εL = 0 kJ/L to 6292 ± 2860 mgO2/L for εL = 180 kJ/L). Some of them were volatile fatty acids. The percentage share of WAS subject to disintegration was also documented as a crucial parameter affecting the efficiency of biogas production. An increase in the value of this parameter from 25% to 100%, even at much lower εL used in disintegration (therefore with much smaller amounts of organic compounds released from sludge flocs) resulted in an increase in biogas production. Conducting disintegration of the entire stream of WAS directed to the fermentation tank at εL 30 kJ/L resulted in an increase in biogas production by 14.1%. Such a surplus would allow production of approximately 360 kWh/d net electricity. Mechanical disintegration of thickened WAS therefore may be an economically justifiable strategy for the intensification of anaerobic sludge stabilisation.

1. Introduction

After Poland’s accession to the structures of the European Union and the adaptation of Polish law to the EU, the handling of municipal sewage sludge has become one of the basic problems of wastewater treatment plants (WWTP), and one of the most challenging environmental and logistic issues in the country. In 2019, 574.6 Mg of sludge (expressed in total solids) was generated in Polish municipal WWTP, i.e., 29.4% more than in 2004 (Poland’s accession to the EU) [1].

As well as constituting waste, wastewater sludge can be a source of renewable energy. It is possible both through using it as biomass fuel and through converting the biogas produced in the process of its anaerobic digestion into electricity. Importantly, Poland as a country has assumed certain obligations resulting from the climate and energy package, among other sources. Pursuant to these obligations, at least 32% of gross final energy consumption in the EU is required to come from renewable energy sources (RES) by 2030 [2]. Consequently, the Polish national strategy stipulates a target of reaching a 21–23% share of RES in gross final energy consumption by 2030 [3]. The data presented by the Central Statistical Office of Poland indicate that in order to fulfil this obligation, it is necessary to intensify the work in this area (the contribution of renewable energy in 2019 was 12.16%) [4].

Approximately 19,000 biogas plants are currently in operation in Europe. The amount of electricity produced in those installations in 2020 exceeded 167,000 GWh [5]. A total of 338 biogas plants currently operate in Poland (data from the end of 2020), including biogas plants in wastewater treatment plants, on waste dumps, and functioning as agricultural biogas plants. The total electric capacity installed in all Polish biogas plants exceeded 256 MW, accounting for only 2.6% of total electric capacity installed in power plants using RES [6]. Nevertheless, Poland is a country with high availability and diversity of feedstock for anaerobic digestion. The national potential of biogas production is estimated at 13–15 billion m3 per year. Meanwhile, natural gas consumption in Poland is approximately 18 billion m3 annually [7]. A huge part of national biogas production comes from wastewater treatment plants—in 2019, more than 30% of energy produced from biogas was from anaerobic digestion of wastewater sludge [4]. Any technology that increases the potential of biogas production in WWTP is therefore very desirable.

An increase in biogas production, and consequently increased utilisation of sludge energy properties, can be achieved through the use of different disintegration processes of waste activated sludge (WAS) directed to the digester, including mechanical [8], thermal [9], chemical [10] and hybrid [11], with the mechanical process found among the most popular in Poland. The hydrolysis of organic polymers occurs in the digester with the involvement of extracellular enzymes. Due to the complexity of molecular structures within the cells of sludge bacteria, the efficiency of their hydrolysis only with bioenzymes (without enzyme bioaugmentation) is relatively low. This results in the presence of ballast in the digester in the form of an inert (non-biodegradable) organic sludge. The disintegration process plays a very important role in transferring the soluble substrate from activated sludge to the anaerobic microorganisms responsible for acetogenesis and methanogenesis, i.e., subsequent phases of the methane fermentation process [12]. The literature provides many examples documenting the possibility of obtaining greater biogas production through the use of mechanical disintegration of sewage sludge [8,13,14,15,16]. For example, with the application of hydrodynamic cavitation, Petkovšek et al. [14] obtained a 12.7% increase in biogas production (pilot-scale). Boni et al. [15] (lab-scale) and Neis et al. [13] (full-scale) reported a 30% increase in biogas production as a result of ultrasonic disintegration. Gil et al. [16] and Liu et al. [8] (lab-scale) using the microwave pretreatment observed a 20% and 38.5% increase in methane yield, respectively. A significant increase in biogas production (by 33.9%) was also achieved in our previous study [17] (full-scale), although we encountered operational problems after long term operation. Therefore, construction works on a new device commenced to avoid these problems, and to allow for the intensification of biogas production.

The article presents the results of tests carried out at a technical scale. They aimed to assess the possibility of increasing the amount of produced biogas as a result of pre-treatment of thickened excess sludge using a newly constructed disintegrator, taking into account the possibility of obtaining a positive energy balance.

2. Methods

2.1. Characteristics of the Disintegration Apparatus

The main component of the newly constructed mechanical cavitation inducer is a specially formed impeller propelled by an 11 kW electrical motor with a rotational speed of 3000 rpm (patent No. P400923).

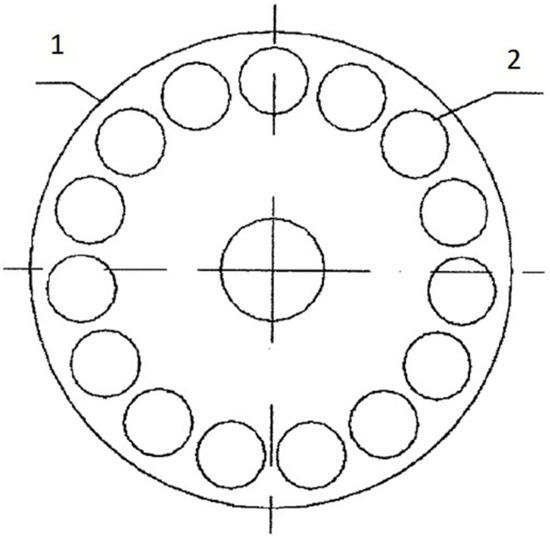

The impeller of the cavitation inducer has a cylindrical shape with a diameter of approximately 200 mm, and the same height. In the impeller, parallel to its axis, round openings were drilled, with a diameter of approximately 30 mm each. The openings were evenly distributed on the circumference. A schematic drawing of the applied cavitation inducer impeller is presented in Figure 1.

Figure 1.

Impeller of the cavitation inducer used in the study (1); openings in the impeller, so-called active spaces (2).

The impeller was additionally equipped with two discs, one on each side, partly covering the openings in the impeller. In the cavitation inducer used in the study, the impeller was installed on a horizontal cylinder. In the casing of the cavitation inducer, on the side of inflow of the processed medium, a space was provided serving as an inflow chamber. Analogically, on the side of the outflow, between the impeller and casing of the cavitation inducer, an outflow chamber was provided.

During the operation of the disintegration apparatus in certain liquid-filled areas of the impeller (so-called active spaces), cavitation is intentionally induced.

The cavitation causes disruption of sludge flocs. The sludge is fed to the apparatus by an external feed pump at pressures of approximately 0.2 bar. The disintegration process is controlled by manipulating the hydraulic retention time in the active spaces (flow through the unit).

2.2. Disintegration Batch Tests

Disintegration batch tests were conducted at the initial stage of the study, with the aim of selecting the energy density level for conducting the process of disintegration of thickened waste activated sludge at the technical scale. The tests were conducted in accordance with the methodology developed in previous studies [17]. A single test involves the analysis of the release of organic compounds (expressed as soluble chemical oxygen demand—SCOD), and generation of volatile fatty acids (VFA) through mechanical disintegration of thickened waste activated sludge, carried out at various levels of energy density (εL). Five batch tests were conducted (T1, T2, …, T5). Each test was conducted on a different batch of thickened waste activated sludge from the wastewater treatment plant in which the installation of the disintegrator was planned (and in which the experiment described in point 2.3 was conducted). Further tests were conducted every four weeks. The concentration of dry mass of particular sludge batches was 3.82% (T1), 3.40% (T2), 4.66% (T3), 4.75% (T4), and 5.20% (T5). The energy density at which particular tests were conducted was changed in a range of 30–180 kJ/L.

The results of disintegration batch tests provided the basis for the determination of the efficiency of SCOD (ESCOD) and VFA (EVFA) released from thickened waste activated sludge:

where:

ESCOD/VFA = (SCOD/VFADis.εL − SCOD/VFAWihoutDis.)/εL, [mg SCOD/kJ] or [mg VFA/kJ],

SCOD/VFADis.εL—concentration of SCOD/VFA in a sample subject to disintegration at a given level of energy density, [mg SCOD/L] or [mg VFA/L];

SCOD/VFAWihoutDis.—concentration of SCOD/VFA in a sample not subject to disintegration, [mg SCOD/L] or [mg VFA/L];

εL—energy density at which the disintegration process was conducted, [kJ/L].

2.3. Evaluation of the Impact of Thickened Waste Activated Sludge Disintegration on the Efficiency of the Anaerobic Digestion Process

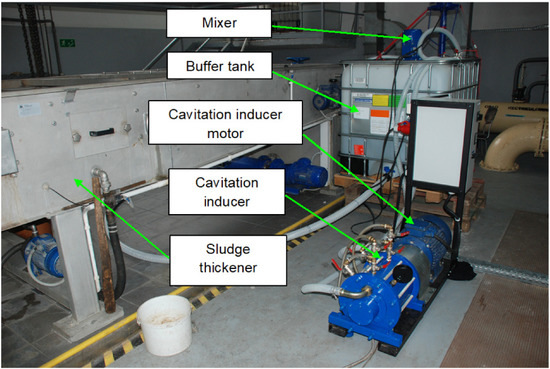

The experiment was carried out over a period of 12 months in a full-scale wastewater treatment plant (Poland). Sludge subject to disintegration was collected from the thickening tank, and first directed to the buffer tank equipped with a mixer. From the buffer tank, the sludge was transferred to the cavitation inducer. After passing through the cavitation inducer, it was again transferred to the buffer tank, from there back to the thickening tank, and further to the anaerobic digestion chamber. Such a system provided greater control and flexibility in the determination of the share of disintegrated sludge and unitary values of energy used in the process. The view of the cavitation inducer installed in a wastewater treatment plant is presented in Figure 2.

Figure 2.

View of a cavitation inducer installed in a wastewater treatment plant.

The experiment consisted of two five-month series, differing in the percentage share of thickened waste activated sludge, subject to disintegration, before directing it to the digester with a working volume of 3000 m3. In Series I, the value of this parameter was equal to 25%. In Series II, the entire flow of thickened waste activated sludge directed to the digester was subject to the disintegration process. The energy density for conducting the process was assumed to be selected based on the results of batch disintegration tests (carried out at the initial stage of the research; methodology described in Section 2.2). No disintegration was performed in a 2-month period between Series I and II. During the experiment, concentrations of total solids (TS) and volatile total solids (VTS) in thickened waste activated sludge directed for disintegration were 5.93 ± 0.40% and 4.44 ± 0.28%, respectively. The values of these indicators for mixed sludge (thickened primary sludge and thickened waste activated sludge) fed to a digester were 4.67 ± 0.14% and 3.34 ± 0.10%, respectively. The daily volume of mixed sludge was 92 m3/d, 35% of which was waste activated sludge (i.e., 32 m3/d). Fermentation was carried out at 33 °C. The hydraulic retention time in the digester was within a range of 25 days.

The scope of the research included the analysis of TS and VTS in sludge introduced and discharged from the digester, dry matter concentration in the sediments, and observation of the amount of produced biogas. Data preceding the installation of the disintegration apparatus by 12 months were also taken into account (Series 0) in the analysis of results.

3. Results and Discussion

3.1. Disintegration Batch Test Results. Selection of Energy Density Level for the Full Scale Experiment

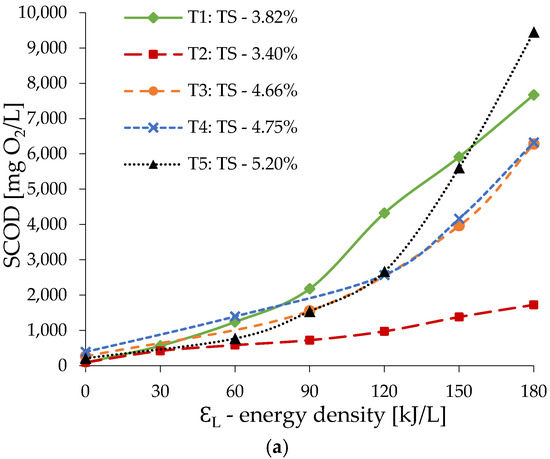

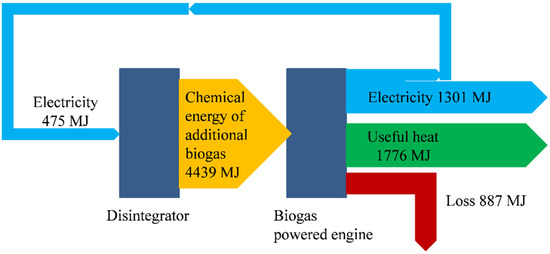

The most commonly used indicator for evaluating the release of organic compounds from activated sludge flocs is soluble COD. An increase in this indicator suggests conversion of the solid phase to the soluble phase, resulting in an increase in sludge bioavailability, and it may consequently result in increased biogas production in the anaerobic digestion process. Changes in the SCOD value and VFA concentration depending on the energy density at which the disintegration process was conducted are shown in Figure 3. The obtained data suggest that in all performed disintegration batch tests, an increase in εL was accompanied by more and more organic compounds released from waste activated sludge, as evidenced by an increase in the SCOD value. Some of these compounds were VFA. However, the intensity of VFA generation significantly decreased when a certain value of εL was exceeded. For T1, T2, T3, and T4, this phenomenon was observed after an increase in εL over 150 kJ/L; in T5 for εL > 120 kJ/L. Figure 3 also shows that SCOD and VFA concentrations for all the analysed εL were significantly lower in test T2 than in the other tests. It was highly likely to be caused by a low concentration of TS in sludge subject to disintegration in T2 in comparison to other tests. The effect of different solids concentrations on SCOD release, resulting from ultrasonication, was evaluated by Pilli et al. [18]. The cited authors determined that an increase in the solids concentration of waste activated sludge from 20.0 to 30.0 and 40.0 g TS/L caused a 1.33- and 1.37-fold increase in SCOD, respectively.

Figure 3.

Effect of energy density on SCOD (a) and VFA (b) release from thickened waste activated sludge.

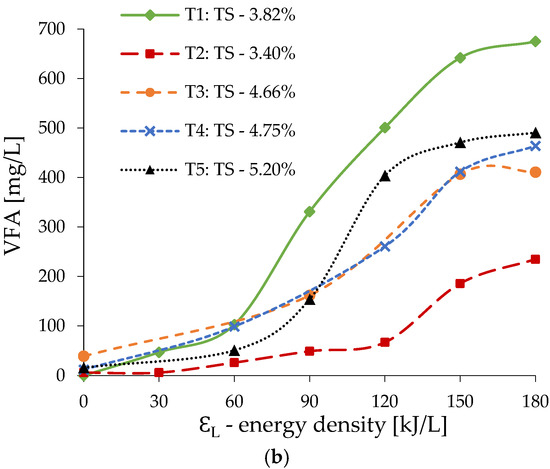

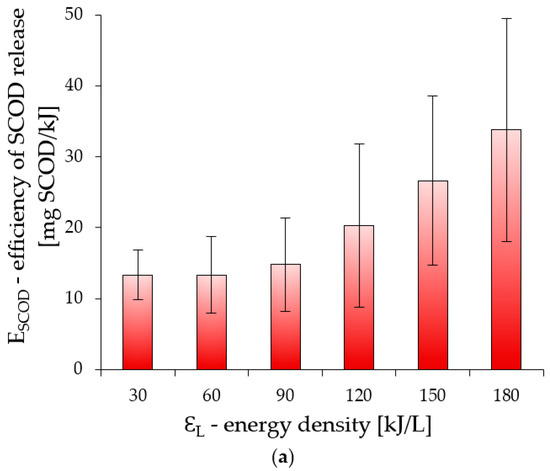

Figure 4 shows the release efficiency of SCOD (ESCOD) and VFA (EVFA) determined for the analysed levels of εL. These parameters, illustrating the amount of SCOD and VFA released in relation to the amount of energy used in the disintegration process, permit the evaluation of the profitability of obtaining these compounds at different levels of εL. The maximum SCOD release efficiency was determined for an energy density of 180 kJ/L (ESCOD = 33.8 ± 15.7 mg SCOD/kJ). For this level of εL, however, a decrease in VFA release efficiency occurred, in relation to the value of this parameter determined for εL = 150 kJ/L with a maximum EVFA (2.7 ± 1.1 mg VFA/kJ). Based on these observations, it was assumed that in the experiment aimed at testing the possibility of increasing the biogas production through the mechanical disintegration of thickened WAS, the disintegration would be carried out at an energy density of 150 kJ/L.

Figure 4.

Effect of energy density on the efficiency of SCOD (a) and VFA (b) release from thickened waste activated sludge.

3.2. Full Scale Experiment Results. Effects of Disintegration of Thickened Waste Activated Sludge on Anaerobic Digestion Efficiency

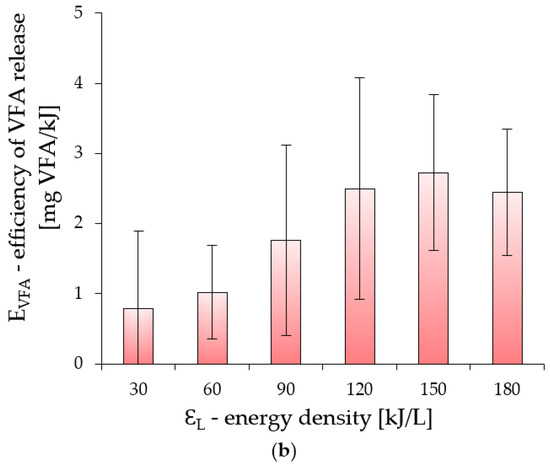

During the 12 months preceding the use of disintegration of WAS in WWTP, the average amount of biogas produced per day and biogas yield were 1365 ± 159 m3/d and 0.45 ± 0.04 m3/kg VTSfed, respectively (Figure 5). Taking into account VTS reduction, the average unit biogas production value was equal to 0.68 ± 0.04 m3/kg VTSred. In order to increase the efficiency of anaerobic digestion, a mechanical disintegration of 25% WAS directed to the digester (Series I) was used. The process was conducted at energy density of150 kJ/L. It allowed for an increase in SCOD from 122 ± 63.5 mg O2/L for sludge before disintegration to 4203 ± 1841 mg O2/L after the disintegration process. However, no increase in the amount of produced biogas was observed over a period of five months (Figure 5). This appears to be due to too little feedstock subject to pretreatment. Since 25% of the WAS stream was disintegrated, the percentage of disintegrated WAS in total mixed sludge stream was only 8.6%. Series II of the research aimed at testing the possibility of increasing biogas production in the case of the entire WAS stream directed to the digester and disintegrated at the same energy density as in Series I (i.e., 150 kJ/L). However, for technical reasons that occurred during the installation of the disintegrator in the wastewater treatment plant, it was not possible to disintegrate the entire WAS stream at εL = 150 kJ/L. Defining the conditions of conducting Series II involved the assumption that the entire WAS stream would be subject to disintegration (which was in line with the assumptions at the planning stage of the experiment), and the energy density at which the pretreatment would be conducted would be derived from that of feeding the cavitation inducer with WAS to the disintegration apparatus, i.e., 30 kJ/L. With such predefined pretreatment conditions, SCOD increased from 104 ± 31.5 mg O2/L to 1070 ± 43.1 mg O2/L. As a result, during the 5 months of operation of the disintegrator at the plant, a 14.1% increase in biogas production was observed compared to the period without WAS disintegration. The production of biogas for this period averaged 1558 ± 111 m3/d (Figure 5). A similar percentage increase in biogas production (12.7%) was observed by Petkovsek et al. [14], who used hydrodynamic cavitation of WAS before mesophilic fermentation. Moreover, when comparing the results obtained in Series II and Series 0, an increase in unit biogas production after the disintegration of the entire WAS stream was also evident (Figure 5). The average value of these parameters for Series II were 0.50 ± 0.04 m3/kg VTSfed and 0.75 ± 0.04 m3/kg VTSred. It can be therefore expected that in Series II, methanogenic bacteria utilised the organic substrate more efficiently.

Figure 5.

Biogas production (a), reduction of volatile total solids (b) and unit biogas production (c) in each series of the experiment.

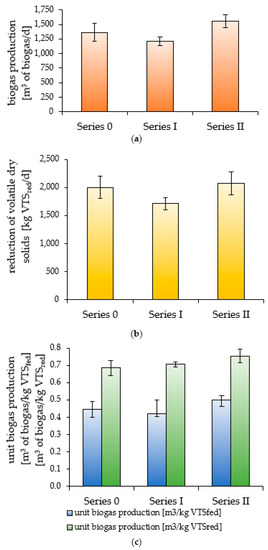

The increase in biogas production observed in Series II should be compared in terms of energy with the amount of energy required for its generation (the energy needed to drive the disintegrator). It is not advisable to use solutions that would provide negative energy balance, i.e., where the amount of energy used by the disintegrator’s drive exceeds the amount of energy that can be gained from the additional portion of biogas. The energy analysis of the sludge disintegration process should also consider the fact that the adopted balance covers different types of energy, i.e., electric power to drive the disintegrator and chemical energy of biogas. The correct balance must take into account the efficiency of the conversion of biogas chemical energy into electricity. For the purposes of the article, this efficiency was assumed to be 40%. This is a typical value of electric efficiency of a biogas powered engine. Based on the measurement data, an additional biogas volume resulting from disintegration can be estimated at approximately 193 m3/d. For a calorific value of biogas equal to 23 MJ/m3, the amount of chemical energy contained in this amount of biogas will be approximate to 4439 MJ. Using this fuel in an internal combustion engine will produce approximately 1776 MJ of electricity and as much functional heat. These values result from the assumed mean efficiencies (electric and thermal) of engines combusting biogas equal to 40% each. In such a situation, electricity production can be described as a product of chemical energy supplied to the engine and its electric efficiency. The amount of produced heat is analogically the product of chemical energy of fuel supplied to the engine and its thermal efficiency. The disintegrator used approximately 475 MJ of electricity daily. This means that the energy balance of the use of the disintegrator at the plant in question is positive. In addition to covering the needs of the disintegrator, the amount of electricity that can be produced from the additional portion of biogas allows for the production of around 1300 MJ/d, i.e., 360 kWh/d net (Figure 6). The comparison of the obtained results with data presented by the aforementioned Petkovsek et al. [14] shows that despite a comparable percent increase in biogas production, the authors [14] recorded a negative energy balance. Houtmeyers et al. [19] applying microwaves and ultrasounds as a method of pretreatment of WAS obtained percent increases in biogas production higher than those obtained in this study (27% for ultrasonic pre-treatment and 20% for microwave pre-treatment). Additionally, in this case, the amount of electricity that can be produced from the additional portion of biogas does not cover the needs of the disintegration processes. The possibility of obtaining positive energy balance with the application of ultrasounds as a disintegration method was evidenced by Lippert et al. [20]. Energy recovery, defined by the authors as the ratio of electrically invested energy and regained energy by additional methane, was 122%. Analogical calculations for data obtained in this study showed a value of energy recovery that was more than doubled; specifically, 273%.

Figure 6.

Energy flows in the tested installation.

In order to assess the achieved benefits, the amount of electricity produced from an additional portion of biogas was compared with the energy used for wastewater treatment processes and sludge management in the tested WWTP. The daily energy consumption for wastewater treatment processes and sludge management in the considered treatment plant averages 10.5 MWh. Considering this value, the amount of energy produced from an additional portion of biogas accounts for approximately 3.5% of the required energy. An increase in the production of own energy leads to a reduction in the amount of purchased energy, and therefore increases energy self-sufficiency.

To sum up, the obtained results show that the application of mechanical disintegration as pre-treatment of waste activated sludge directed to the digester does not always lead to increased biogas production. The percentage share of disintegrated WAS in the total mixed sludge stream subject to the anaerobic digestion process has a significant effect on the efficiency of anaerobic digestion. It seems that obtaining an increase in biogas production with low values of this parameter requires the disintegration process to be conducted at high energy densities. This would allow for the release of organic compounds which, without pre-treatment of sludge, are an inert fraction, i.e., not subject to the biochemical process occurring in the digester. This issue, however, requires further investigation, especially that an increase in energy density at which the disintegration process is conducted is accompanied by an increase in the probability of occurrence of the sludge re-flocculation process, potentially resulting in a decrease in the amount of produced biogas [20]. It cannot be excluded that an almost insufficient percent share of disintegrated WAS in the total mixed sludge stream subject to the anaerobic digestion process; the occurrence of this phenomenon was one of the causes of the lack of an increase in the amount of produced biogas when the disintegration process was conducted at energy density of 150 kJ/L. Considering our own study results at the pilot scale for another type of mechanical disintegrator, however, where a considerable increase in biogas production was recorded when the disintegration process was conducted at 140 kJ/L [21], it was assumed that the primary parameter determining lack of expected results in this study was insufficient percent share of WAS subject to disintegration. In the case of disintegration of the entire WAS stream, however, even at low energy densities, the bioavailability of a significant part of the mixed sludge increases, resulting in an increase in biogas production, as documented in this study. It seems reasonable to perform further studies to optimise the conditions of sludge disintegration (concentration of total solids concentrations, energy density) while taking into account the percentage of disintegrated WAS in the entire mixed sludge stream subject to the anaerobic digestion process. It is worth emphasising that activities aiming to improve the efficiency of the anaerobic digestion process while maintaining a positive energy balance meet the challenges currently faced by wastewater treatment plants in the context of implementation of the rules of the circular economy.

4. Conclusions

- The percent share of waste activated sludge subject to disintegration is a crucial parameter affecting the efficiency of biogas production. Increasing the value of this parameter from 25% to 100%, even at a much lower energy density used in the disintegration (therefore with much smaller amounts of organic compounds released from the sludge flocs) resulted in an increase in biogas production.

- Mechanical disintegration of thickened waste activated sludge in appropriately selected process conditions is an economically justifiable strategy for the intensification of anaerobic sludge stabilisation. Conducting disintegration of the entire stream of waste activated sludge directed to the fermentation tank at energy density of 30 kJ/L resulted in an increase in biogas production by 14.1%. Such a surplus would allow for production of approximately 1300 MJ/d, i.e., 360 kWh/d net electricity.

- The obtained results also permit formulating a recommendation for WWTP operators to carry out a research phase prior to the application in order to define the process conditions and determine whether it is economical to introduce sludge disintegration at the plant in question.

Author Contributions

Conceptualisation: M.Z.-S. and P.K.; Methodology: M.Z.-S.; Investigation: M.Z.-S. and P.K.; Formal analysis: K.S.-S., A.B. and M.Z.-S.; Resources: M.Z.-S., K.S.-S. and A.B.; Writing—original draft preparation: M.Z.-S.; Writing—review and editing: K.S.-S., P.K. and A.B.; Visualisation: K.S.-S. All authors have read and agreed to the published version of the manuscript.

Funding

The study was conducted as part of the research project entitled “Wastewater sludge disintegration technology using mechanical cavitation inducers for application at Polish wastewater treatment plants” (No. 12966), financed by the National Centre of Research and Development (Poland). It was also co-financed by the Strategic Research Project of the Warsaw University of Technology “Circular Economy” (2019/2020).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Statistics Poland, Statistical Products Department. Statistical Yearbook of the Republic of Poland; Central Statistical Office of Poland: Warsaw, Poland, 2020. Available online: https://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/rocznik-statystyczny-rzeczypospolitej-polskiej-2020,2,20.html (accessed on 19 November 2021).

- Directive (EU) 2018/2001 of the European Parlament and of the Council on the Promotion of the Use of Energy from Renewable Sources. 2018. Available online: www.eur-lex.europa.eu (accessed on 19 November 2021).

- Ministry of State Assets (Poland). Poland’s National Energy and Climate Plan for the Years 2021–2030; Ministry of State Assets: Warsaw, Poland, 2019. Available online: www.gov.pl (accessed on 19 November 2021). (In Polish)

- Statistics Poland, Enterprises Department. Energy from Renewable Sources in 2019; Central Statistical Office of Poland: Warsaw, Poland, 2020. Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/energia/energia-ze-zrodel-odnawialnych-w-2019-roku,3,14.html (accessed on 19 November 2021).

- European Biogas Association. EBA Statistical Report 2020 (Abridged Version). Available online: www.europeanbiogas.eu (accessed on 19 November 2021).

- Energy Regulatory Office (Poland). National Potential of RES in Numbers—2021. Available online: www.ure.gov.pl/pl (accessed on 19 November 2021). (In Polish)

- Magazynbiomasa.pl. Biogas in Poland. Report 2020. Available online: www.magazynbiomasa.pl (accessed on 19 November 2021). (In Polish).

- Liu, X.; Xu, Q.; Wang, D.; Wu, Y.; Fu, Q.; Li, Y.; Yang, Q.; Liu, Y.; Ni, B.; Wang, Q.; et al. Microwave pretreatment of polyacrylamide flocculated waste activated sludge: Effect on anaerobic digestion and polyacrylamide degradation. Bioresour. Technol. 2019, 290, 121776. [Google Scholar] [CrossRef] [PubMed]

- Xiao, B.; Tang, X.; Yi, H.; Dong, L.; Han, Y.; Liu, J. Comparison of two advanced anaerobic digestions of sewage sludge with high-temperature thermal pretreatment and low-temperature thermal-alkaline pretreatment. Bioresour. Technol. 2020, 304, 122979. [Google Scholar] [CrossRef] [PubMed]

- Tulun, Ş.; Bilgin, M. Enhancement of anaerobic digestion of waste activated sludge by chemical pretreatment. Fuel 2019, 254, 115671. [Google Scholar] [CrossRef]

- Chen, H.; Yi, H.; Li, H.; Guo, X.; Xiao, B. Effects of thermal and thermal-alkaline pretreatments on continuous anaerobic sludge digestion: Performance, energy balance and, enhancement mechanism. Renew. Energy 2020, 147, 2409–2416. [Google Scholar] [CrossRef]

- Mancuso, G.; Langone, M.; Andreottola, G.; Bruni, L. Effects of hydrodynamic cavitation, low-level thermal and low-level alkaline pre-treatments on sludge solubilization. Ultrason. Sonochem. 2019, 59, 104750. [Google Scholar] [CrossRef] [PubMed]

- Neis, U.; Nickel, K.; Lunden, A. Improving anaerobic and aerobic degradation by ultrasonic disintegration of biomass. J. Environ. Sci. Health Part A 2008, 43, 1541–1545. [Google Scholar] [CrossRef] [PubMed]

- Petkovšek, M.; Mlakar, M.; Levstek, M.; Stražar, M.; Širok, B.; Dular, M. A novel rotation generator of hydrodynamic cavitation for waste-activated sludge disintegration. Ultrason. Sonochem. 2015, 26, 408–414. [Google Scholar] [CrossRef] [PubMed]

- Boni, M.R.; D’Amato, E.; Polettini, A.; Pomi, R.; Rossi, A. Effect of ultrasonication on anaerobic degradability of solid waste digestate. Waste Manag. 2016, 48, 209–217. [Google Scholar] [CrossRef] [PubMed]

- Gil, A.; Siles, J.A.; Martín, M.A.; Chica, A.F.; Estévez-Pastor, F.S.; Toro-Baptista, E. Effect of microwave pretreatment on semi-continuous anaerobic digestion of sewage sludge. Renew. Energy 2018, 115, 917–925. [Google Scholar] [CrossRef]

- Żubrowska-Sudoł, M.; Podedworna, J.; Sytek-Szmeichel, K.; Bisak, A.; Krawczyk, P.; Garlicka, A. The effects of mechanical sludge disintegration to enhance full-scale anaerobic digestion of municipal sludge. Therm. Sci. Eng. Prog. 2018, 5, 289–295. [Google Scholar] [CrossRef]

- Pilli, S.; Yan, S.; Tyagi, R.D.; Surampalli, R.Y. Anaerobic digestion of ultrasonicated sludge at different solids concentrations-Computation of mass-energy balance and greenhouse gas emissions. J. Environ. Manag. 2016, 166, 374–386. [Google Scholar] [CrossRef] [PubMed]

- Houtmeyers, S.; Degrève, J.; Willems, K.; Dewil, R.; Appels, L. Comparing the influence of low power ultrasonic and microwave pre-treatments on the solubilisation and semi-continuous anaerobic digestion of waste activated sludge. Bioresour. Technol. 2014, 171, 44–49. [Google Scholar] [CrossRef] [PubMed]

- Lippert, T.; Bandelin, J.; Musch, A.; Drewes, J.E.; Koch, K. Energy-positive sewage sludge pre-treatment with a novel ultrasonic flatbed reactor at low energy input. Bioresour. Technol. 2018, 264, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Garlicka, A.; Zubrowska-Sudol, M.; Umiejewska, K.; Roubinek, O.; Palige, J.; Chmielewski, A. Effects of Thickened Excess Sludge Pre-Treatment using Hydrodynamic Cavitation for Anaerobic Digestion. Energies 2020, 13, 2483. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).